Abstract

The Acosta method involves rewiring the yeast metabolic pathway to enhance biomass production and prevent a significant increase in higher alcohols during the late stages of fermentation. This study aimed to assess fermentation conditions to achieve Cuban schnapps with reduced concentrations of higher alcohols and replicate the process on an industrial scale. To achieve this, the quality of final sugarcane molasses for fermentation by Saccharomyces cerevisiae (S. cerevisiae) yeast was evaluated. Industrial pre-fermentation and fermentation processes were successfully conducted, followed by laboratory-scale fermentation using the Acosta fermentation method to determine crucial parameters for industrial implementation. Operational parameters for fermentation were identified from the following results: 13.5 °Brix seeding, metabolic pathway inversion of S. cerevisiae at 16 h, and an air concentration of 0.1 m3/min. The resulting Cuban schnapps obtained using this method exhibited a concentration of higher alcohols of 132.5 mg/L, a value that is within the standard parameters, showing a positive impact of this fermentation method on the quality of the schnapps. Scaling up this method to an industrial level, in addition to offering higher quality products and being an economically viable alternative, also stands out for its sustainable and environmentally friendly aspect, and results in higher production of yeast biomass as a byproduct, which can be used for various purposes, such as animal feed. This method constitutes an important update to the schnapps production process as a technological improvement that respects sustainable production trends and the characteristics of the final product.

1. Introduction

Schnapps, or aguardiente, is a high-concentration alcoholic beverage characterized by its dry or aromatic flavor and lack of aging process. It is the result of distilling fermented musts or pastes, which can be derived from various ingredients, such as grains and sugarcane, among others [1]. Its production dates back to ancient traditions, and its popularity has endured over the centuries, becoming a symbolic drink in many cultures. Its versatility makes it suitable for both sipping neat and for use in cocktails and other concoctions [2]. Despite its strong flavor and high alcohol content, aguardiente remains a favored choice among many schnapps enthusiasts.

Currently in Cuba, schnapps production is hindered by the lack of methods to obtain high-quality schnapps [3]. The strict quality standards required to achieve the characteristic bouquet of Cuban rum pose a challenge. The alcoholic fermentation processes used in rum formulation often result in schnapps with high concentrations of higher alcohols [4]. Frequently, excessively high levels of honey are used, and two distillations are required to obtain quality schnapps. For instance, most schnapps produced in Cuba have higher alcohol concentrations in the range of 400 mg/L, while standards demand concentrations lower than 350 mg/L [5]. To meet these standards, adjustments are made using fine alcohol A, which typically contains average concentrations of 10 mg/L of higher alcohols [6].

Higher alcohols, by definition, are alcohols that have more carbon atoms than ethanol; the most significant ones include propanols, butanols, and pentanols, with their common isomers [7]. They are officially determined in Cuba by NC 535:2007 [8], a regulatory standard that establishes their specifications and limits. These alcohols are products of the secondary metabolism of yeast during the fermentation processes, contributing substantially to the sensory profile of beverages and fermented products. Burini et al. [9] highlight their importance in the development of aroma and taste, as they can impart fruity, floral, or spicy notes depending on their concentrations and interactions with other compounds. Moreover, higher alcohols are crucial in the context of alcoholic beverages, in which they contribute to the complexity and depth of flavor, often influencing consumer preferences and product quality assessments [10].

Higher alcohols are predominantly produced from aromatic and branched-chain amino acids, such as isoleucine, leucine, valine, tyrosine, tryptophan, methionine, and phenylalanine [11]. The entry of amino acids into yeast cells is facilitated by transporter proteins located in the plasma membrane [12]. Once inside the cell, the catabolism of these amino acids occurs via the Ehrlich pathway, leading to the formation of higher alcohols through the action of transaminases, decarboxylases, and alcohol dehydrogenases [13]. This metabolic process is essential in the production of various alcoholic beverages, contributing significantly to their flavor and aroma profiles [14]. Higher alcohols are known to impart desirable sensory characteristics such as fruity, floral, or spicy notes, but their presence in excessive amounts can lead to off flavors and contribute to perceived harshness in the final product [15]. Thus, understanding and controlling the production of higher alcohols during fermentation is crucial for achieving the desired sensory attributes in fermented beverages.

The formation of higher alcohols occurs predominantly in the fermentation process, when sugars begin to deplete, several yeast cells die, and their constituents serve as nutrients for other living cells, thus enhancing the production of secondary metabolites such as higher alcohols. However, the process of obtaining raw sugarcane schnapps in Cuba consists of various production stages, in addition to fermentation [16]. Also, molasses (final syrups) constitute the residues from the final crystallization of sugar and simultaneously serve as the raw material for the production of schnapps [17]. They are thick, viscous syrups or liquids with high water and sugar content, the latter being divided into fermentable and non-fermentable sugars. The main fermentable sugars present include sucrose, glucose, fructose, raffinose, and small amounts of mannose in stored syrups [18]. This molasses enters the production process of schnapps in its first two stages, pre-fermentation and fermentation.

Pre-fermentation involves preparing a sufficient quantity of S. cerevisiae yeast for alcohol production [19]. Before introducing the yeast into the pre-fermenters, it is activated and prepared in the laboratory, where its population is initially increased. During pre-fermentation, the yeast is subjected to strong oxygenation through aeration of the medium for complete glucose oxidation and the release of a large amount of energy, which is used for cell synthesis [20]. Under optimal conditions, S. cerevisiae can double its population every 90 min [21]. Typically, the industrial pre-fermentation cycle lasts for 6 to 8 h, during which alcohol formation is minimal, and growth is typically conducted until near the end of the logarithmic phase [22]. After 30% of the initial °Brix is depleted during pre-fermentation, four-fifths are transferred to a fermenter for the incomplete (anaerobic) fermentation of sugars into ethanol [23]. Fermentation is a catabolic process of incomplete oxidation, with the final product being an organic compound [24]. The fundamental basis of alcoholic fermentation is to yield ethyl alcohol and secondary products, known as congeners [25]. This process is closely related to the vital activity of yeast and regulated by the enzymatic load that transforms the sugars present [26]. Ethanol formation can reach concentrations of up to 12 to 14% alcohol by volume, while CO2 represents the second product of alcoholic fermentation [27].

Traditional fermentation occurs under anaerobic conditions from start to finish. In contrast, the Acosta fermentation method involves identifying an optimal point at which ethyl alcohol production is sufficient, and the production of higher alcohols is not excessively high. At this point, air is injected into the fermentation to reverse the yeast’s metabolic pathway and achieve complete oxidation of glucose. This process generates more energy, allowing S. cerevisiae to focus on cellular multiplication, resulting in higher biomass and a fermented broth with a lower degree of higher alcohols [28]. Once fermentation is completed, the fermented broths undergo a single fractional distillation to obtain the schnapps. The objective of distillation is to separate a mixture of various components by exploiting their different volatilities, in this case, separating ethyl alcohol from the other components of the fermented broth. This process yields a schnapps with an alcohol content lower than 80° and contains small quantities of many components, generally classified as congeners [29].

Currently, there are multiple studies on alcoholic fermentation processes using molasses as raw material [30,31,32], but there are no reports aimed at reducing the concentration of higher alcohols in distilled products, with this research being the first to propose a viable method that helps reduce and control the concentration of these alcohols. Furthermore, this research not only proposes a method but also demonstrates that the process is easily reproducible at the industrial level and does not affect the rest of the quality parameters required for the schnapps.

Therefore, this study aims to investigate and demonstrate the feasibility of implementing the Acosta fermentation method in Cuban schnapps production to reduce the concentrations of higher alcohols in accordance with Resolution No. 12/19 of the Ministry of Food Industry of Cuba. This resolution addresses the quality parameters of Cuban schnapps and the requirements to be used in the production of rums. Schnapps may only be produced from fermented musts of the juices and molasses from the manufacture of cane sugar, only cultivated and processed in Cuba. The distillation column must guarantee the necessary contact with the copper, and for the schnapps to pass to the subsequent aging process, it must maintain the characteristic aromatic profile and an alcoholic strength of 74 to 76 °GL [5].

2. Materials and Methods

2.1. Reagents

The raw material used at the Santa Fé Distillery for the fermentation processes was final honey or molasses, the main byproduct of sugar crystallization, from the sugar production process of the sugar mill belonging to the Unidad Empresarial de Base (UEB) Heriberto Duquesne, the same UEB to which the Santa Fé Distillery belongs, located in the municipality of San Juan de los Remedios, Villa Clara, Cuba. The reagents used in the analytical determinations were of reagent grade, SIGMA Aldrich brand (National distributor Tecnoazucar, imported from Madrid, Spain), and the water used was demineralized water produced in the industry itself, the same water used to make the blends that are aged to produce rum. The yeast used was ethanol red yeast, Saccharomyces cerevisiae, marketed by the company Zuker S.A. de C.V (Veracruz, Mexico).

2.2. Guided Study

Once the existing fermentation studies at the plant were completed, a laboratory-scale pre-fermenter setup was assembled for monitoring and implementing the Acosta fermentation method. The laboratory fermenter assembly had a capacity of 10 L and started with a 13 °Brix inoculum, sourced from the plant’s pre-fermentation room. Monitoring of the fermenter was conducted every two hours throughout the fermentation process. After 16 h of fermentation, aeration was initiated, a time established based on the results of the industrial fermentation monitoring.

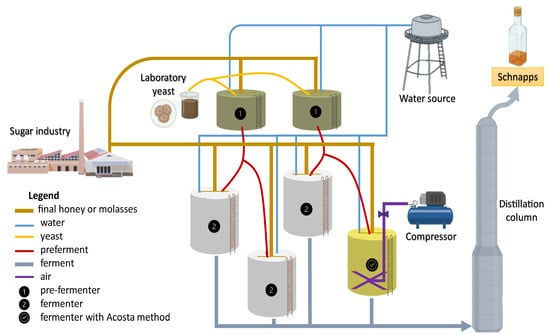

Subsequently, a pilot-scale project was carried out based on the laboratory results. In collaboration with the maintenance department, a fermenter was prepared for this pilot, equipped with the necessary fittings described in Table 1 for industrial testing. The industrial design of the process, which includes a fermenter coupled with aeration for Acosta fermentation, is illustrated in Figure 1, which shows all the stages, from the incorporation of yeast and molasses into the process to the distilled spirit as the final product.

Table 1.

Accessories necessary for scaling the fermenter using the Acosta method.

Figure 1.

Industrial design of the fermentation process, including a fermenter equipped to develop the Acosta fermentation method.

Once the fermenter was conditioned for air supply, it was filled under the proposed fermentation conditions. It should be noted that the proposed fermentation was again monitored every two hours. After fermentation was finished, the fermenter was distilled, and the obtained spirit was characterized.

2.3. Raw Material Characterization

2.3.1. Obtainment of Molasses and Molasses Dilution

The raw material used in this research was the final molasses from the Heriberto Duquesne sugar mill (22.382301; −79.497371), located in the community of the same name, in San Juan de los Remedios, Villa Clara, Cuba. This molasses is extracted during the sugarcane harvest season and stored to ensure a consistent provision of this essential raw material to the distillery.

Additionally, molasses underwent dilution with water to lower the concentration of soluble solids, thereby enhancing yeast activity. For both the pre-fermentation and fermentation stages, only the parameters of soluble solids and temperature were assessed, streamlining the analytical process while providing crucial information for monitoring and optimizing the fermentation process.

2.3.2. Determination of Soluble Solids

Soluble solids were quantified following the standardized methodology outlined in NC 81-06:1988 [33]. The procedure involved measuring the apparent specific gravity of sugar solutions using a hydrometer calibrated specifically for concentrations ranging from 40 to 50% and equipped with an integrated thermometer to ensure precise temperature control. A precisely measured mixture of 400 g of molasses and 400 g of demineralized water was utilized for the analysis. The initial reading obtained from the hydrometer after a 5 min settling period was carefully adjusted using predefined correction tables to accurately express the measurement at a standard temperature of 25 °C. This rigorous approach ensured the reliability and reproducibility of the soluble solid determination in the molasses sample.

In the dilution process of molasses, the determination of soluble solids followed a similar protocol to that of undiluted molasses. However, in this instance, the sample was directly loaded into a 500 mL graduated cylinder. The measurement was conducted using a hydrometer calibrated for concentrations ranging from 10 to 20%. This modified procedure ensured accurate assessment of soluble solids in the diluted molasses solution, facilitating precise control over the concentration levels during the dilution process.

2.3.3. Density Determination

Density was determined directly from tables, utilizing the values obtained from the previous determination of soluble solids versus temperature. By referencing established tables correlating soluble solids concentration with temperature, the density of the molasses solution was accurately calculated. This method facilitated precise density measurements [34].

2.3.4. Determination of Sludge Content

The determination of sludge content in molasses followed the standardized protocol outlined in NC 81-40:1988 [35]. Initially, the sample preparation mimicked that of the soluble solid determination, involving the weighing of 10 mL of the prepared sample. Following this, centrifugation was carried out at a speed of 3000 rpm for a duration of 10 min. The resultant precipitate volume was carefully measured thereafter. To express the results accurately, the percent sludge content was calculated using Equation (1), considering the mass and density of the molasses along with the volume of the precipitate. This meticulous procedure ensured a precise assessment of sludge presence in the molasses sample.

where:

- S → Sludge in molasses sample.

- Pv → Precipitate volume in mL.

- m → Mass of molasses in 10 mL of solution (g).

- ρ → Specific density of molasses.

- 2 → Dilution factor.

2.3.5. pH Determination

pH was determined in accordance with NC 81-41:1988 [36] guidelines using an XS Instruments pH 80 + DHS potentiometer (XS Instruments, Carpi, Italy). For the analysis, a mixture of 20 g of molasses and 80 g of demineralized water was prepared. This standardized procedure ensures accurate pH measurement of the molasses sample, providing valuable insight into its acidity or alkalinity level.

2.3.6. Determination of Total Reducing Sugars

Total reducing sugars were determined following the guidelines outlined in NC 81-42:1988 [37]. Initially, 5 g of final molasses was dissolved in demineralized water to make up a total volume of 500 mL. Subsequently, oxalate of potassium (10%) was added to the solution. Then, the mixture was filtered, 100 mL of the filtrate obtained was taken, and 50 mL of demineralized water was added to it to be brought to 65 °C in a Lamma brand water bath. Once the temperature was reached, 10 mL of 6.34 N hydrochloric acid solution (24.85 °Brix) was added and it was left to rest for 30 min. It was neutralized with 1N sodium hydroxide and 3 drops of phenolphthalein. A volume of 300 mL was completed with demineralized water, and 23 mL was placed with 5 mL of Fheling B solution, 5 mL of Fheling A, and 20 mL of demineralized water. The mixture was allowed to boil for 2 min, and 0.5 mL of 3% methylene blue was added to be titrated with the mixture that had been neutralized (before mixing with the Fheling). Three replicates were made, adding equal amounts of Fehling B and A as in the first, but the volume of water and sample varied.

2.3.7. Determination of Free Reducing Sugars

Free reducing sugars were determined using the filtrate obtained in Section 2.3.6, following similar procedures as those described earlier. Specifically, the filtrate was subjected to a series of chemical reactions designed to quantify the concentration of free reducing sugars present in the sample. These reactions typically involve the reduction of certain compounds by the sugars, leading to measurable changes in color or other properties that can be quantified using spectrophotometric or titrimetric methods. By following standardized protocols, the concentration of free reducing sugars in the sample can be accurately determined, providing valuable information about its composition and quality [34].

2.3.8. Determination of Sucrose

The sucrose content was determined by calculating the difference between the total and free reducing sugars in the sample, as shown in Equation (2). This calculation accounts for the amount of sucrose present in the sample. The resulting value is divided by 0.95 to adjust for the molecular weight of sucrose compared to other reducing sugars. Finally, the calculated value is expressed as a percentage to indicate the proportion of sucrose in the sample relative to its total sugar content [34].

where:

- Suc. → Sucrosa (%).

- TRS → Total reducing sugars (%).

- FRS → Free reducing sugars (%).

2.3.9. Determination of Total Sugars

The total sugar content was determined using Equation (3), summing the concentrations of free reducing sugars and sucrose present in the molasses sample. Free reducing sugars were quantified using specific analytical methods, while sucrose content was calculated separately. By combining these values, the total sugar content of the molasses was accurately determined, providing comprehensive insight into its overall sweetness and composition [34].

where:

- TS → Total sugars (%).

- Suc. → Sucrosa (%).

- FRS → Free reducing sugars (%).

2.3.10. Determination of Infermentable Reducing Sugars

Infermentable reducing sugars were determined indirectly according to NC 81-43:1988 [38], employing a methodology akin to the process utilized for the determination of total reducing sugars. Initially, 12 g of the molasses sample was dissolved in demineralized water, adjusting the pH to a range of 4.6 to 5.2 using a 1% solution of sulfuric acid. Subsequently, yeast was added to the solution, and it was allowed to rest for 24 h at a controlled temperature of (30 ± 2) °C in an incubator. Following incubation, the solution was centrifuged at 3000 rpm for 10 min using a Sigma centrifuge. The resulting supernatant was collected and treated further according to the same procedures described for the determination of total reducing sugars. Infermentable reducing sugars were calculated indirectly using Equation (4), providing valuable information about the fermentability of the molasses sample.

where:

- IRS → Infermentable reducing sugars (%).

- V1 → Average volume of inverted sugar reference solution at 2 mg/mL consumed in the 2 blank titrations (mL).

- V2 → Average volume of inverted sugar reference solution at 2 mg/mL consumed in the 2 sample titrations (mL).

- a → Mass of sample used in the preparation of the test solution (g).

- b → Volume of test solution pipetted (mL).

- 0.002 → Factor corresponding to the concentration of the inverted sugar solution.

- 250 → Dilution factor.

- 100 → Percentage expression.

2.3.11. Determination of Fermentable Reducing Sugars

Additional information regarding the calculation of fermentable reducing sugars involved deducting the concentration of infermentable reducing sugars, as determined by the methodology outlined in NC 81-43:1988 [38], from the total reducing sugar content obtained previously. This calculation enabled the isolation of the portion of reducing sugars that can be readily fermented, offering a deeper understanding of the fermentative potential of the molasses sample. By quantifying fermentable reducing sugars separately, researchers gain valuable insights into the suitability of the molasses for specific fermentation applications and the optimization of fermentation processes.

2.4. Pre-Fermentation and Fermentation States

2.4.1. Analytical Measurements

A basic study of pre-fermentation and alcoholic fermentation was conducted. Analyzed parameters during pre-fermentation included Brix, temperature, pH, cell count, viability, budding, microbial contamination, alcohol percentage, and higher alcohols, measured every hour. During alcoholic fermentation, these parameters were assessed every two hours.

During the pre-fermentation and fermentation stages, analytical monitoring involved several assessments to ensure optimal conditions for fermentation. Soluble solids were measured using a 0 to 10% hydrometer, following the procedure outlined in Section 2.3.2. This method provided valuable information about the concentration of fermentable sugars in the molasses solution, critical for yeast metabolism and ethanol production. pH determination was conducted potentiometrically, as detailed in Section 2.3.5, directly in 100 mL of pre-ferment and fermented solutions. Monitoring pH levels allowed for the assessment of the acidity or alkalinity of the pre-fermentation and fermentation environments, which directly impacts yeast activity and fermentation efficiency.

2.4.2. S. cerevisiae Cell Count

The total cell count was determined by employing Neubauer chamber counting under a microscope. This method involves placing a known volume of the sample onto a specialized counting chamber, in which cells are evenly distributed. The chamber is then observed under a microscope, and cells within the marked grid areas are counted. By multiplying the count by a correction factor based on the chamber’s dimensions and dilution factor, the total cell count per unit volume of the original sample can be calculated accurately [34].

2.4.3. S. cerevisiae Viability

Viability assessment involved the utilization of methylene blue staining to differentiate between live and dead cells. This staining method allowed for the visual identification and quantification of both viable (live) and non-viable (dead) cells within the S. cerevisiae population. By staining the cells with methylene blue, live cells remained unstained, while dead cells absorbed the dye, facilitating their distinction under a microscope. This comprehensive viability assessment provided valuable insights into the overall health and functional capacity of the yeast population, which is essential for optimizing fermentation performance and ensuring the production of high-quality fermentation products [34].

2.4.4. S. cerevisiae Budding

Budding was assessed in accordance with the methodology outlined in Section 2.4.2, with careful consideration given to the size of the daughter cell relative to the mother cell. This assessment involved observing the reproductive activity of S. cerevisiae cells under a microscope, focusing on the formation of daughter cells (buds) and their proportional size compared to the mother cell. By monitoring budding activity and assessing the size of the daughter cells, we gained valuable insights into the reproductive health and vitality of the yeast population. This information was instrumental in evaluating yeast performance during pre-fermentation and optimizing fermentation conditions for the production of desired fermentation products [34].

2.4.5. Microbial Contamination

In addition to counting yeast in the same fields, further characterization of microbial contamination involved assessing the diversity and abundance of different microbial species present. This comprehensive approach allowed for a more thorough understanding of the extent and nature of contamination within the sample, enabling effective mitigation strategies to be implemented [34].

2.4.6. Alcohol Degree Determination

The alcohol content was determined based on the measurement of the density of the hydroalcoholic solutions in the distillates of the test samples, as established by NC 83-26:1987 [39]. From the sample of fermentation broth, 250 mL was taken with 50 mL of demineralized water in a 500 mL distillation flask and slowly distilled with the distillate received in 10 mL of demineralized water. The distilled sample was then transferred to a graduated cylinder, and an alcoholometer ranging from 0 to 10% was inserted. The reading of the alcoholometer stem was taken directly and corrected for temperature.

2.4.7. Determination of Higher Alcohols

The determination of higher alcohol content is based on the reaction of higher alcohols with a solution of 4-p-dimethyl-amino-benzaldehyde in an acidic medium, and the methodology is outlined in NC 535:2007 [8]. The intensity of the solution’s coloration is proportional to the concentration of the complex formed. This concentration is determined using spectrophotometry at 540 nm. For sample preparation, it is distilled as proposed for determining alcohol content in Section 2.3.7, and 20 mL is taken in 30 mL of demineralized water. From this solution, 2 mL is taken and sealed in an ice bath until reaching 15 °C. At this point, 1 mL of 1% 4-p-dimethyl-amino-benzaldehyde solution is added, and it is returned to the ice bath for 3 min. Subsequently, 10 mL of concentrated sulfuric acid is added, and they are placed back in the ice bath for 3 min. After this time, they are transferred to a boiling water bath for 10 min. They are then removed from boiling water and transferred back to the ice bath for 3 min, followed by a water bath at room temperature. Photometric measurement was carried out using an Optizen spectrophotometer (Mecasys Co., Ltd., Gwangju, Republic of Korea), adjusting the instrument to zero with the blank solution using 1 cm light path cuvettes at 540 nm. A calibration curve was prepared using a solution of isobutyl alcohol and isoamyl alcohol, and the result of higher alcohols in mg/L was obtained using Equation (5).

where:

- M → Content of higher alcohols (mg/L).

- C → Concentration value obtained by substituting absorbance on the graph or in the equation of the line of best fit (g/100 L).

- f → Dilution factor of the test sample.

- 103 → Conversion factor to express the result in mg/L of alcohol at 100 °GL.

- Ø → Alcoholic strength of the test sample.

2.5. Cuban Schnapps Product

2.5.1. The Alcohol Content and Higher Alcohol Content

Following distillation, the Cuban schnapps underwent comprehensive characterization for various parameters. The alcohol content was determined using the method of density, as established by NC 83-26:1987 [39], and performed as in Section 2.4.6 directly in 250 mL of schnapps. Higher alcohol content was determined following the methodology of the NC 535:2007 [8] and conducted as in Section 2.4.7 using 5 mL of schnapps.

2.5.2. Total Acidity Determination

Total acidity was determined following the methodology of Vázquez [34] and expressed as acetic acid equivalent via titration with a standardized base solution (sodium hydroxide), which involves preparing a representative sample of the liquid, titrating it with a known concentration of NaOH solution while using an appropriate pH indicator (phenolphthalein), and recording the volume of NaOH required to reach the endpoint. The endpoint is indicated by a permanent color change in the indicator. By applying stoichiometry, the amount of acetic acid present in the sample can be determined, allowing for the calculation of acidity concentration in terms of acetic acid equivalents by Equation (6). This methodology ensures the accurate evaluation of acidity levels in the analyzed liquid.

where:

- TAc → Total acidity (mg/L).

- V → Total volume of 0.025 N sodium hydroxide solution consumed in the titration (mL).

- Vb → Volume of sodium hydroxide consumed in the neutralization of water (mL).

- F → General and alcoholic strength correction factor.

- 1500 → Factor to express the concentration in mg/L.

- Vm → Volume of test sample of brandy in mL.

2.5.3. Total Ester Determination

Esters, pivotal contributors to aroma and flavor, were saponified and titrated following the guidelines outlined in NC 534:2007 [40]. The content of total esters was determined using neutralization volumetric, quantifying the excess of sodium hydroxide from esterification with hydrochloric acid as titrant. The result was expressed as ethyl acetate, and Equation (7) was used to calculate the result. This comprehensive parameter characterization facilitated a nuanced comprehension of the quality and composition of the Cuban schnapps product, enabling a thorough assessment of its sensory attributes and flavor profile.

where:

- B → Total ester content.

- V1 → Volume of the 0.1 N sodium hydroxide solution (mL).

- N1 → Exact normality of the sodium hydroxide solution.

- V2 → Volume of the 0.1 N hydrochloric acid solution consumed in the titration (mL).

- N2 → Exact normality of the hydrochloric acid solution used in the titration.

- e → Volume of the test sample in mL.

- Ø → Alcoholic strength of the test sample.

- 88 → Equivalent gram of ethyl acetate.

- 105 → Conversion factor to express the result in mg/L of alcohol at 100 °GL.

3. Results

3.1. Characterization of the Raw Material

The raw material used in this study was characterized according to Cuban standards and the distillery’s own operating manual. The results are shown in Table 2.

Table 2.

Results of analysis of molasses as raw material.

The results show that the molasses, despite being classified as old because it was processed in the previous year’s harvest (2020–2021) and was in storage, has the required quality to be used in the fermentation processes, with the drawback that NC 715:2009 [41] establishes a minimum °Brix of 85 and the value obtained was lower; however, it is very close to the standard value and is associated with hydration of the honey due to storage. On the other hand, this same standard establishes a maximum limit for sludge content of 8%, and in this study, a value of 6% was obtained, which is beneficial because sludge is often the cause of slow fermentation [42].

On the other hand, fermentable sugars are not considered to be in a range too high to achieve fast fermentations, although they do comply with NC 715:2009 [41], which establishes a minimum of 48.2%. This, in conjunction with the molasses storage time and the infermentable sugar value, may explain why the fermentation times obtained are more than 24 h. Infermentable sugars increase with the age of the molasses, a product of oxidation and degradation reactions of this raw material. The pH value is at the upper limit of the range stipulated by NC 715:2009 [41] (from 5.2 to 5.7).

Based on the results of the raw material, the necessary calculations were made to obtain approximately 5% alcohol in the fermented mash, as required by the plant’s operating manual. The elementary parameter to be calculated is the °Brix of the sowing to obtain 100 L of mixture, considering that honey can be diluted up to 60 times. Using the density data (1.44402 kg/L) and the desired density (1.0466 kg/L), a seeding Brix of 13.5 ° was obtained.

3.2. Study of Pre-Fermentation

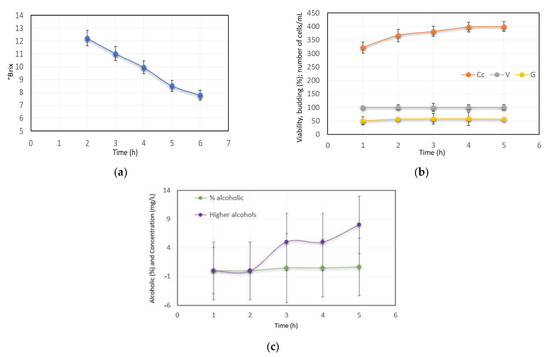

In this case, a pre-fermenter was followed every hour, the parameters analyzed are shown in Figure 2, and the determinations were carried out in triplicate.

Figure 2.

Parameters analyzed over time in the pre-fermentation process: (a) consumption of °Brix; (b) behavior of cell count (Cc), viability (V), and sprouting (G) of S. cerevisiae; (c) evaluation of the formation of ethanol and higher alcohols.

Figure 2a clearly shows how the °Brix decreases over time to values close to 70% of the °Brix with which the pre-fermenter was seeded, as a result of microbial growth, being ready to inoculate a fermenter 4 h after it was seeded, which indicates that the yeast has high potency. On the other hand, this approach is ratified when evaluating the microbiological parameters shown in Figure 2b, including cell count, viability, and budding. During the whole process, cell viability remained at values of 100%, and the twinning remained at values around 50%, which indicates that the cells contained in the pre-ferment were reproducing, evidencing a high potency to inoculate in fermentation, and consequently, to achieve a high alcoholic percentage. All of the above is verified by evaluating the total cell count as it shows an increasing trend throughout.

In the pre-fermentation stage, it is very difficult to find alcohol formation; however, some yeasts, in spite of aerobic conditions, form so-called alcohol phlegm, but in very low concentrations, consequently also form higher alcohols in practically negligible concentrations. This is shown in the graph in Figure 2c. This graph also shows that the standard deviations are relatively large due to the inaccuracy of measuring these parameters at very low concentrations, as well as the limitations of the limit of detection and quantification of the analytical methods used. The potency of the yeast cells and other factors described here agree with those reported by Mesa et al. [43] in their study on ethanol production.

3.3. Study of Fermentation

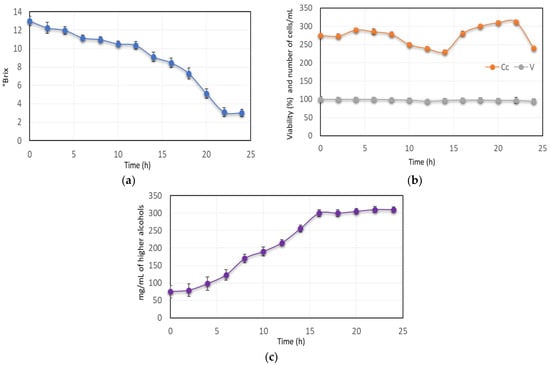

Once the preferment was characterized, it was inoculated in a fermenter. In the same way, the aforementioned parameters were controlled, but this time, every two hours. The graphs of the behavior of the parameters are shown in Figure 3. This study was also carried out in triplicate.

Figure 3.

Parameters analyzed over time in the fermentation process: (a) consumption of °Brix; (b) behavior of cell count (Cc) and viability (V) of S. cerevisiae; (c) evaluation of the formation of ethanol; (d) evaluation of the formation of higher alcohols.

The fermenter studied showed an almost total consumption of sugars, as shown in Figure 3a, translated into a decrease in the °Brix, which shows a good fermentation efficiency. However, the fermentation time is a little long, which may be due to the increase in temperature caused by the process itself in the final stages of fermentation.

On the other hand, the microbial behavior of this process is the inverse of that of pre-fermentation because in this case, the yeast develops in a totally anaerobic medium. Figure 3b shows the decrease in the total cell count, which indicates that many of the cells have entered cell lysis, a process that occurs at certain fermentation times, mainly due to the absence of nutrients, and which, in turn, is detrimental because amino acids such as leucine and isoleucine, which are used by the living yeast cells to form higher alcohols, are released into the environment. Figure 3c clearly shows the formation of alcohol over time during the fermentation process, while Figure 3d shows the formation of higher alcohols. Figure 3d shows an increase in the formation of higher alcohols after 16 h of fermentation, reaching values of 520 mg/L at the end of fermentation.

3.4. Follow-Up of the Fermentation Proposal at the Laboratory Level, Acosta Fermentation Method

Considering the results shown in the previous follow-ups and those reported by Acosta and Jover [28], partial conclusions were reached that set a guideline to move forward in this implementation study.

In contrast to what was reported by Acosta and Jover [28], who state that the inversion of the yeast metabolic pathway should take place after 12 h of fermentation, in this case, it was evidenced after 16 h. It is evident of the formation of higher alcohols from this time; as mentioned above, there are several phenomena that may be occurring synergistically, which justifies this sudden formation of higher alcohols. At this fermentation time, there is an alcoholic percentage of around 4%, and the ferment can be distilled with that alcoholic value.

Therefore, it was decided to set up a fermenter starting from 13 °Brix as calculated by the laboratory for the type of raw material used in a volume of 10 L and with an inoculum volume of 10% from the pre-fermentation room, the same that was characterized before being inoculated, Table 3.

Table 3.

Characterization of the preferment inoculated in the laboratory fermenter.

Figure 4 shows the parameters analyzed in the laboratory-scale fermenter, whereas Figure 4a shows the results of the sugar consumption of the laboratory-scale fermenter using the proposed Acosta fermentation method. As expected, the consumption of sugars behaves in a manner analogous to that of the traditional method, although it is evident that fermentation times decrease because the yeast prefers the metabolic route for the formation of biomass to the alcoholic fermentation route; according to Lehninger et al. [44], this is totally normal under the right conditions. At this point, there is a certain alcoholic percentage formed, which acts as an inhibitor of reproduction because the yeast in the presence of alcohol is inhibited by the final product, but it is not high enough for this process to occur completely; therefore, it manages to reproduce and shortens fermentation times.

Figure 4.

Parameters analyzed over time in the Acosta fermentation process at laboratory scale: (a) consumption of °Brix; (b) behavior of cell count (Cc) and viability (V) of S. cerevisiae; (c) evaluation of the formation of higher alcohols.

Figure 4b shows how once air begins to be supplied after 16 h of fermentation, at a rate of 0.1 m3/min, the yeast resumes its metabolic route toward the formation of biomass, which is manifested through of the total cell count and is confirmed with the percentages of cell viability, which from 95% return to values of 98%.

Regarding the formation of higher alcohols, it is notable that from the point where the air was supplied, there was an alcoholic percentage (4.2%) such that the fermenter can be distilled, and a concentration of higher alcohols low enough to achieve the proposed objectives; if the percentage of the removal of these by the distillation column is added to this, a product with very low concentrations of higher alcohols would be obtained. The values of higher alcohols after 16 h of fermentation remained practically constant, and this effect can be seen in Figure 4c. This was not the case with traditional fermentation, as shown in Figure 3d, in which the trend was upward.

Taking all these results into account, we proceeded to scale up and pilot test an industrial-scale fermenter that is equipped with a connection to supply air and is able to carry out this study satisfactorily.

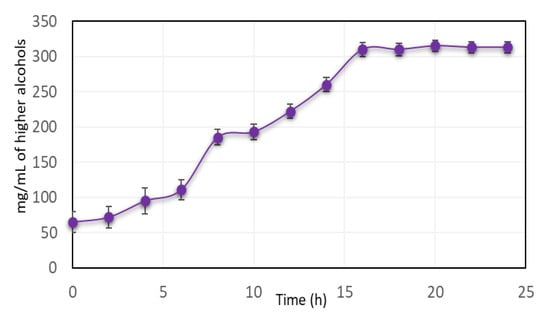

3.5. Follow-Up of the Fermentation Proposal at the Laboratory Level, Acosta Fermentation Method

Figure 5 shows the behavior of higher alcohols on an industrial scale. These behave in an analogous way to the results obtained at the laboratory level because they practically remain constant from the air supply, with a very low rate of increase. The consumption of sugars is again carried out during fermentation with very good efficiency, while the microbial activity values confirm the development of biomass in the medium.

Figure 5.

Formation of higher alcohols over time during industrial-scale pilot fermentation.

Considering that the industrial-scale test was a success for the objectives set, it should be noted that this fermenter was distilled using the column normally used for the distillation of spirits, and the product obtained was characterized in the laboratory.

3.6. Characterization of the Schnapps Obtained

Once the pilot fermenter was ready to be distilled, it was transferred to the distillation process using the schnapps column. The characterization results are shown in Table 4.

Table 4.

Characterization of the schnapps obtained.

When comparing this schnapps with those historically obtained in the plant, in terms of alcoholic strength, we have a product with the same alcoholic concentration between 70 and 75 °GL, while its acidity is within normal parameters, as is the ester content. In the case of higher alcohol, they were within the norm, thus fulfilling the objective that had been proposed. The higher alcohol in fermentation was below the norm that stipulates 350 mg/L for raw cane schnapps; however, the ferment contained 315 mg/L. This, in addition to the removal of the column, resulted in the content of higher alcohol in schnapps being 132.5 mg/L.

4. Discussion

The engineering implementation of the Acosta fermentation method to obtain Cuban schnapps with reduced concentrations of higher alcohols is a fascinating topic that combines the science of fermentation with process engineering to produce a high-quality end product. The Acosta fermentation method is known for its ability to control concentrations of higher alcohols, which can affect both the flavor and quality of schnapps [28]. This method involves several stages, from selecting high-quality raw materials to optimizing pre-fermentation and fermentation and distillation conditions.

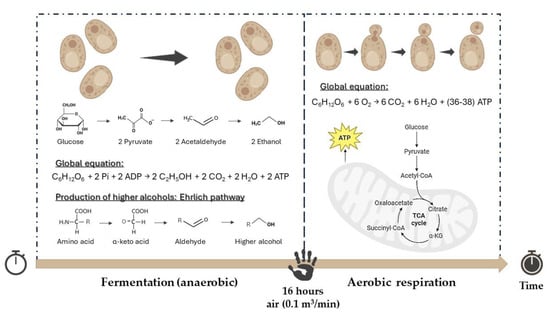

Firstly, the emphasis on achieving an optimal point at which ethyl alcohol production is maximized while minimizing the production of higher alcohols is commendable. This approach ensures that the final product maintains a high level of purity, which is crucial for both industrial and consumer applications. By controlling the fermentation process to favor ethyl alcohol production, the method offers a solution to the challenge of excessive higher alcohol content often encountered in traditional fermentation methods. The injection of air into the fermentation vessel causes aerobic conditions, so that fermentation will cease, and the metabolites will be completely oxidized for the production of energy in the form of ATP, with the consequent production of carbon dioxide and water (Figure 6). During this aerobic respiration process, the cells focus on cell multiplication, avoiding the use of amino acids for the synthesis of higher alcohols. Thus, a second implication of the reversal of the yeast metabolic pathway would be that biomass production is increased because the energy produced during respiration is used for the cell division process. The Acosta fermentation method results in an improvement in terms of fermentation efficiency and biomass yield as a byproduct. This could have significant benefits in terms of scalability and yield, making the Acosta method particularly appealing for industrial-scale ethanol production.

Figure 6.

Metabolic pathways of S. cerevisiae during the Acosta fermentation method.

Additionally, the use of single-fractional distillation to obtain the schnapps offers a practical and efficient means of separating ethyl alcohol from other components of the fermented broth. While some may argue for more complex purification techniques, the simplicity and effectiveness of distillation make it a reliable method for achieving the desired alcohol content in the final product. Moreover, the presence of small quantities of congeners adds depth and complexity to the schnapps, enhancing its flavor profile and appeal to consumers.

The results of implementing this method are of great interest to the schnapps distillation industry, as they can have a significant impact on the quality and sensory profile of the final product. The following are some key points that could arise in a result discussion: Reduction of higher alcohols: One of the main objectives of this research is to reduce the concentrations of higher alcohols, which can contribute to unwanted flavors in schnapps. Also, demonstrate how the Acosta fermentation method achieves this goal through the precise control of fermentation conditions, such as temperature, pH, and yeast nutrition. Improved sensory profile: Lower concentrations of higher alcohols may result in schnapps with a more balanced and pleasant sensory profile.

The engineering implementation of the Acosta fermentation method also involves optimizing production processes to ensure maximum efficiency and consistent product quality. The results could highlight improvements in production yields, product purity, and process reproducibility. Economic considerations: In addition to technical and sensory aspects, the economic viability of this method is crucial for its adoption in the industry. The results could include a cost analysis comparing the profitability of implementing the Acosta fermentation method with other schnapps production methods. Additionally, it could identify areas for future research, such as applying this method to other types of spirits or continuously optimizing fermentation and distillation conditions.

Contribution to the Food Industry and Sustainability

The Acosta fermentation methodology makes significant contributions to both the food industry and environmental sustainability. Firstly, its focus on optimizing ethanol production while minimizing the generation of higher alcohols is particularly relevant for the food and beverage industry. By producing high-purity ethanol with low levels of undesired compounds like higher alcohols, the methodology ensures the quality and safety of the final products. This is crucial in the manufacture of a wide range of foods and beverages, from spirits and beers to baked goods and fermented foods, in which quality and flavor are paramount.

Moreover, the Acosta methodology’s ability to increase cellular biomass production through air injection during fermentation has significant implications for sustainability. Yeast biomass increases as a result of cell multiplication when air is added to the fermenter, and when the fermented must is passed to the distillation column, more yeast biomass remains as a residue at the bottom of the fermenter and can be used for other purposes. In particular, the Santa Fé distillery markets it in both cream and dry active forms for pig and cattle feed. In addition, the production of a schnapps with a low level of higher alcohols does not require mixing with other productions or the addition of production stages to achieve the required quality. By enhancing process efficiency and improving yield, the amounts of raw materials and resources needed to achieve the same production levels is reduced. This can translate into significant savings in natural resources and energy, as well as a reduction in waste and emissions associated with the production of fermented foods and beverages.

In terms of environmental sustainability, the Acosta methodology also offers advantages in waste treatment. By carefully controlling the fermentation process to minimize the generation of unwanted byproducts such as higher alcohols, the amount of organic waste requiring treatment or disposal is reduced. This can have environmental benefits by decreasing the burden on wastewater treatment systems and reducing environmental pollution associated with organic waste management.

5. Conclusions

The molasses used, despite being stored for approximately one year, complied with the stipulations of the standard and with the requirements for fermentable sugars to be able to enter the fermentation process. Monitoring of the industrial fermentation of the Santa Fé distillery showed ferments that present higher alcohol concentrations above 520 mg/L. However, by using the Acosta fermentation method with inversion of the metabolic route after 16 h of fermentation and air concentration of 0.1 m3/min, this value was reduced to 310 mg/L, giving a schnapps as a finished product, with a higher alcohol content of 132.5 mg/L.

The Acosta fermentation method was an effective method for reducing the content of higher alcohols without affecting the rest of the parameters established for the schnapps. Furthermore, it is easily reproducible on an industrial scale, produces a greater biomass of yeast as a byproduct, and can be used for various purposes, among which animal feed stands out. Its application has the potential to promote more sustainable practices in the food industry and contribute to a healthier, more environmentally friendly future.

Author Contributions

Conceptualization, D.R.A.-M., J.A.A.-S. and A.A.V.-A.; methodology, R.V.G.-M. and A.A.V.-A.; software, A.L.G.-B. and A.A.V.-A.; validation, R.B.-S., D.R.A.-M. and A.A.V.-A.; formal analysis, A.A.V.-A., Y.R.-D. and A.L.G.-B.; investigation, A.A.V.-A., J.A.T.-H. and Y.R.-D.; resources, R.B.-S.; data curation, R.B.-S.; writing—original draft preparation, A.A.V.-A. and J.A.T.-H.; writing—review and editing, J.A.T.-H.; visualization, F.R.-F. and J.A.T.-H.; supervision, D.R.A.-M. and F.R.-F.; project administration, D.R.A.-M.; funding acquisition, R.B.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mosquera, J.T. Aspectos Toxicológicos, Psicológicos y Sociales. Relacionados con el Consumo de Bebidas Alcohólicas, 1st ed.; Editorial Universidad Nacional de Colombia: Bogotá, Colombia, 2012. [Google Scholar]

- Nevárez-Loor, G.; Intriago-Flor, F.; Plúa-Barcia, J.L. Evaluación de las condiciones higiénica sanitarias en la elaboración de alcohol artesanal en Manabí. Técnica Rev. Agrocienc. 2021, 11, 28–33. [Google Scholar]

- Díaz, O.C.; de Armas Martínez, A.C.; Carvajal, Y.A.; Aguilar, I.G. Proposal for technological modification in a cuban distillery based on a consumption indexes study. Rev. Centro Azúcar 2021, 48, 117–126. [Google Scholar]

- Borroto-Mato, D.; Lorenzo-Izquierdo, M.; García-Gutiérrez, R.; Herrera-Marrero, N. Determinación de alcoholes superiores por cromatografía de gases en destilados. ICIDCA Sobre Deriv. Caña Azúcar 2021, 55, 63–69. [Google Scholar]

- Quiñones, I. Resolución No. 12/19; Gaceta Oficial de la República de Cuba; Ministerio de la Industria Alimentaria: Havana, Cuba, 2019. [Google Scholar]

- Mulet-Hing, M. Automatización de la destilación de alcohol de la UEB destilería de la ronera Santiago de Cuba. Tecnol. Química 2013, 33, 1–9. [Google Scholar]

- Hua, Y. Research progress of higher alcohols as alternative fuels for compression ignition engines. Fuel 2024, 357, 129749. [Google Scholar] [CrossRef]

- NC 535:2007; Bebidas Alcohólicas. Determinación de Alcoholes Superiores. Método Espectrofotométrico. Oficina Nacional de Normalización: La Habana, Cuba, 2007.

- Burini, J.A.; Eizaguirre, J.I.; Loviso, C.; Libkind, D. Levaduras no convencionales como herramientas de innovación y diferenciación en la producción de cerveza. Rev. Argent. Microbiol. 2021, 53, 359–377. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Tang, P.; Zhang, P.; Lu, J.; Chen, Y.; Xiao, D.; Guo, X. Unraveling the aroma profiling of Baijiu: Sensory characteristics of aroma compounds, analytical approaches, key odor-active compounds in different Baijiu, and their synthesis mechanisms. Trends Food Sci. Technol. 2024, 146, 104376. [Google Scholar] [CrossRef]

- Morales-Cusme, E.J.; Palacios-Macías, M.G. Evaluación en la Implementación de Buenas Prácticas de Manufactura para el Aguardiente de Caña en la Fábrica “Alcívar”. Master’s Thesis, ESPAM MFL, Calceta, Ecuador, 2021. [Google Scholar]

- Muñoz, F.M. Impacto Orgenoléptico Causado por la Variación de Constituyentes Nutricionales, en la Fermentación de un Vino Cabernet Sauvignon. Bachelor’s Thesis, Facultad de Enología y Agroindustrias, Universidad Juan Agustín Maza, Mendoza, Argentina, 2021. [Google Scholar]

- Loviso, C.L.; Libkind, D. Síntesis y regulación de los compuestos del aroma y sabor derivados de la levadura en la cerveza: Alcoholes superiores. Rev. Argent. Microbiol. 2019, 51, 386–397. [Google Scholar] [CrossRef]

- Ferremi Leali, N.; Salvetti, E.; Luzzini, G.; Salini, A.; Slaghenaufi, D.; Fusco, S.; Ugliano, M.; Torriani, S.; Binati, R.L. Differences in the Volatile Profile of Apple Cider Fermented with Schizosaccharomyces pombe and Schizosaccharomyces japonicus. Fermentation 2024, 10, 128. [Google Scholar] [CrossRef]

- Romero-Rodríguez, R.; Durán-Guerrero, E.; Castro, R.; Díaz, A.B.; Lasanta, C. Evaluation of the influence of the microorganisms involved in the production of beers on their sensory characteristics. Food Bioprod. Process. 2022, 135, 33–47. [Google Scholar] [CrossRef]

- Palacios-Bereche, M.C.; Palacios-Bereche, R.; Ensinas, A.V.; Gallego, A.G.; Modesto, M.; Nebra, S.A. Brazilian sugar cane industry—A survey on future improvements in the process energy management. Energy 2022, 259, 124903. [Google Scholar] [CrossRef]

- Santos, F.; Eichler, P.; Machado, G.; De Mattia, J.; De Souza, G. By-products of the sugarcane industry. In Sugarcane Biorefinery, Technology and Perspectives; Academic Press: Cambridge, MA, USA, 2020; pp. 21–48. [Google Scholar]

- Palmonari, A.; Cavallini, D.; Sniffen, C.J.; Fernandes, L.; Holder, P.; Fagioli, L.; Fusaro, I.; Biagi, G.; Formigoni, A.; Mammi, L. Characterization of molasses chemical composition. J. Dairy Sci. 2020, 103, 6244–6249. [Google Scholar] [CrossRef]

- Ghorai, S.; Banik, S.P.; Verna, D.; Chowdhury, S.; Mukherjee, S.; Khowala, S. Fungal biotechnology in food and feed processing. Food Res. Int. 2009, 42, 577–587. [Google Scholar] [CrossRef]

- Torres, D. Estudio de la Etapa de Fermentación Alcohólica Utilizando Mezclas de Diferentes Sustratos; Depertamento de Ingeniería Química, Facultad de Química y Farmacia, Universidad Central Marta Abreu de Las Villas: Santa Clara, Cuba, 2005. [Google Scholar]

- Sherman, F. Getting started with yeast. Methods Enzymol 2002, 350, 3–41. [Google Scholar]

- García, R. Cultivo Mixto en el Desarrollo de la Fermentación Para la Producción de Alcohol Orgánico. Ph.D. Thesis, Depertamento de Licenciatura en Química, Facultad de Química y Farmacia, Universidad Central Marta Abreu de Las Villas, Santa Clara, Cuba, 2006. [Google Scholar]

- Arencibia, Y. Impacto de la Recirculación de Vinazas a la Etapa Fermentativa en el Proceso de Producción de Etanol en la Destilería Heriberto Duquesne. Ph.D. Thesis, Universidad Central Marta Abreu de Las Villas, Santa Clara, Cuba, 2014. [Google Scholar]

- Cirilo, V.S.; Santillán, P.S.; Salado, N.T.; Pérez, J.H. Composición de la pared celular de vástago de coco tratado por fermentación solida usando Pleurotus ostreatus como inóculo. Lat. Am. Arch. Anim. Prod. 2023, 31, 175–179. [Google Scholar]

- Rodríguez-Páez, D.; Zumalacárregui-de Cárdenas, L.; Pérez-Ones, O.; Martínez-Guía, Y. Recuperación de los fondajes de la fermentación alcohólica para su uso como alimento animal. ICIDCA Sobre Deriv. Caña Azúcar 2022, 56, 23–30. [Google Scholar]

- Vera Cajilema, J.L. Plan de Negocio Para la Creación de una Planta Destiladora de Alcohol de Caña de Azúcar, Cantón Guaranda, Provincia del Bolívar. Master’s Thesis, Universidad Laica Vicente Rocafuerte de Guayaquil, Bolívar, Ecuador, 2021. [Google Scholar]

- Campués, J.K.; Tarupí, J.C. Obtención de Alcohol a Partir de Jugo de Caña, Cachaza y Melaza, Mediante la Incorporación de dos Niveles de Fermento (Saccharomyces cerevisiae). Master’s Thesis, Universidad Técnica del Norte, Facultad de Ingeniería en Ciencias Agropecuarias y Ambientales, Ibarra, Ecuador, 2011. [Google Scholar]

- Acosta, D.R.; Jover, J.A. Método de Fermentación “Acosta” Para Obtener Concentraciones de Alcoholes Superiores en Aguardientes Menores de 350 mg/L; Universidad Central “Marta Abreu” de las Villas, Facultad de Química, Departamento de Licenciatura en Química: Santa Clara, Cuba, 2009. [Google Scholar]

- Austin, G.T.; Espinoza, M.E.; Sánchez, J.; Viesca, R. Manual de Procesos Químicos en la Industria; McGraw-Hill: New York, NY, USA, 1992; Volume 1. [Google Scholar]

- Mangwanda, T.W.; Mani, J.S.; Johnson, J.B.; Jackson, S.; McKeown, T.; Naiker, M. Physicochemical and nutritional analysis of molasses for rum fermentation. Biol. Life Sci. Forum 2023, 26, 105. [Google Scholar] [CrossRef]

- Ribeiro, N.N.; Cazadore, V.C.; Madaleno, L.L. Use of Distillery Effluents in Dilution of Molasses for Ethanol Production. Sugar Tech. 2023, 25, 366–372. [Google Scholar] [CrossRef]

- Hawaz, E.; Tafesse, M.; Tesfaye, A.; Kiros, S.; Beyene, D.; Kebede, G.; Boekhout, T.; Groenwald, M.; Theelen, B.; Degefe, A.; et al. Bioethanol production from sugarcane molasses by co-fermentation of Saccharomyces cerevisiae isolate TA2 and Wickerhamomyces anomalus isolate HCJ2F-19. Ann. Microbiol. 2024, 74, 13. [Google Scholar] [CrossRef]

- NC 81-06:1988; Industria Azucarera. Miel Final. Determinación del Contenido de Sólidos Solubles. Oficina Nacional de Normalización: La Habana, Cuba, 1988.

- Vázquez, M. Manual de Técnicas Analíticas para Destilerías; Editorial ICIDCA: La Habana, Cuba, 2013; pp. 7–55. ISBN 978-959-71-65-35-4. [Google Scholar]

- NC 81-40:1988; Industria Azucarera. Miel Final. Determinación del Contenido de Lodos. Oficina Nacional de Normalización: La Habana, Cuba, 1988.

- NC 81-41:1988; Industria Azucarera. Miel Final. Determinación de pH. Oficina Nacional de Normalización: La Habana, Cuba, 1988.

- NC 81-42:1988; Industria Azucarera. Miel Final. Determinación de Azúcares Reductores Totales. Oficina Nacional de Normalización: La Habana, Cuba, 1988.

- NC 81-43:1988; Industria Azucarera. Miel Final. Determinación de Azúcares Fermentables. Método Indirecto. Oficina Nacional de Normalización: La Habana, Cuba, 1988.

- NC 83-26:1987; Industria de Fermentación. Alcohol Etílico. Determinación del Grado Alcohólico. Oficina Nacional de Normalización: La Habana, Cuba, 1987.

- NC 534:2007; Bebidas alcohólicas. Determinación de Ésteres Totales. Método de Saponificación. Oficina Nacional de Normalización: La Habana, Cuba, 2007.

- NC 715:2009; Miel Final (Melaza). Especificaciones. Oficina Nacional de Normalización: La Habana, Cuba, 2009.

- Pérez-Bermúdez, I.; Ribas-García, M.; Ibañez-Fuentes, M.L.; Saura-Laria, G.; GarridoCarralero, N. Análisis de la influencia de la calidad de la miel final y el tiempo perdido sobre la eficiencia industrial en la producción de etanol. ICIDCA Sobre Deriv. Caña Azúcar 2015, 49, 58–63. [Google Scholar]

- Mesa, L.; González, E.; González, M.; Agüero, G. La producción de etanol. Alternativas de materias primas. Rev. Cubana Química 2005, 17, 129–137. [Google Scholar]

- Lehninger, A.L.; Nelson, D.L.; Cox, M.M. Principios de Bioquímica; Ediciones Omega: Barcelona, Spain, 2005. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).