Multi-Porous Medium Characterization Reveals Tight Oil Potential in the Shell Limestone Reservoir of the Sichuan Basin

Abstract

1. Introduction

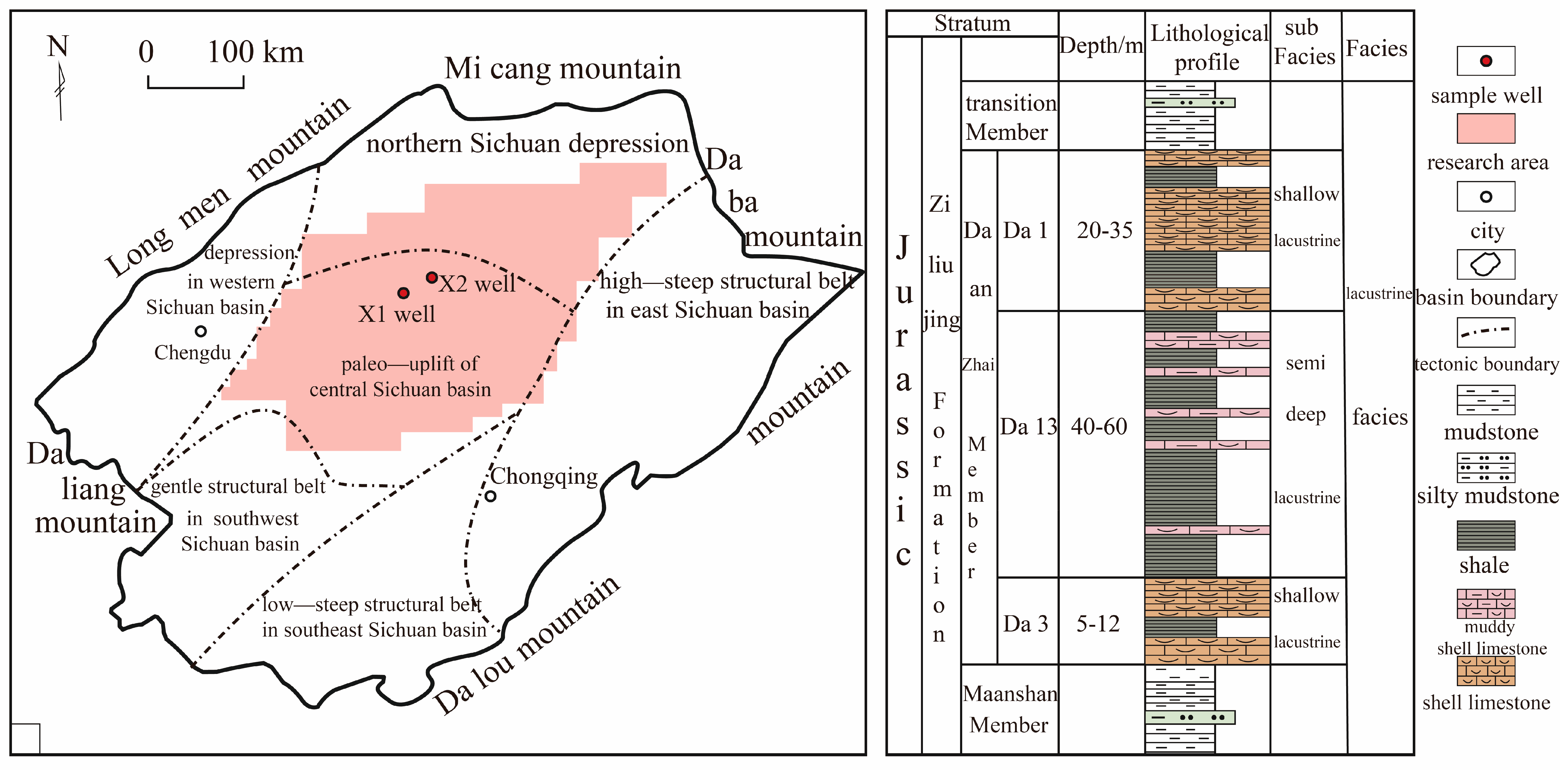

2. Geological Setting

3. Experimental and Material

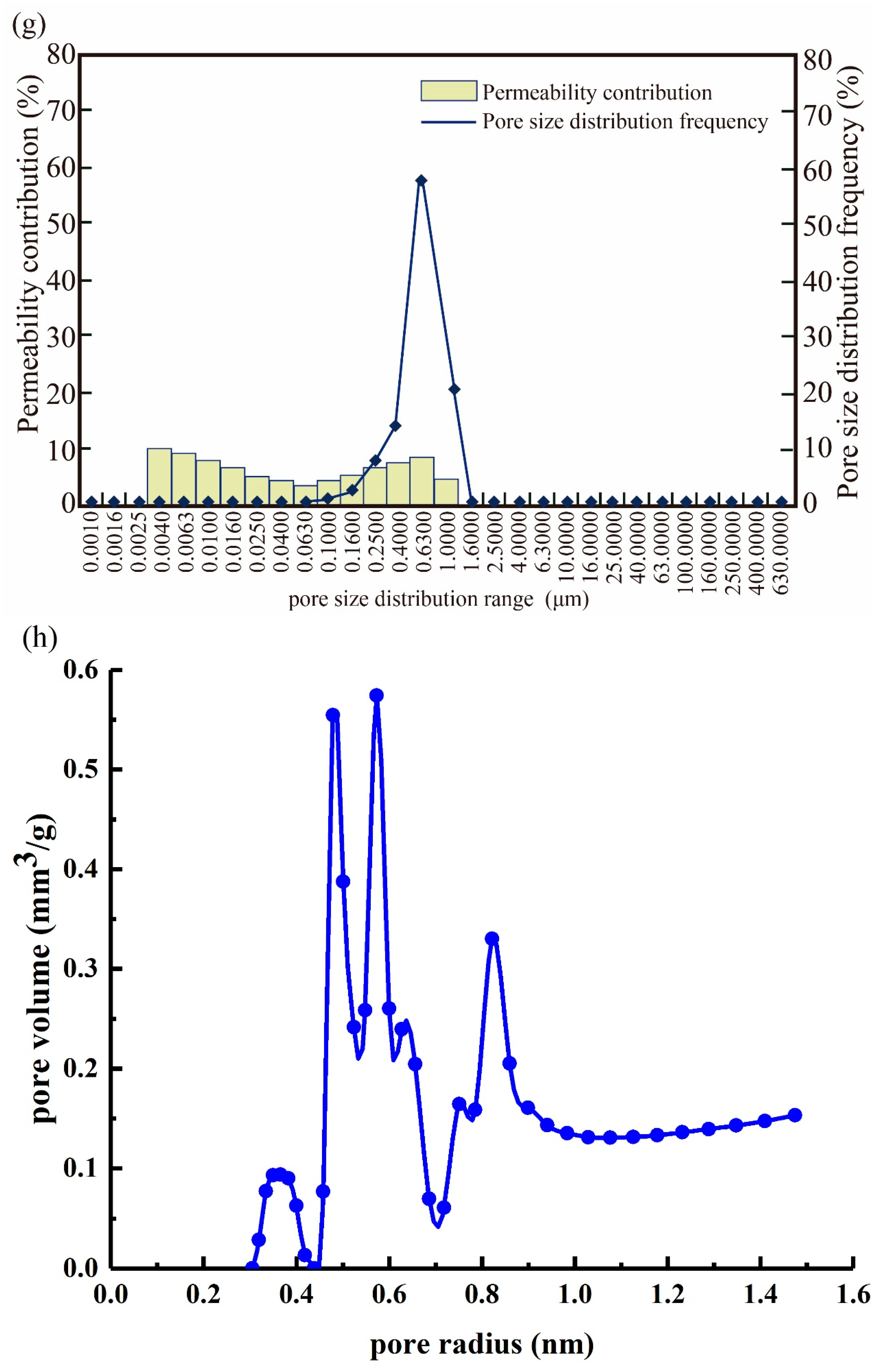

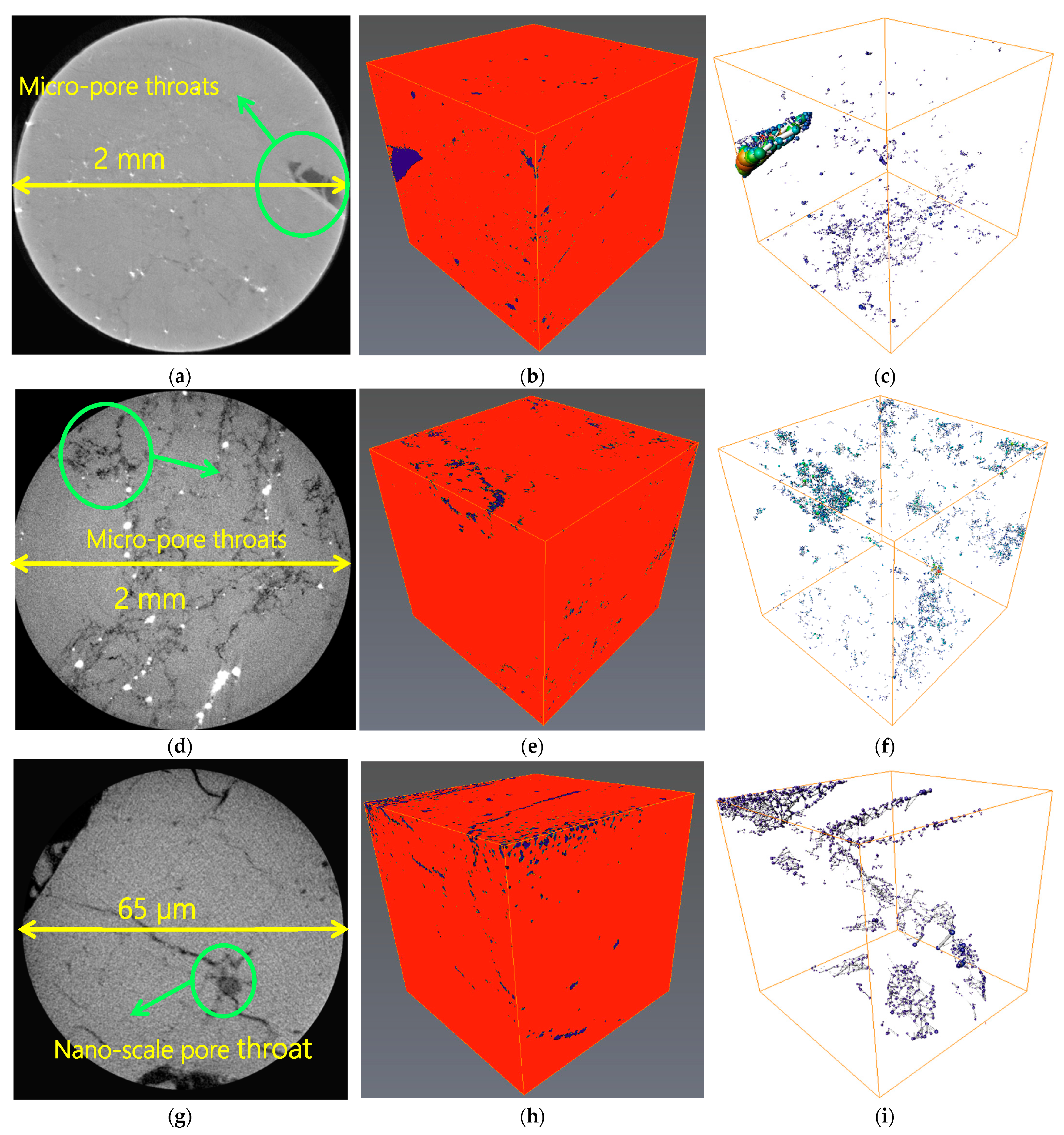

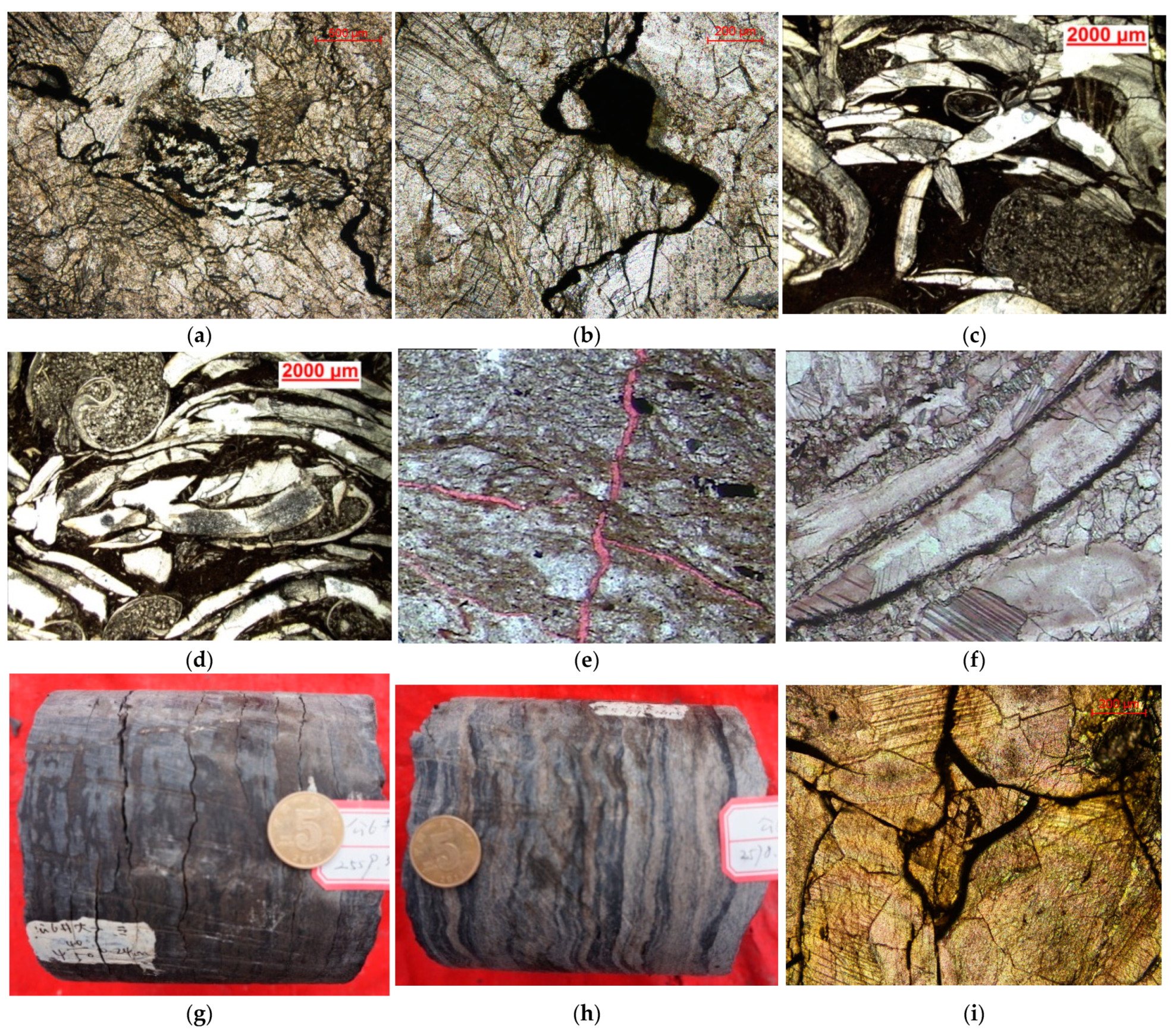

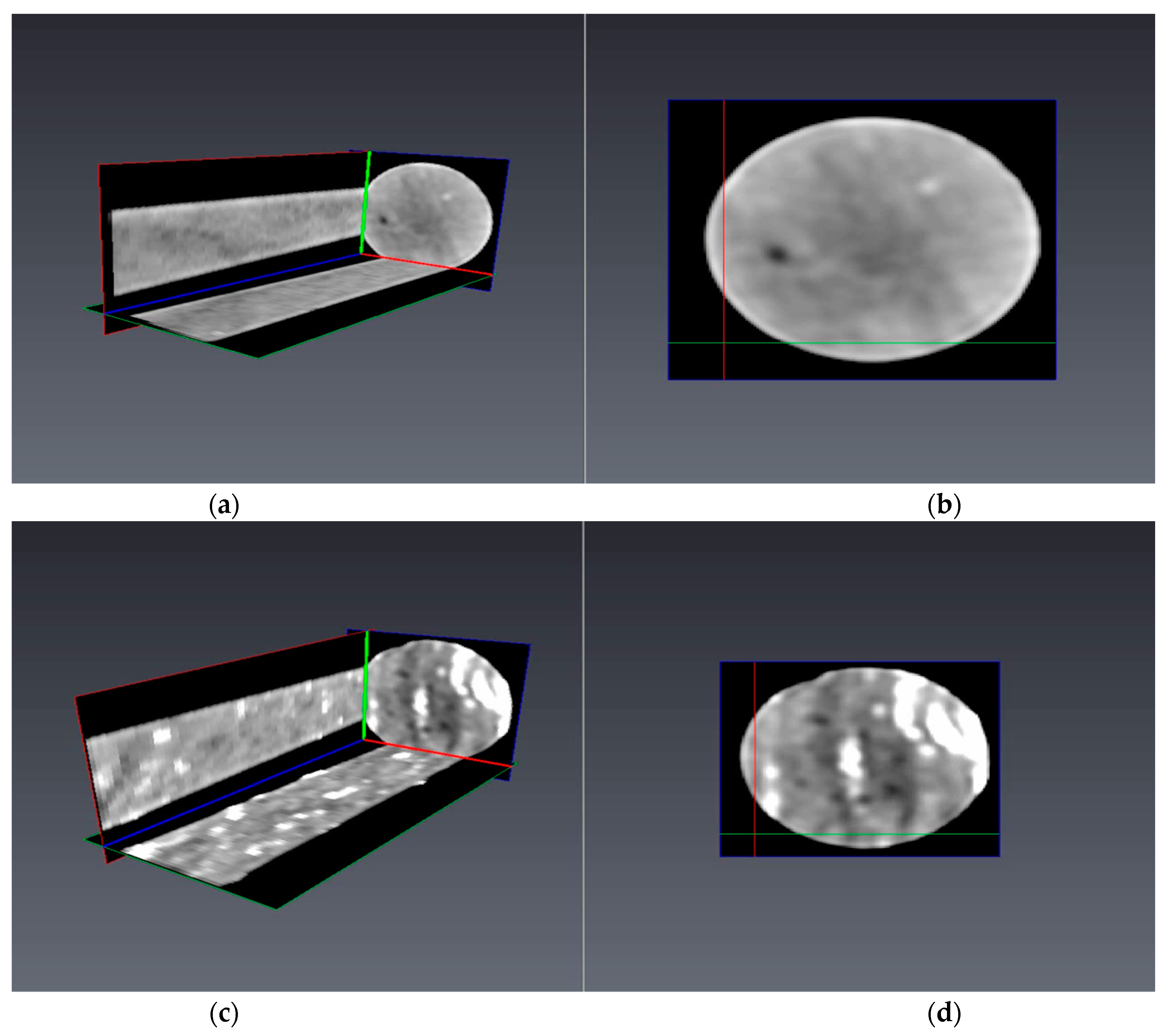

4. Results

5. Discussion

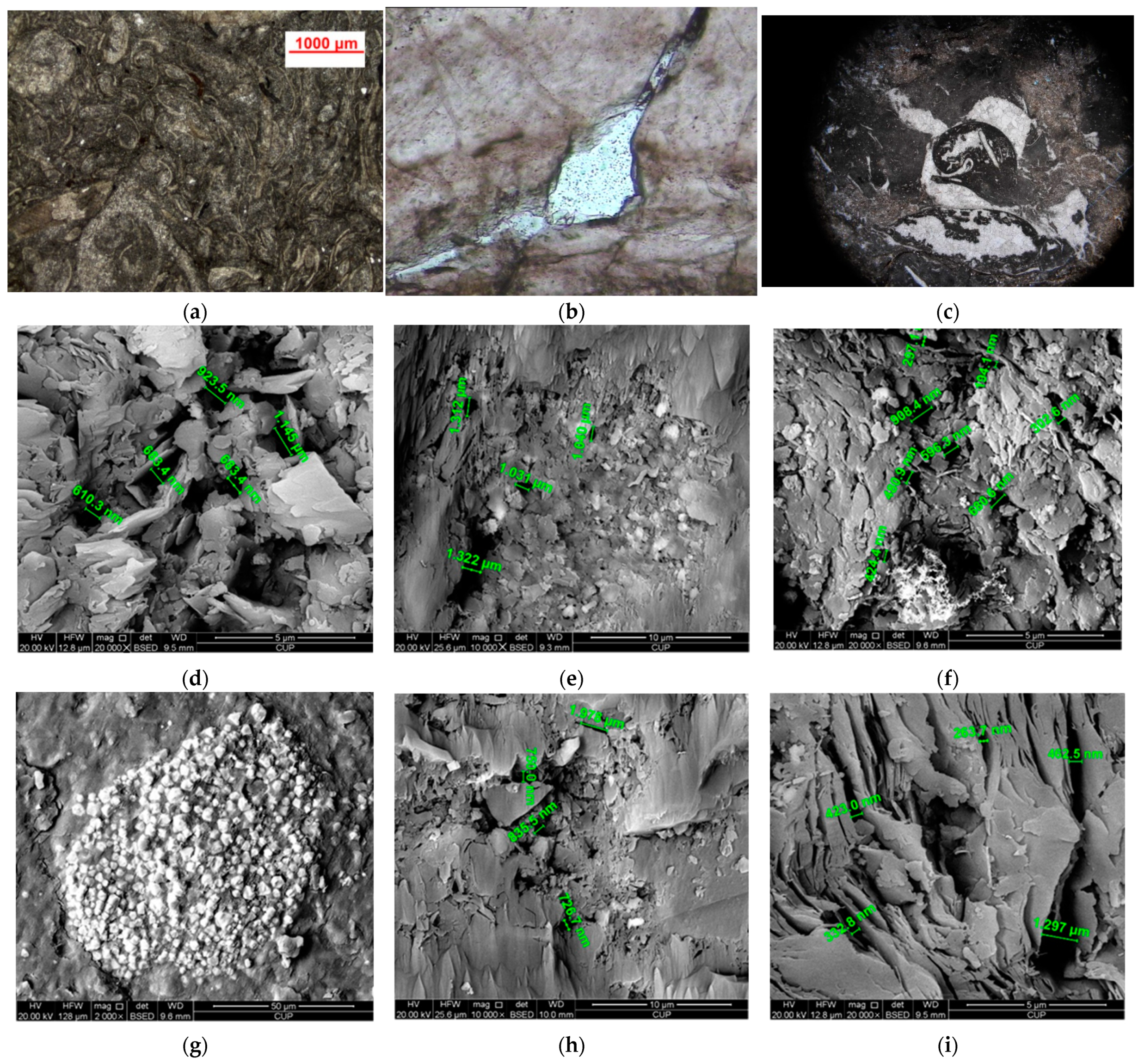

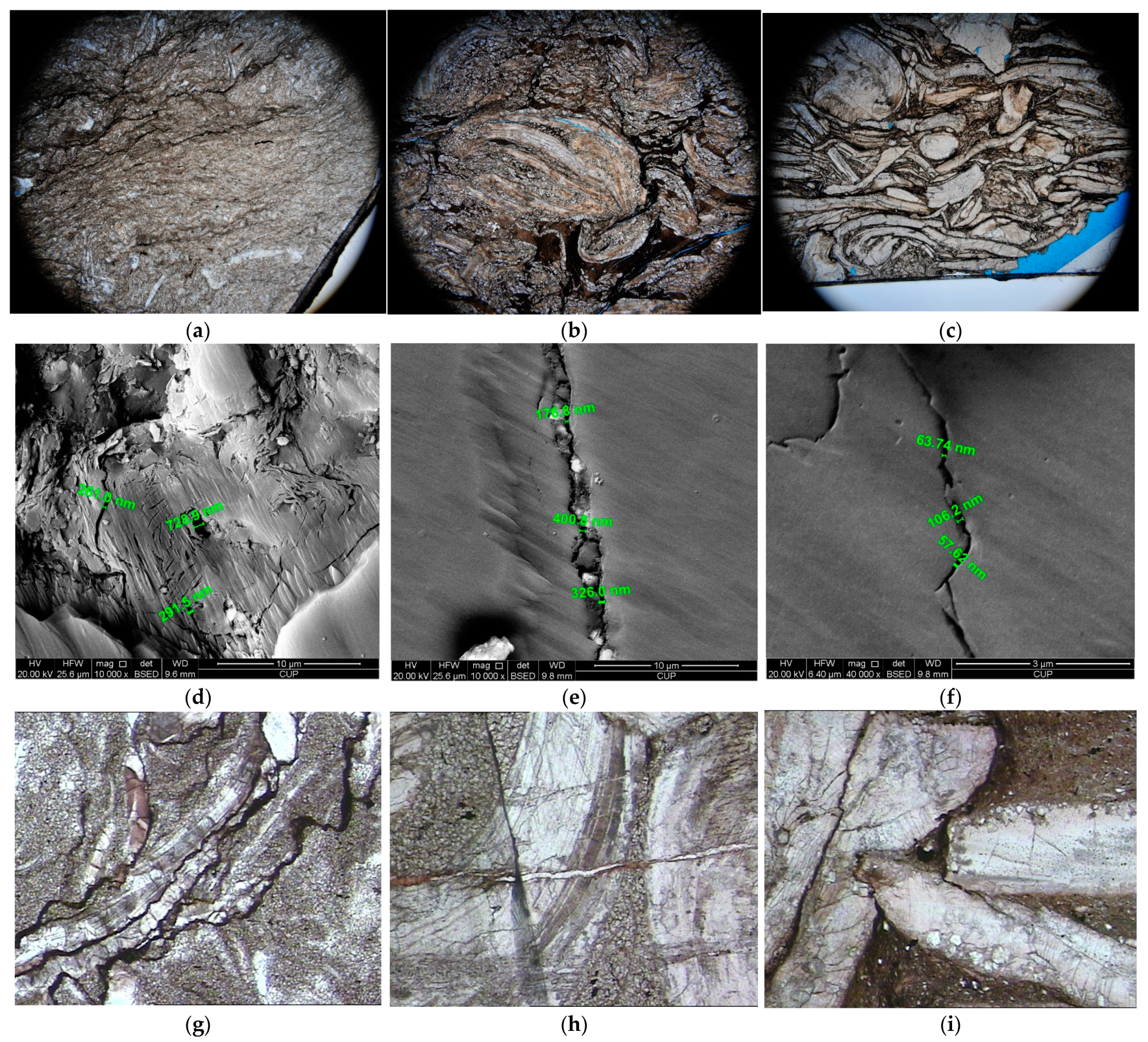

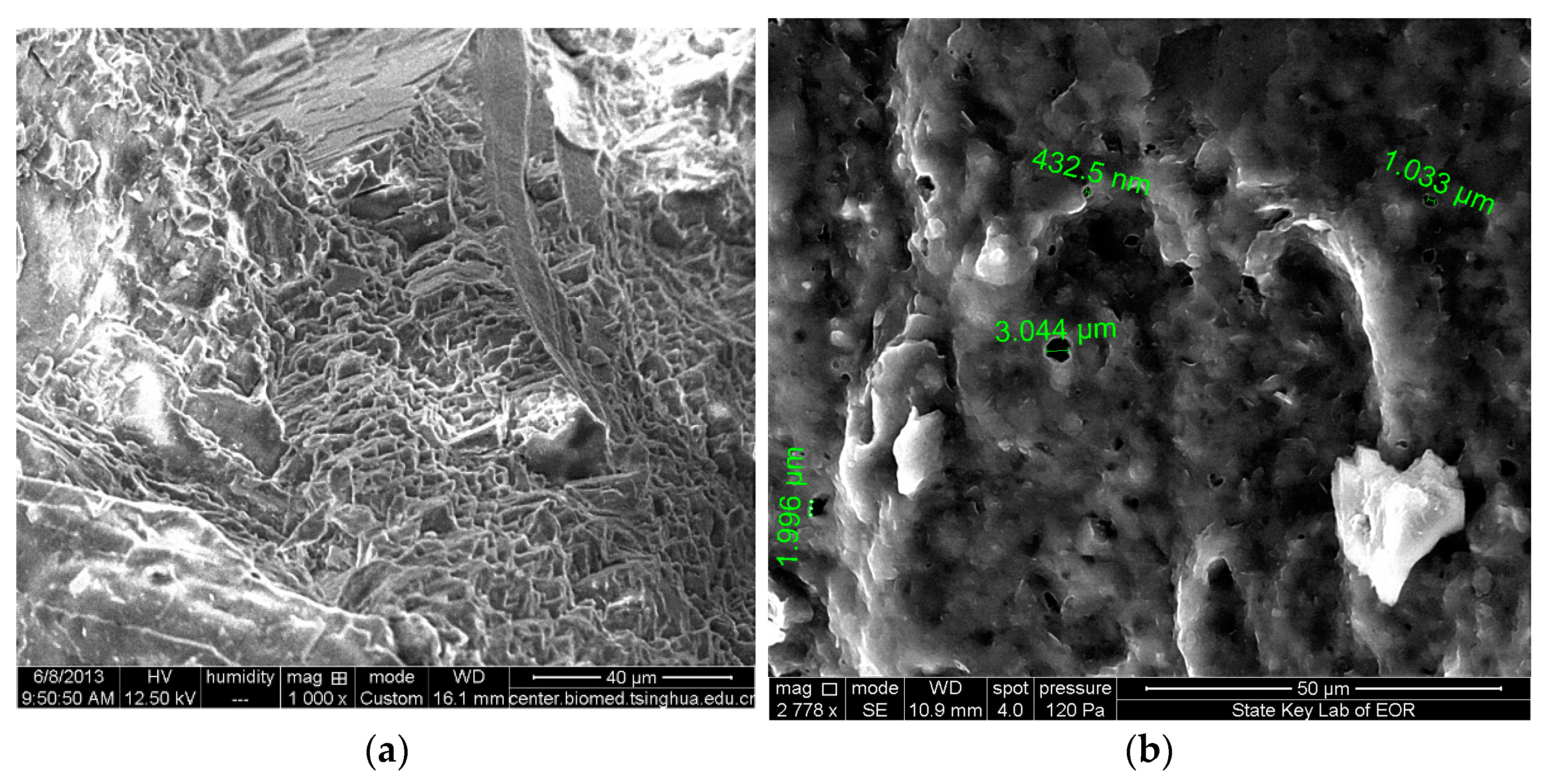

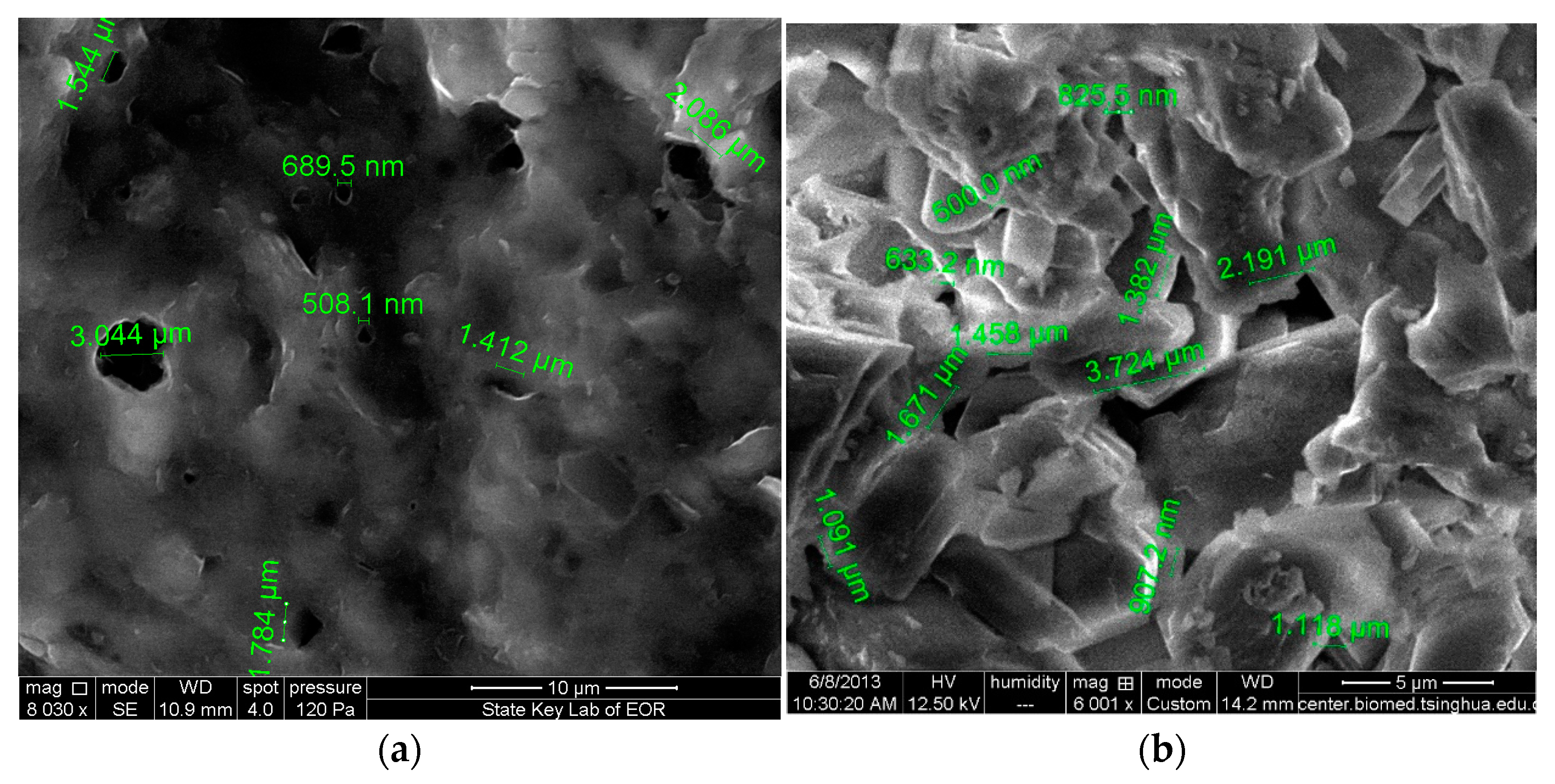

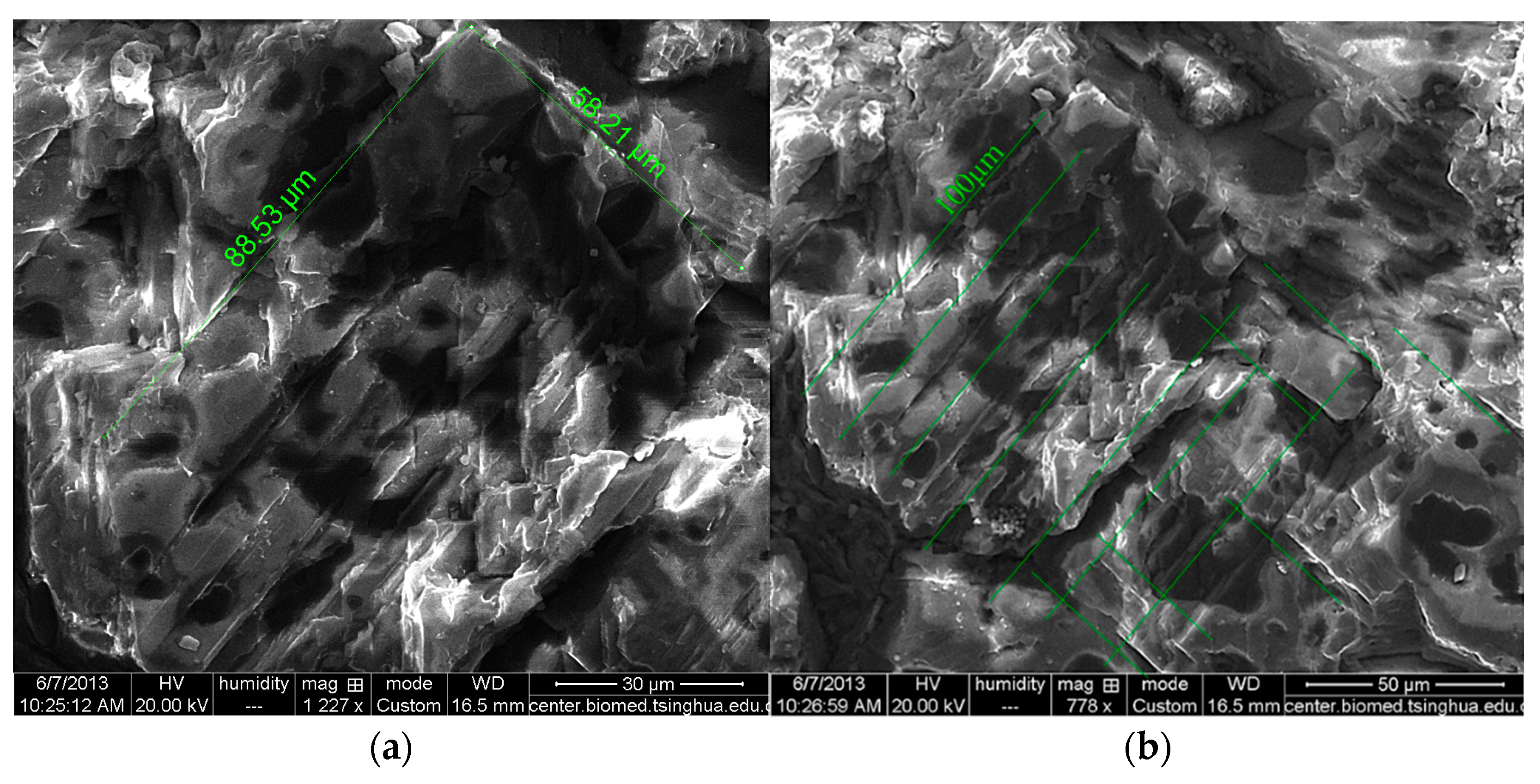

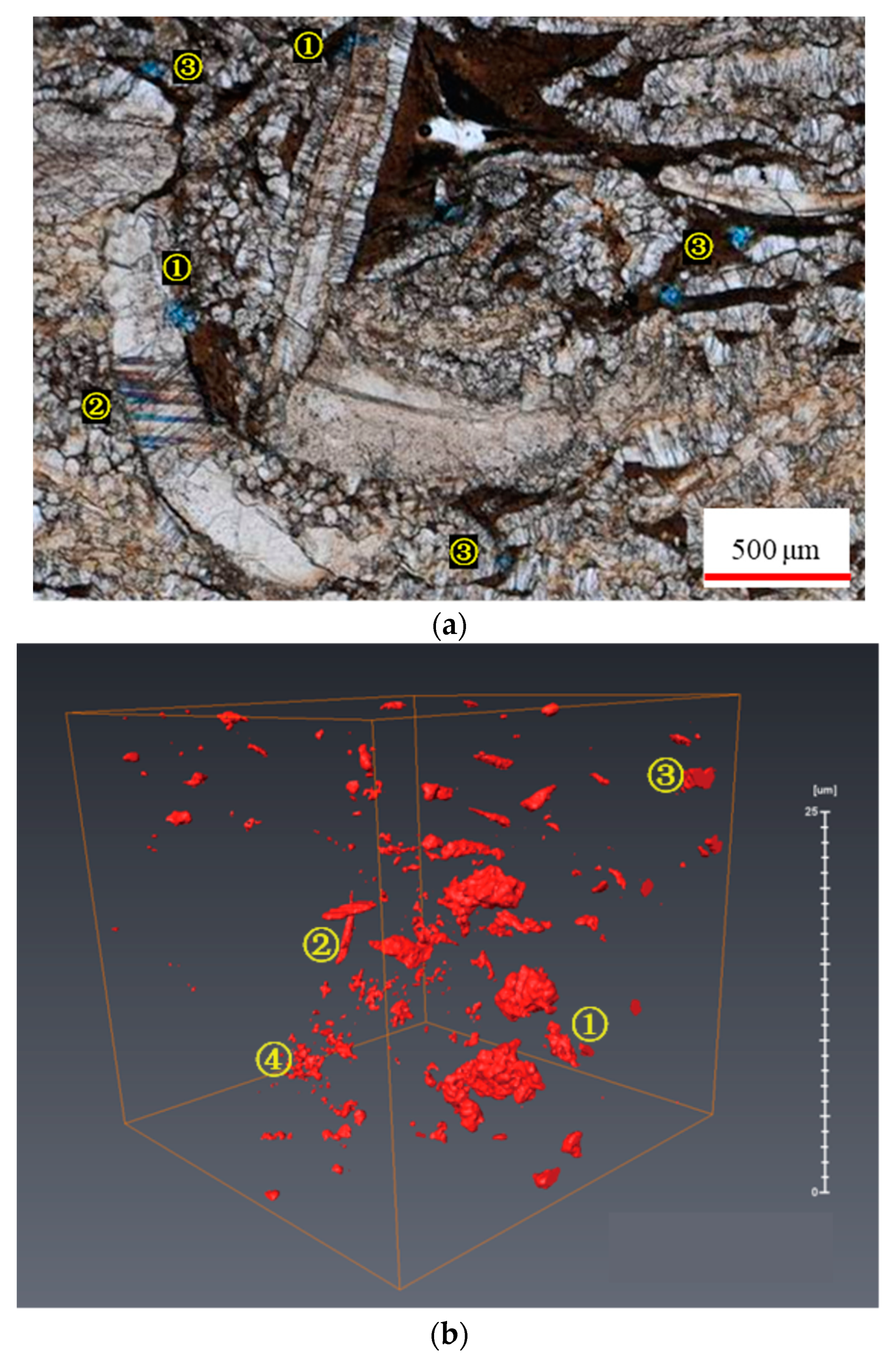

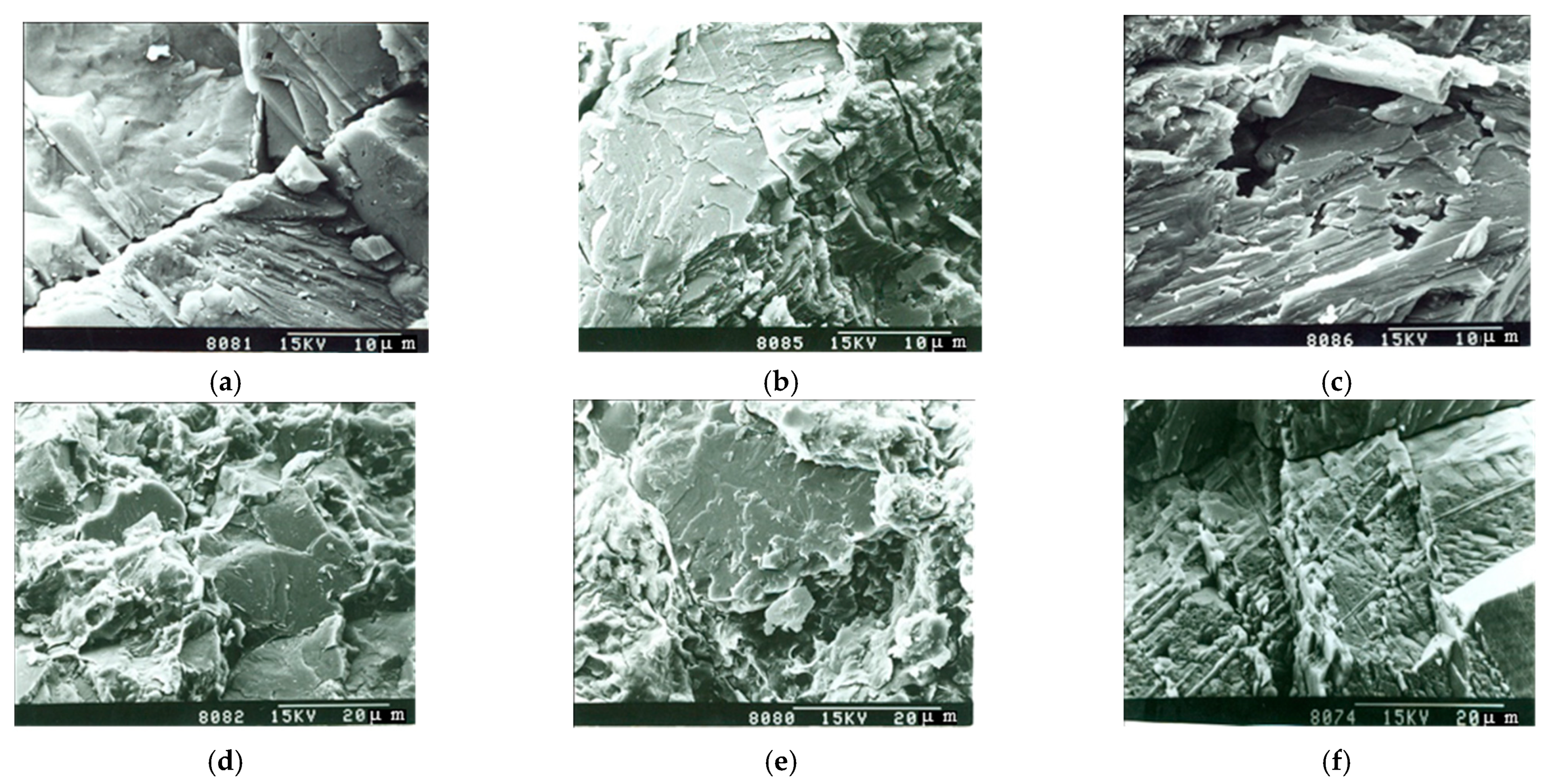

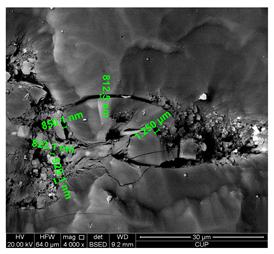

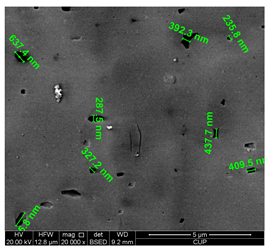

5.1. Reservoir Space of the Shell Limestone Reservoir

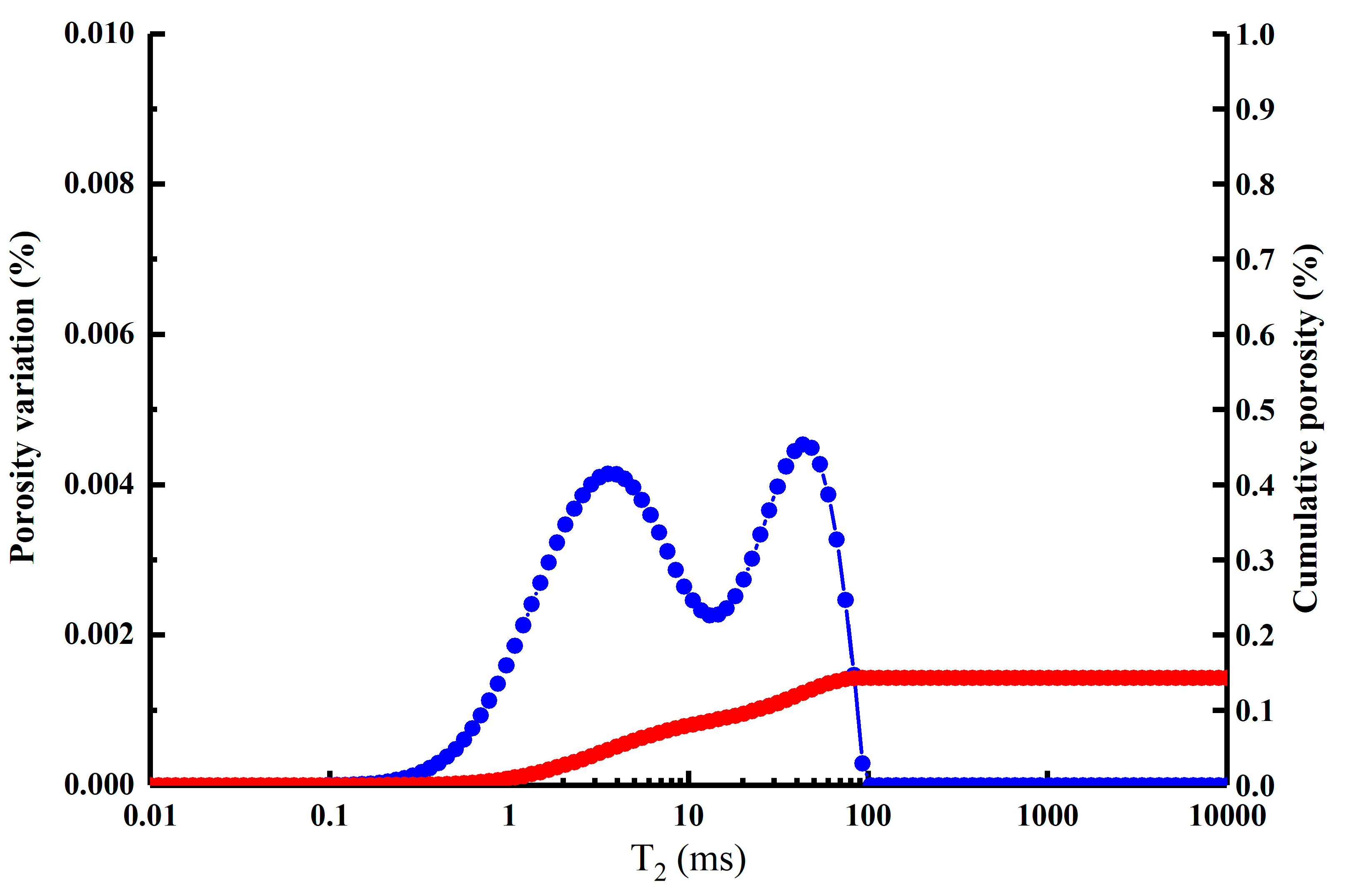

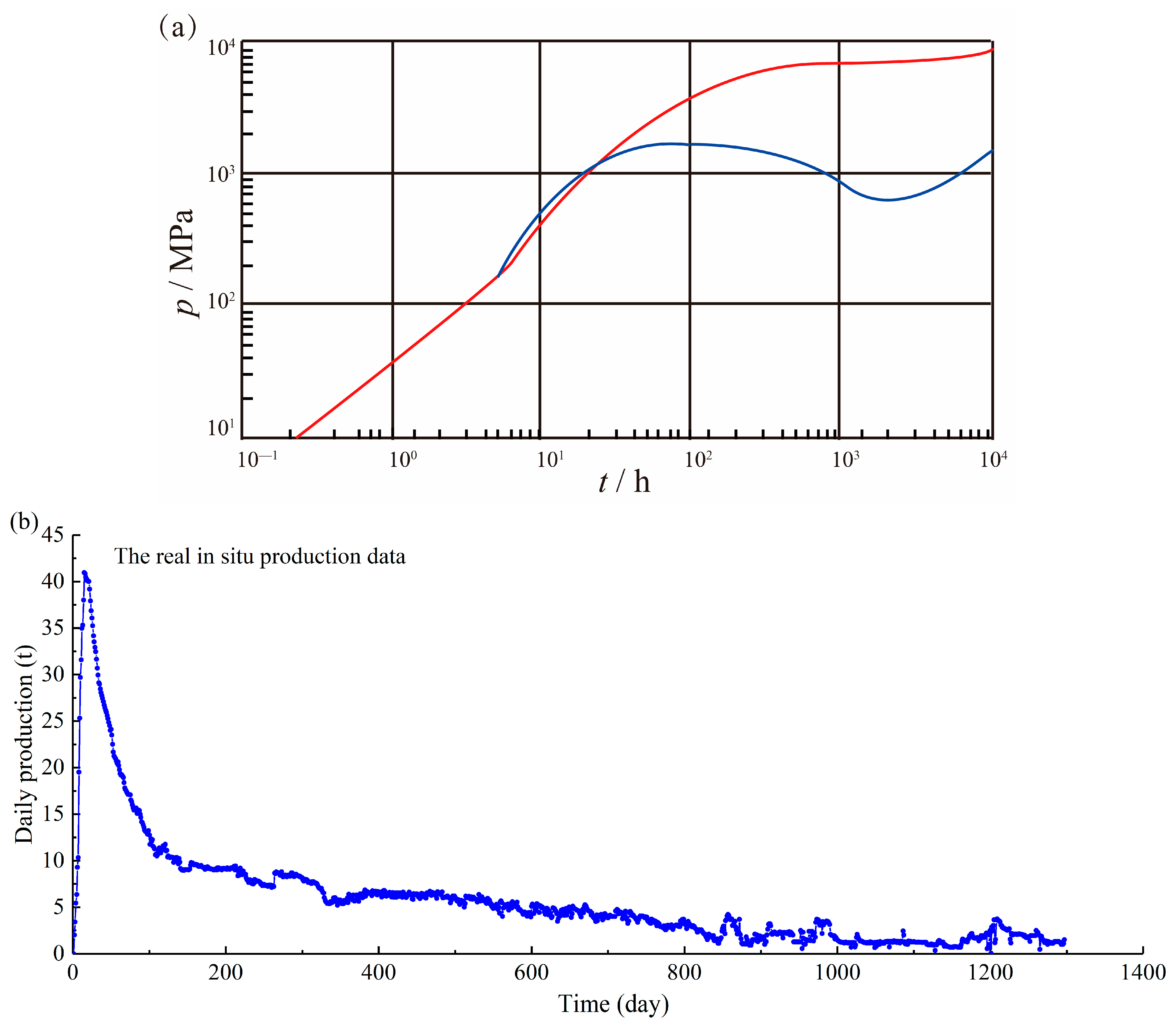

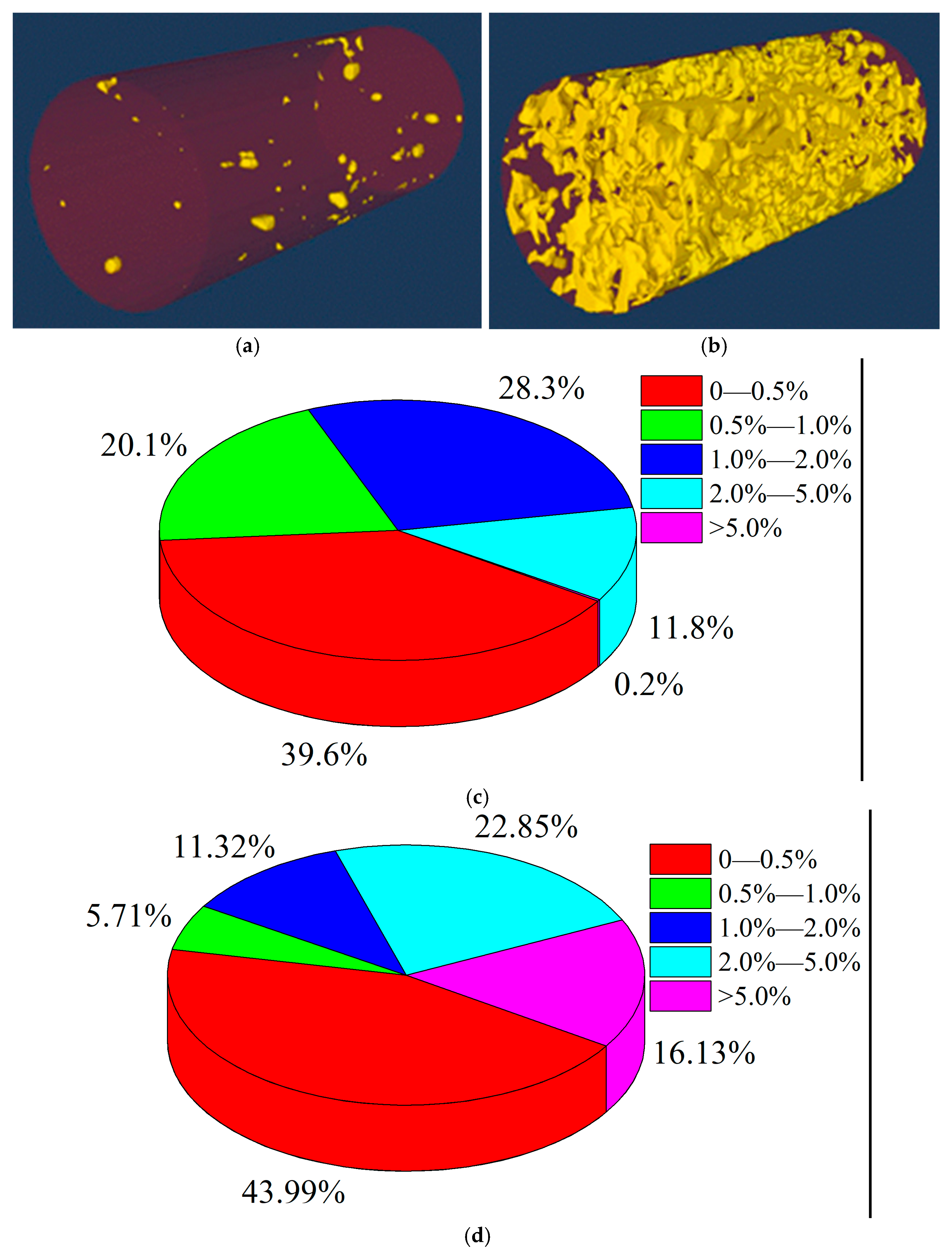

5.2. Reservoir Capacity of Shell Limestone

5.3. Multi-porous Medium Characteristics

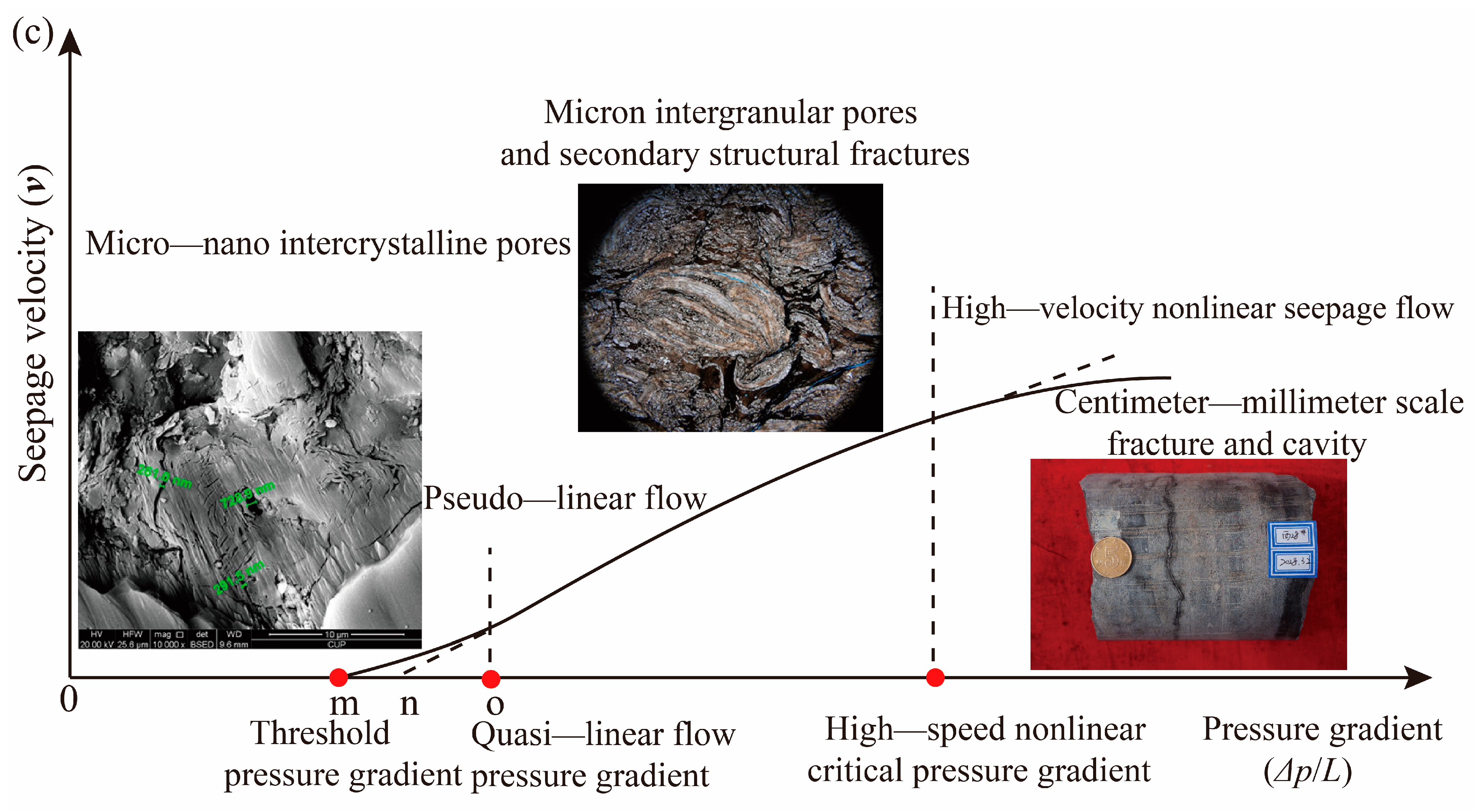

5.4. Reservoir-Permeability Model in Shell Limestone

5.4.1. Pore-Throat Systems of the Shell Limestone Reservoir

5.4.2. Continuous Distribution of Reservoir Permeability Model

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar] [CrossRef]

- Hong, P.; Huo, X.; Pang, X.; Liu, G.; Ma, Q.; Bai, H.; Wang, J.; Zhang, Y.; Huang, S.; Wu, S.; et al. Quantitative characterization of critical reservoir physical properties of tight oil charging in the third member of the Shahejie Formation in the Gaobei Slope of Nanpu Sag, Bohai Bay Basin. Geoenergy Sci. Eng. 2023, 230, 212212. [Google Scholar] [CrossRef]

- Jia, Z.; Cheng, L.; Zhou, J.; Cao, R.; Pu, B.; Jia, P.; Chen, M. Upscaling simulation method of fluid flow for fracturing-shut in-flowback-production process in tight oil reservoirs: Hysteresis effects of capillary pressure and relative permeability. Geoenergy Sci. Eng. 2023, 226, 211792. [Google Scholar] [CrossRef]

- Zhang, J.; Tao, S.; Wu, S.; Liu, G.; Zhao, W.; Li, G. Controlling effect of pore-throat structures on tight oil accumulation effectiveness in the upper Cretaceous Qingshankou formation, Songliao Basin. Geoenergy Sci. Eng. 2023, 225, 211689. [Google Scholar] [CrossRef]

- Cao, A.; Li, Z.; Zheng, L.; Bai, H.; Zhu, D.; Li, B. Nuclear magnetic resonance study of CO2 flooding in tight oil reservoirs: Effects of matrix permeability and fracture. Geoenergy Sci. Eng. 2023, 225, 211692. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, B.; Ma, Y.; Song, X.; Wang, Y.; Xin, X.; Chen, Z. Controlling factors and dynamical formation models of lacustrine organic matter accumulation for the Jurassic Da’anzhai Member in the central Sichuan Basin, southwestern China. Mar. Pet. Geol. 2017, 86, 1391–1405. [Google Scholar] [CrossRef]

- He, Q.; Yang, T.; Cai, L.; Ren, Q.; Dai, J. Porosity and permeability correction of laumontite-rich reservoirs in the first member of the Shaximiao Formation in the Central Sichuan Basin. Mar. Pet. Geol. 2023, 150, 106115. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.; Tang, X.; Ding, J.; Zhao, Q.; Dang, W.; Chen, H.; Su, Y.; Li, B.; Lu, D. Comparative study on micro-pore structure of marine, terrestrial, and transitional shales in key areas, China. Int. J. Coal Geol. 2017, 171, 76–92. [Google Scholar] [CrossRef]

- Su, K.; Lu, J.; Zhang, G.; Chen, S.; Li, Y.; Xiao, Z.; Wang, P.; Qiu, W. Origin of natural gas in Jurassic Da’anzhai Member in the western part of central Sichuan Basin, China. J. Pet. Sci. Eng. 2018, 167, 890–899. [Google Scholar] [CrossRef]

- Xu, Q.; Ma, Y.; Liu, B.; Song, X.; Su, J.; Chen, Z. Characteristics and control mechanism of nanoscale pores in lacustrine tight carbonates: Examples from the Jurassic Da’anzhai Member in the central Sichuan Basin, China. J. Asian Earth Sci. 2019, 178, 156–172. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, B.; Ma, Y.; Song, X.; Wang, Y.; Chen, Z. Geological and geochemical characterization of lacustrine shale: A case study of the Jurassic Da’anzhai member shale in the central Sichuan Basin, southwest China. J. Nat. Gas Sci. Eng. 2017, 47, 124–139. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, D.; Luo, Q.; Liu, L.; Liu, D.; Yan, L.; Zhang, Y. Major factors controlling fracture development in the Middle Permian Lucaogou Formation tight oil reservoir, Junggar Basin, NW China. J. Asian Earth Sci. 2017, 146, 279–295. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Wei, Q.; Gao, W.; Liang, W.; Wang, Z.; Wang, F. Quantitative characterization of pore-fracture system of organic-rich marine-continental shale reservoirs: A case study of the Upper Permian Longtan Formation, Southern Sichuan Basin, China. Fuel 2017, 200, 272–281. [Google Scholar] [CrossRef]

- Yang, G.; Huang, D.; Huang, P.; Yan, W.; Yang, T.; Dai, H.; Lin, J. Control factors of high and stable production of Jurassic Da’anzhai Member tight oil in central Sichuan Basin, SW China. Pet. Explor. Dev. 2017, 44, 866–875. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. Investigating the use of sedimentary geochemical proxies for paleoenvironment interpretation of thermally mature organic-rich strata: Examples from the Devoniane-Mississippian shales. West. Can. Sediment. Basin. Chem. Geol. 2009, 260, 1–19. [Google Scholar]

- Yao, Y.B.; Liu, D.M. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Jarvie, D.M.; Hill, R.J.; Ruble, T.E.; Pollastro, R.M. Unconventional shale-gas systems: The Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale-gas assessment. AAPG Bull. 2007, 91, 475–499. [Google Scholar] [CrossRef]

- Nie, B.; Liu, X.; Yang, L.; Meng, J.; Li, X. Pore structure characterization of different rank coals using gas adsorption and scanning electron microscopy. Fuel 2015, 158, 908–917. [Google Scholar] [CrossRef]

- Clarkson, C.; Solano, N.; Bustin, R.; Bustin, A.; Chalmers, G.; He, L.; Melnichenko, Y.; Radliński, A.; Blach, T. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Zou, C.; Lin, M.; Ma, F.; Liu, H.; Yang, Z.; Zhang, G.; Yang, Y.; Guan, C.; Liang, Y.; Wang, Y.; et al. Development, challenges and strategies of natural gas industry under carbon neutral target in China. Pet. Explor. Dev. 2024, 51, 476–497. [Google Scholar] [CrossRef]

- Liu, H.L.; Zhang, J.H.; Ji, Y.B.; Li, X.B. The controlling effect of kerogen type of shale on asphaltene nanopore and its exploration significance. Unconv. Oil Gas 2022, 9, 1–10. [Google Scholar]

- Yang, Y.; Yang, J.; Yang, G.; Tao, S.; NI, C.; Zhang, B.; He, X.; Lin, J.; Huang, D.; Liu, M.; et al. New research progress of Jurassic tight oil in central Sichuan Basin, SW China. Pet. Explor. Dev. 2016, 43, 954–964. [Google Scholar] [CrossRef]

- Tan, D.; Luo, L.; Song, L.; Liu, F.; Wang, J.; Gluyas, J.; Zhou, H.; Wang, J.; Zhu, C.; Mo, S.; et al. Differential precipitation mechanism of cement and its impact on reservoir quality in tight sandstone: A case study from the Jurassic Shaximiao formation in the central Sichuan Basin, SW China. Geoenergy Sci. Eng. 2023, 221, 111263. [Google Scholar] [CrossRef]

- Yuan, G.; Cao, Y.; Qiu, L.; Chen, Z. Genetic mechanism of high-quality reservoirs in permian tight fan delta conglomerates at the northwestern margin of the junggar basin, northwestern China. AAPG Bull. 2017, 101, 1995–2019. [Google Scholar] [CrossRef]

- Jiang, D.; Chen, H.; Xing, J.; Wang, Y.; Wang, Z.; Tuo, H. A new method for dynamic predicting porosity and permeability of low permeability and tight reservoir under effective overburden pressure based on BP neural network. Geoenergy Sci. Eng. 2023, 226, 211721. [Google Scholar] [CrossRef]

- Li, C.; Kong, L.; Ostadhassan, M.; Gentzis, T. Nanoscale pore structure characterization of tight oil formation: A case study of the Bakken Formation. Energy Fuels 2019, 33, 6008–6019. [Google Scholar] [CrossRef]

- Achour, S.H.; Okuno, R. Advanced modeling of diffusion and convection in multiphase compositional simulation for tight porous media. Geoenergy Sci. Eng. 2023, 230, 212183. [Google Scholar] [CrossRef]

- Massarweh, O.; Abushaikha, A.S. Application of surfactants in enhancing oil recovery from tight carbonates: Physicochemical properties and core flooding experiments. Geoenergy Sci. Eng. 2023, 221, 211400. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Z.; Adenutsi, C.D. Integration of rock physics, geostatistics, and Bayesian algorithm to estimate porosity in tight oil reservoirs. Geoenergy Sci. Eng. 2023, 230, 212224. [Google Scholar] [CrossRef]

| Fabric Control | Reservoir Space | Type of Pore or Fracture | Cause | Characteristics | Scale of Pore or Fracture | ||

|---|---|---|---|---|---|---|---|

| The reservoir space controlled by nonfabric | pore | dissolution pore dissolution pore cavity | formed by calcite dissolution | Irregular patch-like or bay-like | Pore size larger than 0.1 μm | ||

| fracture | structural fracture | formed by tectonic stress | Linear, developed in groups | Fracture width larger than 1 μm | Fracture length: several cm to tens of kilometers | ||

| interlayer fracture | fractures between rock beddings | Saw-toothed, developed in parallel bedding | Fracture width in the range of 1~3 μm | Fracture length: several centimeters to several kilometers | |||

| dissolution fracture | formed by dissolutional modification of pre-existing fractures | Maintaining the original shape of the fractures | Fracture width larger than 0.5 μm | Fracture length: several micrometers to several tens of kilometers | |||

| The reservoir space controlled by fabric | The reservoir space controlled by the shell | pore | Shell fabric pore | the interstitial space of skeleton in the growing shell, visible upon complete preservation | Similar to intergranular pores, but isolated and with poor connectivity | pore diameters in the range of 0.05~0.1 μm | |

| The intercrystalline pores in the shell | formed by recrystallization of the inter-shell | Blocky, with small pores and narrow throats | pore diameters less than 0.5 μm | ||||

| fracture | Fracture in inter-shell | outer margin fracture of the shell | Developed along the edge of bivalve shells | Fracture width less than 0.5 μm | Fracture length: several mm to several cm | ||

| Fracture in inter-shell | formed by local stress-induced cracking of the shell | Mostly in a mesh-like pattern, with relatively intact bivalve shells | Fracture width in the range of 0.1~1 μm | Fracture length: several mm to several tens of cm | |||

| Shell fabric fracture | formed by the preservation of growth lines on the shell | Fractures are short in length, developed in a parallel group pattern, and have poor connectivity | Fracture width less than 0.1 μm | Fracture length: several mm to several tens of cm | |||

| The reservoir space controlled by the matrix | pore | Intercrystalline pore | Pore between carbonate crystals | Dispersed, with small pores and narrow throats | pore diameters in the range of 0.1~1 μm | ||

| Intergranular pore | Intergranular pore in minerals such as quartz and pyrite | Elliptical dispersed, larger than intergranular pores | pore diameters in the range of 0.1~5 μm | ||||

| fracture | Intergranular fracture | Microfractures at the contact edges of calcite crystal grains | Short in length, controlled by the size of the grains | Fracture width less than 0.1 μm | Fracture length: several μm to several mm | ||

| Turtle-shaped facture | Formed by local stress-induced fracturing of the matrix | Turtle shell-like pattern, with relatively good connectivity | Fracture width in the range of 0.1~0.3 μm | Fracture length: several μm to several mm | |||

| Measurement Content | Total Porosity of Connected Pores | Effective Porosity of Connected Pores | Comparative Sample | |||

|---|---|---|---|---|---|---|

| Experimental method | Helium porosity method | Water saturation method | High-pressure mercury intrusion method | Constant velocity pressure mercury porosimetry | N2 adsorption method | Kerosene method, alcohol method |

| Measurement range | All connected pores | Less than helium method | Pore diameter larger than 3.7 nm | Pore diameter larger than 120 nm | Pore diameter less than 150 nm | Less than helium method |

| Porosity/% | 1~5/(avg. 2.12) | 0.5~2/(avg. 1.59) | 0.5~1.5/(avg. 0.97) | 0.1~2.2/(avg. 1.02) | 0.5~2.5/(avg. 1.44) | 0.3~3.9/(avg. 0.99) |

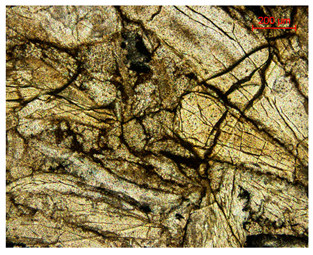

| Type of Pore-Throat System | Model Characteristics | Pattern Figure | Typical Figure | ||||

|---|---|---|---|---|---|---|---|

| Pore (Storage Space) | Throat (Flow Pathway) | Pore-Throat Difference | |||||

| Type | Size | Type | Size and Shape | ||||

| Dissolved pores adjacent to the fracture | Dissolution pore Dissolution pore cavity | Pore diameter larger 10 μm | Structural fracture, secondary microfracture | Long–slender type | Medium |  |  |

| Microfractures controlled by the shell | Fabric fracture in internal shell Fracture in intra-shell Minor vuggy structure | Fracture width less than 1 μm | Microfracture | Long–slender type | None |  |  |

| Microfractures controlled by the filling | Intercrystalline fracture Crazing fracture Minor intercrystalline pore | Fracture width less than 0.3 μm | Microfracture | Long–slender type | None |  |  |

| Intracrystalline (intergranular) pores | Intergranular pore Intercrystalline pore | 0.1~5 μm | Pore contraction section | Short–slender type | Small |  |  |

| Isolated pores | Dissolution pore Dissolution micro-pore Fabric fracture in internal shell Intercrystalline pore | 0.1~10 μm | Pore contraction section | Short–thick type | Small |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Guo, Z.; Wu, D.; Xue, S.; Lin, M.; Wang, W.; Zhen, Z.; Jin, Q. Multi-Porous Medium Characterization Reveals Tight Oil Potential in the Shell Limestone Reservoir of the Sichuan Basin. Processes 2024, 12, 1057. https://doi.org/10.3390/pr12061057

Zhou G, Guo Z, Wu D, Xue S, Lin M, Wang W, Zhen Z, Jin Q. Multi-Porous Medium Characterization Reveals Tight Oil Potential in the Shell Limestone Reservoir of the Sichuan Basin. Processes. 2024; 12(6):1057. https://doi.org/10.3390/pr12061057

Chicago/Turabian StyleZhou, Guangzhao, Zanquan Guo, Dongjun Wu, Saihong Xue, Minjie Lin, Wantong Wang, Zihan Zhen, and Qingsheng Jin. 2024. "Multi-Porous Medium Characterization Reveals Tight Oil Potential in the Shell Limestone Reservoir of the Sichuan Basin" Processes 12, no. 6: 1057. https://doi.org/10.3390/pr12061057

APA StyleZhou, G., Guo, Z., Wu, D., Xue, S., Lin, M., Wang, W., Zhen, Z., & Jin, Q. (2024). Multi-Porous Medium Characterization Reveals Tight Oil Potential in the Shell Limestone Reservoir of the Sichuan Basin. Processes, 12(6), 1057. https://doi.org/10.3390/pr12061057