Optimization of the Assessment Method for Photovoltaic Module Enhancers: A Cost-Efficient Economic Approach Developed through Modified Area and Cost Factor

Abstract

1. Introduction

1.1. Existing Studies on Photovoltaic Module Enhancers

1.2. Assessing Techniques for Improving Solar Panels

1.3. The Current Study’s Rationale

1.4. The Current Study’s Research Questions

- Is the existing performance evaluation method for PV enhancers economically viable?

- How does the proposed modified assessment technique contrast with the existing one regarding the quantity of solar cells employed for PV systems, both with and without enhancements, the total cost of solar cells, and associated expenses?

- What is the effect of the number of solar cells on the solar cell saving when using the proposed modified method compared to the existing one?

2. Methodology

2.1. Methodological Approach

2.2. Evaluating Economic Feasibility Using the Area

2.3. The Modified Economic Method for PV Enhancers

2.3.1. The Modified Minimum Value of the Cost and Area Effectiveness Factor ()

2.3.2. The Range Significance of Values

- If is greater than 1, this indicates that the PV enhancer is not efficient in terms of both area utilization and cost.

- If equals 1, this signifies that the PV enhancer is neutral and meets the threshold value.

- If is greater than or equal to but less than 1, this indicates that the PV enhancer is efficient in terms of both area utilization and cost.

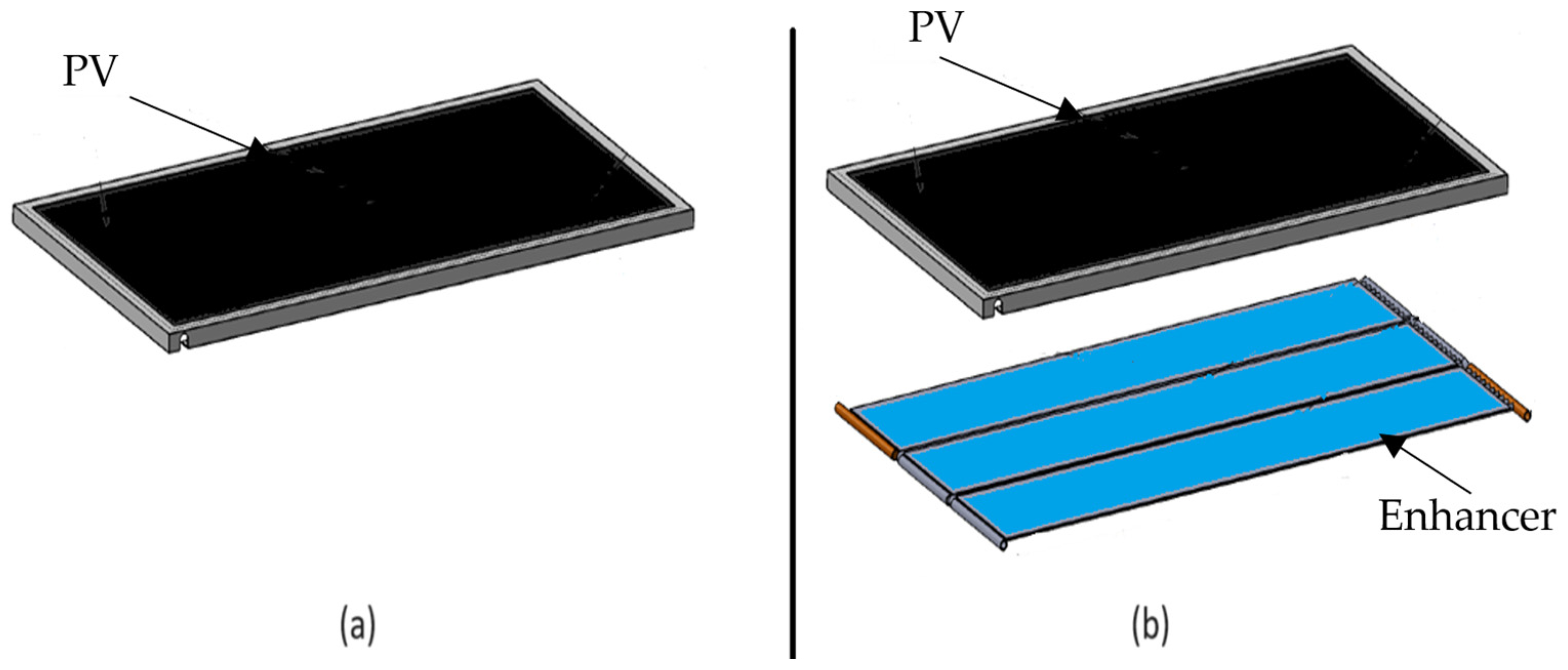

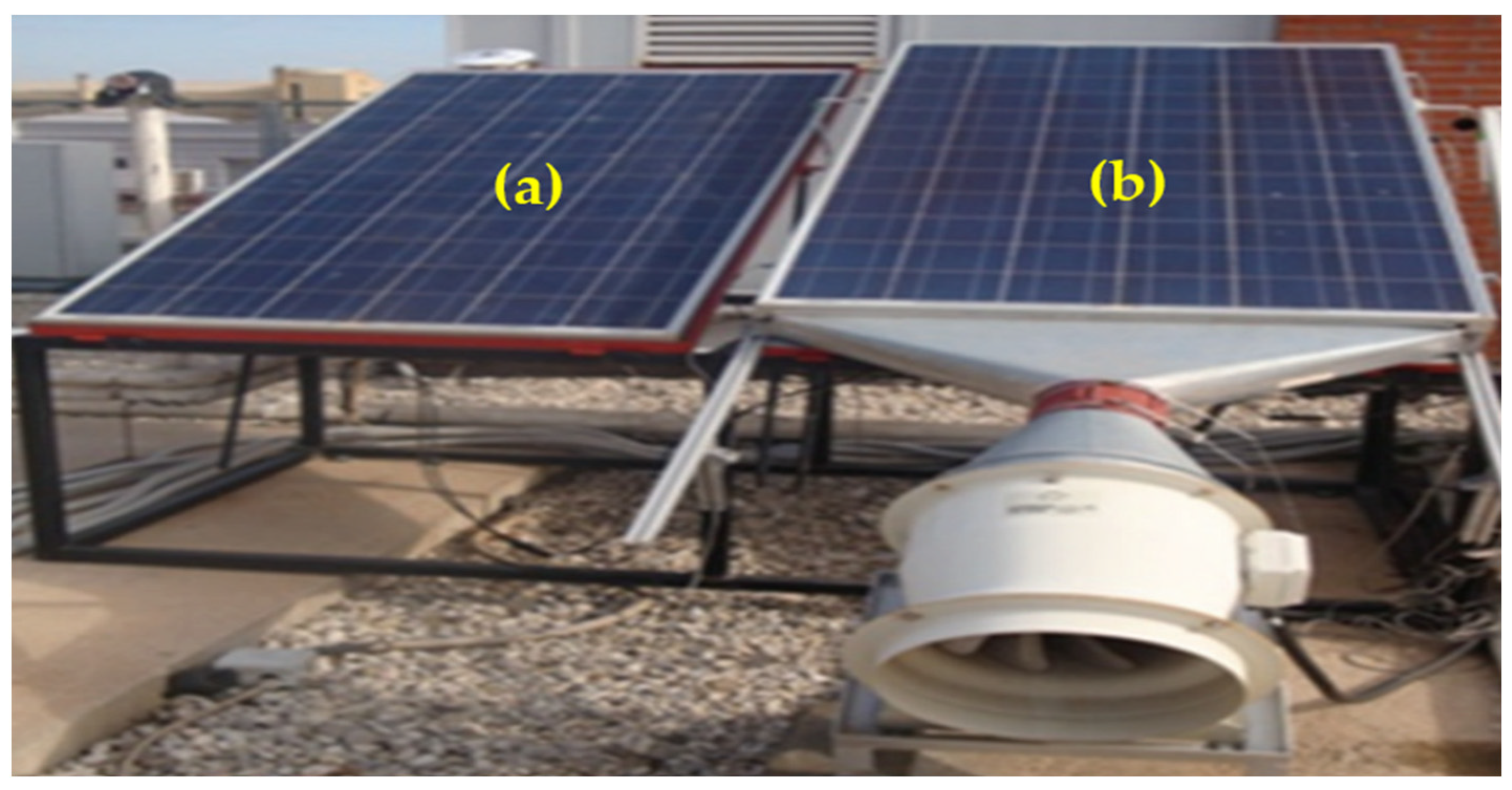

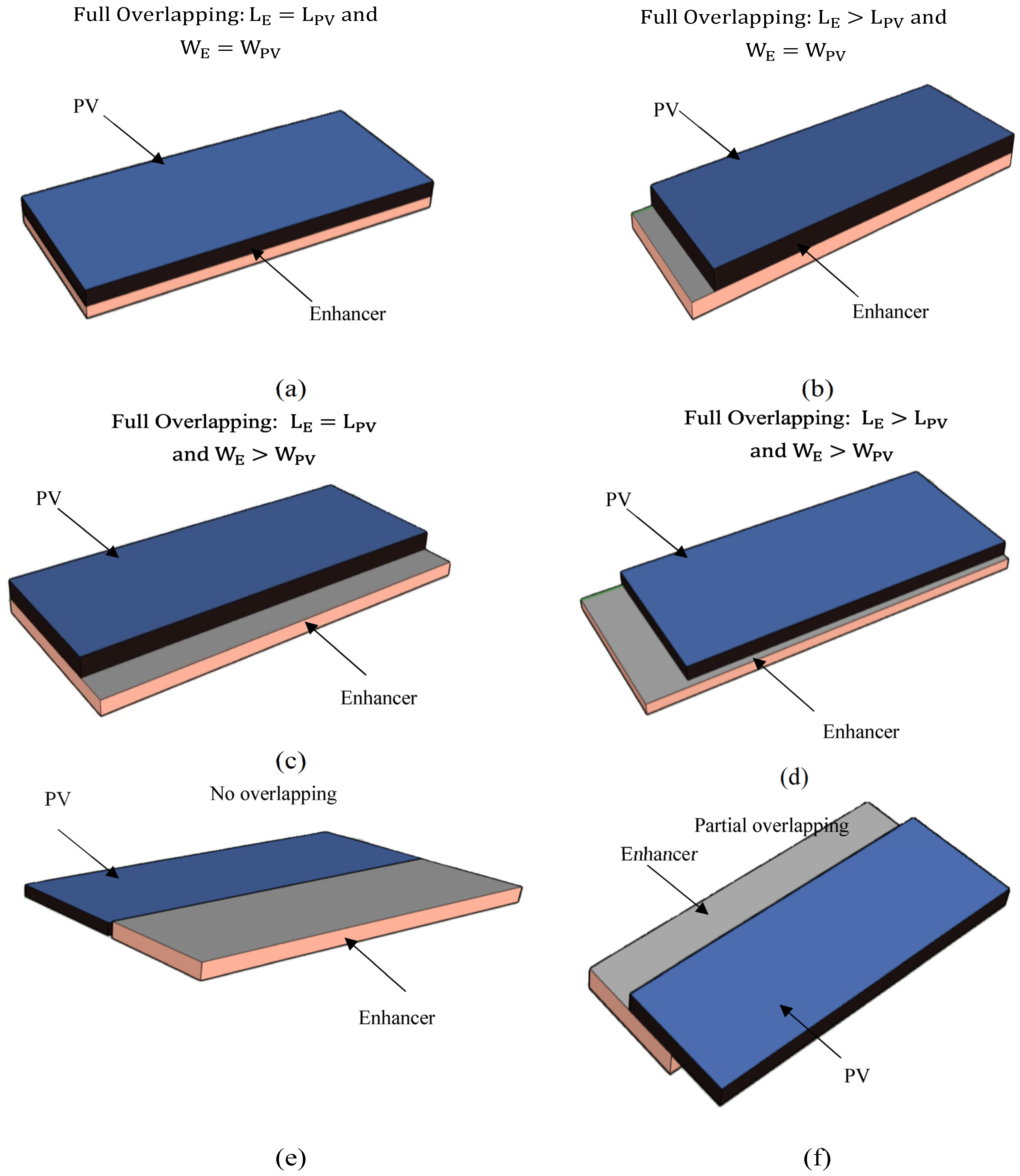

- If the length of the enhancer ( is less than or equal to the length of the PV (), and the width of the enhancer () is less than or equal to the width of the PV (), then the area of the PV with the enhancer () equals the area of the PV () (). This situation occurs when the enhancer fully overlaps with the PV in both length and width, depicted in Figure 5a.

- If the length of the enhancer is greater than the length of the PV but the width of the enhancer is less than or equal to the width of the PV, then the area of the PV with the enhancer () equals the area of the PV () plus the difference in lengths between the enhancer and the PV, multiplied by the width of the enhancer. This scenario occurs when the width of the enhancer fully overlaps with the width of the PV, and the length of the PV is fully encompassed by the enhancer, illustrated in Figure 5b.

- If the width of the enhancer is greater than the width of the PV but the length of the enhancer is less than or equal to the length of the PV, then the area of the PV with the enhancer equals the area of the PV plus the difference in widths between the enhancer and the PV, multiplied by the length of the enhancer. This case arises when the length of the enhancer fully overlaps with the length of the PV, and the width of the PV is fully encompassed by the enhancer, as shown in Figure 5c.

- If both the width and length of the enhancer are greater than the width and length of the PV, respectively, then the area of the PV with the enhancer () equals the area of the enhancer (). This scenario occurs when both the length and width of the PV fully overlap with the length and width of the enhancer, depicted in Figure 5d.

- If there is no overlap between the length and width of the PV and the enhancer, then the area of the PV with the enhancer equals the sum of the areas of the PV and the enhancer (), as shown in Figure 5e.

- In the case of partial overlapping between the PV and the enhancer (as shown in Figure 5f), one needs to calculate the area of the PV with an enhancer that occupies.

2.3.3. The Calculation of the Total Number of Solar Cells and the Percentage of Saving

2.3.4. The Calculation of the Cost of the Total Number of Solar Cells Using the Existing and Modified Methods

2.3.5. The Calculation of the Expenses Cost Using the Existing and Modified Methods

3. Results and Discussion

3.1. Evaluating the Cost Advantage of Utilizing and

3.2. The Effect of Increasing the Number of Solar Cells on and

3.3. The Solar Cell Saving Percentage When Using

3.4. The Effect of the Number of Solar Cells on the Cost of the Total Number of Solar Cells When Using and

3.5. The Effect of the Number of Solar Cells on the Expenses Cost When Using and

4. Conclusions

- A modification to the existing approach is proposed to decrease the assessment expenses. The findings suggest that economic evaluations can be performed using just one solar cell (without an enhancer) and subsequently compared with a PV system incorporating an enhancer with a predetermined quantity of solar cells.

- The modification involves the area and cost-effectiveness factor and its minimum value. Achieving the peak performance for a PV enhancer corresponds to attaining a modified area and cost-effectiveness factor equivalent to this minimum value.

- Equations (14) and (15) have been formulated to estimate the total quantity of solar cells required for both the conventional and modified approaches.

- Equations (18) and (20) have been devised to compute the associated costs for the total number of solar cells using the conventional and modified methodologies, respectively.

- Equations (22) and (24) are also proposed to compute the expenses cost using the existing and modified methods.

- The findings indicate that utilizing leads to a rise in the proportion of solar cell savings to 48.33%, surpassing the current approach. Consequently, the evaluation expenses for PV enhancers may be significantly decreased. Additionally, it was observed that the percentage of savings increases as the number of solar cells increases.

- The proposed method holds potential for adoption by PV enhancer manufacturers and designers, aiding in the classification and decision-making process regarding various PV enhancer types based on their economic aspects.

- Due to the lack of standardized testing protocols for PV enhancers on an international scale, it is advisable to pursue further research aimed at devising supplementary evaluation techniques.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | area, (m2) |

| β | efficiency decrease per unit of increase in temperature, (°C−1) |

| C | cost of total number of solar cells, USD |

| CFD | computational fluid dynamics |

| F | factor, dimensionless |

| I | solar irradiance, (W/m2) |

| L | length, (m) |

| N | total number of solar cells |

| n | number of solar cells in a PV with an enhancer |

| P | power, (W) |

| R | ratio |

| T | temperature, (°C) |

| U | expenses cost, USD |

| PCM | phase change material |

| PV | photovoltaic module |

| PVE | photovoltaic module with an enhancer |

| PVT | photovoltaic thermal collector |

| V | cost of a single solar cell |

| W | width, (m) |

| Y | cost of one watt of PV power |

| Z | manufacturing cost of PV enhancer |

| Subscripts | |

| cell | photovoltaic cell |

| E | photovoltaic module enhancer |

| ED | PV power difference |

| fc | forced convection |

| max | maximum |

| min | minimum |

| PVCT | PV with a cooling technique |

| ref | reference |

| STC | PV’s standard test conditions |

| TDED | PV efficiency difference factor |

| TDPD | modified PV temperature difference factor |

| tot | total |

References

- Paul, R. The photovoltaic effect and its utilization. Sol. Energy 1959, 3, 8–18. [Google Scholar]

- Animasaun, I.L.; Nehad, A.S.; Abderrahim, W.; Basavarajappa, M.; Ramachandran, S.; Olubode, K.K. Ratio of Momentum Diffusivity to Thermal Diffusivity: Introduction, Meta-Analysis, and Scrutinization; Chapman and Hall/CRC: New York, NY, USA, 2022; ISBN 13 978-1032108520/10 1032108525/9781003217374. [Google Scholar] [CrossRef]

- Anonymous. Available from World Wide Web. 2022. Available online: https://www.iea.org/reports/solar-pv (accessed on 29 July 2022).

- Adnan, S.; Feda, M. Emitter layer optimization in heterojunction bifacial silicon solar cells. J. Semicond 2022, 43, 122701. [Google Scholar]

- Zhouyu, T.; Mingxuan, B.; Yiqian, Z.; Deren, Y.; Xiaodong, P. Hyperdoped silicon: Processing, properties, and devices. J. Semicond 2022, 43, 093101. [Google Scholar]

- Shah, N.A.; Animasaun, I.L.; Ibraheem, R.O.; Babatunde, H.A.; Sandeep, N.; Pop, I. Scrutinization of the effects of Grashof number on the flow of different fluids driven by convection over various surfaces. J. Mol. Liq. 2018, 249, 980–990. [Google Scholar] [CrossRef]

- Arash, K.; Ali, S.; Tao, M.; Hao, L. Application of hybrid nanofluids in a novel combined photovoltaic/thermal and solar collector system. Sol. Energy 2022, 239, 102–116. [Google Scholar]

- Anurag, S.; Prakash, A.J.; Yogini, D.B.; Saravanakumar, R.; Mohsen, S.; Hossein, H.; Abdul, R.; Asif, A. A study on the effects of forced air-cooling enhancements on a 150 W solar photovoltaic thermal collector for green cities. Sustain. Energy Technol. Assess. 2022, 49, 101782. [Google Scholar]

- Franz, H.; Christian, H.; Franz, I.; Peter, K. System efficiency of PVT collector driven heat pumps. Int. J. Thermofluids 2020, 5–6, 100034. [Google Scholar]

- Marco, N.; Renato, M.L. Hybrid Photovoltaic–thermal heat pump systems: Energy and economic performance evaluations in different climates. Int. J. Low-Carbon Technol. 2018, 13, 76–83. [Google Scholar]

- Vaishak, S.; Purnanand, V.B. Performance analysis of a heat pump-based photovoltaic/thermal (PV/T) system. Clean Technol. Environ. Policy 2020, 23, 1121–1133. [Google Scholar] [CrossRef]

- Prashant, M.; Shyam, S. Performance enhancement of multi-crystalline silicon photovoltaic modules using mirror reflectors under Western Himalayan climatic conditions. Renew. Energy 2021, 154, 966–975. [Google Scholar]

- Tabor, H. Stationary mirror systems for solar collectors. Sol. Energy 1958, 2, 27–33. [Google Scholar] [CrossRef]

- Anand, V.P.; Khan, M.M.; Ameen, E.; Amuthan, V.; Pesala, B. Performance improvement of solar module system using flat plate reflectors. Int. Conf. Adv. Electr. Eng. ICAEE 2014, 2014, 1–4. [Google Scholar]

- Palaskar, V.N.; Deshmukh, S.P. Design and performance analysis of reflectors attached to commercial PV module. Int. J. Renew. Energy Resour 2014, 4, 240–245. [Google Scholar]

- Bahaidarah, H.M.; Tanweer, B.; Gandhidasan, P.; Rehman, S. A combined optical, thermal and electrical performance study of a V-trough PV system experimental and analytical investigations. Energies 2015, 8, 2803–2827. [Google Scholar] [CrossRef]

- Naseer, K.K.; Ahmed, F.A.; Fadhil, M.E. Improve the performance of solar modules by reflectors. In Proceedings of the Sixth Scientific Conference “Renewable Energy and its Applications”, Karbala, Iraq, 21–22 February 2018; Volume 1032, p. 012031. [Google Scholar]

- Elbreki, A.M.; Muftah, A.F.; Sopian, K.; Jarimi, H.; Fazlizan, A.; Ibrahim, A. Experimental and economic analysis of passive cooling PV module using fins and planar reflector. Case Stud. Therm. Eng. 2021, 23, 100801. [Google Scholar] [CrossRef]

- Moon, K.K.; Khalid, O.A.; Jiying, L.; Joon-Ho, C.; Huiqing, W. Optimal design strategy of a solar reflector combining photovoltaic panels to improve electricity output: A case study in Calgary, Canada. Sustainability 2021, 13, 6115. [Google Scholar] [CrossRef]

- Jin, S.; Choi, B.G.; Choi, J.; Kim, H.; Seung-Tak, R.; Chun, T.R.; Yun-Su, K. New curved reflectors for significantly enhanced solar power generation in four seasons. Energies 2018, 12, 4602. [Google Scholar]

- Amanlou, Y.; Hashjin, T.T.; Ghobadian, B.; Najafi, G. Air cooling low concentrated photovoltaic/thermal (LCPV/T) solar collector to approach uniform temperature distribution on the PV plate. Appl. Therm. Eng. 2018, 141, 413–421. [Google Scholar] [CrossRef]

- Sultan, M.S.; Tso, C.P.; Raheem, K.A.; Sobayel, K.; Abdullah, M.Z.; Sopian, K.; Ahmed, S.A. Revolutionizing photovoltaic excellence: Unveiling a cutting-edge approach to assessing module enhancers for optimal area and cost efficiency. Case Stud. Therm. Eng. 2024, 55, 104139, Erratum in Case Stud. Therm. Eng. 2024, 55, 104310. [Google Scholar] [CrossRef]

- Maatallah, T.; Zachariah, R.; Al-Amri, F.G. Exergo-economic analysis of serpentine flow type water based photovoltaic thermal system with phase change material (PVT-PCM/water). Sol. Energy 2019, 193, 195–204. [Google Scholar] [CrossRef]

- Mazón-Hernández, R.; García-Cascales, J.R.; Vera-García, F.; Káiser, A.S.; Zamora, B. Improving the electrical parameters of a photovoltaic panel by means of an induced or forced air stream. Int. J. Photoenergy 2013, 2013, 830968. [Google Scholar] [CrossRef]

- Joel, J.; Patrick, R.B.; Robert, L.J.; Tonio, B.; Vladimir, B. Pathways for solar photovoltaics. Energy Environ. Sci. 2015, 8, 1200. [Google Scholar]

- Trever, M.; Vasilis, M. A Comprehensive Guide to Solar Energy Systems: With Special Focus on Photovoltaic Systems; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

| Method | Items Needed | Total Number of Solar Cells (Ntot) | Cost of Ntot (C), USD | Expenses Cost (U), USD | Does the Method Represent a Financially Viable Approach? |

|---|---|---|---|---|---|

| The existing method: and , , . | Two PVs that are exactly the same, with one having an enhancer while the other does not. | No | |||

| The modified method: and , , . | A solitary solar cell without enhancement. A PV system with an enhancer. | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sultan, S.M.; Chih Ping, T.; Sobayel, K.; Abdullah, M.Z.; Sopian, K. Optimization of the Assessment Method for Photovoltaic Module Enhancers: A Cost-Efficient Economic Approach Developed through Modified Area and Cost Factor. Processes 2024, 12, 988. https://doi.org/10.3390/pr12050988

Sultan SM, Chih Ping T, Sobayel K, Abdullah MZ, Sopian K. Optimization of the Assessment Method for Photovoltaic Module Enhancers: A Cost-Efficient Economic Approach Developed through Modified Area and Cost Factor. Processes. 2024; 12(5):988. https://doi.org/10.3390/pr12050988

Chicago/Turabian StyleSultan, Sakhr M., Tso Chih Ping, Khan Sobayel, Mohammad Z. Abdullah, and Kamaruzzaman Sopian. 2024. "Optimization of the Assessment Method for Photovoltaic Module Enhancers: A Cost-Efficient Economic Approach Developed through Modified Area and Cost Factor" Processes 12, no. 5: 988. https://doi.org/10.3390/pr12050988

APA StyleSultan, S. M., Chih Ping, T., Sobayel, K., Abdullah, M. Z., & Sopian, K. (2024). Optimization of the Assessment Method for Photovoltaic Module Enhancers: A Cost-Efficient Economic Approach Developed through Modified Area and Cost Factor. Processes, 12(5), 988. https://doi.org/10.3390/pr12050988