Abstract

Fresh aquatic products, due to their high water activity, are susceptible to microbial contamination and spoilage, resulting in a short shelf life. Drying is a commonly used method to extend the shelf life of these products by reducing the moisture content, inhibiting microbial growth, and slowing down enzymatic and chemical reactions. However, the drying process of aquatic products involves chemical reactions such as oxidation and hydrolysis, which pose challenges in obtaining high-quality dried products. This paper provides a comprehensive review of drying processing techniques for aquatic products, including drying preprocessing, drying technologies, and non-destructive monitoring techniques, and discusses their advantages and challenges. Furthermore, the impact of the drying process on the quality attributes of dried products, including sensory quality, nutritional components, and microbial aspects, is analyzed. Finally, the challenges faced by drying processing techniques for aquatic products are identified, and future research prospects are outlined, aiming to further advance research and innovation in this field.

1. Introduction

Aquatic products have nutritional characteristics, such as a high protein content, low fat content, and rich variety of vitamins and trace elements, which are easily digestible [1,2]. However, effective preservation measures or processing techniques must be adopted to prevent the spoilage of fresh aquatic products after harvest [3]. Drying technology for aquatic products aims to reduce the moisture content, improving product stability and shelf life. Simultaneously, drying processing enriches the variety of products and application domains [4]. As a result, drying technology for aquatic products has become a key research topic in the field of food drying, attracting significant attention.

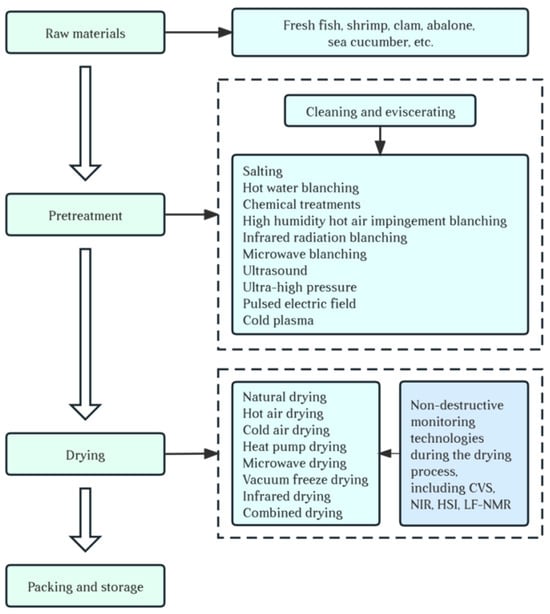

Figure 1 reveals the processing flow of aquatic products. The drying preprocessing techniques, drying technologies, and non-destructive monitoring techniques play an important role in achieving high-quality and -efficiency drying processes of aquatic products [5,6]. Drying preprocessing techniques treat materials by physical or chemical means to improve their drying efficiency and drying quality [6,7,8]. Recent studies have shown that the use of novel preprocessing techniques such as electric fields, ultrasound, and plasma largely solve the problems of traditional preprocessing techniques by changing the internal structure of materials, effectively retaining nutrients, and solving the food safety problems related to chemical residues [9,10], which has gradually become an important research direction in the field of aquatic product drying. Traditional drying and processing technologies, including natural drying and hot air drying, are commonly used because of their significant economic advantages, but they have low drying efficiency and poor drying quality. Therefore, high-quality drying technologies that combine efficiency and quality, such as cold air drying, heat pump drying, microwave drying, vacuum freeze drying, and infrared drying, have become the focus of research in the modern food processing industry. At the same time, combined drying technologies that utilize the advantages of various technologies have been developed to achieve higher drying efficiency, better drying quality, and lower costs. In recent years, many scholars have realized the real-time monitoring of the parameters of moisture, protein, lipid content, and other substances in the drying process through non-destructive monitoring techniques, including computer vision systems, near-infrared spectroscopy, hyperspectral imaging, and low-field nuclear magnetic resonance, which is of great significance for the precise control of drying effects and improvement of drying quality. In addition, studying and analyzing the effects of different drying processes on the sensory quality, nutrient content, and microbiological aspects of aquatic products is essential for obtaining high-quality drying processes.

Figure 1.

Processing flow chart of aquatic products.

In the field of drying technology for aquatic products, there is currently fragmented literature. This paper aims to provide researchers with a comprehensive review, enabling them to obtain a complete understanding of the drying technology for aquatic products and to drive further research and innovation. This paper presents a comprehensive overview of multiple stages in the drying process of aquatic products, including drying preprocessing techniques, drying processing techniques, non-destructive monitoring technologies, and the influence of the drying process on the quality characteristics of aquatic products. It analyzes the characteristics and applicability of various drying processing techniques. Through a summary of the drying technology for aquatic products, this review accurately reveals the existing challenges and future development trends, offering essential references for the research and development of drying processes for aquatic products.

2. Preprocessing Techniques for Drying Aquatic Products

The preprocessing stage is an important preparatory step for aquatic products before drying. Its purpose is to employ various techniques such as physical, chemical, or biological methods to appropriately process the products, thereby altering the material’s structure to enhance product quality. Furthermore, it helps to reduce drying processing time, minimize energy consumption, and improve the quality of dried aquatic products [9,10,11,12]. Preprocessing techniques for product drying can be categorized into two main types: traditional preprocessing and novel preprocessing.

2.1. Traditional Preprocessing Techniques

Traditional preprocessing techniques for drying aquatic products include salting, hot water blanching (HWB), and chemical preprocessing.

Salting is a traditional preprocessing technique widely used in the food industry [13,14]. It reduces the water activity and moisture content in aquatic products through osmotic pressure, leading to the deactivation of harmful microorganisms by dehydration. This technique effectively enhances the water-holding capacity of aquatic products and achieves preservation and antibacterial effects. However, the high-salt environment possesses oxidative properties that accelerate lipid oxidation in aquatic products, resulting in the generation of a significant amount of cholesterol oxidation products. This, in turn, affects the oxidative stability of aquatic products, leading to a decline in product quality and a shortened shelf life [13,14,15,16,17,18,19,20]. In a study by Yu et al. [21], using Pacific saury as the material, changes in the physicochemical characteristics during the salting process were analyzed and determined. The results revealed a 7% decrease in moisture content in Pacific saury flesh after salting preprocessing. Aubourg et al. [22] investigated the impact of different concentrations of salt (5%, 10%, and 20% NaCl) preprocessing on the lipid stability of frozen albacore. The study found that the thiobarbituric acid index (TBA-i) values of the samples increased as the NaCl concentration increased during frozen storage, indicating an accelerated lipid oxidation effect with higher NaCl concentrations on aquatic products.

HWB involves placing aquatic products in boiling pure water or saline solution to eliminate microorganisms and inactivate enzymes, thereby reducing their water-holding capacity and accelerating the drying process [6]. However, HWB treatment can easily compromise the quality of aquatic products, such as softening of texture, significant loss of nutrients, particularly water-soluble substances, and degradation of pigments and flavors [8,23]. Zhu et al. [24] conducted a study on Irish brown seaweed and found that although HWB can reduce the drying time during oven drying, it also affects the color, biological structure, and quality of the seaweed samples. The solid loss of the samples ranged from 4.33 ± 1.81 to 3.13 ± 1.71 g/200 g after blanching treatment.

Chemical preprocessing encompasses liquid-phase immersion preprocessing (high-osmotic-pressure solutions, acid/alkaline solutions, sulfite solutions, etc.) and gas-phase immersion preprocessing (ozone, carbon dioxide, etc.). Liquid-phase immersion preprocessing can enhance the permeation of moisture on the surface of aquatic products, thereby maintaining product quality and improving the drying process. Zhang et al. [25] found that chemical preprocessing reduced the drying time of blueberry fruit by 50%, confirming the feasibility of chemical preprocessing in the field of fruits and vegetables. However, the application of chemical preprocessing in the domain of aquatic products has yet to be reported, requiring further in-depth research in the future. Additionally, the presence of residual chemical agents in aquatic products poses safety concerns, and the proper disposal of large volumes of chemically corrosive waste solutions is also a serious issue. Ozone possesses sterilizing and antibacterial effects with no residual effects; however, ozone preprocessing can enhance protein oxidation in aquatic products, leading to a reduction in protein fiber and changes in the color and odor of the products [26,27]. Carbon dioxide preprocessing offers food safety and environmental friendliness but typically requires a preprocessing time of 12 to 72 h [28].

2.2. Novel Preprocessing Techniques

In recent years, the development and application of new preprocessing techniques have demonstrated significant advancements in preserving the nutritional properties of dried aquatic products, improving drying efficiency, and enhancing their overall effectiveness. Based on the different processing methods, these new preprocessing techniques can be classified into new thermal preprocessing and new non-thermal preprocessing techniques.

New thermal preprocessing techniques include high-humidity hot air impingement blanching (HHAIB), infrared radiation blanching (IRB), microwave blanching (MWB), and other preprocessing methods. Compared to traditional HWB, these techniques offer advantages such as higher heating efficiency and reduced loss of nutritional components [12]. Gao et al. [29] found that HHAIB resulted in an approximately 6% reduction in cooking loss and about a 3.6% increase in water-holding capacity for Pacific white shrimp samples compared to HWB. Shrimp samples treated with HHAIB exhibited superior textural properties (hardness, elasticity, chewiness, and gelatinous characteristics) and visual appearance (color and tissue structure) as compared to those treated with HWB. Binsi et al. [30] investigated the effects of MWB on the quality characteristics of catfish fillets and found that microwave preprocessing increased the hardness and chewiness of the fillets while preserving the inherent sensory properties of catfish meat. Furthermore, the treated catfish fillets exhibited high stability during subsequent storage.

New non-thermal preprocessing techniques, including ultrasound (US), ultra-high pressure (UHP), pulsed electric field (PEF), and cold plasma (CP), have emerged. These techniques offer the potential to overcome the issues associated with thermal preprocessing, such as tissue cell membrane damage, protein denaturation, and thermal degradation of nutrients [7]. They help to maintain the freshness and nutritional value of aquatic products to a certain extent and show significant potential in the field of food drying preprocessing. Ultrasound preprocessing involves the disruption of cell structures using sound waves, enhancing heat and mass transfer during the drying process and improving drying rates while preserving the physicochemical characteristics of the products. Zhao et al. [31] investigated the impact of US preprocessing duration (0, 10, 20, 30 min) on the drying kinetics and quality of scallop adductor muscles using heat pump drying. They found that longer US preprocessing durations resulted in more pronounced cavity and sponge effects at the same moisture ratio, promoting the diffusion of internal moisture to the external surface and enhancing drying efficiency. For example, when scallop adductor muscles reached a moisture ratio of 0.3, the corresponding drying times for US preprocessing durations of 10, 20, and 30 min were 7.11, 6.42, and 6.12 h, respectively. PEF preprocessing involves applying high electric fields to create potential differences across cell membranes, altering cell permeability and disrupting tissue cell membranes. This improves the rate of moisture transfer in aquatic products while minimizing the impact on their physical and chemical properties. Semenoglou et al. [32] evaluated the effect of PEF preprocessing (1.6 kV/cm, 1500 pulses/19.7 kJ/kg) on the osmotic dehydration of sea bass fillets and found that PEF preprocessing increased the effective water diffusion coefficient and solute diffusion coefficient by 50% and 66%, respectively. CP preprocessing involves applying sufficient energy to gas to induce plasma formation at low temperatures. It eliminates microorganisms and deactivates enzymes in aquatic products, reducing their water-holding capacity and extending their shelf life. This technique offers advantages such as high efficiency, environmental friendliness, mild reaction conditions, and strong controllability. Wang et al. [33] demonstrated that CP preprocessing can improve drying efficiency and enhance the quality of meat products. However, the application of CP preprocessing in the drying of aquatic products has not been reported yet and requires further in-depth research.

2.3. Comparative Summary

Pretreating aquatic products before drying significantly enhances their drying characteristics, improves drying efficiency, and enhances drying quality. Table 1 reveals the research findings of drying preprocessing techniques in recent years, leading to two conclusions: (a) Traditional preprocessing techniques, characterized by their low cost, simplicity, and wide applicability, are still extensively used in the preprocessing stage of aquatic product drying. (b) Novel preprocessing techniques aim to maximize the retention of their inherent flavors, textures, and nutrients while enhancing drying efficiency and reducing energy consumption. However, most of these techniques are still in the experimental stage, and their safety, scalability, and cost-effectiveness require further validation. Consequently, developing a new type of drying preprocessing technique that is broadly applicable, less influenced by various factors, and highly beneficial represents a significant challenge for future advancements in preprocessing techniques for drying aquatic products.

Table 1.

Comparison of results of studies on drying pretreatment techniques.

3. Application of Drying Processing Techniques in Aquatic Products

Aquatic products are processed into dried products using various drying techniques, thereby extending their shelf life. These drying techniques utilize different drying principles to control the moisture content. Commonly used drying methods include traditional drying techniques, high-quality drying techniques, and combined drying techniques.

3.1. Traditional Drying Techniques

3.1.1. Natural Drying

As a traditional drying technique, natural drying (ND) possesses significant advantages in terms of economic benefits, making it the primary method for drying aquatic products in many developing countries. ND methods commonly include sun drying, air drying, and shade drying. However, the drying efficiency and quality of the dried products are limited by natural factors. During the drying process, aquatic products are susceptible to contamination from dust and infestation by birds and insects, making it challenging to meet the required quality and food safety standards [33]. In a study conducted by Liu et al. [34] using abalone as the raw material, the drying rate and quality of abalone dried by CAD and natural drying methods were compared. The results showed that CAD exhibited higher drying efficiency, requiring approximately 70% less time compared to natural sun drying. Moreover, the samples dried by cold air retained a greater amount of nutrients. However, due to limitations imposed by objective conditions, ND lacks control, has low drying efficiency, and cannot meet the demands of large-scale production. Consequently, this method is gradually being replaced by modern artificial drying methods.

3.1.2. Hot Air Drying

Hot air drying (HAD) is a traditional drying technique that uses hot air as the drying medium to remove moisture from materials through convection circulation, achieving the desired level of dryness. This method is known for its simplicity, low equipment investment, and high productivity, making it widely adopted by small- and medium-sized enterprises worldwide. Zeng et al. [35], focusing on silver carp, confirmed that hot air temperature is the primary factor influencing the drying rate in HAD. To further investigate the impact of hot air temperature on dried products, Zhao et al. [36] analyzed the effects of different HAD temperatures (70, 80, 90 °C) on the drying characteristics of mackerel. They examined the relationship between hot air temperature, drying efficiency, and product quality. The experimental results further demonstrated that higher hot air temperatures resulted in higher drying efficiency, with a falling-rate drying pattern observed. However, HAD still has limitations. When employing high-temperature hot air for rapid drying, a hard shell and other drying effects may form on the product surface, impeding the diffusion of moisture from the interior, thereby causing uneven drying [37]. Zhao et al. [36] also discovered that increasing hot air temperature significantly increased the hardness and chewiness of dried products. Furthermore, the high-temperature environment of HAD can lead to lipid oxidation and beauty browning, resulting in undesirable odors, tissue structure degradation, and the loss of heat-sensitive components, thus diminishing product quality. Li et al. [38] found through their research that HAD can lead to a reduction in the content of eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) in South American shrimp. Comparing the lipid content in shrimp samples subjected to HAD for 3 min and 7 min with the control group, reductions of approximately 17.2% and 22.6%, respectively, were observed.

3.2. High-Quality Drying Technology

3.2.1. Cold Air Drying

Cold air drying (CAD) is a method that utilizes low temperature, low humidity, and high air velocity to reduce the moisture content of materials and achieve the desired level of dryness. The CAD system controls the temperature and humidity of the drying environment, effectively addressing issues such as lipid oxidation, protein denaturation, and nutrient loss that can occur during HAD. This technique helps maintain the microstructure, appearance, and quality of the materials while also being energy-efficient and environmentally friendly. It is particularly suitable for drying high-fat and high-protein aquatic products. Sun et al. [39] compared CAD and HAD methods for drying oysters. The results indicated that compared to HAD, CAD resulted in milder Maillard reactions and protein oxidation in the dried products. Moreover, the total amino acid content was higher in the products dried using cold air, especially the content of sweet-tasting amino acids. Therefore, oyster products prepared through CAD not only possess high nutritional value but also exhibit a more pronounced flavor, indicating superior quality compared to HAD. Dong et al. [40] conducted a similar study and confirmed that CAD provided better protection to the internal structure of South American white shrimp compared to HAD, resulting in higher-quality dried products. Their research also revealed that after 16 h of CAD, the dried South American white shrimp exhibited optimal appearance, good elasticity, hardness, and a rich flavor, receiving the highest sensory scores. Kilic. [41], using rainbow trout (Oncorhynchus mykiss) as the raw material, investigated the changes in key drying indicators at different CAD temperatures (4, 10, 15, 20 °C). They found that the quality of the dried rainbow trout samples was superior at lower drying temperatures (4 °C). However, due to its lower drying temperature, CAD has a slower drying rate and longer drying time [42].

3.2.2. Heat Pump Drying

Heat pump drying (HPD) is a highly efficient and cost-effective drying method that utilizes the principle of the reverse Carnot cycle. It consumes a small amount of reversible cycle work to absorb heat from a low-temperature heat source and effectively utilize the absorbed heat as useful energy at a higher temperature. The HPD system mainly consists of a compressor, evaporator, internal and external condensers, and expansion valve, among other components. During the HPD process, the high-temperature and high-pressure refrigerant gas discharged from the compressor enters the condenser, where it transfers heat to the air and condenses into a high-pressure liquid at ambient temperature. After throttling through the expansion valve, it enters the evaporator, where it absorbs heat from the moist air coming out of the drying chamber and transforms into a low-temperature and low-pressure gas. It is then drawn into the compressor for compression, completing the repetitive cycle.

Compared to conventional HAD, HPD has the unique performance of heat recovery, making the entire process more efficient and energy-saving. This conclusion was confirmed in the study conducted by Shi et al. [43]. By optimizing the HPD process of bamboo fish using response surface methodology, they achieved superior quality of dried products compared to HAD while significantly reducing energy consumption. Additionally, HPD allows for precise and independent control of the drying medium temperature, humidity, and airflow [44,45], thereby avoiding the oxidation of unsaturated fatty acids in aquatic products, reducing protein thermal denaturation, and preventing material deformation, discoloration, and loss of flavor-related substances [46]. It is particularly suitable for aquatic products containing heat-sensitive and oxygen-sensitive substances. Mu et al. [47] focused on sea cucumbers as the research subject and compared HPD with the traditional “high-temperature salt hanging” method. They found that HPD had a shorter drying time, faster drying rate, simpler process operation, and a higher degree of automation. Sea cucumbers dried using the heat pump method had lower moisture content compared to traditionally dried sea cucumbers, while maintaining their color and appearance and significantly improving sensory quality. Mu et al. [48] conducted drying experiments on arctic shrimp using heat pump technology, which also demonstrated the feasibility of processing aquatic products with HPD. Based on comprehensive experimental indicators, it was determined that at an air temperature, relative humidity, and airflow rate of 35 °C, 20%, and 1.5 m/s, respectively, arctic shrimp achieved good quality while achieving energy-saving effects. However, HPD still faces challenges such as increased energy consumption ratio and reduced drying rate in the middle and later stages of drying, uneven material heating, refrigerant leakage affecting the environment, and high equipment maintenance requirements [38]. Therefore, a common approach is to combine HPD with other drying techniques to achieve complementary advantages.

3.2.3. Microwave Drying

Microwaves are high-frequency electromagnetic waves with frequencies ranging from 300 MHz to 300 GHz, known for their strong penetration capability. In the 1940s, microwave technology was first applied in the food industry and gained popularity due to its advantages such as fast heating, simple operation, and low energy consumption. It found extensive applications in food heating, cooking, drying, and sterilization processes. Microwave drying (MD) is a complex process of heat and mass transfer based on volumetric heating. During the drying process, high-frequency electromagnetic waves generated by radiation are directed into the material, causing rapid rotation and frictional heating of polar molecules (e.g., water) inside the material. This leads to the evaporation of a significant amount of liquid water within the material, followed by diffusion to the surface through internal pressure gradients, resulting in rapid dehydration [49]. This technology revolutionizes the traditional heating methods that primarily heat from the surface. MD has the advantages of uniform drying and rapid temperature rise, preserving the nutritional content and flavor of the food. The resulting dried products exhibit minimal shrinkage, good rehydration properties, excellent sensory quality, and high yield. Moreover, the drying environment can be adjusted by varying the microwave radiation power, making MD easily controllable and suitable for continuous production [50]. Additionally, MD technology offers antimicrobial and preservation effects, reducing the probability of biological contamination during processing and storage, thus enhancing product safety. As a result, MD technology has been extensively studied and applied in the field of aquatic products. Christie et al. [51] concluded through their research that MD is the optimal rapid drying method to replace traditional oven drying for high-moisture foods like fish. To further investigate the characteristics of MD, Alfiya et al. [52] conducted experiments using shrimp as the sample material. They studied the quality changes of dried products under ND and MD conditions and found that compared to ND, MD reduced the drying time by 58.3%. The microwave-dried samples exhibited a superior rehydration rate, shrinkage rate, and effective moisture diffusion coefficient compared to the naturally dried samples. Similarly, to compare the characteristics of HAD and MD, Peng et al. [53] performed drying experiments on grass carp fillets using 50 °C HAD and 400 W MD. Comparing the quality parameters during the drying process of grass carp fillets, they found that MD resulted in a more rapid decrease in moisture content, higher relative protein and fat content after drying, a greater variety of volatile compounds, and improved fish flavor. However, uneven heating caused by microwaves can result in localized charring and the development of off-flavors in certain areas of the material during the final stages of drying. Additionally, it is challenging to determine the drying endpoint accurately with MD, which can lead to over-drying [49].

3.2.4. Vacuum Freeze Drying

Vacuum freeze drying (VFD), also known as sublimation drying, is a high-quality drying technique. The freeze dryer consists of components such as a drying chamber, heating plates, a condenser, and vacuum valves. By adjusting the temperature control of the freeze dryer’s plates, the moisture-containing material is pre-frozen below the eutectic point temperature. Once the internal moisture of the material is completely frozen into small, uniform ice crystals, the condenser is cooled to an appropriate temperature, and then the vacuum pump is used to maintain a vacuum degree of 1.3~13 Pa inside the chamber. The low-temperature and low-pressure environment causes the moisture within the material to directly sublime from solid ice to water vapor, and then the water vapor is condensed by the condenser of the vacuum system, removing the internal moisture of the material to achieve dehydration [54]. VFD, as a semi-automated, low-pressure, and low-temperature dehydration technique, possesses numerous advantages [54,55,56,57]: (a) The low-temperature, low-pressure, and low-oxygen drying environment is suitable for drying heat-sensitive and easily oxidizable aquatic products. (b) Sublimation dehydration after material freezing forms a stable framework internally, allowing for the maximum retention of the material’s original physical form, chemical properties, and biological characteristics. (c) The dried product shows no shrinkage, presenting a porous sponge-like structure internally, which facilitates easy rehydration and excellent reconstitution properties. The quality of the rehydrated product is essentially the same as or even identical to its fresh state before freeze drying. (d) Thorough dehydration removes 95~98% of the moisture from the material, enabling long-term preservation and convenient transportation at room temperature. (e) Since the material is in a frozen state during the drying process, with low temperatures, the heating source does not require high temperatures, and there is minimal heat loss during the process, resulting in high thermal efficiency.

To investigate the impact of VFD technology on the quality of aquatic products, Lin et al. [58] conducted sensory evaluations on Antarctic krill as the experimental material. After undergoing VFD treatment, the dried Antarctic krill products were found to effectively preserve the original protein and fat content and exhibited significantly better appearance and color compared to HAD and vacuum tray drying. Moreover, the flavor compounds in the dried products closely resembled those of the original shrimp. Hu et al. [59] compared the effects of three drying methods, namely HAD, microwave vacuum drying, and vacuum freeze drying (VFD), on the quality of hairtail fish. The results similarly demonstrated the superiority of VFD technology. The moisture content of the vacuum freeze-dried products was only 4.0%, and they exhibited better rehydration ability compared to products dried using other methods. Additionally, they received higher sensory scores in terms of flavor, color, and texture. To analyze the characteristics of VFD, Zhou et al. [60] conducted a flavor analysis of catfish fillets dried using different drying methods. The results indicated that VFD had the least impact on the drying characteristics of catfish fillets. Furthermore, many researchers have optimized the VFD process. For instance, Zhang et al. [61] employed response surface methodology to optimize the VFD process for sea cucumbers. The experimental results showed that the freeze-dried sea cucumbers achieved a sensory evaluation score of 8.62, a moisture content reduction of over 90%, a shrinkage rate of 91.42%, an elasticity of 93.39, and a comprehensive index value of 1.53, which were consistent with the predicted results. The response surface optimization yielded favorable outcomes. VFD has the potential to significantly enhance product quality; however, its adoption in the aquatic product processing industry has been slow. The main reasons for this are the higher equipment and facility requirements, as well as the larger investment needed for equipment. Additionally, the production costs are high due to the prolonged duration of the freeze-drying process, which typically exceeds 20 h and consumes more energy compared to conventional drying methods [54]. Therefore, VFD technology is better suited for the dehydration processing of high-value aquatic products such as sea cucumbers, fish maw, and abalone.

3.2.5. Infrared Drying

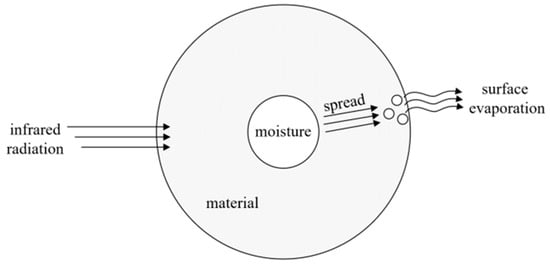

Infrared radiation possesses strong thermal radiation effects and is an electromagnetic wave with a wavelength ranging from 0.75 to 1000 μm. Based on the different wavelengths, it can be divided into near-infrared, mid-infrared, and far-infrared regions [62]. In material drying, far-infrared is mainly used, which, compared with near-infrared and infrared, has a stronger radiation capacity. Infrared drying (ID) is a form of heat transfer radiation drying, distinct from MD, which generates heat through friction. Infrared radiation absorbed by the material’s surface matches the inherent frequency of molecular vibration and internal polar molecule movement, resulting in intense molecular vibrations and frictional heat generation. This process facilitates the rapid diffusion of internal moisture to the material surface, where it vaporizes, achieving efficient drying [63]. Figure 2 illustrates the concept of ID. Energy transfer during ID does not require a medium, making it highly efficient, uniform in heating, and advantageous in terms of product quality, energy consumption, and environmental impact. It is considered an ideal drying method. Moon et al. [64] investigated the drying characteristics of sea cucumbers under two drying methods: far-ID and HAD. They found that far-ID significantly reduced the drying time. Under the same conditions, the moisture content of sea cucumbers changed by 1.38~3.23% per minute more during far-ID compared to HAD. Furthermore, sea cucumbers dried using far-infrared experienced less surface damage and exhibited better quality. Wang et al. [65] studied the influence of infrared wavelength and air velocity on the drying characteristics and product quality of dried squid filaments. They discovered that a wavelength of 2.5–3.0 μm and an air velocity of 0.5 m/s were the optimal drying conditions for squid filaments. Moreover, they observed that compared to HAD, ID resulted in lower drying shrinkage, a brighter color, better rehydration capacity, and a similar muscle fiber structure in rehydrated samples, resembling fresh samples. Ning et al. [66] similarly confirmed that far-ID exhibited faster drying rates, higher quality, and lower energy consumption compared to HAD.

Figure 2.

Schematic diagram of infrared drying.

Although ID demonstrates significant advantages in terms of drying efficiency and energy consumption, it still has certain limitations. Due to the limited penetration ability of infrared radiation and the multi-layer drying of certain aquatic product materials, ID can cause uneven drying. Therefore, ID is only suitable for thin-layer drying [67]. This results in lower production efficiency and higher production costs associated with ID. Hence, the combination of ID with other drying techniques offers a more extensive and efficient application.

3.3. Combined Drying

Combined drying is a composite drying technique used in practical production, which involves the phased combination of two or more drying methods based on the characteristics of the drying material. This approach not only enhances drying efficiency and reduces energy consumption but also improves product quality while preserving the original sensory attributes of the material to the greatest extent possible.

Currently, in the processing of aquatic products, common combined drying techniques include heat pump–hot air combined drying, infrared–heat pump combined drying, infrared–hot air combined drying, microwave–hot air combined drying, and microwave–vacuum freeze drying.

Heat pump–hot air combined drying (HPD + HAD) is a phased combined drying method where HPD is followed by HAD. This approach addresses the issues of increased energy consumption and slower drying rates typically observed in single-stage HPD. It allows for the full utilization of the advantages offered by heat pump technology, resulting in reduced production energy consumption, improved product quality, and alleviation of surface crust formation in aquatic products. In a study conducted by Ren [68], using fresh-frozen squid as the test material, a comparison was made among HAD, HPD, and HPD + HAD in terms of sample quality and energy consumption. The findings demonstrated that combined drying effectively preserved the quality of dried squid, with the combined drying samples exhibiting a Specific Moisture Extraction Ratio (SMER) value of 163.04% compared to HAD samples and 122.95% compared to HPD samples.

Infrared–heat pump combined drying (ID + HPD), compared to HPD alone, contributes to the formation of desirable texture and microscopic porous structure in the drying process of aquatic products. It also addresses the issue of uneven heating caused by the limited penetration ability of infrared radiation in ID. This combined drying method offers advantages such as high efficiency, energy savings, rapid drying rates, no need for heating media, good heating uniformity, and the ability to preserve the overall quality of food products. Deng et al. [69] discovered that compared to HPD alone, ID + HPD resulted in lower levels of trimethylamine, volatile basic nitrogen, and aerobic microorganisms in dried squid slices. Aktaş et al. [70] conducted a study and found that by incorporating an infrared heater into the system for infrared-assisted HPD, the drying time was reduced by 48.8% under HPD conditions (45 °C).

Infrared–hot air combined drying (ID + HAD) is suitable for the drying and processing of most heat-sensitive materials. It offers advantages such as shorter drying time, lower energy consumption, reduced processing costs, and improved product quality. Additionally, ID + HAD can realize sterilization, effectively avoiding microbial contamination issues. Cai et al. [71] investigated the influence of far-infrared-assisted HAD on the drying characteristics and quality of Pacific saury. They found that compared to HAD alone, combined drying reduced the drying time by 10% to 13%. Moreover, the mackerel slices dried through the combined method exhibited superior color, texture properties, and sensory evaluation compared to those dried using hot air alone.

Microwave–hot air combined drying (MD + HAD) addresses the issue of uneven heating encountered in single MD, to avoid localized hotspots during the later stages of drying, which lead to the emergence of burning at the edge of the material or sharp corners. It offers advantages such as reduced drying time, fast dehydration rate, good rehydration properties, retention of characteristic aromatic compounds, and high product quality. Duan et al. [72] conducted MD + HAD on fresh tilapia fillets and found that compared to HAD, combined drying significantly reduced the drying time while maintaining better flavor and quality in the dried tilapia products.

Microwave–vacuum freeze drying (MD + VFD) is a drying method that involves the sublimation drying of frozen solid wet materials under low-temperature and low-pressure conditions, with the application of microwave radiation to provide latent heat of sublimation to the material in its frozen state, thereby reducing the material moisture content. This combined drying method achieves efficient and rapid heating, minimal loss of vitamins and water-soluble nutrients, thorough dehydration with excellent rehydration properties, ease of automation and continuous production, and low energy consumption. It is suitable for high-end and heat-sensitive aquatic products. Wu et al. [73] discovered that the drying time of MD + VFD was approximately one-third shorter than that of VFD. The energy consumption of MD + VFD was about 40% lower compared to VFD. The product quality obtained using microwaves as the heat source for freeze drying showed no significant difference compared to conventional freeze drying. Moreover, MD + VFD exhibited certain bactericidal properties.

3.4. Comparative Summary of Drying Techniques

Table 2 reveals the application status of drying technologies in the aquatic product industry. Through analysis, the following conclusions can be drawn: (a) Although traditional drying techniques have significant advantages in terms of economic benefits, they suffer from drawbacks such as low drying efficiency and poor controllability, making it challenging to obtain high-quality dried products. (b) High-quality drying technologies can yield superior dried products, but they still face disadvantages such as high costs, limiting their extensive application. (c) Combined drying combines the advantages of different drying methods, effectively improving drying efficiency, reducing energy loss, and maximizing the preservation of the original sensory qualities of the materials, thus enhancing product quality. However, most of these technologies are still in the laboratory stage. (d) The continuous pursuit of combined drying technologies with low energy consumption, low costs, and high quality represents the future direction of drying technology.

Table 2.

Application of aquatic product drying.

4. Non-Destructive Monitoring Technology for Drying Processes

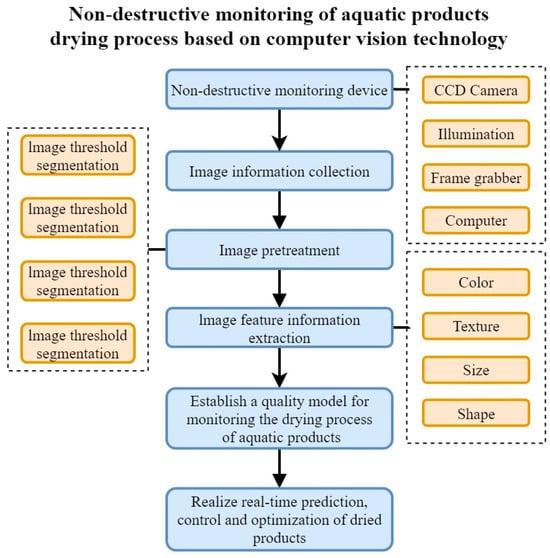

4.1. Computer Vision Technology

The fundamental principle of computer vision (CV) technology is to utilize visual sensors to acquire high-quality image signals of target objects and transmit the image information to a visual system to extract the target’s characteristic information. By analyzing and processing the feature information from different frames, the precise changes in the drying process of the product can be captured [77]. In the drying process of aquatic products, parameters such as color, dehydration status, and texture characteristics can be accurately reflected through images. Therefore, numerous studies have employed CV technology for monitoring the drying process of seafood products. The flow of non-destructive monitoring using CV technology in the drying process is shown in Figure 3. Mohebbi et al. [78] utilized a digital camera to measure the color characteristics in the RGB color space and converted them into the lab system to estimate the dehydration level of shrimp under different drying conditions. Moreover, they also established multiple linear regression and artificial neural network prediction models based on the correlation between shrimp moisture content and color features, with correlation coefficients of 0.80 and 0.86, respectively. To further achieve real-time detection of the drying process, Hosseinpour et al. [79] developed a CV system for continuous and online monitoring of color variations in shrimp during thin-layer drying, integrating it with a hot air dryer. The quadratic regression model established in this study accurately represented the relationship between sample color parameters and drying time, with an absolute coefficient of determination (R2) of 0.9659 and a mean square error (MSE) of 0.0016, demonstrating that the CV system can achieve the real-time prediction, control, and optimization of drying product quality attributes. Furthermore, Hosseinpour et al. [80] designed a novel image processing method to extract translation, rotation, and scale-invariant visual texture feature parameters during shrimp drying, enabling online monitoring and control of product quality.

Figure 3.

Application of computer vision technology in drying process.

CV technology achieves online non-destructive monitoring by capturing information from product images, providing support for precise control of the drying process, and enhancing drying efficiency and product quality. Moreover, this method demonstrates significant advantages in terms of economic costs. However, during the drying process, internal component information of aquatic products, such as protein and lipid content, cannot be obtained through image analysis. Therefore, relying solely on CV technology is insufficient for comprehensive monitoring of the drying process. It is necessary to integrate other intelligent technologies to accurately measure the content and distribution of internal components in aquatic products, thus providing more comprehensive and precise data support for the drying process of aquatic products.

4.2. Near-Infrared Spectroscopy Techniques

Near-infrared (NIR) spectroscopy is an electromagnetic wave spectrum that falls between visible light and mid-infrared light, with wavelengths ranging from 780 to 2526 nm and wave numbers ranging from 12800 to 3959 cm−1 [81]. NIR spectroscopy technology utilizes the non-harmonic vibrational characteristics of chemical bonds to reflect the vibrational behavior of different chemical components [82]. Organic substances in food generate stable signals in the NIR spectral region, and the vibrational forms of different hydrogen-containing groups differ from their environment, leading to differences in absorption peak intensity and position. Therefore, NIR spectroscopic analysis offers advantages such as rapidity, non-destructiveness, high precision, no requirement for chemical reagents, and no need for sample preprocessing. Currently, this technology has been widely applied in various fields, including freshness assessment, quality evaluation, heavy metal content detection, adulteration identification, traceability of origin, and shelf-life prediction for seafood products [83,84,85]. Although NIR spectroscopy can extract vibrational characteristic information of different organic substances, aquatic products contain a wide range of organic compounds, posing challenges in feature extraction. Hence, many studies have incorporated intelligent technologies such as machine learning to enhance feature extraction capabilities. Zhou et al. [86] collected the NIR spectra of mandarin fish in the range of 1000 to 1799 nm and used partial least squares regression (PLSR) to construct prediction models for pH value, the total volatile basic nitrogen (TVB-N) content, the thiobarbituric acid reactive substance (TBARS) value, and adenosine triphosphate (ATP)-related compounds (K value). The correlation coefficients of the models were 0.961, 0.958, 0.961, and 0.829, respectively. The study demonstrated the feasibility of using NIR spectroscopy for rapid freshness detection in mandarin fish. Additionally, Khodabux et al. [87] employed NIR spectroscopy combined with PLSR to develop calibration models for moisture, protein, total fat, and free fat content in tuna. The corresponding model determination coefficients were 0.98, 0.99, 0.95, and 0.96, showcasing the potential of NIR spectroscopy combined with chemometrics for rapid, accurate, and non-destructive determination of nutritional components in fish, enabling tracking and assessment of changes in seafood quality. To further improve detection accuracy, Chen et al. [88] established discrimination models based on infrared and Raman spectroscopy data using three discrimination methods: partial least squares discriminant analysis, least squares support vector machines (LS-SVMs), and random forests. The discrimination models achieved 100% overall correct discrimination when identifying fish poisoned by a single heavy metal or a mixture of heavy metals, and maintained identification accuracy above 90% when analyzing samples with different heavy metal poisoning. The results indicated that NIR spectroscopy could be used for the rapid non-destructive detection of heavy metal (Zn, Cu, Cd) contamination in seafood. In conclusion, NIR spectroscopy is an effective method for the qualitative and quantitative analysis of seafood quality components. However, it still has certain limitations, including challenges in analyzing dispersed samples, limited range of individual region detection, single detection content, and low accuracy due to the non-uniform distribution of sample components [82,85].

4.3. Hyperspectral Imaging Technology

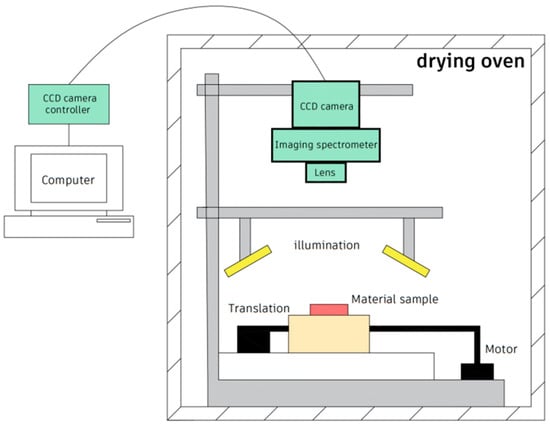

Hyperspectral imaging (HSI) technology is a fusion technique that combines imaging and spectroscopy to obtain both external image information and spectral data in different wavelength bands of the target sample. It can capture the external characteristics, surface defects, and stains of products, as well as analyze the internal physical structure and chemical composition of objects [89,90]. In recent years, HSI technology has been extensively researched and applied in the field of agricultural product quality inspection [91], assessment of foodborne contaminants [92], and food certification aspects [93]. It has also gained increasing attention in the area of non-destructive and rapid quality detection of aquatic products. Figure 4 presents a schematic diagram of an HSI system used in the drying process. Cheng et al. [94] discussed the research and potential industrial applications of HSI technology in the quality inspection, analysis, and control of fish and other marine products. These applications include the detection of nematode contamination, measurement of physical properties such as color, texture, and water-holding capacity, determination of chemical components such as fat, protein, and moisture, detection of microbial spoilage, measurement of moisture content and distribution, food adulteration identification, and prediction of edible meat quantity. Another study by Cheng et al. [95] developed visible–near-infrared HSI technology to determine the content of TVB-N during the frozen storage of grass carp. They established a quantitative calibration model by correlating the spectral data extracted from HSI using PLSR and LS-SVM with the reference measurements of TVB-N. This model aimed to further increase the understanding of the loss of fish freshness during the frozen storage process. The aforementioned research has demonstrated the significant potential of HSI technology in monitoring changes in the quality of aquatic products. However, it also faces certain limitations that need to be addressed in future research and industrial applications. HSI contains much unnecessary information compared to single-color images, resulting in a longer data acquisition time and complex data processing for HSI technology. These limitations restrict its real-time processing applications. Overcoming these drawbacks primarily depends on the advancement of computer technology and improved computational capabilities.

Figure 4.

Schematic diagram of the HSI system used in the drying process.

4.4. Low-Field Nuclear Magnetic Resonance Technology

Low-field nuclear magnetic resonance (LF-NMR) technology applies a radio-frequency pulse to samples placed in a constant magnetic field below 0.5 T to measure the resonance and absorption of proton energy. This process is also known as relaxation [96,97,98]. The relaxation process includes longitudinal relaxation time (T1) and transverse relaxation time (T2), which depend on the state of hydrogen protons and the physical and chemical environment. They effectively reflect the mobility of water molecules in biological systems. For instance, when water is tightly bound to muscle tissue, the T2 value is smaller [99]. Therefore, low-field NMR technology offers fast and non-destructive advantages, making it suitable for detecting water content, water distribution, and water migration processes in aquatic products. It serves as a powerful tool for moisture analysis, adulteration identification, and origin traceability in the field of dried aquatic processing. Song et al. [100] conducted an experiment using abalone as the sample and constructed a highly correlated prediction model for moisture content in abalone samples using the low-field NMR relaxation method. The resulting correlation coefficient was as high as 0.933. Similarly, Deng et al. [101] monitored the rehydration process of dried squid under three drying methods (HPD, freeze drying, and HAD) using LF-NMR technology. The experiments demonstrated that low-field NMR technology accurately reveals the water migration process in different drying techniques for aquatic products. Additionally, this technology can predict the physicochemical changes in aquatic products during the drying process and provide a visual observation of the internal analysis for assessing product quality. To further analyze the drying characteristics of aquatic products, Zang et al. [102] employed low-field NMR technology to investigate the water dynamics during the drying process of dried anchovies. They established prediction models for moisture and fat content in anchovies based on relaxation data obtained from low-field NMR, combined with principal component regression (PCR) and PLSR. The experimental results showed that the established models exhibited good predictive performance for moisture and fat content in anchovies. The cross-validation coefficient of determination (Rcv2) was 0.9877 and 0.9054, and the root mean square error was 0.7132 and 0.1512, respectively. These studies indicate the potential of low-field NMR technology, combined with PLSR and other modern information technologies, for predicting physicochemical indicators during the drying process. However, due to higher economic costs and technical barriers, the application of this technology is somewhat limited, and further optimization is required for future research.

4.5. Comparative Summary of Non-Destructive Monitoring Techniques for Drying Processes

At present, numerous scholars have conducted research and applied non-destructive testing techniques for quality and safety monitoring during the drying process of aquatic products, achieving certain results. Table 3 presents the applications of non-destructive testing techniques in quality monitoring of aquatic products. Through comparative analysis, the following two conclusions can be drawn: (a) Non-destructive monitoring techniques enable rapid, accurate, and non-destructive quality and safety monitoring of the drying process of aquatic products. This not only ensures the quality and safety of dried aquatic products but also improves the efficiency of detection, saving manpower and resources. (b) Non-destructive monitoring techniques have made certain achievements in the field of drying aquatic products, but they still have their respective limitations. Therefore, continuously enhancing the detection capability and accuracy of the testing techniques is the future development direction of non-destructive monitoring technology.

Table 3.

Application of non-destructive monitoring techniques in aquatic product quality monitoring.

5. Effect of Drying Process on Aquatic Product Quality

5.1. Effect of Drying Process on Sensory Quality of Aquatic Products

The sensory quality of dried aquatic products is one of the important indicators reflecting their edible quality and directly influencing consumer purchasing decisions. This quality is affected by the pretreatment processes and drying techniques of aquatic products, primarily manifested in terms of color, flavor, and texture. Among them, color is usually described using three color parameters: L* (lightness), a* (redness–greenness), and b* (yellowness–blueness). Studies have shown that low-temperature drying environments better preserve the original color of aquatic products. Flavor substances include volatile and non-volatile compounds, mainly resulting from chemical reactions such as lipid oxidation, hydrolysis, Maillard reaction, and Strecker degradation during the drying process. Texture refers to the hardness and chewiness of dried aquatic products, and the drying temperature has a significant impact on it. High temperatures can cause denaturation and deformation of muscle proteins, leading to surface hardening. Therefore, the differences in drying processes are key factors influencing the sensory quality of aquatic products. By employing suitable drying techniques and optimizing temperature and duration, it is feasible to attain desirable sensory attributes and economic advantages. Table 4 lists recent studies on the evaluation of the sensory quality of aquatic products using different drying methods.

Table 4.

Comparison of sensory quality evaluation of aquatic products by different drying methods.

5.2. Effect of Drying Process on Nutrient Composition of Aquatic Products

5.2.1. Protein

Aquatic products are rich in high-quality animal proteins that are essential and important for the human body. However, protein denaturation, oxidation, and degradation are prone to occur in complex drying environments [107]. Protein denaturation usually takes place during the high-temperature drying process of aquatic products, as the protein’s internal molecular structure is disrupted and loses its original physical and chemical properties in high-temperature environments [108]. Protein denaturation is a significant influencing factor in the texture of dried aquatic products. It is mainly caused by the rapid evaporation of surface moisture from the aquatic products and muscle protein contraction under the effect of heat, resulting in increased hardness of the dried products [109]. Lv et al. [110] studied the protein denaturation status of scallops using HPD and found that the thermal denaturation of myofibrillar proteins occurred between 55 and 60 °C, leading to myofibrillar protein contraction and the formation of hydrogen bonds between proteins, thereby increasing the hardness and elasticity of the dried products. Protein oxidation refers to the chemical reactions that occur in protein molecules under the influence of oxygen, which is a common phenomenon during the drying process of aquatic products and is usually associated with the adopted drying techniques. Relevant studies have indicated that compared to ND and HAD, CAD exhibits lower levels of protein oxidation. Zhang et al. [111] investigated the changes in tissue structure and rheological properties of dried abalone meat using CAD and ND methods. The results showed that both drying methods led to muscle fiber contraction in abalone meat, but CAD exhibited superior performance in terms of muscle fiber contraction when drying was stopped. Additionally, the elastic modulus, viscous modulus, and fracture strength of cold air-dried abalone meat were lower than those of the original samples. Furthermore, protein carbonylation is a widely used indicator for assessing the degree of protein oxidation in aquatic products. Higher protein carbonyl content indicates a higher degree of protein oxidation. To further study protein oxidation during the drying process, Chen et al. [112] investigated the changes in protein carbonyl content at different stages of drying in scallops. They found that protein carbonyl content was higher under high-temperature and low-moisture conditions. Specifically, after boiling, rinsing, and drying, the protein carbonyl content increased by 4.25-fold, 5.27-fold, and 5.81-fold, respectively. Protein degradation refers to the decomposition of protein molecules into nitrogenous substances, such as Total Volatile Base Nitrogen (TVB-N) and trimethylamine (TMA), under the action of various enzymes and microorganisms. The content of these substances is often used as an important indicator in evaluating the spoilage of aquatic products. Nagwekar et al. [113] investigated the changes in TVB-N and TMA content in fish under different drying methods. The results showed that among the four processes tested, namely, natural sun drying (TSD), hot air drying (HAD), cold air drying (FD), and solar drying (SCD), there was no significant difference in TMA content in the fish. However, compared to the other three methods, fish dried using the SCD process exhibited the lowest TVB-N content, while fish dried using the TSD process exhibited the highest TVB-N content.

5.2.2. Lipid

Lipids are essential nutrients in aquatic products, and retaining lipids during the drying process can enhance the nutritional value of the products. Fatty acids are the primary components of lipids in aquatic products, with unsaturated fatty acids being predominant in fish and saturated fatty acids in shellfish [114]. Under the influence of light, microorganisms, and enzymes, lipids in aquatic products are prone to oxidation and hydrolysis during the drying process. Lipid oxidation, primarily involving unsaturated fatty acids, undergoes chemical reactions in the presence of oxygen, resulting in the formation of acids and ketones [115]. The peroxide value (POV) and total oxidation value of oil (TOTOX) are widely used indicators to measure the degree of lipid oxidation. Lipid hydrolysis refers to the process in which triglycerides in aquatic products are enzymatically hydrolyzed into fatty acids and glycerol, with the acid value (AV) commonly used as an indicator of the degree of lipid hydrolysis [116]. Liu et al. [117] investigated the impact of HAD on lipid oxidation and hydrolysis in Philippine clams and found a positive correlation between POV, TOTOX, and drying temperature. Direct drying of fresh samples increased the AV value, while boiling the samples maintained a stable AV value at different drying temperatures. Lin et al. [118] examined the changes in lipids in dried mackerel fillets during HAD and observed lipid hydrolysis reactions catalyzed by esterases and phosphorylases, with AV increasing with drying time. Therefore, these studies suggest that HAD significantly promotes lipid oxidation and hydrolysis, leading to high levels of oxidation and poor lipid stability in the dried samples.

5.3. Effect of Drying Process on the Microorganism Content of Aquatic Products

The activity of microorganisms is the primary cause of spoilage and deterioration in aquatic products. Due to their relatively fragile muscle tissue, near-neutral pH, high moisture content, and protein content, aquatic products are susceptible to the invasion of spoilage microorganisms, leading to spoilage and deterioration [119]. Therefore, controlling the growth of spoilage bacteria in aquatic products is essential for maintaining their food safety, microstructural integrity, and sensory characteristics. The drying process can remove moisture from aquatic products, reducing their moisture content and inhibiting the proliferation and growth of bacteria. Additionally, heat treatment can disrupt the cellular structure of aquatic products, or processes such as VFD at extremely low temperatures can decrease bacterial activity, thereby reducing bacterial load, extending the shelf life of aquatic products, and preserving their sensory and biochemical attributes [120]. Currently, total viable count is commonly used as an indicator to evaluate the microbial content of seafood products in the food industry. However, there is relatively limited research reported on the variation in microbial content in aquatic products during the drying process. Therefore, future studies can explore dynamic monitoring techniques for microbial changes during the drying process of aquatic products to develop more advanced drying processes and enhance the quality and food safety of dried products.

6. Concluding Remarks

This paper provides a summary of the application of preprocessing techniques, drying methods, and non-destructive monitoring techniques in the drying process of aquatic products, as well as their impact on the quality of aquatic. In the past few decades, drying processes have experienced rapid development; however, several challenges still exist, primarily encompassing the following aspects:

- Preprocessing techniques before drying present challenges such as nutrient loss and chemical residue, making it difficult to meet the practical production demands of the food industry. Preprocessing is a crucial step prior to the drying process of aquatic products as it helps prevent the oxidation of antioxidants during drying, improves drying efficiency, and enhances the quality of dried products. Traditional preprocessing techniques are widely used due to their cost advantages but still suffer from issues related to nutrient loss and residual chemical agents. Novel preprocessing techniques, employing methods such as electric fields, US, or plasma, can modify the internal tissue structure of the material, maximizing the preservation of its original flavor, texture, and nutritional content. However, these techniques are still influenced by various factors, including the drying process, making it challenging to meet the industrial-scale requirements of large-scale drying processes.

- The drying process of aquatic products needs to be optimized. The quality of dried products and the efficiency of the drying process are key considerations in aquatic drying. Traditional drying techniques have significant advantages in terms of economic benefits, but they still face challenges regarding low drying efficiency and the difficulty of obtaining high-quality dried products. Nutrients such as proteins and lipids are prone to losing their original quality in the drying environment. High-quality drying techniques, compared to traditional ones, can achieve higher-quality dried products and better control over the drying process. However, they often have higher energy consumption and lower economic benefits. Combined drying techniques, which leverage the advantages of various processes, can improve drying efficiency and realize a drying process that is comprehensive, energy-efficient, and economically beneficial. Nevertheless, most of these techniques are currently in the theoretical research stage and face challenges in achieving industrial-scale implementation.

- The reliability of non-destructive monitoring techniques in the drying process needs improvement. Non-destructive monitoring techniques in the drying process are a prerequisite for precise drying and provide data support for high-quality drying technologies. These techniques employ intelligent technologies such as CV to achieve real-time online monitoring of material color, texture, moisture content, and distribution during the drying process of aquatic products. The feedback is then integrated into the drying control system to achieve accurate control. However, existing monitoring techniques still have shortcomings. For example, CV techniques face challenges in obtaining moisture content and achieving comprehensive monitoring. Moreover, the high-temperature environment during drying can affect the monitoring capabilities.

In summary, to overcome the limitations of existing aquatic drying processing techniques, researchers should focus on the following aspects:

- Regarding novel preprocessing techniques, researchers will strive to integrate the characteristics of different technologies, study their mechanisms of action, and develop preprocessing techniques that are widely applicable, minimally affected by external factors, and highly beneficial. Different aquatic products have varying tissue structures, and different preprocessing techniques offer distinct advantages. Therefore, future research will focus on combining the characteristics of different techniques, studying their mechanisms, and developing new preprocessing techniques that have a broad scope, fewer influencing factors, and high efficiency. This will enable the achievement of optimal quality in dried products and the optimization of the drying process.

- Exploring new drying processes for aquatic products that are low-cost, highly efficient, and of high quality. Improving drying efficiency, reducing energy consumption, and enhancing the drying quality of aquatic products are crucial issues in the drying process. Existing advanced drying processes optimize drying equipment, utilize new drying media, and control parameters such as humidity and temperature to achieve faster, more uniform, and efficient drying processes. However, these technologies are still in the theoretical research stage, and their promotion costs are high. Therefore, the mainstream direction in the food-drying industry is to optimize drying equipment, improve energy utilization efficiency, and reduce costs. Additionally, the drying environment of aquatic products can cause variations in nutrients such as proteins and lipids. Future research will delve deeper into the changes and reaction mechanisms of substances, including moisture migration, changes in solid matter, and oxidation of proteins and lipids, in order to maximize the retention of sensory and nutritional quality of aquatic products.

- Researching intelligent drying systems integrating non-destructive monitoring and control technologies. Existing non-destructive monitoring technologies rely on powerful data computation, making it difficult to achieve real-time monitoring in edge devices and comprehensively monitor the drying process. Consequently, drying systems cannot adjust drying parameters based on real-time material conditions. Future research needs to address the challenges of real-time and comprehensive monitoring in non-destructive monitoring technologies and utilize information technology, sensor technology, and intelligent control technology to develop advanced automated control systems. Through real-time monitoring and feedback control, precise adjustment of parameters such as temperature, humidity, and airflow during the drying process can be achieved, optimizing and stabilizing the drying process of aquatic products to obtain high-quality dried products.

- Developing more accurate and comprehensive evaluation methods. The quality of dried products is an important indicator for assessing the effectiveness of the drying process. Future research will focus on developing accurate and comprehensive quality evaluation methods and investigating the mechanisms through which the drying process affects the quality of aquatic products. This will help uncover the physical, chemical, and biological changes that occur during the drying process, providing scientific foundations for optimizing drying processes.

Author Contributions

T.G. and W.W.: supervision, conceptualization, methodology, software, and writing—review and editing; H.L.: conceptualization, methodology, software, and writing—original draft preparation; Y.C.: validation, writing—review and editing; Y.L.: methodology and writing—review and editing; J.Z. and J.H.: validation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the 2024 Rural Revitalization Strategy Special Funds Provincial Project (2023LZ04), the National Natural Science Foundation of China (52005188), and Research and Development of Intelligence Agricultural Machinery and Control Technology (FNXM012022020-1-03).

Data Availability Statement

This study did not report any data.

Acknowledgments

The authors acknowledge the editors and reviewers for their constructive comments and all the support on this work.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| HWB | Hot water blanching |

| HHAB | High-humidity hot air impingement blanching |

| IRB | Infrared radiation blanching |

| MWB | Microwave blanching |

| US | Ultrasound |

| UHP | Ultra-high pressure |

| PEF | Pulsed electric field |

| CP | Cold plasma |

| ND | Natural drying |

| HAD | Hot air drying |

| CAD | Cold air drying |

| HPD | Heat pump drying |

| MD | Microwave drying |

| VFD | Vacuum freeze drying |

| ID | Infrared drying |

| HPD + HAD | Heat pump–hot air combined drying |

| ID + HPD | Infrared–heat pump combined drying |

| ID + HAD | Infrared–hot air combined drying |

| MD + HAD | Microwave–hot air combined drying |

| MD + VFD | Microwave–vacuum freeze drying |

| CV | Computer vision |

| NIR | Near-infrared |

| PLSR | Partial least squares regression |

| TVB-N | Total volatile basic nitrogen |

| TBARS | Thiobarbituric acid reactive substance |

| LS-SVM | Least squares support vector machine |

| HSI | Hyperspectral imaging |

| LF-NMR | Low-field nuclear magnetic resonance |

References

- Zhang, W.; Ma, X. Sustainable supply of aquatic food in China. J. Shanghai Ocean. Univ. 2022, 31, 1304–1316. [Google Scholar] [CrossRef]

- Li, X.; Han, T.; Zheng, S.; Wu, G. Nutrition and functions of amino acids in aquatic crustaceans. Adv. Exp. Med. Biol. 2021, 1285, 169–198. [Google Scholar] [CrossRef]

- Baron, C.; Kjærsgård, I.V.H.; Jessen, F.; Jacobsen, C. Protein and lipid oxidation during frozen storage of rainbow trout (Oncorhynchus mykiss). J. Agric. Food Chem. 2007, 55, 8118–8125. [Google Scholar] [CrossRef]

- Fathi, F.; Ebrahimi, S.; Matos, L.; Oliveira, B. Alves RC. Emerging drying techniques for food safety and quality: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 1125–1160. [Google Scholar] [CrossRef]

- Zeng, J.; Song, Y.; Cong, P.; Cao, Y.; Xu, J.; Xue, C. A systematic review of drying in aquatic products. Rev. Aquac. 2023, 1, 47–65. [Google Scholar] [CrossRef]

- Sonarthi, H.; Supreetha, S.; Mall, S. Emerging Novel Technologies for Food Drying. Food Process Eng. Technol. 2023, 1, 3–12. [Google Scholar] [CrossRef]

- Qiu, X.; Chen, S.; Lin, H. Oxidative stability of dried seafood products during processing and storage: A review. J. Aquat. Food Prod. Technol. 2019, 28, 329–340. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Y.; Shi, Q. Research Progress and Future Prospects of Novel Pretreatment Technologies for the Drying of Fruits and Vegetables and Aquatic Products. Sci. Technol. Food Ind. 2022, 43, 32–42. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, M.; Ju, R.; Mujumdar, A.; Yu, D. Novel drying techniques for controlling microbial contamination in fresh food: A review. Dry. Technol. 2023, 41, 172–189. [Google Scholar] [CrossRef]

- Rouaud, O.; Havet, M. 12-Novel drying technologies using electric and electromagnetic fields. In Food Engineering Innovations Across the Food Supply Chain; Academic Press: Cambridge, MA, USA, 2022; pp. 229–236. [Google Scholar] [CrossRef]

- Zeng, Z.; Han, C.; Li, H.; Chen, T.; Zeng, J.; Fang, Z.; Li, B.; Wu, W. Modeling and evaluation in transient analysis of industrialized counter-flow tea drying system. Case Stud. Therm. Eng. 2024, 53, 103781. [Google Scholar] [CrossRef]

- Bassey, E.J.; Cheng, J.; Sun, D. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci. Technol. 2021, 112, 137–148. [Google Scholar] [CrossRef]

- Hülya, T.; İbrahim, E. Salting Technology in Fish Processing. Prog. Food Preserv. 2012, 14, 297–313. [Google Scholar] [CrossRef]

- Jiang, X.; Xue, C. The Pretreatment Technology of Raw Sea Cucumber and New Processing Technology of Salted Sea Cucumber. Adv. Sea Cucumber Process. Technol. Prod. Dev. 2022, 234, 145–169. [Google Scholar] [CrossRef]

- Deng, L.; Mujumdar, A.; Zhang, Q.; Yang, X.; Wang, J.; Zheng, Z.; Gao, Z.; Xiao, H. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes–a comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1408–1432. [Google Scholar] [CrossRef]

- Sampaio, G.; Bastos, D.; Soares, R.; Queiroz, Y.; Torres, E. Fatty acids and cholesterol oxidation in salted and dried shrimp. Food Chem. 2006, 95, 344–351. [Google Scholar] [CrossRef]

- Nieva-Echevarría, B.; Goicoechea, E.; Manzanos, M.; Guillén, M. Fish in vitro digestion: Influence of fish salting on the extent of lipolysis, oxidation, and other reactions. J. Agric. Food Chem. 2017, 65, 879–891. [Google Scholar] [CrossRef]

- Zhou, Y.; Gu, D.; Wang, G.; Xu, Z.; Wang, X.; Cheng, Z.; Fan, J.; Pu, Y.; Zhu, R.; Liao, G. Progress in Research on the Effect of Salt on Lipid Oxidation in Meat Products. Meat Res. 2017, 31, 46–52. [Google Scholar] [CrossRef]

- Mariutti, L.; Bragagnolo, N. Influence of salt on lipid oxidation in meat and seafood products: A review. Food Res. Int. 2017, 94, 90–100. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, B.; Han, C.; Wu, W.; Chen, T.; Dong, C.; Gao, C.; He, Z.; Zhang, F. Performance of Exergetic, Energetic and Techno-Economic Analyses on a Gas-Type Industrial Drying System of Black Tea. Foods 2022, 11, 3281. [Google Scholar] [CrossRef]

- Yu, H.; Sato, M.; Wang, X. Changes in physico-chemical properties during salting of Cololabis saira. Food Ferment. Ind. 2016, 42, 75–80. [Google Scholar] [CrossRef]

- Aubourg, S.; Ugliano, M. Effect of brine pre-treatment on lipid stability of frozen horse mackerel (Trachurus trachurus). Eur. Food Res. Technol. 2002, 215, 91–95. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Zhao, G.; Song, L.; Wu, Z.; Jiang, P.; Zhou, D.; Zhu, B. Studying on effects of boiling on texture, microstructure and physiochemical properties of sea cucumber body wall and its mechanism using second harmonic generation (SHG) microscopy. Food Chem. 2023, 400, 134055. [Google Scholar] [CrossRef]

- Zhu, X.; Healy, L.; Sevindik, O.; Sun, D.; Selli, S.; Kelebek, H.; Tiwari, B. Impacts of novel blanching treatments combined with commercial drying methods on the physicochemical properties of Irish brown seaweed Alaria esculenta. Food Chem. 2022, 369, 130949. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, W.; Li, Q.; Ding, S. Effects of Chemical Osmotic Pretreatment on Drying Characteristics and Quality of Blueberry under Hot Air Drying. Agric. Sci. Technol. 2019, 20, 1–12+19. [Google Scholar] [CrossRef]

- Antos, P.; Kurdziel, A.; Sadlo, S.; Balawejder, M. Preliminary Study on the Use of Ozonation for the Degradation of Dithiocarbamate Residues in the Fruit Drying Process: Mancozeb Residue in Blackcurrant is the Example Used. J. Plant Prot. Res. 2013, 53, 48–52. [Google Scholar] [CrossRef]

- Miller, F.; Silva, C.; Brandao, T. A review on ozone-based treatments for fruit and vegetables preservation. Food Eng. Rev. 2013, 5, 77–106. [Google Scholar] [CrossRef]

- Chen, K.; Gao, L.; Li, Q.; Li, H.; Zhang, Y. Effects of CO2 pretreatment on the volatile compounds of dried Chinese jujube (Zizyphus jujuba Miller). Food Sci. Technol. 2017, 37, 578–584. [Google Scholar] [CrossRef][Green Version]

- Gao, Y.; Qiao, S.; Lin, Y.; Xie, Y.; Ai, Z.; Mowafy, S.; Li, J.; Li, X. Effects of high-humidity hot air impingement cooking on physicochemical properties and microstructure of Pacific white shrimp (Penaeus vannamei). LWT 2023, 182, 114836. [Google Scholar] [CrossRef]

- Binsi, P.; Ninan, G.; Zynudheen, A.; Neethu, R.; Ronda, V.; Ravishankar, C. Compositional and chill storage characteristics of microwave-blanched sutchi catfish (Pangasianodon hypophthalmus) fillets. Int. J. Food Sci. Technol. 2014, 49, 364–372. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, Z.; Liu, J.; Wu, X.; Shi, Q. Effect of Ultrasonic Pretreatment Time on the Drying Kinetics and Quality Attributes of Heat Pump-Dried Scallop Adductors. Food Sci. 2022, 43, 93–101. [Google Scholar] [CrossRef]

- Semenoglou, I.; Dimopoulos, G.; Tsironi, T.; Taoukis, P. Mathematical modelling of the effect of solution concentration and the combined application of PEFs on mass transfer during osmotic dehydration of sea bass fillets. Food Bioprod. Process. 2020, 121, 186–192. [Google Scholar] [CrossRef]

- Zhang, G.; Mao, Z. Research advances of aquatic product drying technologies. Trans. CSAE 2004, 20, 297–300. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, C.; Huang, J.; Xu, J.; Fu, X.; Gao, X. Comparation and analysis of cold-blast air drying and ND of abalone. Fish. Mod. 2012, 39, 42–47. [Google Scholar] [CrossRef]

- Zeng, L.; Zhao, S.; Xiong, S.; Guo, X. Modeling and moisture diffusion properties of salted silver carp during hot-air drying. Trans. CSAE 2008, 24, 280–283. [Google Scholar] [CrossRef]

- Zhao, H.; Meng, D.; Xu, Y.; Wang, M.; Guo, X.; Li, J. Study on hot air drying kinetics and quality changes of scomber japonicus. Packag. Food Mach. 2022, 40, 8–14. [Google Scholar] [CrossRef]