Research on Multi-Physical Field Characteristics of Deep Coal Seam Mining Based on the Rock-Coal-Rock Model

Abstract

1. Introduction

2. Methods

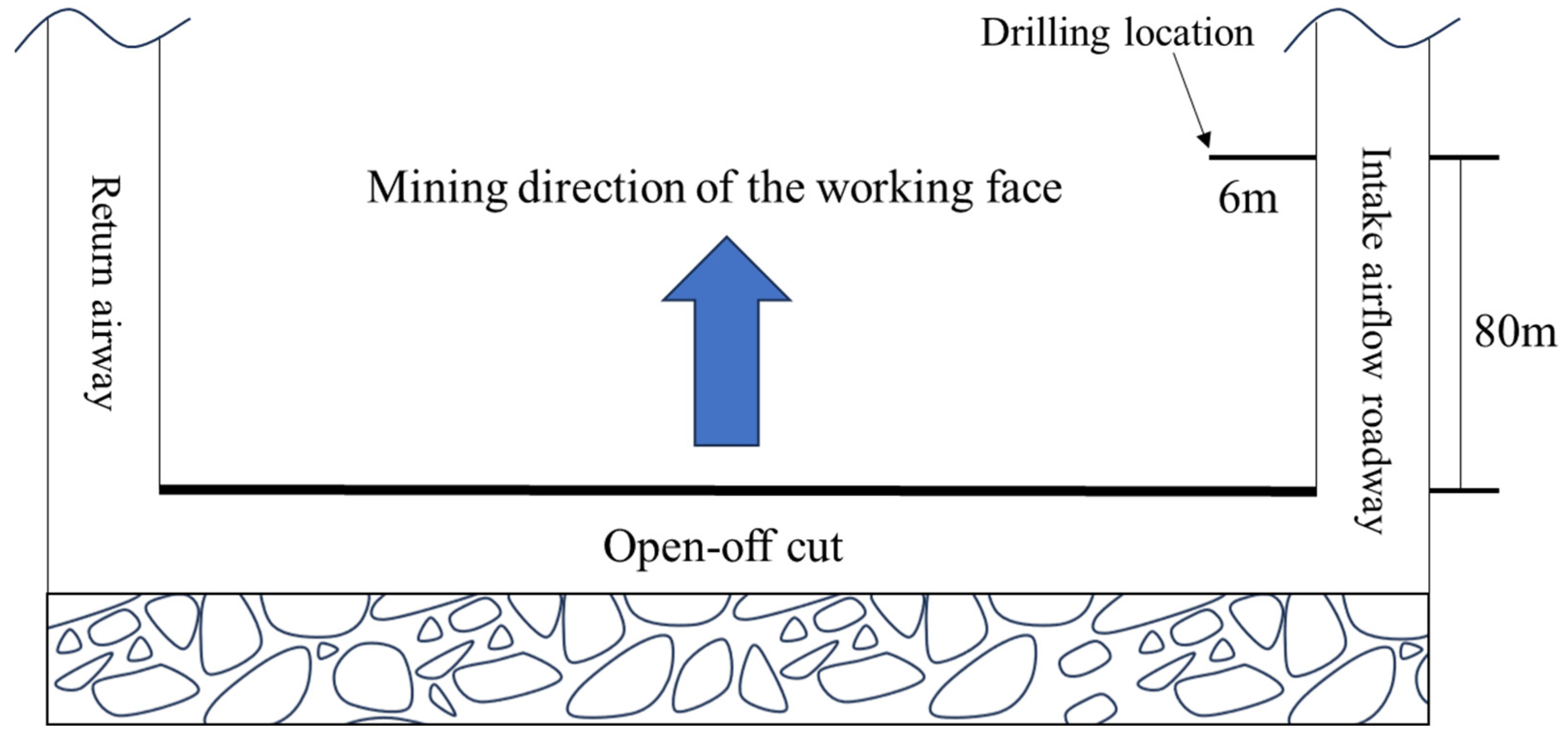

2.1. Overview of the Working Face

2.2. Establishment of the Constitutive Model

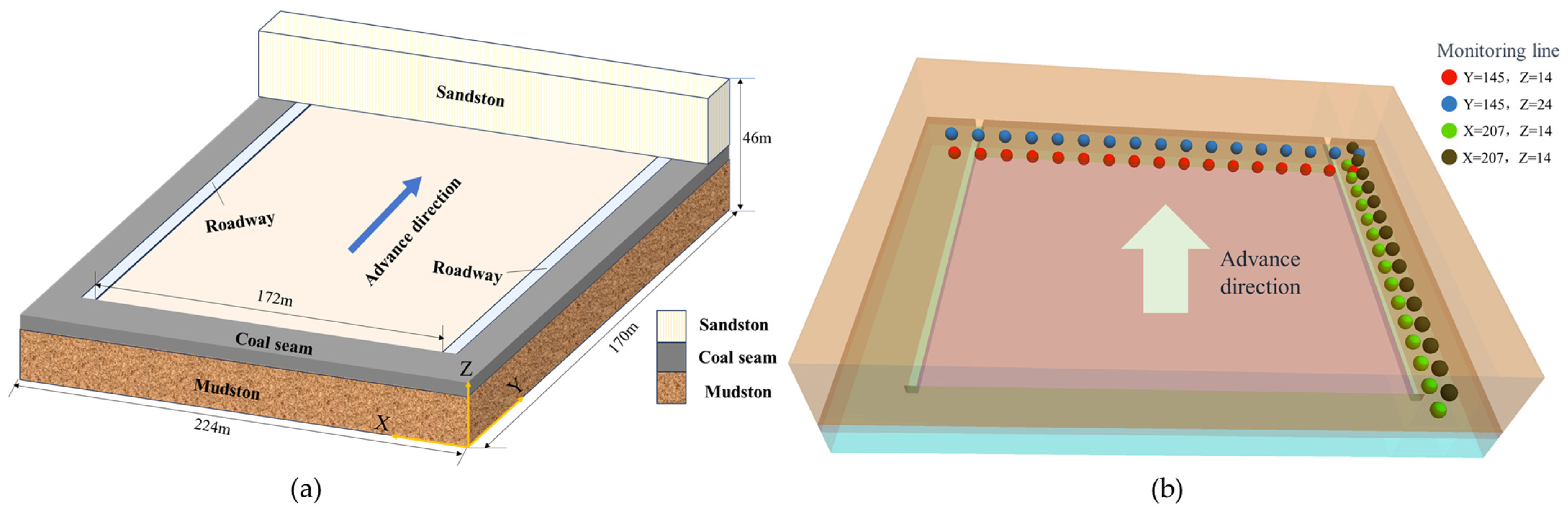

2.3. Model Establishment

- (1)

- This overall model is separated into three parts: the top plate, coal seam, and bottom plate. It is known as the “rock-coal-rock” model. The top and bottom plates are regarded as a single, cohesive whole;

- (2)

- Apply vertical stress at the top of the model instead of simulating the rock layers.

3. Simulation Results Analysis

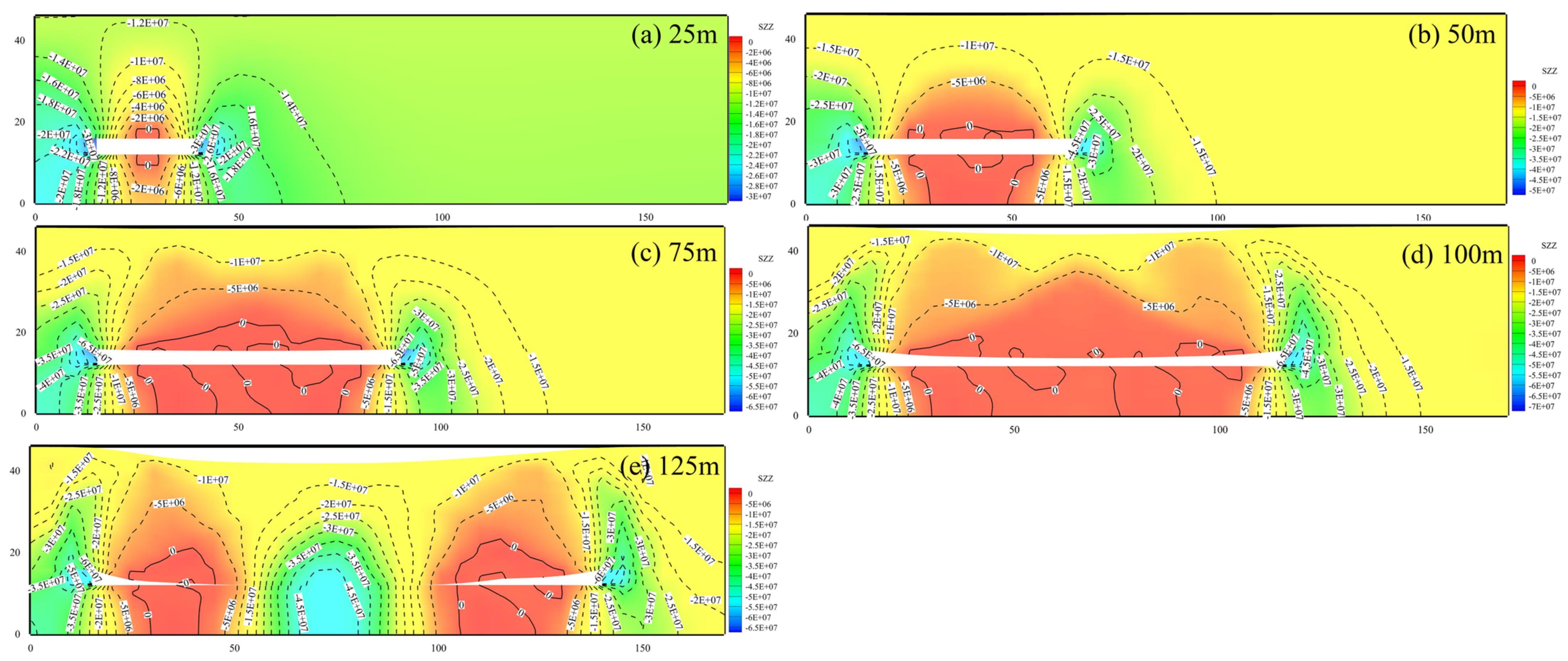

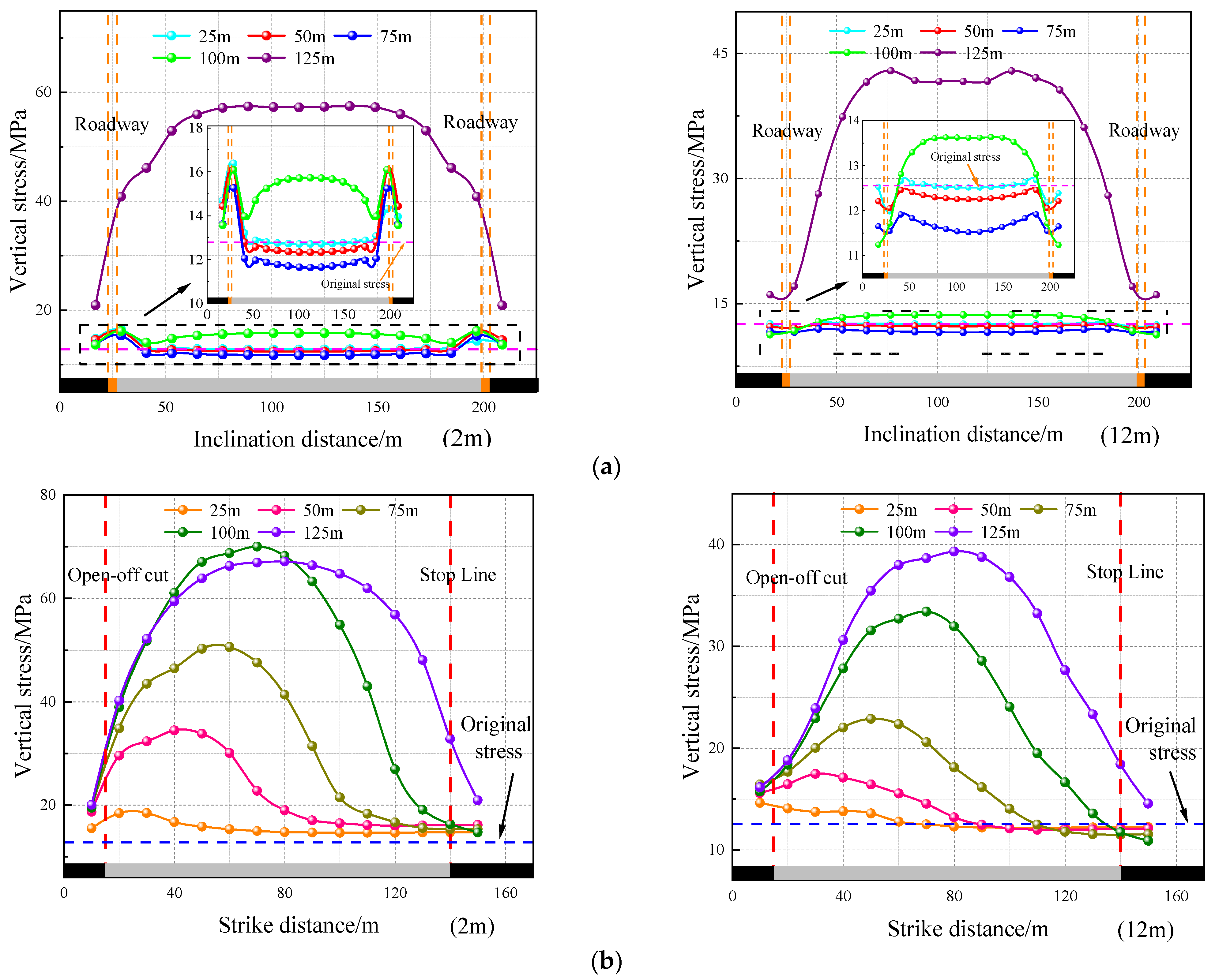

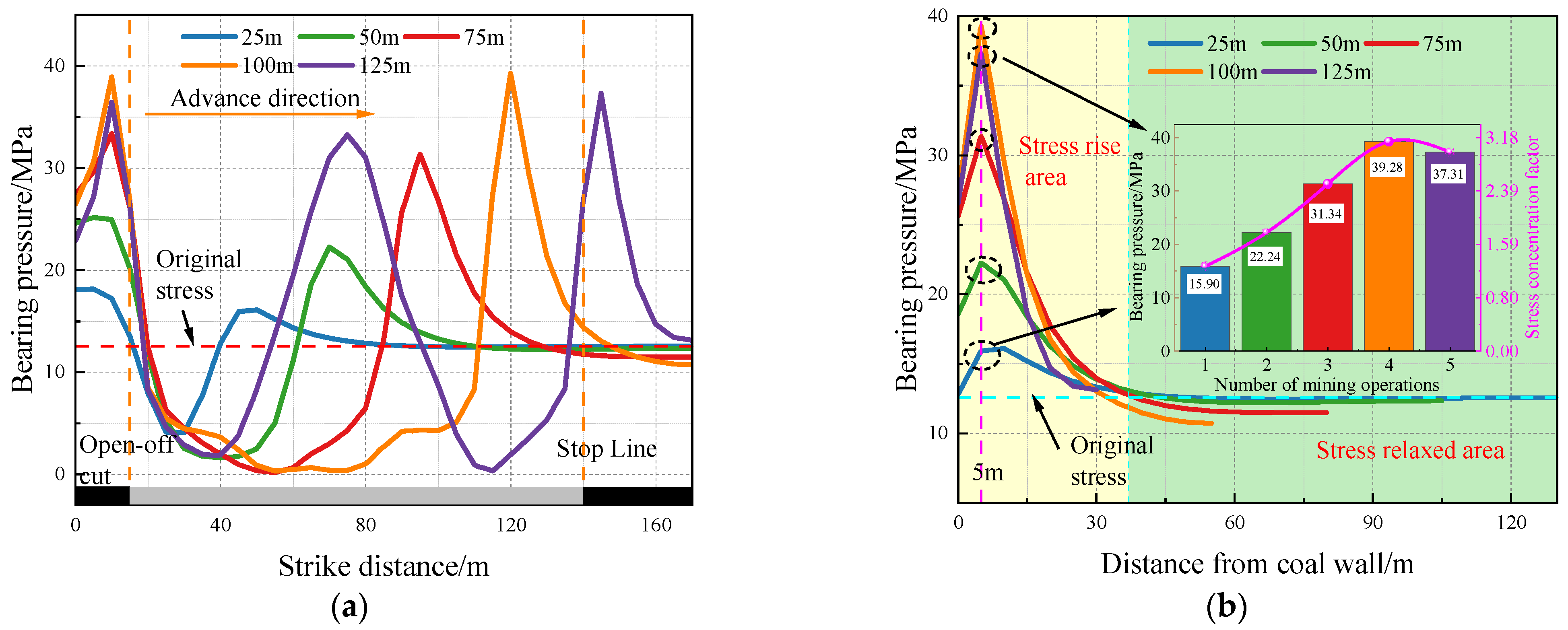

3.1. Dynamic Evolution Law of Stress Fields in Coal Seams and Overlying Strata

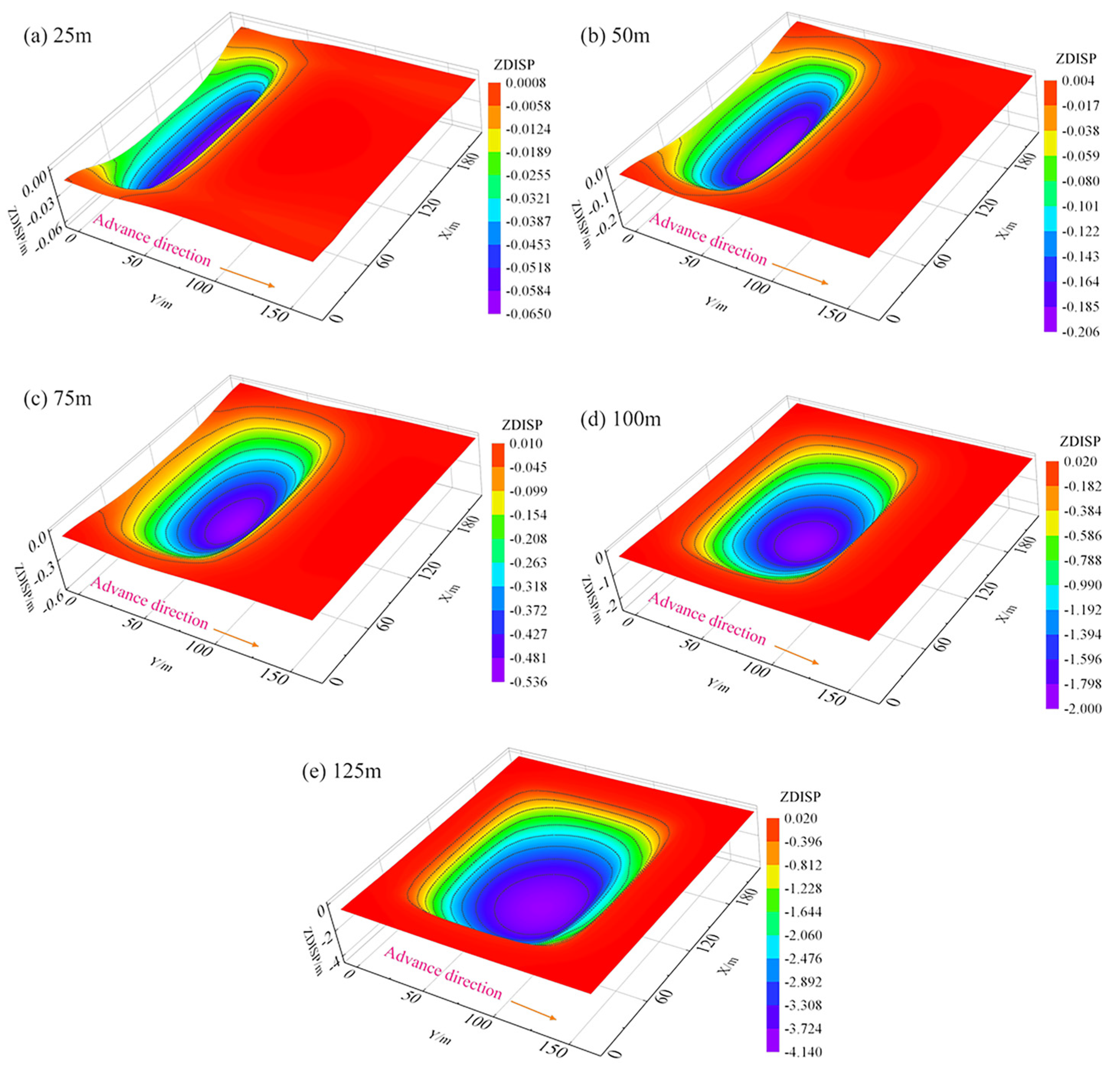

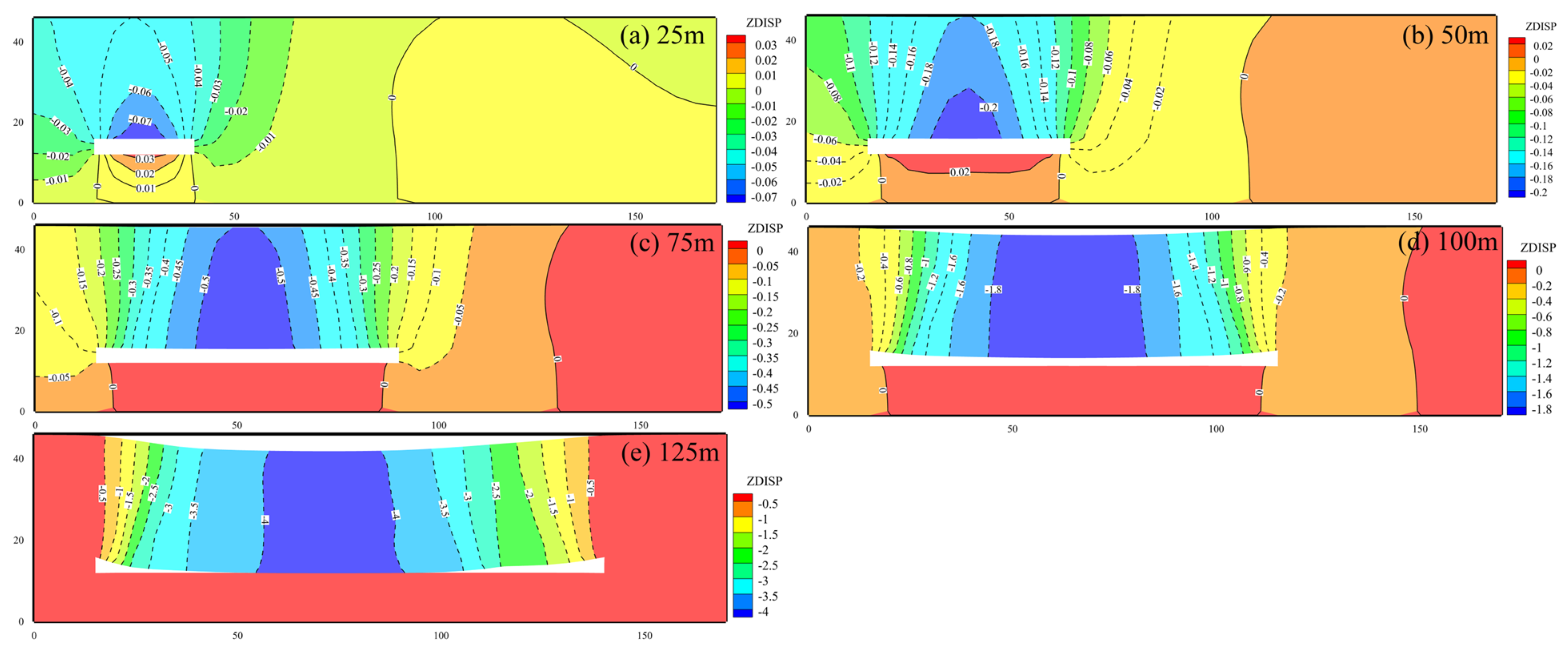

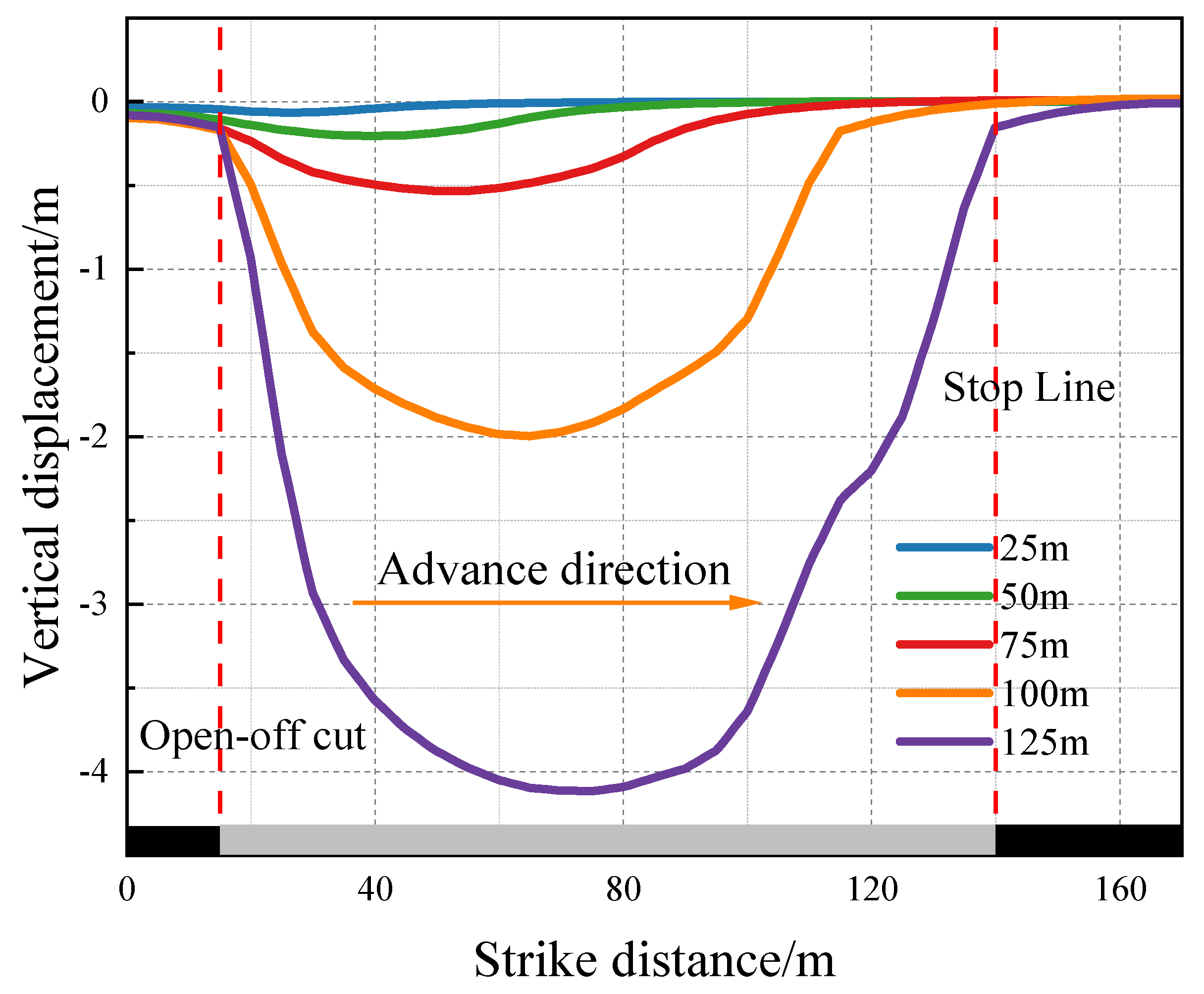

3.2. Dynamic Evolution Law of Displacement Fields in Coal Seams and Overlying Strata

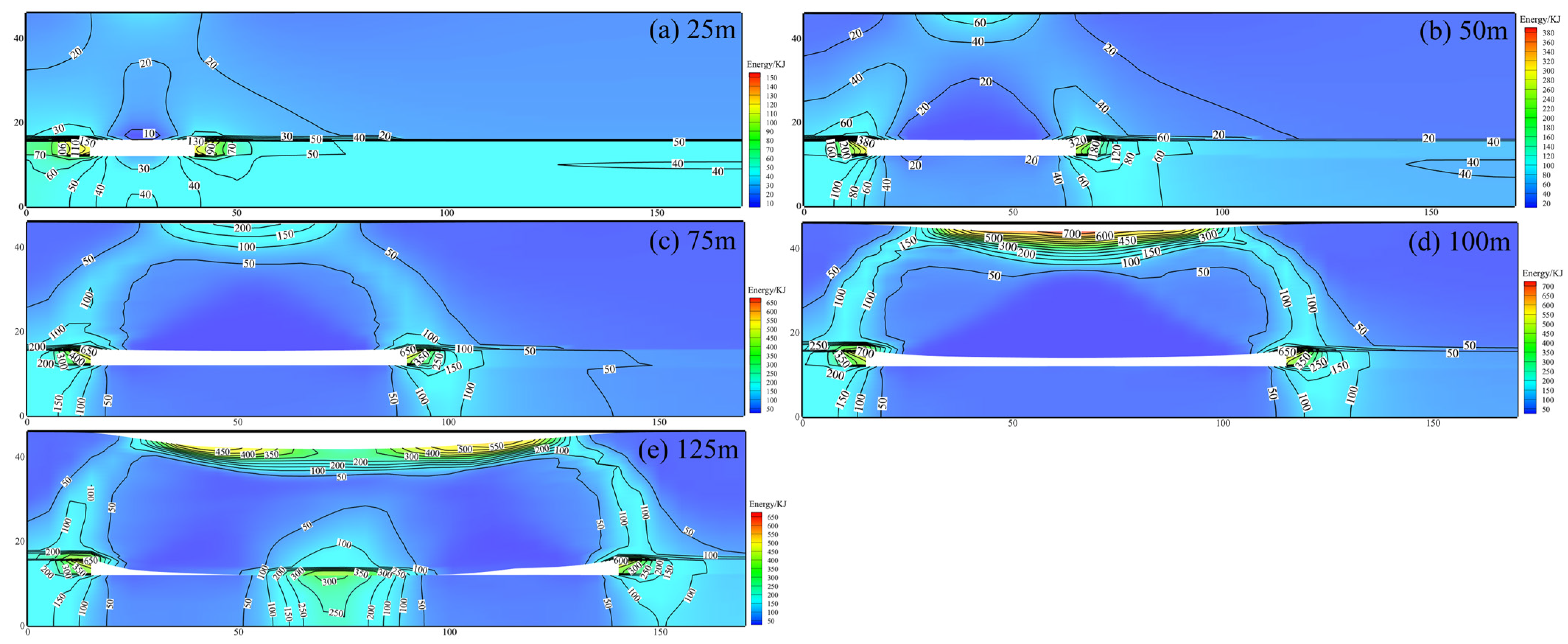

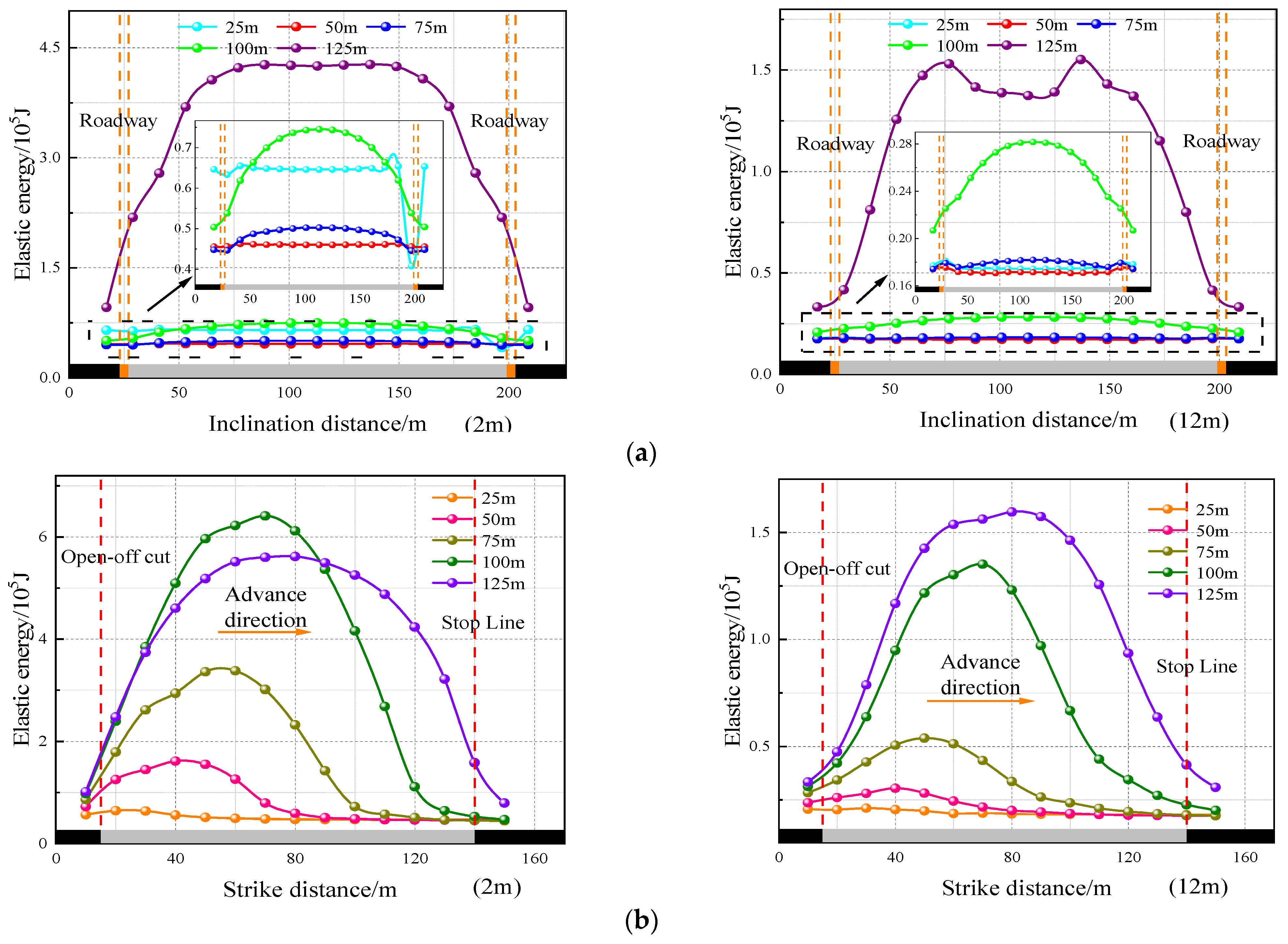

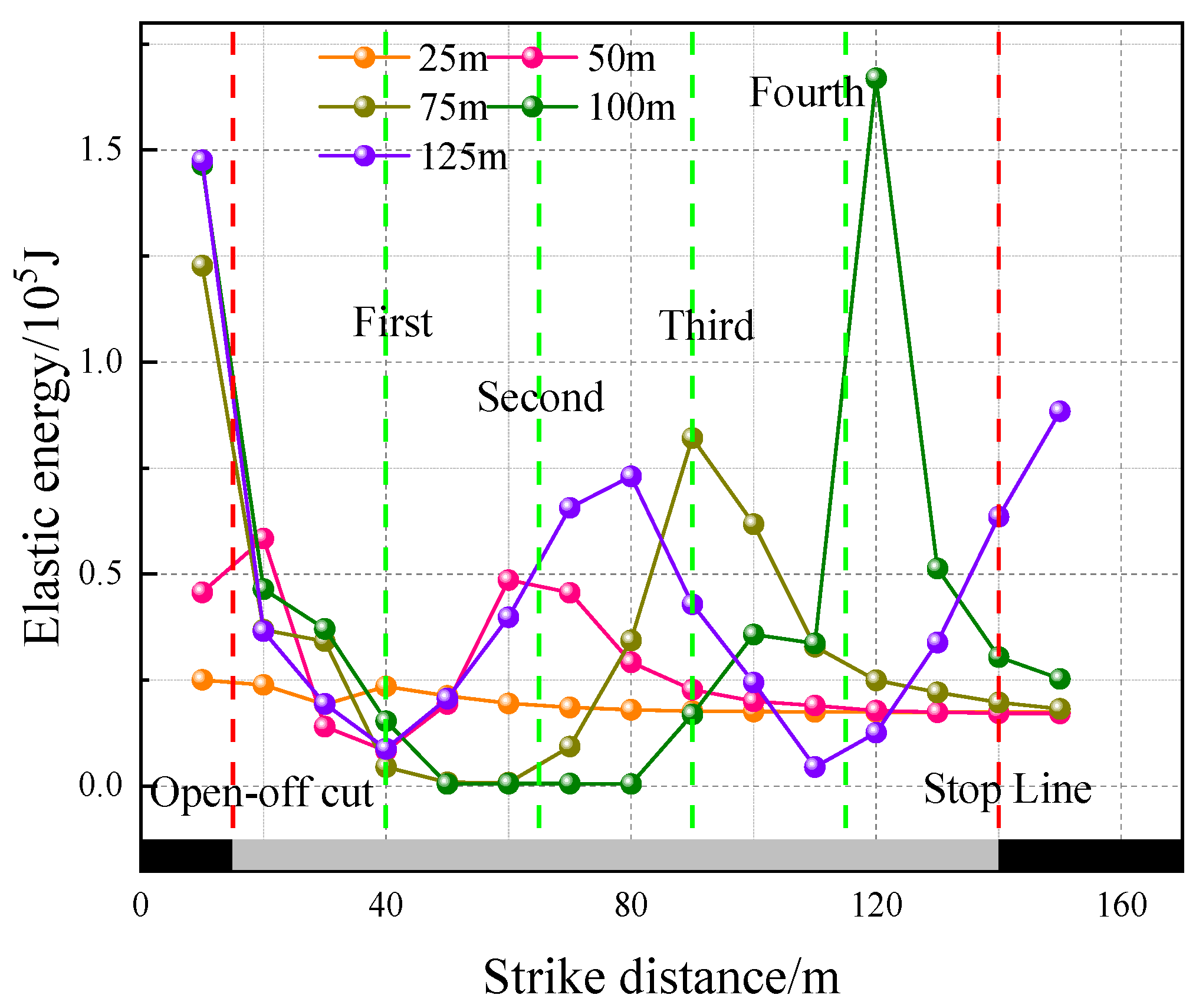

3.3. Dynamic Evolution Law of Energy Fields in Coal Seams and Overlying Strata

3.4. Evolution Law of Plastic Zones in Overlying Strata

4. Discussion

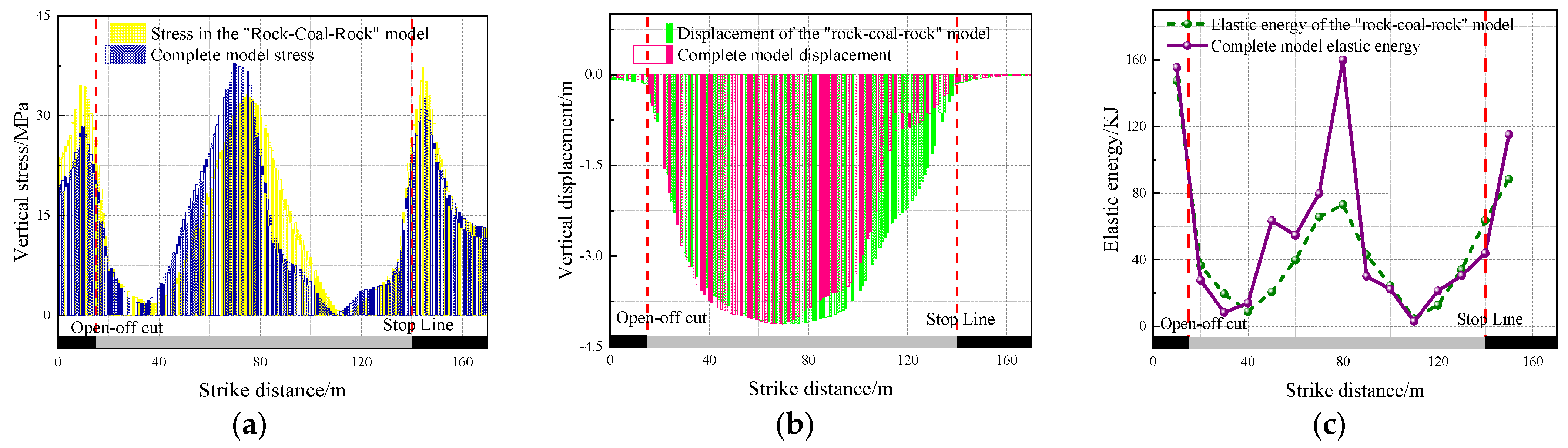

4.1. Comparative Analysis between the “Rock-Coal-Rock” Model and the Complete Model

4.2. Multi-Physical Field Characteristics under Deep Coal Seam Mining

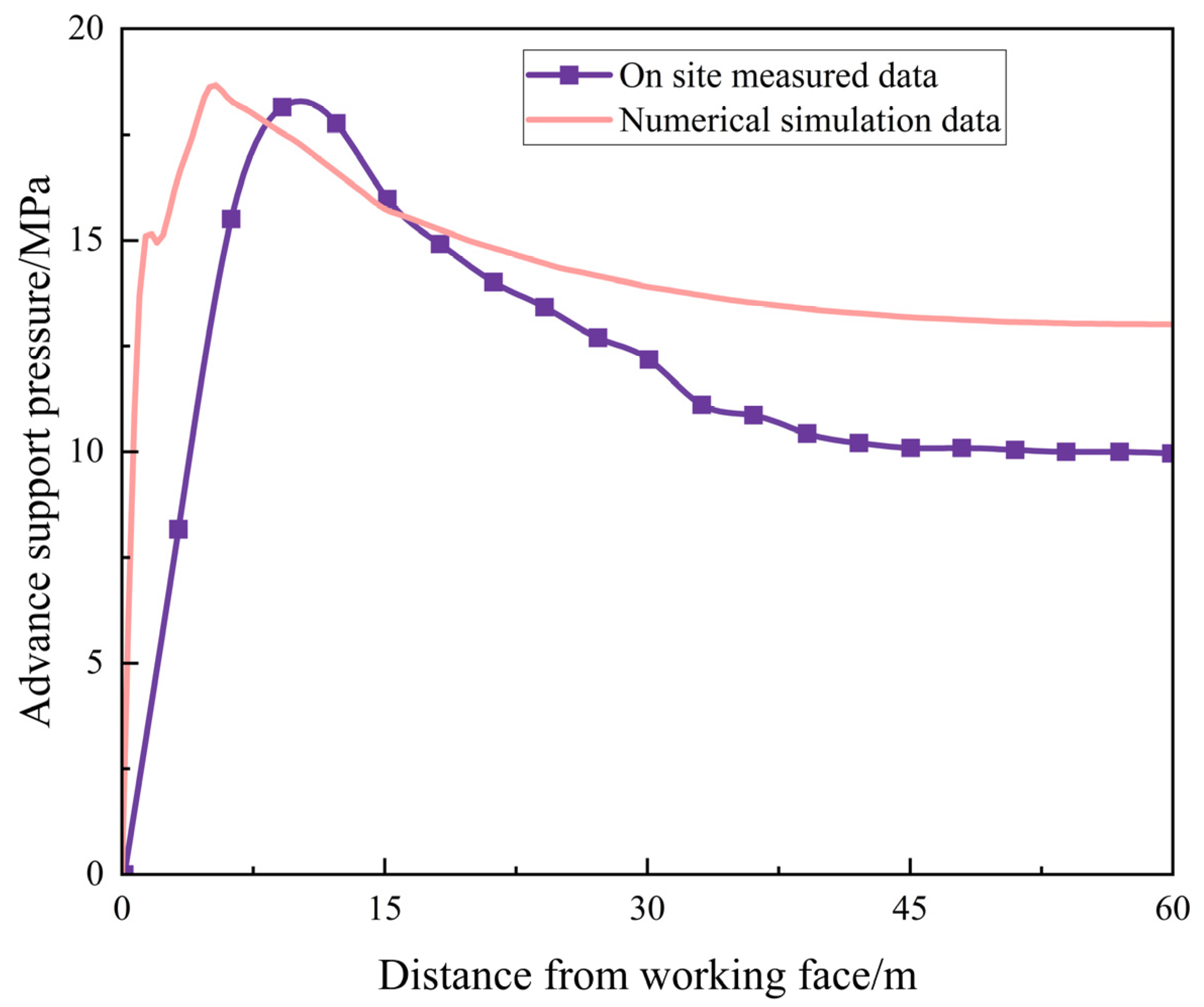

4.3. On-Site Advanced Support Pressure Observation

5. Conclusions

- (1)

- By means of numerical modeling, the multi-physical field properties under conditions of deep coal seam mining were acquired. Following coal seam mining, an advanced support pressure develops in front of the working face. This pressure reaches its peak around 5 m in front of the coal wall, where it reaches 39.28 MPa. From 1.28 to 3.13, the stress concentration coefficient rises and then falls to 2.97. In the center of the goaf, there is a pressure relief zone where some places have a minimum pressure of 0 MPa. Overall, the pressure relief zone evolves from a rectangle to an outward square and to a circular distribution. The deformation and failure of rock layers form a fracture field around the goaf and the range of the fracture field increases with the increase in goaf distance. After the coal seam is fully mined, the roof collapses and the floor bulges. The maximum settlement value is 4 m, situated in the middle of the goaf, and the settlement gradually reduces from the center to the surrounding region;

- (2)

- Depending on the Mohr–Coulomb criterion, the “stress energy” characteristics of the coal rock body were obtained. The degree of stress concentration drops and the maximal elastic energy drops from 700 KJ to 650 KJ when the roof collapses. Part of the elastic performance accumulates in the compacted area in the middle of the goaf, with a maximum value of 350 KJ. The elastic energy curve of the overlaying rock in the center of the goaf has two peak points during the course of the coal seam mining era. The peak point of the protective coal pillar after the goaf rises with the length of the goaf distance, from 25.1 KJ to 147.6 KJ. As the goaf distance increases, the peak point on the working face’s coal wall continues to advance;

- (3)

- The results of the “rock-coal-rock” model were validated by constructing a complete numerical model. The results indicate that the stress curve, displacement curve, and elastic energy curve trends of the two models are basically consistent. Finally, the on-site measured advanced support pressure was compared with the numerical simulation results and the effect was good. Therefore, the train of thought of the “rock-coal-rock” model proposed in this study is valid.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xie, H.; Li, C.; He, Z.; Li, C.; Lu, Y.; Zhang, R.; Gao, M.; Gao, F. Experimental study on rock mechanical behavior retaining the in situ geological conditions at different depths. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2021, 138, 104548. [Google Scholar] [CrossRef]

- Höök, M.; Zittel, W.; Schindler, J.; Aleklett, K. Global coal production outlooks based on a logistic model. Fuel 2010, 89, 3546–3558. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Ghosh, N.; Singh, A.P.; Kumar, R.; Tewari, S.; Bhattacharjee, R. Evaluation of energy accumulation, strain burst potential and stability of rock mass during underground extraction of a highly stressed coal seam under massive strata-a field study. Eng. Geol. 2023, 322, 107178. [Google Scholar] [CrossRef]

- Ranjith, P.; Zhao, J.; Ju, M.; De Silva, R.V.; Rathnaweera, T.; Bandara, A.K. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Khan, M.; He, X.Q.; Guo, J.; Song, D.Z. Accurate prediction of indicators for engineering failures in complex mining environ-ments. Eng. Fail. Anal. 2024, 155, 107736. [Google Scholar] [CrossRef]

- Driad-Lebeau, L.; Lahaie, F.; Al Heib, M.; Josien, J.; Bigarré, P.; Noirel, J. Seismic and geotechnical investigations following a rockburst in a complex French mining district. Int. J. Coal Geol. 2005, 64, 66–78. [Google Scholar] [CrossRef]

- Du, F.; Wang, K.; Zhang, X.; Xin, C.P.; Shu, L.Y.; Wang, G.D. Experimental Study of Coal–Gas Outburst: Insights from Coal–Rock Structure, Gas Pressure and Adsorptivity. Nat. Resour. Res. 2020, 29, 2481–2493. [Google Scholar] [CrossRef]

- Du, F.; Ma, J.; Guo, X.; Wang, T.; Dong, X.; Li, J.; He, S.; Nuerjuma, D. Rockburst mechanism and the law of energy accumulation and release in mining roadway: A case study. Int. J. Coal Sci. Technol. 2022, 9, 6. [Google Scholar] [CrossRef]

- Jiránková, E.; Petroš, V.; Šancer, J. Assessment of stress around mine workings at the time of rockburst occurrence. Géoméch. Geoengin. 2013, 8, 297–303. [Google Scholar] [CrossRef]

- Yuan, L. Research progress of mining response and disaster prevention and control in deep coal mines. J. China Coal Soc. 2021, 46, 716–725. [Google Scholar]

- Rajwa, S.; Janoszek, T.; Prusek, S. Model tests of the effect of active roof support on the working stability of a longwall. Comput. Geotech. 2020, 118, 103302. [Google Scholar] [CrossRef]

- Li, Y.; Ren, Y.; Peng, S.S.; Cheng, H.; Wang, N.; Luo, J. Measurement of overburden failure zones in close-multiple coal seams mining. Int. J. Min. Sci. Technol. 2021, 31, 43–50. [Google Scholar] [CrossRef]

- Iwanec, A.S.; Carter, J.; Hambleton, J. Geomechanics of subsidence above single and multi-seam coal mining. J. Rock Mech. Geotech. Eng. 2016, 8, 304–313. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Tu, S.H.; Tu, H.S.; Li, W.L. Evolution mechanism and control technology of mining-induced stress in the bifurcation and merging area of deep coal seam. J. Min. Saf. Eng. 2022, 39, 702–710. [Google Scholar]

- Bu, Q.W.; Tu, M.; Zhang, X.Y.; Yuan, B.Q.; Zhao, Q.C.; Dang, J.X. Study on fracture instability and energy accumulation-release evolution of thick-hard roof in stope. J. Min. Saf. Eng. 2022, 39, 867–878. [Google Scholar]

- Zhao, S.K.; Qi, Q.X.; Li, Y.P.; Deng, Z.G.; Li, Y.Z.; Su, Z.G. Theory and practice of rockburst stress control technology in deep coal mine. J. China Coal Soc. 2020, 45, 626–636. [Google Scholar]

- Suchowerska, A.; Merifield, R.; Carter, J. Vertical stress changes in multi-seam mining under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2013, 61, 306–320. [Google Scholar] [CrossRef]

- Xie, H.; Gao, M.; Zhang, R.; Peng, G.; Wang, W.; Li, A. Study on the Mechanical Properties and Mechanical Response of Coal Mining at 1000 m or Deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Yin, D.W.; Chen, S.J.; Chen, B.; Liu, X.Q.; Ma, H.F. Strength and failure characteristics of the rock-coal combined body with single joint in coal. Geomech. Eng. 2018, 15, 1113–1124. [Google Scholar]

- Li, S.W.; Gao, M.Z.; Yang, X.J.; Zhang, R.; Li, R.; Zhang, Z.P.; Li, G.; Zhang, Z.T.; Xie, J. Numerical simulation of spatial dis-tributions of mining-induced stress and fracture fields for three coal mining layouts. J. Rock Mech. Geotech. Eng. 2018, 10, 907–913. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Prakash, A.; Roy, L.B.; Tewari, S. Underground extraction methodology of contiguous coal seams ensuring the safety of the parting and the surface structures. Saf. Sci. 2020, 121, 215–230. [Google Scholar] [CrossRef]

- Chen, S.J.; Qu, X.; Yin, D.W.; Liu, X.Q.; Ma, H.F. Investigation lateral deformation and failure characteristics of strip coal pillar in deep mining. Geomech. Eng. 2018, 14, 421–428. [Google Scholar]

- Ning, J.; Wang, J.; Tan, Y.; Zhang, L.; Bu, T. In situ investigations into mining-induced overburden failures in close multiple-seam longwall mining: A case study. Géoméch. Eng. 2017, 12, 657–673. [Google Scholar] [CrossRef]

- Xiao, Z.; Gu, S.; Zhang, Y.; Wang, H. A coal seam-roof-floor coupling destressing control method of fault coal bursts induced by deep coal seam mining. Energy Sci. Eng. 2022, 10, 2170–2190. [Google Scholar] [CrossRef]

- Jia, C.Y.; Wang, H.L.; Sun, X.Y.; Yu, X.B.; Luan, H.J. Study on rockburst prevention technology of isolated working face with thick-hard roof. Geomech. Eng. 2020, 20, 447–459. [Google Scholar]

- Lu, J.; Jiang, C.; Jin, Z.; Wang, W.; Zhuang, W.; Yu, H. Three-dimensional physical model experiment of mining-induced deformation and failure characteristics of roof and floor in deep underground coal seams. Process. Saf. Environ. Prot. 2021, 150, 400–415. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, B.; Liu, T.; Zheng, Y.; Kong, J.; Li, Q.; Song, H. Mechanism of multifield coupling-induced outburst in mining-disturbed coal seam. Fuel 2020, 272, 117716. [Google Scholar] [CrossRef]

- Tuncay, D.; Tulu, I.B.; Klemetti, T. Investigating different methods used for approximating pillar loads in longwall coal mines. Int. J. Min. Sci. Technol. 2021, 31, 23–32. [Google Scholar] [CrossRef]

- Unver, B.; Yasitli, N. Modelling of strata movement with a special reference to caving mechanism in thick seam coal mining. Int. J. Coal Geol. 2006, 66, 227–252. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, L.; Kong, D.; Wang, Y.; Cheng, Z. Overlying strata failure mechanism and gas migration law in close distance outburst coal seams: A case study. Eng. Fail. Anal. 2023, 148, 107214. [Google Scholar] [CrossRef]

- Jiang, H. Simple three-dimensional Mohr-Coulomb criteria for intact rocks. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2018, 105, 145–159. [Google Scholar] [CrossRef]

- Liu, W.; Pang, L.; Xu, B.; Sun, X. Study on overburden failure characteristics in deep thick loose seam and thick coal seam mining. Geomat. Nat. Hazards Risk 2020, 11, 632–653. [Google Scholar] [CrossRef]

- Basarir, H.; Oge, I.F.; Aydin, O. Prediction of the stresses around main and tail gates during top coal caving by 3D numerical analysis. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2015, 76, 88–97. [Google Scholar] [CrossRef]

- Shi, M.J. Study on Distribution Characteristics and Control of Deviatoric Stress Field in Surrounding Rock of Deep Coal Roadway. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2022. [Google Scholar]

- Xie, H.; Li, L.; Peng, R.; Ju, Y. Energy analysis and criteria for structural failure of rocks. J. Rock Mech. Geotech. Eng. 2009, 1, 11–20. [Google Scholar] [CrossRef]

- Tu, Q.; Cheng, Y.; Xue, S.; Ren, T.; Cheng, X. Energy-limiting factor for coal and gas outburst occurrence in intact coal seam. Int. J. Min. Sci. Technol. 2021, 31, 729–742. [Google Scholar] [CrossRef]

- Gao, R.; Yu, B.; Xia, H.; Duan, H. Reduction of Stress Acting on a Thick, Deep Coal Seam by Protective-Seam Mining. Energies 2017, 10, 1209. [Google Scholar] [CrossRef]

- Liu, H.; Huo, T.; Li, Y.; Luo, M.; Zhou, G.; He, Z. Numerical Simulation Study on the Distribution Law of Deviatoric Stress of Floor under the Influence of Mining. Geofluids 2021, 2021, 1–14. [Google Scholar] [CrossRef]

| Rock Strata | Thickness/(m) | Density/(kg·m−3) | Friction Angle/(°) | Cohesion/MPa | Bulk Modulus/GPa | Shear Modulus/GPa | Tensile Strength/MPa |

|---|---|---|---|---|---|---|---|

| Sandstone | 30 | 2500 | 32 | 4.6 | 5.4 | 2.5 | 1.70 |

| Coal Seam | 4 | 1500 | 26 | 2.5 | 2.2 | 1.5 | 0.65 |

| Mudstone | 12 | 2461 | 28 | 3.0 | 2.5 | 2.0 | 0.90 |

| Rock Strata | Thickness/ (m) | Density/ (kg·m−3) | Friction Angle/(°) | Cohesion/ MPa | Bulk Modulus/ GPa | Shear Modulus/ GPa | Tensile Strength/MPa |

|---|---|---|---|---|---|---|---|

| Sandy Mudstone | 11 | 2461 | 28 | 3.0 | 2.5 | 2.0 | 0.90 |

| Siltstone | 7 | 2500 | 33 | 1.2 | 4.5 | 2.3 | 2.00 |

| Sandy Mudstone | 6 | 2461 | 28 | 3.0 | 2.5 | 2.0 | 0.90 |

| Medium Grained Sandstone | 6 | 2500 | 32 | 4.6 | 5.4 | 2.5 | 1.70 |

| Coal Seam 3# | 4 | 1500 | 26 | 2.5 | 2.2 | 1.5 | 0.65 |

| Sandy Mudstone | 6 | 2461 | 28 | 3.0 | 2.5 | 2.0 | 0.90 |

| Mudstone | 6 | 2461 | 27 | 3.0 | 2.5 | 2.0 | 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, F.; Zhang, Y.; Dai, L.; Cui, W.; Wang, B.; Sun, J. Research on Multi-Physical Field Characteristics of Deep Coal Seam Mining Based on the Rock-Coal-Rock Model. Processes 2024, 12, 726. https://doi.org/10.3390/pr12040726

Du F, Zhang Y, Dai L, Cui W, Wang B, Sun J. Research on Multi-Physical Field Characteristics of Deep Coal Seam Mining Based on the Rock-Coal-Rock Model. Processes. 2024; 12(4):726. https://doi.org/10.3390/pr12040726

Chicago/Turabian StyleDu, Feng, Yi Zhang, Linchao Dai, Weilong Cui, Bo Wang, and Jiazhi Sun. 2024. "Research on Multi-Physical Field Characteristics of Deep Coal Seam Mining Based on the Rock-Coal-Rock Model" Processes 12, no. 4: 726. https://doi.org/10.3390/pr12040726

APA StyleDu, F., Zhang, Y., Dai, L., Cui, W., Wang, B., & Sun, J. (2024). Research on Multi-Physical Field Characteristics of Deep Coal Seam Mining Based on the Rock-Coal-Rock Model. Processes, 12(4), 726. https://doi.org/10.3390/pr12040726