Abstract

Optimized production scheduling can greatly improve efficiency and reduce waste in the steel manufacturing industry. With the increasing demands on the economy, the environment, and society, more and more factors need to be considered in the production scheduling process. Currently, only a few methods are developed for the comprehensive evaluation and prioritization of scheduling schemes. This paper proposes a novel MCGDM (multi-criteria group decision making) method for the ranking and selection of production scheduling schemes. First, a novel indicator system involving both qualitative and quantitative indicators is put forward. Diverse statistical methods and evaluation functions are proposed for the evaluation of quantitative indicators. The evaluation method of qualitative indicators is proposed based on heterogeneous data, cloud model theory, and group decision-making techniques. Then, a novel Group AHP model is proposed to determine the weights of all evaluation indicators. Finally, a novel cloud-model-enhanced TOPSIS (technique for order of preference by similarity to ideal solution) method is proposed to rank alternative production scheduling schemes. A practical example is presented to show the implementation details and demonstrate the feasibility of our proposed method. The results and comparative analysis indicate that our hybrid MCGDM method is more reasonable, flexible, practical, and effective in evaluating and ranking production scheduling schemes in an uncertain environment.

1. Introduction

With the increasing demand for steel products and extending production scale, production planning in a steel mill plant is becoming more complex [1]. Iron and steel enterprises are characterized by long production lines, multiple processes, and complex equipment. The full-flow manufacturing of steel generally includes ironmaking, steelmaking, hot rolling, cold rolling, and finishing processes, which is a complex process with a mixture of continuous and discrete production and manufacturing. The formulation of a steel production scheduling scheme is the key to the stability of steel production and the smooth flow of logistics [2]. Optimal scheduling of steelmaking production contributes to boosting productivity, reducing costs, and achieving sustainable manufacturing for an integrated steel company [3,4]. Therefore, in the field of steel production, it is often necessary to develop and prioritize scheduling schemes.

Steel scheduling is known to be one of the most difficult industrial scheduling problems [5]. Many approaches have been put forward to establish and optimize production planning and scheduling problems, such as the mathematical model method, the artificial intelligence method, and the parallel scheduling method [6]. Mathematical programming is a powerful tool for production planning. However, practical production scheduling problems may be extremely complex, with large numbers of variables, constraints, and dynamic changes. It is difficult to develop an optimization mathematical model that can be solved efficiently. Most models are relatively simple in the setting of optimization objectives and constraints and ignore the indicators that are difficult to quantify and the experts’ empirical knowledge that is difficult to express. As a result, many models fail to reflect the actual production conditions, leading to insufficient application feasibility of the solutions. Moreover, most schedule schemes mainly focus on ensuring the continuity of production, increasing productivity, and reducing resource consumption with little consideration of environmental or even social factors such as waste emissions, let alone with comprehensive analysis of production efficiency and environmental and social factors, which results in most scheduling designs lagging behind the strategic development needs of steel plants. In addition, the schemes obtained using multi-objective optimization models are usually Pareto solutions, and it is necessary to select the optimal scheme through a rational comprehensive evaluation. What is more, in a production environment with inevitable dynamic disturbances, scheduling often needs to be adjusted and re-planned, and an effective evaluation system will benefit the optimization of the scheme.

Currently, only a few methods are employed to aid in the preference for an optimal scheduling scheme and almost no practical evaluation system is available for steel production scheduling schemes. With the increasing demands of manufacturing on the economy, the environment, and society, more and more factors need to be considered in the production scheduling process. It is particularly urgent to develop a comprehensive evaluation method for production scheduling under multiple indicators. Multi-criteria decision making (MCDM) methods have shown promising results in comprehensive evaluation and prioritization of scheduling schemes [7,8,9]. Recently, as a preliminary trial in production scheduling, Thenarasu et al. carried out the performance evaluation of a flexible job shop by employing discrete event simulation and hybrid MCDM approaches [7]. The weights of five indicators were assigned by a fuzzy analytic hierarchy process (AHP). Then, TOPSIS was used to prioritize the jobs. It is found that the MCDM-based rules perform better for large-scale problems by considering multiple realistic indicators. Carlucci proposed a decision model for scheduling in a job-shop manufacturing system that simultaneously deals with the power constraint and the variable speed of machine tools [10]. Gharoun presented a new bi-objective model to deal with an integrated production planning and reliability-based multi-level preventive maintenance scheduling problem using a hybrid multi-attribute decision making (MADM) approach to identify profitable customers [11].

As a branch of operations research, MCDM has been widely applied in decision-making processes and selection, ranking, and evaluation problems in many fields. However, some issues still need to be addressed such as the determination of different indicator weights and the process of various data types. Joshi and Kumar proposed a trapezium cloud model-based TOPSIS method to incorporate uncertainty, hesitancy, and inconsistency using both qualitative and quantitative information [12]. Morente-Molinera et al. proposed an MCDM method that is capable of working in heterogeneous and dynamic environments [13]. Liu et al. developed an integrated failure mode and effect analysis model based on cloud model theory and the hierarchical TOPSIS method to evaluate and rank the risk of failure modes [14]. Lourenzutti and Krohling introduced a generalization of the TOPSIS method, which is capable of processing multiple decision makers and different types of information (crisp, interval, fuzzy, and intuitionistic fuzzy numbers) [15]. Khan et al. developed an MCDM approach for ranking the effectiveness of COVID-19 tests based on the TOPSIS method and complex hesitant fuzzy sets [16]. More recently, Zheng et al. proposed an MCDM method to evaluate the mental state of personnel by combining cloud model theory, AHP, and TOPSIS [17].

From the previous studies, it can be seen that (1) as a mathematical tool, MCDM is effective in comprehensively evaluating various alternative solutions based on multiple performance indicators. (2) The indicators of the MCDM evaluation system are usually multidimensional and complex, and the performance of the MCDM method largely depends on whether the indicator weights are set reasonably and whether heterogeneous data processing is effective. However, simple MCDM tools cannot solve these problems, and other models and tools must be combined to improve the effectiveness of the MCDM method. (3) AHP integrates the relationships between multiple indicators into a hierarchical structure, thereby determining the weights more accurately. (4) The data types reflected by multi-criteria decision evaluation indicators may be complex and diverse, such as precise numbers, interval numbers, linguistic terms, or expressions. Effective methods are also needed to support the processing of fuzzy information and uncertain data. Cloud model theory and TOPSIS have been widely studied to effectively handle fuzzy information and uncertain data and enhance the scientific nature of evaluation ranking. Undoubtedly, MCDM is appropriate for the evaluation of steel production scheduling schemes, but it has its limitations. To improve the effectiveness of MCDM, it is necessary to explore a Hybrid MCDM model.

This paper proposes a novel MCGDM method for production scheduling based on Group AHP and cloud-model-enhanced TOPSIS. Relative to previous work by other researchers, the major contribution of this study has the following novel features: (1) An evaluation system specifically for evaluating the production scheduling effect of steel plants is proposed, which evaluates and ranks production scheduling schemes, and provides some guidance for the optimization direction of scheduling schemes. (2) Evaluation indicators including both qualitative and quantitative indicators are built from multiple dimensions of economic, environmental, and social aspects with the consideration of key factors that affect the production process and results, which break through the limitations of most evaluation indicators that are limited to a single production process or a single indicator dimension. (3) A novel Group AHP is used for indicator weighting, which greatly enhances the rationality of group decision-making. (4) A novel cloud-model-enhanced TOPSIS is proposed to describe the natural uncertainty and manage various data types, and the final results contain both magnitude and uncertainty information. The proposed method enables a more scientific selection of the optimal scheduling scheme. In addition, it can assist in the optimization process of scheduling schemes by adjusting the scheme and then comparing the evaluation results.

The rest of this paper is organized as follows. Section 2 reviews some preliminaries related to cloud model theory, linguistic terms, and the conversion of heterogeneous data. In Section 3, the evaluation indicator system, Group AHP model, and cloud-model-enhanced TOPSIS are proposed in detail. An application example is presented in Section 4 to show the implementation details and demonstrate the feasibility of the proposed method. Furthermore, the discussion is given in Section 5. Finally, some concluding remarks and suggestions for future research are described in Section 6.

2. Preliminaries

In this section, we first review the cloud model theory. Then, we introduce some basic concepts and representation methods about linguistic terms and linguistic expressions. Finally, the conversion from heterogeneous data to its corresponding normal cloud model (NCM) is presented.

2.1. Cloud Model Theory

The cloud model is a mathematical model of uncertainty proposed based on fuzzy sets and probability theory. It offers a flexible computing tool that can effectively process fuzzy information and uncertain data. Thus far, NCM has been applied widely in various fields. In the following part of this subsection, we review some basic concepts and operations of the NCM.

Definition 1

([18]). Let U be the universe of discourse and T be a qualitative concept in U. Expectation (Ex), Entropy (En), and Hyper-entropy (He) are three numerical characteristics of the qualitative concept T, where En ≥ 0 and He ≥ 0. If is a random instantiation of T, which satisfies , , and the certainty degree of x belonging to T satisfies

then the distribution of x in U is called as a NCM and each x with its certainty degree is called as a cloud droplet of T.

Definition 2

([19]). Given any two NCMs T1 = (Ex1, En1, He1) and T2 = (Ex2, En2, He2) in the same universe of discourse, the basic operations are defined as follows:

Definition 3

([19]). Let Ti = (Exi, Eni, Hei) (i = 1, 2, …, n) be n NCMs in the same universe of discourse. Then cloud synthetic operator fCS is a mapping as

Definition 4

([19]). Let Ti = (Exi, Eni, Hei) (i = 1, 2, …, n) be a collection of NCMs in the same universe of discourse, and wi > 0 is the weight of Ti. Then the cloud-weighted average operator fCWA is a mapping as

According to the derivation by Yang et al. [19], if wi > 0 is an exact number for all i = 1, 2, …, n, and , then Equation (7) can be simplified as

Definition 5.

Let T1 = (Ex1, En1, He1) and T2 = (Ex2, En2, He2) be two arbitrary NCMs in the same universe of discourse. Then the distance between them is defined as

Definition 6

([20]). Let T1 = (Ex1, En1, He1) and T2 = (Ex2, En2, He2) be two arbitrary NCMs in the same universe of discourse. Then the comparison method for NCMs is given as follows:

- (1)

- If Ex1 > Ex2, then T1 > T2;

- (2)

- If Ex1 = Ex2 and En1 < En2, then T1 > T2;

- (3)

- If Ex1 = Ex2, En1 = En2, and He1 < He2, then T1 > T2;

- (4)

- If Ex1 = Ex2, En1 = En2, and He1 = He2, then T1 = T2.

2.2. Linguistic Terms

Qualitative assessment results are more suitable to be expressed as natural language. Thus, Zadeh proposed the concept of linguistic variables [21] and the idea of “computing with words” [22]. Linguistic terms are employed to handle cases that are excessively complex or inadequately defined to be adequately represented by quantitative expressions. Linguistic terms are usually modeled by fuzzy sets or NCMs. The NCM is a good tool to deal with the fuzziness and randomness of a linguistic term.

Peng et al. proposed an iterative self-organizing data analysis clustering algorithm combined with DDTW, and a structure dictionary learning-based method for multimode process monitoring; furthermore, a data-driven method was used to estimate the prediction interval of the attributes [23,24,25,26]. Shen et al. proposed a new manifold visualization method, SLISEMAP, to reduce the feature dimensions with interpretability [24].

Determining how to convert linguistic terms into NCMs is a challenging problem. Wang and Feng [27] used the golden ratio method to generate NCMs. Wang et al. [28] presented a linguistic scale function model to carry out the conversion between linguistic terms and NCMs. In general, words carry different interpretations for different individuals. Exploring methods to capture and represent such variations is a prominent subject of interest in academic research. For this reason, Yang et al. [29] applied fuzzy statistics and membership function fitting to encode 32 linguistic terms into NCMs based on a dataset collected from 175 individuals. A linguistic term is represented by an NCM as T(Ex, En, He). Recently, nine of these linguistic terms have been applied to large-scale group decision making [30]. The present study also adopts the nine linguistic terms with various scales of uncertainties as listed in Table 1.

Table 1.

Nine linguistic terms encoded by NCMs.

In addition, when conducting qualitative evaluations, a decision maker may hesitate among multiple linguistic terms or pursue a richer linguistic expression, such as “between medium and very high” or “greater than medium” to express his/her opinion. To manage such situations, Huang and Yang [31] introduced the concept of the hesitant cloud linguistic term set.

Definition 7

([31]). Let be a finite and totally ordered discrete linguistic term set, where Ti is a linguistic term encoded by an NCM (Exi, Eni, Hei). An HCLTS HS is defined as one ordered finite subset of the consecutive linguistic terms in H.

The comparative linguistic methods defined by context-free grammars GH [32] are much closer to human beings’ expressions, and thus can be used to elicit linguistic expressions.

Definition 8

([32]). Let GH be a context-free grammar, and H = {T0, …, Tn} be a linguistic term set. The elements of GH = (VN, VT, I, P) are defined as follows:

VN = {<primary term>, <composite term>, <unary relation>, <binary relation>, <conjunction>};

VT = {lower than, greater than, at least, at most, between, and, T0, T1, …, Tn};

I VN;

P = {I ::= <primary term>|<composite term>,

<primary term> ::= T0|T1|…|Tn,

<composite term> ::= <unary relation><primary term>|

<binary relation><primary term> <conjunction><primary term>,

<unary relation> ::= lower than|greater than|at least|at most,

<binary relation> ::= between,

<conjunction> ::= and}.

2.3. Conversion of Heterogeneous Data

In multi-criteria group decision making, diverse types of data representations are appropriate for the evaluations of different indicators, such as exact numbers, interval numbers, linguistic terms, or linguistic expressions. Thus, the evaluation results of different indicators or from different decision makers may have different representation forms. To process these heterogeneous results, the conversion methods of heterogeneous data proposed in [30,33] are used herein.

Both En and He of an exact number should be zero. Thus, the conversion from an exact number v to its corresponding NCM is defined as

According to the “3σ rule”, approximately 99.7% of values are within the interval [Ex − 3 × En, Ex + 3 × En]. Thus, the conversion from an interval number to its corresponding NCM is defined as

The preference formats of decision makers can be represented by the following four structures: utility functions, preference orderings, multiplicative preference relations, and fuzzy preference relations [34,35,36]. In this study, the preferences of decision makers are expressed as linguistic terms, which can be transformed into fuzzy functions. A decision maker can select one of the nine linguistic terms listed in Table 1 to express his/her evaluation result. Thus, the linguistic term t is converted into its corresponding NCM.

In Equation (12), the fencoded method represents the encoded method based on fuzzy statistics and membership function fitting.

A decision maker may provide an evaluation result using a linguistic expression. Let the linguistic term set H be defined as listed in Table 1. The context-free grammars GH in Definition 8 are used to generate a linguistic expression. First, each linguistic expression is transformed into an HCLTS by the transformation function .

Then, the HCLTS is converted into its corresponding NCM using the cloud synthetic operator fCS in Equation (6).

Therefore, the conversion from a linguistic expression Lt to its corresponding NCM is defined as

Example 1.

Let H be the set of the nine linguistic terms listed in Table 1. Suppose a decision maker represents his evaluation result as “between slightly high and very high” using context-free grammar. Then, this linguistic expression is transformed into an HCLTS as HS = {T5, T6, T7}. Eventually, its corresponding NCM is calculated by (6) as (8.5410, 1.4855, 0.0640).

Consequently, exact numbers, interval numbers, linguistic terms, and linguistic expressions can all be converted into their corresponding NCMs. Furthermore, the uncertainties associated with heterogeneous data are preserved and propagated throughout the following calculations.

3. Methods

3.1. Indicator System

The comprehensive evaluation of production scheduling is a multi-criteria decision-making problem. An evaluation indicator system can be constructed to measure it. Based on the practices of several large-scale steel enterprises and the literature review on production scheduling in the steel industry in recent years, a total of 14 evaluation indicators are selected from three aspects: the economy, the environment, and society, as listed in Table 2. There are 8 indicators under the economic domain: total processing time (C1), order production delay time (C2), number of furnaces in the same casting plan (C3), change in steel grade between adjacent furnaces (C4), furnace residual capacity (C5), balance of production capacity between processes (C6), bottleneck process planning (C7), and penalties for jumping production specifications (C8). There are 3 indicators under the environmental domain: total energy consumption (C9), consumption of tools (C10), and waste discharge (C11). There are 3 indicators under the social domain: job satisfaction (C12), worker workload balance (C13), and hazard exposure (C14). These indicators can be categorized into two directions: benefit (+) and cost (−). For a benefit indicator, a higher value is better, while the cost indicators are the opposite. In terms of the availability of quantitative data in the evaluation process, these indicators can be categorized into two types: quantitative and qualitative. A quantitative indicator has clear quantitative data, while a qualitative indicator usually requires subjective evaluation by experts.

Table 2.

Evaluation indicators and their properties for production scheduling evaluation.

The total processing time (C1) is the total time required from the start of production to the end of production, including the waiting time required for the replacement of tools.

where g is the number of castings; Tccj denotes the casting time of the j-th casting; Tchj denotes the time for replacement of tools after the j-th casting.

The smaller the value of C1, the better it is.

The order production delay time (C2) is the number of days that the completion of the production date exceeds the contractual delivery date.

where Pr and Dr are the completion of production date and the contractual delivery date of the r-th order, respectively.

To reflect the complexity of reality, a nonlinear segmented function is used to calculate the penalty value of Xr.

where Tmin denotes the tolerable non-punishable overdue date and Tmax denotes the maximum allowable overdue date.

The total penalty value of C2 can be calculated as

where R is the number of orders.

The smaller the calculated total penalty value f(C2), the better it is.

The number of furnaces in the same casting plan (C3) denotes the number of steelmaking furnaces in one casting plan. The number of furnaces in one casting must not exceed the maximum permissible value Nmax. The evaluation of C3 can be expressed as

where g is the number of castings and Nj denotes the number of furnaces in the j-th casting.

The larger the calculated value of f(C3), the better it is.

The change in steel grade between adjacent furnaces (C4) is the total steel grade change between all adjacent furnaces.

where g is the number of castings; nj is the number of furnaces in the j-th casting; Gij denotes the steel grade of the i-th furnace of the j-th casting.

The smaller the value of C4, the better it is.

The furnace residual capacity (C5) is the sum of the residual capacity of all furnaces.

where g is the number of castings; nj is the number of furnaces in the j-th casting; Mc denotes the maximum permissible capacity; Wij denotes the capacity of the i-th furnace of the j-th casting.

The smaller the value of C5, the better it is.

The balance of production capacity between processes (C6) is the sum of the absolute value of the difference between the production capacity and the planned production of each unit.

where D is the number of days of production; M is the number of units; Cam denotes the daily production capacity of the m-th unit; Wamd denotes the planned production of the m-th unit on the d-th day.

The smaller the value of C6, the better it is.

The bottleneck process planning (C7) is the sum of the absolute value of the difference between the production capacity and the planned production of the bottleneck process.

where D is the number of days of production; B denotes the daily production capacity of the bottleneck process; Wbd denotes the planned production of the bottleneck process on the d-th day.

The smaller the value of C7, the better it is.

Penalties for jumping production specifications (C8) include width jumping penalties FW and thickness jumping penalties FH of adjacent productions.

The FW indicates the sum of width penalty values generated by adjacent slab rolling width jumps throughout the rolling program.

where Q is the total number of blocks rolled; Ws and Ws−1 denote the widths of the s-th and (s−1)-th rolled steel, respectively; fW is a segmented linear function denoted as

where Wmax denotes the maximum permissible jumping width; the values of penalty coefficients , , , , , and are 1.5, 1.2, 1.0, 0.6, 0.5, and 0.4, respectively.

Similarly, the thickness jumping penalties FH can be calculated, and the segmented linear function fH for thickness jumping penalties is denoted as

where Hm denotes the maximum thickness of steel that can be produced; HL denotes the critical sensitive thickness of steel; Hs denotes the thickness of the s-th rolled steel; the values of penalty coefficients , , , and are 200, 20, 18, and 18, respectively.

The smaller the calculated penalty value of C8, the better it is.

The indicators of total energy consumption (C9), consumption of tools (C10), and waste discharge (C11) are related to the organization and implementation of the production plan, hot delivery and hot loading, and many other factors. Thus, these indicators are difficult to directly quantify and usually require qualitative empirical evaluations using group decision-making techniques.

The steelmaking process is a process of physicochemical changes in molten iron at high temperatures, and the whole process is carried out at high temperatures. The operation process requires the use of high-voltage electricity, high-pressure water, high-pressure oxygen, large-tonnage trucks, and other high-pressure systems. It will produce a lot of smoke, harmful gases, and noise, polluting the environment and deteriorating labor conditions. Reasonable production scheduling can reduce transportation route intersections and reduce the risk of extreme loads on equipment, etc. For the indicators under the social domain, such as job satisfaction (C12), worker workload balance (C13), and hazard exposure (C14), the relevant conditions and boundaries are difficult to quantitatively define. Thus, these indicators also need to be qualitatively evaluated with the help of experienced experts.

3.2. Weighting Algorithm Based on Group AHP

After constructing the indicator system, it is crucial to determine the weights of these indicators since each indicator holds varying degrees of importance. The AHP proposed by Saaty [37] has been widely applied for determining the weights of different indicators, using pairwise comparisons based on the pyramidal structure of the indicator system. Due to the cognitive limitations or personal biases of a single decision maker, group decision making provides a means for tapping into the “wisdom of the crowd”. Group AHP is an extension of the traditional AHP in the context of group decision making, allowing for the participation of multiple decision makers. There are two fundamentally accepted aggregation procedures within Group AHP [38]. One is the aggregation of individual judgments (AIJ) [39,40], and the other is the aggregation of individual priorities (AIP) [41]. Saaty pointed out that if the decision makers are experts, they may wish to aggregate only their final weight vectors (priorities) but not their judgments [42].

Following Saaty’s suggestions, the AIP method is used herein. Firstly, a pairwise comparison matrix (PCM) is elicited from each decision maker. Then, the individual weight vector of independent PCM is determined. Lastly, the weight vectors of all decision makers are aggregated to form the group decision result.

Let C = {c1, c2, …, cn} be a finite set of n indicators, where ci denotes the ith indicator. The individual PCM on C is represented as an n × n matrix A = (aij)n×n, where aij = 1/aji and aij belongs to Saaty’s 1–9 fundamental ratio scale representing the relative importance dominance of ci over cj. The weight vector can be determined using the eigenvalue method. The normalized eigenvector corresponding to the largest eigenvalue of the matrix A represents the relative weights of n indicators.

A PCM is perfectly consistent if and only if aij = aikakj for ∀i,j,k, 1 ≤ i,j,k ≤ n. In real-life decision-making situations, it is hard to achieve complete consistency [43]. Moreover, there can be significant differences in the degree of consistency for different PCMs. Thus, the Consistency Ratio (CR) is defined to describe and reflect the quality of a PCM A.

where CI is the Consistency Index (CI) of A and RI is the average random CI derived from a large number of randomly generated n × n PCMs (see Table 3).

where is the largest eigenvalue of A.

Table 3.

The RI with different order n.

A smaller CR indicates a higher quality of PCM. In general, if CR < 0.10, then PCM A is acceptably consistent. Otherwise, if CR is greater than 0.10, then the credibility of the PCM is questionable.

Let D = {DM1, DM2, …, DMm} be a finite set of m decision makers. The PCM of DMd is represented as Ad, d = 1, 2, …, m. The largest eigenvalue of the matrix Ad is calculated as . Thus, the CI and CR of Ad are calculated as CId and CRd by (29) and (28). The weight vector of DMd represented as is the normalized eigenvector corresponding to the largest eigenvalue of the matrix Ad.

Previously, many papers assigned equal weights to each decision maker in Group AHP models. However, it could be more reasonable to assign different weights to different decision makers according to the quality of their PCMs. Assigning the weight to each decision maker within a group is a key component in the group decision process and plays an important role in obtaining the final group decision result in the Group AHP model. Thus, a method for calculating a decision maker’s weight using CRd is proposed in this paper.

where CRd (d = 1, 2, …, m) is the CR of the matrix Ad from DMd.

The weight of indicator ci represented as wi is computed by the weighted arithmetic mean of m decision makers’ weight vectors.

where (i = 1, 2, …, n, d = 1, 2, …, m) is the weight of indicator ci from the weight vector wd of DMd. Eventually, w = [w1, w2, …, wn] is the weight vector of n indicators using Group AHP.

Based on the aforementioned ideas, the algorithm for assigning weights of production scheduling evaluation indicators is described in Algorithm 1.

| Algorithm 1: Group AHP for Production Scheduling Evaluation Indicators Weighting. |

| 1: Collect PCMs {(Ad)n×n} on n indicators from m decision makers (d = 1,2, …, m). 2: for d = 1 to m do 3: Calculate the largest eigenvalue and its normalized eigenvector wd of Ad. 4: Calculate CRd of Ad by Equation (28). 5: end for 6: for d = 1 to m do 7: Calculate each decision maker’s weight by Equation (30). 8: end for 9: for i = 1 to n do 10: Calculate the weight of indicator ci represented as wi by Equation (31). 11: end for 12: Output the weight vector of n indicators as w = {w1, w2, …, wn}. |

Based on the pyramid structure of the indicator system, PCMs are conducted on indicators belonging to the same parent indicator at each level to obtain the weight vector for these indicators. Therefore, the weights of the bottom-level indicators can be obtained by multiplying the weight vectors layer by layer from the top to the bottom.

3.3. Cloud Model Enhanced TOPSIS

3.3.1. Problem Description

The evaluation and selection process of production scheduling schemes is a multi-stakeholder and multi-criteria decision-making problem. Let the alternative production scheduling scheme set be A = {A1, A2, …, As} (s ≥ 2), the indicator set be C = {C1, C2, …, Cn}, and the decision maker set be D = {DM1, DM2, …, DMm}. The weights of indicators can be calculated by the Group AHP method as described in Section 3.2. Let X = [xij]s×n be the matrix that represents the performance of the scheme set A on the indicator set C, as shown in (32).

where xij is the performance evaluation value of scheme Ai on indicator Cj.

Remark 1.

The performance evaluation value xij can be a precisely quantified numerical value obtained through statistical calculations or some qualitative evaluation data from a group of stakeholders. For a qualitative indicator Cj, the evaluation data are derived from multiple stakeholders utilizing group decision making techniques. Additionally, each stakeholder can use an exact number, an interval number, a linguistic term, or a linguistic expression to represent his/her opinion on indicator Cj. Thus, the evaluation data on a qualitative indicator may be multiple heterogeneous data. This is significantly different from reference [8].

Based on the problem description, the following subsection aims to address the established multi-stakeholder and multi-criteria decision-making problem using a novel hybrid MCGDM method.

3.3.2. Main Steps of the Proposed Method

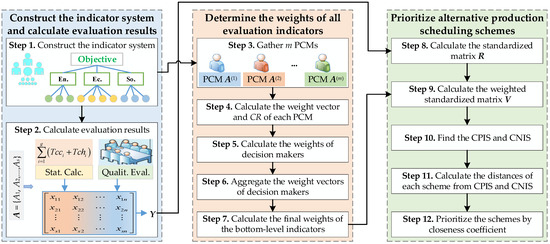

In this subsection, a novel hybrid MCGDM method based on group decision making principles, cloud model theory, and the TOPSIS method is developed to prioritize alternative production scheduling schemes. The proposed method is composed of three main stages and its flowchart is depicted in Figure 1. Firstly, the indicator system is constructed and the evaluation results of indicators are calculated. Secondly, the weights of indicators are derived based on the Group AHP method. Finally, the ranking of alternative production scheduling schemes is determined by implementing a cloud-model-enhanced TOPSIS method.

Figure 1.

Flowchart of the proposed method for prioritizing production scheduling schemes.

Stage 1: Construct the indicator system and calculate evaluation results.

Step 1. Construct the indicator system for the comprehensive evaluation of alternative production scheduling schemes.

As aforementioned in Section 3.1, the evaluation indicators can be selected from three aspects: the economy, society, and the environment. The board of directors or the decision-making committee of the production planning department determines the final evaluation indicator system according to the practical situation.

Step 2. Calculate evaluation results of all quantitative and qualitative indicators.

For a quantitative indicator, the evaluation result xij can be calculated using a statistical method or an evaluation function as described in Section 3.1. The results of indicators C1, C4, C5, C6, and C7 are directly obtained through statistical calculations, while the results of indicators C2, C3, and C8 are calculated by evaluation functions.

For a qualitative indicator, the evaluation results are typically derived through the involvement of multiple stakeholders utilizing group decision-making techniques. Different indicators can be evaluated by distinct groups of decision makers. For instance, indicators related to society are primarily evaluated by decision makers responsible for social concerns, while indicators related to the environment are primarily evaluated by decision makers responsible for environmental concerns. As described in Section 3.3.1, the evaluation data of a qualitative indicator Cj on Ai can be represented as a set , where provided by the k-th decision maker can be an exact number, an interval number, a linguistic term, or a linguistic expression. Firstly, heterogeneous evaluation data from multiple decision makers are transformed into NCMs using the methods described in Section 2.3. Then, multiple NCMs are aggregated using the cloud-weighted average operator in (8) to calculate the evaluation result of the qualitative indicator. The indicators C9~C14 are evaluated by experts using group decision-making techniques.

In order to represent evaluation results in a uniform manner, evaluation results of quantitative indicators are transformed into NCMs by (10). Therefore, the evaluation result of each quantitative or qualitative indicator is uniformly represented as an NCM. The original performance matrix X is transformed into a matrix Y represented by NCMs.

where yij is the evaluation result of indicator Cj on Ai represented by an NCM.

Stage 2: Determine the weights of all evaluation indicators.

Step 3. Gather PCMs from m decision makers.

Based on the indicator system, each decision maker provides a PCM for each level of indicator belonging to the same parent indicator. Saaty’s classic 1~9 ratio scale method is used for pairwise comparison of every two indicators belonging to the same parent indicator.

Step 4. Calculate the weight vector and CR of each PCM.

The weight vector of each PCM is calculated using the eigenvalue method. The CR of each PCM is calculated by (28).

Step 5. Calculate the weights of decision makers.

The weight of each decision maker is calculated by (30) based on the CR of decision makers’ PCMs.

Step 6. Aggregate the weight vectors of decision makers.

The group result is calculated by aggregating m weight vectors using the weighted arithmetic mean method. Therefore, the weight vector of multiple indicators belonging to the same parent indicator at each level can be calculated.

Step 7. Calculate the final weights of the bottom-level indicators.

After obtaining the relative weights of each level’s indicators, the weights of the bottom-level indicators are calculated by multiplying the weights layer by layer from the top to the bottom.

Stage 3: Prioritize alternative production scheduling schemes.

Step 8. Calculate the standardized matrix R = [rij].

In order to obtain accurate evaluation results, performance scales need to be standardized. This involves converting the values of each indicator to a range between 0 and 1, thereby eliminating the influence of different measurement scales.

For benefit indicators (where a higher value is better):

For cost indicators (where a lower value is better):

Step 9. Calculate the weighted standardized matrix V = [rij].

where wj is the weight of indicator Cj.

Step 10. Find the cloud-positive ideal solution (CPIS) and the cloud-negative ideal solution (CNIS) in the weighted standardized matrix V.

CPIS A+ denotes maximizing the scores of all indicators, and CNIS A− denotes minimizing the scores of all indicators.

Step 11. Calculate the distances of each scheme from CPIS and CNIS.

Step 12. Prioritize the schemes by closeness coefficient.

The closeness coefficient CCi of each scheme is calculated by

The larger the value of CCi, the better the scheme Ai performs. As a result, the ranking order of all schemes is able to be determined according to their closeness coefficients CCi (i = 1, 2, …, s) in descending order.

4. An Application Example

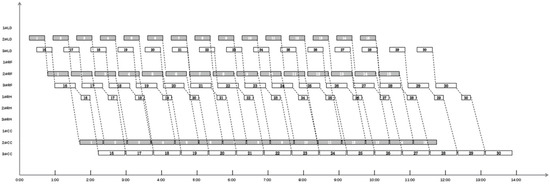

In this section, an application example of prioritizing production scheduling schemes adapted from the real world is presented to show the implementation details and demonstrate the feasibility of the proposed method. Steel scheduling is the sequencing and planning of steel ladle under conditions that satisfy process constraints as well as equipment requirements to ensure the quality of the product and the efficiency of production. Among them, process constraints mainly include width, hardness, and temperature jumps between neighboring ladles. Figure 2 presents a steel scheduling scheme, which shows the sequence and timing of different ladles being processed on different types of equipment.

Figure 2.

The schematic diagram of a steel scheduling scheme.

4.1. Obtain the Evaluation Matrix

The data are derived and adapted from a practical production scheduling of a steel plant. Five competitive scheduling schemes A1, A2, A3, A4, and A5 were obtained using several different mathematical optimization models, simulation methods, and expert or rule-based scheduling methods. Using the methods described in Section 3.1, the performance of 5 schemes on 14 indicators was obtained as shown in Table 4. The performance of quantitative indicators C1~C8 was calculated by (15)~(27). The performances of qualitative indicators C9~C11 were evaluated by three decision makers responsible for environmental concerns using heterogeneous data. The performance of qualitative indicators C12~C14 was evaluated by four decision makers responsible for social concerns using heterogeneous data.

Table 4.

The performance of 5 schemes on 14 indicators.

Then, these quantitative and qualitative performance data were transformed into NCMs as shown in Table 5.

Table 5.

The performance of 5 schemes on 14 indicators.

4.2. Calculate the Weights of Indicators

The weights of indicators can be calculated according to Steps 3 to 7 as described in Section 3.3.2.

For the first level of the indicator system, there are three indicators, i.e., the economy, the environment, and society, that require pairwise comparisons. Six 3 × 3 PCMs were collected from six decision makers as listed in Table 6.

Table 6.

Six PCMs for the first level indicators.

The weight vectors of six PCMs were calculated as [0.6483, 0.2297, 0.1220], [0.5714, 0.2857, 0.1429], [0.6301, 0.2184, 0.1515], [0.5954, 0.2764, 0.1283], [0.6337, 0.1919, 0.1744], and [0.5714, 0.2857, 0.1429], respectively. The CRs were calculated as 0.0036, 0, 0.0015, 0.0053, 0.0088, and 0, respectively. Then, the weights of the six decision makers were calculated as 0.1661, 0.1722, 0.1696, 0.1630, 0.1569, and 0.1722, respectively. Finally, the weight vector of three indicators was calculated as [0.6078, 0.2487, 0.1434] by the weighted arithmetic mean of six weight vectors.

Similarly, five 8 × 8 PCMs were collected from five decision makers for the second-level indicators under economy. The weight vector of eight indicators under economy was calculated as [0.0855, 0.1509, 0.1080, 0.0866, 0.1747, 0.1294, 0.1339, 0.1311]. Three 3 × 3 PCMs were collected from three decision makers for the second-level indicators under environment. The weight vector of three indicators under environment was calculated as [0.5390, 0.2973, 0.1638]. Three 3 × 3 PCMs were collected from three decision makers for the second-level indicators under society. The weight vector of three indicators under society was calculated as [0.3146, 0.2024, 0.4830].

Therefore, the weights of 14 bottom-level indicators were calculated as 0.0520, 0.0917, 0.0656, 0.0526, 0.1062, 0.0786, 0.0814, 0.0797, 0.1340, 0.0739, 0.0407, 0.0451, 0.0290, and 0.0693, respectively. The indicator with the largest weight is C9, while the smallest is C13.

4.3. Prioritize Alternative Schemes

Firstly, the standardized matrix R was calculated as listed in Table 7 by normalizing the matrix Y in Table 5.

Table 7.

The standardized performance matrix of 5 schemes on 14 indicators.

Then, according to the weights of 14 bottom-level indicators calculated in Section 4.2, the weighted standardized matrix V was calculated as listed in Table 8.

Table 8.

The weighted standardized performance matrix of 5 schemes on 14 indicators.

Therefore, as seen in Table 8, the CPIS and CNIS were [(0.0520, 0, 0), (0.0917, 0, 0), (0.0656, 0, 0), (0.0526, 0, 0), (0.1062, 0, 0), (0.0786, 0, 0), (0.0814, 0, 0), (0.0797, 0, 0), (0.1340, 0.0267, 0.0010), (0.0739, 0.0226, 0.0009), (0.0407, 0.0129, 0.0005), (0.0451, 0.0129, 0.0006), (0.0290, 0.0097, 0.0004), (0.0693, 0.0211, 0.0008)] and [(0, 0, 0), (0, 0, 0), (0, 0, 0), (0, 0, 0), (0, 0, 0), (0, 0, 0), (0, 0, 0), (0, 0, 0), (0, 0.0141, 0.0005), (0, 0.0161, 0.0007), (0, 0.0093, 0.0004), (0, 0.0080, 0.0003), (0, 0.0064, 0.0002), (0, 0.0201, 0.0006)], respectively.

Additionally, the distances of five schemes from CPIS and CNIS were calculated as listed in Table 9.

Table 9.

The distances of five schemes from CPIS and CNIS.

Finally, the closeness coefficients of five schemes were calculated as (0.4120, 0.0613, 0.0025), (0.8111, 0.0860, 0.0033), (0.1551, 0.0473, 0.0018), (0.9031, 0.0916, 0.0035), and (0.4118, 0.0613, 0.0025), respectively. Thus, these five schemes were ranked as in descending order of their closeness coefficients. It can be seen that A4 is the most desired scheduling scheme among the five schemes.

5. Discussion

As the final ranking is based on the performance of 14 bottom-level indicators, further analysis is performed to reveal the results on each indicator, as listed in Table 10. According to the standardized performance matrix in Table 7, A4 and A2 show the best performance on seven and four indicators, respectively, and A1 and A5 both perform the best performance on two indicators. A3 only has better performance than both A1 and A5 on two indicators. In addition, A4 and A2 dominate A3 on all indicators. A3 does not show the best performance on any indicator but shows the worst performance on 11 indicators. Therefore, it could be concluded that A3 performs the worst while A4 performs the best. A1 optimizes C3 and C7, and A5 optimizes C12 and C13, but their performance on other indicator sets is negative. Thus, A1 and A5 should be inferior to A2. These results are in accordance with the final ranking. As a result, the final decision can be made: A4 will be chosen as the production scheduling scheme.

Table 10.

The rankings of five schemes on each indicator.

Based on the analysis above, it is found that one scheduling scheme can only ensure superiority on partial indicators. Thus, it is valuable to address the comprehensive evaluation of scheduling schemes to find the potential all-around optimal solution using MCDM approaches. The proposed cloud-model-enhanced TOPSIS method enables a more scientific selection of the optimal scheduling scheme by considering both qualitative and quantitative indicators, involving heterogeneous data with various uncertainties, and using group decision-making techniques.

When solving MCDM problems, various studies usually use one or two of the following methods: AHP (including Grey AHP, GAHP, and FAHP), Cloud model, or TOPSIS, but rarely integrate these three together. This paper integrates the three in our proposed decision method. Then a further comparative analysis is carried out to demonstrate the notable features of the method. The comparisons of our proposed method with two recent methods are listed in Table 11.

Table 11.

The comparative analysis with recent methods.

From the above table, it can be seen that the other two methods mainly consider quantitative indicators; the performances of quantitative indicators calculated by plain statistical methods usually cannot reflect their real benefits. In Ref. [2], cumulative prospect theory is used to reflect the psychological sensitivities of decision-makers to gains and losses, but the same value function and parameters used make it difficult to express the diversity of different indicators. In this paper, the performances of quantitative indicators are calculated by diverse statistical methods or/and evaluation functions to accurately reflect their real benefits. In addition, the performances of qualitative indicators are evaluated using group decision-making techniques under uncertainty in our proposed method. As shown in Table 11, different from the other two methods, which focus on dealing with exact numbers, our proposed method performs well in managing heterogeneous data involving exact numbers, interval numbers, linguistic terms, and linguistic expressions. When assigning weights to indicators, we adopt group decision-making techniques and the proposed Group AHP model that allows the participation of multiple decision makers to determine the weights of indicators. Finally, the proposed cloud-model-enhanced TOPSIS is able to manage and propagate uncertain information during the evaluation process. The final result contains both magnitude and uncertainties. However, previous methods are unable to manage uncertainties, and the final outcome is deterministic. For example, suppose the closeness coefficients of two schemes A1 and A2 are calculated by our proposed method as (0.8120, 0.5610, 0.0725) and (0.8119, 0.0601, 0.0005), respectively. Although the expectation of the closeness coefficient of A1 is slightly higher than that of A2, the uncertainty of A1 is significantly greater than A2. Therefore, for those who are concerned with uncertainty avoidance, A2 should be preferred.

From the application example and the above comparative analysis, it can be concluded that a more rational and effective ranking of scheduling schemes can be achieved using the developed novel MCDM method based on Group AHP and cloud-model-enhanced TOPSIS. Compared with previous methods, the advantages of our proposed method are summarized as follows:

- (1)

- We propose a systematic evaluation system for steel production scheduling, which is more reasonable, flexible, practical, and effective in evaluating and ranking steel production scheduling schemes in an uncertain environment. It can also provide some guidance for the optimization direction of scheduling schemes according to indicator performance.

- (2)

- The evaluation indicators include both qualitative and quantitative indicators, which are built from the entire production scheduling process, simultaneously considering key factors that affect the production process and results from multiple dimensions of economic, environmental, and social aspects, breaking through the limitations of most evaluation indicators that are limited to a single production process or a single indicator dimension.

- (3)

- We present diverse statistical methods and evaluation functions to evaluate quantitative indicators to accurately reflect their real benefits, and develop a hybrid decision method integrating Group AHP, a cloud model, and the TOPSIS method to evaluate qualitative indicators. The hybrid method has good data capabilities of managing uncertainties of heterogeneous data, achieving better multi-indicator trade-offs, enhancing group decision-making rationality, and obtaining a more effective full and distinguishing ranking of schemes; hence, enhancing the effectiveness of evaluation.

- (4)

- The proposed hybrid MCGDM method is transparent with well-defined problem descriptions and implementation procedures and is evaluated on a real practical steel production scheduling dataset.

6. Conclusions

In this study, a novel hybrid MCGDM method based on group decision-making principles, cloud model theory, and the TOPSIS method is developed to prioritize alternative production scheduling schemes. A novel indicator system involving both qualitative and quantitative indicators is put forward for the comprehensive evaluation of production scheduling schemes. Diverse statistical methods or/and evaluation functions are proposed for the evaluation of quantitative indicators. Heterogeneous data, cloud model theory, and group decision-making techniques are utilized for the evaluation of qualitative indicators. Moreover, a novel Group AHP model is proposed to determine the weights of all evaluation indicators. Then, a novel cloud-model-enhanced TOPSIS method is proposed to rank production scheduling schemes. The proposed hybrid MCGDM method provides a structured and systematic framework for the comprehensive evaluation of production scheduling schemes and overcomes many weaknesses of previous methods. Finally, a practical example is presented to demonstrate the feasibility and effectiveness of our proposed method. The results and comparative analysis indicate that the hybrid MCGDM method developed in this study is more reasonable, flexible, practical, and effective in evaluating and ranking production scheduling schemes under an uncertain environment.

Even though there are a large number of articles on the development of production scheduling schemes, the literature on the selection/ranking of alternative schemes is scarce. Furthermore, the existing literature does not consider both qualitative and quantitative indicators and involves heterogeneous data for comprehensive evaluation and prioritization of production scheduling schemes. This study fills this gap.

Despite all the advantages, the proposed hybrid MCGDM method has some drawbacks that suggest directions for future research. Although a novel Group AHP model is proposed, only subjective judgments are utilized to determine the weights of indicators. Nevertheless, a comprehensive weighting method considering both subjective and objective weights is meaningful for further research, such as the Goal-based Participatory weighting scheme [44]. The consensus among different experts’ opinions should also be considered to maintain the robustness of the method [45]. In addition, it should be pointed out that the proposed hybrid MCGDM method has the potential for prioritizing jobs in large-scale flexible job shop scheduling problems. Future research will be concerned with more practical applications using the proposed method presented in this article.

Author Contributions

Conceptualization, X.Z. and Z.L.; methodology, X.Z., Z.L. and Y.L.; investigation, X.Z. and X.X.; data curation, X.Z. and Y.L.; writing—original draft preparation, X.Z. and Y.L.; writing—review and editing, X.Z. and Z.L.; visualization, X.Z., X.X. and D.X.; project administration, X.Z. and Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the National Key Research and Development Plan under grant number 2022YFB3304905 and 2020YFB1713600.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

Authors X.Z., Z.L., Y.L., X.X. and D.X. were employed by the University of Science and Technology Beijing. All the authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Lin, J.; Liu, M.; Hao, J.; Jiang, S. A multi-objective optimization approach for integrated production planning under interval uncertainties in the steel industry. Comput. Oper. Res. 2016, 72, 189–203. [Google Scholar] [CrossRef]

- Li, Q.; Wang, X.; Zhang, X. A Scheduling Method Based on NSGA2 for Steelmaking and Continuous Casting Production Process. IFAC—PapersOnLine 2018, 51, 174–179. [Google Scholar] [CrossRef]

- Jiang, S.-L.; Liu, M.; Lin, J.-H.; Zhong, H.-X. A prediction-based online soft scheduling algorithm for the real-world steelmaking-continuous casting production. Knowl.-Based Syst. 2016, 111, 159–172. [Google Scholar] [CrossRef]

- Jiang, S.-L.; Peng, G.; Bogle, I.D.L.; Zheng, Z. Two-stage robust optimization approach for flexible oxygen distribution under uncertainty in integrated iron and steel plants. Appl. Energy 2021, 306, 118022. [Google Scholar] [CrossRef]

- Pacciarelli, D.; Pranzo, M. Production scheduling in a steelmaking-continuous casting plant. Comput. Chem. Eng. 2004, 28, 2823–2835. [Google Scholar] [CrossRef]

- Long, J.-Y.; Zheng, Z.; Gao, X.-Q.; Gong, Y.-M. Production Planning System for the Whole Steelmaking Process of Panzhihua Iron and Steel Corporation. J. Iron Steel Res. Int. 2014, 21, 44–50. [Google Scholar] [CrossRef]

- Thenarasu, M.; Rameshkumar, K.; Rousseau, J.; Anbuudayasankar, S. Development and analysis of priority decision rules using MCDM approach for a flexible job shop scheduling: A simulation study. Simul. Model. Pract. Theory 2021, 114, 102416. [Google Scholar] [CrossRef]

- Zhang, P.; Qiao, F.; Wang, J.; Sutherland, J.W. Novel Multi-Criteria Sustainable Evaluation for Production Scheduling Based on Fuzzy Analytic Network Process and Cumulative Prospect Theory-Enhanced VIKOR. IEEE Robot. Autom. Lett. 2022, 7, 9969–9976. [Google Scholar] [CrossRef]

- Nakhaeinejad, M.; Nahavandi, N. An interactive algorithm for multi-objective flow shop scheduling with fuzzy processing time through resolution method and TOPSIS. Int. J. Adv. Manuf. Technol. 2012, 66, 1047–1064. [Google Scholar] [CrossRef]

- Carlucci, D.; Renna, P.; Materi, S. A Job-Shop Scheduling Decision-Making Model for Sustainable Production Planning with Power Constraint. IEEE Trans. Eng. Manag. 2021, 70, 1923–1932. [Google Scholar] [CrossRef]

- Gharoun, H.; Hamid, M.; Torabi, S.A. An integrated approach to joint production planning and reliability-based multi-level preventive maintenance scheduling optimisation for a deteriorating system considering due-date satisfaction. Int. J. Syst. Sci.—Oper. Logist. 2022, 9, 489–511. [Google Scholar] [CrossRef]

- Joshi, D.K.; Kumar, S. Trapezium cloud TOPSIS method with interval-valued intuitionistic hesitant fuzzy linguistic information. Granul. Comput. 2017, 3, 139–152. [Google Scholar] [CrossRef]

- Morente-Molinera, J.; Wu, X.; Morfeq, A.; Al-Hmouz, R.; Herrera-Viedma, E. A novel multi-criteria group decision-making method for heterogeneous and dynamic contexts using multi-granular fuzzy linguistic modelling and consensus measures. Inf. Fusion 2019, 53, 240–250. [Google Scholar] [CrossRef]

- Liu, H.-C.; Wang, L.-E.; Li, Z.; Hu, Y.-P. Improving Risk Evaluation in FMEA with Cloud Model and Hierarchical TOPSIS Method. IEEE Trans. Fuzzy Syst. 2018, 27, 84–95. [Google Scholar] [CrossRef]

- Lourenzutti, R.; Krohling, R.A. A generalized TOPSIS method for group decision making with heterogeneous information in a dynamic environment. Inf. Sci. 2016, 330, 1–18. [Google Scholar] [CrossRef]

- Khan, M.S.A.; Anjum, F.; Ullah, I.; Senapati, T.; Moslem, S. Priority Degrees and Distance Measures of Complex Hesitant Fuzzy Sets with Application to Multi-Criteria Decision Making. IEEE Access 2022, 11, 13647–13666. [Google Scholar] [CrossRef]

- Zheng, X.; Hao, T.; Wang, H.; Xu, K. Quantification study of mental load state based on AHP–TOPSIS integration extended with cloud model: Methodological and experimental research. Complex Intell. Syst. 2023, 9, 5501–5525. [Google Scholar] [CrossRef]

- Li, D.Y.; Du, Y. Artificial Intelligence with Uncertainty; Chapman & Hall/CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Yang, X.J.; Zeng, L.; Zhang, R. Cloud Delphi method. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2012, 20, 77–97. [Google Scholar] [CrossRef]

- Yang, X.J.; Zeng, L.; Luo, F.; Wang, S.X. Cloud hierarchical analysis. J. Inf. Comput. Sci. 2010, 7, 2468–2477. [Google Scholar]

- Zadeh, L.A. The concept of a linguistic variable and its application to approximate reasoning—I. Inf. Sci. 1975, 8, 199–249. [Google Scholar] [CrossRef]

- Zadeh, L. Fuzzy logic = computing with words. IEEE Trans. Fuzzy Syst. 1996, 4, 103–111. [Google Scholar] [CrossRef]

- Peng, G.; Xu, D.; Zhou, J.; Yang, Q.; Shen, W. A Novel Curve Pattern Recognition Framework for Hot-Rolling Slab Camber. IEEE Trans. Ind. Inform. 2022, 19, 1270–1278. [Google Scholar] [CrossRef]

- Peng, G.; Cheng, Y.; Zhang, Y.; Shao, J.; Wang, H.; Shen, W. Industrial big data-driven mechanical performance prediction for hot-rolling steel using lower upper bound estimation method. J. Manuf. Syst. 2023, 65, 104–114. [Google Scholar] [CrossRef]

- Peng, G.; Cheng, Y.; Wang, H.; Shen, W. Industrial IoT-enabled prediction interval estimation of mechanical performances for hot-rolling steel. IEEE Trans. Instrum. Meas. 2022, 71, 1–10. [Google Scholar] [CrossRef]

- Huang, K.; Wu, Y.; Yang, C.; Peng, G.; Shen, W. Structure Dictionary Learning-Based Multimode Process Monitoring and its Application to Aluminum Electrolysis Process. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1989–2003. [Google Scholar] [CrossRef]

- Wang, H.L.; Feng, Y.Q. On multiple attribute group decision making with linguistic assessment information based on cloud model. Control Decis. 2005, 20, 679–685. [Google Scholar]

- Wang, P.; Xu, X.; Huang, S.; Cai, C. A Linguistic Large Group Decision Making Method Based on the Cloud Model. IEEE Trans. Fuzzy Syst. 2018, 26, 3314–3326. [Google Scholar] [CrossRef]

- Yang, X.; Yan, L.; Peng, H.; Gao, X. Encoding words into Cloud models from interval-valued data via fuzzy statistics and membership function fitting. Knowl.-Based Syst. 2014, 55, 114–124. [Google Scholar] [CrossRef]

- Yang, X.; Xu, Z.; Xu, J. Large-scale group Delphi method with heterogeneous decision information and dynamic weights. Expert Syst. Appl. 2023, 213, 118782. [Google Scholar] [CrossRef]

- Huang, H.-C.; Yang, X. Representation of The Pairwise Comparisons in AHP Using Hesitant Cloud Linguistic Term Sets. Fundam. Informaticae 2016, 144, 349–362. [Google Scholar] [CrossRef]

- Rodríguez, R.M.; Martínez, L.; Herrera, F. A group decision making model dealing with comparative linguistic expressions based on hesitant fuzzy linguistic term sets. Inf. Sci. 2013, 241, 28–42. [Google Scholar] [CrossRef]

- Yang, X.J.; Xu, Z.F.; He, R.M.; Xue, F.X. Credibility assessment of complex simulation models using cloud models to represent and aggregate diverse evaluation results. In Intelligent Computing Methodologies; Huang, D.S., Huang, Z.K., Hussain, A., Eds.; ICIC 2019; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2019; Volume 11645, pp. 306–317. [Google Scholar]

- Zhang, B.; Dong, Y.; Herrera-Viedma, E. Group Decision Making with Heterogeneous Preference Structures: An Automatic Mechanism to Support Consensus Reaching. Group Decis. Negot. 2019, 28, 585–617. [Google Scholar] [CrossRef]

- Chiclana, F.; Herrera, F.; Herrera-Viedma, E. Integrating multiplicative preference relations in a multipurpose decision-making model based on fuzzy preference relations. Fuzzy Sets Syst. 2001, 122, 277–291. [Google Scholar] [CrossRef]

- Xu, Z. Multiple-Attribute Group Decision Making with Different Formats of Preference Information on Attributes. IEEE Trans. Syst. Man Cybern. Part B Cybern. 2007, 37, 1500–1511. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Ossadnik, W.; Schinke, S.; Kaspar, R.H. Group Aggregation Techniques for Analytic Hierarchy Process and Analytic Network Process: A Comparative Analysis. Group Decis. Negot. 2016, 25, 421–457. [Google Scholar] [CrossRef]

- Dong, Q.; Cooper, O. A peer-to-peer dynamic adaptive consensus reaching model for the group AHP decision making. Eur. J. Oper. Res. 2016, 250, 521–530. [Google Scholar] [CrossRef]

- Grošelj, P.; Dolinar, G. Group AHP framework based on geometric standard deviation and interval group pairwise comparisons. Inf. Sci. 2023, 626, 370–389. [Google Scholar] [CrossRef]

- Yang, X.; Yan, L.; Zeng, L. How to handle uncertainties in AHP: The Cloud Delphi hierarchical analysis. Inf. Sci. 2013, 222, 384–404. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Pant, S.; Kumar, A.; Ram, M.; Klochkov, Y.; Sharma, H.K. Consistency Indices in Analytic Hierarchy Process: A Review. Mathematics 2022, 10, 1206. [Google Scholar] [CrossRef]

- Correa Machado, A.M.; Ekel, P.I.; Libório, M.P. Goal-based participatory weighting scheme: Balancing objectivity and subjectivity in the construction of composite indicators. Qual. Quant. 2023, 57, 4387–4407. [Google Scholar] [CrossRef]

- Herrera-Viedma, E.; Cabrerizo, F.J.; Kacprzyk, J.; Pedrycz, W. A review of soft consensus models in a fuzzy environment. Inf. Fusion 2014, 17, 4–13. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).