Online Partition-Cooling System of Hot-Rolled Electrical Steel for Thermal Roll Profile and Its Industrial Application

Abstract

1. Introduction

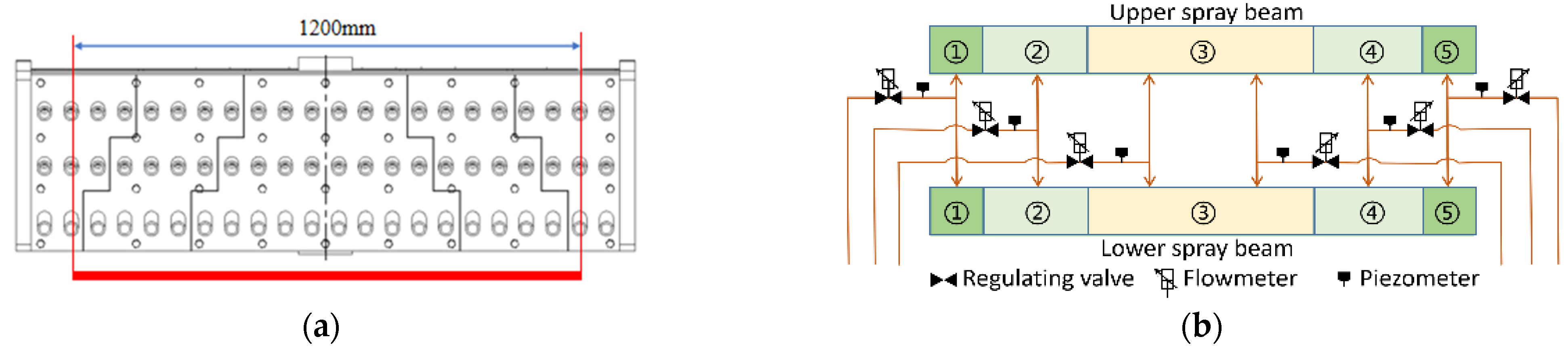

2. New Partition-Cooling Device of Hot Rolling and Its Online Control Method

3. Control Model of Partition-Cooling System

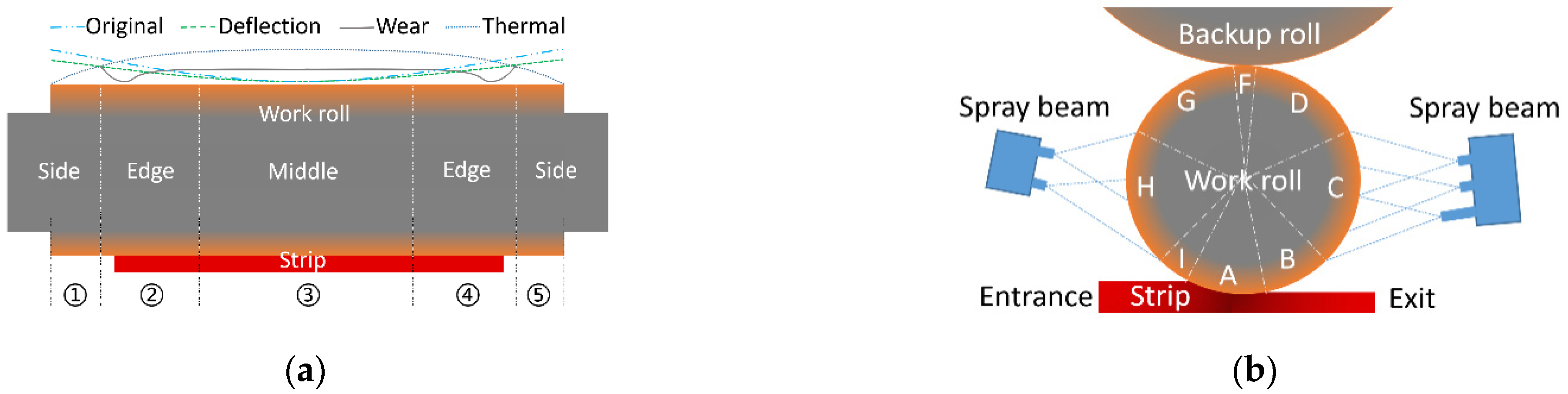

3.1. Dynamic Conditions of Complex Roll Temperature Field

3.2. Setting Rules of Partition-Cooling System

3.3. Effective Model of Thermal Roll Profile

4. Experimental Results

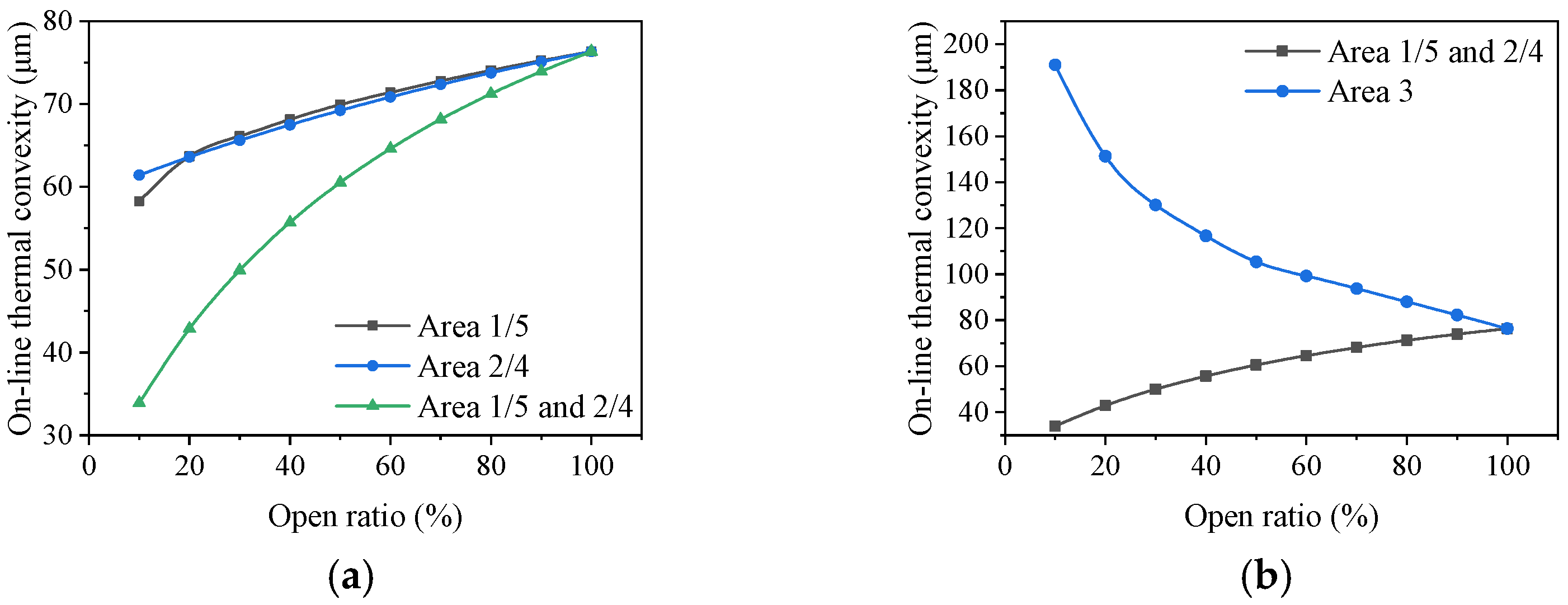

4.1. Analysis of Partition Water Flow Rates

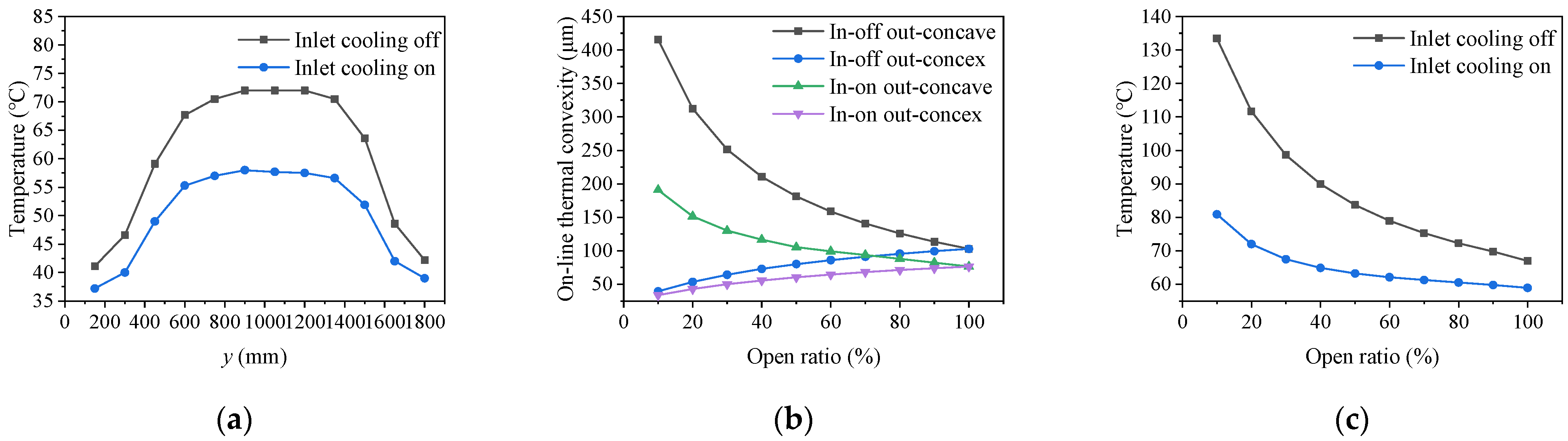

4.2. Influence of the Inlet Water Flow on the Roll Profile

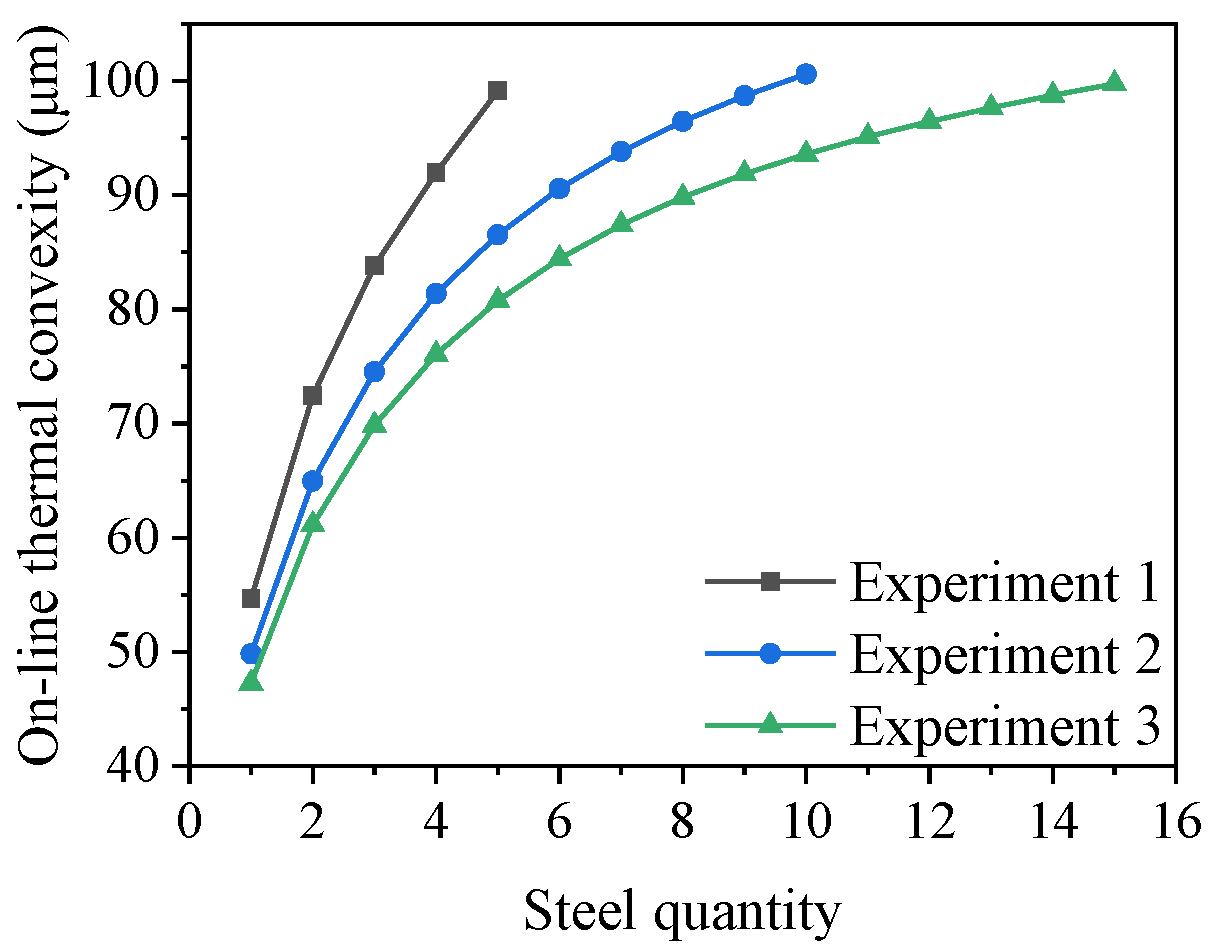

4.3. Influence of Cooling Curve on Thermal Roll Profile

5. Industry Application

6. Conclusions

- A new partition-cooling system of the hot rolling process has been designed to achieve online control of the thermal profile and the precise setting of the lateral roll gap. This enables rapid adjustments of the water flow and the distribution according to the rolling process goals, which provides an effective method for quickly adjusting the local roll gap and the strip shape or the edge drop.

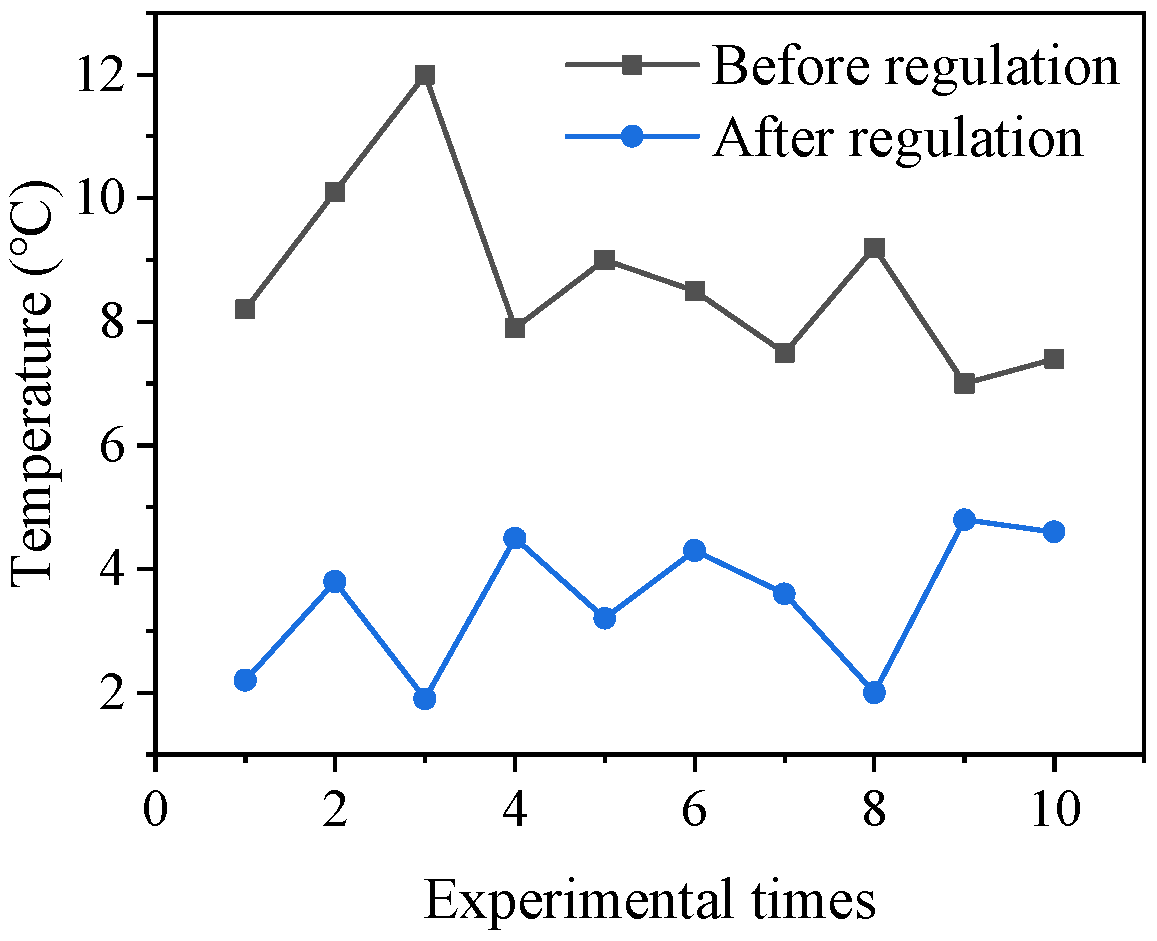

- An online temperature prediction model has been constructed for the partition-cooling process. Based on the practical production conditions and the partition-cooling modes, most cases were handled to achieve accurate temperature prediction by considering complex conditions in hot continuous rolling. According to the experimental results of partition cooling, the prediction error was within 5%.

- After application of the partition-cooling system, the temperature difference between the upper and lower rolls was within 5 °C, the lateral edge temperature difference was within 0.7 °C, and the hit rate of C40 increased by 33%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Özgür, A.; Uygun, Y.; Hütt, M.-T. A Review of Planning and Scheduling Methods for Hot Rolling Mills in Steel Production. Comput. Ind. Eng. 2021, 151, 106606. [Google Scholar] [CrossRef]

- Huang, Q. Research Progress on Key Equipment and Technology of High Quality Steel Plate and Strip Rolling. J. Mech. Eng. 2023, 59, 34–63. [Google Scholar]

- Peng, Y.; Shi, B.; Liu, C.; Xing, J. Review of the Integrated Development of Strip Rolling Equipment process-product Quality Control. J. Mech. Eng. 2023, 59, 96–118. [Google Scholar]

- Müller, M.; Prinz, K.; Steinboeck, A.; Schausberger, F.; Kugi, A. Adaptive Feedforward Thickness Control in Hot Strip Rolling with Oil Lubrication. Control Eng. Pract. 2020, 103, 104584. [Google Scholar] [CrossRef]

- Shi, X.; Feng, D.; Sun, F.; Liu, X.; Zhang, F. Hor Rolling Equipments and Technical Progress for Electrical Steel in China. Electr. Steel 2022, 4, 6–15. [Google Scholar]

- Shao, J.; He, A.; Yang, Q.; Jiang, L.; Yao, C.; Zhou, B. Multi-parameter Coupled Subsection Cooling Regulation Characteristics of Work Rolls in Aluminum Cold Rolling. Chin. J. Eng. 2015, 37, 1092–1097. [Google Scholar]

- Zhang, Y.; Li, X.; Zhao, M.; Qu, F.; Zhang, Y.; Peng, W.; Zhao, D.; Di, H.; Zhang, D. Novel Analytical Heat Source Model for Cold Rolling Based on an Energy Method and Unified Yield Criterion. Int. J. Adv. Manuf. Technol. 2022, 122, 3725–3738. [Google Scholar] [CrossRef]

- Wang, P.; Deng, J.; Li, X.; Hua, C.; Su, L.; Deng, G. A Novel Strategy Based on Machine Learning of Selective Cooling Control of Work Roll for Improvement of Cold Rolled Strip Flatness. J. Intel. Manuf. 2023, 11. [Google Scholar] [CrossRef]

- Gao, S.; Liu, H.; Xi, A.; Yang, X. Closed-loop Control Strategy of Segmented Cooling in Hot Rolling of Aluminum Alloys. J. Mech. Eng. 2016, 52, 207–212. [Google Scholar] [CrossRef]

- Guo, X.; He, A.; Shao, J.; Zhou, B.; Li, Q. Modeling and Simulation of Subsectional Cooling System during Hot Aluminum Rolling. J. Mech. Eng. 2013, 49, 70–74. [Google Scholar] [CrossRef]

- Bohacek, J.; Raudensky, M.; Kotrbacek, P. Remote Cooling of Rolls in Hot Rolling; Applicability to Other Processes. Metals 2021, 11, 1061. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, W.; Ai, Y. Influence of Edge Thermal Spraying on the Temperature Field and Thermal Crown of Work Roll during Cold Rolling of Aluminum Alloy Strip. Int. J. Adv. Manuf. Technol. 2023, 127, 4331–4338. [Google Scholar] [CrossRef]

- Yang, L.; Wang, D.; Yu, B.; Wang, Y. Research on the Quick Simulation Model for the Transient Temperature Field of the Hot Roll. J. Plast. Eng. 2010, 17, 123–128. [Google Scholar]

- Gavalas, E.; Papaefthymiou, S. Thermal Camber and Temperature Evolution on Work Roll during Aluminum Hot Rolling. Metals 2020, 10, 1434. [Google Scholar] [CrossRef]

- Han, G.; Li, H.; Zhang, J.; Kong, N.; Liu, Y.; You, X.; Xie, Y.; Shang, F. Prediction and Analysis of Rolling Process Temperature Field for Silicon Steel in Tandem Cold Rolling. Int. J. Adv. Manuf. Technol. 2021, 115, 1637–1655. [Google Scholar] [CrossRef]

- Wu, H.; Sun, J.; Lu, X.; Peng, W.; Wang, Q.; Zhang, D. Predicting Stress and Flatness in Hot-Rolled Strips during Run-out Table Cooling. J. Manuf. Process. 2022, 84, 815–831. [Google Scholar] [CrossRef]

- Hu, K.; Xue, R.; Shi, Q.; Han, W.; Zhu, F.; Chen, J. FEM Simulation of Thermo-Mechanical Stress and Thermal Fatigue Life Assessment of High-Speed Steel Work Rolls during Hot Strip Rolling Process. J. Therm. Stress. 2022, 45, 538–558. [Google Scholar] [CrossRef]

- Li, Z.; Liu, L.; Yin, B.; Kuang, S.; Wang, J.; Bai, Z. Research on Roll Temperature Field and Hot Roll Crown of Hot Continuous Rolling Mills. Iron Steel. 2023, 10. [Google Scholar] [CrossRef]

- Bao, Q.; Zhang, S.; Guo, J.; Xu, Z.; Zhang, Z. Modeling of Dynamic Data-Driven Approach for the Distributed Steel Rolling Heating Furnace Temperature Field. Neural Comput. Applic. 2022, 34, 8959–8975. [Google Scholar] [CrossRef]

- Li, F.; He, A.; Song, Y.; Wang, Z.; Xu, X.; Zhang, S.; Qiang, Y.; Liu, C. Deep Learning for Predictive Mechanical Properties of Hot-Rolled Strip in Complex Manufacturing Systems. Int. J. Min. Met. Mater. 2023, 30, 1093–1103. [Google Scholar] [CrossRef]

- Meng, L.; Ding, J.; Dong, Z.; Sun, J.; Zhang, D.; Gou, J. Prediction of Roll Wear and Thermal Expansion Based on Informer Network in Hot Rolling Process and Application in the Control of Crown and Thickness. J. Manuf. Process. 2023, 103, 248–260. [Google Scholar] [CrossRef]

- Yang, L.; Jiang, Z.; Zhu, J.; Yu, H. Analysis of Transient Heat Source and Coupling Temperature Field during Cold Strip Rolling. Int. J. Adv. Manuf. Technol. 2018, 95, 835–846. [Google Scholar] [CrossRef]

- Li, Y.; Cao, J.; Qiu, L.; Yang, G.; Kong, N.; He, A.; Zhou, Y. Effect of Strip Edge Temperature Drop of Electrical Steel on Profile and Flatness during Hot Rolling Process. Adv Mech. Eng. 2019, 11, 753305129. [Google Scholar] [CrossRef]

- Chen, C.; Shao, J.; He, A. Research on Online Calculation Methods of Temperature Field of Hot Strip. J. Mech. Eng. 2014, 50, 135–142. [Google Scholar] [CrossRef]

- Wang, L.; Ma, L.; Song, Z. Shape Control Model of Magnesium Alloy Single-stand Four-high Mill. J. Netshape Form. Eng. 2022, 14, 36–43. [Google Scholar]

- Peng, G.; Xu, D.; Zhou, J.; Yang, Q.; Shen, W. A Novel Curve Pattern Recognition Framework for Hot-Rolling Slab Camber. IEEE Trans. Ind. Inform. 2023, 19, 1270–1278. [Google Scholar] [CrossRef]

- Peng, G.; Cheng, Y.; Wang, H.; Shen, W. Industrial Big Data-driven Mechanical Performances Prediction for Hot-rolling Steel Using Lower Upper bound Estimation Method. J. Manuf. Syst. 2022, 65, 104–114. [Google Scholar] [CrossRef]

| Steel Grade | Width (mm) | Force (kN) | Rhythm (s) | Throughput | Roll Diameter (mm) |

|---|---|---|---|---|---|

| S14 | 1200 | 11,882 | 125 | 50 | 680 |

| Area 1 (%) | Area 2 (%) | Area 3 (%) | Area 4 (%) | Area 5 (%) | |

|---|---|---|---|---|---|

| Experiment 1 | 100 | 100 | 32 | 100 | 100 |

| Experiment 2 | 100 | 100 | 43 | 100 | 100 |

| Experiment 3 | 100 | 100 | 56 | 100 | 100 |

| Steel Grade | Width (mm) | Exit Thickness (mm) | Rhythm (s) | Force (kN) | Throughput | |

|---|---|---|---|---|---|---|

| Experiment 1 | S14 | 1129 | 2.6 | 133 | 10804 | 56 |

| Experiment 2 | S14 | 1150 | 2.6 | 124 | 11647 | 60 |

| Area 1 (%) | Area 2 (%) | Area 3 (%) | Area 4 (%) | Area 5 (%) | |

|---|---|---|---|---|---|

| Experiment 1 | 10 | 30 | 90 | 30 | 10 |

| Experiment 2 | 70 | 80 | 40 | 80 | 70 |

| Area 1 (%) | Area 2 (%) | Area 3 (%) | Area 4 (%) | Area 5 (%) | |

|---|---|---|---|---|---|

| Before adjustment | 70 | 80 | 100 | 80 | 70 |

| After adjustment | 56 | 74 | 100 | 86 | 84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Sun, J.; Yang, J.; Wang, H.; Dong, L.; Jiao, Y.; Li, J.; Zhi, Z.; Yang, L. Online Partition-Cooling System of Hot-Rolled Electrical Steel for Thermal Roll Profile and Its Industrial Application. Processes 2024, 12, 410. https://doi.org/10.3390/pr12020410

Wang Q, Sun J, Yang J, Wang H, Dong L, Jiao Y, Li J, Zhi Z, Yang L. Online Partition-Cooling System of Hot-Rolled Electrical Steel for Thermal Roll Profile and Its Industrial Application. Processes. 2024; 12(2):410. https://doi.org/10.3390/pr12020410

Chicago/Turabian StyleWang, Qiuna, Jiquan Sun, Jiaxuan Yang, Haishen Wang, Lijie Dong, Yanlong Jiao, Jieming Li, Zhenyang Zhi, and Lipo Yang. 2024. "Online Partition-Cooling System of Hot-Rolled Electrical Steel for Thermal Roll Profile and Its Industrial Application" Processes 12, no. 2: 410. https://doi.org/10.3390/pr12020410

APA StyleWang, Q., Sun, J., Yang, J., Wang, H., Dong, L., Jiao, Y., Li, J., Zhi, Z., & Yang, L. (2024). Online Partition-Cooling System of Hot-Rolled Electrical Steel for Thermal Roll Profile and Its Industrial Application. Processes, 12(2), 410. https://doi.org/10.3390/pr12020410