Steam-Alternating CO2/Viscosity Reducer Huff and Puff for Improving Heavy Oil Recovery: A Case of Multi-Stage Series Sandpack Model with Expanded Sizes

Abstract

1. Introduction

2. Methodology and Experiment

2.1. Materials

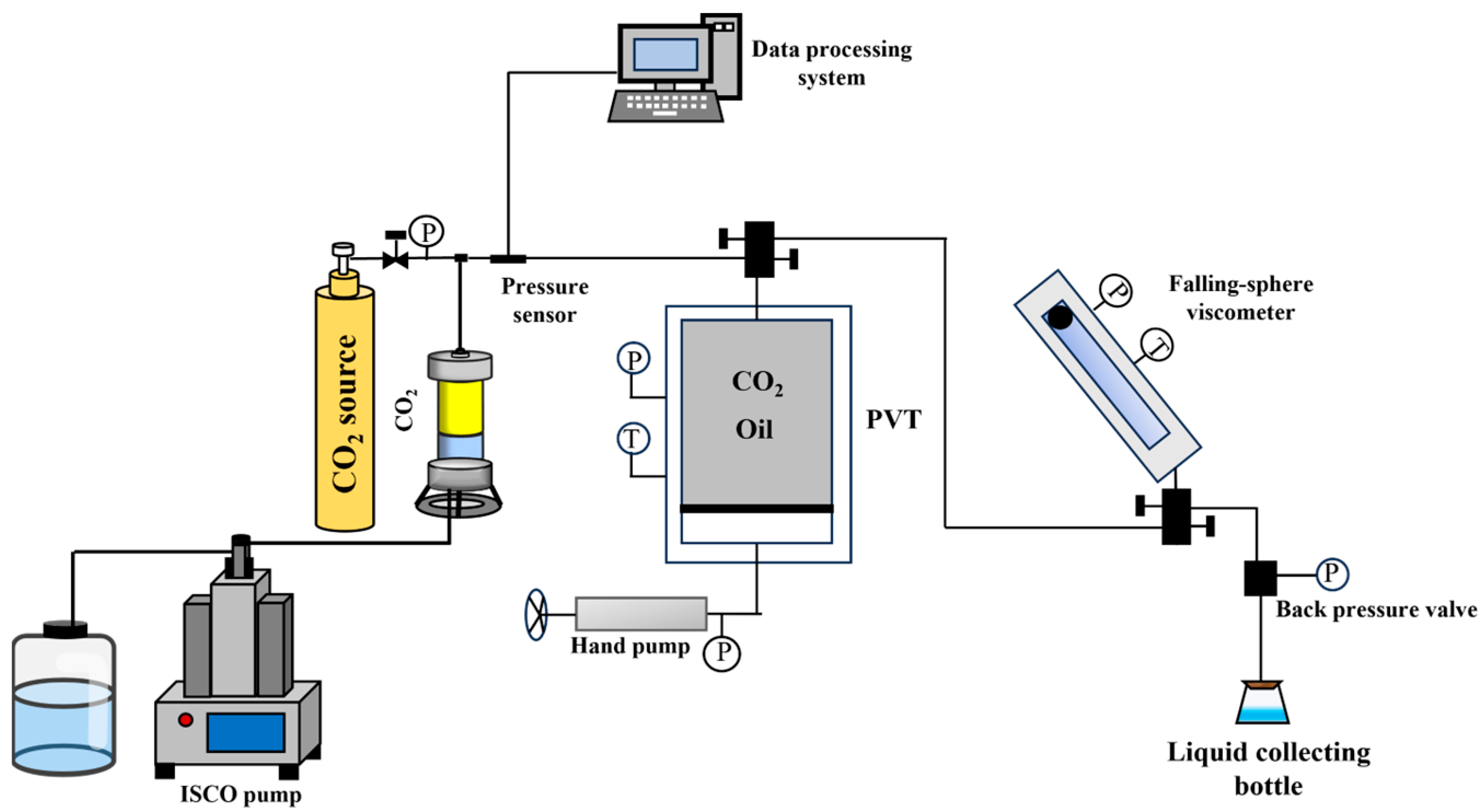

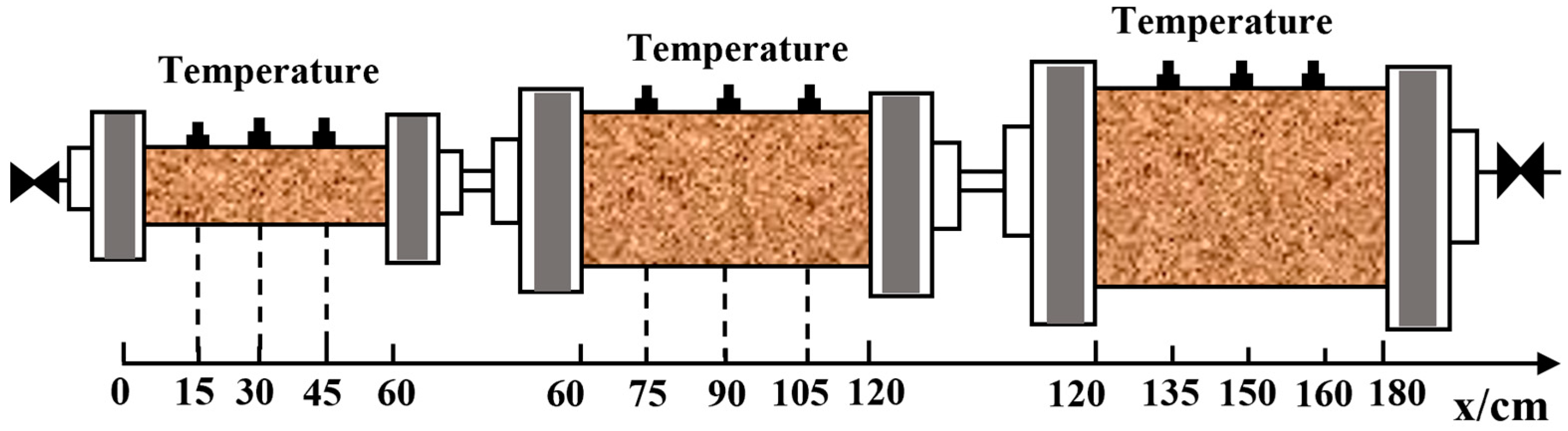

2.2. Apparatus for Huff and Puff Experiments

Apparatus for PVT Tests

2.3. Pre-Experimental Test Preparation and Experimental Procedure

2.3.1. The Impact of Viscosity Reducers and CO2 on the Physical Properties of Heavy Oil

- Heat the experimental equipment and experimental medium to the designed temperature.

- Fill the PVT meter with experimental liquid and experimental gas according to the design.

- Turn the hand pump to inject water into the other side of the piston of the mixing container of the PVT meter and record the volume change.

- Start the forward/reverse button to accelerate the dissolution and diffusion of the liquid and gas rest and record the pressure value when the pressure reaches equilibrium.

- Repeat steps 1–4 to record multiple sets of data.

- The experiment is completed, natural cooling of the experimental container to room temperature after the discharge of the experimental medium.

- (1)

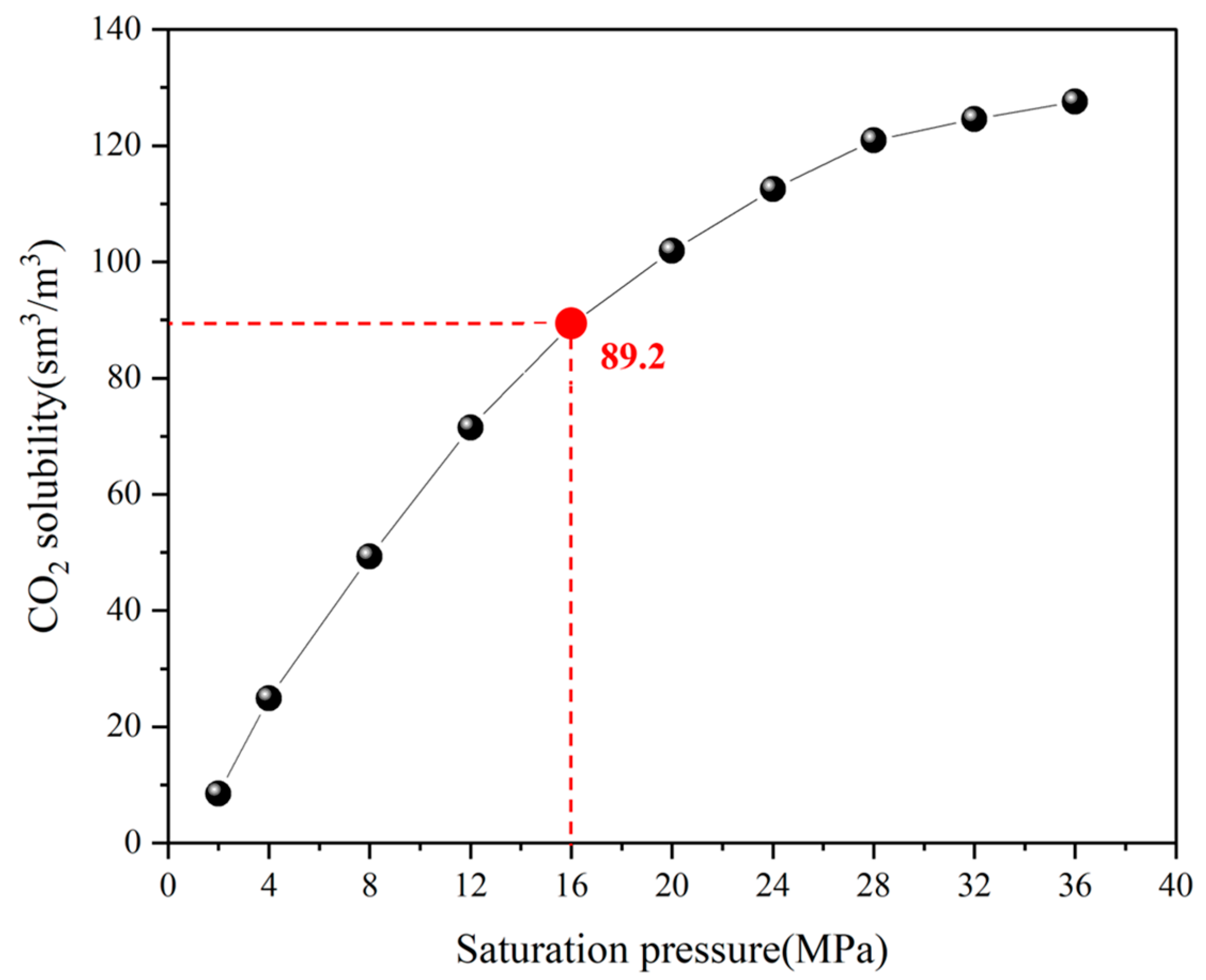

- The solubility and viscosity changes of CO2 in heavy oil are measured at 68 °C and varying pressures. The pressure-solubility relationship is shown in Figure 3. The red line in Figure 3 refers that a saturation pressure of 16 MPa, CO2 solubility in heavy oil is 89.2 Sm3/m3, indicating that solubility increases with pressure. Under low pressure, the larger molecular gap in crude oil allows CO2 molecules to dissolve more easily. However, as saturation pressure rises, increased oil density due to compression reduces the molecular gap, making it more difficult for CO2 to dissolve in the oil.

- (2)

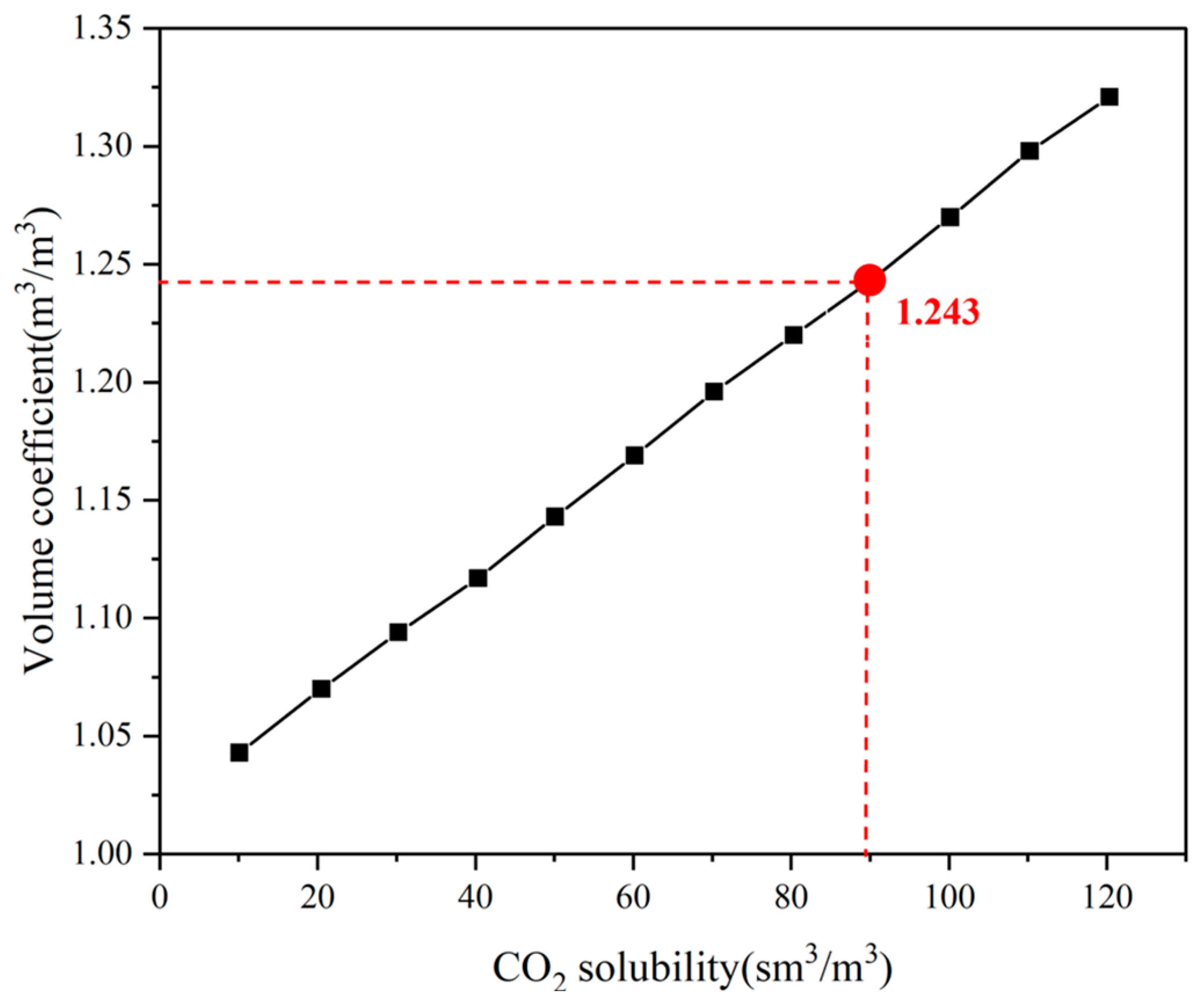

- The volume expansion coefficients of heavy oil are analyzed at varying CO2 solubilities (10–110 Sm3/m3), revealing the relationship between the volume coefficient and CO2 solubility. Figure 4 shows that the volume coefficient of heavy oil increases linearly with rising CO2 solubility at 68 °C. Specifically, the red line in Figure 3 refers that the volume coefficient reaches approximately 1.234 at the maximum experimental CO2 solubility of 89.2 Sm3/m3 and about 1.32 at 120 Sm3/m3. This indicates that as CO2 solubility increases, the volume expansion of the formation oil also rises, enhancing its elasticity and suggesting a more significant oil increase effect with higher energy.

- (3)

- The viscosity of heavy oil is assessed at different CO2 solubilities. Figure 5 illustrates how heavy oil viscosity and the viscosity reduction rate change with varying CO2 solubilities at 68 °C. The results indicate that CO2 injection effectively reduces heavy oil viscosity. As CO2 solubility increases, crude oil viscosity rises. At a CO2 solubility of 90 Sm3/m3, the viscosity reduction rate is about 95.6%, and at 120 Sm3/m3, it reaches 96.3%.

- (4)

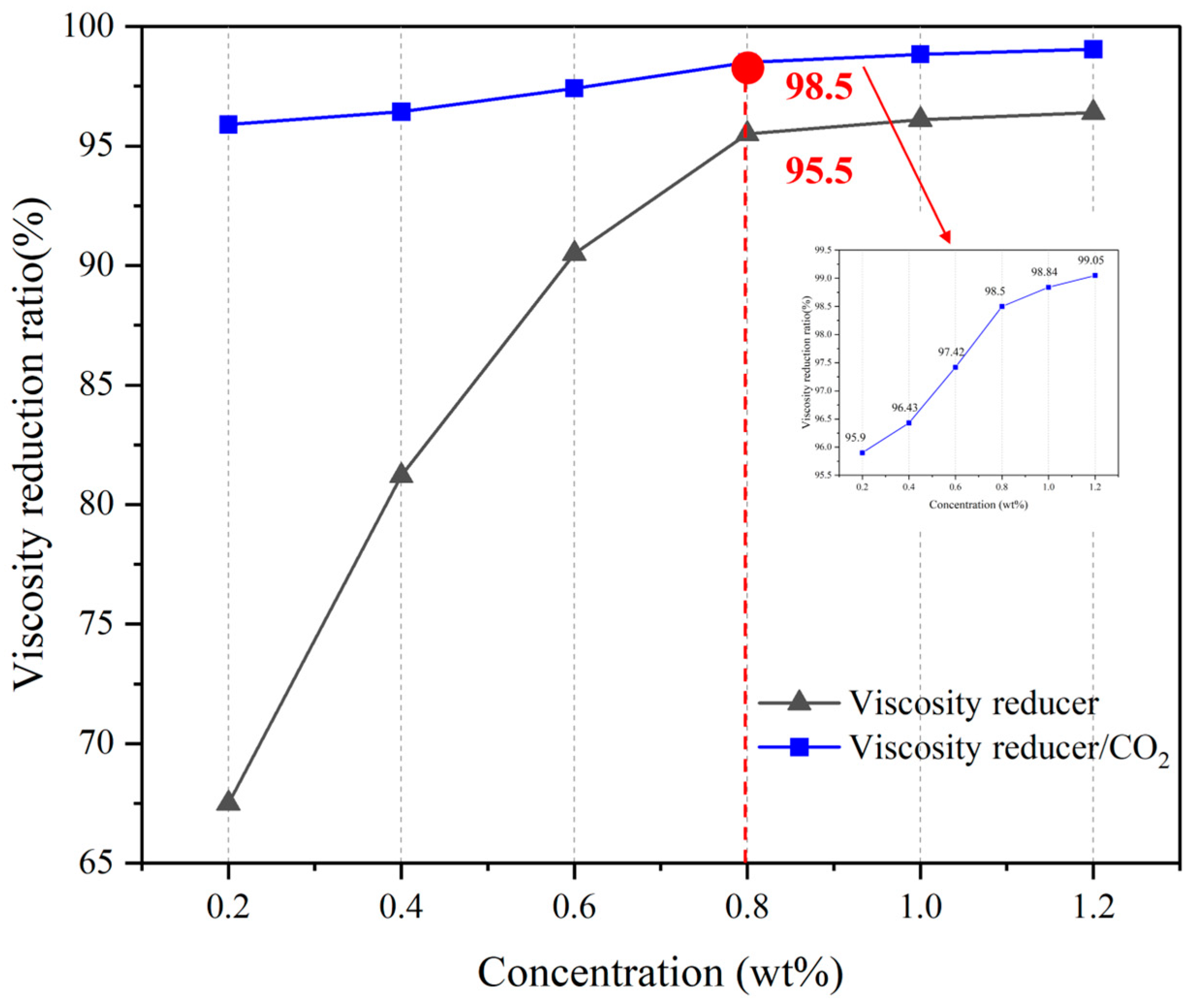

- The effect of synergistic viscosity reduction using CO2 and a water-soluble viscosity reducer is studied. Seven viscosity reducers with concentrations of 0.2 wt%, 0.4 wt%, 0.6 wt%, 0.8 wt%, 1.0 wt%, 1.2 wt%, and 1.4 wt% were added to heavy oil. The viscosity is measured at 16 MPa, 68 °C, and a CO2 dissolved gas–oil ratio of 89.2 Sm3/m3. Figure 6 shows the viscosity reduction rate with the combined use of the water-soluble viscosity reducer and CO2 at the specified ratio. Results indicate that increasing viscosity reducer concentration correlates with higher viscosity reduction rates. Between concentrations of 0.2 wt% and 1.2 wt%, the rate rises rapidly; however, above 0.8 wt%, the increase slows. The best economy of effect is at a concentration of 0.8 wt%. Notably, the synergistic viscosity reduction rate reaches 98.5% at 0.8 wt%, compared to 95.5% for the viscosity reducer alone.

2.3.2. Huff and Puff Experiment

- (1)

- The sand-fill model should be prepared by filling the sandpack with the prepared sand mixture. The airtightness of the model should then be checked, and the dry weight of the core tube should be measured.

- (2)

- The sandpacks are evacuated for a period of four hours and then saturated with water. Following saturation, the core tubes are weighed, and the porosity is calculated based on the weight difference. Permeability is tested by injecting a constant flow of water by Darcy’s law.

- (3)

- Heavy oil is injected into the core via a plunger pump, and each of the three sandpacks is saturated with oil at a rate of 1 mL/min until no additional water flows out. Once saturation is complete, the three sandpacks are assembled and placed in a thermostat. The tubes are maintained at 68 °C for 12 h. The saturation process is conducted at a rate of 1 mL/min until no further water is observed to flow out. The three sandpacks are then assembled and placed in a thermostat for an additional 12 h at 68 °C.

- (4)

- Install the experimental equipment according to the flow chart. Turn on the steam generator to preheat in advance, the temperature of the steam generator is set to 300 °C. When the temperature of the sandpack and the steam generator reaches a stable temperature, start the experiment. According to the experimental design, set the steam injection rate to 3 mL/min; the steam injection rate is equivalent water; when the pressure sensor at the inlet end of the sandpack reaches 16 MPa, stop the injection and record the PV number of injected steam. Close all valves and soak for 200 min, open the inlet valve, set the back pressure to 2 MPa, record the temperature at the time of opening the well, and keep the downward pressure mining at a decreasing rate of 0.2 MPa/min, so that the oil and water spout out, until the pressure in the sandpack is reduced to the point that there is no fluid coming out of the tube after the back pressure is applied.

- (5)

- The CO2/viscosity reducer huff and puff procedure begins with the injection of a water-soluble viscosity reducer at an optimal concentration into the sandpack at a flow rate of 0.5 mL/min, with an injection volume of 0.1 PV. Subsequently, CO2 is injected at a rate of 10 mL/min, and the injection is terminated when the pressure sensor at the inlet end reaches 16 MPa. The volume of injected CO2 is recorded. Once all the valves have been closed, the sandpack is allowed to simmer for 200 min. The inlet valve should then be opened, the back pressure is set at 2 MPa, and the downward pressure extraction is maintained at a rate of 0.2 MPa/min. This process continues until the pressure in the sandpack is reduced to a point where no further fluid is extracted. The extracted fluid is then collected at the outlet end.

- (6)

- Steps (4) and (5) are repeated until six cycles of alternating throughput (H + C + H + C + H + C) are completed. In these cycles, H represents steam huff and puff, while C represents CO2 composite huff and puff. Following this, step (4) is repeated for pure steam huff and puff until six cycles of huff and puff (H + H + H + H + H + H) are completed. Detailed parameters of the two groups of huff and puff experiments are shown in Table 1.

3. Experimental Results and Discussion

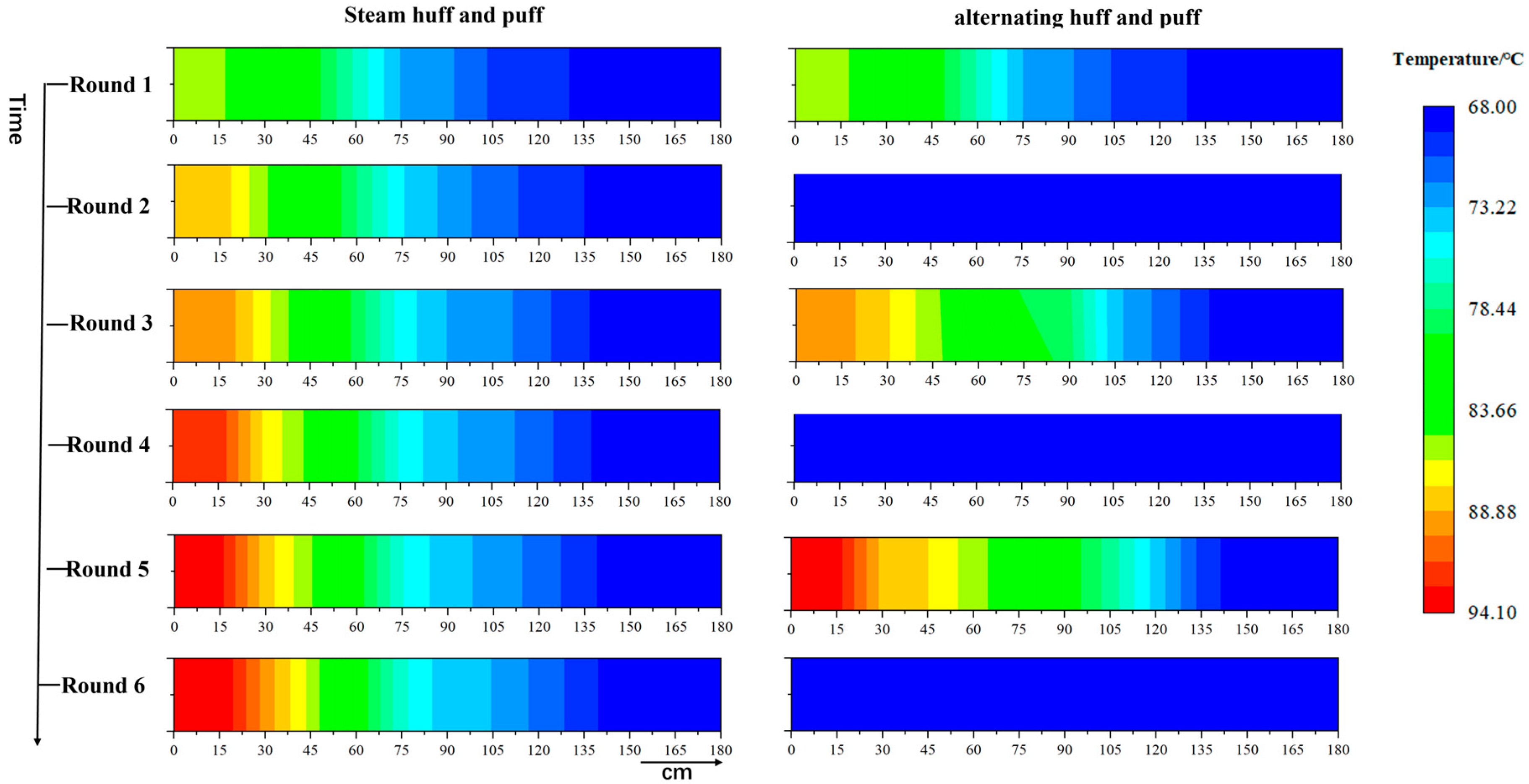

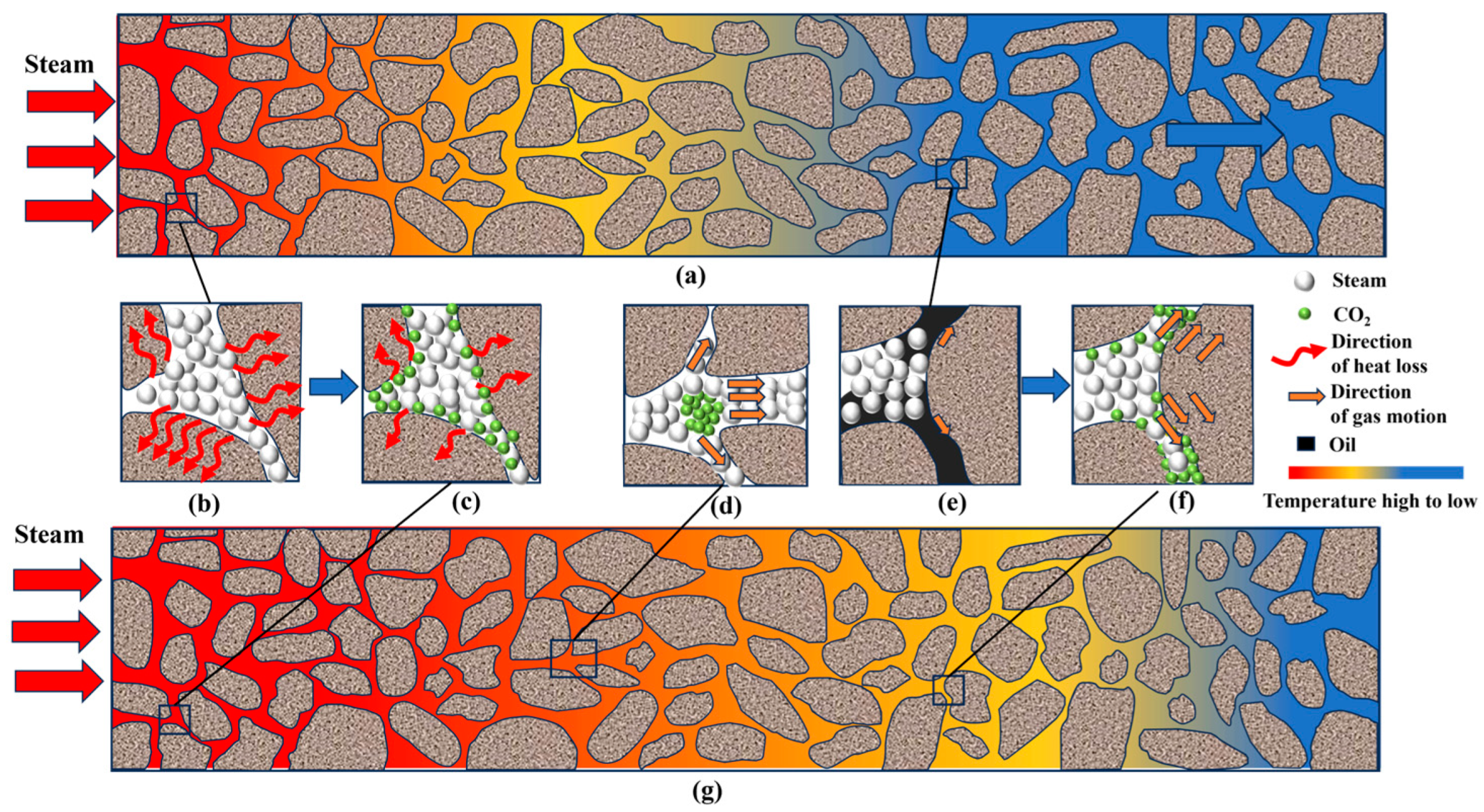

3.1. Temperature Field Analysis

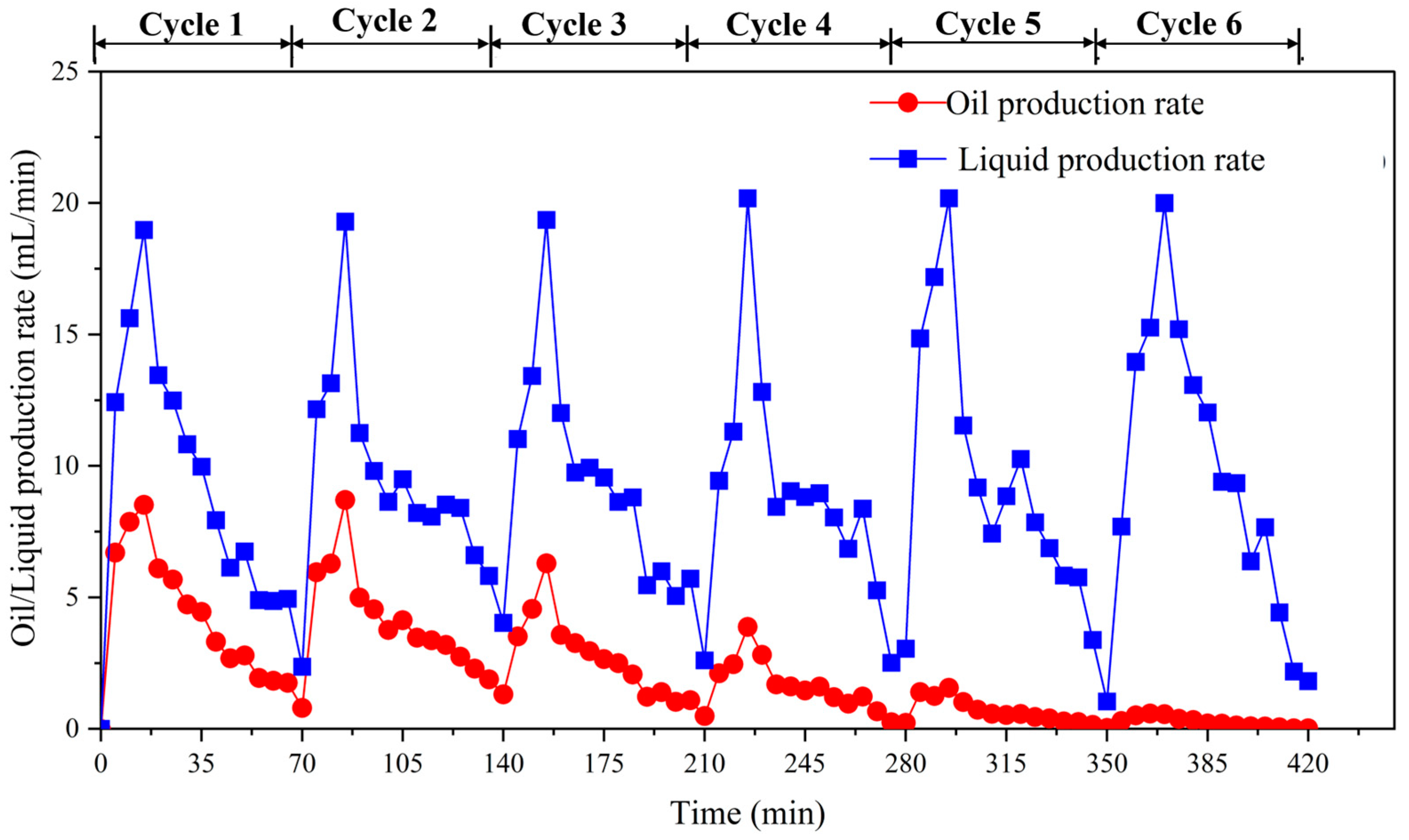

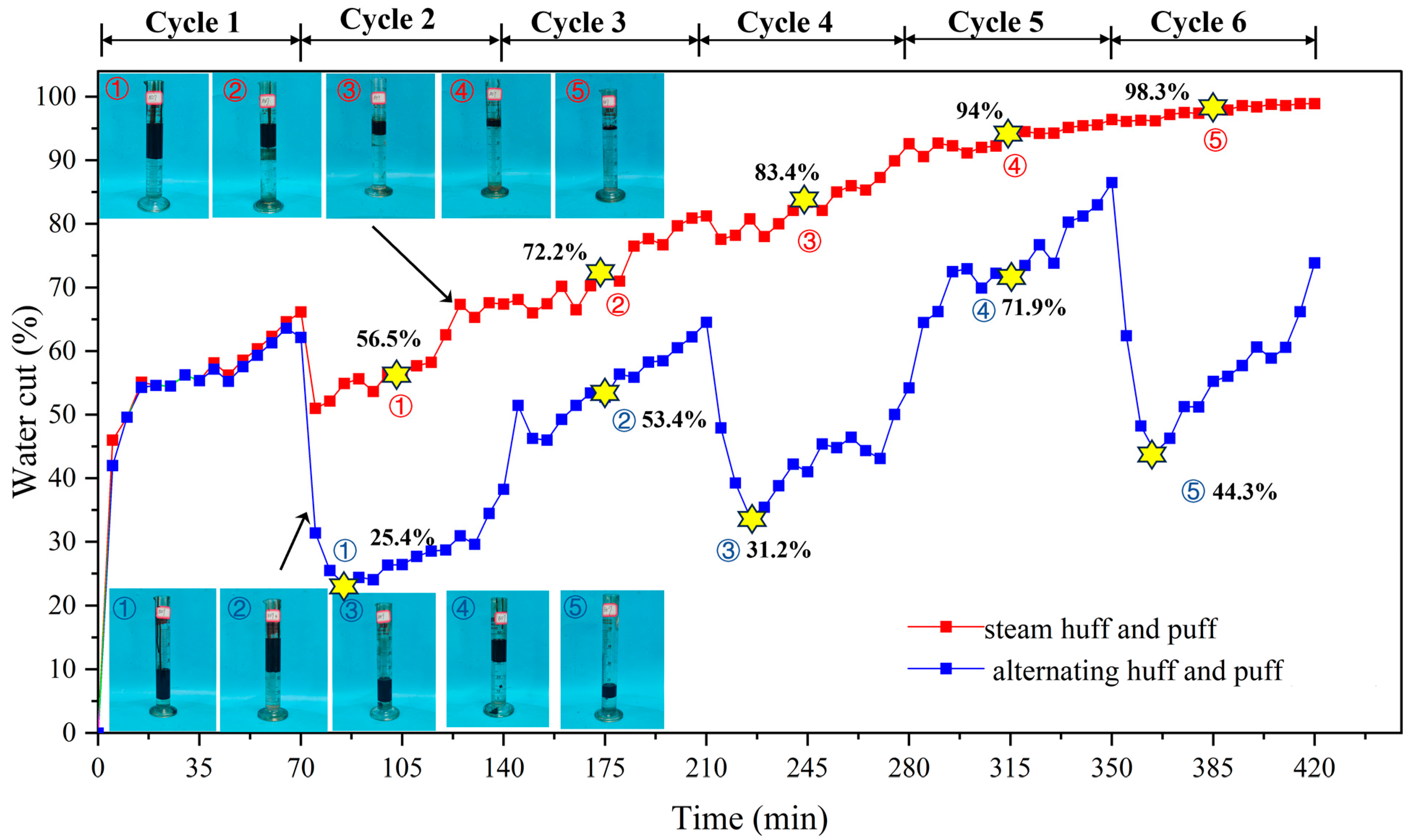

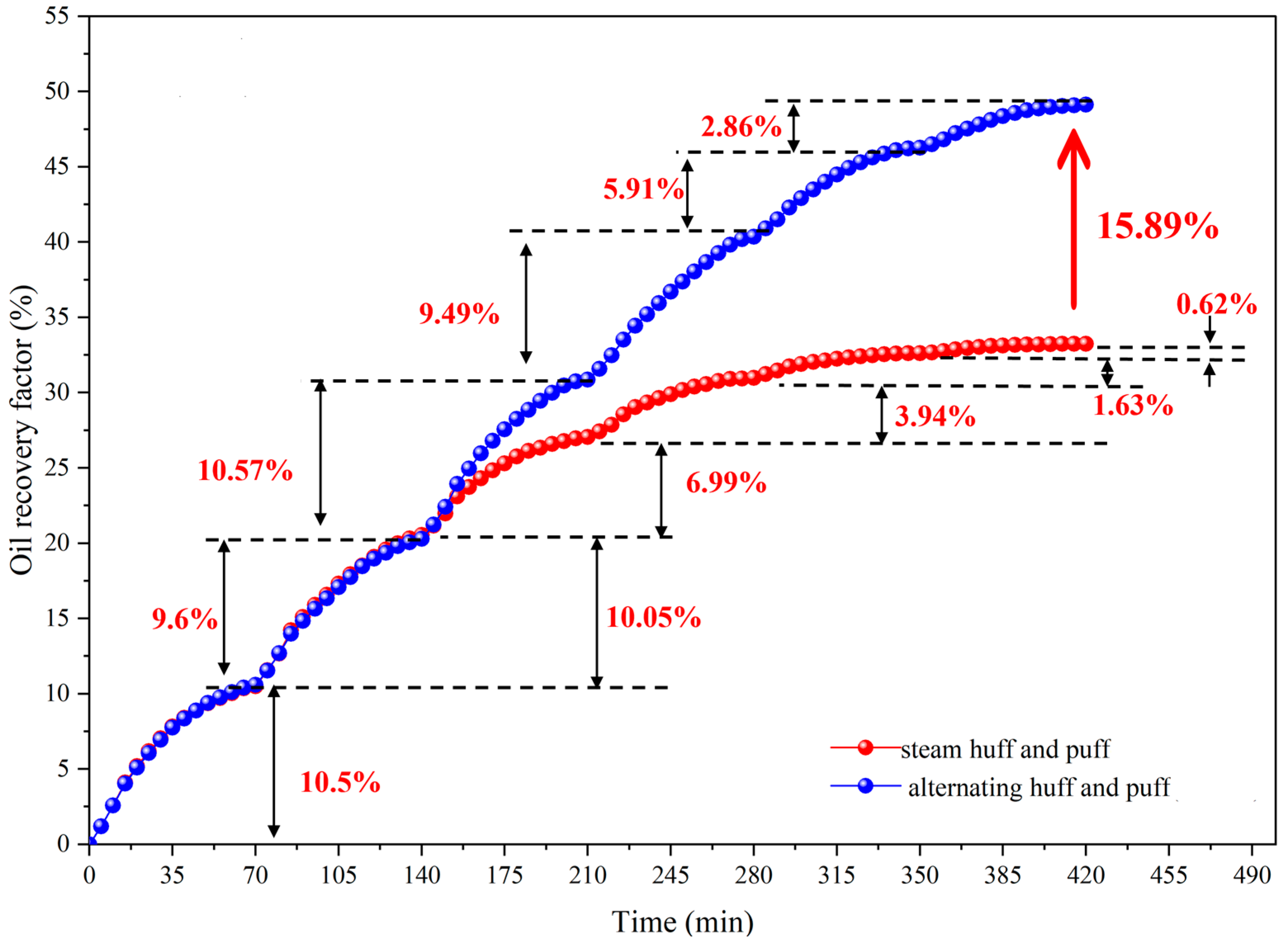

3.2. Analysis of Production Dynamics

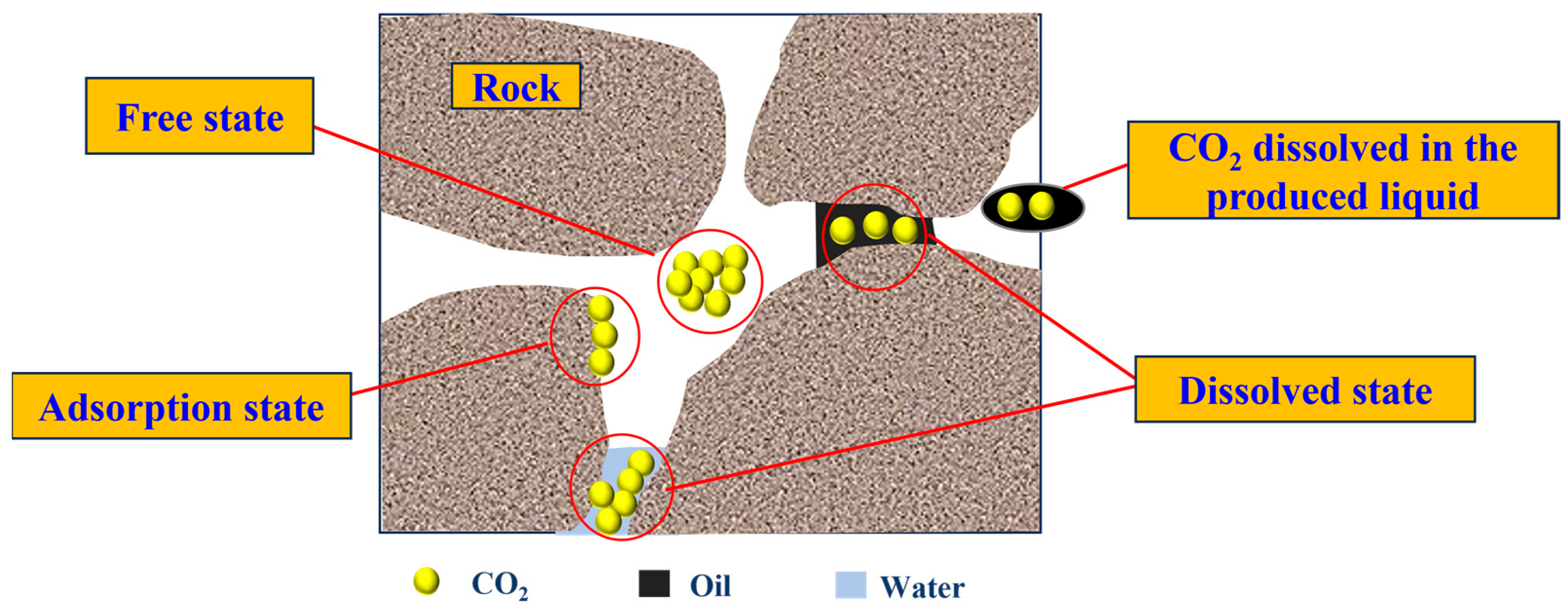

3.3. CO2 Storage Efficiency During Alternating Huff and Puff Processes

4. Conclusions

- (1)

- At a CO2 solubility of approximately 89.2 Sm3/m3, the volume coefficient of the target heavy oil is about 1.234, with a viscosity reduction rate of 95.6% due to CO2. The optimal concentration of the water-soluble viscosity reducer is 0.8 wt%, achieving a viscosity reduction rate of 95.5%. When combined, the synergistic effect of CO2 and the viscosity reducer enhances the viscosity reduction rate to 98.5%.

- (2)

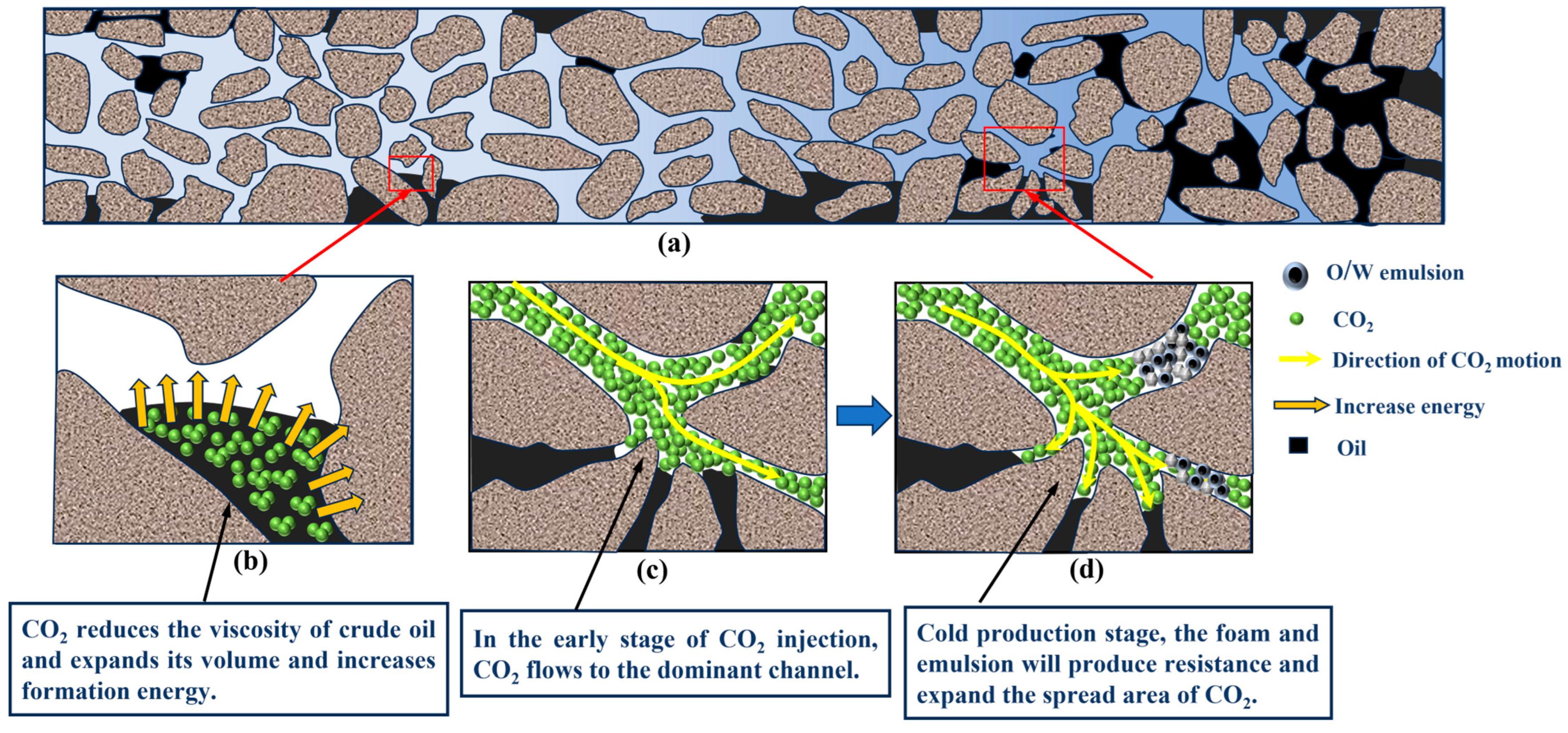

- The insulation effect of CO2 as a non-condensable gas, combined with its thermal expansion push effect, enhances recovery. Additionally, the cold production of CO2/viscosity huff and puff opens seepage channels for subsequent thermal recovery, reducing steam seepage resistance and extending the steam heating range. Therefore, steam–CO2/viscosity reducer huff and puff have a longer steam reach than pure steam huff and puff. In the fifth cycle of alternate huff and puff, the high temperature of about 80 °C is pushed forward by an extra 45 cm, with the heat spreading farther.

- (3)

- Due to the viscosity reducer’s ability to alleviate blockage in the near-well zone, CO2 dissolved in heavy oil decreases viscosity and enhances elastic repulsion energy. Additionally, the emulsion formed by the viscosity reducer seals the dominant CO2 flow channels, increasing the CO2 wave size. Therefore, the CO2/viscosity reducer huff and puff method significantly reduces the water cut during the cold production stage and extends the production cycle after subsequent thermal recovery. The IOR of the steam–CO2/viscosity reducer huff and puff method is 15.89% higher than pure steam huff and puff.

- (4)

- In the early stage of CO2/viscosity reducer huff and puff, the CO2 storage rate was the highest, 76.8%. In the late stage of huff and puff, the sequestration rate of huff and puff gradually decreased due to the increase of CO2 solubility in heavy oil, and the free pore space became saturated with CO2. After six cycles, the sequestration rate of CO2 was only 15.2%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Guo, J.; Li, C.; Xiong, R.; Chen, X.; Zhang, X. Advancements and future prospects in in-situ catalytic technology for heavy oil reservoirs in China: A review. Fuel 2024, 374, 132376. [Google Scholar] [CrossRef]

- Wang, L.; Pang, Z.; Jin, Y.; Liu, D. Thermodynamic Characteristics of cold and hot non-condensable gases simultaneously flowing along vertical wellbore. J. Petrol. Sci. Eng. 2022, 208, 109451. [Google Scholar] [CrossRef]

- Zhao, F.; Liu, Y.; Lu, N.; Xu, T.; Zhu, G.; Wang, K. A review on upgrading and viscosity reduction of heavy oil and bitumen by underground catalytic cracking. Energy Rep. 2021, 7, 4249–4272. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Li, Z. A novel strategy to reduce carbon emissions of heavy oil thermal recovery: Condensation heat transfer performance of flue gas-assisted steam flooding. Appl. Therm. Eng. 2022, 205, 118076. [Google Scholar] [CrossRef]

- Guo, K.; Li, H.; Yu, Z. In-situ heavy and extra-heavy oil recovery: A review. Fuel 2016, 185, 886–902. [Google Scholar] [CrossRef]

- Sun, X.; Cai, J.; Li, X.; Zheng, W.; Wang, T.; Zhang, Y. Experimental investigation of a novel method for heavy oil recovery using supercritical multithermal fluid flooding. Appl. Therm. Eng. 2021, 185, 116330. [Google Scholar] [CrossRef]

- Liu, S.; Wu, X.; Li, Y.; Cui, S.; Shen, X.; Tan, G. Hydrophobic in-situ SiO2-TiO2 composite aerogel for heavy oil thermal recovery: Synthesis and high temperature performance. Appl. Therm. Eng. 2021, 190, 116745. [Google Scholar] [CrossRef]

- Soler, C.A.C.; Malagueta, D.C.; Martin, C.A.G. Feasibility of implementation of solar thermal energy in steam-assisted gravity drainage (SAGD) in extra-heavy oil field in Colombia. Geoenergy Sci. Eng. 2023, 222, 211463. [Google Scholar] [CrossRef]

- Hou, J.; Wei, B.; Du, Q.; Wang, J.; Wang, Q.; Zhang, G. Production prediction of cyclic multi-thermal fluid stimulation in a horizontal well. J. Petrol. Sci. Eng. 2016, 146, 949–958. [Google Scholar] [CrossRef]

- Tian, Z.; Gan, W.; Qi, Z.; Tian, M.; Gao, W. Experimental study of organic Rankine cycle with three-fluid recuperator for cryogenic cold energy recovery. Energy 2022, 242, 122550. [Google Scholar] [CrossRef]

- Cao, H.; Li, Y.; Gao, W.; Cao, J.; Sun, B.; Zhang, J. Experimental investigation on the effect of interfacial properties of chemical flooding for enhanced heavy oil recovery. Colloids Surf. A 2023, 677, 132335. [Google Scholar] [CrossRef]

- Zamani, A.M.; Moslemi, A.; Hassani, K. Experimental investigation into effects of the natural polymer and nanoclay particles on the EOR performance of chemical flooding in carbonate reservoirs. Petrol. Sci. 2024, 21, 951–961. [Google Scholar] [CrossRef]

- Coskuner, G.; Naderi, K.; Babadagli, T. An enhanced oil recovery technology as a follow up to cold heavy oil production with sand. J. Petrol. Sci. Eng. 2015, 133, 475–482. [Google Scholar] [CrossRef]

- He, H.; Li, Q.; Zheng, H.; Liu, P.; Tang, J.; Ma, Y. Simulation and evaluation on enhanced oil recovery for steam huff and puff during the later phase in heavy oil Reservoir—A case study of block G in Liaohe oilfield, China. J. Pet. Sci. Eng. 2022, 219, 111092. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, W.; Zou, X.; Wang, S.; Sun, Q.; Li, B.; Li, S.; Bhusal, A.; Wang, S.; Li, Z. Experimental study on thermochemical composite system huff-n-puff process in ultra-heavy oil production. Fuel 2022, 332, 126014. [Google Scholar] [CrossRef]

- Wan, T.; Wang, X.; Jing, Z.; Gao, Y. Gas injection assisted steam huff-n-puff process for oil recovery from deep heavy oil reservoirs with low-permeability. J. Petrol. Sci. Eng. 2022, 12, 4631. [Google Scholar] [CrossRef]

- Shedid, S.A. Influences of fracture orientation on oil recovery by water and polymer flooding processes: An experimental approach. J. Pet. Sci. Eng. 2020, 185, 106613. [Google Scholar] [CrossRef]

- Wang, X.; Wang, J.; Qiao, M. Horizontal well, nitrogen and viscosity reducer assisted steam huff and puff technology: Taking super heavy oil in shallow and thin beds, Chunfeng Oilfield, Junggar Basin, NW China, as an example. Pet. Explor. Dev. 2013, 40, 104–110. [Google Scholar] [CrossRef]

- Nian, Y.L.; Han, B.B.; Cheng, W.L. Experimental study on combination hot water-CO2-chemical flooding with effects on oil recovery and heat transfer. Appl. Therm. Eng. 2020, 166, 114683. [Google Scholar] [CrossRef]

- Ebrahimzadeh, E.; Matagi, J.; Fazlollahi, F.; Baxter, L.L. Alternative extractive distillation system for CO2–ethane azeotrope separation in enhanced oil recovery processes. Appl. Therm. Eng. 2016, 96, 39–47. [Google Scholar] [CrossRef]

- Jia, B.; Tsau, J.S.; Barati, R. Role of Molecular Diffusion in Heterogeneous, Naturally Fractured Shale Reservoirs during CO2 Huff-N-Puff. J. Petrol. Sci. Eng. 2018, 164, 31–42. [Google Scholar] [CrossRef]

- Zakin, J.L.; Pinaire, R.; Borgmeyer, M.E. Transport of oils as oil-in-water emulsions. J. Fluids Eng. 1979, 101, 100–104. [Google Scholar] [CrossRef]

- Sullivan, A.P.; Kilpatrick, P.K. The effects of inorganic solid particles on water and crude oil emulsion stability. Ind. Eng. Chem. Res. 2022, 41, 3389–3404. [Google Scholar] [CrossRef]

- Zhou, X.; Zeng, F.; Zhang, L.; Jiang, Q.; Yuan, Q.; Wang, J.; Zhu, J.; Huang, X. Experimental and mathematical modeling studies on foamy oil stability using a heavy oil–CO2 system under reservoir conditions. Fuel 2020, 264, 116771. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, H.; Zhao, C.; Zhu, E. Investigating phase dynamics of reservoir fluids in CO2 huff-n-puff enhanced oil recovery. Geoenergy Sci. Eng. 2024, 238, 212925. [Google Scholar] [CrossRef]

- Yang, Y.; Song, H.; Li, Y.; Liu, F.; Zhang, Q.; Wang, J.; Imani, G.; Zhang, L.; Sun, H.; Zhong, J.; et al. Microscopic mechanism of CO2 huff-n-puff promoting shale oil mobilization in nanopores. Fuel 2024, 371, 131841. [Google Scholar] [CrossRef]

- Xu, R.; Zeng, K.; Zhang, C.; Jiang, P. Assessing the feasibility and CO2 storage capacity of CO2 enhanced shale gas recovery using Triple-Porosity reservoir model. Appl. Therm. Eng. 2017, 115, 1306–1314. [Google Scholar] [CrossRef]

- Yang, F.; Zhu, W.; Yu, X.; Tang, Y.; Shi, W. Application of in-situ generation gas huff-n-puff process in W5 heavy oil reservoir of Jiangsu Oilfield. Complex Hydrocarb. Reserv. 2013, 6, 71–75. [Google Scholar]

- Wang, L.; Shao, Y.; Chen, X.; Wang, C.; Yang, X.; Doranehgard, M.H.; Che, D. Thermofluidic characteristics for a novel complementary adsorption-absorption post-combustion partial CO2 capture system. Appl. Therm. Eng. 2023, 226, 120301. [Google Scholar] [CrossRef]

- Shi, Y.; Wu, B.; Wang, H.; Li, Y.; Liu, Z.; Xu, C.; Qin, J.; Li, Y.; Song, Z.; Liu, H. Insights into CO2 huff-n-puff mechanisms from laboratory experiment and single-well pilot test in the Lucaogou tight oil reservoir, Jimsar sag, China. Geoenergy Sci. Eng. 2024, 232, 212456. [Google Scholar] [CrossRef]

- Yang, M.; Huang, S.; Zhao, F.; Sun, H.; Chen, X. Experimental investigation of CO2 huff-n-puff in tight oil reservoirs: Effects of the fracture on the dynamic transport characteristics based on the nuclear magnetic resonance and fractal theory. Energy 2024, 294, 130781. [Google Scholar] [CrossRef]

- Sayegh, S.G.; Maini, B.B. Laboratory evaluation of the CO2 huff-n-puff process for heavy oil reservoirs. J. Can. Petrol. Technol. 1984, 23, 0302. [Google Scholar] [CrossRef]

- Li, S.; Li, B.; Zhang, Q.; Li, Z.; Yang, D. Effect of CO2 on heavy oil recovery and physical properties in huff-n-puff processes under reservoir conditions. J. Energy. Resour. Technol. 2018, 140, 072907. [Google Scholar] [CrossRef]

- Seyyedsar, S.M.; Farzaneh, S.A.; Sohrabi, M. Investigation of low-density CO2 injection for enhanced oil recovery. Ind. Eng. Chem. Res. 2017, 56, 5443–5454. [Google Scholar] [CrossRef]

- Li, S.; Zhang, K.; Jia, N.; Liu, L. Evaluation of four CO2 injection schemes for unlocking oils from low-permeability formations under immiscible conditions. Fuel 2018, 234, 814–823. [Google Scholar] [CrossRef]

- Zhang, K.; Jia, N.; Li, S.; Liu, L. Millimeter to nanometer-scale tight oil-CO2 solubility parameter and minimum miscibility pressure calculations. Fuel 2018, 220, 645–653. [Google Scholar] [CrossRef]

- Zhang, K.; Jia, N.; Li, S.; Liu, L. Static and dynamic behavior of CO2 enhanced oil recovery in shale reservoirs: Experimental nanofluidics and theoretical models with dual-scale nanopores. Appl. Energy 2019, 255, 113752. [Google Scholar] [CrossRef]

- Hao, Y.; Wu, Z.; Chen, Z.; Li, L.; Sun, Y.; Liu, R.; Guo, F. The characteristics and effects of Huff-n-Puff in shale with brine, aqueous surfactant solutions and CO2. J. CO2 Util. 2024, 79, 102655. [Google Scholar] [CrossRef]

- Zeng, T.; Miller, C.S.; Mohanty, K.K. Combination of a chemical blend with CO2 huff-n-puff for enhanced oil recovery in oil shales. J. Petrol. Sci. Eng. 2020, 194, 107546. [Google Scholar] [CrossRef]

- Lee, J.H.; Jeong, M.S.; Lee, K.S. Comprehensive modeling of CO2 Huff-n-Puff in asphaltene-damaged shale reservoir with aqueous solubility and nano-confinement. J. Ind. Eng. Chem. 2020, 90, 232–243. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Q.; Li, S.; Li, Z. Enhanced heavy oil recovery via surfactant-assisted CO2 huff-n-puff processes. J. Petrol. Sci. Eng. 2017, 159, 25–34. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, T.; Pang, S.; Sun, S. Thermal effects of organic porous media on absorption and desorption behaviors of carbon dioxide. Appl. Therm. Eng. 2024, 254, 123920. [Google Scholar] [CrossRef]

- Carro, A.; Chacartegui, R.; Ortiz, C.; Carneiro, J.; Becerra, J.A. Energy storage system based on transcritical CO2 cycles and geological storage. Appl. Therm. Eng. 2021, 193, 116813. [Google Scholar] [CrossRef]

- Zhou, X.; Wu, Y.S.; Chen, H.; Elsayed, M.; Yu, W.; Zhao, X.; Murtaza, M.; Kamal, M.S.; Khan, S.Z.; Al-Abdrabalnabi, R.; et al. Review of Carbon dioxide utilization and sequestration in depleted oil reservoirs. Renew. Sustain. Energy Rev. 2024, 202, 114646. [Google Scholar] [CrossRef]

- Zhang, X.; Li, L.; Su, Y.; Fu, J.; Wang, R.; Chen, F. Microfluidic investigation on asphaltene interfaces attempts to carbon sequestration and leakage: Oil-CO2 phase interaction characteristics at ultrahigh temperature and pressure. Appl. Energy 2023, 348, 121518. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Mehrad, M.; Rukavishnikov, V.S. Carbon dioxide sequestration through enhanced oil recovery: A review of storage mechanisms and technological applications. Fuel 2024, 366, 131313. [Google Scholar] [CrossRef]

- Fareed, A.G.; Khoja, A.H.; De Felice, F.; Petrillo, A.; Sultan, M.A.; Jalalzai, Z.K.; Daood, S.S. Underground geological sequestration of carbon dioxide (CO2) and its effect on possible enhanced gas and oil recovery in a fractured reservoir of Eastern Potwar Basin, Pakistan. Sci. Total Environ. 2023, 905, 167124. [Google Scholar] [CrossRef] [PubMed]

- Syah, R.; Alizadeh, S.M.; Nasution, M.K.; Kashkouli, M.N.I.; Elveny, M.; Khan, A. Carbon dioxide-based enhanced oil recovery methods to evaluate tight oil reservoirs productivity: A laboratory perspective coupled with geo-sequestration feature. Energy Rep. 2021, 7, 4697–4704. [Google Scholar] [CrossRef]

- Shi, B.; Wang, J.; Liao, Q.; Wang, T.; Wang, S.; Yang, M.; Xiao, Y.; Zhang, H.; Song, C.; Gong, J. Simulation of multi-method CO2 capture and purification process. Nat. Gas Ind. 2021, 8, 464–474. [Google Scholar] [CrossRef]

- Chaudhry, A.U.; Muneer, R.; Lashari, Z.A.; Hashmet, M.R.; Osei-Bonsu, K.; Abdala, A.; Rabbani, H.S. Recent advancements in novel nanoparticles as foam stabilizer: Prospects in EOR and CO2 sequestration. J. Mol. Liq. 2024, 407, 125209. [Google Scholar]

- Massarweh, O.; Abushaikha, A.S. CO2 sequestration in subsurface geological formations: A review of trapping mechanisms and monitoring techniques. Earth-Sci. Rev. 2024, 253, 104793. [Google Scholar] [CrossRef]

| Extraction Method | Porosity (%) | Permeability (10−3 μm2) | Oil Saturation (%) | Saturated Oil Volume (mL) |

|---|---|---|---|---|

| steam huff and puff | 32 | 1795.6 | 71.2 | 2810 |

| alternating huff and puff | 33 | 1685.5 | 70.2 | 2821 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, L.; Yin, G.; Shi, W.; Bai, J.; Xu, Z.; Zhang, N.; Zhu, Q.; Wang, C.; Song, Y.; Cao, L. Steam-Alternating CO2/Viscosity Reducer Huff and Puff for Improving Heavy Oil Recovery: A Case of Multi-Stage Series Sandpack Model with Expanded Sizes. Processes 2024, 12, 2920. https://doi.org/10.3390/pr12122920

Tao L, Yin G, Shi W, Bai J, Xu Z, Zhang N, Zhu Q, Wang C, Song Y, Cao L. Steam-Alternating CO2/Viscosity Reducer Huff and Puff for Improving Heavy Oil Recovery: A Case of Multi-Stage Series Sandpack Model with Expanded Sizes. Processes. 2024; 12(12):2920. https://doi.org/10.3390/pr12122920

Chicago/Turabian StyleTao, Lei, Guangzhi Yin, Wenyang Shi, Jiajia Bai, Zhengxiao Xu, Na Zhang, Qingjie Zhu, Chunhao Wang, Yong Song, and Lili Cao. 2024. "Steam-Alternating CO2/Viscosity Reducer Huff and Puff for Improving Heavy Oil Recovery: A Case of Multi-Stage Series Sandpack Model with Expanded Sizes" Processes 12, no. 12: 2920. https://doi.org/10.3390/pr12122920

APA StyleTao, L., Yin, G., Shi, W., Bai, J., Xu, Z., Zhang, N., Zhu, Q., Wang, C., Song, Y., & Cao, L. (2024). Steam-Alternating CO2/Viscosity Reducer Huff and Puff for Improving Heavy Oil Recovery: A Case of Multi-Stage Series Sandpack Model with Expanded Sizes. Processes, 12(12), 2920. https://doi.org/10.3390/pr12122920