2.1. Energy Recovery Mechanism for Electric Vehicles

When an EV decelerates, it can recover energy through a regenerative braking system. During this process, the electric motor plays the role of a generator, transforming the vehicle’s kinetic energy into electrical energy and preserving it in the battery for reuse [

9,

10]. This system consists of several key components, including the bipolar transistor

, motor

, inductor

, resistor

, and capacitor

. Regenerative braking reduces energy loss and increases the range of EVs. The circuit diagram of BER is denoted in

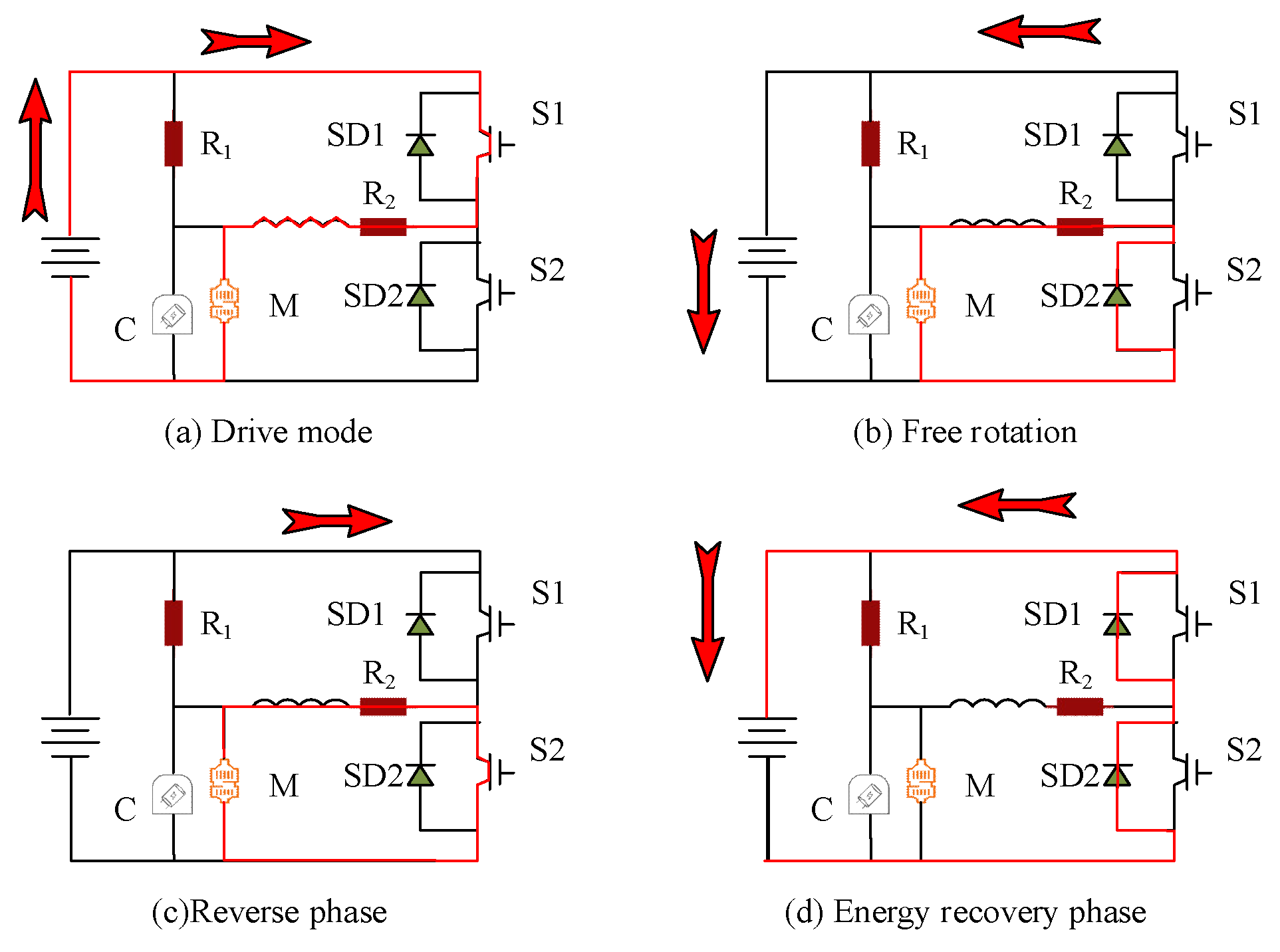

Figure 1.

In

Figure 1, the BER circuit diagram is divided into four stages. In the first stage of driving mode, as shown in

Figure 1a, the vehicle relies on an electric motor for propulsion. At this time, only when the transistor

is closed,

remains disconnected, allowing current to be extracted from the battery pack to drive the motor. In the next stage, when the vehicle starts braking, the entire system enters the “free rotation” stage, as shown in

Figure 1b. During this stage, the vehicle’s braking does not immediately cut off the current but allows the current to continue flowing through the power switch

. The third stage is the reverse phase, as shown in

Figure 1c. After the braking action is maintained for a period of time, the motor starts to work in the reverse direction. At this time, the current flow direction changes, as

is currently open and

is closed. The fourth stage is the energy recovery phase, as shown in

Figure 1d. During this period,

is turned off, and the self-inductance effect of the inductor is utilized to allow current to pass through

and charge the battery. This stage is a crucial part of the entire process for the principle of energy conservation, where the influence of vehicle transmission systems and road resistance is ignored. The EV drops from the initial speed

to the speed

during braking, and its energy conservation formula is shown in Formula (1).

In Formula (1),

represents the speed of the EV.

represents the work done by the car during braking.

represents the mass of an object in the law of conservation of kinetic energy, which specifically represents the mass of a car in the study.

represents the work done by air resistance.

represents the work done by rolling resistance. The power calculation of the input braking system is shown in Formula (2).

In Formula (2),

represents the input braking system power.

represents the instantaneous speed of the car.

represents wind resistance.

represents rolling resistance,

represents the radius of the wheel.

means the battery’s charging current.

represents the braking factor of the drive shaft, with values generally in the (0, 1) range. The power of the regenerative braking input transmission shaft is shown in Formula (3).

In Formula (3),

represents the regenerative braking factor.

represents the longitudinal deceleration of the vehicle. The research assumes that the charging efficiency of the battery is

, and the energy recovered into the battery is shown in Formula (4).

In Formula (4),

represents the speed ratio of the vehicle’s transmission.

represents the speed ratio of the main reducer of an EV. The efficiency of EVs in recovering kinetic energy is directly affected by braking distance and power generation efficiency. Therefore, during the stable braking of the vehicle, adjusting the braking torque can control the rotation speed of the motor, thus affecting the amount of current during charging. The amount of recoverable energy for braking a car is shown in Formula (5).

In Formula (5), represents the length of the entire braking distance of the car. In the BER in EVs, there are always some necessary energy consumption and energy loss, and it is generally impossible to fully achieve all energy recovery and utilization. Furthermore, the study will analyze the energy lost in this part.

2.2. Energy Recovery Analysis of Regenerative Braking Process

During the braking of EVs, there is energy consumption and even mechanical energy loss, resulting in a corresponding reduction in the storage capacity in the energy storage system. The main factors for energy reduction include friction braking, bearing mechanical loss, rotational inertia loss, transmission loss, motor loss, and energy storage loss, as shown in

Figure 2.

In

Figure 2, there are six main factors affecting energy reduction, among which external conditions, driving forms, and control strategies are more affected by environmental factors, while output torque limitation and battery SOC estimation during motor braking are more affected by their own factors. Therefore, the study mainly analyzes these two factors [

11,

12]. The power generation efficiency of the motor itself is greatly affected by the motor speed and output torque. The functional relationship between the motor speed and the motor torque is denoted in

Figure 3.

In

Figure 3, when the actual speed is lower than the motor speed, the motor will output the maximum torque according to a fixed torque value, and the motor is in constant torque mode. On the contrary, if the threshold is exceeded, the motor enters a constant power mode to maintain a stable output power. The mathematical relationship between the actual wheel speed and the motor speed during the braking task of an EV can be indicated by Formula (6) [

13].

In Formula (6),

represents the motor speed.

represents transmission efficiency. According to the motor peak characteristic curve in

Figure 3, the method of motor torque is indicated in Formula (7).

In Formula (7),

represents the value of motor speed.

represents the maximum torque.

represents maximum power, and

represents the torque in dynamic changes. Therefore, the expression for the regenerative braking force of automobiles under the peak torque limit of the generator is shown in Formula (8).

Through Formula (8), it can be observed that when an EV is subjected to rapid braking, the motor speed will correspondingly increase. However, at this point, the braking torque of the motor will become smaller, which limits the efficiency of regenerative BER. After high-voltage electricity is converted into low-voltage electricity through a power converter, these low-voltage currents are then stored in the battery, providing a mechanism for EVs to capture and utilize energy [

14]. The relationship between SOC and charging current is shown in

Figure 4.

In

Figure 4, the relationship between the controller and the SOC value can be seen. When the SOC value is low, the motor can achieve regenerative braking. When the SOC value is high, the motor will stop regenerative braking. To solve the problems of uncertainty and complex nonlinear system processing in the kinetic energy recovery of EVs, a fuzzy control strategy will be adopted for real-time and adaptable energy management, ensuring that the regenerative braking process can realize efficient energy recovery under various working conditions and effectively protect the battery.

2.3. Energy Control Strategy for Electric Vehicles Based on Improved Fuzzy Control

The research will achieve intelligent adjustment of key parameters such as motor speed, torque, and battery SOC by designing appropriate fuzzy rule sets and membership functions. When studying the fuzzy control strategy of composite power supply for pure EVs, the total power

required by the vehicle, the state variable

of the power battery, and the state variable

of the supercapacitor were considered as inputs to the control system. The key parameter outputted by the controller is the energy distribution coefficient

of the supercapacitor, which is used to guide how the composite power supply provides power. When supplying power to cars through this system, the calculation of the above indicator parameters is shown in Formula (9) [

15,

16].

In Formula (9), the required power of the supercapacitor is represented by

, the required power of the power battery pack is represented by

, and the required power of the motor is represented by

. When pure EVs are in operation, the allocation ratio

of supercapacitors should be fuzzified within the range of 0 to 1. To ensure the stable power output of the power battery, it is necessary to set appropriate value ranges for the charging state

of the power battery and the charging state

of the supercapacitor. The research sets the state value range of the power battery between 0.20 and 0.95, and considering the inherent loss of supercapacitors when outputting energy, its state value range is therefore set to 0.25 to 0.75. By introducing the allocation ratio

of motor demand power, the study aims to appropriately map input variables to their corresponding fuzzy intervals, simplifying the conversion process in the calculation process. The fuzzy range of the allocation ratio

between

and supercapacitors is also set to the range of 0 to 1. In the above system, the fuzzification category of

and

are set to

. The categories of

and

are set to

. The initial input variables are used in the fuzzy control system, and these variables usually represent the state of the electric vehicle under various working conditions. Therefore, the initial input variables are battery SOC, driving demand power, and supercapacitor charge state. The language values of the input and output variables were low (0.0–0.3), medium (0.3–0.7), and high (0.7–1.0). Driving demand power (0–0.5* maximum power), medium (0.5* maximum power–0.8* maximum power), high (0.8* maximum power–maximum power); Supercapacitor SOCs are low (0.0–0.3), medium (0.3–0.7), and high (0.7–1.0). The output variables and language values are low (0.0–0.3), medium (0.3–0.7), and high (0.7–1.0). The inference rules are formulated based on the relationship between the input variables and how they affect the output variables. Specifically, if the battery SOC is high and the driving demand power is low, the supercapacitor allocation coefficient is medium. If the battery SOC is medium, and the driving demand power is medium, the supercapacitor allocation coefficient is high; If the battery SOC is low and the supercapacitor SOC is low, the supercapacitor allocation coefficient is low. If the driving demand power is high and the supercapacitor SOC is high, the supercapacitor allocation coefficient is medium; If the battery SOC is low and the driving demand power is high, the ultracapacitor allocation coefficient is low. The study sets fuzzy rules based on the above information, as shown in

Figure 5.

In

Figure 5, the charging status of the power battery pack and supercapacitor pack is managed through dedicated control subsets, respectively. These subsets are distinguished based on Z-shaped, Gaussian-shaped, and S-shaped membership functions, representing relatively low (

and

) and moderate (

,

,

) and relatively high (

and

) membership. However, under such a fuzzy control framework, excessive reliance on manual tuning may lead to insufficient adaptation of the system to rapidly changing environments, thereby affecting response speed and control efficiency. In the above fuzzy control, manual adjustment is mainly relied on. In the face of rapidly changing working conditions, the response time and execution efficiency of the control system are poor. Therefore, the study will use SSA to optimize fuzzy control [

17,

18]. There are three types of sparrows in the SSA, each with different action patterns, including “discoverers”, “followers”, and “vigilantes”. The study uses

to represent the variable of the number of sparrows, and then the position update strategy of the “discoverer” sparrow is denoted using Formula (10) [

19].

In Formula (10), the step of defining

as the number of iterations is studied.

is the position update variable for sparrows. The variable

is a random number in the interval [0, 1].

means the value of an alarm signal.

is a set safety value, while

is a random variable that follows a normal distribution, and

represents a matrix. When the value of

is lower than

, it means that sparrows are in a safe foraging area. If

is greater than

, it denotes that the area where the sparrow is located is threatened. As for the follower-type sparrows, updating their position depends on their respective fitness. If their adaptability is poor, it means they cannot obtain food like the discoverer and need to leave the current area in search of new sources of food. If the fitness is good, it can search for food near the optimal sparrow. The position update method of the follower type sparrow is denoted in Formula (11) [

20].

In Formula (11),

represents the worst individual region.

represents the best individual region. The expression for updating the position of a sparrow of the vigilante type is shown in Formula (12).

In Formula (12),

represents the optimal position sought, while

is a step size control parameter.

represents a random value within the interval [−1, 1].

is a non-zero constant, and

represents the individual’s fitness value. When managing the composite power supply of pure EVs, it will consider two main energy management modes: energy output and recovery. In power supply mode, supercapacitors are the preferred energy source. However, in the BER mode, if the SOC level of the supercapacitor is high, the task of BER is transferred to the battery to complete. According to the fuzzy control optimized by SSA, the fuzzification and variation trend of its variables are shown in

Figure 6.

From

Figure 6, in the early stages of the SSA optimization, it is necessary to conduct extensive global exploration through a large number of discoverers. As the algorithm progresses and continues to iterate, the number of discoverers should be gradually reduced in order to concentrate on completing a local and detailed search of the solution space. At the same time, the relationship between population diversity and the proportion of discoverers also needs to be considered. When population diversity is insufficient, the number of discoverers should be increased to achieve in-depth exploration of the search space. However, once the population exhibits high diversity, the share of discoverers can be correspondingly reduced to promote search centralization. In the SSA algorithm, first define the size of the sparrow population, for example, set to 50. Each sparrow in the population is divided into three categories: finder, follower, and watcher. Initially, all sparrows randomly initialize their positions in the search space. Next, the performance of each sparrow was assessed against the fitness function, which is an indicator related to the target problem. Sparrows with the highest fitness score of 70% were labeled as finders. These sparrows are responsible for searching within safe feeding areas to find a better solution. Ten percent of sparrows with fitness scores in the medium range were designated followers. The sparrows learn from the location of the finder, move closer to it, and make appropriate adjustments. Sparrows with the lowest 20 percent fitness scores were marked as watchdogs, avoiding possible predators by constantly changing positions while trying to improve their fitness.