Reactivation of Abandoned Oilfields for Cleaner Energy Generation: Three-Dimensional Modelling of Reservoir Heterogeneity and Geometry

Abstract

1. Introduction

1.1. Background of Air Injection

1.2. Reservoir Heterogeneity

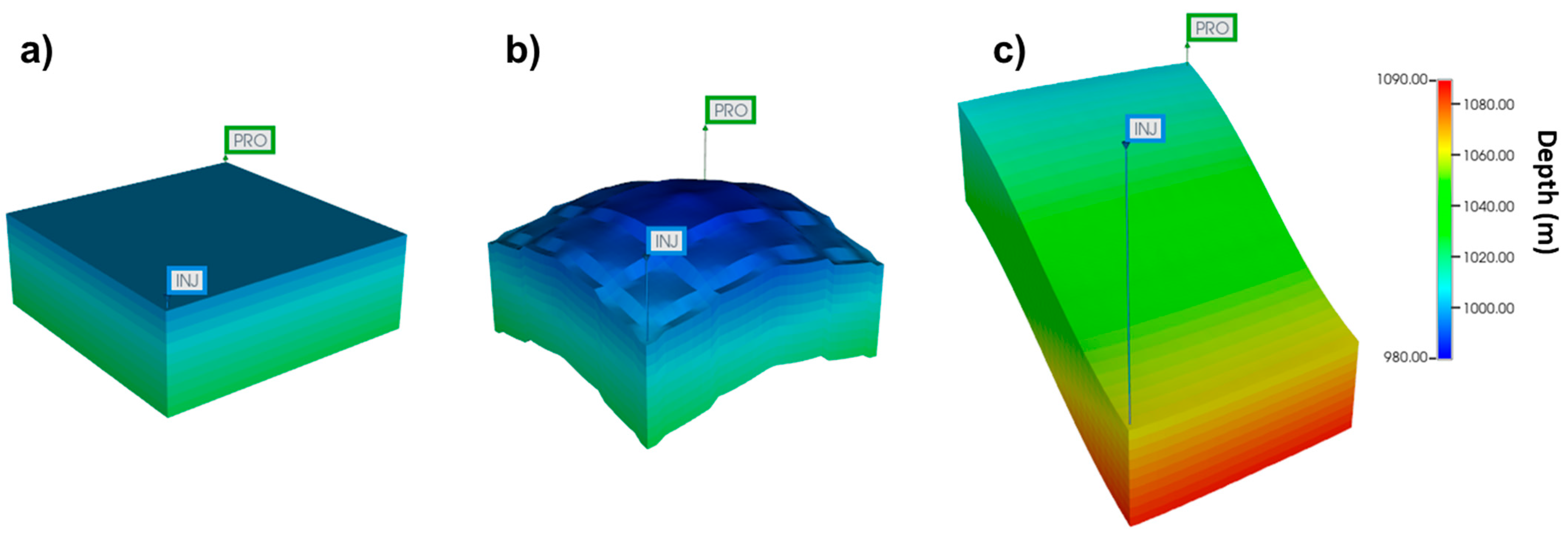

1.3. Reservoir Trap Geometry

- A four-way dip closure structure, also known as a periclinal fold;

- A tilted fault block, and;

- The added influence of randomly distributed, facies-controlled, and diagenetically controlled heterogeneity within these trap structures.

2. Methodology

2.1. Fluid and Reaction Models

| Component | API Gravity | MW | C Atoms | Pc | Tc | KV1 | KV4 | KV5 | ρ | β | α | μ @ 38 °C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| °API | kg mol−1 | kPa | °C | kPa | °C | °C | kg m−3 | kPa−1 | °C−1 | Cp | ||

| Heavy oil | 14 | 0.355 | 22 | 853.1 | 508.8 | 1,726,140 | −5214.3 | −114.5 | 928.4 | 9.08 × 10−7 | 2.96 × 10−3 | 2118.8 |

| Light oil | - | 0.027 | - | 2710.0 | 318.5 | 4,890,000 | −4655.9 | −273.2 | 742.0 | 1.00 × 10−6 | 9.00 × 10−4 | 40.1 |

| H2O | - | 0.018 | - | - | - | - | - | - | 994.9 | 4.43 × 10−7 | 3.79 × 10−4 | 0.8 |

| CO2 | - | 0.028 | - | 7376.4 | 31.1 | 5,323,400 | −2002.1 | −273.2 | 500.0 | 5.98 × 10−6 | 2.96 × 10−3 | 0.1 |

| O2 | - | 0.032 | - | 5046.0 | −118.6 | 5,323,400 | - | - | - | - | - | - |

| NCG | - | 0.028 | - | 3394.4 | −147.0 | 906,661 | −705.2 | −273.2 | 318.0 | 6.00 × 10−6 | 3.00 × 10−5 | 1.7 |

| Coke | - | 0.012 | - | - | - | - | - | - | 917.0 | - | - | - |

| Geo-Model | Sub-Model | Geometry | Type | Porosity (%) | Permeability (mD) | kv/kh | V |

|---|---|---|---|---|---|---|---|

| 1 | A | Cube | Uniform | 20 | 700 | 0.1 | 0 |

| B | Cube | Random | 20 | 700 | 0.1 | 0.66 | |

| C | Cube | Facies | 5 (20 Channel) | 7 (700) | 0.1 | 0.05 | |

| D | Cube | Layered | 5 (20) | 8 (700) | 0.1 | 0.95 | |

| 2 | A | Pericline | Uniform | 20 | 700 | 0.1 | 0 |

| B | Pericline | Random | 20 | 700 | 0.1 | 0.66 | |

| C | Pericline | Facies | 5 (20 Channel) | 7 (700) | 0.1 | 0.05 | |

| D | Pericline | Layered | 5 (20) | 8 (700) | 0.1 | 0.95 | |

| 3 | A | Tilted block | Uniform | 20 | 700 | 0.1 | 0 |

| B | Tilted block | Random | 20 | 700 | 0.1 | 0.66 | |

| C | Tilted block | Facies | 5 (20 Channel) | 7 (700) | 0.1 | 0.05 | |

| D | Tilted block | Layered | 5 (20) | 8 (700) | 0.1 | 0.95 |

2.2. Geological Models

2.3. Key Aspects of Model Outputs

3. Results

3.1. Petrophysically Homogeneous Models (Model A)

3.1.1. Cube Geometry (Model 1-A)

3.1.2. Four-Way Dip Closure (Model 2-A)

3.1.3. Tilted Fault Block (Model 3-A)

3.2. Randomly Distributed Petrophysical Heterogeneity (Model B)

3.2.1. Cube Geometry (Model 1-B)

3.2.2. Four-Way Dip Closure (Model 2-B)

3.2.3. Tilted Fault Block (Model 3-B)

3.3. Facies Controlled Petrophysical Heterogeneity (Model C)

3.3.1. Cube Geometry (Model 1-C)

3.3.2. Four-Way Dip Closure (Model 2-C)

3.3.3. Tilted Fault Block (Model 3-C)

3.4. Diagenetically Controlled Petrophysically Layered Reservoir (Model D)

3.4.1. Cube Geometry (Model 1-D)

3.4.2. Four-Way Dip Closure (Model 2-D)

3.4.3. Tilted Fault Block (Model 3-D)

3.5. Effect on Enthalpy at the Production Well

4. Comparison of Models and Discussion

4.1. The Effect of Trap Geometry

4.1.1. Trap Geometry and Temperature

Homogeneous Reservoir

Randomly Distributed Heterogeneity

Facies Controlled Heterogeneity

Layered Reservoir

4.1.2. Trap Geometry and Velocity

Homogeneous Reservoir

Randomly Distributed Heterogeneity

Facies Controlled Heterogeneity

Layered Reservoir

4.1.3. Trap Geometry and Fire Front Propagation Stability

Homogeneous

Randomly Distributed Heterogeneity

Facies Controlled Heterogeneity

Layered Model

4.1.4. Trap Geometry and Enthalpy

4.2. The Effect of Heterogeneity

4.2.1. Type of Heterogeneity and Temperature

Cube

Periclinal Fold

Tilted Fault Block

4.2.2. Type of Heterogeneity and Velocity

Cube

Periclinal Fold

Tilted Fault Block

4.2.3. Type of Heterogeneity and Fire Front Propagation Stability

Cube

Periclinal Fold

Tilted Fault Block

4.2.4. Types of Heterogeneity and Enthalpy

4.3. Overall Controls

4.4. Significance and Limitations of Models

- The grid block size used to represent the heterogeneity of the reservoirs is not sufficiently fine to resolve any sub-metre-scale heterogeneities that might be present, it is however necessary to upscale when running a field scale simulation.

- The channelled heterogeneity models do not include random heterogeneity that may be present within both the channel and surrounding media.

- The heavy oil component of the reaction scheme is based on correlations of viscosity and API gravity from literature sources rather than experimental data. It would be preferable to generate new kinetic data from a specific depleted field that is planned for ISC exploitation using dedicated laboratory analyses.

- Related to the previous limitation, the four-reaction combustion scheme is a necessary simplification of the complexity of thermal breakdown and oxidation reactions that occur during ISC. More sophisticated reaction schemes may be required after reservoir selection because oil compositions are unique to each reservoir.

5. Conclusions

- A periclinal four-way dip closure generally acts to increase the temperature of the fire front in all heterogeneous models, with the exceptions of the channelled model, though the temperatures seen in the homogenous cube model are anomalously high. In all cases, the pericline geometry acts to decrease the velocity of the fire front compared to the cube model. This effect is greater towards the top layers than the lower layers of the grid. The effect of the periclinal fold on propagation stability of the fire front is generally negligible other than the upper layer of the homogeneous model and the channelled model. However there is no considerable fire front developed.

- The tilted fault block acts to decrease the temperature of the fire front in the homogeneous and randomly distributed heterogeneity model in the lower layers and increase it in the upper two layers. The effect on temperature in the channelled model is of no consequence as there is no significant fire front formed in these models. In the layered model, the temperature is increased in all but Layer 9 in the tilted fault block when compared to the cube model, although the temperature is anomalously higher in the lower layer of these models. The effect on velocity in the tilted fault block is ambiguous depending on the heterogeneity. There is a strong effect on the propagation stability in the tilted fault block; regardless of the heterogeneity present, there is always a preference for the fire front to migrate up-dip and, in this case, to the top-left of the grid.

- The strongest effect of the heterogeneity is on the propagation stability, with the channel causing the fire front to meander in the direction of the structure as well as the randomly distributed porosity and permeability having some minor influence on the direction of the movement of the fire front. There is an effect on peak temperature observed between the different heterogeneities with the temperature decreasing with the addition of a channel, as in these models, there is no significant fire front formed in any case other than the cube model. The layered system always has increased temperature in the lower layers of the grid when compared to all but the cube model. The effect of the addition of heterogeneity on velocity shows an increase in all layered models, in particular in the lower layers of the reservoir. Whereas the cube model shows a higher velocity at the top, and lower at the bottom, the layered model has a broadly uniform distribution of velocity through the layers than the homogeneous model, which has a much higher velocity at the top.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Templeton, J.D.; Ghoreishi-Madiseh, S.A.; Hassani, F.; Al-Khawaja, M.J. Abandoned petroleum wells as sustainable sources of geothermal energy. Energy 2014, 70, 366–373. [Google Scholar] [CrossRef]

- Li, K.; Zhang, L. Exceptional enhanced geothermal systems from oil and gas reservoirs. In Proceedings of the Thirty-Third Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 28–30 January 2008. [Google Scholar]

- Han, Y.; Li, K.; Jia, L. Modeling study on reviving abandoned oil reservoirs by in situ combustion without CO2 production while recovering both oil and heat. J. Energy Resour. Technol. 2021, 143, 082902. [Google Scholar] [CrossRef]

- Storey, B.M.; Worden, R.H.; McNamara, D.D. The geoscience of in-situ combustion and high-pressure air injection. Geosciences 2022, 12, 340. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, K.; Liu, C.; Mgijimi, M.B. Geothermal power production from abandoned oil reservoirs using in situ combustion technology. Energies 2019, 12, 4476. [Google Scholar] [CrossRef]

- Antolinez, J.D.; Miri, R.; Nouri, A. In situ combustion: A comprehensive review of the current state of knowledge. Energies 2023, 16, 6306. [Google Scholar] [CrossRef]

- Cheng, W.-L.; Li, T.-T.; Nian, Y.-L.; Xie, K. Evaluation of working fluids for geothermal power generation from abandoned oil wells. Appl. Energy 2014, 118, 238–245. [Google Scholar] [CrossRef]

- Cinar, M. Creating enhanced geothermal systems in depleted oil reservoirs via in situ combustion. In Proceedings of the Thirty-Eigth Workshop on Geothermal Reservoir Enginerring, Stanford, CA, USA, 11–13 February 2013. [Google Scholar]

- Shepherd, M. Chapter 5—Factors influencing recovery from oil and gas fields. In Oil Field Production Geology. AAPG Memoir 9; American Association of Petroleum Geologists: Tulsa, OK, USA, 2009; pp. 37–46. [Google Scholar]

- Chattopadhyay, S.K.; Binay, R.; Bhattacharya, R.N.; Das, T.K. Enhanced oil recovery by in-situ combustion process in Santhal Field of Cambay Basin, Mehsana, Gujarat, India—A case study. In Proceedings of the SPE/DOE Fourteenth Symposium on Improved Oil Recovery, Tulsa, OK, USA, 17–21 April 2004. [Google Scholar]

- Kovscek, A.R.R.; Castanier, L.M.M.; Gerritsen, M.G.G. Improved predictability of in-situ-combustion enhanced oil recovery. Soc. Pet. Eng. Reserv. Eval. Eng. 2013, 16, 172–182. [Google Scholar] [CrossRef]

- Mahinpey, N.; Ambalae, A.; Asghari, K. In situ combustion in enhanced oil recovery (EOR): A review. Chem. Eng. Commun. 2007, 194, 995–1021. [Google Scholar] [CrossRef]

- Ado, M.R. A detailed approach to up-scaling of the Toe-to-Heel Air Injection (THAI) In-Situ Combustion enhanced heavy oil recovery process. J. Pet. Sci. Eng. 2020, 187, 106740. [Google Scholar] [CrossRef]

- Hvizdos, L.J.; Howard, J.V.; Roberts, G.W. Enhanced oil recovery through oxygen-enriched in-situ combustion: Test results from the Forest Hill Field in Texas. J. Pet. Technol. 1983, 35, 1061–1070. [Google Scholar] [CrossRef]

- Ado, M.R. Improving heavy oil production rates in THAI process using wells configured in a staggered line drive (SLD) instead of in a direct line drive (DLD) configuration: Detailed simulation investigations. J. Pet. Explor. Prod. Technol. 2021, 11, 4117–4130. [Google Scholar] [CrossRef]

- Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. A guide to high pressure air injection (HPAI) based oil recovery. In Proceedings of the Society of Petroleum Engineers/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 13–17 April 2002. [Google Scholar]

- Malozyomov, B.V.; Martyushev, N.V.; Kukartsev, V.V.; Tynchenko, V.S.; Bukhtoyarov, V.V.; Wu, X.; Tyncheko, Y.A.; Kukartsev, V.A. Overview of methods for enhanced oil recovery from conventional and unconventional reservoirs. Energies 2023, 16, 4907. [Google Scholar] [CrossRef]

- Speight, J.G. Thermal methods of recovery. In Heavy Oil Production Processes; Elsevier Science & Technology: Saint Louis, MO, USA, 2013; pp. 93–130. [Google Scholar]

- Babadagli, T. Philosophy of EOR. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019. [Google Scholar]

- Alvarado, V.; Manrique, E. Enhanced oil recovery: An update review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Ren, S.R.; Greaves, M.; Rathbone, R.R. Air injection LTO Process: An IOR technique for light-oil reservoirs. Soc. Pet. Eng. J. 2002, 7, 90–99. [Google Scholar] [CrossRef]

- Sarathi, P.S. In-Situ Combustion Handbook—Principles and Practices; Office of Scientific and Technical Information (OSTI): Tulsa, OK, USA, 1999.

- Wolcott, E.R. Method of Increasing the Yield of Oil Wells. U.S. Patent 1,457,479, 5 June 1923. [Google Scholar]

- Wu, C.H.; Fulton, P.F. Experimental simulation of the zones preceding the combustion front of an in-situ combustion process. Soc. Pet. Eng. J. 1971, 11, 38–46. [Google Scholar] [CrossRef]

- Gluyas, J.G.; Swarbrick, R.E. Petroleum Geoscience; Blackwell Publishing: Malden, MA, USA, 2004. [Google Scholar]

- Gluyas, J.G.; Arkley, P. The Innes Field, Block 30/24, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 488–497. [Google Scholar] [CrossRef]

- Tucker, M.E. Sedimentary Petrology an Introduction to the Origin of Sedimentary Rocks/Maurice E. Tucker, 3rd ed.; Blackwell Science: Oxford, UK, 2001. [Google Scholar]

- Tillman, R.W.; Weber, K.J. Reservoir Sedimentology; Society of Economic Paleontologists and Mineralogists: Tulsa, OK, USA, 1987. [Google Scholar]

- Morad, S.; Al-Ramadan, K.; Ketzer, J.M.; De Ros, L.F. The impact of diagenesis on the heterogeneity of sandstone reservoirs: A review of the role of depositional facies and sequence stratigraphy. AAPG Bull. 2010, 94, 1267–1309. [Google Scholar] [CrossRef]

- Moraes, M.A.S.; Surdam, R.C. Diagenetic heterogeneity and reservoir quality: Fluvial, deltaic, and turbiditic sandstone reservoirs, Potiguar and Reconcavo rift basins, Brazil. AAPG Bull. 1993, 77, 1142–1158. [Google Scholar] [CrossRef]

- van de Graaff, W.J.E.; Ealey, P.J. Geological modeling for simulation studies. AAPG Bull. 1989, 73, 1436–1444. [Google Scholar] [CrossRef]

- Burchette, T.P. Carbonate rocks and petroleum reservoirs: A geological perspective from the industry. Adv. Carbonate Explor. Reserv. Anal. 2012, 370, 17–37. [Google Scholar] [CrossRef]

- Jahn, F.; Cook, M.; Graham, M. Hydrocarbon Exploration and Production by Frank Jahn, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Dandekar, A.Y. Petroleum Reservoir Rock and Fluid Properties, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Sun, X.; Alcalde, J.; Gomez-Rivas, E.; Owen, A.; Griera, A.; Martín-Martín, J.D.; Cruset, D.; Travé, A. Fluvial sedimentation and its reservoir potential at foreland basin margins: A case study of the Puig-reig anticline (South-eastern Pyrenees). Sediment. Geol. 2021, 424, 105993. [Google Scholar] [CrossRef]

- Roger, G.W. Deep-water sandstone facies and ancient submarine fans: Models for exploration for stratigraphic traps. AAPG Bull. 1978, 62, 932–966. [Google Scholar] [CrossRef]

- Braccini, E.; de Boer, W.; Hurst, A.; Huuse, M.; Vigorito, M.; Templeton, G. Sand injectites. Oilfield Rev. 2008, 20, 34–49. [Google Scholar]

- Glennie, K. Petroleum Geology of the North Sea: Basic Concepts and Recent Advances; Wiley-Blackwell: Hoboken, NJ, USA, 2009. [Google Scholar]

- Robertson, K.; Heath, R.; Macdonald, R. The Blane Field, Block 30/3a, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 382–389. [Google Scholar] [CrossRef]

- Robertson, A.G.; Ball, M.; Costaschuk, J.; Davidson, J.; Guliyev, N.; Kennedy, B.; Leighton, C.; Nash, T.; Nicholson, H. The Clair Field, Blocks 206/7a, 206/8, 206/9a, 206/12a and 206/13a, UK Atlantic Margin. Geol. Soc. Lond. Mem. 2020, 52, 931–951. [Google Scholar] [CrossRef]

- Parkes, L.; Wood, P.; Macdonald, C. The Kraken and Kraken North fields, Block 9/2b, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 863–874. [Google Scholar] [CrossRef]

- Moore, I.; Archer, J.; Peavot, D. The Alba Field, Block 16/26a, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 637–650. [Google Scholar] [CrossRef]

- Hodgins, B.; Moy, D.J.; Carnicero, P.A. The Captain Field, Block 13/22a, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 705–716. [Google Scholar] [CrossRef]

- Pelletier, F.; Gunn, C. The Gryphon, Maclure, Tullich and Ballindalloch fields, Blocks 9/18b, 9/18c, 9/19a, 9/23d and 9/24e, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 837–849. [Google Scholar] [CrossRef]

- Kelly, S.; Worden, R.H.; Mc Ardle, P. The value of core in mature field development—Examples from the UK North Sea. Geol. Soc. Spec. Publ. 2023, 527, 261–278. [Google Scholar] [CrossRef]

- Lawan, A.Y.; Worden, R.H.; Utley, J.E.P.; Crowley, S.F. Sedimentological and diagenetic controls on the reservoir quality of marginal marine sandstones buried to moderate depths and temperatures: Brent Province, UK North Sea. Mar. Pet. Geol. 2021, 128, 104993. [Google Scholar] [CrossRef]

- Fitch, P.J.R.; Lovell, M.A.; Davies, S.J.; Pritchard, T.; Harvey, P.K. An integrated and quantitative approach to petrophysical heterogeneity. Mar. Pet. Geol. 2015, 63, 82–96. [Google Scholar] [CrossRef]

- Wells, M.; Bowman, A.; Kostic, B.; Campion, N.; Finucane, D.; Santos, C.; Kitching, D.; Brown, R.; AlAnzi, H.R.; Rahmani, R.A.; et al. Lower Cretaceous deltaic deposits of the main pay reservoir, Zubair Formation, southeast Iraq: Depositional controls on reservoir performance. In Siliciclastic Reservoirs of the Arabian Plate; The American Association of Petroleum Geologists: Tulsa, OK, USA, 2019; Volume 116, pp. 219–260. [Google Scholar]

- Tiab, D.; Donaldson, E.C. Petrophysics Theory and Practice of Measuring Reservoir Rock and Fluid Transport Properties, 5th ed.; Gulf Professional Pubishing: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Bjørlykke, K. Petroleum Geoscience from Sedimentary Environments to Rock Physics, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Brown, A.M.; Milne, A.D.; Kay, A. The Thistle Field, Blocks 211/18a, 211/19a, UK North Sea. Geol. Soc. Lond. Mem. 2003, 20, 383–392. [Google Scholar] [CrossRef]

- Rose, P.T.S.; Byerley, G.W.; College, E.; Pyle, J.R.; Ralph, D.J.; Rowbotham, P.S.; Oorschot, L.A.v.; Towart, J.; Vaughan, O.; Vermaas, M. The Forties Field, Blocks 21/10 and 22/6a, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 454–467. [Google Scholar] [CrossRef]

- Mackertich, D. The Fife Field, UK central North Sea. Pet. Geosci. 1996, 2, 373–380. [Google Scholar] [CrossRef]

- Bottia-Ramirez, H.; Aguillon-Macea, M.; Lizcano-Rubio, H.; Delgadillo-Aya, C.L.; Gadelle, C. Numerical modeling on in-situ combustion process in the Chichimene Field: Ignition stage. J. Pet. Sci. Eng. 2017, 154, 462–468. [Google Scholar] [CrossRef]

- Ito, Y.; Chow, A.K.-Y. A field scale in-situ combustion simulator with channeling considerations. Soc. Pet. Eng. Reserv. Eng. 1988, 3, 419–430. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, C.; Chen, Y.; Gong, Y.; Song, Y.; Tang, J. In-situ combustion simulation from laboratory to field scale. Geofluids 2021, 2021, 8153583. [Google Scholar] [CrossRef]

- Ado, M.R. Comparisons of predictive ability of THAI in situ combustion process models with pre-defined fuel against that having fuel deposited based on Arrhenius kinetics parameters. J. Pet. Sci. Eng. 2022, 208, 109716. [Google Scholar] [CrossRef]

- Ji, D.; Xu, J.; Lyu, X.; Li, Z.; Zhan, J. Numerical modeling of the steam chamber ramp-up phase in steam-assisted gravity drainage. Energies 2022, 15, 2933. [Google Scholar] [CrossRef]

- Yang, M.; Harding, T.G.; Chen, Z. Field-scale modeling of hybrid steam and in-situ-combustion recovery process in oil-sands reservoirs using dynamic gridding. Soc. Pet. Eng. Reserv. Eval. Eng. 2019, 23, 311–325. [Google Scholar] [CrossRef]

- CMG. STARS User Manual. 2020, 2020.24. Available online: https://www.cmgl.ca/solutions/software/stars/ (accessed on 6 December 2024).

- Vinsome, P.K.W.; Westerveld, J. A simple method for predicting cap and base rock heat losses in’ thermal reservoir simulators. J. Can. Pet. Technol. 1980, 19, PETSOC-80-03-04. [Google Scholar] [CrossRef]

- Esmail, M.N. Problems in numerical simulation of heavy oil reservoirs. J. Can. Pet. Technol. 1985, 24, 80–82. [Google Scholar] [CrossRef]

- Silcock, S.Y.; Baptie, R.J.; Iheobi, A.; Frost, S.; Simms, A.; Brettle, M. The Mariner Field, Block 9/11a, UK North Sea. Geol. Soc. Lond. Mem. 2020, 52, 886–896. [Google Scholar] [CrossRef]

- Ng, J.T.H.; Egbogah, E.O. An improved temperature-viscosity correlation for crude oil systems. In Proceedings of the 34th Annual Technical Meeting of The Petroleum Society, Banff, AB, Canada, 10–13 May 1983. [Google Scholar]

- Standing, M.B. A pressure-volume-temperature correlation for mixtures of California oils and gases. In Drilling and Production Practice; OnePetro: Richardson, TX, USA, 1947. [Google Scholar]

- Storey, B.M.; Worden, R.H.; McNamara, D.D.; Wheeler, J.; Parker, J.; Kristen, A. One-dimensional modelling of air injection into abandoned oil fields for heat generation. Geoenergy 2024, 2, geoenergy2023-050. [Google Scholar] [CrossRef]

- Esmaeili, S.; Sarma, H.; Harding, T.; Maini, B. Correlations for effect of temperature on oil/water relative permeability in clastic reservoirs. Fuel 2019, 246, 93–103. [Google Scholar] [CrossRef]

- Crookston, R.B.; Culham, W.E.; Chen, W.H. A numerical simulation model for thermal recovery processes. Soc. Pet. Eng. J. 1979, 19, 37–58. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, J.J. Numerical modeling on air injection in a light oil reservoir: Recovery mechanism and scheme optimization. Fuel 2016, 172, 70–80. [Google Scholar] [CrossRef]

- Anderson, T.I.; Kovscek, A.R. Analysis and comparison of in-situ combustion chemical reaction models. Fuel 2022, 311, 122599. [Google Scholar] [CrossRef]

- Kozeny, J. Über kapillare Leitung des Wassers im Boden: (Aufstieg, Versickerung und Anwendung auf die Bewässerg); Hölder-Pichler-Tempsky, A.-G. [Abt.: ] Akad. d. Wiss.: Vienna, Austria, 1927. [Google Scholar]

- Carman, P.C. Fluid flow through granular beds. Chem. Eng. Res. Des. 1997, 75, S32–S48. [Google Scholar] [CrossRef]

- Dykstra, H.; Parsons, R. The prediction of oil recovery by water flood. Second. Recovery Oil United States 1950, 2, 160–174. [Google Scholar]

- Adagulu, G.D.; Akkutlu, I.Y. Influence of in-situ fuel deposition on air injection and combustion processes. J. Can. Pet. Technol. 2007, 46, 54–61. [Google Scholar] [CrossRef]

- Akkutlu, I.Y.; Yortsos, Y.C. The effect of heterogeneity on in-situ combustion: Propagation of combustion fronts in layered porous media. Soc. Pet. Eng. J. 2005, 10, 394–404. [Google Scholar] [CrossRef]

- Awoleke, O.G. An experimental investigation of in-situ combustion in heterogeneous media. In Proceedings of the SPE Annual Technical Conference and Exhibition, Anaheim, CA, USA, 11–14 November 2007. [Google Scholar]

- Muggeridge, A.; Cockin, A.; Webb, K.; Frampton, H.; Collins, I.; Moulds, T.; Salino, P. Recovery rates, enhanced oil recovery and technological limits. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20120320. [Google Scholar] [CrossRef]

| Reservoir Properties and Initial Conditions | Value |

|---|---|

| Reservoir property | |

| Initial reservoir temperature (°C) | 38 |

| Initial reservoir pressure (kPa) | 10,000 |

| Oil saturation | 0.5 |

| Water saturation | 0.5 |

| Reservoir geometry | |

| Dimensions i, j, k (m) | 70 × 70 × 25 |

| Dimensions i, j, k (grid blocks) | 29 × 29 × 10 |

| Depth (m) | 1000 |

| Rock and fluid thermal properties | |

| Formation compressibility (kPa−1) | 1.80 × 10−5 |

| Volumetric heat capacity (J m−3 °C−1) | 2.35 × 106 |

| Thermal conductivity phase mixing reservoir rock (J m−3 °C−1) | 1.50 × 105 |

| Oil phase heat capacity (J m−3 °C−1) | 1.15 × 105 |

| Water phase heat capacity (J m−3 °C−1) | 5.45 × 104 |

| Gas phase heat capacity (J m−3 °C−1) | 4000 |

| Volumetric heat capacity—overburden (J m−3 °C−1) | 2.35 × 106 |

| Volumetric heat capacity—underburden (J m−3 °C−1) | 2.35 × 106 |

| Thermal conductivity—overburden (J m−1 day °C−1) | 1.50 × 105 |

| Thermal conductivity—underburden (J m−1 day °C−1) | 1.50 × 105 |

| Well constraints | |

| Injector well constraints—BHP Max (kPa) | 11,000 |

| Injector well constraints—surface gas rate max (m3 day−1) | 15,000 |

| Producer well constraints—BHP min (kPa) | 9800 |

| Injected fluid | |

| Injected fluid—inert gas (mole fraction) | 0.79 |

| Injected fluid—oxygen (mole fraction) | 0.21 |

| Injected fluid—temperature (°C) | 15 |

| Injected fluid—pressure (kPa) | 12,000 |

| Reaction | Ea1 (J mol−1) | A (day−1 kPa−1) | H (J mol−1) |

|---|---|---|---|

| 1 | 2.10 × 105 | 3.34 × 1016 | 0 |

| 2 | 1.32 × 105 | 5.69 × 1012 | 2.01 × 107 |

| 3 | 5.34 × 104 | 4.86 × 1011 | 2.16 × 106 |

| 4 | 3.41 × 104 | 2.49 × 105 | 2.00 × 105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Storey, B.M.; Worden, R.H.; McNamara, D.D.; Wheeler, J.; Parker, J.; Kristen, A. Reactivation of Abandoned Oilfields for Cleaner Energy Generation: Three-Dimensional Modelling of Reservoir Heterogeneity and Geometry. Processes 2024, 12, 2883. https://doi.org/10.3390/pr12122883

Storey BM, Worden RH, McNamara DD, Wheeler J, Parker J, Kristen A. Reactivation of Abandoned Oilfields for Cleaner Energy Generation: Three-Dimensional Modelling of Reservoir Heterogeneity and Geometry. Processes. 2024; 12(12):2883. https://doi.org/10.3390/pr12122883

Chicago/Turabian StyleStorey, Benjamin Michael, Richard H. Worden, David D. McNamara, John Wheeler, Julian Parker, and Andre Kristen. 2024. "Reactivation of Abandoned Oilfields for Cleaner Energy Generation: Three-Dimensional Modelling of Reservoir Heterogeneity and Geometry" Processes 12, no. 12: 2883. https://doi.org/10.3390/pr12122883

APA StyleStorey, B. M., Worden, R. H., McNamara, D. D., Wheeler, J., Parker, J., & Kristen, A. (2024). Reactivation of Abandoned Oilfields for Cleaner Energy Generation: Three-Dimensional Modelling of Reservoir Heterogeneity and Geometry. Processes, 12(12), 2883. https://doi.org/10.3390/pr12122883