1. Introduction

Higher-order differential equations often provide an accurate representation of the dynamic behavior of industrial processes. These processes frequently exhibit overdamped behavior, identifiable by S-shaped curves in their step responses. However, designing control systems for such complex dynamics poses significant challenges. To address these, first-order plus dead time (FOPDT) models are commonly employed, offering a simplified yet effective alternative. Numerous step response methods exist for extracting FOPDT model parameters, i.e., gain

K, time-constant

T and delay time

L, from the behavior of an overdamped system [

1,

2,

3,

4,

5]. In the subsequent paragraphs, we will present a concise overview of different control strategies that employ FOPDT models.

In recent years, researchers have directed their attention towards the study and exploration of advanced control technologies using FOPDT models, e.g., model predictive control [

6,

7,

8], fractional control [

9,

10], sliding mode control [

11], fuzzy control [

12], etc. One of the most versatile methods among these is the fractional order counterpart of PID (FOPID). The tuning of FOPID controllers for FOPDT models is predicated on the generalization of PID controllers, taking into account the fractional order characteristics of the control parameters such as empirical rules based on the Ziegler–Nichols method [

13], the Fractional Maximum sensitivity constrained Integral Gain Optimization (F-MIGO)-based tuning rule [

14], the optimization-based tuning using specific frequency domain criteria such as phase margin, gain crossover frequency, and iso-damping criteria [

15]. Another captivating method among these technologies is model predictive control (MPC) with constraint handling capabilities. The landscape of MPC design using FOPDT models encompasses a multitude of distinct methods such as Artificial Neural Network (ANN)-based MPC [

6], tuning rule-based MPC [

7], and the feedback predictive approach [

8].

Despite significant advancements in control algorithms, the industry continues to rely predominantly on PID controllers due to their simplicity and ease of implementation [

16]. These controllers are typically tuned using mathematical process models, with the Ziegler–Nichols method being one of the most widely recognized approaches for PID tuning. This method employs step response and ultimate gain analysis to derive controller parameters [

1]. However, despite its widespread use, control systems designed using Ziegler–Nichols rules often exhibit overly aggressive performance characteristics, making them unsuitable for certain process types [

17]. To address these limitations, Åström and Hägglund proposed the Approximate M-constrained Integral Gain Optimization (AMIGO) method [

18]. AMIGO aims to enhance performance by maximizing the integral gain while ensuring stability through a maximum sensitivity constraint, effectively balancing system response and robustness. Similarly, Skogestad advanced PID controller tuning by introducing the Internal Model Control (IMC)-based method for overdamped systems with S-shaped response curves [

19], further refined in later work [

20]. Additional IMC-based PID tuning methods have been developed, incorporating strategies such as pole-zero conversion, loop shaping, and direct synthesis [

21,

22,

23,

24]. These methods, along with Ziegler–Nichols, AMIGO, and SIMC, are classified as indirect PID autotuners, as they depend on obtaining a system model for effective tuning.

In some cases, especially in large industrial plants with significant subsystem interactions, developing a precise process model can be challenging. In such situations, direct PID autotuning methods, which do not rely on process models, are particularly useful. Among these, the method introduced by Ziegler and Nichols [

1] is perhaps the most widely recognized. This approach determines controller parameters based on the critical gain and critical frequency of the system, obtained through experimental measurements. However, the original Ziegler–Nichols tuning procedure often results in closed-loop systems with poor robustness. To address these shortcomings, numerous enhancements and alternative methods have been proposed. Åström and Hägglund adapted the Ziegler–Nichols concept, incorporating robust loop-shaping techniques to balance performance and robustness [

25]. A direct autotuner based on the relay feedback test, which uses describing function analysis to estimate the critical gain and frequency of the system automatically. Variants of this method include the introduction of hysteresis into the relay for noise immunity and the use of artificial time delays to modify the oscillation frequency during relay feedback tests [

26]. For PI controller tuning based on relay feedback, equations for phase and amplitude assignment are employed. In the case of PID controllers, modifications to the Ziegler–Nichols method include introducing a parameter,

, as the ratio between the integral and derivative time constants [

27]. However, as the control performance is highly sensitive to the choice of

, researchers have proposed improved autotuning techniques, such as adding a third condition to enhance robustness against open-loop gain variations [

28]. Moreover, an autotuning principle for direct PID autotuners has been proposed in [

29], outperforming the aforementioned traditional methods in terms of step response and disturbance rejection capabilities [

30,

31]. This approach, referred to as the initial robustness-based autotuner in this study, marked a significant step forward in improving direct autotuning strategies.

The initial robustness-based autotuner allows two design specifications, namely gain margin (GM) and phase margin (PM) [

29]. Its concept defines a forbidden region by two design constraints, and then PID controller parameters are tuned in such a way that the Nyquist diagram of the open loop frequency response must not enter this forbidden region. Alas, the method requires two experiments: (i) a relay test is employed to determine/estimate the critical frequency of the process, and (ii) a sine test is used to estimate the process frequency response components [

29]. These two experiments might be a time-consuming and expensive task despite their superiority over the other aforementioned methods. Alternatively, integrating the strengths of the initial robustness-based autotuner with time-domain response analysis might allow for a more practical and efficient autotuning approach. This combination leverages the benefits of both methods, leading to improved tuning results with reduced complexity and improved performance.

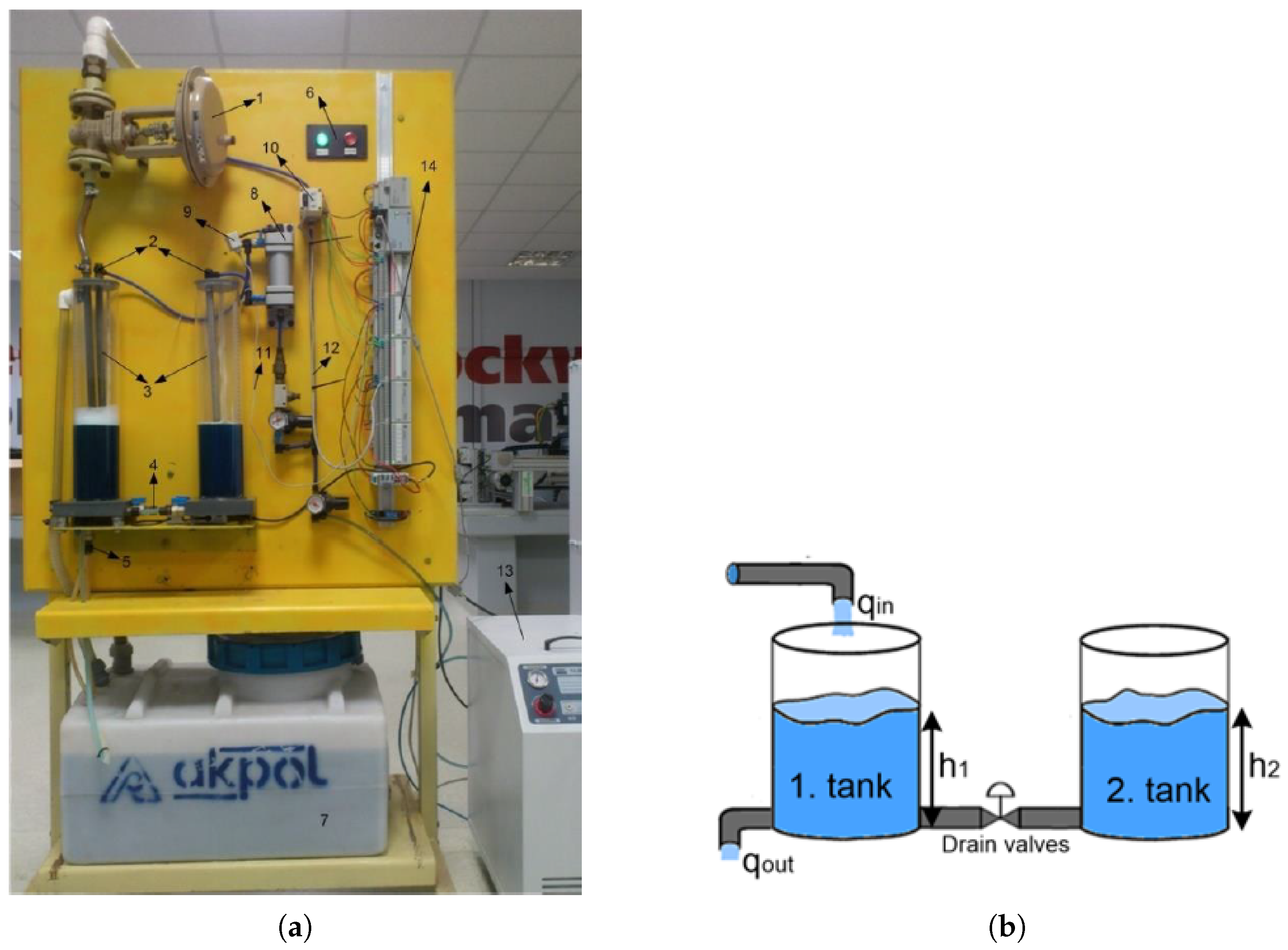

In this paper, a novel approach to the robustness-based autotuner is proposed. Unlike the initial autotuner, which relied on relay and sine tests to determine fundamental parameters, our approach provides a fully automated calculation for these parameters based solely on the time-domain response test. This eliminates the need for additional calculations from the relay and sine tests. To achieve this, the method automatically estimates these values using first-order plus dead time (FOPDT) models. To begin, five diverse step response methods are introduced to ascertain the model parameters in the approach. Second, three alternative estimation methods for the critical frequency of the system are proposed through (i) solving a nonlinear equation, (ii) employing a linear approximation, and (iii) using a power regression. These methods offer flexibility and options for estimating the fundamental parameters. Lastly, the model parameters are then employed to calculate the system frequency response and its derivative at the critical frequency. The subsequent design steps remain unchanged from the initial autotuner. The simulation studies focus on the comparison between the proposed approach and the initial robustness-based autotuning method using two types of overdamped systems. Furthermore, the impact of the step response methods and the proposed estimation methods within the novel approach on system response and control signal is investigated. The designed controllers, utilizing the new approach to the initial autotuner, are implemented on a two-tank liquid-level system. The experimental outcomes align with the simulation results, providing confirmation of the validity and compatibility of the findings.

Existing autotuning methods often rely on relay or sine tests, which are time-consuming, experimentally intensive, and computationally burdensome in industrial settings. Furthermore, while many approaches aim to improve robustness or efficiency, few offer a comprehensive framework that integrates model parameter estimation, critical frequency determination, and robust controller design in a unified process. This gap highlights the need for methods that streamline these steps while ensuring performance and robustness across varying system dynamics. The main contributions of this paper are as follows: (i) A novel approach based on time domain response to the initial autotuner is presented for overdamped systems, (ii) this approach offers a fully automated calculation for fundamental design parameters by eliminating the additional computational burden required by the initial autotuner, (iii) in this approach, three estimation methods for the critical frequency are derived using FOPDT models, and the corresponding algorithms are clearly given, (iii) the effect of the proposed estimation methods in the approach as well as step response methods on system response and control signal are shown in the simulation studies and (iv) PID controllers designed using new approach are applied on a real-time system and perform well as in the initial autotuner.

This paper is organized as follows: the principle of the initial autotuner is discussed in

Section 2.

Section 3 presents the new approach. The simulation studies are carried out to show the performance of the proposed approach and the effect of proposed estimation methods as well as step response methods on system response in

Section 4.

Section 5 presents a real-time application of PID controllers designed using the new approach.

Section 6 gives some discussions and future studies.

2. The Initial Robustness Based Autotuner

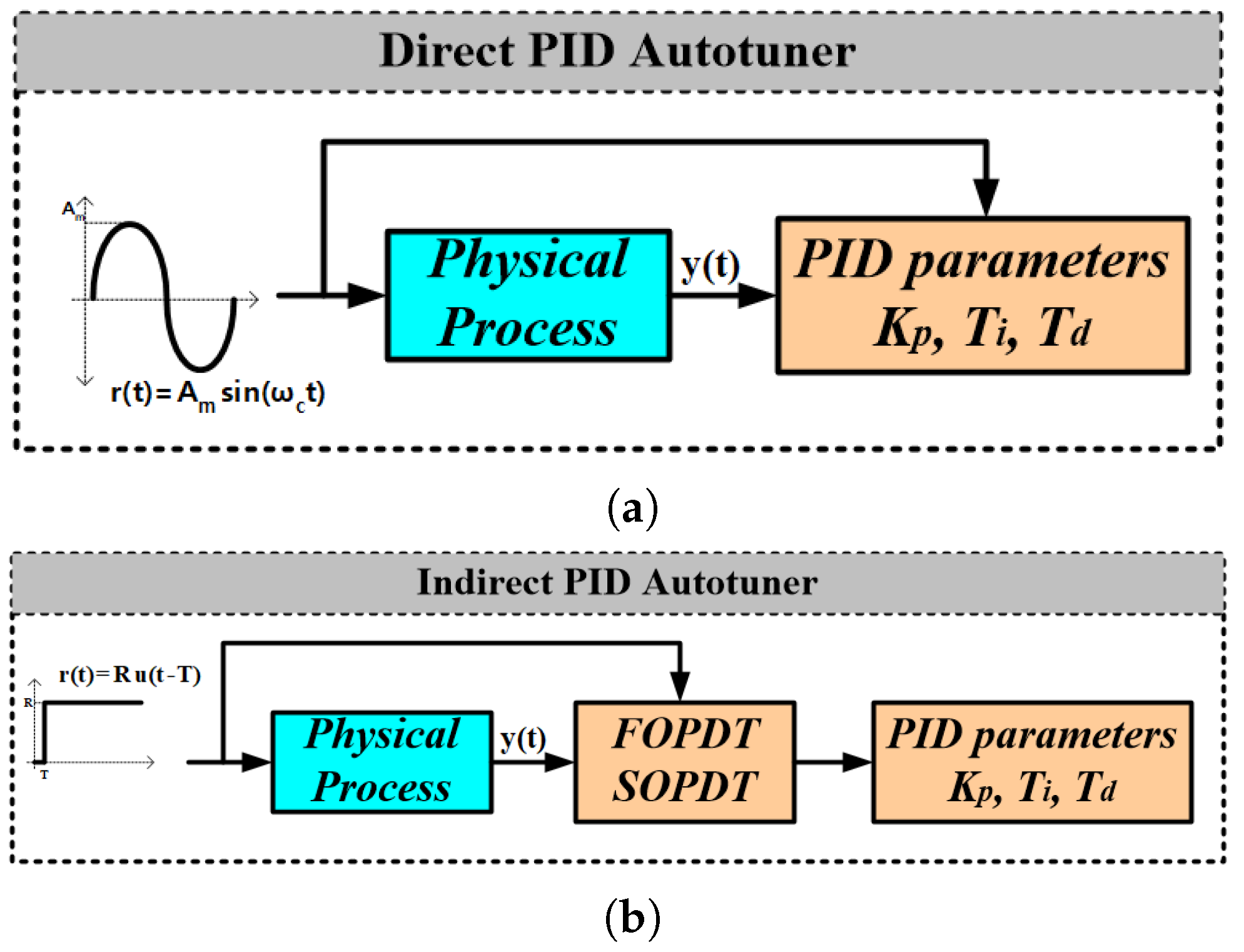

Autotuning methods are divided into two types: Indirect and Direct methods. Indirect methods require the system model to be found with the help of the step response of the system, while direct methods use the system frequency response. The block diagram of these two methods is given in

Figure 1. The robust autotuner revisited here is one of the direct PID autotuning methods based on gain margin (GM) and phase margin (PM) specifications. In this method, a quarter-circle, referred to as the ‘forbidden region’, is drawn on the Nyquist plane using these two specifications. The forbidden region is shown in

Figure 2 with a red quarter circle. Each point on the forbidden region border can be defined using the radius

R and angle

. The robust PID controller is then designed to minimize the following measures:

where

and

denote the real and imaginary parts of the forbidden region border;

and

represent the real and imaginary parts of the open loop frequency response, which is given in

Figure 2 with black curve. Therefore,

denotes the slope of the forbidden region border in a point with the angle

, and is calculated as the selected maximum value of

, i.e.,

. Moreover,

is the slope of open-loop frequency response at the critical frequency

of the unknown process

. The critical frequency is described as

This method necessitates two tests: (i) a relay test illustrated in

Figure 3a is used to estimate the critical frequency, and (ii) a sine test illustrated in

Figure 3b to calculate the process frequency response and frequency response slope at the critical frequency [

29]. These two tests additionally require further calculations. For instance, the system’s output signal from the relay test contains multiple frequencies as a result of nonlinearity. To determine the dominant frequency, the Fast Fourier Transform (FFT) of the output signal must be applied. After identifying the dominant frequency, during the sine test, a sinusoidal input signal

is applied to the physical process, producing an output signal

. To compute the phase slope, an additional signal

, representing the derivative of the output, is obtained through a filtering operation. This derivative is derived as

, where

is processed from

using a specific filter,

. The magnitude and phase are calculated from the amplitude ratio and time shift between the input and output signals, while the phase slope is computed from the processed data. The proposed methodology eliminates the need for additional calculations from the relay and sine tests.

The section is structured as follows:

Section 2.1 defines the forbidden region on the Nyquist plane, detailing the calculation of its border slope using gain and phase margin specifications.

Section 2.2 explains the determination of the open-loop frequency response slope at the critical frequency, incorporating process frequency components from relay and sine tests.

2.1. The Forbidden Region Border Slope Determination

The following relation defines any points

S on the forbidden region border shown in

Figure 2:

where

C and

R represents the circle center and the circle radius, respectively. One of the two thick points in

Figure 2 is determined by relation

, and the other is determined by relation

. This leads to the equality

. From this, the values of the circle center

C and circle radius

R can be found as described in [

29]:

In this study, phase and gain margins are taken as

and 2, respectively [

29]. The slope of any points

S on the forbidden region border can be found using the following formula:

where

and

denote the real and imaginary parts of the forbidden region border, respectively. This slope corresponds to the slope of the blue line in

Figure 2.

2.2. The Open Loop Frequency Response Slope Determination

The open loop frequency response

is described as follows:

where

and

denote the frequency responses of process and PID controller, respectively.

The derivative of the open loop frequency response

at the critical frequency

is calculated using the following formula:

Here, the process frequency components, i.e.,

and

are obtained utilizing the sine test shown in

Figure 3b. For the controller frequency components, i.e.,

and

the transfer function structure of PID controller can be given as

where

is the gain of the controller. In the method, it is assumed that the integral time constant

is equal to four times the derivative time constant

. This is a commonly used choice to simplify the tuning procedure; it assumes two identical real zeros in the PID controller [

29]. The frequency response of the PID controller is then determined as follows:

On the other hand, since the frequency response values of open loop transfer function

and process

at

are known, the frequency response value of PID controller

at

could easily be calculated employing the following equation:

Note that

is equal to a point on the forbidden region border. Finally, the PID controller parameters in (

9), i.e.,

and

are found using the numerical value of

in (

10).

The derivative of the frequency response of the PID controller with respect to frequency is found as

Then, the numerical value of

is obtained by replacing

with

in (

11). After finding all the unknown variables in (

7),

is separated into real

and imaginary

parts as follows:

Finally, the open loop frequency slope value is determined as the ratio of the imaginary and real parts,

3. The Proposed Strategy

The new strategy relies on only the time domain response test instead of two experiments in the initial robustness-based autotuner. Moreover, the new strategy eliminates the need for additional calculations required by these two experiments, such as FFT computation, filtering, and time-domain convolution. Instead, it proposes a fully automated calculation based solely on the time-domain response test. This strategy concentrates on the processes having an S-shaped time domain response which could simply be described by the FOPDT model. The transfer function of the FOPDT model can be given as

Here,

and

L are the time constant, gain and time delay of the model, respectively. These parameters are discovered using a step response method in the new strategy. Both the critical frequency and the frequency components of the process at this frequency are estimated by employing the model parameters. The remaining steps are identical to the initial autotuner.

The steps of the initial robustness-based autotuner and the new strategy that we propose in this paper are summarized in

Figure 4. It should be noted that the initial autotuner requires two tests, i.e., the relay and sine tests given in

Figure 3, whereas the new strategy relies just on the process step response test.

This section is organized as follows: The proposed strategy begins with FOPDT model parameter determination in

Section 3.1, where model parameters such as time constant, gain, and delay time are derived using step response methods. These include (i) Smith (SmM), (ii) Sundaresan–Krishnaswamy (SKM), (iii) Ziegler–Nichols (ZNM), (iv) Nishikawa (NiM), and (v) Optimization (Opt). Next, the strategy moves to Critical Frequency Estimation in

Section 3.2, which is achieved through one of three methods: (a) solving a nonlinear equation for accurate determination, (b) employing a linear approximation for simplicity, or (c) applying a power regression for data-driven estimation. Once the critical frequency is determined, the strategy proceeds to Frequency Component Estimation in

Section 3.2, calculating the process frequency response and its derivative at this frequency. Finally, the PID Controller Design step involves using the estimated parameters to compute the proportional gain, integral time, and derivative time for the controller.

3.1. The First Order Plus Dead Time (FOPDT) Model Parameters Determination

There exist various step response methods to find FOPDT model parameters: Smith step response Method (SmM) [

2], Sundaresan–Krishnaswamy step response Method (SKM) [

3], Ziegler–Nichols step response Method (ZNM) [

1], Nishikawa step response Method (NiM) [

4], etc. Firstly, Smith’s and Sundaresan–Krishnaswamy step response methods employ the normalized response

by applying a step function

.

The gain is found by using the following formula:

where

and

denote the final and initial values of the output signal, respectively. In SmM, two different times are specified such that the normalized response reaches

at

and

at

of its final value, which is illustrated in

Figure 5a. In SKM, two different times are again specified such that the normalized response reaches

at

and

at

of its final value, which is depicted in

Figure 5b. FOPDT model parameters are found using (

15a) and (15b) via two different samples in SmM and SKM, respectively.

Secondly, a line at an inflection point of the step response is drawn to obtain the model parameters in ZNM.

Figure 6a illustrates how to find model parameters using this line. The difference between the time instants

and

when the line through the inflection point intersects the vertical lines

and

, respectively, gives time constant value

T of the model. On the other hand, the time delay

L of the model is found via the time difference

.

Thirdly, green and yellow colored areas shown in

Figure 6b must be calculated to find model parameters via NiM.

must be found using (

16a) so that the area

can be calculated. Then, FOPDT model parameters are found using (16b) in NiM.

Finally, the model parameters can be found by minimizing the following performance index via an optimization algorithm, e.g., a genetic algorithm with a cost function defined as follows:

where

and

denote real-time system and model responses, respectively. This step response method is referred to as Opt in the study.

3.2. Estimation of the Critical Frequency

In the subsection, three estimation methods are proposed for the critical frequency of the system: Nonlinearity-based, Linear approximation-based, and Power regression-based estimation methods.

3.2.1. Nonlinearity-Based Estimation Method

The analytical expression of the frequency response of the model in (

13) is obtained as follows:

The magnitude and phase responses of the analytical expression are as follows:

For the critical frequency estimation

, the phase response must be equal to

. Therefore, the following nonlinear equation has to be solved:

Using the phase response in (

19), the following equation is obtained:

This equation might be reorganized as

The function

is defined within the range

. Specifically, when

=

, the corresponding value of

is given by

, which represents the upper bound. Conversely, when

, the value of

becomes

, representing the lower bound. Therefore, the solutions of the nonlinear equation are located within the following intervals:

For example, consider that the model parameters are

. The Nyquist diagram of the model can be illustrated in

Figure 7a. Moreover,

Figure 7b depicts the solutions inside the first three intervals, i.e.,

. These solutions are consistent with the results obtained by Nyquist diagram.

Among several solutions of the nonlinear equation, it is necessary to determine the frequency at which the greatest magnitude is located. It corresponds to the smallest frequency because the magnitude response in (

19) diminishes as

increases. For

, the nonlinear equation becomes the following:

and the solution

is located in the interval

. The nonlinear equation might be solved employing fixed point iteration [

32]. In this study, we propose two estimation methods to simplify it: (I) Linear approximation-based, and (ii) Power Regression-based estimation methods, described hereafter.

3.2.2. Linear Approximation-Based Estimation Method

Another method can be that a linear function

in the mentioned interval is approximated for the function

. The start point of the function

is

and the endpoint of the function

is

Then, the slope of the linear function for

can be calculated as

The linear approximation for the function

is obtained as

Finally, the approximated critical frequency can be found using the following formula:

3.2.3. Power Regression-Based Estimation Method

The third method uses regression analysis. For this aim, the critical frequency values are found for different

and

. The surface shown in

Figure 8a illustrates these frequency values. It can be observed from this figure that the test frequency values for FOPDT models are more dependent on time delay than time constant (or settling time). If the effect of time constant is ignored, the following power function can be derived in terms of time delay using MATLAB Curve Fitting Toolbox [

33]:

Figure 8b illustrates the derived function in (

28) alongside the test frequency values. The color of the points in the figure varies based on the time constant.

3.3. The Frequency Components Estimation at the Critical Frequency

After the estimation of the critical frequency

, the following frequency response of the system model is used to estimate the process frequency response at the critical frequency

Firstly, we need to take the derivative of the system model with respect to

s so as to calculate the derivative of the frequency response with respect to frequency. Secondly, when

s is replaced with

, the derivative of the frequency response with respect to frequency is calculated using the following formula:

After estimating the critical frequency and its corresponding frequency components, the steps outlined in

Figure 4 should be followed to determine the PID controller parameters. These steps are detailed in Algorithms A1 and A2 in

Appendix A, summarizing the procedures of the initial robustness-based autotuner and its new strategy, respectively.

When a PID controller is applied in practice, incorporating a filter into the derivative term, i.e., is often essential. In this study, the filter is adjusted to ensure that the added artificial pole does not affect the system’s dominant dynamics. For both simulation and real-time experiments, the time constant of the filter is set to .

6. Conclusions

In this paper, a novel approach to an initial frequency response-based autotuner is presented in order to enable the design of robust PID controllers for overdamped systems characterized by an S-shaped step response. In the prior autotuner, which is inherently robust, the critical frequency is established through a relay test, and the process frequency response alongside its derivative at that frequency are acquired via a sine test. In contrast, the new approach, which offers a fully automated calculation for these values, necessitates solely a step test and approximates these values by utilizing FOPDT models obtained based on a step test. Initially, five distinct step response methods are introduced to determine the model parameters. Subsequently, three alternative methods for estimating the critical frequency of the system are put forward by (i) solving a nonlinear equation, (ii) utilizing a linear approximation, and (iii) applying a power regression. Finally, the model parameters are utilized to compute the frequency response and its derivative at the critical frequency. The subsequent design steps remain consistent with the initial frequency-based autotuner. The simulation studies are carried out on two types of overdamped systems, i.e., overdamped systems with concurrent poles and with the real half-plane zero. The controllers developed through the new approach are also put into practice in a two-tank liquid-level system, as an alternative to the initial autotuner. The experimental results align with the outcomes from the simulation, providing confirmation of the accuracy and consistency of the obtained findings. The critical frequency estimation has been observed to yield similar results among various step response methods in both simulation and real-world applications. Furthermore, it has been noted that the nonlinear and analytical methods provide quite similar results when estimating the critical frequency.

The impact of step response methods on PID controller design has been investigated. The robust autotuners employing the four step response methods, excluding the Ziegler–Nichols method, produce satisfactory outcomes. Namely, the autotuner based on SKM or NiM leads to the least overshoot and the fastest settling time. Moreover, the influence of critical frequency estimation methods on PID controller design has also been examined. The autotuners using the three proposed estimation methods yield satisfactory results. Particularly, the nonlinear and analytical methods produce highly similar results, characterized by the least overshoot and the fastest settling time. However, one limitation of the proposed strategy is that it may struggle to provide accurate results when dealing with systems that exhibit high levels of noise or extreme nonlinearities.