Numerical Optimization of Burner Deflection Angle at Half Load for a 660 MW Tangentially Fired Boiler

Abstract

1. Introduction

1.1. Motivation

1.2. Literature Review

1.3. Main Focuses of This Study

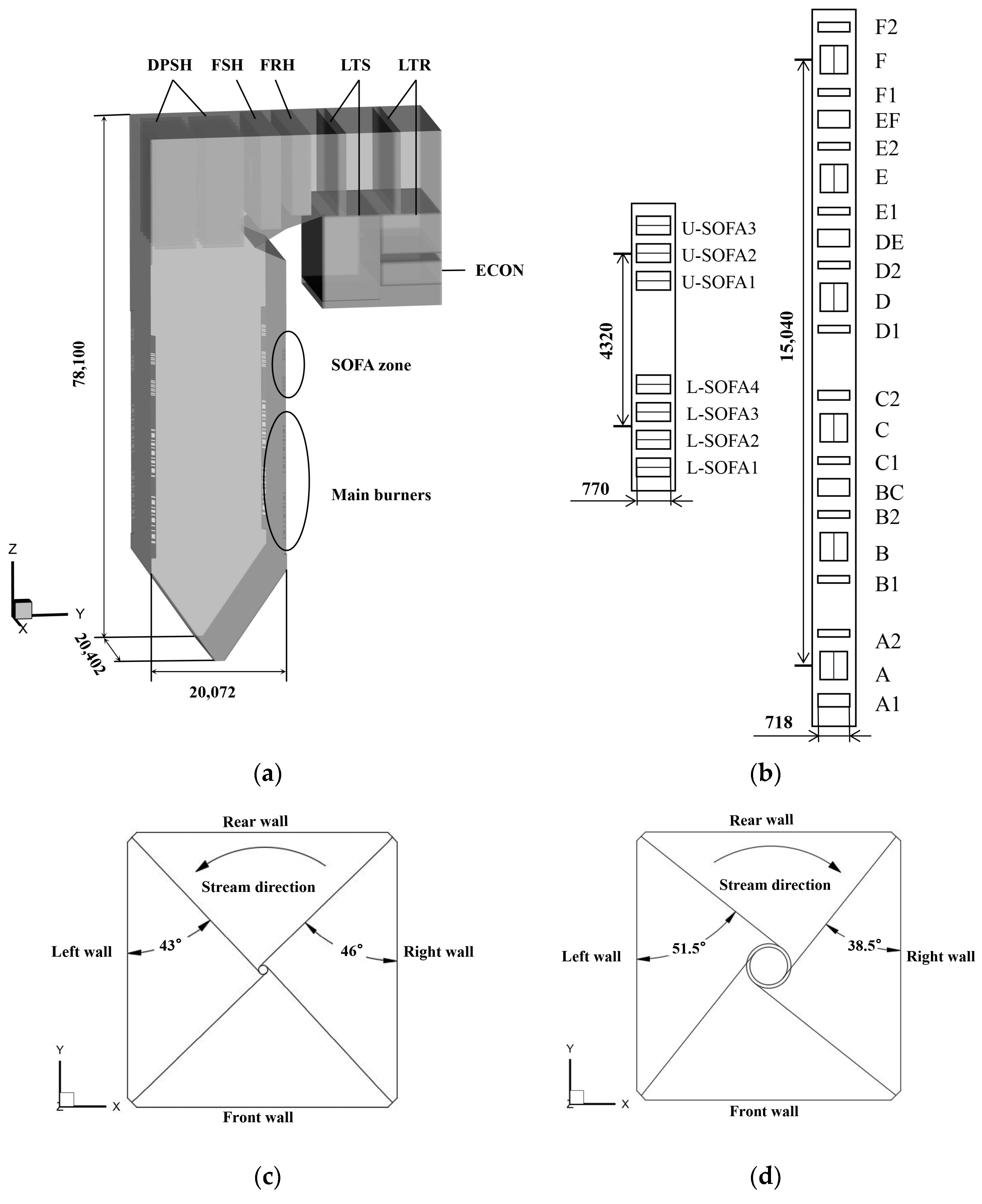

2. Boiler Specifications

3. Numerical Calculation Details

3.1. Simulation Calculation Models

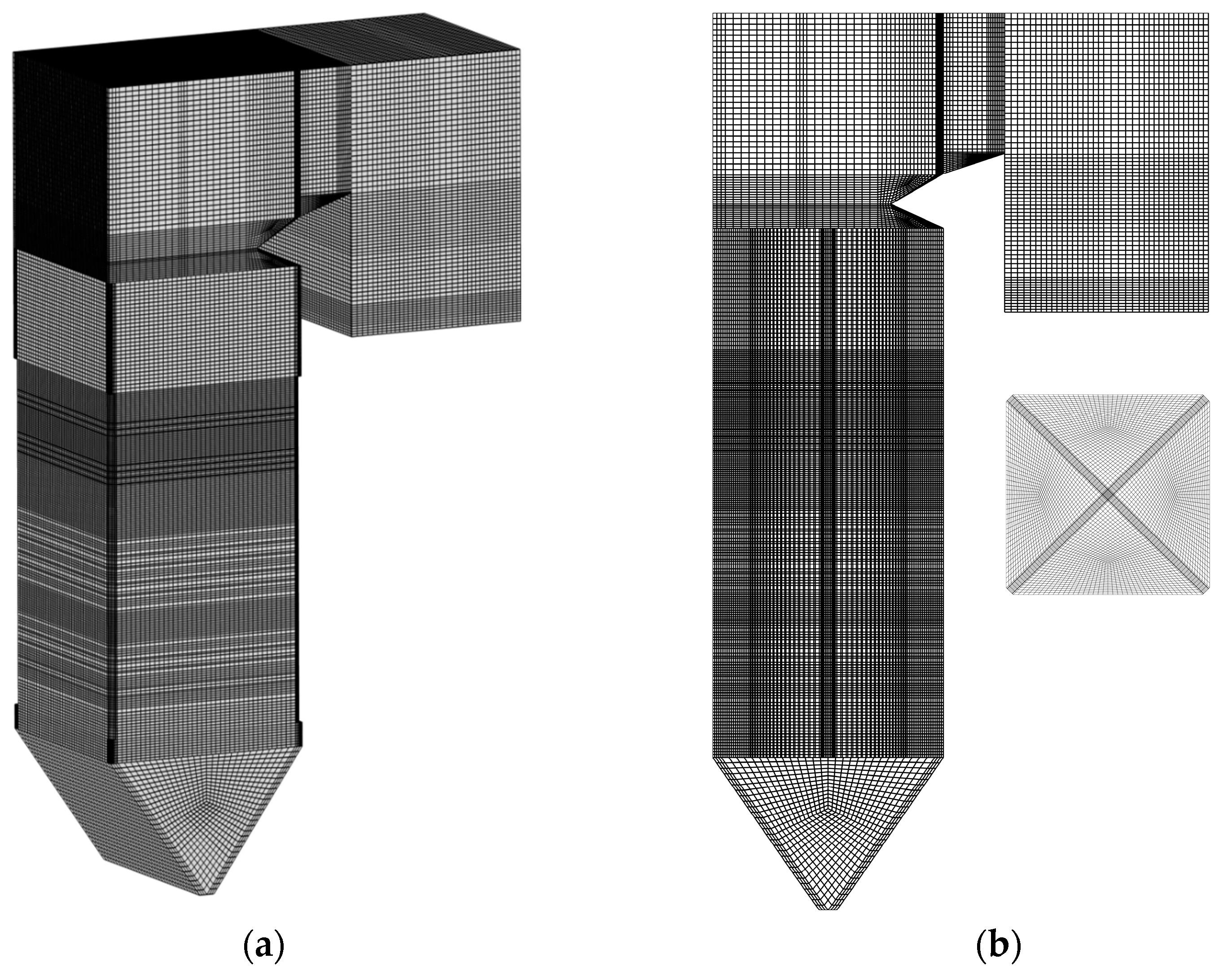

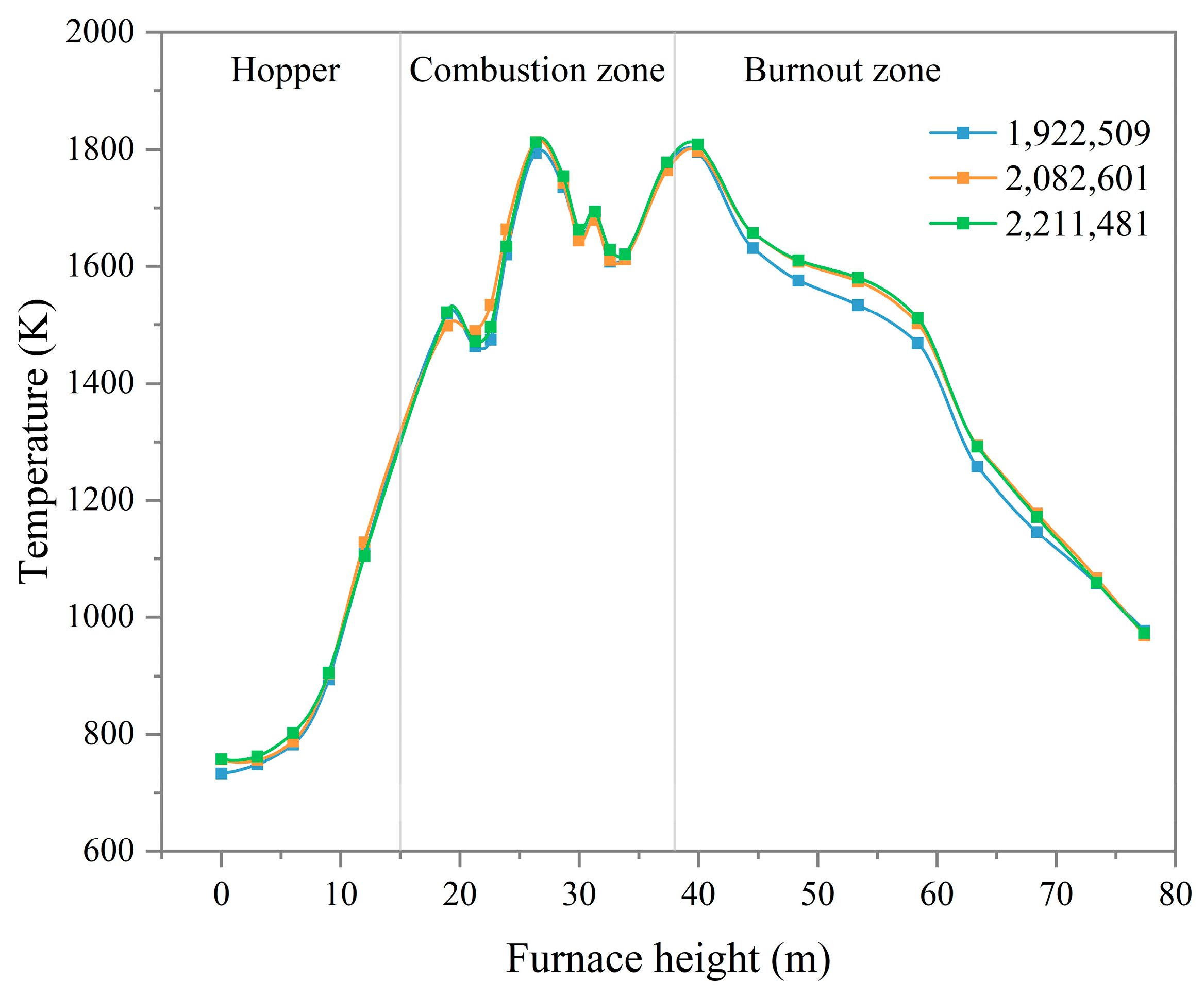

3.2. Computational Mesh System

3.3. Case Setting and Description of Calculation Conditions

4. Results and Discussion

4.1. Effect of Different SOFA Ratios on Combustion

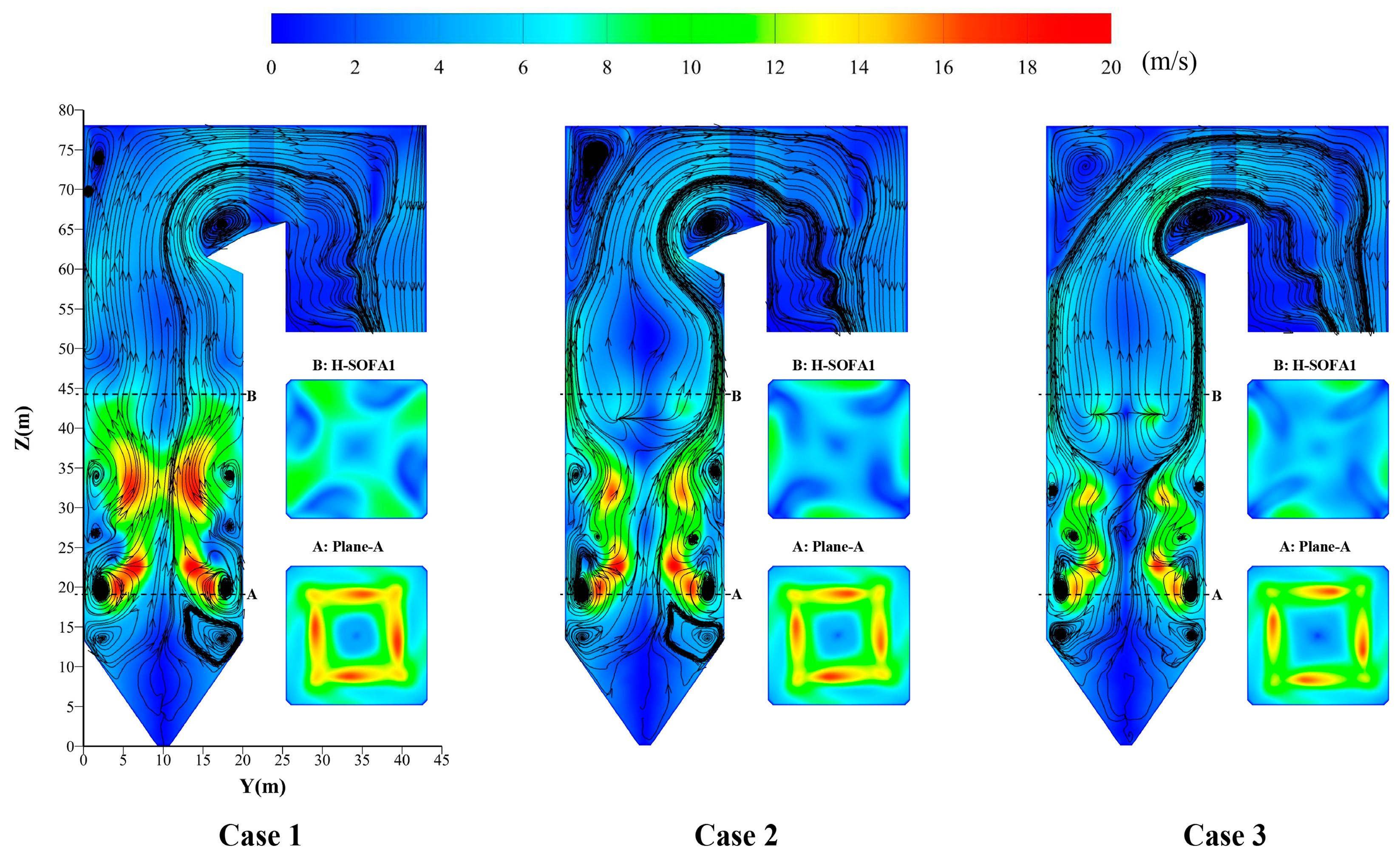

4.1.1. Distribution of Velocity Under Different SOFA Ratios

4.1.2. Distribution of Temperature Under Different SOFA Ratios

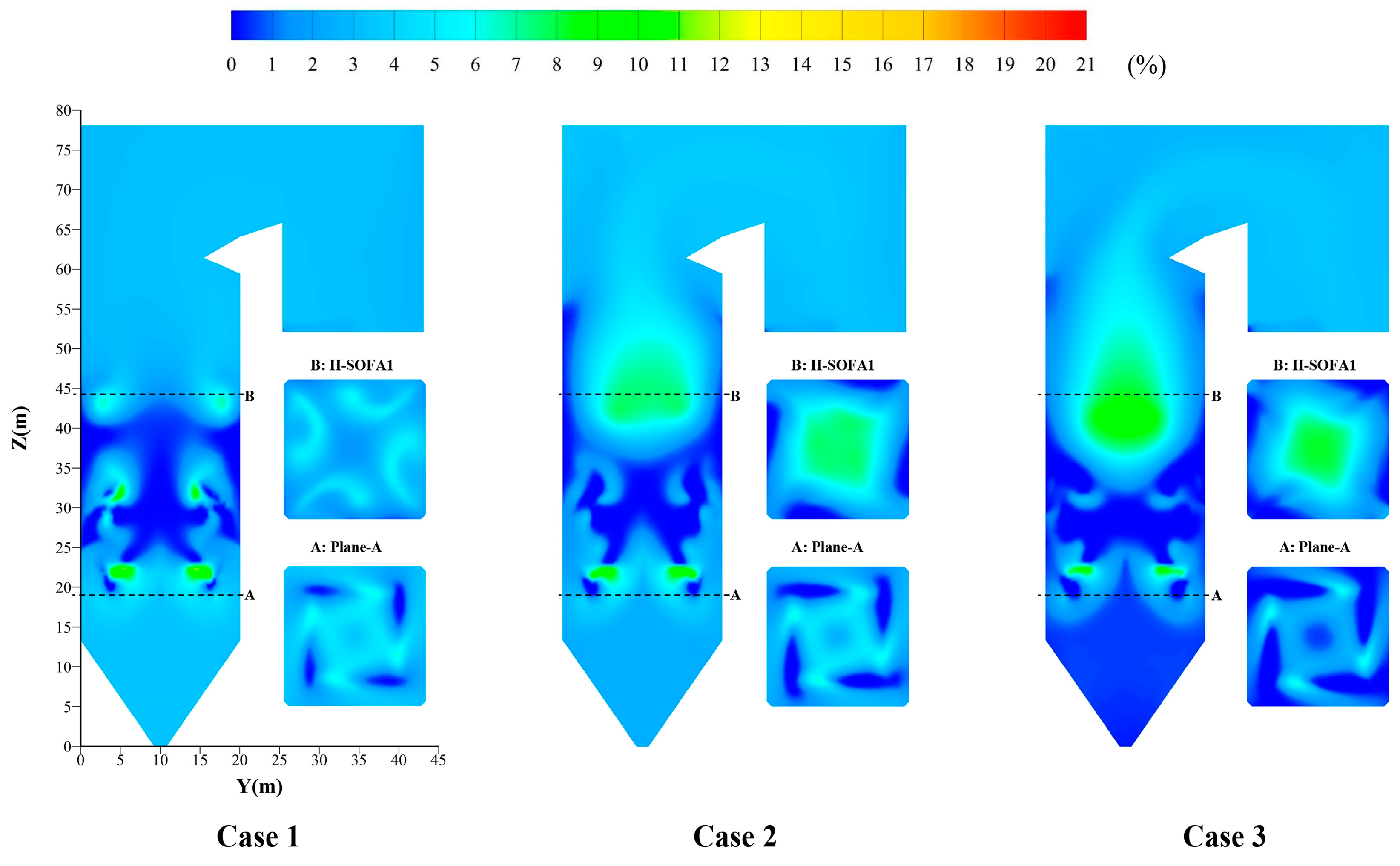

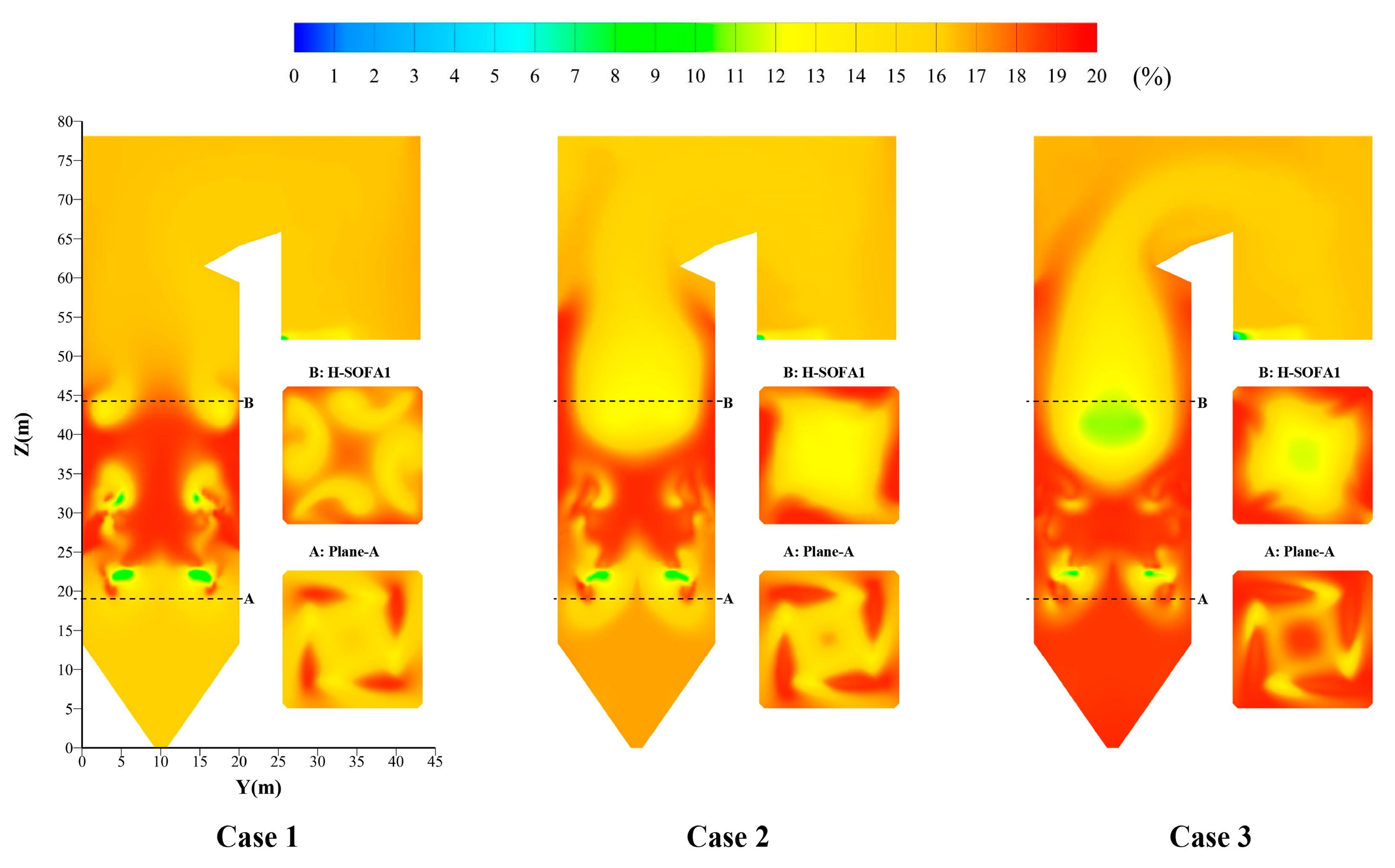

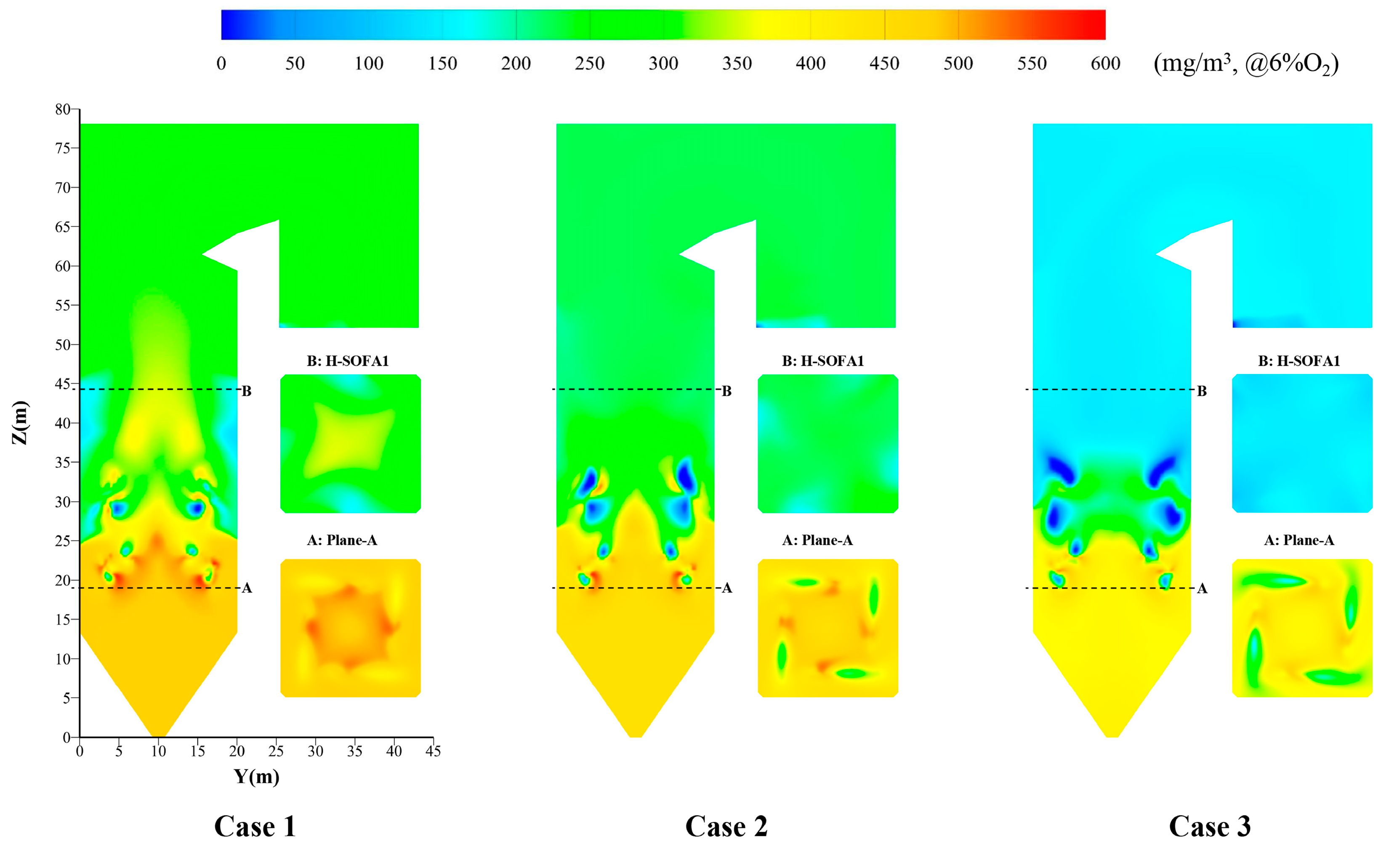

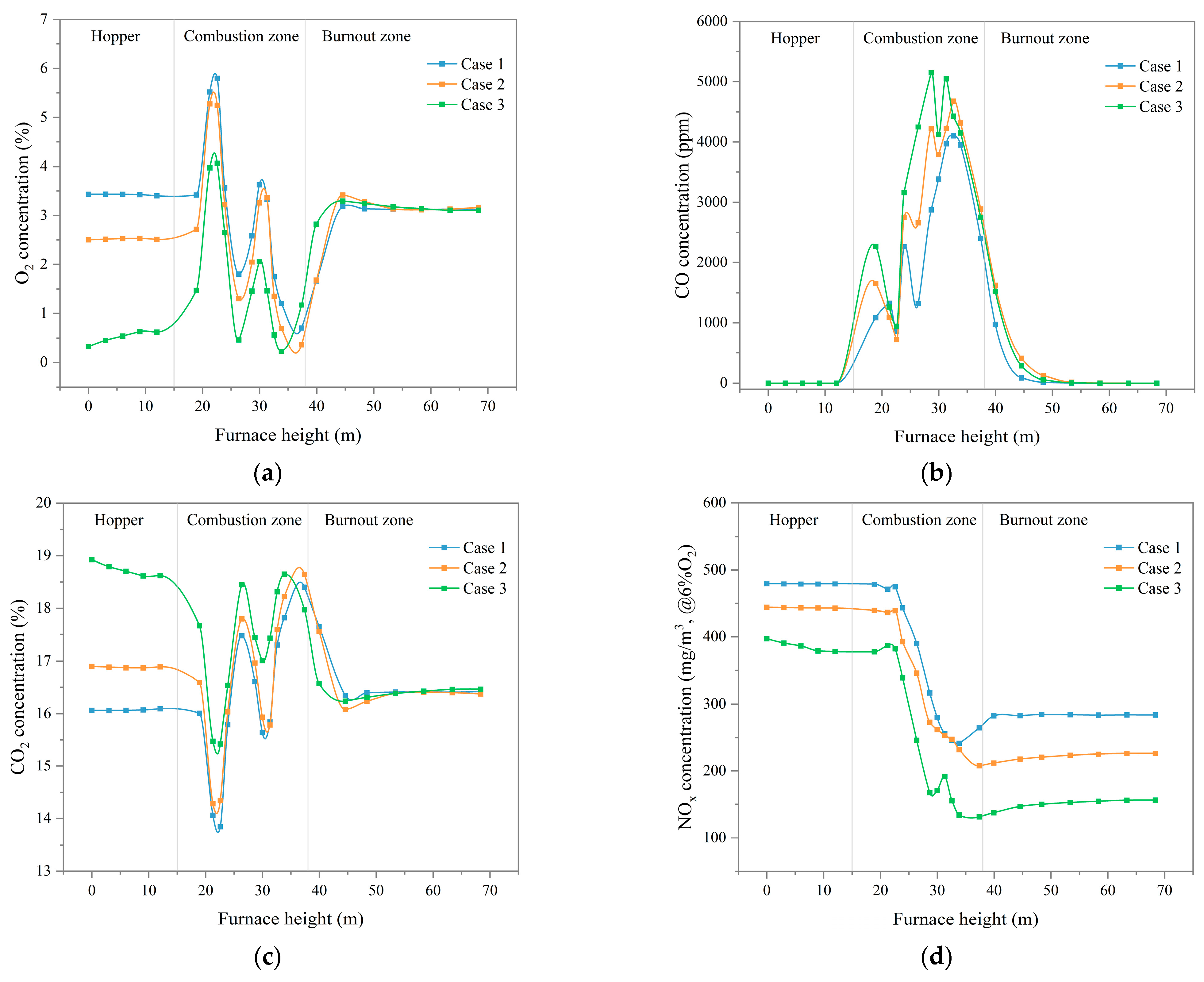

4.1.3. Distribution of Species Under Different SOFA Ratios

4.2. Effect of Different Burner Angles on Combustion

4.2.1. Distribution of Velocity Under Different Burner Angles

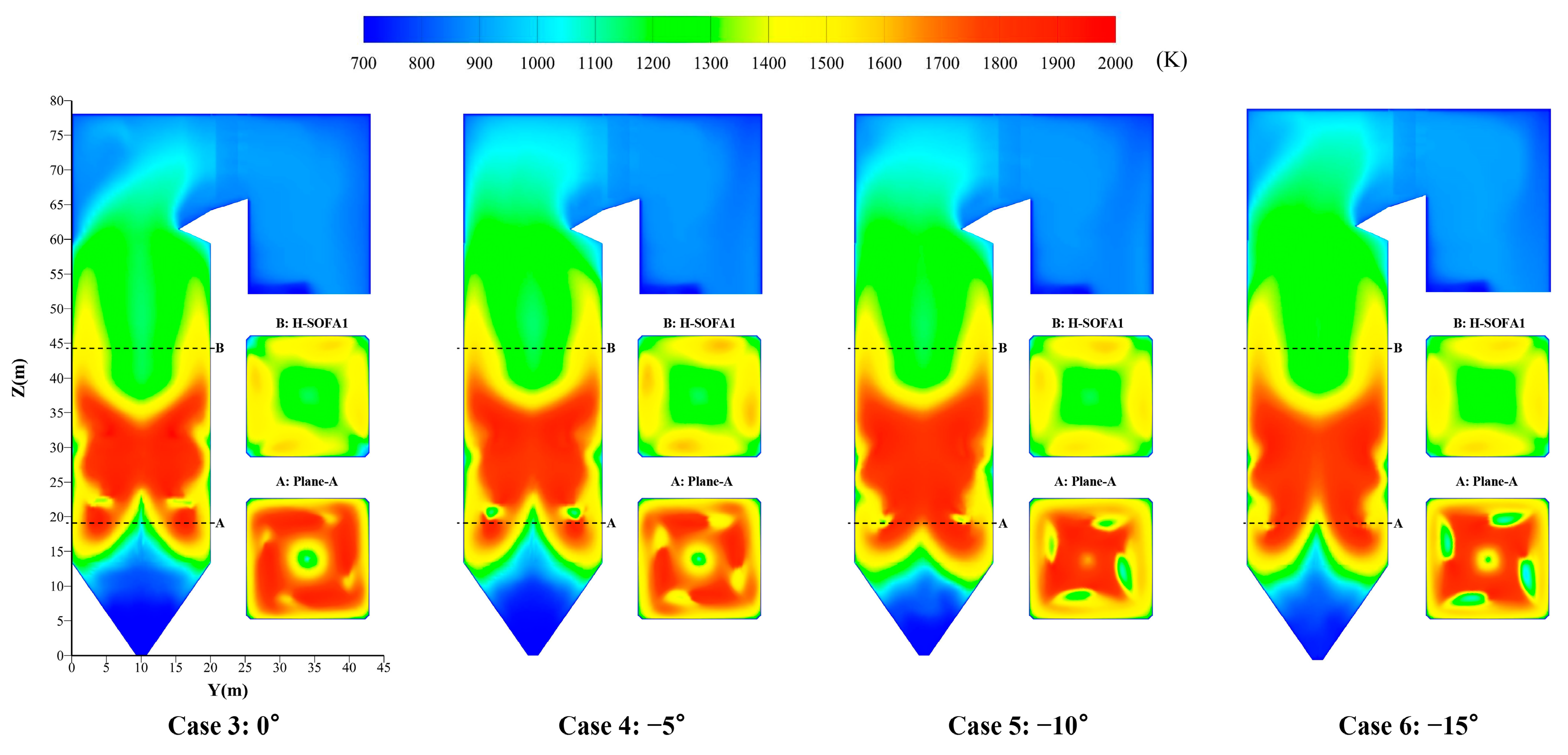

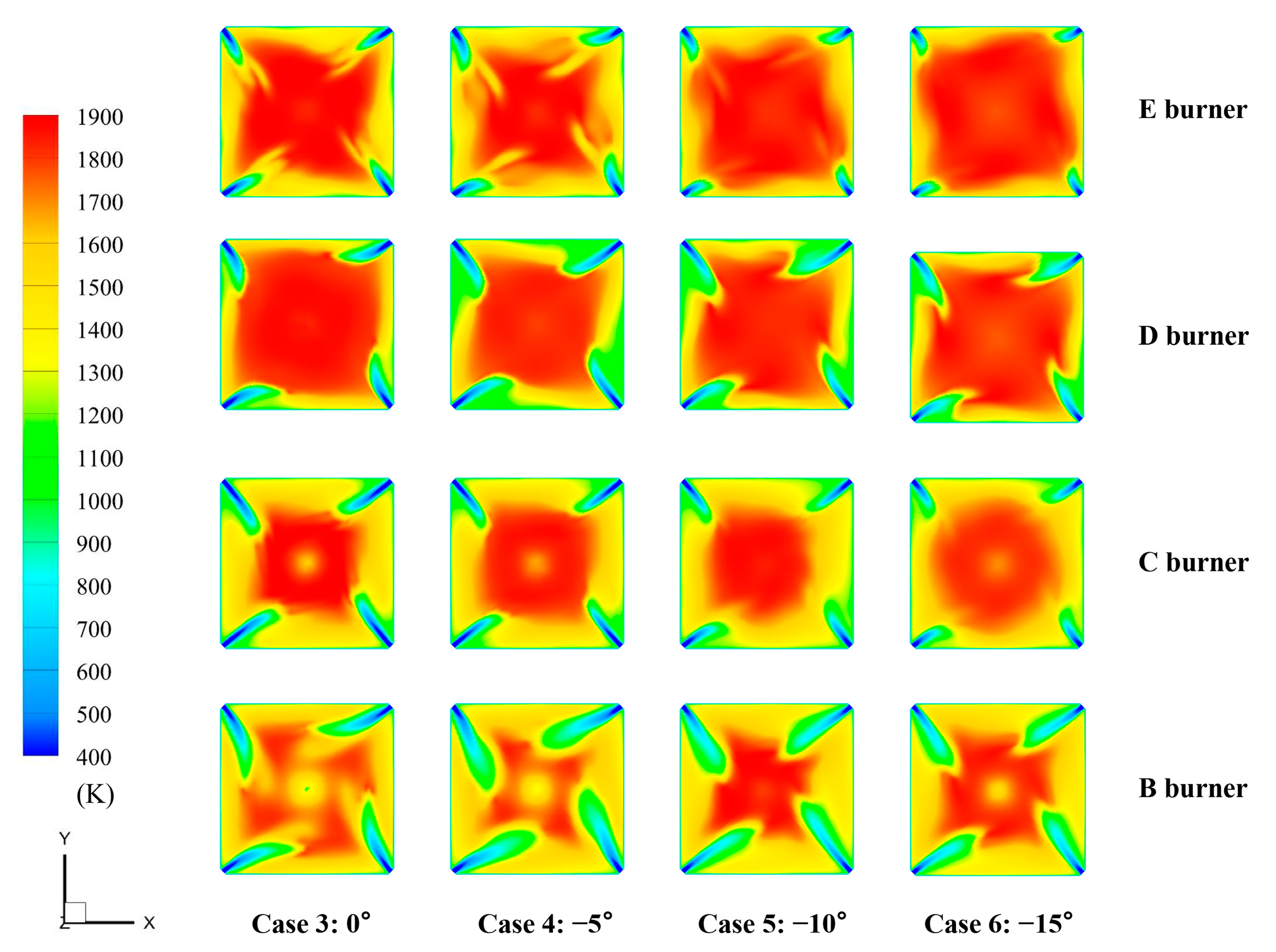

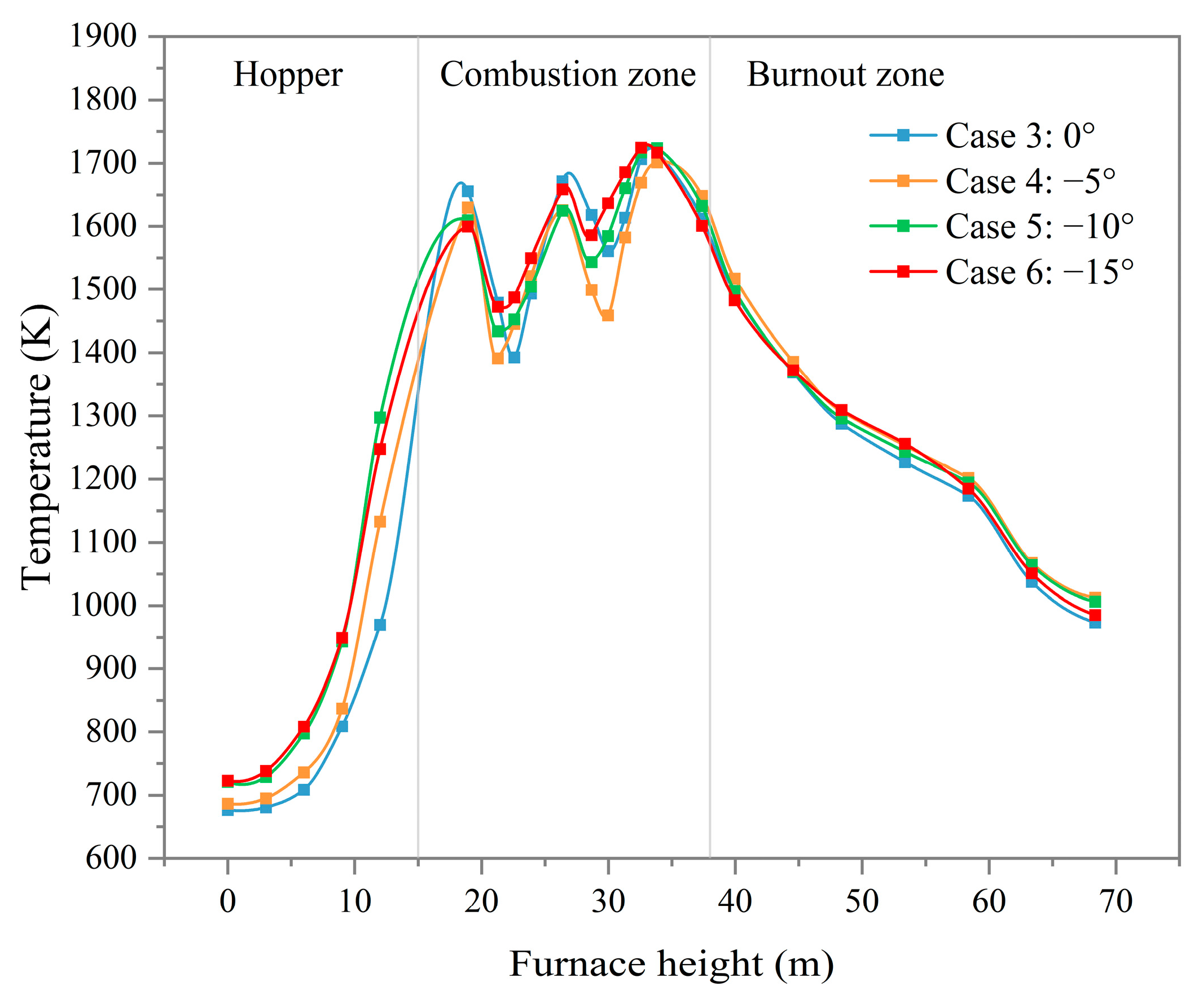

4.2.2. Distribution of Temperature Under Different Burner Angles

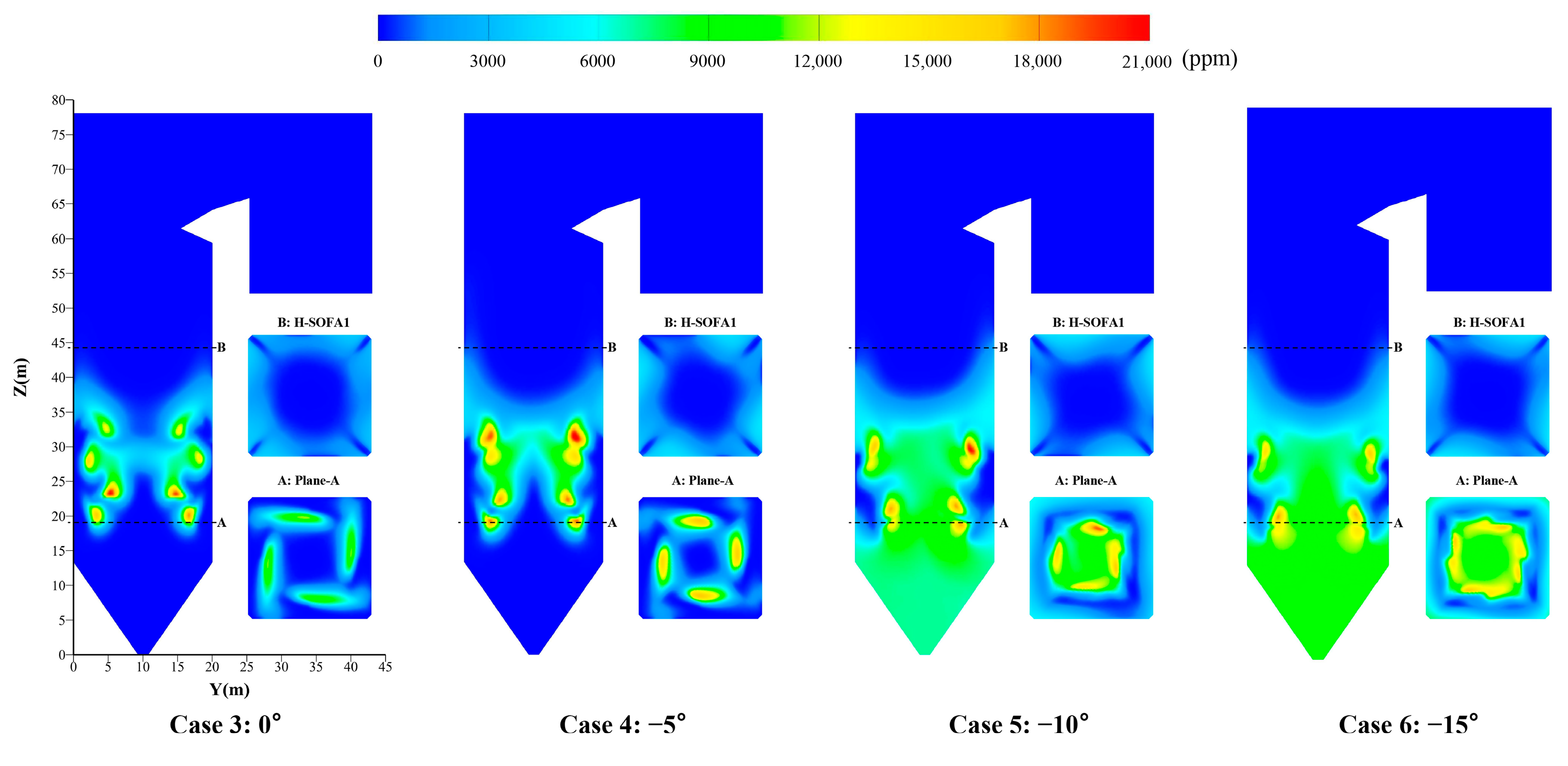

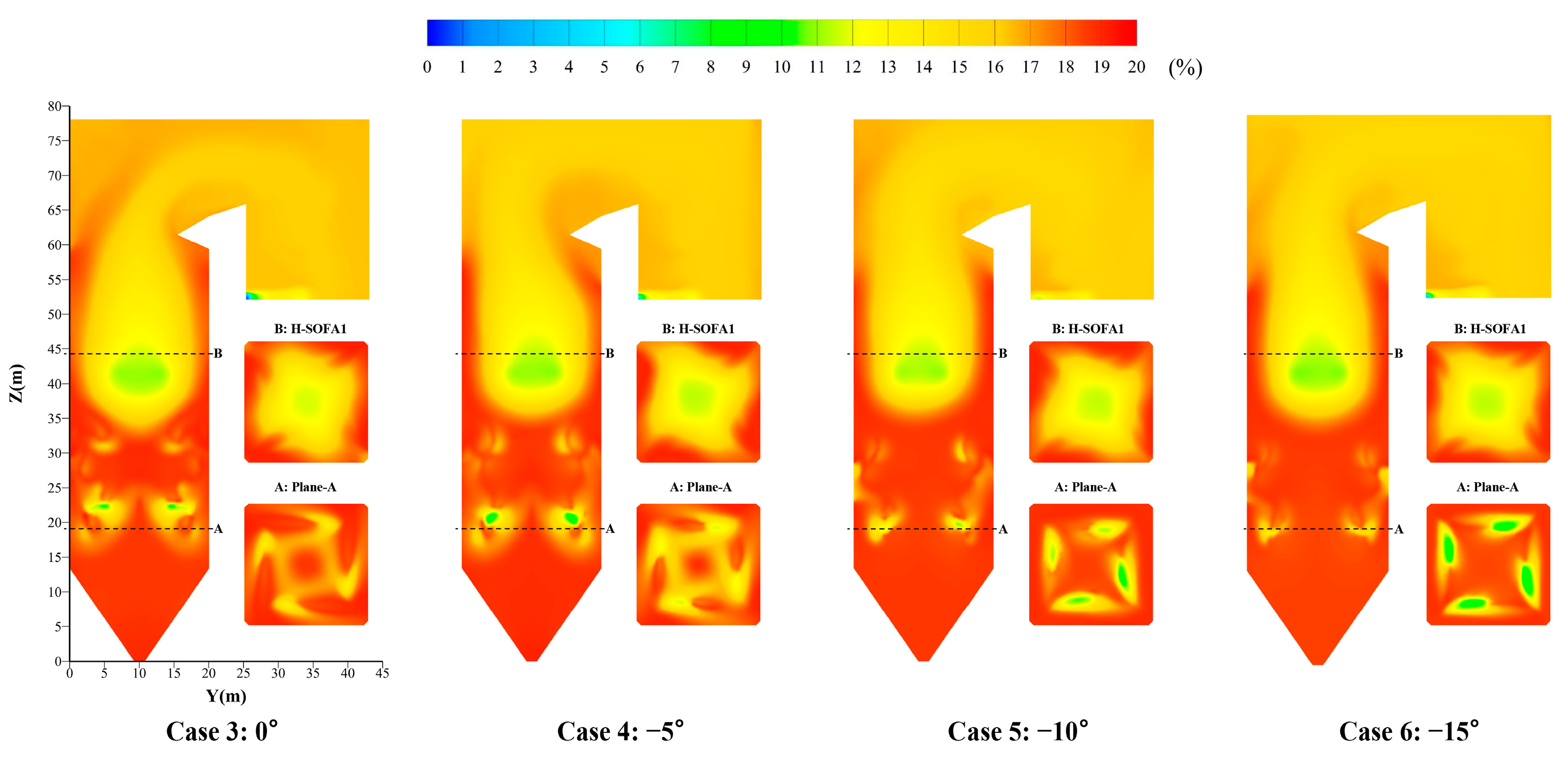

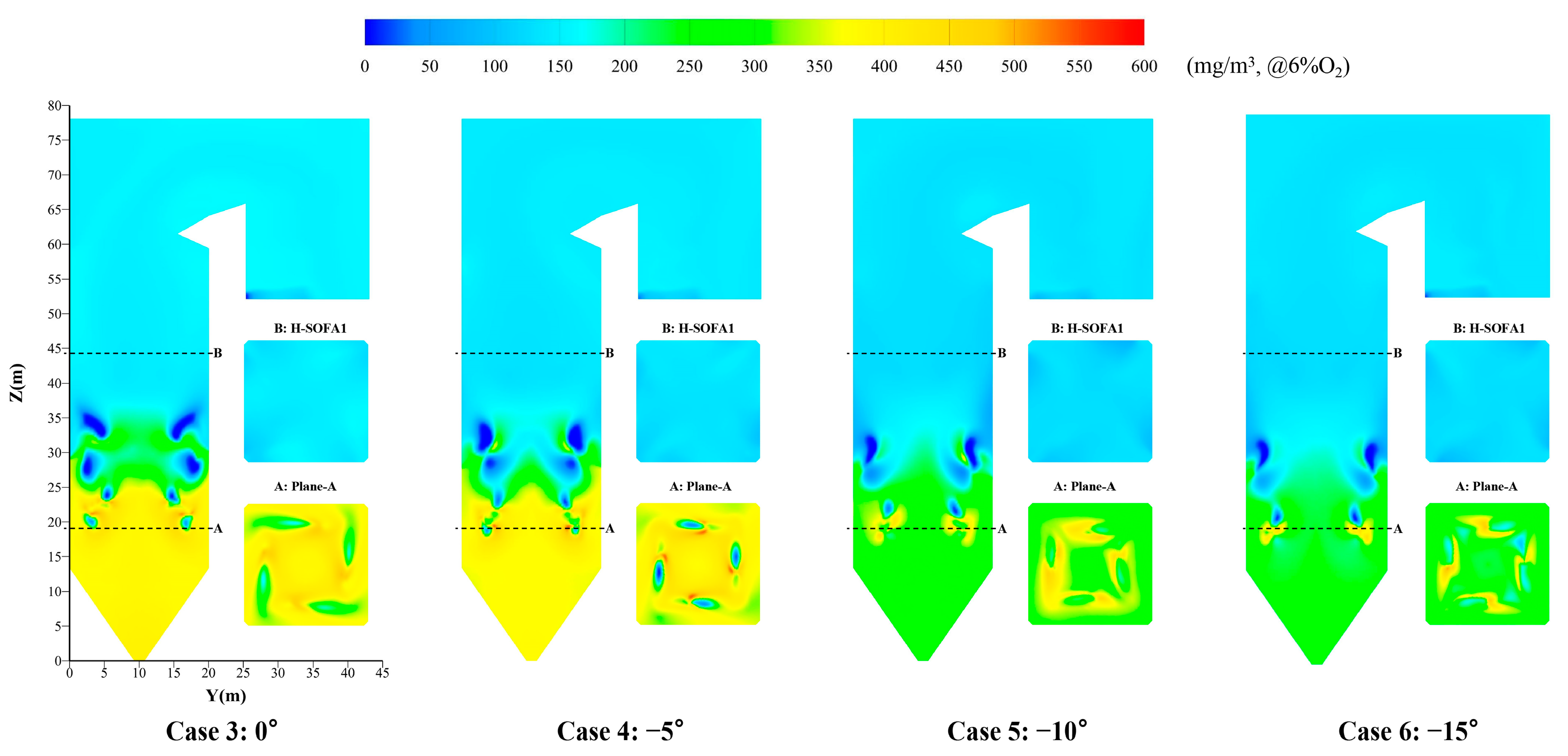

4.2.3. Distributions of Species Under Different Burner Angles

5. Conclusions

- (1)

- The temperature in the main combustion zone increased slightly after the SOFA ratio increased from 17.6% to 27.6% in Cases 1–3. However, the large eddy formed in the top zone affects the horizontal flue flow field. The uneven flue gas distribution affects the heat exchange.

- (2)

- The increase in the SOFA ratio resulted in a significant decrease in the NOx concentration. In the burnout zone, compared with the NOx concentration of 284 mg/m3 in Case 1 (17.6% SOFA ratio), the NOx concentration in Case 3 (27.6% SOFA ratio) is only 156 mg/m3, which is a decrease of 45.1%.

- (3)

- The downward deflection of the burner angle adjusts the flow field in the furnace. The eddy in the top zone current decreases and then increases. At a deflection angle of −5° (Case 4), the flow field at the top of the chamber is more uniform. At the same time, the increase in the deflection angle makes the combustion zone extend downward, which reduces the temperature fluctuation in the combustion zone.

- (4)

- The deflection of the burner angle attenuates the mixing of pulverized coal and air. The insufficient combustion of pulverized coal makes the CO concentration higher, which effectively reduces the NOx production. In the burnout zone, adjusting the deflection angles (−5°, −10°, and −15°) in Cases 4–6 reduced the NOx concentrations in this zone by 5.8%, 11.5%, and 10.3%, respectively, compared to the NOx concentration in Case 3 without adjusting the burner angle (156 mg/m3). However, the attenuating effect of angular deflection on NOx concentration gradually decreased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Qiao, X.; Miao, Z. Low load performance of tangentially-fired boiler with annularly combined multiple airflows. Energy 2021, 224, 120131. [Google Scholar] [CrossRef]

- BP. BP Statistical Review of World Energy 2024; BP: London, UK, 2024. [Google Scholar]

- Nie, Y.; Zhang, G.; Zhou, Y.; Su, B.; Zhang, K.; Yao, L. Characteristics and mechanism analysis of the clean evolution of China’s power generation structure. J. Clean. Prod. 2024, 457, 142236. [Google Scholar] [CrossRef]

- Zhang, B.; Niu, N.; Li, H.; Wang, Z. Assessing the efforts of coal phaseout for carbon neutrality in China. Appl. Energy 2023, 352, 121924. [Google Scholar] [CrossRef]

- Wang, G.; Sbai, E.; Wen, L.; Sheng, S. The Impact of Renewable Energy on Extreme Volatility in Wholesale Electricity Prices: Evidence from Organisation for Economic Co-operation and Development Countries. J. Clean. Prod. 2024, 484, 144343. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Q.; Ye, N.; Zhang, Z.; Wu, X.; Fan, H. A review on flexible peak shaving development of coal-fired boilers in China under the carbon peak and carbon neutrality goals. Therm. Sci. Eng. Prog. 2024, 55, 103004. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Zhu, J.; Hui, J.; Liu, Y.; Zhang, J.; Lin, J.; Lyu, Q. Preheated combustion characteristics and fuel-nitrogen conversion paths for bituminous coal and anthracite in wide-range preheating temperature. J. Energy Inst. 2023, 108, 101222. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Zhu, J.; Liu, Y.; Zhang, J.; Hui, J.; Ding, H.; Cao, X.; Lyu, Q. Preheating and combustion characteristics of anthracite under O2/N2, O2/CO2 and O2/CO2/H2O atmospheres. Energy 2023, 274, 127419. [Google Scholar] [CrossRef]

- Životić, M.; Nikolić, N.; Stojiljković, D.; Bajuk-Bogdanović, D.; Životić, D. Devolatilization behaviour of Kolubara and Kostolac lignite (Serbia) during the combustion process: A case study. Int. J. Coal Geol. 2024, 295, 104641. [Google Scholar] [CrossRef]

- Wei, D.; An, D.; Wang, T.; Zhang, H.; Guo, Y.; Sun, B. Influence of fuel distribution on co-combustion of sludge and coal in a 660 MW tangentially fired boiler. Appl. Therm. Eng. 2023, 227, 120344. [Google Scholar] [CrossRef]

- Ding, X.; Li, W.; Liu, P.; Kang, Z. Numerical calculation on combustion process and NO transformation behavior in a coal-fired boiler blended ammonia: Effects of the injection position and blending ratio. Int. J. Hydrogen Energy 2023, 48, 29771–29785. [Google Scholar] [CrossRef]

- Suyatno, S.; Hariana, H.; Prismantoko, A.; Putra, H.P.; Sunyoto, N.M.S.; Darmawan, A.; Ghazidin, H.; Aziz, M. Assessment of potential tropical woody biomass for coal co-firing on slagging and fouling aspects. Therm. Sci. Eng. Prog. 2023, 44, 102046. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, Q.; Kang, X.; Hou, B.; Zhu, Y.; Zhou, H. Comparative experimental study on the co-firing characteristics of water electrolysis gas (HHO) and lean coal/lignite with different injection modes in a one-dimensional furnace. Fuel 2024, 378, 132968. [Google Scholar] [CrossRef]

- Ding, Y.; Li, D.; Zhang, X.; Lv, M.; Qin, S.; Zhao, P.; Guo, C. Research on the co-combustion characteristics and kinetics of rice husk hydrochar with anthracite. Energy 2024, 299, 131339. [Google Scholar] [CrossRef]

- Ni, Y.; Hu, S.; Zhang, Y.; Zhang, M.; Li, H.; Zhou, H. Research on the effects of the fly ash reburning on element migration and ash deposition characteristics of high-alkali coal in a full-scale slag-tapping boiler. Fuel 2023, 335, 126952. [Google Scholar] [CrossRef]

- Zhong, Y.-X.; Wang, X.; Xu, G.; Ning, X.; Zhou, L.; Tang, W.; Wang, M.-H.; Wang, T.; Xu, J.; Jiang, L.; et al. Investigation on slagging and high-temperature corrosion prevention and control of a 1000 MW ultra supercritical double tangentially fired boiler. Energy 2023, 275, 127455. [Google Scholar] [CrossRef]

- Novendianto, I.B.; Utomo, M.; Muchammad, M.; Kuswa, F.M.; Ghazidin, H.; Karuana, F.; Santoso, P.A.; Prismantoko, A.; Cahyo, N.; Kusmiyati, K.; et al. Investigation of the slagging and fouling aspects of co-firing coal and organic refuse-derived fuel. Therm. Sci. Eng. Prog. 2024, 49, 102447. [Google Scholar] [CrossRef]

- Yin, H.; Liu, X.; Li, M.; Li, C.; Li, X.; Wang, H. Integrated DNN and CFD model for real-time prediction of furnace waterwall slagging of coal-fired boiler. Fuel 2025, 383, 133847. [Google Scholar] [CrossRef]

- Chen, B.; Xiong, Z.; Zhao, Y.; Zhang, J. Transformation of Mg-bearing minerals and its effect on slagging during the high-alkali coal combustion. Fuel Process. Technol. 2025, 267, 108166. [Google Scholar] [CrossRef]

- Kang, W.; Jo, H.; Lee, J.; Jang, K.; Ryu, C. Numerical investigations on overfire air design for improved boiler operation and lower NOx emission in commercial wall-firing coal power plants. Appl. Therm. Eng. 2023, 219, 119604. [Google Scholar] [CrossRef]

- Chang, J.; Ma, X.; Wang, X.; Li, X. CPFD modeling of hydrodynamics, combustion and NOx emissions in an industrial CFB boiler. Particuology 2023, 81, 174–188. [Google Scholar] [CrossRef]

- Tong, Y.; Gao, J.; Yue, T.; Liu, J.; Yuan, Y. Spatio-temporal heterogeneity and synergistic effects of air pollutants and CO2 emissions from Chinese coal-fired industrial boilers. Resour. Conserv. Recycl. 2024, 204, 107504. [Google Scholar] [CrossRef]

- Su, K.; Ouyang, Z.; Li, S.; Chen, Q.; Wang, H.; Ding, H.; Wang, W. Exploration on deep pulverized coal activation and ultra-low NOx emission strategies with novel purifying-combustion technology. Energy 2024, 313, 133814. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, S.; He, X.; Ding, X.; Li, W.; Liu, P. Combustion stability and NOx emission characteristics of three combustion modes of pulverized coal boilers under low or ultra-low loads. Appl. Energy 2024, 353, 121998. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Bai, N.; Han, J. Experimental investigation of the characteristics of NOx emissions with multiple deep air-staged combustion of lean coal. Fuel 2020, 280, 118416. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Junga, R.; Błaszczuk, A.; Modliński, N.; Sobek, S.; Marczak-Grzesik, M.; Adrian, Ł.; Dzikuć, M. Numerical modeling of the co-firing process of an in situ steam-torrefied biomass with coal in a 230 MW industrial-scale boiler. Energy 2023, 263, 125918. [Google Scholar] [CrossRef]

- Yuan, Z.; Chen, Z.; Zhang, B.; Gao, X.; Li, J.; Qiao, Y.; Li, Z. Study on the slagging trends of the pre-combustion chamber in industrial pulverized coal boiler under different excess air coefficients by CFD numerical simulation. Energy 2023, 264, 126184. [Google Scholar] [CrossRef]

- Bian, C.; Huang, J.; Sun, R. Numerical optimization of combustion and NOX emission in a retrofitted 600MWe tangentially-fired boiler using lignite. Appl. Therm. Eng. 2023, 226, 120228. [Google Scholar] [CrossRef]

- Zima, W.; Grądziel, S.; Cebula, A.; Rerak, M.; Kozak-Jagieła, E.; Pilarczyk, M. Mathematical model of a power boiler operation under rapid thermal load changes. Energy 2023, 263, 125836. [Google Scholar] [CrossRef]

- Taler, J.; Trojan, M.; Dzierwa, P.; Kaczmarski, K.; Węglowski, B.; Taler, D.; Zima, W.; Grądziel, S.; Ocłoń, P.; Sobota, T.; et al. The flexible boiler operation in a wide range of load changes with considering the strength and environmental restrictions. Energy 2023, 263, 125745. [Google Scholar] [CrossRef]

- Zhu, S.; Hui, J.; Lyu, Q.; Ouyang, Z.; Liu, J.; Zhu, J.; Zeng, X.; Zhang, X.; Ding, H.; Liu, Y.; et al. Experimental study on pulverized coal combustion preheated by a circulating fluidized bed: Preheating characteristics for peak shaving. Fuel 2022, 324, 124684. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, S.; He, X.; Zhang, J.; Ding, X. Combustion stability and NOX emission characteristics of a 300 MWe tangentially fired boiler under ultra-low loads with deep-air staging. Energy 2023, 269, 126795. [Google Scholar] [CrossRef]

- Du, H.; Li, Z.; Liu, Z.; Zhang, M.; Huang, C.; Jiang, G.; Chen, Z.; Song, J.; Fang, F.; Su, J.; et al. Industrial measurement of combustion and NOx formation characteristics on a low-grade coal-fired 600MWe FW down-fired boiler retrofitted with novel low-load stable combustion technology. Fuel 2022, 321, 123926. [Google Scholar] [CrossRef]

- Jin, W.; Si, F.; Kheirkhah, S.; Yu, C.; Li, H.; Wang, Y.O. Numerical study on the effects of primary air ratio on ultra-low-load combustion characteristics of a 1050 MW coal-fired boiler considering high-temperature corrosion. Appl. Therm. Eng. 2023, 221, 119811. [Google Scholar] [CrossRef]

- Fan, H.J.; Zhang, Z.X.; Dong, J.C.; Xu, W. China’s R&D of advanced ultra-supercritical coal-fired power generation for addressing climate change. Therm. Sci. Eng. Prog. 2018, 5, 364–371. [Google Scholar]

- Lu, H.; Huang, S.; Li, H.; Cheng, Z.; Chang, X.; Dong, L.; Kong, D.; Jing, X. Numerical simulation of combustion characteristics in a 660 MW tangentially fired pulverized coal boiler subjected to peak-load regulation. Case Stud. Therm. Eng. 2023, 49, 103168. [Google Scholar] [CrossRef]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Jiang, Y.; Lee, B.-H.; Oh, D.-H.; Jeon, C.-H. Influence of various air-staging on combustion and NOX emission characteristics in a tangentially fired boiler under the 50% load condition. Energy 2022, 244, 123167. [Google Scholar] [CrossRef]

- Inc, F. Ansys Fluent Theory Guide; Fluent Inc.: New York, NY, USA, 2023. [Google Scholar]

- Kobayashi, H.; Howard, J.B.; Sarofim, A.F. Coal devolatilization at high temperatures. Symp. (Int.) Combust. 1977, 16, 411–425. [Google Scholar] [CrossRef]

- Baum, M.; Street, P. Predicting the combustion behaviour of coal particles. Combust Sci. Technol. 1971, 3, 231–243. [Google Scholar] [CrossRef]

- Sazhin, S.S.; Sazhina, E.M.; Faltsi-Saravelou, O.; Wild, P. The P-1 model for thermal radiation transfer: Advantages and limitations. Fuel 1996, 75, 289–294. [Google Scholar] [CrossRef]

- Anetor, L.; Odetunde, C.; Osakue, E.E. Computational analysis of the extended Zeldovich mechanism. Arab. J. Sci. Eng. 2014, 39, 8287–8305. [Google Scholar] [CrossRef]

- De Soete, G.G. Overall reaction rates of NO and N2 formation from fuel nitrogen. Symp. (Int.) Combust. 1975, 15, 1093–1102. [Google Scholar] [CrossRef]

- Liu, S.; Fan, W. Formation characteristics of NO and N2O during air-staged combustion of pulverized coal. Fuel 2024, 372, 132093. [Google Scholar] [CrossRef]

| Proximate (As Received, wt%) | Coal 1 | Coal 2 | Ultimate (As Received, wt%) | Coal 1 | Coal 2 |

|---|---|---|---|---|---|

| Moisture | 28.80 | 17.00 | Carbon | 53.87 | 39.94 |

| Ash | 3.28 | 29.81 | Hydrogen | 2.24 | 2.00 |

| Volatile | 21.03 | 20.13 | Oxygen | 10.99 | 10.64 |

| Fixed carbon | 46.89 | 33.06 | Nitrogen | 0.42 | 0.41 |

| Net heating value (MJ/kg) | 18.74 | 13.86 | Sulfur | 0.40 | 0.20 |

| Load Condition | 100% Load | 50% Load |

|---|---|---|

| Total air flow (t/h) | 2210.20 | 1347.95 |

| Primary air flow (t/h) | 590.12 | 409.08 |

| Secondary air flow (t/h) | 1120.57 | 566.84 |

| Over-fire air flow (t/h) | 499.51 | 372.03 |

| Total coal flow (t/h) | 332.38 | 177.36 |

| Primary air temperature (K) | 338.15 | 338.15 |

| Secondary air temperature (K) | 638.15 | 585.15 |

| Blending ratio (%) | 60.00 | 100.00 |

| Excess air ratio | 1.14 | 1.67 |

| Layer of burners | BCDEF | BCDE |

| Load Condition | 100% Load | 50% Load | |

|---|---|---|---|

| Main steam flow | t/h | 2030.00 | 915.74 |

| Main steam outlet pressure | MPa.g | 28.25 | 13.81 |

| Main steam outlet temperature | °C | 605.00 | 605.00 |

| Feed-water pressure | MPa.g | 32.05 | 15.70 |

| Feed-water temperature | °C | 303.00 | 255.30 |

| Separator pressure | MPa.g | 30.10 | 14.70 |

| Reheat steam flow | t/h | 1637.22 | 782.13 |

| Reheat steam outlet pressure | MPa.g | 5.80 | 2.75 |

| Reheat steam outlet temperature | °C | 603.00 | 590.00 |

| Reheat steam inlet pressure | MPa.g | 6.00 | 2.85 |

| Reheat steam inlet temperature | °C | 360.00 | 370.30 |

| Flue gas temperature at air preheater inlet | °C | 396.00 | 363.00 |

| Exhaust gas temperature | °C | 134.00 | 124.00 |

| Exhaust gas temperature (revised) | °C | 130.00 | 118.00 |

| Carbon loss | % | 0.30 | 0.80 |

| Boiler thermal efficiency | % | 94.05 | 93.93 |

| Terms | Models | Numerical Descriptions |

|---|---|---|

| Turbulence model | Realizable k-ɛ | |

| Gas–solid model | Particle trajectory | |

| Volatiles combustion | Eddy-dissipation | |

| Coal devolatilization | Two-competing-rates | |

| Char combustion | Diffusion/kinetic-limited | |

| Radiation model | P-1 | |

| NO model | Thermal NO | |

| Fuel NO | As shown in Figure 2 |

| Load Condition | 100% Load | 50% Load | |

|---|---|---|---|

| The gas temperature at the bottom of the DPSH (K) | Simulated | 1479.49 | 1146.16 |

| Measured | 1423.15 | 1198.78 | |

| Relative error | 3.96% | −4.39% | |

| The gas temperature at the side of the FSH and FRH (K) | Simulated | 1132.67 | 942.40 |

| Measured | 1183.55 | 973.64 | |

| Relative error | −4.30% | −3.21% | |

| Furnace outlet of O2 (vol%) | Simulated | 2.75 | 3.07 |

| Measured | 2.73 | / | |

| Designed | / | 3.00 | |

| Relative error | 0.73% | 2.33% | |

| 5 | |||

| Furnace outlet of NOx (mg/m3, @6%O2) | Simulated | 157.02 | 151.60 |

| Measured | 152.37 | 150.18 | |

| Relative error | 3.05% | 0.94% |

| Case Name | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 |

|---|---|---|---|---|---|---|

| SOFA ratio | 17.5% | 22.5% | 27.5% | 27.5% | 27.5% | 27.5% |

| Angle of burner | 0° | 0° | 0° | −5° | −10° | −15° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.; Lu, H. Numerical Optimization of Burner Deflection Angle at Half Load for a 660 MW Tangentially Fired Boiler. Processes 2024, 12, 2823. https://doi.org/10.3390/pr12122823

Huang S, Lu H. Numerical Optimization of Burner Deflection Angle at Half Load for a 660 MW Tangentially Fired Boiler. Processes. 2024; 12(12):2823. https://doi.org/10.3390/pr12122823

Chicago/Turabian StyleHuang, Shangwen, and Hao Lu. 2024. "Numerical Optimization of Burner Deflection Angle at Half Load for a 660 MW Tangentially Fired Boiler" Processes 12, no. 12: 2823. https://doi.org/10.3390/pr12122823

APA StyleHuang, S., & Lu, H. (2024). Numerical Optimization of Burner Deflection Angle at Half Load for a 660 MW Tangentially Fired Boiler. Processes, 12(12), 2823. https://doi.org/10.3390/pr12122823