Towards Flexible Control of Production Processes: A Requirements Analysis for Adaptive Workflow Management and Evaluation of Suitable Process Modeling Languages

Abstract

1. Introduction

2. Foundations and Related Work

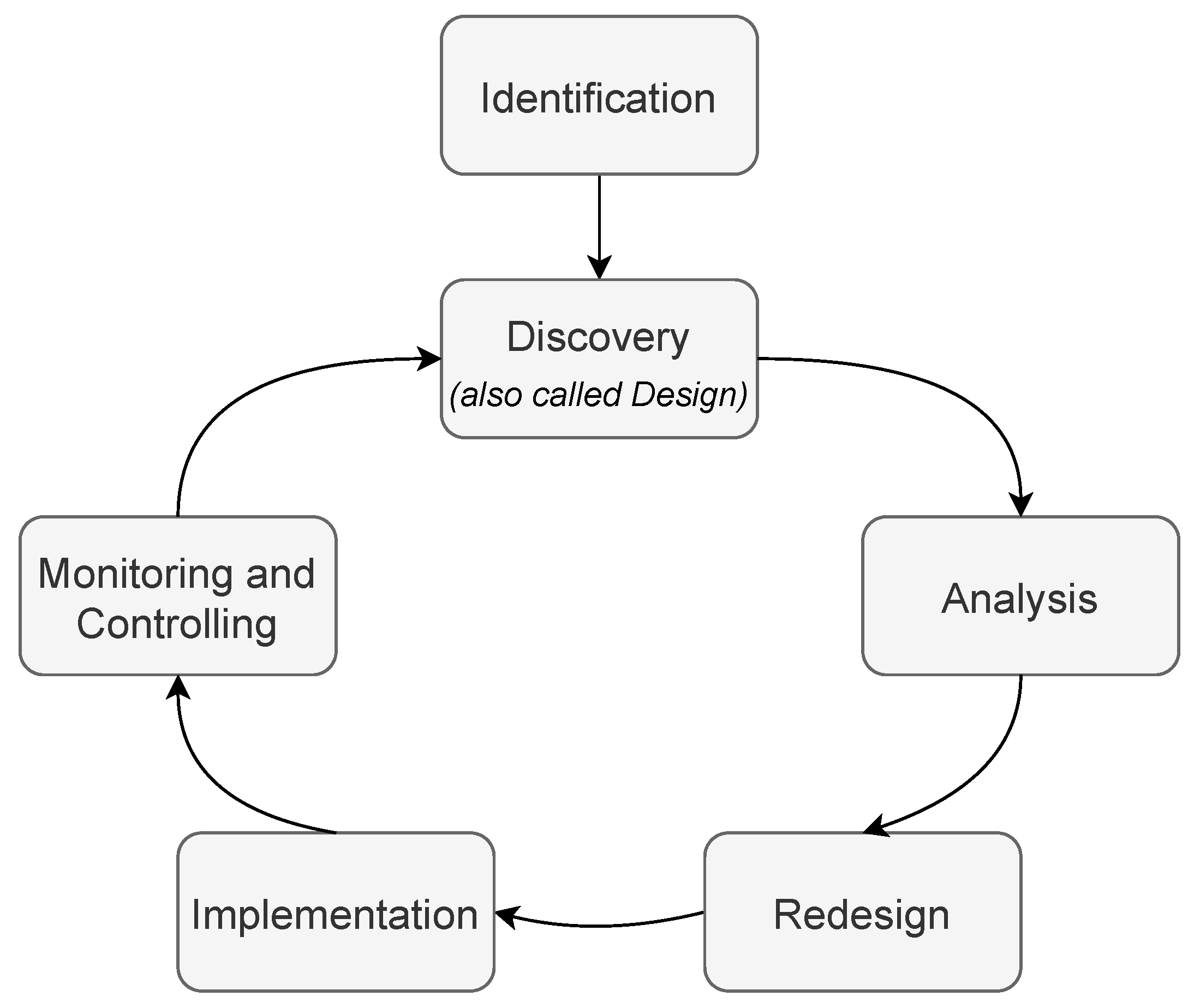

2.1. Business Process Management

2.2. Adaptive Workflow Management and AI Planning

2.3. Process Modeling Languages

2.4. Literature Reviews on Process Modeling Languages

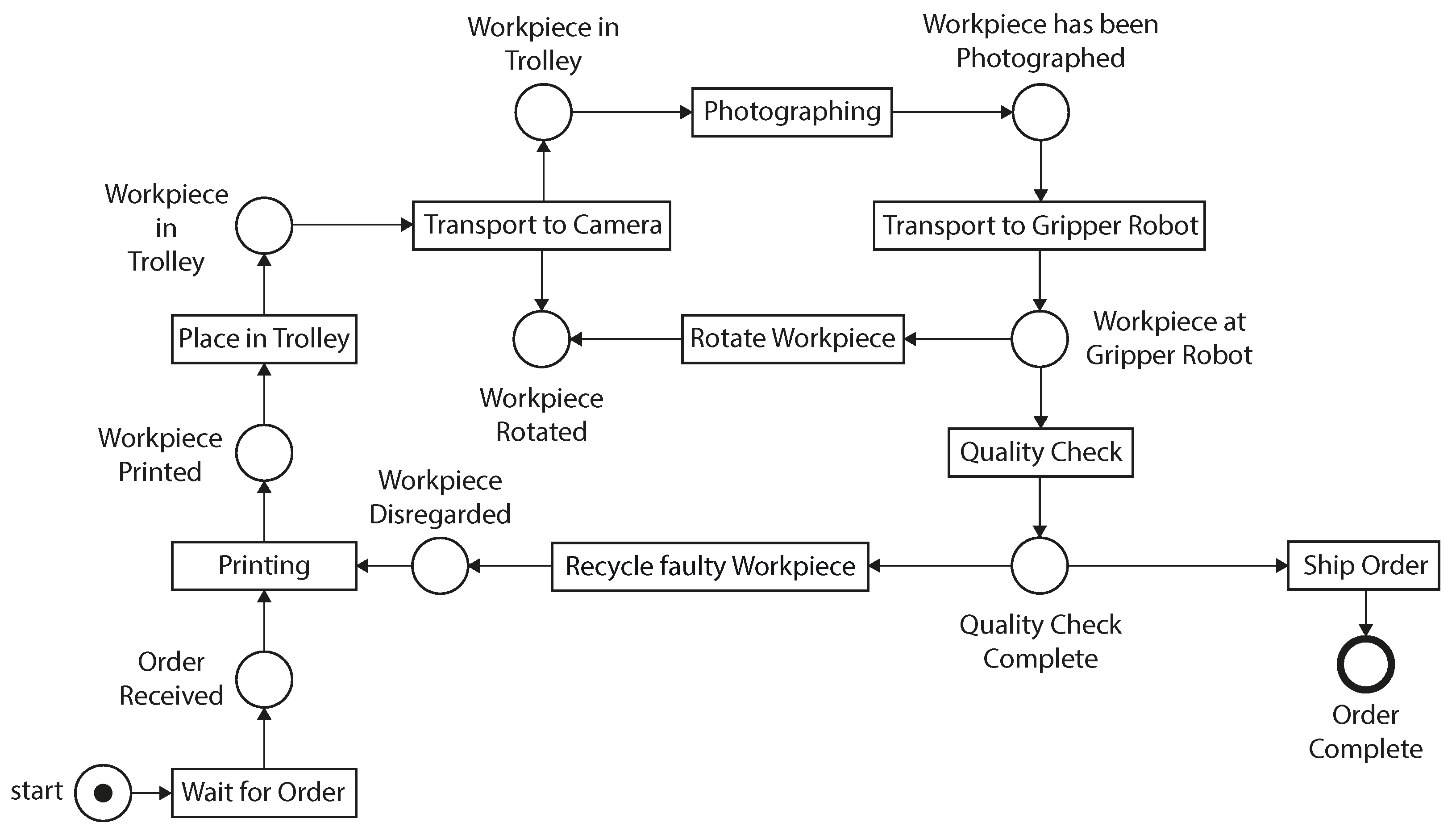

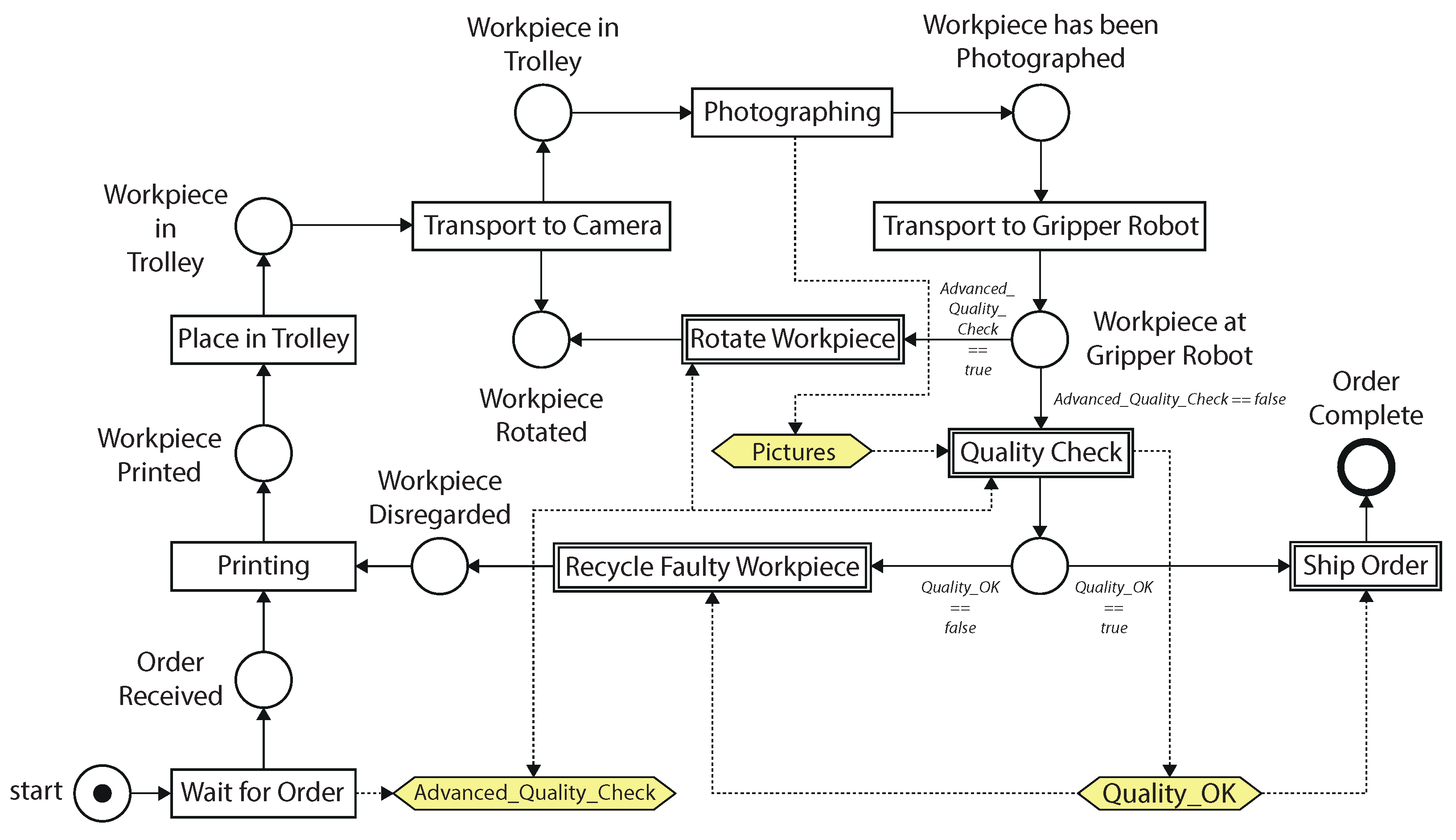

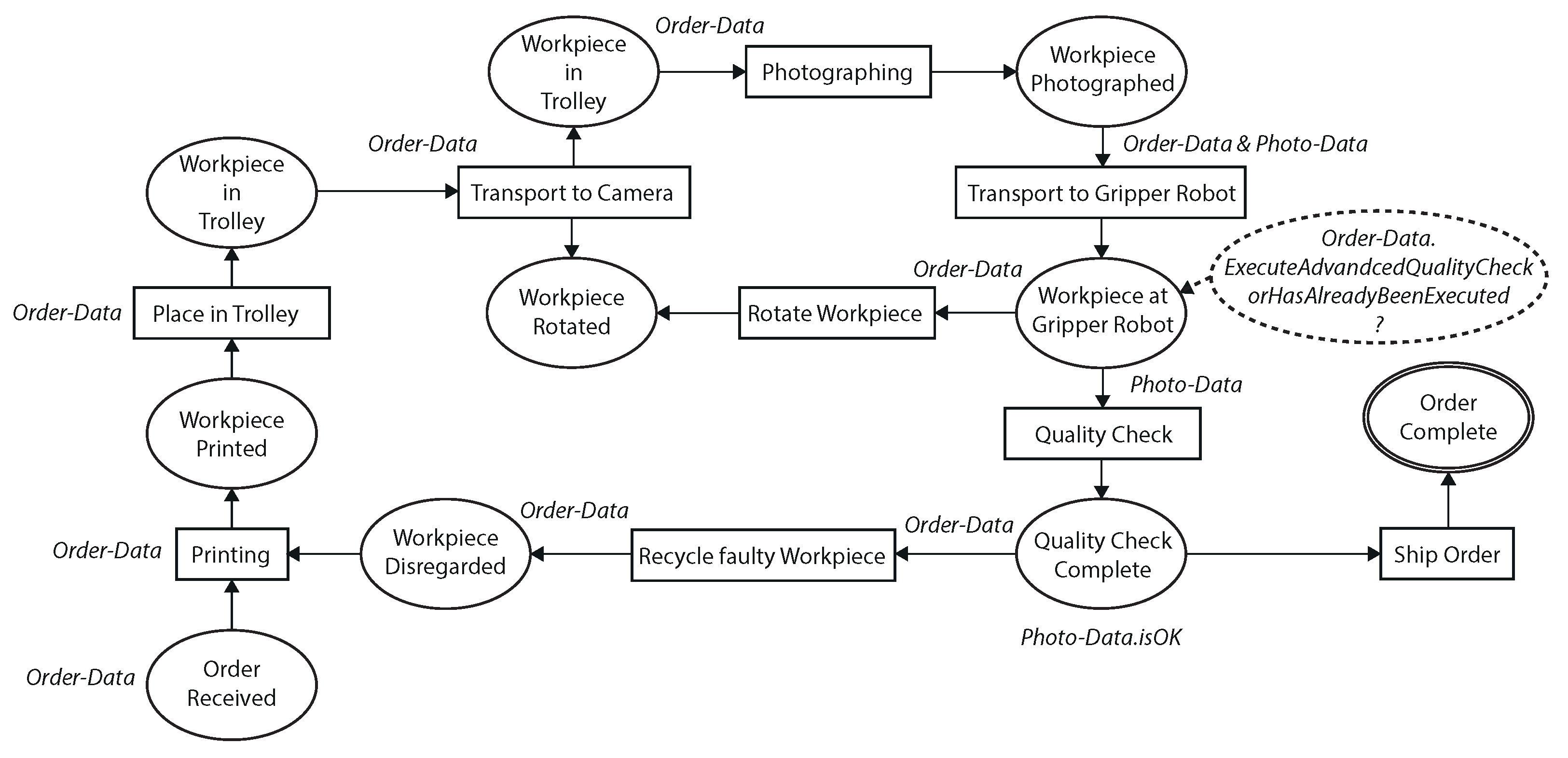

3. Process Modeling Languages for Manufacturing

4. Requirements for Flexible Control and the Representation of Corresponding Processes

4.1. Requirements for Process Flexibility

- Req. 1 (PF): Supported Process Types. The flexible process control should support production processes with different levels of automation, e.g., from human workstations to completely automated processes. The information should be able to be transferred to the central planning system in a standardized form, e.g., via HTTPS, regardless of the degree of automation, to be considered in the flexible control. This communication should be possible both synchronously and asynchronously. Single-stage, linear, as well as modular production scenarios, such as matrix production, should be able to be represented in the process flexibility. Supporting processes, such as a transport process, are also integrated, but no external processes are considered due to safety precautions.

- Req. 2 (PF): Robustness of the Processes. The flexible manufacturing processes should explicitly support redundant components and production paths to achieve process stability and a high level of robustness. This promises a high level of resilience to potential errors, as alternative paths are available in the event of failures, allowing the production processes to continue.

- Req. 3 (PF): Variable Scalability of the Processes. The process flexibility should have variable scalability in its components. The batch size of the products to be manufactured should be freely variable, as should the number of process stations. Additionally, the stations should allow for flexible reconfiguration.

- Req. 4 (PF): Process Data. Four sub-requirements are defined for the data generated as part of the flexible manufacturing processes. These are presented in the following.

- Req. 4a (PF): Data Capture. In the context of process flexibility, it should be possible to prioritize certain parts of the available data during the collection and processing to allow for lower latency by ignoring irrelevant data. Additionally, the volume of data to be captured and processed should also be variable. For example, it should be allowed to increase the volume captured above the normal level during a failure analysis to better understand the nature of the failure.

- Req. 4b (PF): Near-Real-Time Data Processing. The data from flexible manufacturing processes should be provided with minimal latency to enable near real-time monitoring and dynamic integration. This allows for quick reactions and interventions to rectify failures or events that impair performance. Automated checking and logging of data should be variable, allowing users to select process-specific data and choose a logging level.

- Req. 4c (PF): Data Representation. The data generated during the flexible manufacturing processes is transferred to a data model. This model should be based on established standards such as the Asset Administration Shell (AAS) [80] or the Open Platform Communications Unified Architecture (OPC-UA) [81]. So, the data can be processed automatically by as wide a range of systems as possible, or existing converters can be used. The model for data representation should support different types of data sources, such as process descriptions of individual tasks, shifts of different employees, lists of parts, machine status, images for quality inspection, measurement curves, or manually recorded data.

- Req. 4d (PF): Data Access. It should be possible to grant access to data on different levels of abstraction. For example, sometimes it is beneficial to be able to access unprocessed data instead of the already processed abstracted data. The availability and origin of the data should be transparently traceable, with clear and transparent access authorizations ensuring data sovereignty. Data lifetimes should be planned according to user requirements, ranging from a few days to permanently.

- Req. 5 (PF): Optimization Criteria Support for Intelligent Process Planning. When planning flexible manufacturing processes, it should be possible to consider various optimization criteria, both at a global and a local level. At the global level, e.g., this could be the shop floor, for which the production times are optimized, or at the local level, e.g., a machine, or product for which the costs incurred are to be minimized. It should also be possible to define more abstract target values for the optimization, such as a high error tolerance for the production process or sustainability criteria, such as minimizing the CO2 footprint.

4.2. Requirements for Process Discovery

- Req. 1 (PD): Representation of the Entire Control Flow. The PML must enable a representation of the control flow as it is present in business processes. This can only be an imperative language (see Section 2.3). However, the PML should further enables the representation of possible branches running in parallel and the associated gates within the control flows to be able to simulate real production processes. The data required for execution of the process must also be presentable.

- Req. 2 (PD): Compatibility with ERP and MES Systems. The PML should be compatible with established Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES) systems to minimize the hurdles for industrial use. This is achieved through generic connectors so that only minimal adaptations are necessary for the respective system. In addition, standardized data spaces should be used to further simplify the connection, e.g., by using established information models such as the AAS [80] or the Gaia-X Federation Services (GXFS) [82]. This should enable execution in distributed cloud-based data infrastructure ecosystems, for example, with an edge-cloud continuum [6].

- Req. 3 (PD): Interfaces to Other Process Modeling Languages. Flexible process control requires suitable forms of representation of manufacturing processes that can be interpreted by computers and used as input for AI-based planning approaches. The aim is to achieve a broad compatibility, e.g., with processes that are already formally represented, but also with unstructured forms, such as natural language. Therefore, the systems implemented based on the PML should contain interfaces that are as generic as possible so that converters or adapters for other PMLs can be connected to them. To make this possible, the PML should be as established and as well documented as possible.

- Req. 4 (PD): Included Data. In addition to the data that describes the actual processes (see Req. 1 (PD)), manufacturing companies also have a wide range of other information that can be useful for controlling processes. The PML used for the flexible control of production processes should, therefore, further include information about the process environment in addition to information about the actual production process. This information can include, e.g., information about employee shifts or the shop floor of the workshop.

- Req. 5 (PD): Semantic Information. To enable the processes using AI-planning procedures, it is necessary that the processes are described semantically. The PML should allow the semantic modeling of the individual work steps. It must be possible to query the current status of the running process at any time. An established standard for this is the OWL-S standard [83], in which services contain the following descriptions:

- (a)

- Inputs: information passed to the service,

- (b)

- Outputs: information returned after execution,

- (c)

- Preconditions: conditions that need to be met in order for the service to be executable,

- (d)

- Effects: changes to the world state after the service has been executed.

These attributes or a suitable equivalent must be supported by the PML. The need for semantic enrichment of the process representation is already identified in the research area of Semantic Business Process Management [84].

5. Analysis of Process Modeling Languages

5.1. Pre-Selection

- The Occurrence in Literature Reviews (see Section 2.4) provides information about the relevance and acceptance of the language in the scientific community. Frequent occurrence indicates high popularity, while rare or no occurrence indicates low acceptance.

- The number of Citations of the Basic Paper that introduces the PML or scientifically elaborates on it is used, whereby citations of basic papers are more meaningful than those of elaborating publications. For some languages, it should be noted that no basic paper is available or that this is not a scientifically established paper (e.g., for BPDM [55], BPMN [56], SPEM [73], or UML [85]).

- The number of Search Results on Google Scholar (https://scholar.google.de) provides information on how frequently the PML is used and how established it is. Here, the languages are searched for in written form and not as abbreviations.

5.2. Detailed Comparison

6. Integration of Semantics

6.1. Extension of BPMN

- (a)

- (b)

- Design of New Custom Extension: If the existing extension approaches turn out to be unsuitable for flexible control, this variant would be an alternative. This would make it possible to extend the BPMN standard with precisely those elements that process planning requires.

6.2. Outsourcing of Semantics

6.3. Preferred Solution

7. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AAS | Asset Administration Shell |

| AI | Artificial Intelligence |

| AWM | Adaptive Workflow Management |

| BPEL | Business Process Execution Language |

| BPMN | Business Process Model and Notation |

| BPM | Business Process Management |

| BWW | Bunge-Wand-Weber |

| CBP | Case-Based Planning |

| CBR | Case-Based Reasoning |

| CPN | Couloured Petri Nets |

| DPN | Data Petri Nets |

| DSR | Design Science Research |

| ECC | Edge-Cloud Continuum |

| EPC | Event-Driven Process Chains |

| ERP | Enterprise Resource Planning |

| FL | Federated Learning |

| I4.0 | Industry 4.0 |

| IoT | Internet of Things |

| MES | Manufacturing Execution System |

| ML | Machine Learning |

| PDDL | Planning Domain Definition Language |

| PML | Process Modeling Language |

| PN | Petri Nets |

| POCBR | Process-Oriented Case-Based Reasoning |

| REA | Resource Event Agent |

| TCBR | Temporal Case-Based Reasoning |

| UML-AD | Unified Modeling Language Activity Diagram |

| UML | Unified Modeling Language |

| YAWL | Yet Another Event-Driven Process Chain |

References

- Gilchrist, A. Industry 4.0: The Industrial Internet of Things; Apress: Berkeley, CA, USA, 2016. [Google Scholar] [CrossRef]

- Janiesch, C.; Koschmider, A.; Mecella, M.; Weber, B.; Burattin, A.; Ciccio, C.D.; Gal, A.; Kannengiesser, U.; Mannhardt, F.; Mendling, J.; et al. The Internet-of-Things Meets Business Process Management. A Manifesto. IEEE Syst. Man Cybern. Mag. 2020, 6, 34–44. [Google Scholar] [CrossRef]

- Malburg, L.; Hoffmann, M.; Bergmann, R. Applying MAPE-K control loops for adaptive workflow management in smart factories. J. Intell. Inf. Syst. 2023, 61, 83–111. [Google Scholar] [CrossRef]

- De Luzi, F.; Leotta, F.; Marrella, A.; Mecella, M. On the Interplay Between Business Process Management and Internet-Of-Things: A Systematic Literature Review. Bus. Inf. Syst. Eng. 2024. [Google Scholar] [CrossRef]

- Marrella, A. What Automated Planning Can Do for Business Process Management. In Proceedings of the BPM 2017 Workshops; LNBIP; Springer: Berlin/Heidelberg, Germany, 2018; Volume 308, pp. 7–19. [Google Scholar] [CrossRef]

- Schultheis, A.; Alt, B.; Bast, S.; Guldner, A.; Jilg, D.; Katic, D.; Mundorf, J.; Schlagenhauf, T.; Weber, S.; Bergmann, R.; et al. EASY: Energy-Efficient Analysis and Control Processes in the Dynamic Edge-Cloud Continuum for Industrial Manufacturing. Künstliche Intell. 2024. [Google Scholar] [CrossRef]

- Schonenberg, H.; Mans, R.; Russell, N.; Mulyar, N.; van der Aalst, W.M.P. Process Flexibility: A Survey of Contemporary Approaches. In Advances in Enterprise Engineering I. 4th International Workshop CIAO! and 4th International Workshop EOMAS, Held at CAiSE 2008, Montpellier, France, June 16–17, 2008, Proceedings; LNBIP; Springer: Berlin/Heidelberg, Germany, 2008; Volume 10, pp. 16–30. [Google Scholar] [CrossRef]

- Reichert, M.; Weber, B. Enabling Flexibility in Process-Aware Information Systems—Challenges, Methods, Technologies; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Dumas, M.; Rosa, M.L.; Mendling, J.; Reijers, H.A. Fundamentals of Business Process Management, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Green, C. Application of Theorem Proving to Problem Solving. In Proceedings of the 1st IJCAI, IJCAI’69, Washington, DC, USA, 7–9 May 1969; pp. 219–240. [Google Scholar]

- Haslum, P. Admissible Heuristics for Automated Planning. Ph.D. Thesis, Institutionen för Datavetenskap—Umeå Universitet, Umeå, Sweden, 2006. [Google Scholar]

- Aamodt, A.; Plaza, E. Case-Based Reasoning: Foundational Issues, Methodological Variations, and System Approaches. AI Commun. 1994, 7, 39–59. [Google Scholar] [CrossRef]

- Malburg, L.; Brand, F.; Bergmann, R. Adaptive Management of Cyber-Physical Workflows by Means of Case-Based Reasoning and Automated Planning; LNBIP; Springer: Cham, Switzerland, 2022; Volume 466, pp. 79–95. [Google Scholar] [CrossRef]

- Chinosi, M.; Trombetta, A. BPMN: An introduction to the standard. Comput. Stand. Interfaces 2012, 34, 124–134. [Google Scholar] [CrossRef]

- Hu, J.; Aghakhani, G.; Hasic, F.; Serral, E. An Evaluation Framework for Design-Time Context-Adaptation of Process Modelling Languages. In The Practice of Enterprise Modeling 10th IFIP WG 8.1. Working Conference, PoEM 2017, Leuven, Belgium, November 22–24, 2017, Proceedings; LNBIP; Springer: Cham, Switzerland, 2017; Volume 305, pp. 112–125. [Google Scholar] [CrossRef]

- Kožíšek, F.; Vrana, I. Business Process Modelling Languages. AGRIS On-Line Pap. Econ. Inform. 2017, 9, 39–49. [Google Scholar] [CrossRef]

- Brouns, N.; Tata, S.; Ludwig, H.; Asensio, E.S.; Grefen, P. Modeling IoT-aware Business Processes—A State of the Art Report. arXiv 2018, arXiv:1811.00652. [Google Scholar] [CrossRef]

- von Garrel, J.; Schenk, M.; Seidel, H. Flexibilisierung der Produktion—Maßnahmen und Status-Quo. Flex. Produktionskapazität Innov. Manag. 2014, 81–126. [Google Scholar] [CrossRef]

- Houy, C.; Reiter, M.; Fettke, P.; Loos, P. Towards Green BPM—Sustainability and Resource Efficiency through Business Process Management. In Proceedings of the BPM Workshops; LNBIP; Springer: Berlin/Heidelberg, Germany, 2010; Volume 66, pp. 501–510. [Google Scholar] [CrossRef]

- Marrella, A. Automated Planning for Business Process Management. J. Data Semant. 2019, 8, 79–98. [Google Scholar] [CrossRef]

- Zhang, Y.; Ge, L. Method for process planning optimization with energy efficiency consideration. J. Adv. Manuf. Technol. 2015, 77, 2197–2207. [Google Scholar] [CrossRef]

- Zonta, T.; Da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Schultheis, A. Exploring a Hybrid Case-Based Reasoning Approach for Time Series Adaptation in Predictive Maintenance. In Proceedings of the 32nd ICCBR Workshops, CEUR Workshop Proceedings, Mérida, Mexico, 1 July 2024; Volume 3708, pp. 230–235. [Google Scholar]

- Bertrand, Y.; Belle, R.V.; Weerdt, J.D.; Serral, E. Defining Data Quality Issues in Process Mining with IoT Data. In Process Mining Workshops ICPM 2022 International Workshops, Bozen-Bolzano, Italy, October 23–28, 2022, Revised Selected Papers; LNBIP; Springer: Cham, Switzerland, 2022; Volume 468, pp. 422–434. [Google Scholar] [CrossRef]

- Schultheis, A.; Malburg, L.; Grüger, J.; Weich, J.; Bertrand, Y.; Bergmann, R.; Serral Asensio, E. Identifying Missing Sensor Values in IoT Time Series Data: A Weight-Based Extension of Similarity Measures for Smart Manufacturing. In Case-Based Reasoning Research and Development 32nd International Conference, ICCBR 2024, Merida, Mexico, July 1–4, 2024, Proceedings; LNCS; Springer: Cham, Switzerland, 2024; Volume 14775, pp. 240–257. [Google Scholar] [CrossRef]

- Malburg, L.; Klein, P.; Bergmann, R. Converting semantic web services into formal planning domain descriptions to enable manufacturing process planning and scheduling in industry 4.0. Eng. Appl. Artif. Intell. 2023, 126, 106727. [Google Scholar] [CrossRef]

- Hammond, K.J. Case-Based Planning: A Framework for Planning from Experience. Cogn. Sci. 1990, 14, 385–443. [Google Scholar] [CrossRef]

- Curtis, B.; Kellner, M.I.; Over, J. Process Modeling. Commun. ACM 1992, 35, 75–90. [Google Scholar] [CrossRef]

- Workflow Management Coalition. Terminol. Gloss. 1999.

- Mili, H.; Tremblay, G.; Jaoude, G.B.; Lefebvre, E.; Elabed, L.; El-Boussaidi, G. Business process modeling languages: Sorting through the alphabet soup. ACM Comput. Surv. 2010, 43, 1–56. [Google Scholar] [CrossRef]

- Fahland, D.; Lübke, D.; Mendling, J.; Reijers, H.; Weber, B.; Weidlich, M.; Zugal, S. Declarative versus Imperative Process Modeling Languages: The Issue of Understandability. In Enterprise, Business-Process and Information Systems Modeling 10th International Workshop, BPMDS 2009, and 14th International Conference, EMMSAD 2009, held at CAiSE 2009, Amsterdam, The Netherlands, June 8–9, 2009, Proceedings; Springer: Berlin/Heidelberg, Germany, 2009; pp. 353–366. [Google Scholar] [CrossRef]

- Conradi, R.; Jaccheri, M.L. Process Modelling Languages. In Software Process: Principles, Methodology, Technology; LNCS; Springer: Berlin/Heidelberg, Germany, 1999; Volume 1500, pp. 27–52. [Google Scholar] [CrossRef]

- Luo, W.; Alex Tung, Y. A framework for selecting business process modeling methods. Ind. Manag. Data Syst. 1999, 99, 312–319. [Google Scholar] [CrossRef]

- Söderström, E.; Andersson, B.; Johannesson, P.; Perjons, E.; Wangler, B. Towards a Framework for Comparing Process Modelling Languages. In Advanced Information Systems Engineering 14th International Conference, CAiSE 2002 Toronto, Canada, May 27–31, 2002 Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 2002; Volume 2348, pp. 600–611. [Google Scholar] [CrossRef]

- Aguilar-Savén, R.S. Business process modelling: Review and framework. Int. J. Prod. Econ. 2004, 90, 129–149. [Google Scholar] [CrossRef]

- Nysetvold, A.G.; Krogstie, J. Assessing Business Processing Modeling Languages Using a Generic Quality Framework. In Proceedings of the 10th EMMSAD, CEUR Workshop Proceedings, Porto, Portugal, 13–14 June 2005; Volume 363, pp. 159–170. [Google Scholar]

- List, B.; Korherr, B. An Evaluation of Conceptual Business Process Modelling Languages. In Proceedings of the SAC 2006, Dijon France, 23–27 April 2006; ACM: New York, NY, USA, 2006; pp. 1532–1539. [Google Scholar] [CrossRef]

- Korherr, B. Business Process Modelling—Languages, Goals, and Variabilities. Ph.D. Thesis, Technische Universität Wien, Vienna, Austria, 2008. [Google Scholar]

- Recker, J.; Rosemann, M.; Indulska, M.; Green, P.F. Business Process Modeling—A Comparative Analysis. J. Assoc. Inf. Syst. 2009, 10, 1. [Google Scholar] [CrossRef]

- zur Muehlen, M.; Indulska, M. Modeling languages for business processes and business rules: A representational analysis. Inf. Syst. 2010, 35, 379–390. [Google Scholar] [CrossRef]

- Campos, A.C.S.M.; de Almeida, A.T. Multicriteria framework for selecting a process modelling language. Enterp. Inf. Syst. 2016, 10, 17–32. [Google Scholar] [CrossRef]

- García-Borgoñón, L.; Barcelona, M.A.; García-García, J.A.; Alba, M.; Escalona, M.J. Software process modeling languages: A systematic literature review. Inf. Softw. Technol. 2014, 56, 103–116. [Google Scholar] [CrossRef]

- Goedertier, S.; Vanthienen, J.; Caron, F. Declarative business process modelling: Principles and modelling languages. Enterp. Inf. Syst. 2015, 9, 161–185. [Google Scholar] [CrossRef]

- Farshidi, S.; Kwantes, I.B.; Jansen, S. Business process modeling language selection for research modelers. Softw. Syst. Model. 2024, 23, 137–162. [Google Scholar] [CrossRef]

- Kitchenham, B.; Charters, S. Guidelines for Performing Systematic Literature Reviews in Software Engineering; EBSE 2007-001; Keele University: Keele, UK; Durham University: Durham, UK, 2007. [Google Scholar]

- Reichert, M.; Dadam, P. ADEPTflex-Supporting Dynamic Changes of Workflows Without Losing Control. J. Intell. Inf. Syst. 1998, 10, 93–129. [Google Scholar] [CrossRef]

- Lu, R.; Sadiq, S.W.; Governatori, G. On managing business processes variants. Data Knowl. Eng. 2009, 68, 642–664. [Google Scholar] [CrossRef]

- Pesic, M.; van der Aalst, W.M.P. Aalst, W.M.P. A Declarative Approach for Flexible Business Processes Management. In Business Process Management Workshops BPM 2006 International Workshops, BPD, BPI, ENEI, GPWW, DPM, semantics4ws, Vienna, Austria, September 4–7, 2006, Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 2006; Volume 4103, pp. 169–180. [Google Scholar] [CrossRef]

- Goedertier, S.; Vanthienen, J. Designing Compliant Business Processes with Obligations and Permissions. In Business Process Management Workshops BPM 2006 International Workshops, BPD, BPI, ENEI, GPWW, DPM, semantics4ws, Vienna, Austria, September 4–7, 2006, Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 2006; Volume 4103, pp. 5–14. [Google Scholar] [CrossRef]

- Ghallab, M.; Knoblock, C.; Wilkins, D.; Barrett, A.; Christianson, D.; Friedman, M.; Kwok, C.; Golden, K.; Penberthy, S.; Smith, D.; et al. PDDL—The Planning Domain Definition Language; Technical Report; ISAE: Toulouse, France, 1998. [Google Scholar]

- Slaats, T.; Schunselaar, D.M.M.; Maggi, F.M.; Reijers, H.A. The Semantics of Hybrid Process Models. In On the Move to Meaningful Internet Systems: OTM 2016 Conferences Confederated International Conferences: CoopIS, C&TC, and ODBASE 2016, Rhodes, Greece, October 24–28, 2016, Proceedings; LNCS; Springer: Cham, Switzerland, 2016; Volume 10033, pp. 531–551. [Google Scholar] [CrossRef]

- Buchmann, T.; Bank, M.; Westfechtel, B. BXtendDSL: A layered framework for bidirectional model transformations combining a declarative and an imperative language. J. Syst. Softw. 2022, 189, 111288. [Google Scholar] [CrossRef]

- Eertink, H.; Janssen, W.; Luttighuis, P.O.; Teeuw, W.B.; Vissers, C.A. A Business Process Design Language. In FM’99—Formal Methods World Congress on Formal Methods in the Developement of Computing Systems, Toulouse, France, September 20–24, 1999, Proceedings, Volume I; LNCS; Springer: Berlin/Heidelberg, Germany, 1999; Volume 1708, pp. 76–95. [Google Scholar] [CrossRef]

- Khalaf, R.; Mukhi, N.; Curbera, F.; Weerawarana, S. The Business Process Execution Language for Web Services. In Process-Aware Information Systems: Bridging People and Software Through Process Technology; Wiley: Hoboken, NJ, USA, 2005; pp. 317–342. [Google Scholar] [CrossRef]

- Object Management Group (OMG). Business Process Definition MetaModel Volume II: Process Definitions; Object Management Group: Needham, MA, USA, 2008. [Google Scholar]

- Object Management Group (OMG). Business Process Model and Notation (BPMN); Version 2.0; Object Management Group: Needham, MA, USA, 2011. [Google Scholar]

- Cognini, R.; Hinkelmann, K.; Martin, A. A Case Modelling Language for Process Variant Management in Case-Based Reasoning. In Business Process Management Workshops BPM 2015, 13th International Workshops, Innsbruck, Austria, August 31–September 3, 2015, Revised Papers; LNBIP; Springer: Cham, Switzerland, 2015; Volume 256, pp. 30–42. [Google Scholar] [CrossRef]

- Schiffers, M.; Wedde, H.F. Analyzing Program Solutions of Coordination problems by CP-Nets. In Mathematical Foundations of Computer Science 1978 7th Symposium Zakopane, Poland, September 4–8, 1978. Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 1978; Volume 64, pp. 462–473. [Google Scholar] [CrossRef]

- Nikolic, D.; Priami, C.; Zunino, R. A Rule-Based and Imperative Language for Biochemical Modeling and Simulation. In Software Engineering and Formal Methods 10th International Conference, SEFM 2012, Thessaloniki, Greece, October 1–5, 2012. Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7504, pp. 16–32. [Google Scholar] [CrossRef]

- Liu, L.; Özsu, M.T. Data Flow Diagrams. In Encyclopedia of Database Systems; Springer: New York, NY, USA, 2009; p. 581. [Google Scholar] [CrossRef]

- Lazic, R.; Newcomb, T.C.; Ouaknine, J.; Roscoe, A.W.; Worrell, J. In Nets with Tokens which Carry Data. Fundam. Informaticae 2008, 88, 251–274. [Google Scholar]

- van Hee, K.M.; Oanea, O.; Sidorova, N. Colored Petri Nets to Verify Extended Event-Driven Process Chains. In On the Move to Meaningful Internet Systems 2005: CoopIS, DOA, and ODBASE OTM Confederated International Conferences, CoopIS, DOA, and ODBASE 2005, Agia Napa, Cyprus, October 31–November 4, 2005, Proceedings Part I; LNCS; Springer: Berlin/Heidelberg, Germany, 2005; Volume 3760, pp. 183–201. [Google Scholar] [CrossRef]

- Keller, G.; Nüttgens, M.; Scheer, A.W. Semantische Prozessmodellierung auf der Grundlage Ereignisgesteuerter Prozessketten (epk); Institut für Wirtschaftsinformatik—Universität des Saarlandes: Saarbrücken, Germany, 1992. [Google Scholar]

- Chapin, N. Flowchart. In Encyclopedia of Computer Science; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2003; pp. 714–716. [Google Scholar]

- Bergmann, R.; Gil, Y. Similarity assessment and efficient retrieval of semantic workflows. Inf. Syst. 2014, 40, 115–127. [Google Scholar] [CrossRef]

- Petrasch, R.; Hentschke, R. Process modeling for industry 4.0 applications: Towards an industry 4.0 process modeling language and method. In Proceedings of the 13th JCSSE, Khon Kaen, Thailand, 13–15 July 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Mayer, R.J.; Menzel, C.P.; Painter, M.K.; Dewitte, P.S.; Blinn, T.; Perakath, B. Information Integration for Concurrent Engineering (IICE) IDEF3 Process Description Capture Method Report; Knowledge Based Systems Inc. (KBSI): College Station, TX, USA, 1995. [Google Scholar]

- Mukund, M. Linear-Time Temporal Logic and Büchi Automata; Tutorial Talk; Winter School on Logic and Computer Science, Indian Statistical Institute: Calcutta, India, 1997. [Google Scholar]

- Anderl, R.; Raßler, J. PML, an Object Oriented Process Modeling Language. In Computer-Aided Innovation (CAI) IFIP 20th World Computer Congress, Proceedings of the Second Topical Session on Computer-Aided Innovation, WG 5.4/TC 5 Computer-Aided Innovation, September 7–10, 2008, Milano, Italy, 2nd ed.; IFIP Advances in Information and Communication Technology; Cascini, G., Ed.; Springer: Boston, MA, USA, 2008; Volume 277, pp. 145–156. [Google Scholar] [CrossRef]

- Petri, C.A. Kommunikation Mit Automaten. Ph.D. Thesis, Universität Hamburg, Hamburg, Germany, 1962. [Google Scholar]

- Wilson, J.M. Business Processes: Modelling and Analysis for Re-engineering and Improvement. J. Oper. Res. Soc. 1996, 47, 595–596. [Google Scholar] [CrossRef]

- McCarthy, W.E. The REA Accounting Model: A Generalized Framework for Accounting Systems Shared Data Environment. Account. Rev. 1982, 554–578. [Google Scholar]

- Object Management Group (OMG). Software Process Engineering Metamodell SPEM 2.0 Revised Submission; Object Management Group: Needham, MA, USA, 2006. [Google Scholar]

- Lamport, L. The Temporal Logic of Actions. ACM Trans. Program. Lang. Syst. 1994, 16, 872–923. [Google Scholar] [CrossRef]

- Dumas, M.; ter Hofstede, A.H.M. UML Activity Diagrams as a Workflow Specification Language. In UML 2001—The Unified Modeling Language. Modeling Languages, Concepts, and Tools 4th International Conference, Toronto, Canada, October 1–5, 2001. Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 2001; Volume 2185, pp. 76–90. [Google Scholar] [CrossRef]

- Object Management Group. OMG Unified Modeling Language, Specification; Version 1.3; Object Management Group: Needham, MA, USA, 2000. [Google Scholar]

- Andrews, T.; Curbera, F.; Dholakia, H.; Goland, Y.; Klein, J.; Leymann, F.; Liu, K.; Roller, D.; Smith, D.; Thatte, S.; et al. Business Process Execution Language for Web Services; Version 1.1; Standards Proposal by BEA Systems: San Jose, CA, USA; International Business Machines Corporation: Armonk, NY, USA; Microsoft Corporation: Redmond, WA, USA, 2003. [Google Scholar]

- Mendling, J.; Neumann, G.; Nüttgens, M. Yet Another Event-Driven Process Chain. In Business Process Management 3rd International Conference, BPM 2005, Nancy, France, September 5–8, 2005, Proceedings; Springer: Berlin/Heidelberg, Germany, 2005; Volume 3649, pp. 428–433. [Google Scholar] [CrossRef]

- Rabiee, F. Focus-Group Interview and Data Analysis. Proc. Nutr. Soc. 2004, 63, 655–660. [Google Scholar] [CrossRef]

- Wei, K.; Sun, J.; Liu, R. A Review of Asset Administration Shell. In Proceedings of the 2019 IEEM, Macao, China, 15–18 December 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1460–1465. [Google Scholar] [CrossRef]

- Leitner, S.; Mahnke, W. OPC UA—Service-oriented Architecture for Industrial Applications. Softwaretechnik-Trends 2006, 26. [Google Scholar]

- Kraemer, P.; Niebel, C.; Reiberg, A. Gaia-X and Business Models: Types and Examples; White Paper 1/2023; Gaia-X Hub: München, Germany, 2023. [Google Scholar]

- Martin, D.; Burstein, M.; Hobbs, J.; Lassila, O.; Mcdermott, D.; Mcilraith, S.; Narayanan, S.; Paolucci, M.; Parsia, B.; Payne, T.; et al. OWL-S: Semantic markup for Web services. W3C Memb. Submiss. 2004, 22. [Google Scholar]

- Hepp, M.; Leymann, F.; Domingue, J.; Wahler, A.; Fensel, D. Semantic Business Process Management: A Vision Towards Using Semantic Web Services for Business Process Management. In Proceedings of the 2005 ICEBE, Beijing, China, 12–18 October 2005; IEEE Computer Society: Piscataway, NJ, USA, 2005; pp. 535–540. [Google Scholar] [CrossRef]

- Object Management Group (OMG). Unified Modeling Language; Object Management Group: Needham, MA, USA, 2008. [Google Scholar]

- Billington, J.; Christensen, S.; van Hee, K.M.; Kindler, E.; Kummer, O.; Petrucci, L.; Post, R.; Stehno, C.; Weber, M. The Petri Net Markup Language: Concepts, Technology, and Tools. In Applications and Theory of Petri Nets 2003 24th International Conference, ICATPN 2003, Eindhoven, The Netherlands, June 23–27, 2003, Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 2003; Volume 2679, pp. 483–505. [Google Scholar] [CrossRef]

- Kindler, E. Using the Petri Net Markup Language for exchanging business processes? Potential and limitations. XML4BPM 2004, 43–60. [Google Scholar]

- Booch, G.; Jacobson, I.; Rumbaugh, J. The Unified Modeling Language for Object-Oriented Development. UNIX Rev. 1996, 14, 5. [Google Scholar]

- Marrella, A.; Mecella, M.; Sardiña, S. Intelligent Process Adaptation in the SmartPM System. ACM Trans. Intell. Syst. Technol. 2017, 8, 1–43. [Google Scholar] [CrossRef]

- Wong, P.Y.H.; Gibbons, J. A Process Semantics for BPMN. In Formal Methods and Software Engineering 10th International Conference on Formal Engineering Methods ICFEM 2008, Kitakyushu-City, Japan, October 27–31, 2008, Proceedings; LNCS; Springer: Berlin/Heidelberg, Germany, 2008; Volume 5256, pp. 355–374. [Google Scholar] [CrossRef]

- Intrigila, B.; Penna, G.D.; D’Ambrogio, A. A Lightweight BPMN Extension for Business Process-Oriented Requirements Engineering. Computers 2021, 10, 171. [Google Scholar] [CrossRef]

- Ardito, C.; Caivano, D.; Colizzi, L.; Verardi, L. BPMN Extensions and Semantic Annotation in Public Administration Service Design. In Human-Centered Software Engineering 8th IFIP WG 13.2 International Working Conference, HCSE 2020, Eindhoven, The Netherlands, November 30–December 2, 2020, Proceedings; LNCS; Springer: Cham, Switzerland, 2020; Volume 12481, pp. 118–129. [Google Scholar] [CrossRef]

- Braun, R.; Esswein, W. Semantics in the Context of BPMN Extensions—State of Affairs and Research Challenges. In Proceedings of the MKWI 2016, Ilmenau, Germany, 8–11 March 2016; Universitätsverlag Ilmenau: Ilmenau, Germany, 2016; Volume II, pp. 1119–1130. [Google Scholar]

- Malburg, L.; Klein, P.; Bergmann, R. Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0. In Proceedings of the IN4PL 2020; SciTePress: Setúbal, Portugal, 2020; pp. 32–43. [Google Scholar] [CrossRef]

- Diedrich, C.; Belyaev, A.; Blumenfeld, R.; Bock, J.; Grimm, S.; Hermann, J.; Klausmann, T.; Köcher, A.; Maurmaier, M.; Meixner, K.; et al. Information Model for Capabilities, Skills & Services; Plattform Industrie 4.0; Plattform Industrie: Berlin, Germany, 2022. [Google Scholar] [CrossRef]

- Uschold, M.; Gruninger, M. Ontologies: Principles, methods and applications. Knowl. Eng. Rev. 1996, 11, 96–136. [Google Scholar] [CrossRef]

- Martin, D.L.; Burstein, M.H.; McIlraith D., V.; McIlraith, S.A.; Paolucci, M.; Sycara, K.P.; McGuinness, D.L.; Sirin, E.; Srinivasan, N. Bringing Semantics to Web Services with OWL-S. World Wide Web 2007, 3, 243–277. [Google Scholar] [CrossRef]

- Sesboüé, M.; Delestre, N.; Kotowicz, J.; Khudiyev, A.; Zanni-Merk, C. An Operational Architecture for Knowledge Graph-Based Systems. Procedia Comput. Sci. 2022, 207, 1667–1676. [Google Scholar] [CrossRef]

- Malburg, L.; Schultheis, A.; Bergmann, R. Modeling and Using Complex IoT Time Series Data in Case-Based Reasoning: From Application Scenarios to Implementations. In Proceedings of the 31st ICCBR Workshops, CEUR Workshop Proceedings, Aberdeen, Scotland, 17–20 July 2023; Volume 3438, pp. 81–96. [Google Scholar]

- Sacerdoti, E.D. Planning in a Hierarchy of Abstraction Spaces. Artif. Intell. 1974, 5, 115–135. [Google Scholar] [CrossRef]

| Language Name | Acronym | Reference |

|---|---|---|

| Architectural Modeling Box for Enterprise Redesign | AMBER | [53] |

| Business Process Execution Language | BPEL | [54] |

| Business Process Definition Metamodel | BPDM | [55] |

| Business Process Model and Notation | BPMN | [56] |

| Case Management Model and Notation | CMMN | [57] |

| Coloured Petri Nets | CPN | [58] |

| ConDec | ConDec | [48] |

| COSBI LAB Language | [59] | |

| Data Flow Diagrams | DFD | [60] |

| Data Petri Nets | DPN | [61] |

| extended/enhanced Event-Driven Process Chains | eEPC | [62] |

| Event-Driven Process Chains | EPC | [63] |

| Flow Charts | FC | [64] |

| NEST Graphs | NEST | [65] |

| Industry 4.0 Process Modeling Language | I4PML | [66] |

| Integrated Definition/ICAM Definition | IDEF3 | [67] |

| Linear-Time Temporal Logik | LTL | [68] |

| Process Modeling Language | PML | [69] |

| Petri Nets | PN | [70] |

| Role Activity Diagrams | RAD | [71] |

| Resource Event Agent | REA | [72] |

| Software Process Engineering Metamodel Specification | SPEM | [73] |

| Temporal Logic of Actions | TLA | [74] |

| Unified Modeling Language Activity Diagram | UML AD | [75] |

| Unified Modeling Language Sequence Diagrams | UML SD | [76] |

| Business Process Executable Language for Web Services | WS-BPEL | [77] |

| Yet Another Event-Driven Process Chain | YAWL | [78] |

| PML | Req. 1 | Req. 2 | Req. 3 | Req. 4 | Req. 5 |

|---|---|---|---|---|---|

| BPMN | ✓ | ✓ | ✓ | (✓) | ✗ |

| EPC | ✓ | (✓) | ✗ | (✓) | ✗ |

| PN | ✓ | ✓ | ✓ | ✗ | ✗ |

| CPN | ✓ | (✓) | (✓) | ✓ | (✓) |

| DPN | ✓ | ✗ | (✓) | ✓ | (✓) |

| REA | ✗ | ∕ | ∕ | ∕ | ∕ |

| UML AD | ✓ | ✓ | (✓) | ✗ | ✗ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schultheis, A.; Jilg, D.; Malburg, L.; Bergweiler, S.; Bergmann, R. Towards Flexible Control of Production Processes: A Requirements Analysis for Adaptive Workflow Management and Evaluation of Suitable Process Modeling Languages. Processes 2024, 12, 2714. https://doi.org/10.3390/pr12122714

Schultheis A, Jilg D, Malburg L, Bergweiler S, Bergmann R. Towards Flexible Control of Production Processes: A Requirements Analysis for Adaptive Workflow Management and Evaluation of Suitable Process Modeling Languages. Processes. 2024; 12(12):2714. https://doi.org/10.3390/pr12122714

Chicago/Turabian StyleSchultheis, Alexander, David Jilg, Lukas Malburg, Simon Bergweiler, and Ralph Bergmann. 2024. "Towards Flexible Control of Production Processes: A Requirements Analysis for Adaptive Workflow Management and Evaluation of Suitable Process Modeling Languages" Processes 12, no. 12: 2714. https://doi.org/10.3390/pr12122714

APA StyleSchultheis, A., Jilg, D., Malburg, L., Bergweiler, S., & Bergmann, R. (2024). Towards Flexible Control of Production Processes: A Requirements Analysis for Adaptive Workflow Management and Evaluation of Suitable Process Modeling Languages. Processes, 12(12), 2714. https://doi.org/10.3390/pr12122714