Abstract

With the evolution of additive manufacturing technologies, concerning their material processing techniques, range of material choices and deposition speed, 3D printers are extensively employed in academia and industry for a number of purposes. It is no longer uncommon to have a portable, desktop 3D printer and build specific designs in a matter of minutes or hours. The functionality, costs, materials and applications of desktop 3D printers differ. Among the several desktop 3D printers with a variety of characteristics, it might be challenging to choose which one is optimal for the intended applications and uses. In this study, a variety of commercially available thermoplastic and photopolymer resin desktop 3D printers are presented and compared for user selection. This article intends to provide end-users of desktop 3D printers with fundamental information and guidelines via a comparison of desktop 3D-printing technologies and their technical characteristics, enabling them to assess and select appropriate desktop 3D printers for a variety of applications.

1. Introduction

One definition of a 3D printer is “a computer-aided manufacturing equipment that makes three-dimensional objects by connecting or solidifying specified materials” [1,2]. Recent breakthroughs in 3D manufacturing, specifically 3D printing or additive manufacturing, as well as the discovery of novel materials and process optimization, have ushered in a new manufacturing trend in a variety of scientific and technical fields [2,3]. Currently, three-dimensional printers are widely adopted by academics and end-users or general customers. Consequently, any user familiar with computer-aided design (CAD) software may upload G-code files to 3D printers and see their created things within a few minutes or hours [4,5,6,7,8,9,10,11,12,13]. In this context, initial prototypes used for aesthetic validation, functional prototypes used for operational assessment, and end-use products can be fabricated [14,15,16,17,18]. In this study, overviews of leading thermoplastic and photopolymer resin desktop 3D printers and their selection criteria—based on specifications, key performance factors, and characteristics for targeted end-users—are presented.

Three-dimensional printing was invented in the 1980s as a method of producing prototype products more quickly and affordably compared to conventional methods [18,19,20]. Using photopolymers, Hideo Kodama created a quick prototyping system in 1981. Three years later, Charles Hull invented stereolithography using a liquid photopolymer resin that transforms into solid when struck by an ultraviolet laser. This is referred to as stereolithographic equipment (SLA). In the same decade, the first selective laser sintering machine using powder raw material as opposed to a liquid (SLS), was also introduced. At the turn of the millennium, the Wake Forest Institute of Regenerative Medicine manufactured synthetic bladder scaffolds and infused them with human transplant cells. Shortly thereafter, other universities bio-printed the first blood arteries and created a small working kidney and prosthetic limb [21].

Nowadays, professionals use desktop 3D printers to create products that can be used as functional end-use products. Three-dimensional printers utilize software to slice a digital model file (usually of stl, 3 mf or obj format) and translate the printing parameters into G-code, the printer’s native language [22]. Desktop printers are currently widely utilized in a variety of industries to produce custom models at a lower acquisition cost and raw material price [23,24]. Teachers and educators emphasize educational applications for their pupils in a variety of subject areas [25,26] due to their mobility, simplicity, and low cost of maintenance.

In recent years, the desktop 3D-printing industry has witnessed substantial ad-vancements, particularly in terms of printing speeds. Both thermoplastics and resin-based printers have evolved to meet the growing demand for faster and more efficient production. Thermoplastic desktop 3D printers can now achieve remarkable speeds of up to 600 mm/s (compared to a maximum speed of about 100 mm/s almost 5 years ago) thanks to innovations in hardware and software [23]. Concurrently, SLA (stereolithography) and DLP (digital light processing) desktop 3D printers have also made significant improvements, incorporating more powerful light sources and advanced curing techniques to drastically reduce print times. These advancements are revolutionizing the capabilities of desktop 3D printing, making it a more viable option for a wide range of applications and from rapid prototyping to custom manufacturing [27,28,29].

Regarding thermoplastic fused deposition modeling/fused filament fabrication (FDM/FFF) 3D printers, the leap in performance is primarily due to improvements in extruder technology, optimized firmware and enhanced motion control systems. High-speed printers now feature lightweight print heads and sturdy frame constructions that minimize vibrations and maintain print quality at elevated speeds [30]. Additionally, the integration of advanced cooling systems ensures that the thermoplastic materials solidify quickly, preventing warping and maintaining dimensional accuracy. These innovations not only reduce the time required for prototyping and production but also make high-speed 3D printing more accessible to hobbyists and professionals alike [31].

Similarly, desktop SLA (stereolithography) and DLP (digital light processing) 3D printers have seen remarkable improvements in printing speeds. These advancements are largely attributed to more powerful light sources, such as high-intensity LEDs and laser systems, which cure resin layers faster and more uniformly [32]. Enhanced algorithms for light pattern projection and more efficient resin formulations have also contributed to faster layer curing times without compromising detail and precision. Some desktop SLA/DLP printers now feature continuous printing techniques, like continuous digital light manufacturing (CDLM), which further accelerates the printing process by eliminating the traditional layer-by-layer approach [33]. These developments enable users to produce high-resolution and complex parts at unprecedented speeds, broadening the applications of resin-based 3D printing in industries such as dentistry, jewelry and custom manufacturing [34].

In this context, the desktop 3D-printing industry has not only seen improvements in printing speeds but also significant advancements in the variety and quality of available raw materials. This diversification of materials has expanded the scope of what can be achieved with desktop 3D printers. For thermoplastics, new blends and composites, including high-strength, flexible and heat-resistant filaments, have been developed to cater to more specialized applications [35]. Innovations such as carbon fiber-infused and metal-filled filaments provide enhanced mechanical properties, making it possible to produce parts that are not only functional prototypes but also end-use components [36,37,38]. These advanced materials have enabled users to create more durable, precise and versatile objects, pushing the boundaries of what desktop 3D printing can accomplish.

Likewise, the advancements in resin materials for SLA (stereolithography) and DLP (digital light processing) desktop 3D printers have been transformative. New resin formulations offer improved mechanical properties, greater flexibility and enhanced thermal resistance. Biocompatible resins have been introduced, expanding the applications of 3D printing in the medical and dental fields. Additionally, specialty resins such as those with ceramic, rubber-like and castable properties have broadened the range of possible applications, from creating high-detail jewelry molds to producing functional engineering parts [39]. These advancements in raw materials are not only enhancing the performance and reliability of 3D printed objects but are also opening up new possibilities for creating innovative products across various industries [40].

However, 3D printing is limited by its reliance on the fixed and unchanging initial shape of the pre-designed geometry, making it unsuitable for dynamic environments. Four-dimensional (4D) printing is introduced as an evolution of traditional 3D printing by utilizing materials that can respond to stimuli incorporating a fourth dimension—time—into 3D printing [41]. This is particularly useful in dynamic environments where printed objects need to interact with their surroundings in a predetermined way. Moreover, 4D-printed items undergo gradual changes in their appearance or function (physicochemical and biological) in response to external environmental stimuli [42,43]. This advancement allows for the creation of objects with specific attributes, opening up a wide rande of possibilities. Four-dimensional printing enables printed items to change their shape or functionality over time in response to various stimuli, like heat, water, electricity or light. The fundamental difference between 4D and 3D printing lies in the utilization of intelligent design or responsive materials to create time dependent deformations in objects [44]. Also, 4D-printed structures require meticulous pre-programming by manipulating controlled smart materials with time-dependent material deformations. For example, a thermal polyurethane (TPU) filament that is sensitive to temperature can either contract or expand in response to specific temperatures. Furthermore, the usage of multimaterials with different environmental properties is beneficial for 4D printing [45].

Moreover, 4D printing is still in its early stages, and as a result, it has certain drawbacks. A major drawback of 4D printing is the restricted availability of appropriate materials. At present, the range of polymers suitable for 4D printing is limited, and they are expensive. Another disadvantage is the intricate procedure of programming the conversion of the printed product. Furthermore, it is worth noting that 4D-printed items may lack the same level of strength and durability as those produced through conventional manufacturing techniques. Due to its complexity, 4D printing is still in its early stages, and it is likely that additional research will be necessary to address these limitations [46].

2. Materials and Methods

2.1. Types of Desktop AM (Additive Manufacturing) Processes

Throughout the past few decades, a number of AM techniques have emerged. In this article, the authors choose to focus to AM methods that feature the option to be utilized via desktop, portable equipment. In this context, according to the ASTM (American Society for Testing and Materials), the following AM processes are being discussed [47]: (1) Fused deposition modeling (FDM or FFF), (2) stereolithography (SLA), (3) digital light processing (DLP) and (4) selective laser sintering (SLS).

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is a well-established 3D-printing method that constructs objects by depositing layers of thermo-plastic materials in a sequential manner. This technique has become an essential element of contemporary 3D printing due to its cost-effectiveness, user-friendly interface, and versatility. Fused deposition modeling (FDM), invented by S. Scott Crump in the late 1980s and brought to the market by Stratasys Ltd., Prairie, MN, USA, in 1992, has greatly revolutionized the process of creating prototypes and producing final products in various industries [48].

The origin of this technique may be traced back to 1988 when S. Scott Crump and a co-founder of Stratasys Ltd. started their research using a heated adhesive gun and a blend of polyethylene and wax to fabricate items. Crump acknowledged the capacity of this method to generate intricate shapes with accuracy and consistency. In 1989, he submitted a patent application, and by 1992, the process became commercially accessible with the launch of the first FDM 3D printer, named the 3D Modeler. This breakthrough established the groundwork for a novel era in the creation of objects and prototypes [49].

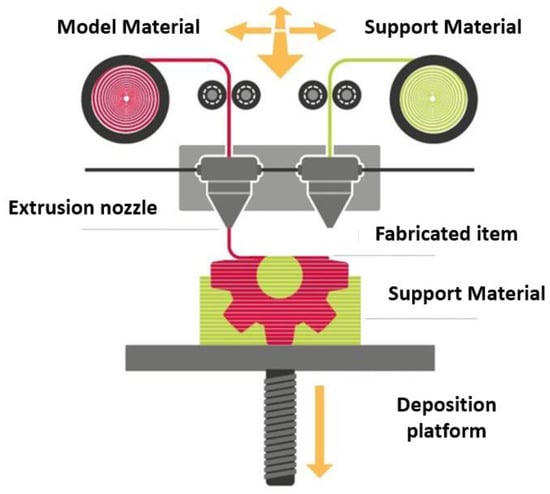

FDM 3D-printing technology comprises various essential elements and consecutive stages that are interchanged to construct a 3D object according to a digital model. The essential elements comprise the extruder, build platform, stepper motors and filament. The extruder, which is the primary element of an FDM printer, has the dual function of supplying and heating the thermoplastic filament. The system comprises two components: a cold end and a hot end. The cold end is tasked with retrieving the filament from the spool and delivering it to the hot end. At the high-temperature region, the filament undergoes a phase change from solid to liquid and is then forwarded through a small opening. The build platform functions as the substrate onto which the object is fabricated. The material can be heated, which improves the adherence of the first layer and reduces distortion during printing. Stepper motors control the motion of the extruder and build platform in the X, Y, and Z directions, guaranteeing accurate positioning and arrangement of layers. Cohesion between individual layers of the same layer and adjacent layers is affected by the thermal energy of the partially melted material and the diffusion process. The mechanical properties of FDM-manufactured objects are determined not only by the material used, but also by the chosen manufacturing settings. A literature survey shows that the quality of FDM parts is related to their strength, surface quality and dimensional accuracy. The quality of the manufactured object is determined by basic printing parameters, including the thickness of each layer, the direction in which the filament layers are deposited, the width of each layer, and the size of the gaps between the layers [50]. Thermoplastic filament is commonly found in conventional diameter options of either 1.75 mm or 2.85 mm. Figure 1 illustrates a schematic representation of the main functional parts of a fused deposition modeling (FDM) 3D printer.

Figure 1.

Schematic representation of the main functional parts of an FDM fused deposition modeling 3D printer.

On the other hand, the stereolithography apparatus (SLA) technique is renowned for its precision and accuracy [51]. First introduced by the company 3D Systems in 1986, it was the first 3D-printing method to become commercially accessible. This approach allows parts to be produced directly from a CAD file, providing higher levels of accuracy and resolution compared to alternative 3D-printing methods. Although the majority of 3D-printing processes typically achieve layer thickness accuracy of 50–200 μm, stereolithography stands out because it is capable of manufacturing objects with a layer thickness accuracy of 20 μm [52]. The geometry of structures can be obtained from 3D CAD files or scan data from imaging methods such as magnetic resonance imaging (MRI) or 3D scanning. This makes it extremely useful for biomedical engineering, allowing the production of patient-specific or implant-specific models.

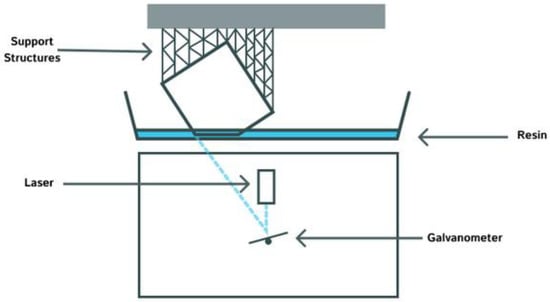

This method starts with a liquid polymer that undergoes solidification upon exposure to high radiation. An electronic beam of UV light is precisely aimed at the surface of a reservoir containing liquid photocurable resin, systematically following the contours of each layer of the object [53]. The liquid light-curing resin undergoes solidification when exposed to the light beam. This process causes the resin to harden to a certain depth and adhere to a support platform. After the initial layer has solidified, the platform is lowered and a new layer of liquid resin is added. The slightly increased cure depth guarantees strong adhesion between layers, as the resin that did not react in the initial layer undergoes polymerization with the resin in the next layer. The process of repositioning the platform and solidifying the layers is repeated to create a fully formed 3D object. Once the object is drained and cleaned to remove any excess resin, the object is almost ready. However, initial polymerization often lacks completeness, so UV post-polymerization is commonly used to increase the mechanical characteristics of the result [54]. Figure 2 schematically illustrates the basic components that make up a selective laser sintering 3D printer [55].

Figure 2.

Basic components that make up an SLA 3D printer [55].

The precise control of solidified layer thickness is critical in stereolithography. The depth to which a resin hardens is dictated by the energy of the light to which it is exposed. This action can be controlled by changing the power of the light source and the scanning speed (for laser systems) or the exposure period (for light projector systems). As mentioned above, initial polymerization often lacks completeness, so UV post-polymerization is commonly used to increase the mechanical characteristics of the final object. Post-processing is an essential step in stereolithography that guarantees the desired mechanical properties and aesthetic quality of the final printed piece. After the 3D-printing process is complete, the object goes through several critical post-processing processes, all of which play a role in enhancing and improving the quality and functionality of the final product [56].

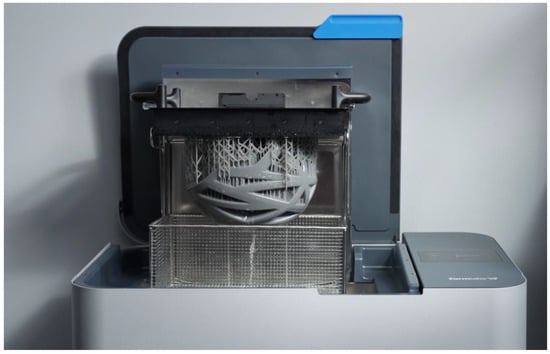

The initial stage of post-processing involves the cleaning process. The printed object is carefully removed from the build platform and thoroughly cleaned to remove any remaining liquid resin. Typically, this is accomplished by immersing the object in a bath of isopropyl alcohol (IPA) or using ultrasonic cleaners. These techniques guarantee the complete removal of any uncured resin from both the surface and intricate parts of the product, thus preparing it for the next steps [56]. Figure 3 illustrates an isopropyl alcohol (IPA) bath apparatus, with the 3D-printed object visible as it is drawn through the apparatus [57].

Figure 3.

An isopropyl alcohol (IPA) bath apparatus, with the 3D-printed object visible as it is drawn through the apparatus [57].

After the cleaning process, it is necessary to dry the object in order to eliminate any residual IPA. This can be achieved through the method of air drying, in which the item is left in a regulated atmosphere, or by using compressed air to speed up the drying process. It is essential to be sure that the object is completely dry before proceeding to the final light-curing stage [56,58].

Final light curing is an essential process in which the object, after being cleaned and dried, is placed inside a UV curing chamber. The purpose of this chamber is to subject the object to additional ultraviolet (UV) radiation, thereby completing the resin polymerization process. This phase is critical to improve the mechanical properties, strength and stability of the final product. The use of UV radiation guarantees complete solidification of any residual liquid resin within the product, thus enhancing its overall strength and performance [56,58]. Figure 4 illustrates a final photopolymerization chamber apparatus using UV rays, with the 3D-printed object visible through the apparatus [56].

Figure 4.

Final photopolymerization chamber apparatus using UV rays, with the 3D-printed object visible through the apparatus [56].

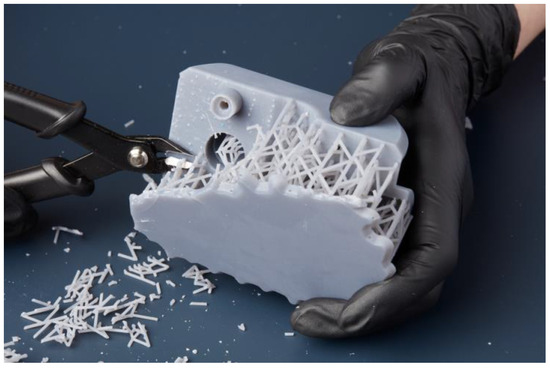

After the final photopolymerization, it is necessary to remove any supports that were used during the printing process. The process of removing the supports is performed with great care to avoid any damage to the object. The execution of this process can be carried out either by manual means or with the help of tools, depending on the complexity and fragility of the supporting structures. The efficient removal of supports is crucial to maintain the desired form and characteristics of the object while minimizing any unwanted defects [56,58]. Post-processing phases, including cleaning, drying, final UV photopolymerization, removal of support structures, and finishing, are necessary to ensure that parts created by stereolithography meet the necessary criteria for mechanical performance and surface polish of the object. Each step in the process is carefully designed to improve the item, ensuring it is fit for its intended use. In this context, stereolithography can create precise and high-quality parts that meet both functional and aesthetic requirements through careful post-processing. Figure 5 illustrates the manual process of removing support structures on an object made on a 3D stereolithography printer.

Figure 5.

Manual process of removing support structures on an object made on a 3D stereolithography printer.

On the other hand, digital light processing (DLP) additive manufacturing (AM) is an AM technique that utilizes digital light projection technology to solidify photopolymer resins into tangible 3D objects. DLP AM employs a digital projector screen to rapidly display a singular image of every layer across the entire platform simultaneously. This image is a computerized depiction of the object’s cross-sectional view at a particular layer. The method commences by utilizing a liquid photopolymer resin confined within a reservoir. The construction platform is originally situated at a little distance above the bottom of the reservoir. When the projector emits light onto the resin, it specifically causes the resin to harden and become solid in the form of the cross-section of the layer. Once the layer has undergone the curing process and the build platform ascends (or descends and depending on the configuration) by a thickness equivalent to one layer, the subsequent layer is projected and cured. This process continues iteratively until the entire item is fully constructed.

Although DLP and stereolithography (SLA) are both types of photopolymerization technology, they differ significantly in their layering process and overall efficiency. DLP use a digital light projector to project a whole image of a layer in one go. This implies that the full cross-section of the object is treated at the same time. The projector commonly employs a digital micromirror device (DMD) to precisely direct light and enabling rapid layer curing. On the other hand, SLA employs a laser beam to meticulously follow the contour of each layer, one place at a time. The laser cures the resin in a selective manner by traversing the build region, resulting in a longer time needed compared to the simultaneous layer curing of DLP.

In addition, DLP is frequently faster than SLA due to its ability to cure each layer in a single operation, while the SLA method of curing point by point requires more time to complete a layer. The high efficiency of DLP makes it particularly well suited for the rapid production of parts, especially when working with bigger surface areas. Nonetheless, the level of detail in DLP projection is limited by the pixel size of the projector. In contrast, an SLA concentrated laser beam can attain higher resolutions in specific situations, making it more suitable for rendering extremely small details. In addition, the components created by DLP may exhibit pixelation or stair-stepping effects on curved surfaces, as the projector’s pixels are separate. However, SLA is capable of producing smoother finishes.

Both processes are utilized in fields that need meticulous accuracy and intricate designs, such as the dentistry, jewelry and medical sectors. Nevertheless, the speed and efficiency of DLP technology sometimes render it more appropriate for the swift creation of prototypes and the manufacturing of modestly sized components. To summarize, the decision between DLP and SLA is contingent upon the particular project’s needs, encompassing factors such as velocity, precision and surface excellence.

On the other hand, selective laser sintering (SLS) is a sophisticated 3D-printing method used extensively to create complex parts. SLS, which stands for selective laser sintering, was created at the University of Texas at Austin and brought to market by companies such as DTM Corporation and EOS GmbH Electro Optical Systems. It has now become a fundamental technique in the field of 3D printing [59]. SLS involves the step-by-step manufacturing of objects using powdered materials, usually plastics, metals, ceramics or composites. The process begins with a three-dimensional computer-aided design (CAD) model, which is divided into thin layers using specialized software. Each layer acts as a precise guide for the laser to adhere to during the printing process [59].

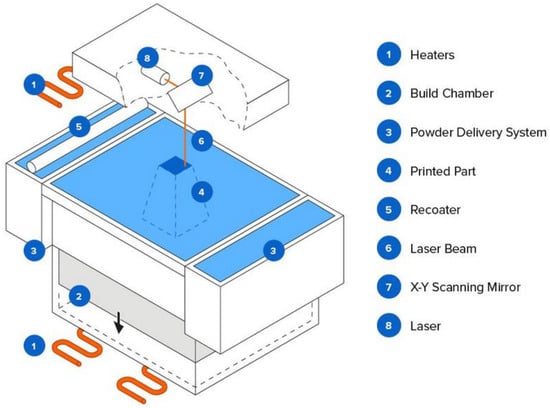

A selective laser sintering (SLS) machine includes basic components such as a control computer, a fabrication chamber, a powder supply system, a repainting mechanism, and a high-power laser. Inside the build chamber, there is a vertically moving platform that adjusts to facilitate the creation of each successive layer. The process begins by evenly spreading a thin layer of powder on the build platform using a repainting tool such as a roller or blade. A high-powered CO2 laser is used to scan the surface and selectively sinter (heat and fuse) the powder particles together based on the CAD data. The laser trajectory is adjusted with high precision to selectively liquefy the powder exclusively within the defined areas, resulting in the formation of a cohesive layer. The adjacent powder remains unconsolidated, providing reinforcement to the frame and avoiding the need for additional support elements [60]. Figure 6 shows a desktop 3D stereolithography printer. A special feature is the color removable protection cap, which ensures that the liquid light-curing resin is not polymerized by ambient light when the 3D printer is not in use [61].

Figure 6.

Basic components that make up a selective laser sintering (SLS) 3D printer [61].

After the sintering process is complete, the build platform is lowered by a single layer thickness and a fresh powder coating is spread evenly over the entire surface. This process is repeated, one layer at a time, until the complete object is created. The ability to manufacture sophisticated geometries incrementally provides substantial design flexibility, making SLS suitable for manufacturing elaborate and precise parts that would be difficult or infeasible to manufacture using conventional manufacturing techniques [60].

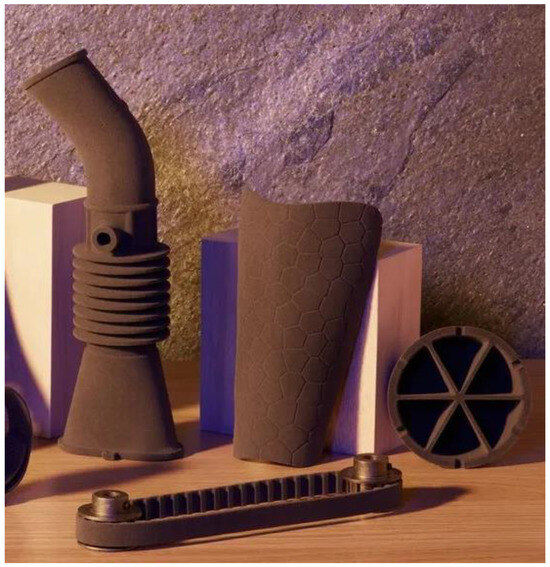

An advantage of selective laser sintering (SLS) is its ability to manufacture compo-nents with excellent mechanical properties. High temperatures and precise laser manipulation facilitate strong adhesion between layers, yielding components with exceptional strength and longevity. In addition, the powder that has not been sintered can be recycled and reused, resulting in a more economical and environmentally friendly process [60]. Figure 7 depicts objects made with a selective laser sintering 3D printer [62]. Characteristic is the slightly grainy surface finish, with hardly any visible layer lines. It is recommended to use post-treatment methods such as sandblasting to achieve a smoother final finish.

Figure 7.

Objects made with a selective laser sintering 3D printer [62].

Post-processing is an essential step in the selective laser sintering (SLS) 3D-printing technique, significantly improving the quality, functionality and appearance of manufactured parts. The post-processing phases consist of a series of processes, each of requiring specialized equipment and techniques to obtain the intended characteristics of the final product [63].

After printing is complete, the build chamber is cooled to start the process. Performing this step is critical in order to mitigate thermal stresses that can lead to warping or other forms of distortion in the components. The duration of the cooling process can vary, from a few hours to several hours, depending on the dimensions and complexity of the structure. In order to provide consistent cooling, specialized cooling systems or controlled conditions are often used.

After the build chamber reaches a lower temperature, the printed pieces are carefully removed. This process entails extracting the complete structure, which is still surrounded by unsintered powder. The components are then isolated from the surrounding dust using either manual tools or automated mechanisms specifically designed to mitigate any potential damage to the components. Excess unsintered powder is initially removed using brushes, compressed air or specialized vacuum systems. Automated dust removal stations, with rotating and stirring mechanisms, guarantee complete dust elimination by efficiently collecting and reusing the dust for subsequent applications [63].

The additional cleaning of components is often required to remove any remaining microscopic particles. Ultrasonic or high-pressure air cleaners are often used to effectively remove any remaining particles, especially from complex shapes and internal passages. Surface finishing processes are then used to improve the visual aesthetics and surface characteristics of SLS parts. One of the processes commonly used for surface treatment is sandblasting. Sandblasting involves the use of a high-pressure stream of abrasive material to smooth the surface and eliminate any residual dust [63]. Figure 8 shows a complete setup of a selective laser sintering 3D printer along with post-processing devices.

Figure 8.

Setup of a selective laser sintering 3D printer along with post-processing devices [63].

Thermal post-treatment techniques, such as annealing or heat treatment, are commonly used to improve the mechanical properties of printed parts. These processes involve subjecting the parts to high temperatures in order to alleviate internal stresses and enhance the material’s characteristics, such as elasticity and flexibility. For specific purposes, filtration and coating can also be used. Infiltration is the process of introducing secondary materials, such as resin or metal, into the pores of parts in order to enhance their strength, density and surface finish. Coatings such as painting, plating or sealing can be used to enhance appearance, provide further protection or add functional layers.

If the selective laser sintering (SLS) process involved support structures, it is imperative that they are thoroughly eliminated. While SLS typically uses unsintered powder as a support, some designs may require the use of additional supports that must be removed by hand. This process guarantees that the part maintains its structural integrity and ideal shape [63].

In the final phase of post-processing, a thorough examination and quality control are carried out to verify that the parts conform to the specified dimensions and mechanical properties. Different procedures are used to confirm the quality of parts, such as visual inspection, dimensional evaluation using calipers or coordinate measuring machines (CMM), and non-destructive testing methods such as X-ray scanning or CT scanning.

2.2. Common Thermoplastic and Photopolymer Resin Materials for Desktop 3D Printers

Below is a list of thermoplastic and photopolymer resin materials that are most widely used in desktop 3D printers. The majority of them are polymeric polymers, either in solid or liquid form. Composite, carbon fiber, metal-based, wood, nylon, and silicone materials are excluded. Some of the materials used in particular printers have brand names, such as flex or Ninjaflex, and they fall into one of the following categories:

- Polylactic Acid (PLA).

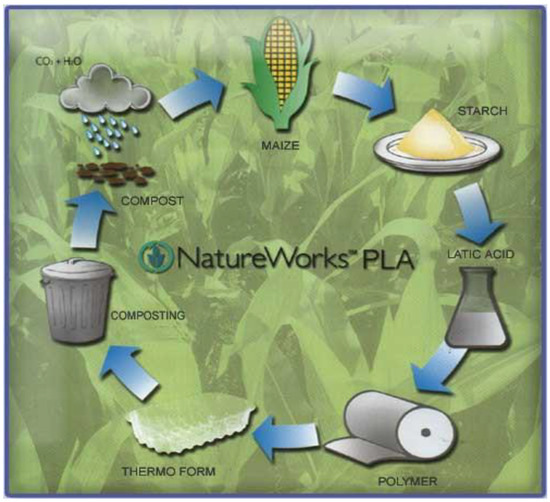

Polylactic acid (PLA) is a highly adaptable thermoplastic used extensively in 3D printing, especially by individual users in portable, desktop 3D printers. What sets PLA apart from other thermoplastic materials is its source of origin: it is made from renewable organic materials such as cornmeal, sugar cane and tapioca roots. This feature positions it as an ecologically conscious substitute for petroleum-derived plastics, in line with the growing modern trend towards sustainable production [64]. The production method of PLA involves fermenting vegetable carbohydrates to create lactic acid, which is then polymerized to create polylactic acid. This approach not only utilizes sustainable resources but also helps reduce carbon emissions [64].

PLA is widely recognized for its printability and ease of use, largely due to its low melting point and minimal warping during the printing process. However, its crystalline morphology significantly impacts its mechanical properties and post-printing behavior. PLA’s semi crystalline structure contributes to its rigidity but also limits its thermal resistance, with the material softening around 60 °C. Recent advancements have focused on modifying PLA with various additives and fillers to enhance its properties [64]. For example, plasticizers are incorporated to improve flexibility, while natural fibers or carbon fibers are added to increase strength and reduce brittleness. These modifications not only improve PLA’s durability and versatility for functional parts but also make it suitable for applications that demand greater mechanical performance, such as in engineering prototypes or medical models [65]. Moreover, the development of PLA blends with enhanced thermal stability has broadened its application scope, allowing for use in more demanding environments without compromising print quality.

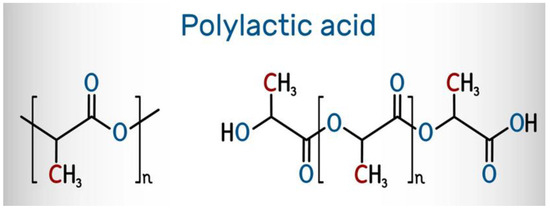

One of the main factors contributing to the widespread use of PLA in 3D printing is its user-friendly nature. Polylactic acid (PLA) exhibits a very moderate melting point, typically ranging from 180 to 220 °C, facilitating a seamless and uniform extrusion process. The lowered melting point also reduces the chance of distortion, a common problem in 3D printing, especially when dealing with complex geometries and sharp edges. The material’s minimal coefficient of thermal expansion enhances its stability during the printing process, ensuring that the pieces maintain their defined dimensions [65]. In addition, when subjected to heat, PLA emits a soft and pleasant aroma, which is significantly less dangerous compared to the particles emitted by other types of plastics. This feature makes PLA a safer choice for both home and educational environments [65]. Figure 9 illustrates the chemical formula of PLA.

Figure 9.

Chemical formula of PLA.

PLA is widely recognized for its ability to biodegrade, distinguishing it from many other materials used in 3D printing. PLA can undergo complete degradation into carbon dioxide, water and biomass when subjected to industrial composting conditions. This property makes it a desirable choice for users aiming to reduce their environmental footprint. PLA has high stiffness and offers sufficient strength for a wide range of applications, including prototypes and functional parts, in terms of its mechanical properties. The material’s rigidity and printability make it ideal for creating objects that require fine detail and precision, such as architectural models, educational tools, and complex design aspects [66]

However, PLA has some limitations. The heat resistance of this material is limited, as it has a glass transition temperature of about 60 °C. PLA components may deform or com-promise their structural integrity when subjected to high temperatures, making them un-suitable for applications requiring heat resistance or prolonged exposure to direct heat [67]. Additionally, PLA exhibits greater brittleness compared to other commonly used 3D-printing materials, such as ABS (Acrylonitrile Butadiene Styrene). The inherent brittleness of this material can lead to fracture or rupture when subjected to pressure or impact, thus limiting its application in situations requiring flexibility or resistance to physical stress. While PLA is truly biodegradable, its decomposition requires specialized conditions found only in industrial composting facilities. PLA does not degrade rapidly in common household composting facilities or in natural habitats, so it has the potential to contribute to plastic waste if not properly disposed of [67,68]. Figure 10 schematically illustrates the manufacturing process of PLA, up to its final composting [67].

Figure 10.

Schematic illustration of the manufacturing process of PLA, up to its final composting [67].

- Acrylonitrile Butadiene Styrene (ABS).

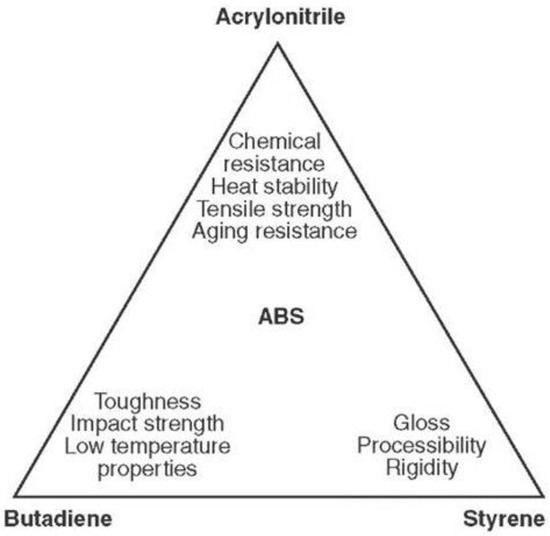

ABS, short for Acrylonitrile Butadiene Styrene, is a thermoplastic polymer widely used in the field of 3D printing. This material is synthesized through the polymerization of three distinct monomers: acrylonitrile, butadiene, and styrene. Each of these components imparts distinct characteristics to the final product: acrylonitrile contributes to chemical resistance, hardness, thermal stability and aging resistance; butadiene enhances hardness and impact resistance and contributes to achieving the desired properties at low temperatures; and styrene imparts rigidity and gloss and facilitates the construction of the material [52]. Figure 11 shows a schematic representation of the three aforementioned monomers required for the synthesis of the ABS material.

Figure 11.

Schematic illustration of the polymers that ABS consists of.

ABS is known for its superior strength, toughness, and high temperature resistance, making it a preferred choice for functional prototypes and end-use parts. Its morphology, characterized by a combination of amorphous and rubbery phases, contributes to its impact resistance and durability [69]. However, ABS’s tendency to warp during printing due to its high shrinkage rate can pose challenges, particularly for larger prints. This issue is often mitigated by using heated print beds and enclosed chambers. Recent developments have introduced ABS formulations with enhanced adhesion properties and reduced shrinkage, improving print stability. Additionally, modifiers such as carbon fibers, glass fibers, or elastomers are increasingly used to enhance ABS’s mechanical properties, making it suitable for high-stress applications. These advancements allow for higher dimensional accuracy and better surface finish, even in more complex geometries, expanding ABS’s role in the automotive, aerospace, and industrial sectors.

The production of ABS typically commences with the synthesis of its monomers. Acrylonitrile is produced through the reaction of propylene and ammonia in the presence of a catalyst. This process results in the formation of a highly reactive molecule that is well known for its chemical resistance and hardness. Butadiene is a secondary product derived from the process of refining petroleum. It is created by subjecting naphtha or gas oil to a procedure called steam cracking. It improves the strength and resilience of the finished copolymer under tension. Styrene is produced by the dehydrogenation of ethylbenzene and possesses both stiffness and ease of manipulation [69]. The manufacturing of ABS comprises a series of successive phases in the polymerization process.

ABS is a commonly utilized substance in 3D printing because of its unique blend of properties, which offer numerous advantages but also present specific challenges [70]. ABS possesses an inherent advantage because of its remarkable strength and durability. The material’s exceptional hardness is widely recognized, making it very suitable for producing functional components that need to endure significant mechanical strain. Because of its exceptional impact resistance and hardness, this material is ideal for producing automobile components, electronic enclosures, and various industrial components. In addition, ABS has a higher melting point compared to other commonly used 3D-printing materials like PLA. ABS possesses the ability to retain its form and structural strength even when exposed to elevated temperatures, rendering it especially well-suited for applications involving heat exposure [70].

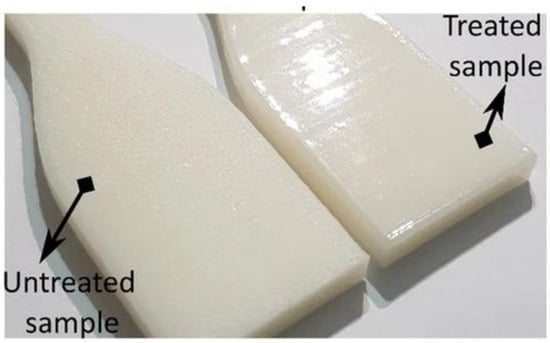

ABS also offers the advantage of easy post-processing. ABS parts may be subjected to grinding, drilling and machining processes, allowing for flexibility in cleaning and customizing printed products. Additionally, ABS can be made smoother using acetone vapor, making it easier to achieve a polished and professional appearance [71]. Figure 12 shows ABS components after exposure to acetone vapors, giving them a characteristic gloss compared to their original “matte” finish [72].

Figure 12.

ABS components after exposure to acetone vapors, giving them a characteristic gloss compared to their original “matte” finish [72].

ABS is a favored material for producing prototypes and final things that need a high-quality surface finish since it has the capability to execute post-processing.

Nevertheless, ABS also possesses its disadvantages. One significant challenge related to ABS is its inclination to warp or deform while being printed. As Acrylonitrile Butadiene Styrene (ABS) undergoes cooling, it undergoes a reduction in size, resulting in the detachment or distortion of the printed object from the print surface, particularly for bigger prints [73]. This distortion might result in imprecise measurements and a fragile connection to the printing surface. To address this issue, it is frequently essential to employ a heated print bed, and enclosing the printing process within a sealed chamber can assist in maintaining a consistent temperature, hence reducing the likelihood of distortion. The inclusion of these supplementary requirements can increase intricacy and cost into the print configuration [74].

ABS emits fumes when heated, which can be unpleasant and potentially hazardous if breathed in for long durations. The act of printing releases volatile organic compounds (VOCs) and other particles into the air. In order to ensure a secure printing environment, it is imperative to have sufficient ventilation or utilize air purifiers. Users who are printing in limited or communal areas should take this element into account [75].

- Polyethylene Terephthalate Glycol (PETG).

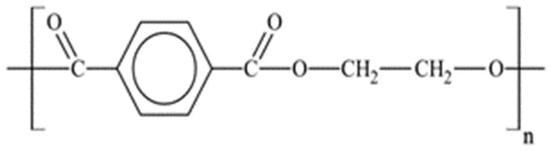

PETG, short for polyethylene terephthalate glycol, is a widely used material in 3D printing that combines the advantages of both PLA and ABS. It is a thermoplastic polymer material that belongs to the polyester family. It is produced by modifying polyethylene terephthalate (PET) with glycol. By including glycol, the material’s tendency to crystallize and become brittle is prevented, resulting in a thread that is more durable and impact resistant. Figure 13 schematically illustrates the chemical formula of PETG.

Figure 13.

Chemical formula of PETG [76].

PETG is appreciated for its balance between strength, flexibility, and chemical resistance, making it a versatile material for both functional and aesthetic applications. Its amorphous nature helps prevent crystallization, reducing warping during the printing process. PETG’s high impact resistance and moderate heat tolerance (up to 80 °C) make it a strong alternative to PLA, especially in environments requiring chemical or moisture resistance. Modifiers such as UV stabilizers and fillers like glass or carbon fibers further enhance its mechanical performance and broaden its application range [77]. These modifications allow PETG to be used in more demanding environments, such as outdoor applications, while maintaining excellent transparency and surface finish. Recent innovations in PETG blends have also addressed its inherent stringing issues during printing, resulting in cleaner prints with minimal post-processing.

PETG is produced by chemically altering conventional PET (polyethylene terephthalate) by introducing glycol. This modification is essential to impede the formation of crystals, thereby decreasing fragility and improving adaptability for various uses, such as 3D printing. The manufacturing method of this product commences by utilizing ethylene glycol along with either terephthalic acid or dimethyl terephthalate as crucial components. These substances undergo a process of polymerization. Initially, either terephthalic acid or dimethyl terephthalate reacts chemically with ethylene glycol—a process referred to as esterification. The utilization of dimethyl terephthalate in the process is referred to as transesterification [77]. The chemical reaction results in the formation of bis (hydroxyethyl terephthalate) (BHET) and generates water or methanol as a by-product. BHET subsequently undergoes a polycondensation reaction, wherein the minuscule molecules are chemically bonded together to form elongated PET molecular chains. During this stage, the addition of glycol alters the constitution of the polymer, leading to the creation of PETG. The presence of glycol disrupts the crystalline arrangement of the material, leading to a translucent and more pliable end product in comparison to regular PET [78]. Once the polymerization process reaches its conclusion, the PETG is cooled and subsequently extruded through a narrow aperture to create delicate filaments. Subsequently, these strands are broken down into pellets or granules, which are then converted into a liquid state and extruded once more into the form of thread [78]. The filament is subjected to a cooling process, subsequently coiled onto spools, and finally packaged for use in 3D printers.

The entirety of this manufacturing process ensures the retention of PETG’s desirable attributes, including clarity, strength, and impact resistance. Glycol is employed to mitigate brittleness and enhance material performance in various applications, particularly in the realm of 3D printing. Its amiable disposition and exceptional mechanical qualities [79] make it highly favored in this field.

PETG, as a material used in 3D printing, has both advantages and limitations that make it acceptable for some applications but challenging for others. A major advantage of PETG is its excellent combination of strength and flexibility. This material has high elasticity and resistance to external forces, allowing it to withstand significant stresses and impacts without breaking. Consequently, it is highly suitable for manufacturing functional prototypes and mechanical components that require long-term performance. PETG exhibits superior temperature resistance compared to PLA, allowing it to maintain its structural integrity even at high temperatures. In addition, PETG has superior chemical resistance compared to PLA, making it suitable for scenarios where the printed object may encounter a range of chemicals. This demonstrated chemical resistance is a property required in both industries such as medical device manufacturing and protective equipment manufacturing [80].

In addition, PETG exhibits low warping, a common problem associated with ABS, and adheres effectively to the print surface, thereby reducing the potential for print failures. PETG, unlike ABS, does not release strong odors during printing, which enhances its suitability for use in confined or poorly ventilated environments. The smooth surface finish and clarity of this material, when accurately printed, make it an excellent choice for aesthetic pieces and components that require a glossy appearance [81].

However, PETG has some disadvantages. Although it has a commendable combination of features, it does not have the same level of printability as PLA. Achieving optimal results requires the further optimization of printing parameters. Additionally, PETG exhibits greater heat resistance compared to PLA but falls short of the heat resistance offered by ABS. Also, while PETG has high strength, it does not have the same level of stiffness as ABS, which can be a disadvantage in applications that require high stiffness. Finally, PETG is typically more expensive than PLA and may have limited availability in certain regions or for certain color options and formulations, which could be a factor to consider for projects with financial constraints [81]. Due to its viscosity, PETG can be susceptible to unwanted residue, which requires careful management of retraction settings during the printing process. Figure 14 illustrates such a case.

Figure 14.

Item made from PETG with obvious unwanted residue due to incorrect retraction settings [82].

In summary, PETG is a versatile and reliable 3D-printing material that provides a good combination of durability, flexibility, chemical resistance and ease of printing. However, meticulous modifications to print settings are required, and there are limitations in terms of heat resistance and stiffness.

- Thermoplastic Polyurethane (TPU).

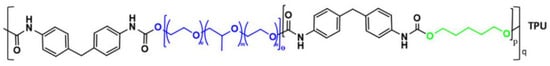

TPU is a highly flexible and durable material known for its elastic properties and resistance to abrasion, making it ideal for applications requiring flexibility and impact resistance, such as in footwear, automotive parts, or medical devices. Its morphology is defined by alternating soft and hard segments, which provide a unique combination of flexibility and toughness. TPU’s ability to stretch significantly without breaking makes it an excellent material for complex, flexible parts. Recent advancements in TPU formulations focus on improving printability, reducing common issues such as clogging and stringing by optimizing extrusion temperatures and print settings. Furthermore, the addition of fillers like carbon black or silica can enhance its wear resistance, making TPU more suitable for high-performance applications. With these modifications, TPU is increasingly used in dynamic environments that demand both elasticity and mechanical durability [83]. Figure 15 illustrates the chemical formula of TPU.

Figure 15.

Chemical formula of TPU [84].

Thermoplastic polyurethane (TPU) is created by polymerizing diisocyanates and polyols, which leads to the creation of elongated molecules with alternating stiff and flexible segments. The production of TPU commences with the fabrication of two primary components: diisocyanates, which contribute to the formation of rigid components, and polyols, which generate the flexible components. Methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI) are frequently utilized diisocyanates. Polyols are often based on polyester or polyether materials [85].

The production process commences by precisely blending the diisocyanates with the polyols in certain amounts. One can use catalysts, stabilizers, and other additives to control the rate of the reaction and improve the characteristics of the material. Next, the mixture undergoes a polymerization reaction, in which the diisocyanate chemically combines with a portion of the polyol to form a pre-polymer. In a subsequent stage, the pre-polymer is reacted with the leftover polyol. This technique enables the advanced modulation of the polymer structure and characteristics [83].

The process occurs within a controlled environment of a reactor, where temperature and pressure are meticulously regulated to guarantee the achievement of full polymerization. During the course of the reaction, the mixture experiences a series of changes and ultimately transforms into a thick and liquefied polymer. Afterward, the polymer is cooled and hardened into pellets or granules, which can be subsequently transformed into different shapes like films, sheets, or filaments. TPU beads are extruded into thin filaments to create a raw material for 3D printing. The extrusion technique entails the fusion of TPU beads, followed by the propulsion of the liquefied polymer through a nozzle to generate an uninterrupted filament. After being cooled, these filaments are coiled onto spools, rendering them appropriate for utilization in 3D printers [85].

During the manufacturing process, various quality control measures are implemented to ensure that the TPU meets specific requirements and performance criteria. The resulting TPU material has a characteristic blend of flexibility, durability and elasticity, making it suitable for a wide range of applications, including 3D printing. It is highly valued for its ability to produce flexible and impact-resistant components [86].

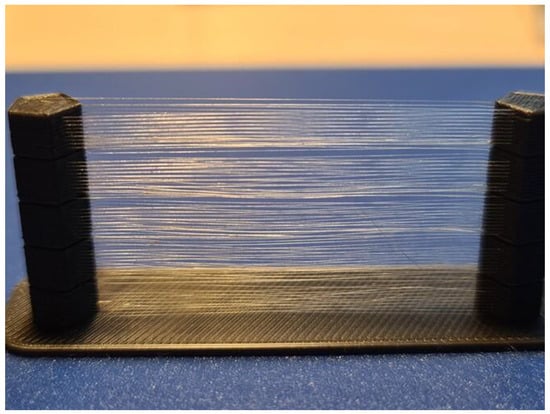

As mentioned above, the manufacture of TPU involves the precise mixing and reaction of diisocyanates and polyols, resulting in a flexible yet durable polymer. The process requires the careful tuning of the reaction conditions and subsequent extrusion into a filamentous form, while ensuring the desired material properties for many applications, including 3D printing. One of the main advantages of TPU is its remarkable flexibility. Unlike rigid materials like PLA or ABS, TPU has the ability to stretch and bend significantly without breaking, allowing for the creation of flexible and elastic parts. Figure 16 shows an object made of TPU where its characteristic elastic properties are evident.

Figure 16.

Object made of TPU where its characteristic elastic properties are evident [87].

This material also exhibits excellent abrasion resistance, which is essential for parts that undergo regular wear. In addition, TPU has excellent shock absorption properties, making it suitable for applications that require shock absorption [88].

TPU also exhibits excellent chemical resistance, allowing it to withstand exposure to oils, greases and other chemicals without degradation. Furthermore, it exhibits excellent performance in a wide range of temperatures and maintains its properties in both low and high-temperature environments. TPU is a flexible material suitable for outdoor applications and products exposed to various weather conditions [88].

However, TPU has inherent disadvantages as a material for 3D printing. The flexibility of the material, while advantageous in many cases, can create challenges when it comes to printing. TPU filaments are prone to problems such as unwanted residue, leakage, and poor adhesion to the print platform if the print settings are not properly optimized. The tendency of the material to compress in the extruder can lead to jams and require the precise management of the extrusion and detent settings. TPU printing often requires reduced print speed and specialized equipment, such as a direct extruder [89]

Another limitation of TPU is its reduced dimensional stability compared to more rigid materials. Over time, printed parts may show slight distortions, especially when exposed to constant stress or load. Additionally, while TPU has favorable resistance to various chemicals, its heat resistance is inferior to materials such as ABS, which limits its suitability for high-temperature applications [89].

- Photopolymer resins.

Light-curing resins, also known as photopolymer or UV-curable resins, are raw materials in the field of 3D printing, in stereolithography (SLA)/digital light processing (DLP) technologies. These resins are fluid substances that solidify when exposed to specific wavelengths of light, specifically ultraviolet (UV) light. This process is called photopolymerization and involves converting a liquid resin into a solid polymer by activating photoinitiators. Photoinitiators are compounds present in the resin that cause a reaction when exposed to light, which then initiates the polymerization of the resin monomers and oligomers [90].

Light-curing resins are key components of SLA and DLP 3D-printing technologies. They are carefully crafted through a compounding process involving a combination of chemical ingredients. The production of these resins begins with the selection of suitable monomers and oligomers, which serve as the main building blocks. These compounds are usually acrylic or methacrylate, chosen for their ability to form strong and cross-linked polymer networks when exposed to ultraviolet (UV) light [90].

Photopolymer resins, primarily used in stereolithography (SLA) and digital light processing (DLP) 3D printing, offer exceptional precision and surface finishes due to their fine layer resolution and curing process. These resins typically exhibit an amorphous structure, which provides excellent dimensional accuracy but can result in brittle prints unless modified. Recent advancements focus on enhancing the mechanical properties of photopolymer resins through the inclusion of fillers such as glass fibers or ceramic particles, as well as incorporating flexible and biocompatible additives [90]. These modifications improve not only the strength and impact resistance but also the thermal stability and durability of resin-based prints. For example, flexible resins have been developed for applications requiring elasticity, while high-temperature and tough resins are increasingly used for engineering prototypes that demand higher load bearing capacity. Additionally, biocompatible and medical-grade resins are gaining traction in the medical and dental fields, where precision and sterility are crucial. These enhancements allow for greater versatility in SLA/DLP applications, enabling resin-based prints to meet the stringent demands of industries such as healthcare, jewelry, and engineering [90].

The manufacturing process begins with mixing the monomers and oligomers in precise proportions to obtain the desired viscosity and mechanical properties of the final resin. These components are in a liquid state at room temperature, which allows them to flow and completely fill the print container with ease. Photoinitiators are added to this mixture. Photoinitiators are substances that absorb ultraviolet (UV) light and undergo decomposition to form reactive species such as free radicals or cations, which then initiate the polymerization process [91]. The choice of a photoinitiator depends on the wavelength of the light source used in the 3D printer, ensuring the efficient and rapid curing of the resin.

Monomers, oligomers, photoinitiators and various additives are included to improve resin performance and stability. These additives may include stabilizers, which prevent premature polymerization and extend the life of the resin, and inhibitors, which control the rate of reaction and ensure uniform curing. Pigments or dyes can be incorporated to impart certain colors to the resin, while fillers can be included to change mechanical properties such as hardness or flexibility [92].

After the aforementioned substances are thoroughly mixed, the resin is filtered to re-move any impurities or undissolved particles that may affect the quality of the final print. The refined resin is then packaged in waterproof containers to prevent inadvertent exposure to UV light, which could prematurely initiate the curing process [92].

The final product is a refined light-curing resin that can change from a liquid to a solid state when exposed to UV light. This transition occurs through a process known as crosslinking, when monomers and oligomers combine to form a strong and interconnected polymer network. The precision of this process guarantees that the resin can create intricate and highly accurate 3D-printed objects with a smooth surface and detailed features.

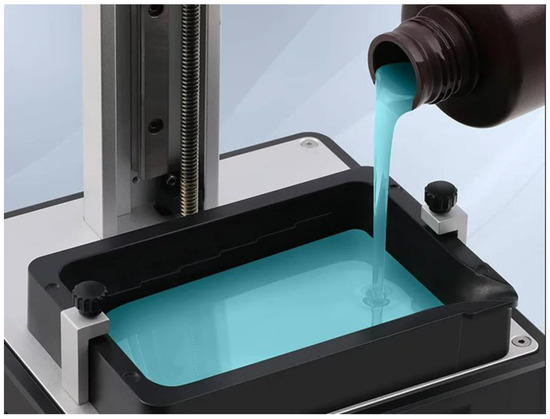

The production of light-curing resins requires the careful selection and combination of chemical components, as well as rigorous mixing and filtration procedures and strict quality control measures. This guarantees the reliable performance of resins in 3D-printing applications and enables the creation of complex and expensive objects in many industries [91]. Figure 17 illustrates the filling of a DLP 3D printer with photopolymerizable liquid resin.

Figure 17.

Filling of a DLP 3D printer with photopolymerizable liquid resin.

Light-curing resins are commonly used in various applications in 3D printing due to their ability to create complex and precise objects. In the medical field, these resins play a key role in the production of customized dental devices such as crowns, bridges and orthodontic appliances. Their high-resolution and silky finish make them ideal for creating precise and comfortable dental components. In addition, medical professionals use light-curing resins to make surgical guides and custom prostheses. The precision of these guides is essential to ensure precise surgical procedures, and custom prosthetics benefit from the resin’s ability to conform to the patient’s specific anatomy, improving both comfort and functionality [93].

In the field of jewelry design, the use of light-curing resins allows for the creation of highly detailed and fragile prototypes that can be cast directly into metals. This feature allows designers to explore complex geometries and intricate details that would be difficult to achieve using conventional manufacturing methods. The ability to quickly create and refine designs speeds up the development process and reduces the costs associated with making molds for casting [94].

The engineering and manufacturing sectors see significant benefits from the use of light-curing resins. These materials are used to make prototypes that closely mimic the characteristics of the final product. Engineers can evaluate these prototypes for suitability in terms of application, form and function and make necessary modifications before proceeding to mass production. The strength of some light-cured resins makes them suitable for the production of end-use components, such as parts in machinery or consumer products. The ability to print complex internal structures and fine details improves the performance and aesthetics of these components [94].

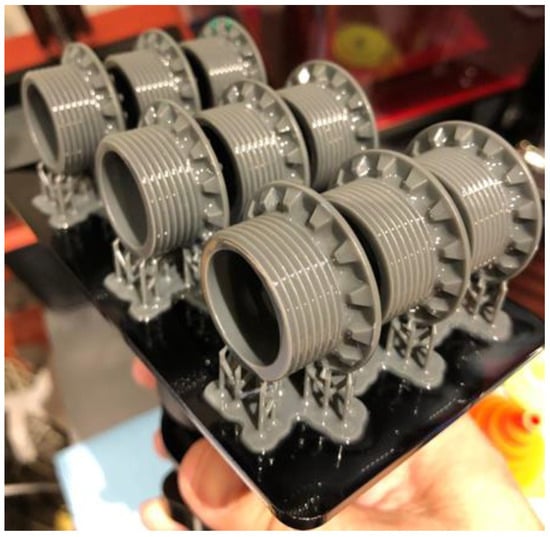

Additionally, in the electronics field, photocurable resins are used to print components such as housings, connectors, and custom housings. The precision and reliability of these resins ensure that electronic components fit perfectly and operate precisely. The material properties can be improved to provide the required electrical insulation and mechanical strength [95]. Figure 18 shows objects made via SLA 3D printing, using liquid light-curing resin as raw material. The high quality of the surface finish is evident.

Figure 18.

Objects made via SLA 3D printing.

3. Desktop 3D Printer Technical Characteristics

Desktop 3D Printers

Desktop 3D printers represent a continuously evolving segment in additive manufacturing, enabling quick prototype and small-scale production for end-users. Their small size and portability make them suitable for usage in various contexts, including home workshops, classrooms, small enterprises and design studios. Desktop 3D printers, albeit smaller than industrial-grade models, feature respectable capabilities that allow users to quickly and precisely bring their ideas to reality. Desktop 3D printers may not have the same scale or throughput as industrial equipment, but they stand out in adaptability, enabling experimentation with various materials and applications. They enable single users and small organizations to express their creativity and ingenuity by manufacturing detailed prototypes, personalized items, educational initiatives and various creative efforts.

This section involves conducting a comprehensive comparative examination of five desktop 3D printer manufacturers that are currently accessible in the market and recognized as the category flagships due to their innovative characteristics. The primary objective of this comparison is to collect and analyze data on the suitable selection criteria for applications and the specific requirements of end-users. By doing so, we aim to provide a thorough understanding of what makes these printers stand out in the market and how they cater to various user needs.

The attributes compared in this study include a wide range of factors that are crucial for determining the overall performance and suitability of each printer. These factors include build size, which refers to the maximum dimensions that a printer can handle; layer height, which affects the resolution and smoothness of printed objects; and printing speed, a critical factor for efficiency and productivity. Additionally, we examine file format compatibility, ensuring that the printers can work with various design files commonly used in 3D printing.

Furthermore, the comparison encompasses the printing software provided with each printer, as this software significantly impacts user experience and the ease of preparing and managing print jobs. We also consider nozzle and bed temperature settings, where applicable, since these influence the types of materials that can be printed and the quality of the prints. The power supply of each printer is evaluated to ensure reliable and efficient operation.

General features, such as ease of use, maintenance requirements, and additional functionalities, are also assessed. Price is another critical attribute, as it directly affects the accessibility and affordability of the printers for different user groups. Compatibility with different filaments or materials is analyzed to determine the versatility of each printer in handling various printing materials, which is essential for users with diverse printing needs.

In this comparison, our objective is to present the pros and cons of each printer in a detailed manner. This approach allows end-users to make informed decisions based on their specific requirements and preferences. Table 1 demonstrates a brief comparison between the five selected 3D printers, summarizing the key attributes and performance metrics for each model. This comparative analysis enables end-users to choose the most economically advantageous printers that best meet their unique needs, ensuring that they can make the most of their investment in 3D-printing technology.

Table 1.

Comparison of the five flagship desktop 3D printers currently available in the global market.

Table 2 provides a detailed comparison between two flagship FFF 3D printers: the Bambu Lab X1 Carbon and the Creality K1 Max, utilizing thermoplastic raw materials. These printers are known for their high performance and advanced features, catering to both professional and hobbyist users. The comparison covers essential aspects such as build volume, printing speed, layer resolution, extruder type, and filament compatibility and additional features like bed leveling, connectivity and software support. This comprehensive overview will help users make an informed decision based on their specific 3D-printing needs and preferences.

Table 2.

Comparison of technical specifications between Bambu Lab X1-Carbon and Creality K1 Max 3D printers.

- Bambu Lab X1-Carbon.

The Bambu Lab X1 Carbon is a notable entrant in the field of 3D printing, distinguished by its advanced technology and operational principles. This printer operates on the basis of fused filament fabrication (FFF), utilizing a direct drive extruder system to precisely deposit thermoplastic materials layer by layer. This approach ensures high precision and repeatability in the printing process, which is crucial for producing intricate designs and functional prototypes [96].

The advantages of the Bambu Lab X1 Carbon include its versatility in material compatibility, supporting a wide rande of filaments such as PLA, ABS, PETG, and TPU, and even composite materials like carbon fiber. This capability enables users to tailor prints to specific mechanical and aesthetic requirements, catering to diverse applications from prototyping to small-scale production.

Furthermore, the printer’s robust build quality and high-speed printing capabilities enhance efficiency, making it suitable for both professional and educational environments where rapid prototyping and iterative design processes are essential. The inclusion of features like automatic bed leveling and a user-friendly interface further streamline operation, reducing setup time and minimizing potential errors during printing.

Nevertheless, the Bambu Lab X1 Carbon does have certain restrictions. The intricacy of its configuration and functioning may present difficulties for inexperienced users, necessitating a learning curve to effectively utilize its capabilities. Furthermore, the initial cost of the printer can be too high for people or small businesses who are mindful of their budget, particularly when taking into account the continuous expenses for maintenance and filament.

The Bambu Lab X1 Carbon is a versatile and high-performance 3D printer that utilizes advanced FDM technology to produce precise and customizable prints using different materials. Although it provides substantial benefits in terms of functionality and speed, prospective users should carefully consider these advantages in relation to the initial investment and operational complexity in order to determine its appropriateness for their specific needs and workflow requirements. Figure 19 illustrates a Bambu Lab X1-Carbon 3D printer.

Figure 19.

Bambu Lab X1-Carbon 3D printer [96].

- Creality K1-Max.

The Creality K1 Max represents another recent addition to the field of desktop FFF 3D printing, characterized by its innovative features and operational principles. This printer operates on the basis of fused filament fabrication (FFF), utilizing a direct drive extrusion system to precisely deposit thermoplastic filaments layer by layer. This methodology ensures accuracy and reliability in the printing process, essential for creating intricate designs and functional prototypes with consistent quality [97].

The advantages of the Creality K1 Max include its substantial build volume and accommodation of prints up to 300 × 300 × 300 mm in size. This capability caters to the production of larger objects or batches of smaller components in a single print job, facilitating efficient workflows in both professional and educational settings. Additionally, the printer’s high printing speed, reaching up to 600 mm/s, enhances productivity by reducing overall print times, thereby supporting rapid prototyping and iterative design cycles.

Furthermore, the Creality K1 Max boasts compatibility with a variety of filament materials such as PLA, ABS, PETG and TPU, enabling users to choose materials tailored to specific project requirements. This versatility extends its utility across diverse applications and from functional prototypes to artistic creations.

However, the Creality K1 Max also features drawbacks. The printer’s open-frame design may lead to challenges in maintaining consistent print temperatures towards protecting prints from external factors such as drafts or contamination. Additionally, while the printer offers high speed, achieving optimal print quality at maximum speeds may require careful calibration and monitoring to avoid issues such as layer adhesion or dimensional inaccuracies.

Thus, the Creality K1 Max stands as a robust and versatile 3D printer and leverages advanced FFF technology to deliver large-scale prints with speed and precision. Its expansive build volume, coupled with compatibility across multiple filament types, positions it favorably for applications demanding efficiency and scalability. Prospective users should consider the printer’s capabilities alongside its operational requirements and potential challenges, ensuring alignment with their specific project needs and operational environment. Figure 20, depicts a Creality K1 Max 3D printer.

Figure 20.

Creality K1 Max 3D printer [97].

The following table presents a comprehensive comparison of three prominent 3D printers: the Creality HALOT MAGE S 14K, the Anycubic Photon Mono M7 Pro, and the Formlabs Form 3L. Each printer represents recent, distinct advancements in additive manufacturing technology, catering to various professional and creative applications. The comparison encompasses essential technical specifications such as printing technology, build volume, layer resolution, material compatibility, connectivity options and software support. This overview aims to assist prospective users in making informed decisions based on their specific requirements for precision, speed, material versatility and overall printing capabilities.Table 3, depicts a comparison of technical specifications between resin desktop 3D printers.

Table 3.

Comparison of technical specifications between resin desktop 3D printers.

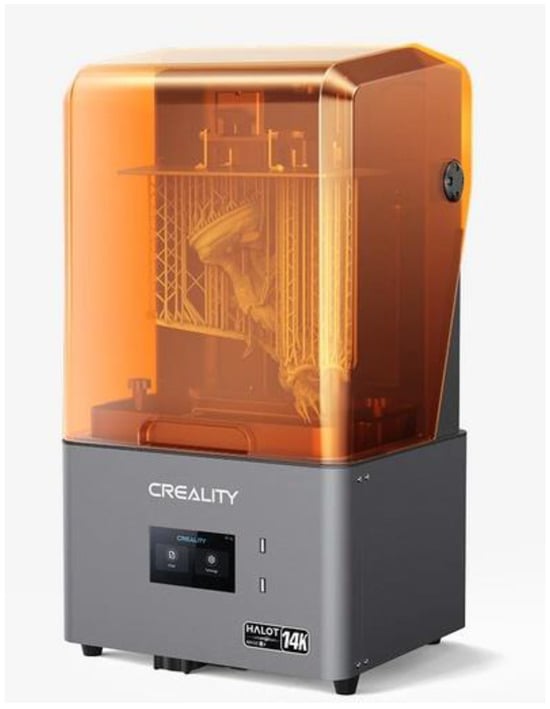

- Creality HALOT MAGE S 14K.

The Creality HALOT MAGE S 14K represents an advanced iteration in resin-based 3D printing, recognised for its innovative features and operational principles. Employing LCD (Liquid Crystal Display) resin printing technology, the HALOT MAGE S 14K utilizes a UV light source to selectively cure liquid resin into solid layers, resulting in high-resolution prints characterized by smooth surfaces and fine details [98].

The advantages of the Creality HALOT MAGE S 14K include its high resolution capabilities, with layer thicknesses typically ranging from 0.025 to 0.05 mm. This precision enables the production of intricate designs and complex geometries with exceptional detail, making it well-suited for applications in jewelry design, dental prosthetics and other fields requiring meticulous craftsmanship.

Moreover, the printer’s LCD technology facilitates faster curing times compared to traditional SLA (stereolithography) printers, enhancing overall print speed and efficiency. This feature is complemented by a user-friendly interface and intuitive software, simplifying workflow processes and enabling seamless integration into various design and manufacturing environments.

Furthermore, the Creality HALOT MAGE S 14K supports a wide rande of resin materials, including standard resins, tough resins and flexible resins, offering versatility to meet diverse project requirements. Its compatibility with third-party resins further expands material options, allowing users to optimize prints for specific mechanical, aesthetic or functional properties.

However, potential drawbacks of the HALOT MAGE S 14K include the need for post-processing steps such as resin cleaning and UV curing, which are common in resin-based printing to achieve optimal print quality. Additionally, while LCD technology offers advantages in speed and resolution, it may have limitations in print durability compared to industrial-grade SLA printers.

In summary, the Creality HALOT MAGE S 14K stands as a proficient choice for users seeking high-resolution resin printing capabilities with enhanced speed and versatility. Its ability to deliver detailed prints across a spectrum of materials makes it suitable for applications demanding precision and aesthetic finesse. Prospective users should consider the printer’s strengths alongside operational requirements and potential post-processing needs to determine its suitability for their specific projects and production goals. Figure 21 depicts a Creality HALOT MAGE S 14K 3D printer.

Figure 21.

Creality HALOT MAGE S 14K 3D printer [97].

- Anycubic Photon Mono M7 Pro.

The Anycubic Photon Mono M7 Pro is a also a recent 3D printer model in resin-based 3D-printing technology, renowned for its functionality and output quality. The Photon Mono M7 Pro uses monochrome LCD resin printing technology to create prints with precise details and smooth surfaces. It achieves this by selectively curing liquid resin layer by layer using a UV light source [99].

One notable advantage of the Anycubic Photon Mono M7 Pro is its improved printing speed, capable of reaching speeds up to 170 mm/h. This feature greatly reduces the total printing time in comparison to conventional resin printers, making it perfect for applications that necessitate quick prototype and iterative design cycles. Moreover, the printer provides remarkable layer resolution, typically ranging from 0.025 to 0.05 mm, guaranteeing high-definition prints that accurately capture intricate details and fine features. The Photon Mono M7 Pro is highly versatile and may be used for a wide range of applications, such as jewelry design, miniatures, and functional prototypes that require precise dimensions and surface quality.

The user experience is improved by the printer’s intuitive touchscreen interface and user-friendly software, which streamline workflow management and seamlessly integrate with numerous design software packages. The inclusion of automatic resin calibration and leveling mechanisms enhances user-friendliness, decreases setup time, and minimizes potential errors throughout the printing process.

Additionally, the Anycubic Photon Mono M7 Pro is compatible with a range of resin materials, such as conventional resins, castable resins for jewelry production, and durable resins for functional prototypes. Users have the ability to choose materials that are customized to meet specific project requirements, whether it is for aesthetic purposes or functional testing.

Nevertheless, like any technology, there are certain factors to bear in mind. Post-processing steps, including as resin cleaning and UV curing, are essential in order to attain the highest level of print quality and durability. In addition, although monochrome LCD technology has advantages in terms of speed and precision, it may have limitations in print durability when compared to industrial-grade SLA (stereolithography) printers.

Overall, the Anycubic Photon Mono M7 Pro is a strong option for those who want rapid and high-quality resin printing capabilities that are suitable for various applications. The combination of its speed, precision, and user-friendly features makes it an appealing choice for professionals and enthusiasts seeking to efficiently achieve detailed and high-quality prints. Prospective users should evaluate the printer’s capabilities in relation to their specific project requirements and operational considerations in order to determine its acceptability. Figure 22 shows an Anycubic Photon Mono M7 Pro 3D printer.

Figure 22.

Anycubic Photon Mono M7 Pro 3D printer [99].

- FormLabs Form 3L.

The Formlabs Form 3L is a highly regarded model of SLA (stereolithography) desktop 3D-printing technology, recognized for its accuracy, dependability, and advanced capabilities. The Form 3L is highly proficient in creating high-resolution prints with exceptional surface quality and dimensional precision by using a laser to cure liquid resin layer by layer [100].

One of the primary benefits of the Form 3L is its substantial build volume, which allows for prints as large as 335 × 200 × 300 mm. The extensive capacity of this technology allows users to create larger-scale prototypes, intricate models, and batch production runs in a single print job, making it especially suitable for professional and industrial applications. The printer utilizes SLA technology to achieve precise layer resolutions ranging from 25 to 300 microns. This enables the creation of intricate and complex geometries with smooth surfaces. Precision and intricate details are of utmost importance in applications such as dental prosthetics, engineering prototypes, and personalized jewelry, making this expertise important.