A Novel Approach to DBS Electrode Prototyping

Abstract

1. Introduction

2. Materials and Methods

- Polyamide 6 or 12: Used for injection of low viscosity, this material is one of the most used in the field of implantable medical devices

- Silver thread: Conductive core of the Electrode with a diameter of 0.213 mm (35 gauge), measuring 300 mm in length. A total of six threads will be used.

- Silver rings: These rings serve as connections to the cable. Five rings are required at one end and three at the other, soldered to the cables. They have a thickness of 0.2 mm and a width of 8 mm.

- Silicon Eco Flex 0030: Type of platinum-catalyzed silicone, cured at room temperature, low viscosity, super soft, hypoallergenic

- Stainless steel wire: Conductive core of the electrode with a diameter of 0.2 mm, measuring 300 mm in length. A total of eight wires will be used.

- Stainless steel rings: These rings serve as connections to the cable. Five rings are required at one end and three at the other, soldered to the cables. They have a thickness of 0.2 mm and a width of 8 mm.

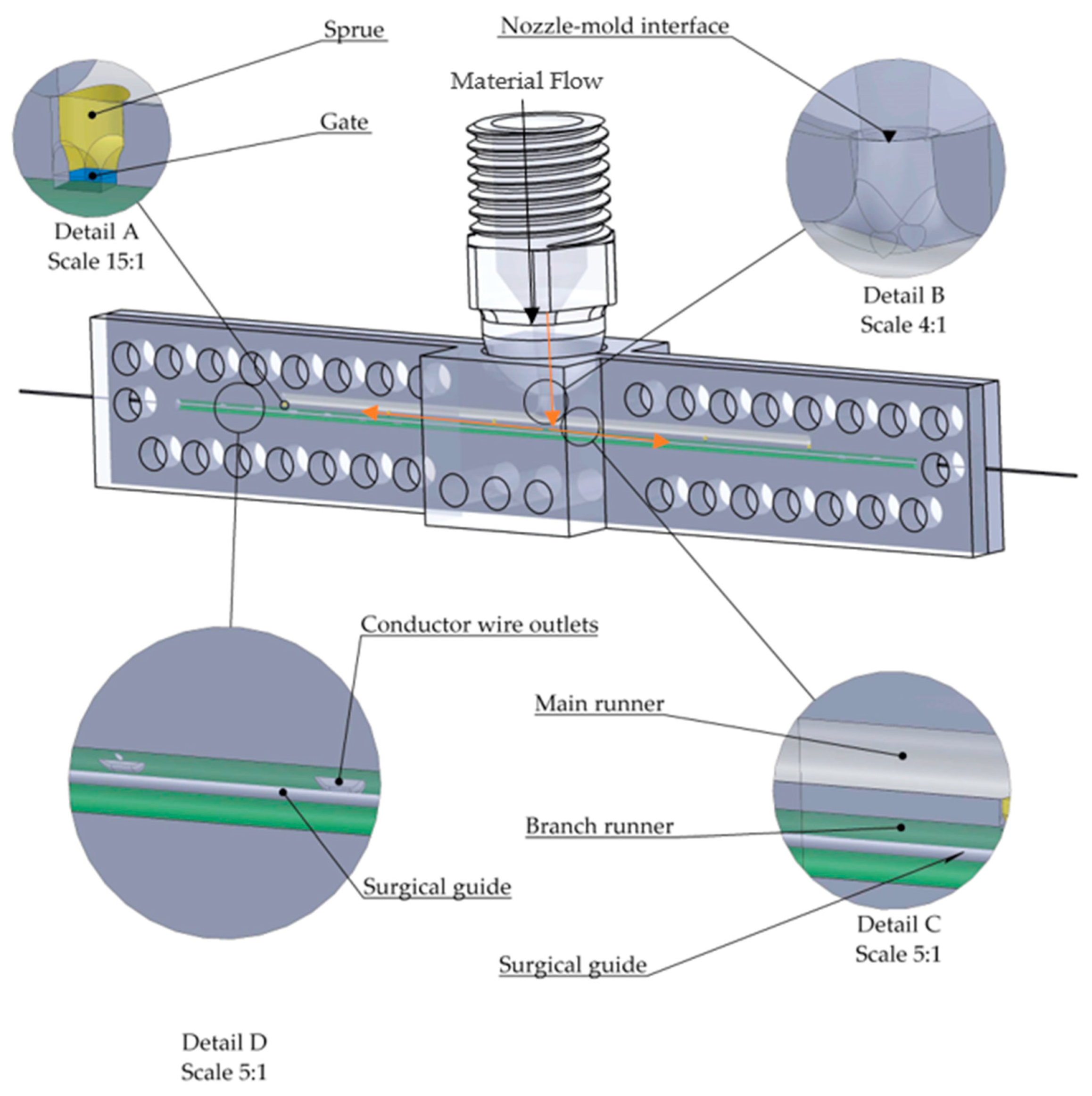

2.1. High-Temperature Mold Calculations

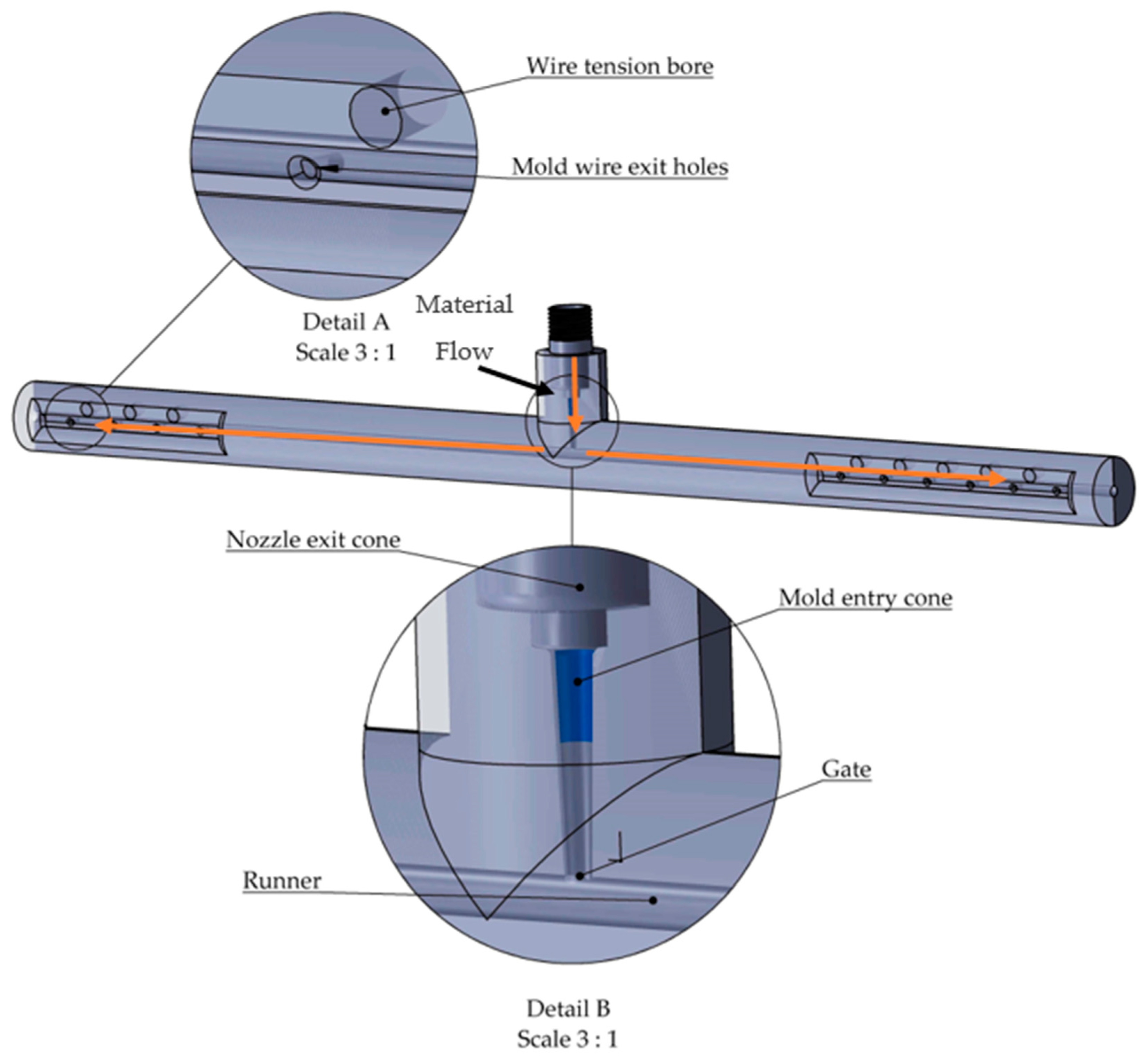

2.2. Injection Mold Calculations at Room Temperature

2.3. Injection Nozzle Calculations

3. Results

3.1. Hot Casting Injection

3.2. Cold Casting Injection

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Parkinson Disease. Available online: https://www.who.int/news-room/fact-sheets/detail/parkinson-disease#:~:text=Global%20estimates%20in%202019%20showed,of%20over%20100%25%20since%202000 (accessed on 7 April 2024).

- Kulisevsky, J.; Luquin, M.R.; Arbelo, J.M.; Burguera, J.A.; Carrillo, F.; Castro, A.; Chacón, J.; García-Ruiz, P.J.; Lezcano, E.; Mir, P.; et al. Advance Parkinson’s disease: Clinical Characteristics and treatment: Part II. Neurología 2013, 28, 564–565. [Google Scholar]

- Deep Brain Stimulator. Available online: https://www.sciencedirect.com/topics/nursing-and-health-professions/deep-brain-stimulator (accessed on 7 April 2024).

- Sibylle, D.; Paul, E.H. Deep brain stimulation in the treatment of depression. Dialogues Clin. Neurosci. 2014, 16, 83–91. [Google Scholar]

- Meijuan Zhou, D.O.U. Electrodo de Estimulación Cerebral Profunda, Dispositivo y Método. Patente. MX2017004133A, 31 October 2017. [Google Scholar]

- Moffitt, M.A.; Oleksyn, T.A.; Bradley, K.; Peterson, D.K.L.; Lane, C.; Pianca, A.M. Deep Brain Stimulation Current Steering with Split Electrodes. U.S. Patent 14542401, 14 November 2014. pp. 18–19. [Google Scholar]

- Sasse, P.; Chambers, T.; Kummer, R.D.; Armstrong, J.; Reece, D.; Lam, H. Method of Manufacturing Electrical Cable, and Resulting Product, with Reduced Required Installation Pulling Force. U.S. Patent US11776715B2, 3 October 2023. [Google Scholar]

- Sasse, P.; Andrea, T. Electrical Cable Having Crosslinked Insulation with Internal Pulling Lubricant. U.S. Patent US11046851B2, 29 June 2021. p. 21. [Google Scholar]

- Draz, H.H.; Gabran, S.R.I.; Basha, M.; Mostafa, H.; Abu-Elyazeed, M.F.; Zaki, A. Comparative mechanical analysis of deep brain stimulation electrodes. Biomed. Eng. Online 2018, 17, 123–129. [Google Scholar] [CrossRef] [PubMed]

- Tool—Temp International. Available online: https://tooltemp.com/es/sectores-sistemas-de-control-de-temperatura/plastico-inyeccion-sistema-decontrol-de-temperatura/ (accessed on 8 April 2024).

- Torres-Sanmiguel, C.R.; Hernández-Gómez, J.J.; Urriolagoitia-Sosa, G.; Romero-ángeles, B.; Martínez-Sáez, L. Design and manufacture of a customised temporomandibular prosthesis. Rev. Int. Metodos Numer. Calc. Diseno Ing. 2019, 35. [Google Scholar] [CrossRef]

- Paulson Training Programs. Available online: https://www.paulsontraining.com/simtech-challenge/ (accessed on 8 April 2024).

- Menges, G.; Mohren, G. Moldes para Inyección de Plásticos, 3rd ed.; Figure 28; Editorial Gustavo Gili, S.L.: Barcelona, Spain, 1983; pp. 47, 59, 60. [Google Scholar]

- Moffitt, M.A.; Olenksyn, T.A.; Bradley, K.; Peterson, D.K.L.; Lane, C.; Margaret, A.; Monica, P.S. Deep Brain Stimulation Current Steering with Split Electrodes. U.S. Patent US9211402B2, 15 December 2015. p. 18. [Google Scholar]

- Bronstein, J.M.; Tagliati, M.; Alterman, R.L.; Lozano, A.M.; Okun, M.S. Deep brain stimulation for Parkinson disease: An expert consensus and review of key issues. Mov. Disord. 2011, 68 (Suppl. S2), 165. [Google Scholar] [CrossRef] [PubMed]

- Schlaepfer, T.E.; Lieb, K. Deep brain stimulation for treatment of refractory depression. Lancet 2005, 366, 1420–1422. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, J.D. Development of a Computational Model for Prediction of Response to Deep Brain Stimulation in Obsessive-Compulsive Disorder. Front. Comput. Neurosci. 2014, 8, 100. [Google Scholar]

- Philpot, T.A. Mechanics of Materials, 4th ed.; Missouri University of Science and Technology: Rolla, MO, USA; Wiley: Hoboken, NJ, USA, 2017; p. 604. [Google Scholar]

- Akulon. Akulon IG-HG7. Available online: https://plasticsfinder.envalior.com/en/datasheet/Akulon%C2%AE%20IG-HG7/p2dqO (accessed on 15 November 2024).

| Parameters | Available Equipment | Selected Liquid Plastic (Low-Pressure Injection, Plastic Developed for 3D Printing) | Liquid Plastic (High-Pressure Injection) |

|---|---|---|---|

| Flow path | 300 mm | 300 mm | 300 mm |

| Electrode diameter | 2 mm | 2 mm | 2 mm |

| Material | N/A | SnapPrint PA6 | PA6 or 12 |

| Average inlet pressure (P) | 0.8 MPa | 0.5 MPa–2 MPa | 17.5 MPa |

| Projected area (S) | 18.84 | 18.84 | 18.84 |

| Thrust force (PxS) | 1507.944 N or 153.71 kg | 942.46 N or 96 kg | 32.986 KN or 3.36 tons |

| Mold clamping force | 177 kg | 111 kg | 4 tons |

| Applied Theories | Equation | Results (MPa) |

|---|---|---|

| Theory of thick-walled vessels | (σr) max = −Po | |

| Theory of thick-walled vessels | ||

| Failure theory, Von Mises criterion |

| Applied Theories | Equation | Results |

|---|---|---|

| Theory of thick-walled vessels | (σr) max = −Po | −0.634 MPa |

| Theory of thick-walled vessels | −0.719 MPa | |

| Failure theory, Von Mises criterion | 0.681 MPa | |

| Safety factor | 3.4 |

| Operation | Description | Machine Type | Tool Preparation | Preparation Time (min) | Operation Time (min) | Material Part |

|---|---|---|---|---|---|---|

| 1 | Mounting | Manual operation | Injectir preparation | 2 | 0 | Manual injector |

| 2 | Assembly | Manual operation | Mold assembly 1 with electrode wires | 15 | 0 | Mold made by FDM |

| 3 | Assembly | Manual operation | Assembly of mold 1 with mold 2 | 10 | 0 | Mold made by FDM |

| 4 | Assembly | Manual operation | Clamps assembly on the complete mold | 10 | 0 | Clamps made by FDM |

| 5 | Mixed | Manual operation | Homogenization of equal parts of fluid A and fluid B | 1 | Silicon plus catalyst for hardening by smoothing on | |

| 6 | Injection | Manual Injector | Silicon Injection prepared in a mold | 1 | 10 | Smooth on manual injector |

| 7 | Drying | Manual operation | Waiting time at rest of the injected mold | 0 | 480 | Not apply |

| 8 | Disassembly | Manual operation | Removal of the screw from clamps | 2 | 10 | Not apply |

| 9 | Disassembly | Manual operation | Disassembly of mold 2 with mold 1 | 2 | 10 | Not apply |

| 10 | Disassembly | Manual operation | Mold electrode demolding 1 | 2 | 5 | DBS electrode injected into a conductive core |

| 11 | Stapled | Manual operation | Stamping of the conductive rings with the conductive core | Conductive material rings |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina-Rodríguez, J.E.; Piña-Díaz, A.J.; Flores-Campos, J.A.; Silva-Garces, K.N.; Oropeza-Osornio, A.; Torres San Miguel, C.R. A Novel Approach to DBS Electrode Prototyping. Processes 2024, 12, 2694. https://doi.org/10.3390/pr12122694

Medina-Rodríguez JE, Piña-Díaz AJ, Flores-Campos JA, Silva-Garces KN, Oropeza-Osornio A, Torres San Miguel CR. A Novel Approach to DBS Electrode Prototyping. Processes. 2024; 12(12):2694. https://doi.org/10.3390/pr12122694

Chicago/Turabian StyleMedina-Rodríguez, Jesús Eduardo, Armando Josue Piña-Díaz, Juan Alejandro Flores-Campos, Karla Nayeli Silva-Garces, Armando Oropeza-Osornio, and Christopher René Torres San Miguel. 2024. "A Novel Approach to DBS Electrode Prototyping" Processes 12, no. 12: 2694. https://doi.org/10.3390/pr12122694

APA StyleMedina-Rodríguez, J. E., Piña-Díaz, A. J., Flores-Campos, J. A., Silva-Garces, K. N., Oropeza-Osornio, A., & Torres San Miguel, C. R. (2024). A Novel Approach to DBS Electrode Prototyping. Processes, 12(12), 2694. https://doi.org/10.3390/pr12122694