A State-of-the-Art Review of Fracture Toughness of Silicon Carbide: Implications for High-Precision Laser Dicing Techniques

Abstract

:1. Introduction

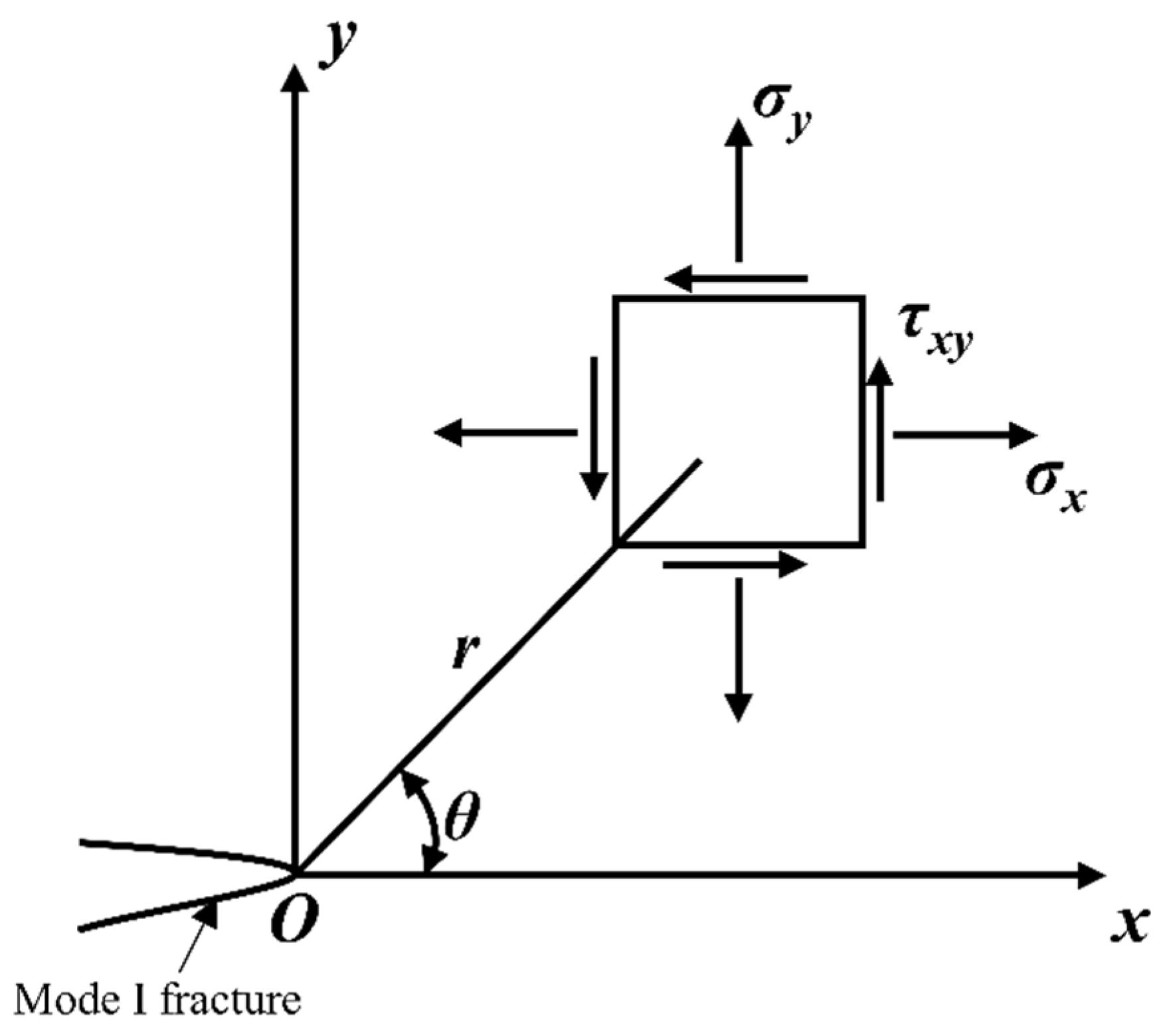

2. Stress Intensity Factor and Fracture Toughness

3. Fracture-Toughness Measurement Techniques

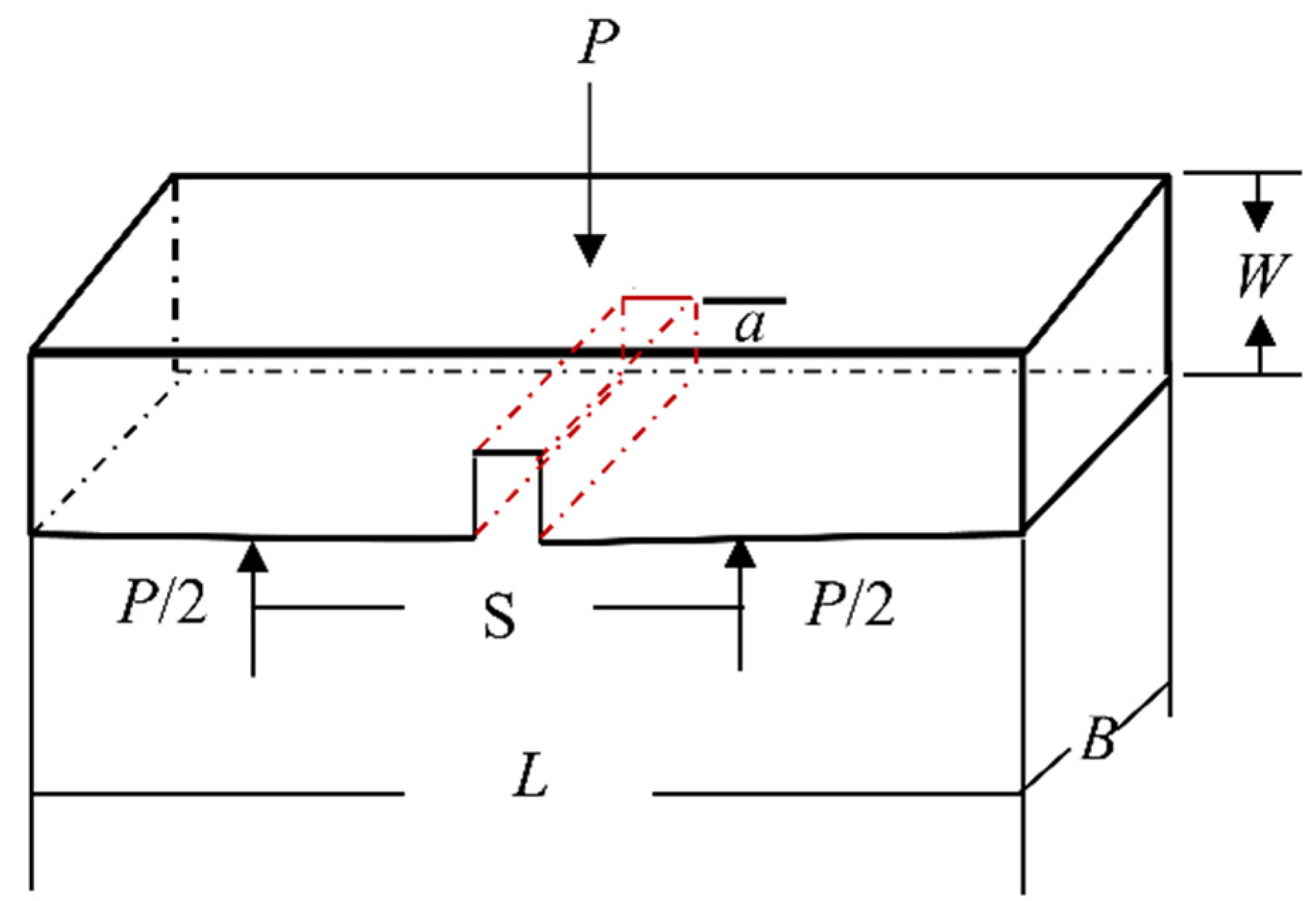

3.1. Single-Edge Notched Beam (SENB) Tests

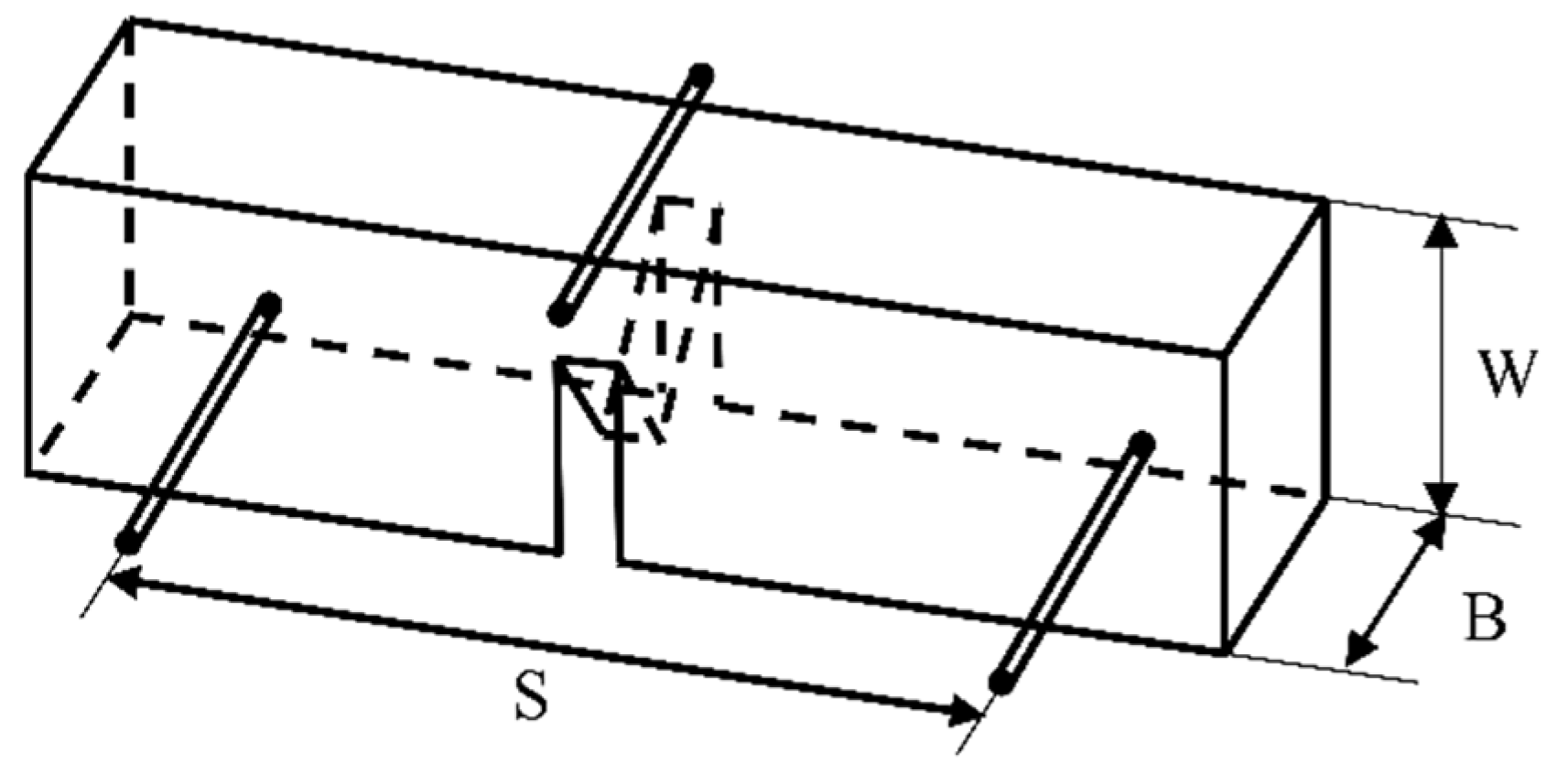

3.2. Chevron Notched Beam (CNB) Tests

3.3. Single-Edge Precracked Beam (SEPB) Test

3.4. Double Torsion (DT) Tests

3.5. Double Cantilever Beam (DCB) Tests

3.6. Surface Crack in Flexure (SCF) Method

3.7. Indentation Method (Vickers, Knoop, Berkovich, Nano-Indentation)

4. Fracture Toughness and Influencing Factors

4.1. Fracture Toughness Value

4.2. Toughness Anisotropy

4.3. Temperature Dependence of Fracture Toughness

4.4. Effect of Grain Size and Microstructure on Fracture Toughness

5. Fracture Mechanism

6. Implications for Laser Processing

- Substrate Preparation: Prior to dicing, polish or treat the SiC substrate surface to remove any pre-existing surface defects that might propagate into larger cracks during cutting. For finer grains, a smooth surface is especially advantageous, as it enables the laser to follow a predictable path.

- Laser-Type Selection: For SiC dicing, ultrashort-pulse lasers, such as femtosecond or picosecond lasers, offer precise control over the heat-affected zone and are ideal for brittle materials. The nanosecond lasers, while effective, can introduce more heat into the surrounding area.

- Laser Speed: A higher laser speed can help manage the heat-affected zone while preventing excessive heat accumulation that could cause microcracks.

- Focal Positioning: Position the laser focal point at a shallow depth, around 30 μm below the surface. This setting promotes controlled surface-level heating that guides crack propagation along the cutting path, reducing unintended lateral cracking.

- Pulse Frequency and Power: Increase pulse frequency (e.g., >50 kHz) with moderate power to enhance the smoothness of the cut while controlling the crack direction. This balance minimizes rough edges and helps maintain the integrity of fine-grained SiC.

- Short Pulse Width: Set a short pulse width (e.g., <10 ps) to achieve precise energy delivery, confining heat to the immediate area around the laser path and minimizing diffusion into surrounding grains.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Zhang, C.; Liu, F.; Zheng, H.; Cheng, G.J. Ultrafast Pulsed Laser Stealth Dicing of 4H-SiC Wafer: Structure Evolution and Defect Generation. J. Manuf. Processes 2022, 81, 562–570. [Google Scholar] [CrossRef]

- Li, S.; Chen, P.; Qin, F.; Tu, S.; Wu, K. Stealth Dicing of SiC Using Femtosecond Laser Bessel Beam. In Proceedings of the 2023 24th International Conference on Electronic Packaging Technology (ICEPT), Shihezi, China, 8–11 August 2023. [Google Scholar]

- Kim, E.; Shimotsuma, Y.; Sakakura, M.; Miura, K. 4H-SiC Wafer Slicing by Using Femtosecond Laser Double-Pulses. Opt. Mater. Express. 2017, 7, 2450–2460. [Google Scholar] [CrossRef]

- Jiang, K.; Zhang, P.; Song, S.; Sun, T.; Chen, Y.; Shi, H.; Yan, H.; Lu, Q.; Chen, G. A Review of Ultra-Short Pulse Laser Micromachining of Wide Bandgap Semiconductor Materials: SiC and GaN. Mater. Sci. Semicond. Process. 2024, 180, 108559. [Google Scholar] [CrossRef]

- Kumagai, M.; Uchiyama, N.; Ohmura, E.; Sugiura, R.; Atsumi, K.; Fukumitsu, K. Advanced Dicing Technology for Semiconductor Wafer—Stealth Dicing. IEEE Trans. Semicond. Manuf. 2007, 20, 259–265. [Google Scholar] [CrossRef]

- Ohmura, E.; Kumagai, M.; Nakano, M.; Kuno, K.; Fukumitsu, K.; Morita, H. Analysis of Processing Mechanism in Stealth Dicing of Ultra Thin Silicon Wafer. J. Adv. Mech. Des. Syst. Manuf. 2008, 2, 540–549. [Google Scholar] [CrossRef]

- Tseng, S.-F.; Luo, C.-X.; Hsiao, W.-T. Characterization Analysis of 355 Nm Pulsed Laser Cutting of 6H-SiC. Int. J. Adv. Manuf. Technol. 2024, 130, 3133–3147. [Google Scholar] [CrossRef]

- Xie, X.; Peng, Q.; Chen, G.; Li, J.; Long, J.; Pan, G. Femtosecond Laser Modification of Silicon Carbide Substrates and Its Influence on CMP Process. Ceram. Int. 2021, 47, 13322–13330. [Google Scholar] [CrossRef]

- Qiao, S.; Hu, J.; Wei, Y.; Zeng, A.; Huang, H. Fine Optimization of Aberration Compensation for Stealth Dicing. Opt. Laser Technol. 2024, 174, 110668. [Google Scholar] [CrossRef]

- Okada, T.; Tomita, T.; Matsuo, S.; Hashimoto, S.; Ishida, Y.; Kiyama, S.; Takahashi, T. Formation of Periodic Strained Layers Associated with Nanovoids inside a Silicon Carbide Single Crystal Induced by Femtosecond Laser Irradiation. J. Appl. Phys. 2009, 106, 054307. [Google Scholar] [CrossRef]

- Song, Q.; Zhang, Z.; Xu, Z.; Wen, Z.; Shi, H.; Zhang, K.; Li, M.; Zhang, Z.; Hou, Y.; Song, Z. Investigation on the Processing Quality of Nanosecond Laser Stealth Dicing for 4H-SiC Wafer. ECS J. Solid State Sci. Technol. 2023, 12, 033012. [Google Scholar] [CrossRef]

- Samant, A.N.; Dahotre, N.B. Laser Machining of Structural Ceramics—A Review. J. Eur. Ceram. Soc. 2009, 29, 969–993. [Google Scholar] [CrossRef]

- Han, S.; Yu, H.; He, C.; Zhao, S.; Ning, C.; Jiang, L.; Lin, X. Laser Slicing of 4H-SiC Wafers Based on Picosecond Laser-Induced Micro-Explosion via Multiphoton Processes. Opt. Laser Technol. 2022, 154, 108323. [Google Scholar] [CrossRef]

- Wen, Q.; Yang, Y.; Lu, J.; Huang, H.; Cui, C. Study on Picosecond Laser Stealth Dicing of 4H-SiC along and Crystal Orientations on Si-Face and C-Face. Opt. Laser Technol. 2023, 162, 109300. [Google Scholar] [CrossRef]

- Li, J.; Liu, F.; Zhou, W.; Zhang, Y. The Influence of Cracks in the Coupling Region of Micro-Grinding and Laser Stealth Combined Dicing on the Quality of Cutting Side Walls. J. Manuf. Processes 2024, 119, 856–866. [Google Scholar] [CrossRef]

- Xie, X.; Liu, T.; Lv, K.; Huang, Y.; Huang, Y.; Hu, W.; Long, J. The Internal Modified Layer Structure of Silicon Carbide Induced by Ultrafast Laser and Its Application in Stealth Dicing. Precis. Eng. 2024, 88, 895–904. [Google Scholar] [CrossRef]

- Sun, C.-T.; Jin, Z.-H. Fracture Mechanics; Academic Press: Waltham, MA, USA, 2012. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 4th ed.; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: London, UK, 2017. [Google Scholar]

- Fan, Z.Q.; Jin, Z.-H.; Johnson, S.E. Oil-Gas Transformation Induced Subcritical Crack Propagation and Coalescence in Petroleum Source Rocks. Int. J. Fract. 2014, 185, 187–194. [Google Scholar] [CrossRef]

- Tada, H.; Paris, P.C.; Irwin, G.R. The Stress Analysis of Cracks Handbook, 3rd ed.; ASME Press: New York, NY, USA, 2000. [Google Scholar]

- Fan, Z.Q.; Jin, Z.-H.; Johnson, S.E. Modelling Petroleum Migration through Microcrack Propagation in Transversely Isotropic Source Rocks: Modelling Petroleum Migration. Geophys. J. Int. 2012, 190, 179–187. [Google Scholar] [CrossRef]

- Jin, Z.-H.; Johnson, S.E.; Fan, Z.Q. Subcritical Propagation and Coalescence of Oil-filled Cracks: Getting the Oil out of Low-permeability Source Rocks. Geophys. Res. Lett. 2010, 37, 2009GL041576. [Google Scholar] [CrossRef]

- C28 Committee ASTM International. Test Methods for Determination of Fracture Toughness of Advanced Ceramics at Ambient Temperature; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Sakai, M.; Bradt, R.C. Fracture Toughness Testing of Brittle Materials. Int. Mater. Rev. 1993, 38, 53–78. [Google Scholar] [CrossRef]

- Morrell, R. Fracture Toughness Testing for Advanced Technical Ceramics: Internationally Agreed Good Practice. Adv. Appl. Ceram. 2006, 105, 88–98. [Google Scholar] [CrossRef]

- Bellante, J.J.; Kahn, H.; Ballarini, R.; Zorman, C.A.; Mehregany, M.; Heuer, A.H. Fracture Toughness of Polycrystalline Silicon Carbide Thin Films. Appl. Phys. Lett. 2005, 86, 071920. [Google Scholar] [CrossRef]

- Zhu, X.-K.; Joyce, J.A. Review of Fracture Toughness (G, K, J, CTOD, CTOA) Testing and Standardization. Eng. Fract. Mech. 2012, 85, 1–46. [Google Scholar] [CrossRef]

- Launey, M.E.; Ritchie, R.O. On the Fracture Toughness of Advanced Materials. Adv. Mater. 2009, 21, 2103–2110. [Google Scholar] [CrossRef]

- Srinivasan, S.; Scattergood, R.O. Comment on “Indentation Fracture Toughness of Sintered Silicon Carbide in the Palmqvist Crack Regime”. J. Am. Ceram. Soc. 1991, 74, 887–888. [Google Scholar]

- Moradkhani, A.; Baharvandi, H.; Tajdari, M.; Latifi, H.; Martikainen, J. Determination of Fracture Toughness Using the Area of Micro-Crack Tracks Left in Brittle Materials by Vickers Indentation Test. J. Adv. Ceram. 2013, 2, 87–102. [Google Scholar]

- Wiederhorn, S.M.; Shorb, A.M.; Moses, R.L. Critical Analysis of the Theory of the Double Cantilever Method of Measuring Fracture-Surface Energies. J. Appl. Phys. 1968, 39, 1569–1572. [Google Scholar]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar]

- Withey, P.A.; Brett, R.L.; Bowen, P. Use of Chevron Notches for Fracture Toughness Determination in Brittle Solids. Mater. Sci. Technol. 1992, 8, 805–810. [Google Scholar]

- Jiang, L.; Chen, Y.H.; Han, F.; Jiang, L. Fracture Behavior of Silicon Carbide Measured by Different Test Methods. Adv. Mater. Res. 2010, 177, 140–143. [Google Scholar] [CrossRef]

- Vargas-Gonzalez, L.; Speyer, R.F.; Campbell, J. Flexural Strength, Fracture Toughness, and Hardness of Silicon Carbide and Boron Carbide Armor Ceramics. Int. J. Appl. Ceram. Technol. 2010, 7, 643–651. [Google Scholar] [CrossRef]

- Orange, G.; Tanaka, H.; Fantozzi, G. Fracture Toughness of Pressureless Sintered Silicon Carbide: A Comparison of KIC Measurement Methods. Ceram. Int. 1987, 13, 159–165. [Google Scholar] [CrossRef]

- Chen, X.; Eichhubl, P.; Olson, J.E. Effect of Water on Critical and Subcritical Fracture Properties of Woodford Shale. J. Geophys. Res.-Solid Earth. 2017, 122, 2736–2750. [Google Scholar] [CrossRef]

- Liang, K.M.; Orange, G.; Fantozzi, G. Evaluation by Indentation of Fracture Toughness of Ceramic Materials. J. Mater. Sci. 1990, 25, 207–214. [Google Scholar] [CrossRef]

- Evans, A.G.; Lange, F.F. Crack Propagation and Fracture in Silicon Carbide. J. Mater. Sci. 1975, 10, 1659–1664. [Google Scholar] [CrossRef]

- Li, Z.; Ghosh, A.; Kobayashi, A.S.; Bradt, R.C. Indentation Fracture Toughness of Sintered Silicon Carbide in the Palmqvist Crack Regime. J. Am. Ceram. Soc. 1989, 72, 904–911. [Google Scholar] [CrossRef]

- Ghosh, A.; Jenkins, M.G.; White, K.W.; Kobayashi, A.S.; Brad, R.C. Elevated-Temperature Fracture Resistance of a Sintered α-Silicon Carbide. J. Am. Ceram. Soc. 1989, 72, 242–247. [Google Scholar] [CrossRef]

- Woodilla, D.; Buonomo, M.; Bar-On, I.; Katz, R.N.; Whalen, T. Elevated-Temperature Behavior of High-Strength Silicon Carbide. J. Am. Ceram. Soc. 1993, 76, 249–252. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.K.; Datta, S.K.; Chakraborty, D. Fracture Toughness of Structural Ceramics. Ceram. Int. 1999, 25, 447–454. [Google Scholar] [CrossRef]

- Gong, J.H.; Guan, Z.D. Fracture from Knoop Indentation-Induced Flaws in Sintered Silicon Carbide and Hot-Pressed Silicon Nitride. Key Eng. Mater. 2002, 224–226, 765–770. [Google Scholar] [CrossRef]

- Kaur, S.; Cutler, R.A.; Shetty, D.K. Short-Crack Fracture Toughness of Silicon Carbide. J. Am. Ceram. Soc. 2009, 92, 179–185. [Google Scholar] [CrossRef]

- Yang, X.; Liu, X.; Huang, Z.; Yao, X.; Liu, G. Vickers Indentation Crack Analysis of Solid-Phase-Sintered Silicon Carbide Ceramics. Ceram. Int. 2013, 39, 841–845. [Google Scholar] [CrossRef]

- Cui, J.; Liu, H.; Guan, K.; Rao, P. Load-deflection Behavior of Fracture Toughness Testing of Ceramics by SEVNB Method. Int. J. Appl. Ceram. Technol. 2018, 15, 1310–1315. [Google Scholar] [CrossRef]

- Barick, P.; Chatterjee, A.; Majumdar, B.; Saha, B.P.; Mitra, R. Comparative Evaluations and Microstructure: Mechanical Property Relations of Sintered Silicon Carbide Consolidated by Various Techniques. Metall. Mater. Trans. A 2018, 49, 1182–1201. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, L.G.; Roy, A. A Multiscale-Indentation Study of Deformation and Fracture in 6H Polycrystalline Silicon Carbide. Mater. Sci. Technol. 2020, 36, 1111–1124. [Google Scholar] [CrossRef]

- Himsolt, G.; Fett, T.; Keller, K.; Munz, D. Fracture Toughness Measurements on Silicon Carbide. Materialwiss. Werkstofftech. 1989, 20, 148–153. [Google Scholar] [CrossRef]

- Nobuta, Y.; Homma, H.; Haraguchi, H. Fracture Toughness of Silicon Carbide Evaluated Using Pre-Cracked Specimens. JSME Int. J. Ser. A-Solid Mech. Mat. Eng. 1988, 31, 575–579. [Google Scholar] [CrossRef]

- Nose, T.; Fujii, T. Evaluation of Fracture Toughness for Ceramic Materials by a Single-Edge-Precracked-Beam Method. J. Am. Ceram. Soc. 1988, 71, 328–333. [Google Scholar] [CrossRef]

- Cockeram, B.V. Fracture Toughness and Flexural Strength of Chemically Vapor-Deposited Silicon Carbide As Determined Using Chevron-Notched and Surface Crack in Flexure Specimens. J. Am. Ceram. Soc. 2004, 87, 1093–1101. [Google Scholar] [CrossRef]

- Kitahara, H.; Noda, Y.; Yoshida, F.; Nakashima, H. Mechanical Behavior of Single Crystalline and Polycrystalline Silicon Carbides Evaluated by Vickers Indentation. J. Ceram. Soc. Jpn. 2001, 109, 602–606. [Google Scholar] [CrossRef]

- Kunka, C.; Trachet, A.; Subhash, G. Interaction of Indentation-Induced Cracks on Single-Crystal Silicon Carbide. J. Am. Ceram. Soc. 2015, 98, 1891–1897. [Google Scholar] [CrossRef]

- Eswar Prasad, K.; Ramesh, K.T. Hardness and Mechanical Anisotropy of Hexagonal SiC Single Crystal Polytypes. J. Alloys Compd. 2019, 770, 158–165. [Google Scholar] [CrossRef]

- Chai, P.; Li, S.; Li, Y.; Yin, X. Study on Damage of 4H-SiC Single Crystal through Indentation and Scratch Testing in Micro–Nano Scales. Appl. Sci. 2020, 10, 5944. [Google Scholar] [CrossRef]

- Ming, L.; Dongyang, H.; Chenghui, G. Study on Fracture Toughness of Semiconductor Material Using Vickers and Berkovich Indenters. Chin. J. Theor. Appl. Mech. 2021, 53, 413–423. [Google Scholar]

- Hou, D.; Liu, M.; Liu, S.; Yang, F. Indentation Fracture of 4H-SiC Single Crystal. Int. J. Mech. Sci. 2024, 270, 109096. [Google Scholar] [CrossRef]

- Henshall, J.L.; Rowcliffe, D.J.; Edington, J.W. Fracture Toughness of Single-Crystal Silicon Carbide. J. Am. Ceram. Soc. 1977, 60, 373–375. [Google Scholar] [CrossRef]

- Henshall, J.L.; Brookes, C.A. The Measurement of KIC in Single Crystal SiC Using the Indentation Method. J. Mater. Sci. Lett. 1985, 4, 783–786. [Google Scholar] [CrossRef]

- Yin, L.; Vancoille, E.Y.J.; Ramesh, K.; Huang, H. Surface Characterization of 6H-SiC (0001) Substrates in Indentation and Abrasive Machining. Int. J. Mach. Tools Manuf. 2004, 44, 607–615. [Google Scholar] [CrossRef]

- Qian, J.; Daemen, L.L.; Zhao, Y. Hardness and Fracture Toughness of Moissanite. Diam. Relat. Mater. 2005, 14, 1669–1672. [Google Scholar] [CrossRef]

- Sernicola, G.; Giovannini, T.; Patel, P.; Kermode, J.R.; Balint, D.S.; Britton, T.B.; Giuliani, F. In Situ Stable Crack Growth at the Micron Scale. Nat. Commun. 2017, 8, 108. [Google Scholar] [CrossRef]

- Datye, A.; Schwarz, U.; Lin, H.-T. Fracture Toughness Evaluation and Plastic Behavior Law of a Single Crystal Silicon Carbide by Nanoindentation. Ceramics 2018, 1, 198–210. [Google Scholar] [CrossRef]

- Kishida, K.; Shinkai, Y.; Inui, H. Room Temperature Deformation of 6H–SiC Single Crystals Investigated by Micropillar Compression. Acta Mater. 2020, 187, 19–28. [Google Scholar] [CrossRef]

- Liu, X.; Wang, R.; Zhang, J.; Lu, Y.; Zhang, Y.; Yang, D.; Pi, X. Anisotropic Deformation of 4H-SiC Wafers: Insights from Nanoindentation Tests. J. Phys. D-Appl. Phys. 2022, 55, 494001. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, X.; Ritchie, R.O. Effects of Grain-Boundary Structure on the Strength, Toughness, and Cyclic-Fatigue Properties of a Monolithic Silicon Carbide. J. Am. Ceram. Soc. 2000, 83, 2079–2081. [Google Scholar] [CrossRef]

- Kim, W.; Kim, Y.; Cho, D. Texture and Fracture Toughness Anisotropy in Silicon Carbide. J. Am. Ceram. Soc. 1998, 81, 1669–1672. [Google Scholar] [CrossRef]

- Sharpe, W.N.; Beheim, G.M.; Evans, L.J.; Nemeth, N.N.; Jadaan, O.M. Fracture Strength of Single-Crystal Silicon Carbide. J. Microelectromech. Syst. 2008, 17, 244–254. [Google Scholar] [CrossRef]

- Ribeiro, S.; Ribeiro, G.C.; Rodrigues, J.A. Fracture toughness of silicon carbide, alumina and red clay based ceramics by IF and SEVNB methods. Cerâmica 2014, 60, 509–515. [Google Scholar] [CrossRef]

- Wang, P.; Ge, P.; Bi, W.; Meng, J. Interaction of Lateral Cracks in Double Scratching of Single-Crystal Silicon Carbide. Theor. Appl. Fract. Mech. 2019, 104, 102378. [Google Scholar] [CrossRef]

- Al Nasiri, N.; Ni, N.; Saiz, E.; Chevalier, J.; Giuliani, F.; Vandeperre, L.J. Effect of Microstructure and Grain Boundary Chemistry on Slow Crack Growth in Silicon Carbide at Ambient Conditions. J. Eur. Ceram. Soc. 2015, 35, 2253–2260. [Google Scholar] [CrossRef]

- Lee, S.; Kim, Y.; Mitomo, M. Relationship between Microstructure and Fracture Toughness of Toughened Silicon Carbide Ceramics. J. Am. Ceram. Soc. 2001, 84, 1347–1353. [Google Scholar] [CrossRef]

- Kim, D.; Kim, C.H. Toughening Behavior of Silicon Carbide with Additions of Yttria and Alumina. J. Am. Ceram. Soc. 1990, 73, 1431–1434. [Google Scholar] [CrossRef]

- Faber, K.T.; Evans, A.G. Intergranular Crack-Deflection Toughening in Silicon Carbide. J. Am. Ceram. Soc. 1983, 66, C94–C96. [Google Scholar] [CrossRef]

- Qu, M.; Zhang, Y.; Huang, C. Interface Failure Behavior and Mechanisms of 4H-SiC Wafer with Alloy Backside Layer Caused by Different Dicing Technologies. J. Manuf. Processes 2024, 120, 1115–1123. [Google Scholar] [CrossRef]

- Han, L.; Wang, Q.; Ma, C.; Gu, B.; Li, X.; Wei, W. Research on the Formation and Evolution Mechanism of Cracks in Laser Stealth Dicing of Silicon Carbide Crystals. J. Mol. Graph. Model. 2024, 132, 108830. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Zhong, M.; Wu, L.; Chen, Z.; Lu, S. Multi Scale Simulation of Crack Propagation in Polycrystalline SiC. Theor. Appl. Fract. Mech. 2024, 129, 104231. [Google Scholar] [CrossRef]

- Matsumoto, M.; Huang, H.; Harada, H.; Kakimoto, K.; Yan, J. On the Phase Transformation of Single-Crystal 4H–SiC during Nanoindentation. J. Phys. D Appl. Phys. 2017, 50, 265303. [Google Scholar] [CrossRef]

- Sridhara, S.G.; Eperjesi, T.J.; Devaty, R.P.; Choyke, W.J. Penetration Depths in the Ultraviolet for 4H, 6H and 3C Silicon Carbide at Seven Common Laser Pumping Wavelengths. Mater. Sci. Eng. B. 1999, 61–62, 229–233. [Google Scholar] [CrossRef]

- Xu, B.; Zou, M.; Men, H.; Dou, F.; Ji, X.; Tang, J. Research on the Invisible Cutting Method of Silicon Carbide Using Femtosecond Laser. In Proceedings of the 2023 7th International Conference on Measurement Instrumentation and Electronics (ICMIE), Hangzhou, China, 14–16 April 2023. [Google Scholar]

- Yang, B.; Wang, H.; Peng, S.; Cao, Q. Precision Layered Stealth Dicing of SiC Wafers by Ultrafast Lasers. Micromachines 2022, 13, 1011. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, C.; Liu, F.; Zheng, H.; Cheng, G.J. Process Mechanism of Ultrafast Laser Multi-Focal-Scribing for Ultrafine and Efficient Stealth Dicing of SiC Wafers. Appl. Phys. A 2022, 128, 872. [Google Scholar] [CrossRef]

| Testing Method | Advantages | Disadvantages |

|---|---|---|

| Single-Edge Notched Beam (SENB) | - Standardized method and widely used for brittle materials. - Simple to perform and provides consistent results for bulk materials. | - Requires careful machining of a sharp notch, which can be challenging for SiC. - Crack may not propagate as cleanly in SiC. |

| Chevron Notched Beam (CNB) | - Reduces variability by stabilizing the crack growth during testing. - V-shaped notch ensures consistent crack propagation. | - Machining the chevron notch can be difficult and time-consuming. - Requires highly controlled test setup. - Not as commonly available as SENB. |

| Single-Edge Precracked Beam (SEPB) | - Improved reproducibility over SENB. - Precrack eliminates initial notch limitations. | - Precracking introduces complexity - Sample preparation can be time-intensive. - Requires specialized equipment for precracking. |

| Double Torsion (DT) | - Allows stable, controlled crack growth under Mode I (tensile) loading. - Suitable for high-temperature fracture-toughness testing. - Crack-propagation monitoring is straightforward. | - Requires careful loading and test conditions for stable crack propagation. - Requires calibration for testing equipment. |

| Double Cantilever Beam (DCB) | - Provides stable crack growth and direct measurement of crack-growth resistance. -Rigorous analytical solution. | - Complex specimen preparation. - Limited applicability for certain geometries and thin specimens. - Alignment and measurement of crack length are critical for accuracy. |

| Surface Crack in Flexure (SCF) | - Simple experimental setup with fewer complex geometries. -Provides direct insights into the crack-tip stress field. | - Requires precise measurement of crack front geometry. - Possible existence of residual stress. |

| Vickers Indentation | - Simple and quick technique. - Provides localized fracture toughness. - Useful for small or thin samples. | - Sensitivity to crack pattern visibility. - Influenced by surface conditions and residual stresses. - May not reflect bulk fracture toughness of the material. |

| Knoop Indentation | - Good for anisotropic materials due to elongated indent shape. - Lower penetration depth, ideal for thin coatings or surface layers. | - Similar limitations as Vickers (e.g., sensitivity to surface quality). - Complex crack pattern analysis required. |

| Berkovich Indentation | - Triangular indenter offers better precision in measuring localized plastic deformation. - Effective for evaluating thin films and coatings. | - Need for advanced image processing techniques to improve crack pattern accuracy. - Limited to surface-level fracture toughness, not ideal for bulk analysis. |

| Nano-Indentation | - High spatial resolution; excellent for small-scale materials. - Can measure hardness, elastic modulus, and fracture toughness, simultaneously. | - Extremely sensitive to surface roughness and preparation. - Can only assess very small volumes of material, making it less representative of bulk properties. |

| SiC Type | Testing Method | Testing Temperature | ) | References |

|---|---|---|---|---|

| sintered α-SiC | Double torsion | Up to 1773 K | 3.0 | [39] |

| Single-edge notched beam | Room | 4.1–4.5 | [36] | |

| Chevron notched beam | Room | 2.8–3.6 | ||

| Vickers indentation | Room | 3.6–4.4 | [40] | |

| Chevron-notch and straight-notch three-point bending | Up to 1773 K | 3.0 | [41] | |

| Three-point bending with single-edge precracked beam | Room | 0.25 | [42] | |

| sintered β-SiC | Single-edge notched beam | Room | 3.5–4.3 | [36] |

| Chevron notched beam | Room | 3.1–3.9 | ||

| sintered SiC | Single-edge notched beam | Room | 2.51 | [43] |

| Chevron notched beam | Room | 3.5 | ||

| Modified Knoop indented bending | Room | 2.3–3.5 | [44] | |

| Chevron-notch and straight-notch three-point-bending | Room | 2.3–3.3 | ||

| Single-edge notched beam | Room | 2.6–3.6 | ||

| Single-edge precracked beam | Room | 2.5–6.4 | [45] | |

| Vickers indentation | Room | 2.8 | [46] | |

| Single-edge V-notched beam | Room | 3.2 ± 0.15 | [47] | |

| Single-edge notched beam | Room | 3.5 ± 0.42 | [48] | |

| 6H polycrystalline silicon carbide | Vickers indentation | Room | 1.36–2.52 | [49] |

| hot-pressed SiC | Four-point bending with straight through notches, Chevron notches, and Knoop indentation cracks | Up to 1773 K | 2.5–5.0 | [50] |

| SiC | Three- and four-point-bending of precracked specimen | Room | 2.2 ± 0.2 | [51] |

| Single-edge precracked beam method | Room-1773 K | 3.59 ± 0.17 Room2.42.67@1773 K | [52] | |

| Knoop indentation | Room to 1363 K | 4.3–5.5 | [53] | |

| Four-point bend of a Chevron-notched specimen | Room to 1363 K | 2.8–3.9 | [53] | |

| 4H-SiC | Vickers indentation | Room | 1.6–3.1 | [54] |

| Knoop | Room | 1.4–1.8 | [55] | |

| Berkovich indentation | Room | 3.33 | [56] | |

| Berkovich indentation | Room | 3.42 | [57] | |

| Vickers and Berkovich indentations | Room | 2.89 | [58] | |

| Nano-indentation | Room | 2.97–3.61 | ||

| Berkovich indentation | Room | 2.1 | [59] | |

| Vickers indentation | Room | 1.9 | ||

| Knoop indentation | Room | 2.4–2.7 | ||

| 6H-SiC | Single-edge notched beam | 300 K, 873 K | 3.3 | [60] |

| Single-edge notched beam | 1773 K | 5.8 | ||

| Berkovich indentation | Room | 3.2 ± 0.3 | [61] | |

| Vickers indentations | Room | 3.2 ± 0.2 | ||

| Vickers indentation | Room | 1.7–3.4 | [54] | |

| Vickers indentation | Room | 3.3 | [62] | |

| Vickers indentation | Room | 1.8 | [63] | |

| Knoop indentation | Room | 1.8 | ||

| Knoop | Room | 1.5–1.9 | [55] | |

| Double cantilever beam | Room | 1.8 ± 0.26 | [64] | |

| Berkovich indentation | Room | 3.2 | [65] | |

| Berkovich indentation | Room | 3.45 | [56] | |

| Three-point bending tests for Chevron-notched specimens | Room | 1.37 ± 0.13 | [66] | |

| 1.57 ± 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Zhang, J.; Wang, Z.; Shan, C.; Huang, C.; Wang, F. A State-of-the-Art Review of Fracture Toughness of Silicon Carbide: Implications for High-Precision Laser Dicing Techniques. Processes 2024, 12, 2696. https://doi.org/10.3390/pr12122696

Fan Z, Zhang J, Wang Z, Shan C, Huang C, Wang F. A State-of-the-Art Review of Fracture Toughness of Silicon Carbide: Implications for High-Precision Laser Dicing Techniques. Processes. 2024; 12(12):2696. https://doi.org/10.3390/pr12122696

Chicago/Turabian StyleFan, Zhiqiang, Jiaxin Zhang, Zhuoqun Wang, Chong Shan, Chenguang Huang, and Fusheng Wang. 2024. "A State-of-the-Art Review of Fracture Toughness of Silicon Carbide: Implications for High-Precision Laser Dicing Techniques" Processes 12, no. 12: 2696. https://doi.org/10.3390/pr12122696

APA StyleFan, Z., Zhang, J., Wang, Z., Shan, C., Huang, C., & Wang, F. (2024). A State-of-the-Art Review of Fracture Toughness of Silicon Carbide: Implications for High-Precision Laser Dicing Techniques. Processes, 12(12), 2696. https://doi.org/10.3390/pr12122696