A Study on the Sustainability of Petrochemical Industrial Complexes Through Accident Data Analysis

Abstract

1. Introduction

2. Research Subjects and Analytical Methods

3. Results and Discussion

3.1. Chemical Accidents in General Work

3.1.1. Classification of Chemical Accident Data in General Work

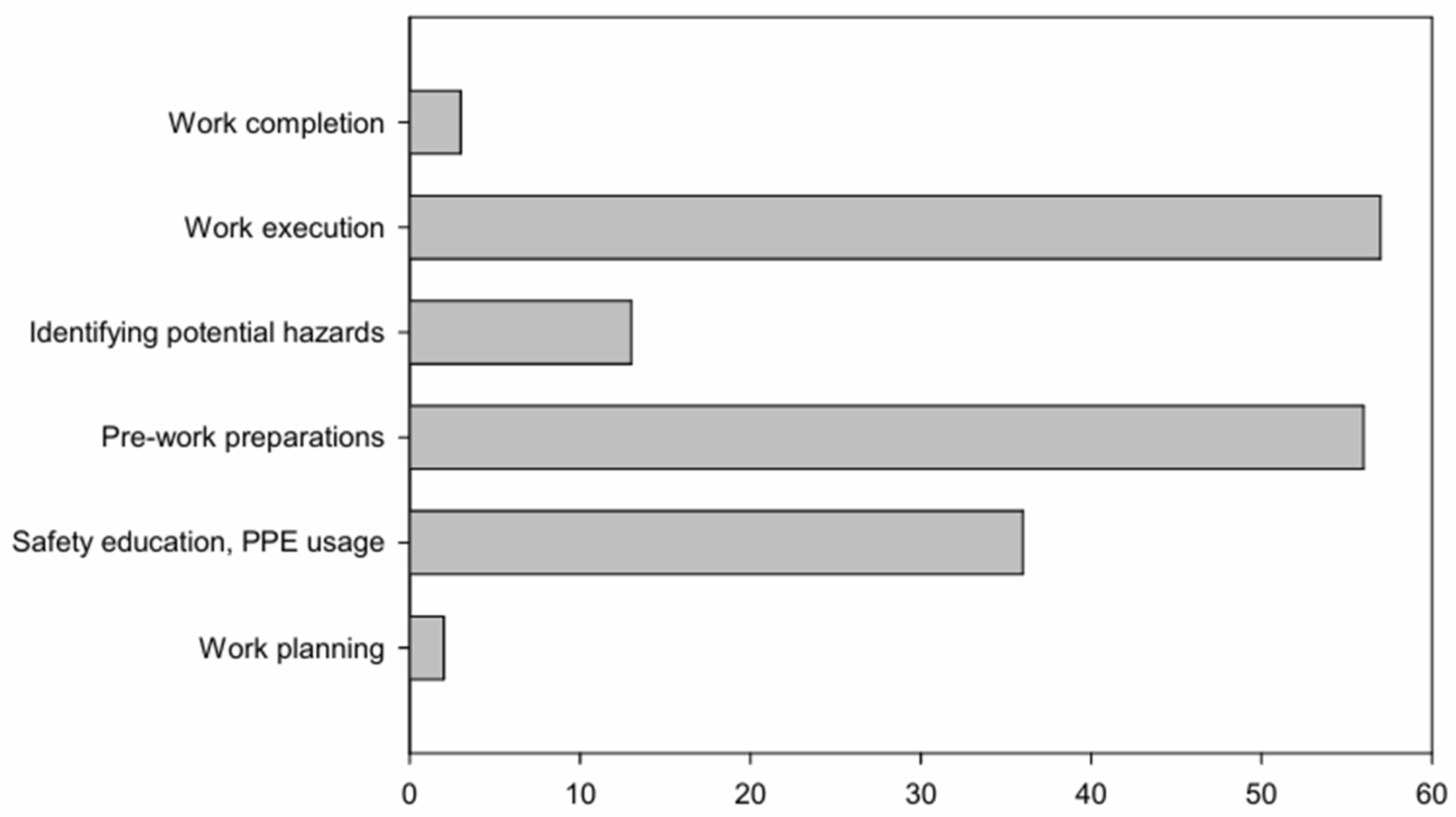

3.1.2. Incident Distribution by Stage in General Work Chemical Accidents

3.2. Hot-Work Chemical Accidents

3.2.1. Classification of Hot-Work Chemical Accident Data

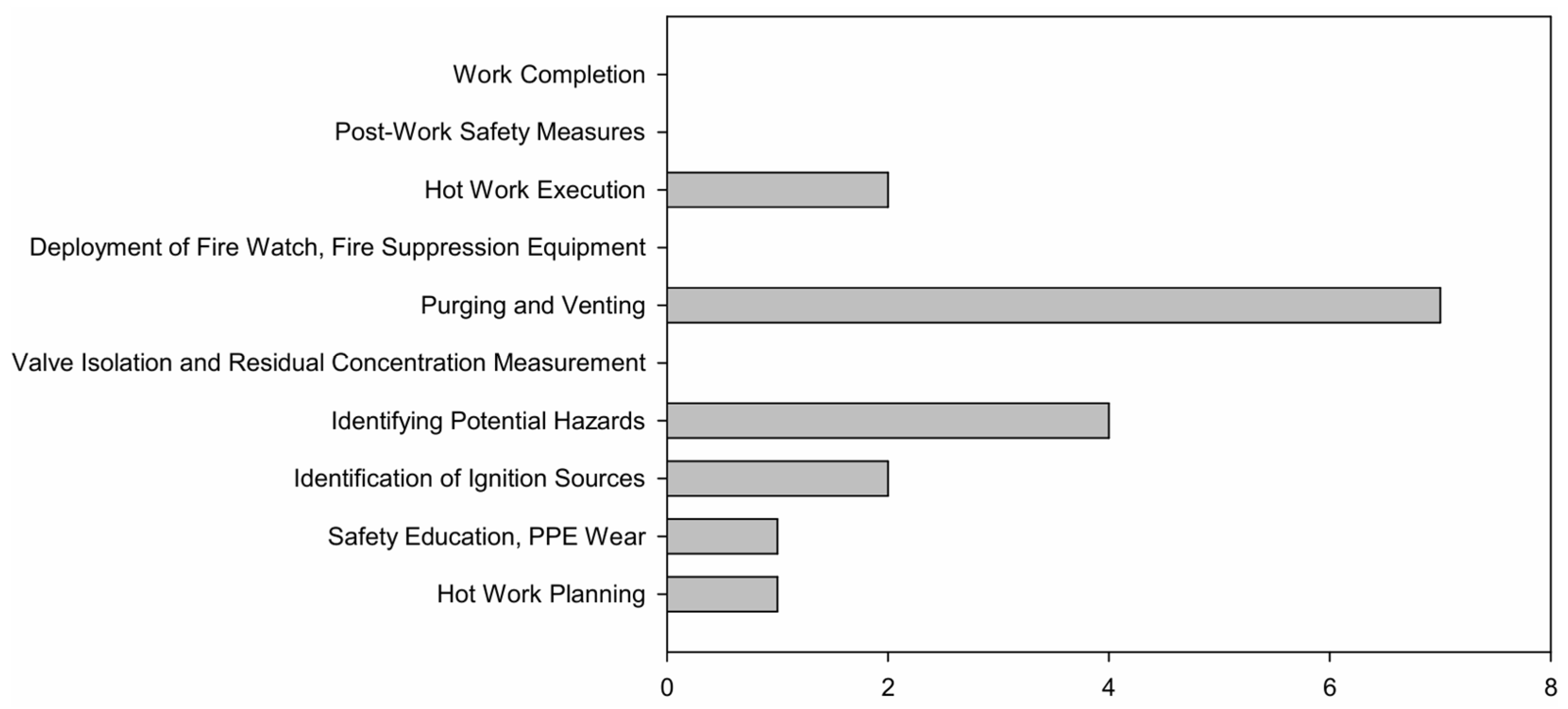

3.2.2. Incident Distribution by Stage in Hot-Work Chemical Accidents

3.3. Confined-Space Work Chemical Accidents

3.3.1. Classification of Confined-Space Work Chemical Accident Data

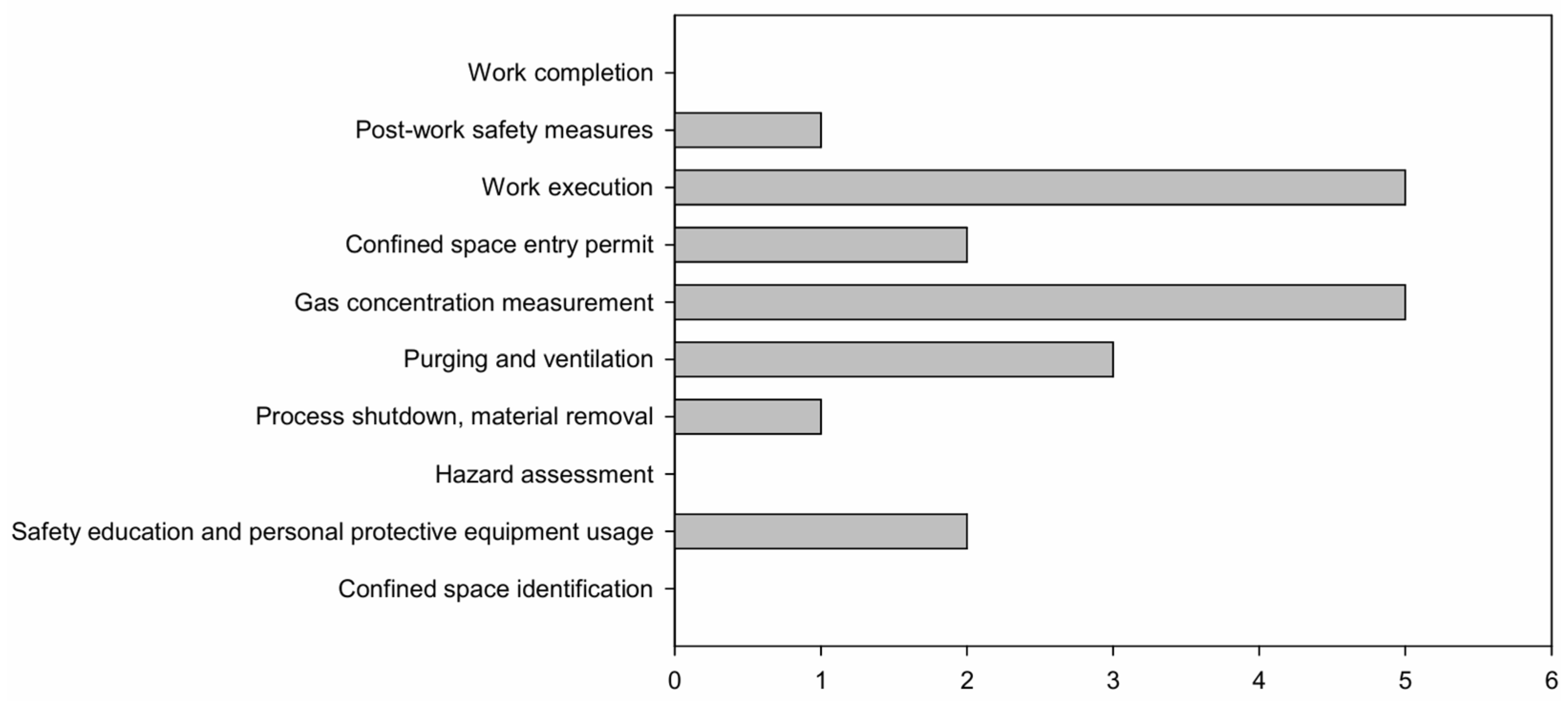

3.3.2. Incident Distribution by Stage in Confined-Space Work Chemical Accidents

3.4. Process Chemical Accidents

3.4.1. Classification of Process Chemical Accident Data

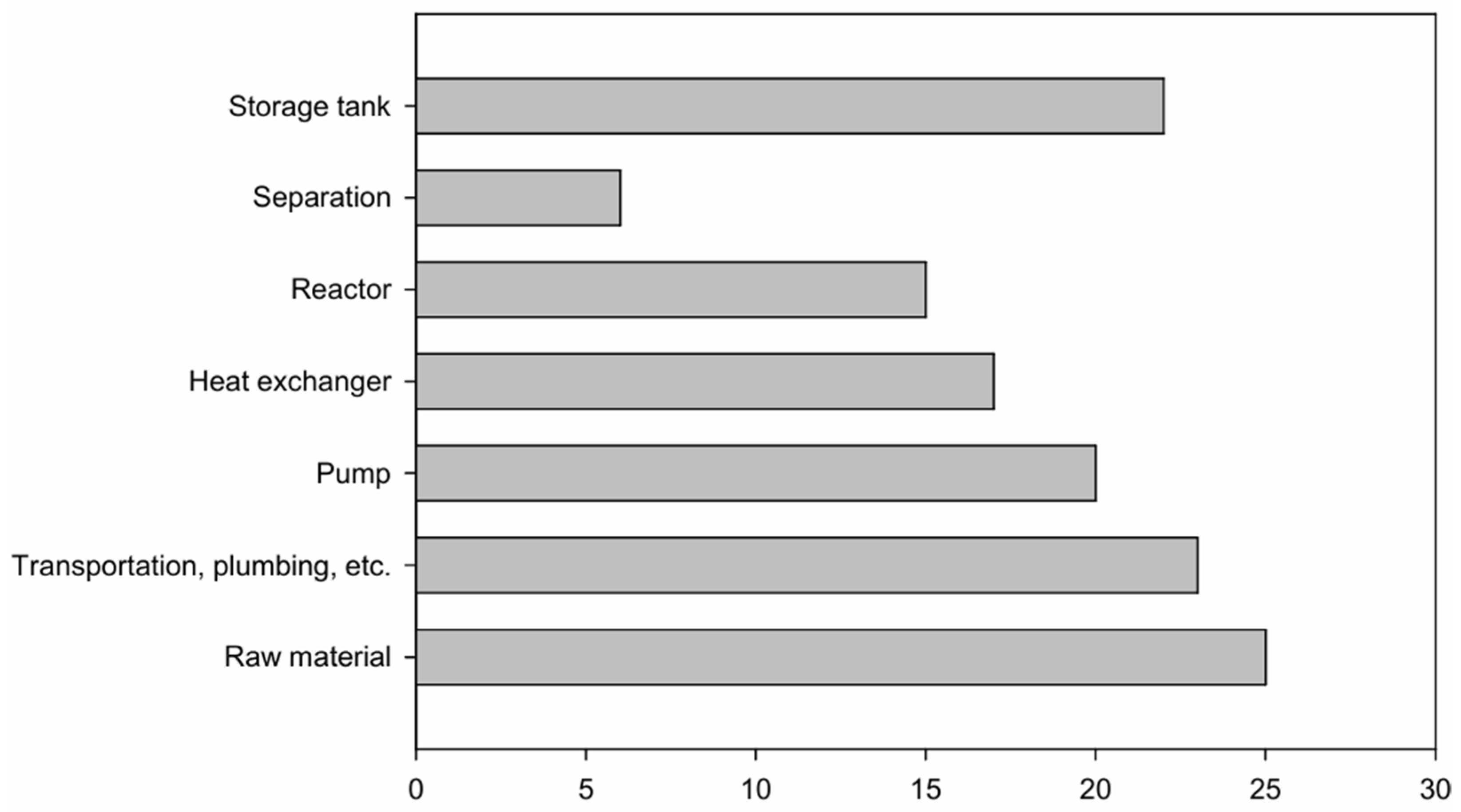

3.4.2. Incident Distribution by Stage in Process Chemical Accidents

3.5. Development of New Technologies Based on Work and Process Classification Results

3.6. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chung, Y.I. South Korea in the Fast Lane: Economic Development and Capital Formation; Oxford University Press: Oxford, UK, 2007. [Google Scholar]

- Omer, A.M. Green energies and the environment. Renew. Sustain. Energy Rev. 2008, 12, 1789–1821. [Google Scholar] [CrossRef]

- Azam, M.; Khan, A.Q.; Ozturk, I. The effects of energy on investment, human health, environment and economic growth: Empirical evidence from China. Environ. Sci. Pollut. Res. 2019, 26, 10816–10825. [Google Scholar] [CrossRef] [PubMed]

- Mignan, A.; Spada, M.; Burgherr, P.; Wang, Z.; Sornette, D. Dynamics of severe accidents in the oil & gas energy sector derived from the authoritative ENergy-related severe accident database. PLoS ONE 2022, 17, e0263962. [Google Scholar]

- Burgherr, P.; Giroux, J.; Spada, M. Accidents in the energy sector and energy infrastructure attacks in the context of energy security. Eur. J. Risk Regul. 2015, 6, 271–283. [Google Scholar] [CrossRef]

- Liu, S.; Wu, S.; Hu, Y.; Li, H. Comparative analysis of air and CO2 as working fluids for compressed and liquefied gas energy storage technologies. Energy Convers. Manag. 2019, 181, 608–620. [Google Scholar] [CrossRef]

- Lee, K.; Kwon, H.M.; Cho, S.; Kim, J.; Moon, I. Improvements of safety management system in Korean chemical industry after a large chemical accident. J. Loss Prev. Process Ind. 2016, 42, 6–13. [Google Scholar] [CrossRef]

- Pan, L.; Zheng, Y.; Zheng, J.; Xu, B.; Liu, G.; Wang, M.; Yang, D. Characteristics of chemical accidents and risk assessment method for petrochemical enterprises based on improved FBN. Sustainability 2022, 14, 12072. [Google Scholar] [CrossRef]

- Chemical Safety Agency Comprehensive Information System for Chemical Substances, Chemical Accident Status and Cases. Available online: https://icis.me.go.kr/main.do (accessed on 15 January 2024).

- Jung, S.; Woo, J.; Kang, C. Analysis of severe industrial accidents caused by hazardous chemicals in South Korea from January 2008 to June 2018. Saf. Sci. 2020, 124, 104580. [Google Scholar] [CrossRef]

- Akhondi, M.R.; Talevski, A.; Carlsen, S.; Petersen, S. Applications of Wireless Sensor Networks in the Oil, Gas and Resources Industries. In Proceedings of the 2010 24th IEEE International Conference on Advanced Information Networking and Applications, Perth, Australia, 20–23 April 2010; pp. 941–948. [Google Scholar]

- Lee, H.J.; Oh, H. A study on the deduction and diffusion of promising artificial intelligence technology for sustainable industrial development. Sustainability 2020, 12, 5609. [Google Scholar] [CrossRef]

- Atkinson, R.D.; Castro, D. Digital Quality of Life: Understanding the Personal and Social Benefits of the Information Technology Revolution; SSRN: New York, NY, USA, 2008. [Google Scholar]

- Zhao, B.; Chen, S.; Wang, Y.X.; Li, J.H. Maintenance decision methodology of petrochemical plant based on fuzzy curvelet neural network. Appl. Soft Comput. 2018, 69, 203–212. [Google Scholar] [CrossRef]

- Yuan, Q.; Wang, Q.; Gao, J. The research of risk-and condition-based maintenance decision-making and task optimizing system for rotating equipment in large petrochemical plants. Int. J. Reliab. Qual. Saf. Eng. 2012, 19, 1250017. [Google Scholar] [CrossRef]

- Patel, V.; Chesmore, A.; Legner, C.M.; Pandey, S. Trends in workplace wearable technologies and connected-worker solutions for next-generation occupational safety, health, and productivity. Adv. Intell. Syst. 2022, 4, 2100099. [Google Scholar] [CrossRef]

- Benotsmane, R.; Kovács, G.; Dudás, L. Economic, social impacts and operation of smart factories in Industry 4.0 focusing on simulation and artificial intelligence of collaborating robots. Soc. Sci. 2019, 8, 143. [Google Scholar] [CrossRef]

- Aybars, A.; Ataünal, L.; Gürbüz, A.O. ESG and financial performance: Impact of environmental, social, and governance issues on corporate performance. In Handbook of Research on Managerial Thinking in Global Business Economics; IGI Global: Pennsylvania, PA, USA, 2019; pp. 520–536. [Google Scholar]

- Kwilinski, A.; Lyulyov, O.; Pimonenko, T. Unlocking Sustainable Value through Digital Transformation: An Examination of ESG Performance. Information 2023, 14, 444. [Google Scholar] [CrossRef]

- Hsieh, M.Y. An empirical investigation into the enhancement of decision-making capabilities in corporate sustainability leadership through Internet of Things (IoT) integration. Internet Things 2024, 28, 101382. [Google Scholar] [CrossRef]

- Pozzi, F.A.; Dwivedi, D. ESG and IoT: Ensuring Sustainability and Social Responsibility in the Digital Age. In International Conference on Artificial Intelligence: Towards Sustainable Intelligence; Springer: Cham, Switzerland, 2023; pp. 12–23. [Google Scholar]

- Korea Occupational Safety and Health Agency. Safe Work Permit Guidelines (P-94-2021); Korea Occupational Safety and Health Agency: Ulsan Metropolitan City, Republic of Korea, 2021. [Google Scholar]

- Ministry of Employment and Labor, Explanation of Risk Assessment Guidelines. Available online: https://www.moel.go.kr/policy/policydata/view.do?bbs_seq=20220101267 (accessed on 28 January 2022).

- Korea Occupational Safety and Health Agency. Technical Guidelines for Work Risk Assessment (P-140-2020); Korea Occupational Safety and Health Agency: Ulsan Metropolitan City, Republic of Korea, 2020. [Google Scholar]

- Glenn, D.D. Job safety analysis: Its role today. Prof. Saf. 2011, 56, 48–57. [Google Scholar]

- Ministry of the Interior and Safety, Lifecycle Safety Training Guide Booklet. Available online: https://www.mois.go.kr/frt/a01/frtMain.do (accessed on 4 July 2016).

- Ministry of Employment and Labor, Fire Watcher Work Manual and Guide for Workplace Fire Prevention. Available online: https://www.moel.go.kr/policy/policydata/view.do?bbs_seq=20221201296 (accessed on 19 December 2022).

- Lee, S.R. An experimental study on the fire risk at welding· cutting process. Fire Sci. Eng. 2012, 26, 60–66. [Google Scholar] [CrossRef]

- Occupational Safety & Health Research Institute, Research on System Improvement Measures for the Prevention of Fire and Explosion in Welding Work. Available online: http://oshri.docubrain.co.kr/documanage/872 (accessed on 30 June 2019).

- Yonhapnews, ‘1 dead, 6 injured’ Incheon Bupyeong Fire... Occurs During Welding (2nd Step in Total). Available online: https://www.yna.co.kr/view/AKR20180330089152065 (accessed on 30 March 2018).

- Yonhapnews, Police, Suwon Gwanggyo Officetel Construction Site Fire Site Joint Inspection. Available online: https://www.yna.co.kr/view/AKR20171226007400061 (accessed on 26 December 2017).

- Korea Occupational Safety and Health Agency. Technical Guidelines on Fire Work Safety in Small Businesses (P-35-2012); Korea Occupational Safety and Health Agency: Ulsan Metropolitan City, Republic of Korea, 2012. [Google Scholar]

- Korea Occupational Safety and Health Agency, Confined Space Suffocation Disaster Prevention Safety Work Guide. Available online: https://www.kosha.or.kr/kosha/data/mediaBankMain.do?medSeq=43647&codeSeq=1100000&medForm=&menuId=-1100000&mode=detail (accessed on 7 December 2021).

- Suruda, A.J.; Pettit, T.A.; Noonan, G.P.; Ronk, R.M. Deadly rescue: The confined space hazard. J. Hazard. Mater. 1994, 36, 45–53. [Google Scholar] [CrossRef]

- Sauvageau, A.; Boghossian, E. Classification of asphyxia: The need for standardization. J. Forensic Sci. 2010, 55, 1259–1267. [Google Scholar] [CrossRef]

- Guide to Safety Work to Prevent Suffocation in Confined Spaces; Korea Occupational Safety and Health Agency (KOSHA): Ulsan, Republic of Korea, 2021.

- Occupational Safety & Health Research Institute, Review of Criteria for Submission of Changes to the Manufacturing Industry Hazard Risk Prevention Plan. Available online: http://oshri.docubrain.co.kr/documanage/693 (accessed on 30 November 2022).

- Korea Atomic Energy Research Institute, Technical Reviews on the Petroleum Refining Industry and the Petrochemical Industry for the Development of Industrial Application of Radioisotope. Available online: https://inis.iaea.org/collection/NCLCollectionStore/_Public/39/121/39121461.pdf?r=1 (accessed on 4 August 2024).

- Korea Occupational Safety and Health Agency. Technical Guidelines on 4M Risk Assessment Techniques (X-14-2014); Korea Occupational Safety and Health Agency: Ulsan Metropolitan City, Republic of Korea, 2014. [Google Scholar]

- Korea Occupational Safety and Health Agency. Explosion Accident in NCC Cracking Gas Compression Process. Available online: https://www.kosha.or.kr/kosha/data/screening_e.do?mode=view&articleNo=418293&attachNo=#/list (accessed on 12 October 2020).

- Korea Occupational Safety and Health Agency. (7 Chemical Accident Case Studies in 2022) No. 1. Leakage Accident Caused by Overpressure Rupture of Sulfuric Acid Pipe. Available online: https://www.kosha.or.kr/kosha/business/screening_e.do?mode=download&articleNo=433696&attachNo=244369 (accessed on 2 August 2022).

- Zhao, Y. The bottleneck and innovation key of MEMS-based metal oxide semiconductors gas sensor for petrochemical industry. Chem. Eng. J. 2024, 489, 151431. [Google Scholar] [CrossRef]

- Kwon, H.S. A Study on IOT Sensor Network Implementation Process for Prevention of Disaster in Petrochemical Industrial. Ph.D. Thesis, Soongsil University, Seoul, Republic of Korea, 2015. [Google Scholar]

- Golait, S.S.; Kumar, R.; Pandey, T.; Yerpude, S.; Pandey, K.; Ghadole, A. Sensing Harmful Gases in Industries Using IOT and WSN. Int. J. Sci. Res. Comput. Sci. Eng. Inf. Technol. 2020, 6, 113–119. [Google Scholar] [CrossRef]

- Aba, E.N.; Olugboji, O.A.; Nasir, A.; Olutoye, M.A.; Adedipe, O. Petroleum pipeline monitoring using an internet of things (IoT) platform. SN Appl. Sci. 2021, 3, 180. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Chen, Y.; Sun, Z.; Tong, F.; Mukherjee, M. Detecting the dangerous area of toxic gases with wireless sensor networks. IEEE Trans. Emerg. Top. Comput. 2017, 8, 137–147. [Google Scholar] [CrossRef]

- Vinothkumar, C.; Kumar, K.; Elavarasan, R. An integrated surveillance system to detect fire and gas leakage in petrochemical industry using Zigbee protocol. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2014, 3, 11146–11154. [Google Scholar]

- Bhupal, P.R.; Soujanya, M. Real-time Monitoring and Preventive Measures of Leakage Accidents in Gas and Petrochemical Industries using Zigbee. Int. J. Eng. Res. Appl. 2012, 2, 830–834. [Google Scholar]

- Chen, Y.; Lee, G.M.; Shu, L.; Crespi, N. Industrial internet of things-based collaborative sensing intelligence: Framework and research challenges. Sensors 2016, 16, 215. [Google Scholar] [CrossRef]

- Lai, X.; Liu, Q.; Wei, X.; Wang, W.; Zhou, G.; Han, G. A survey of body sensor networks. Sensors 2013, 13, 5406–5447. [Google Scholar] [CrossRef]

- Xu, C.; Xie, J.; Zhang, W.; Kong, Q.; Chen, G.; Song, G. Experimental investigation on the detection of multiple surface cracks using vibrothermography with a low-power piezoceramic actuator. Sensors 2017, 17, 2705. [Google Scholar] [CrossRef]

- Shu, L.; Li, K.; Zen, J.; Li, X.; Sun, H.; Huo, Z.; Han, G. A smart helmet for network level early warning in large scale petrochemical plants. In Proceedings of the 14th International Conference on Information Processing in Sensor Networks, Seattle, WA, USA, 13 April 2015; pp. 390–391. [Google Scholar]

- Kim, S.Y.; Hwang, I.C.; Kim, D.S.; Moon, B.M.; Oh, S.Y. A Study on IoT/ICT Convergence Smart Safety Management System for Safety of High Risk Workers. J. Korea Soc. Disaster Inf. 2019, 15, 39–48. [Google Scholar]

- Jia, J.; Wang, X.; Xu, Y.; Song, Z.; Zhang, Z.; Wu, J.; Liu, Z. Digital twin technology and ergonomics for comprehensive improvement of safety in the petrochemical industry. Process Saf. Prog. 2024, 43, 507–522. [Google Scholar] [CrossRef]

- Ding, L.; Jiang, W.; Zhou, C. IoT sensor-based BIM system for smart safety barriers of hazardous energy in petrochemical construction. Front. Eng. Manag. 2022, 9, 1–15. [Google Scholar] [CrossRef]

- Cabuk, A.S. Experimental IoT study on fault detection and preventive apparatus using Node-RED ship’s main engine cooling water pump motor. Eng. Fail. Anal. 2022, 138, 106310. [Google Scholar] [CrossRef]

- Ahmed, E.; Yaqoob, I.; Hashem, I.A.T.; Khan, I.; Ahmed, A.I.A.; Imran, M.; Vasilakos, A.V. The role of big data analytics in Internet of Things. Comput. Netw. 2017, 129, 459–471. [Google Scholar] [CrossRef]

- Udugama, I.A.; Bayer, C.; Baroutian, S.; Gernaey, K.V.; Yu, W.; Young, B.R. Digitalisation in chemical engineering: Industrial needs, academic best practice, and curriculum limitations. Educ. Chem. Eng. 2022, 39, 94–107. [Google Scholar] [CrossRef]

- Gomes, J.B.; Rodrigues, J.J.; Rabêlo, R.A.; Kumar, N.; Kozlov, S. IoT-enabled gas sensors: Technologies, applications, and opportunities. J. Sens. Actuator Netw. 2019, 8, 57. [Google Scholar] [CrossRef]

- Choi, Y.J.; Choi, H. Accident Prevention in Confined Space Using IoT Technology. J. Korea Inst. Inf. Commun. Eng. 2018, 22, 1159–1164. [Google Scholar]

- Shu, L.; Mukherjee, M.; Pecht, M.; Crespi, N.; Han, S.N. Challenges and research issues of data management in IoT for large-scale petrochemical plants. IEEE Syst. J. 2017, 12, 2509–2523. [Google Scholar] [CrossRef]

- Kumar, M.R.; Devi, B.R.; Rangaswamy, K.; Sangeetha, M.; Kumar, K.V.R. IoT-Edge Computing for Efficient and Effective Information Process on Industrial Automation. In Proceedings of the 2023 International Conference on Networking and Communications (ICNWC), Chennai, India, 5–6 April 2023; pp. 1–6. [Google Scholar]

- Montanaro, T.; Sergi, I.; Stefanizzi, I.; Landi, L.; Di Donato, L.; Patrono, L. Iot-aware architecture to guarantee safety of maintenance operators in industrial plants. Appl. Syst. Innov. 2023, 6, 46. [Google Scholar] [CrossRef]

- Du, Z.; Mao, Y.; Lu, M. Design and implementation of safety management system for oil depot based on Internet of Things. In Proceedings of the 2012 IEEE International Conference on Green Computing and Communications, Besancon, France, 20–23 November 2012; pp. 249–252. [Google Scholar]

- Landaluce, H.; Arjona, L.; Perallos, A.; Falcone, F.; Angulo, I.; Muralter, F. A review of IoT sensing applications and challenges using RFID and wireless sensor networks. Sensors 2020, 20, 2495. [Google Scholar] [CrossRef]

- Thibaud, M.; Chi, H.; Zhou, W.; Piramuthu, S. Internet of Things (IoT) in high-risk Environment, Health and Safety (EHS) industries: A comprehensive review. Decis. Support Syst. 2018, 108, 79–95. [Google Scholar] [CrossRef]

- Zradziński, P.; Karpowicz, J.; Gryz, K.; Morzyński, L.; Młyński, R.; Swidziński, A.; Ramos, V. Modelling the influence of electromagnetic field on the user of a wearable iot device used in a WSN for monitoring and reducing hazards in the work environment. Sensors 2020, 20, 7131. [Google Scholar] [CrossRef] [PubMed]

- Chraim, F.; Erol, Y.B.; Pister, K. Wireless gas leak detection and localization. IEEE Trans. Ind. Inform. 2015, 12, 768–779. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, Y.G. Development of IoT-based Safety Management Method through an Analysis of Risk Factors for Industrial Valves. J. Korean Inst. Gas 2019, 23, 35–43. [Google Scholar]

| City | Number of Incidents | City | Number of Incidents |

|---|---|---|---|

| Seoul | 25 | Incheon | 39 |

| Gyeonggi-do Province | 224 | Daejeon | 22 |

| Gangwon-do Province | 12 | Sejong | 6 |

| Chungcheongbuk-do Province | 51 | Gyeongsangbuk-do Province | 90 |

| Chungcheongnam-do Province | 76 | Gyeongsangnam-do Province | 44 |

| Jeollabuk-do Province | 49 | Gwangju | 11 |

| Jeollanam-do Province | 61 | Ulsan | 86 |

| Jeju-do Province | 3 | Daegu | 22 |

| Busan | 44 |

| Type | Contents |

|---|---|

| Hot work | Welding, cutting, grinding, drilling, and other tasks that generate flames or sparks |

| General work | Tasks involving potential hazards other than those associated with hot work |

| Confined space work | Operations conducted in confined spaces where there is a risk of asphyxiation or the presence of flammable gases |

| Lockout/tagout | Inspection and maintenance operations that involve power shutdown |

| Radiation work | Non-destructive inspection tasks or maintenance of facilities using radiation |

| Working at heights | Tasks performed at elevated locations using scaffolding, ladders, etc. |

| Heavy equipment operations | Handling, lifting, and performing repairs or inspections using heavy equipment |

| Step | Contents |

|---|---|

| 1 | Work planning |

| 2 | Safety education and personal protective equipment usage |

| 3 | Prework preparations |

| 4 | Identifying potential hazards |

| 5 | Work execution |

| 6 | Work completion |

| Step | Contents |

|---|---|

| 1 | Hot-work planning |

| 2 | Safety education and personal protective equipment usage |

| 3 | Identification of ignition sources |

| 4 | Identifying potential hazards |

| 5 | Valve isolation and residual concentration measurement |

| 6 | Purging and venting |

| 7 | Deployment of fire watch and fire suppression equipment |

| 8 | Hot-work execution |

| 9 | Post-work safety measures |

| 10 | Work completion |

| Step | Contents |

|---|---|

| 1 | Confined-space identification |

| 2 | Safety education and personal protective equipment usage |

| 3 | Hazard assessment |

| 4 | Process shutdown, material removal |

| 5 | Purging and ventilation |

| 6 | Gas concentration measurement |

| 7 | Confined-space entry permit |

| 8 | Work execution |

| 9 | Post-work safety measures |

| 10 | Work completion |

| Step | Contents |

|---|---|

| 1 | Raw material |

| 2 | Transportation, plumbing, etc. |

| 3 | Pump |

| 4 | Heat exchanger |

| 5 | Reactor |

| 6 | Separation |

| 7 | Storage tank |

| Type | Contents | |

|---|---|---|

| Human factors | Human factors | Worker characteristics, lack of attention, and human error |

| Physical factors | Preventive measures | Work permit, risk assessment, and equipment database management |

| Work and operation | Preparation before and after work, personal protective equipment, equipment defects, manual operations, and hazardous tasks | |

| Maintenance | Internal material removal and cleaning, equipment inspection, and piping welding | |

| Monitoring | Valves, piping, manholes, and equipment condition diagnosis | |

| Accident response | Integrated control and alarm systems | |

| Type | Contents |

|---|---|

| Process definition | Operation of a real-time leakage risk assessment system for compression equipment (e.g., compressors) and a degradation (fatigue, wear, etc.) risk assessment system for facilities |

| Key components | Gas leakage risk assessment system using fixed-point low-level gas leak sensors on compression equipment (such as compressors) with potential leakage risks |

| Hazardous area alert system based on gas sensor data and consequence analysis (CA) gas dispersion model analysis | |

| Facility degradation risk assessment system utilizing stress (pressure) sensors and thickness sensors related to key influencing factors in compression equipment (such as fatigue and wear) |

| Type | Contents |

|---|---|

| Process definition | Real-time leakage risk assessment system operation for hazardous substances, equipment degradation (such as chemical reactions, fatigue, and wear) and abnormal high-pressure preparedness |

| Key components | Gas leakage risk assessment system utilizing fixed-point low-level gas leak sensors on equipment for identifying leak risk locations due to hazardous substances, equipment degradation (such as chemical reactions, fatigue, and wear), and abnormal high pressure |

| Gas sensor data and hazardous area alert system based on consequence analysis (CA) and gas dispersion model analysis |

| Type | Before | |||

| Work Configuration | Reaction | Cooling | Neutralization/Washing | Distillation |

| Utilization method | Pre-accident unnoticed minor leaks and inadequate management of equipment susceptible to degradation (such as fatigue and wear) | |||

| Type | After | |||

| Work Configuration | Reaction | Cooling | Neutralization/Washing | Distillation |

| Utilization method | Pre-accident assessment of signs and risk through changes in minor leak characteristics, and risk information alert through risk assessment of equipment vulnerable to degradation (such as fatigue and wear) | |||

| Type | Before | |||

| Work Configuration | Reaction | Cooling | Neutralization/Washing | Distillation |

| Utilization method | Unawareness of explosion risk due to failure to review material characteristics during design, improper construction of components and facilities, and equipment malfunction in maintaining functionality | |||

| Type | After | |||

| Work Configuration | Reaction | Cooling | Neutralization/Washing | Distillation |

| Utilization method | Enhancement of material reaction review during design, strengthened installation and supervision of components, and a system evaluating signs and risks for improved safety prior to accidents, with risk information alerts | |||

| Type | Contents |

|---|---|

| Gas sensors | MEMS-based metal oxide semiconductor gas sensors that are known for their excellent cost, size, and performance, makes them popular in petrochemical monitoring [42]. |

| Toxic and explosive gas sensors | Sensors that use real-time data stored in a database server to automatically run atmospheric dispersion prediction modeling programs in the event of toxic gas leak. They are designed to communicate via IEEE 1451.x standard interfaces and produce predictive scenario results [43]. |

| Explosive gas sensors | Sensors that continuously detect leakage amounts and can detect gases like liquefied natural gas (LNG) butane, methane, acetylene, ethylene, and carbon dioxide. They are certified by Republic of Korea Fire Verification Corporation or industrial technology testing organizations [43]. |

| Fire and explosive gas sensors | On-site fire and gas detection, with real-time information transmission to a comprehensive disaster management system, and monitoring services [43]. |

| Fire sensors | Sensors alert the operation terminal of signal failure in the event of sensor malfunctions [43]. |

| Intelligent smart fire sensors | Combining heat and smoke sensing to collect temperature measurement data [43]. |

| Gas detection sensors | Detecting harmful and toxic gases such as methane (CH4) and carbon monoxide (CO), and issuing appropriate warnings [44]. |

| Toxic gas detection sensors | Monitoring and storage of information on toxic gas concentrations, temperature, and humidity indoors over extended periods [44]. |

| Pipe damage detection sensors | Detecting real-time damage locations in existing pipelines [45]. |

| Perforation sensors | Detection of pipeline vibration signals and potential signals for data collection requires three installations for monitoring and transmission through wireless networks, with a detection sensitivity of more than 1000 mV [43]. |

| Weather observation sensors | Sensors that are integrated with atmospheric dispersion programs and capable of interfacing via IEEE 1451.x standard [43]. |

| Seismic detection sensors | Sensors with RS-232C, RS-422, RS-485, and TCP/IP interfaces for self-diagnosis and sensor signal correction. The accelerometer temperatures ranging from −10 °C to 50 °C [43]. |

| Image sensors | Sensors that detect shading changes in colorimetric strips reacting to various hazardous gases [44]. |

| Toxic gas leak monitoring | Utilization of wireless sensor networks (WSN) for networking and concentration detection to identify hazardous gas leak areas [45]. |

| Fire and gas surveillance monitoring | It uses Zigbee to provide attendance registration, real-time precise location tracking, dynamic gas concentration monitoring, real-time data transmission, and hazard alerts [46]. |

| Gas leak monitoring | It enables real-time detection and control of gas leaks [47]. |

| Plant monitoring | It is widely deployed with wireless sensor nodes (static or mobile) across large petrochemical plants for efficient and reliable detection of hazardous areas. It supports production monitoring, pollution analysis, leak detection, and asset tracking [48]. |

| Body information monitoring | It offers methods for continuously monitoring various body metrics like blood pressure, heart rate, and body temperature [49] |

| Pipe monitoring | Detection of three types of cracks in thin aluminum beams within 1–2 s of excitation time. Crack detection is most effective when the amplitude exceeds 80 V [50]. |

| Smart helmets | The integration of static sensor nodes and wearable equipment, including an STM32 processing chip, various environmental sensors, a camera, a GPS positioning module, and a heart rate sensor [51]. |

| Safety tag systems | Use of acceleration sensors to detect worker immobility. Alerts are made via Piezo buzzers and LEDs, with the danger state communicated through LoRa communication modules. The system is designed based on SOP analysis and feedback from fire field personnel [52]. |

| Command systems | The system receives risk signals from safety tags and can issue evacuation. |

| Control server systems | Real-time data collection from command terminals, providing on-site status and evacuation orders to 119 comprehensive situation rooms or control centers [53]. |

| Production process planning and control systems | Digital twin (DT) technology helps to improve safety in the petrochemical industry through dynamic and real-time monitoring, leak warnings, and process safety alerts [54]. |

| Ergonomic design systems | HSEE focuses on safety and health as the central axis of the workplace, fostering continuous improvement and proactive risk management for a safer and more sustainable work environment in the petrochemical industry [54]. |

| Building safety barrier model systems | BIM is used to quickly identify on-site risks in real-time, collects personnel movement information using location sensors, and enables virtual construction site management, personnel information management, task information management, and risk area monitoring [55]. |

| Data analysis and monitoring systems | Node-RED is used in software development to connect graphical blocks. Integrates easily with web services and a wide range of hardware devices, while operating with low power requirements [56]. |

| Category | Type | Accident Rate | Main Cause of Accidents |

| By work type | General work | 50% (167 cases) | Work execution stage: 34% (57 cases), identification of potential hazards: 33% (56 cases) |

| Process work | 39% (128 cases) | Raw material stage: 19% (25 cases), transportation/piping: 18% (23 cases) | |

| Confined-space work | 6% (19 cases) | Gas concentration measurement: 26% (10 cases), work execution: 26% (10 cases) | |

| Hot work | 5% (17 cases) | Purging and venting stage: 41% (7 cases) | |

| Category | Type | Main Cause of Accidents | |

| By accident type | Fire/explosion | 43% (144 cases) | |

| Leakage | 24% (78 cases) | ||

| Trauma | 22% (74 cases) | ||

| Compound accident | 7% (24 cases) | ||

| Category | Type | Main Cause of Accidents | |

| By equipment type | Reactor | 25% (82 cases) | |

| Connections/control | 23% (78 cases) | ||

| Storage | 19% (63 cases) | ||

| Unknown | 11% (36 cases) | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, L.S.; Yoon, C.; Lee, D.; Shin, G.; Jung, S. A Study on the Sustainability of Petrochemical Industrial Complexes Through Accident Data Analysis. Processes 2024, 12, 2637. https://doi.org/10.3390/pr12122637

Kim LS, Yoon C, Lee D, Shin G, Jung S. A Study on the Sustainability of Petrochemical Industrial Complexes Through Accident Data Analysis. Processes. 2024; 12(12):2637. https://doi.org/10.3390/pr12122637

Chicago/Turabian StyleKim, Lee Su, Cheolhee Yoon, Daeun Lee, Gwyam Shin, and Seungho Jung. 2024. "A Study on the Sustainability of Petrochemical Industrial Complexes Through Accident Data Analysis" Processes 12, no. 12: 2637. https://doi.org/10.3390/pr12122637

APA StyleKim, L. S., Yoon, C., Lee, D., Shin, G., & Jung, S. (2024). A Study on the Sustainability of Petrochemical Industrial Complexes Through Accident Data Analysis. Processes, 12(12), 2637. https://doi.org/10.3390/pr12122637