Study on the Performance of a Novel Double-Section Full-Open Absorption Heat Pump for Flue Gas Waste Heat Recovery

Abstract

1. Introduction

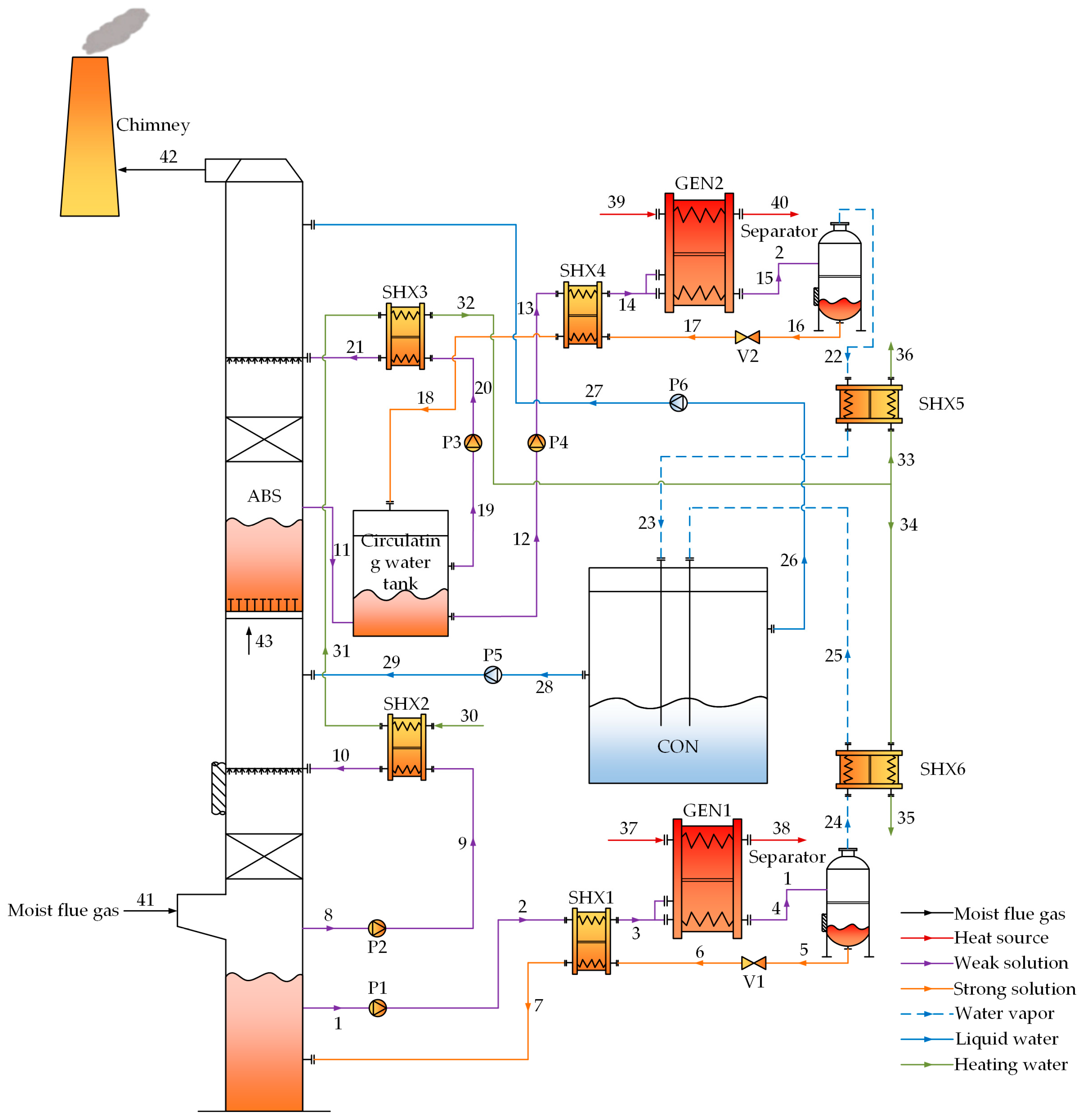

2. System Description

- (1)

- The use of a full-open absorption cycle system allows for direct contact in heat transfer and mass transfer across all components, including the generator, condenser, and absorber, without any solid interfaces. This improvement not only significantly reduces investment costs but also enhances the moisture absorption performance of the liquid desiccant, enabling deep dehumidification of the flue gas. This greatly increases the system’s heat recovery capacity, allowing it to recover heat from flue gases at lower temperatures.

- (2)

- Following treatment, the condensate water can be reused, thereby reducing the moisture content in the flue gas and mitigating the formation of “white smoke”. Additionally, the adoption of direct contact heat exchangers in place of wall-type heat exchangers resolves numerous issues associated with the latter in practical applications.

- (3)

- A dual-layer structure design is implemented for the absorber in the open absorption heat pump, where the generation and absorption processes in the upper and lower layers operate independently. This enables distributed independent adjustment of the solution temperature in the system, enhancing flexibility and expanding operational conditions.

- (4)

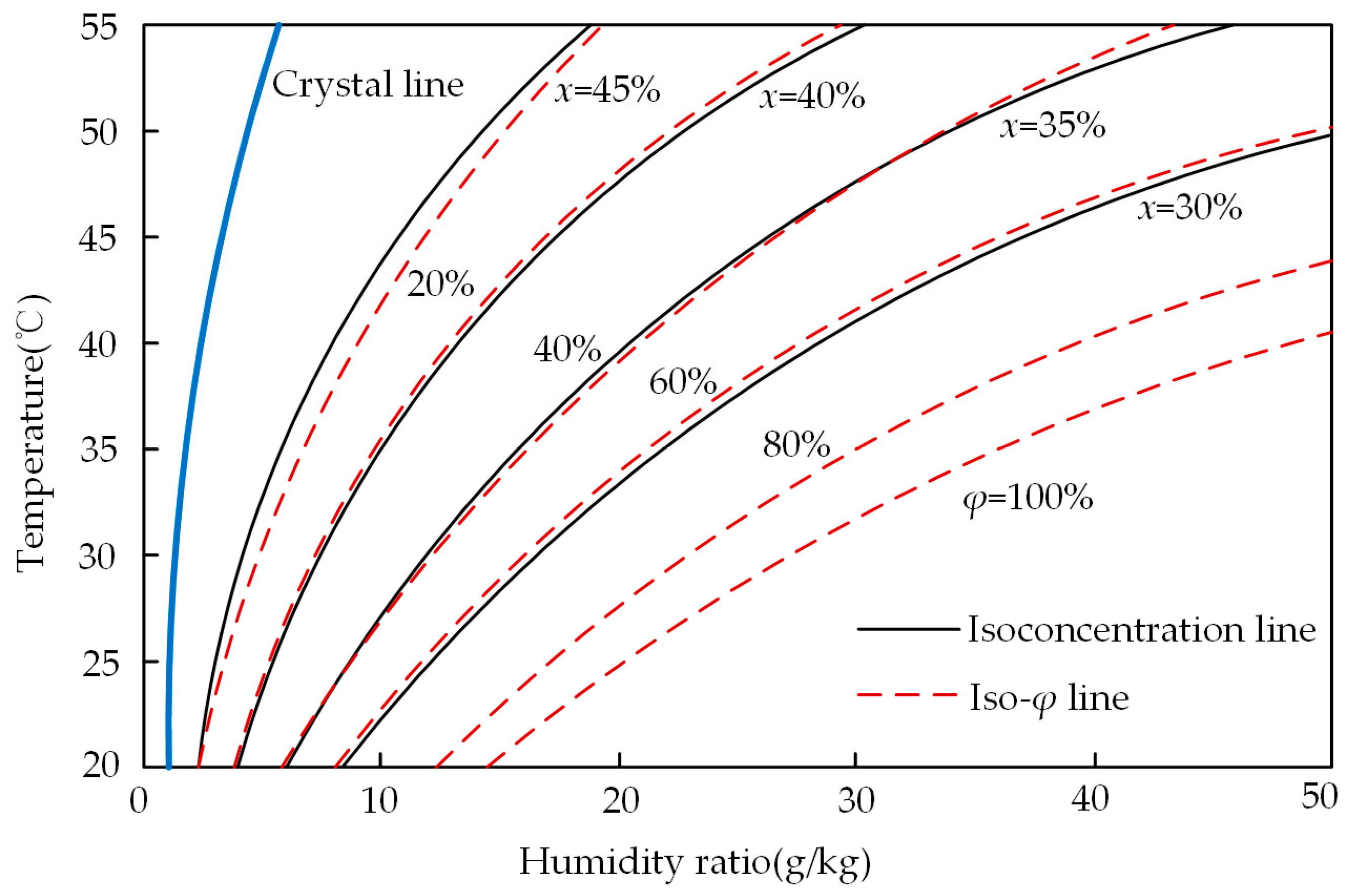

- Replacing LiBr/H2O with LiCl/H2O in the open absorption heat pump can significantly reduce the risk of equipment corrosion. Furthermore, the LiCl solution helps reduce the tendency of water vapor molecules in the solution stream to migrate back to the water stream during the absorption process. Therefore, LiCl/H2O can better facilitate the absorption process, increasing the heat absorbed while also expanding the range of flue gas temperatures that can be recovered.

3. Mathematical Models

3.1. Energic Model of the DS-FOAHP System

- (1)

- The system operates in a steady state;

- (2)

- The heat losses along the pipelines and the pressure drop in the pipes are ignored;

- (3)

- The throttling process is considered an isenthalpy process, while the solution pump pressurization process is considered an isentropic process;

- (4)

- The solutions at the outlets of the absorber and separator are in a saturated state;

- (5)

- The effectiveness of SHX is 0.8.

3.2. Modeling of Economic Analysis

3.3. Performance Evaluation Indices

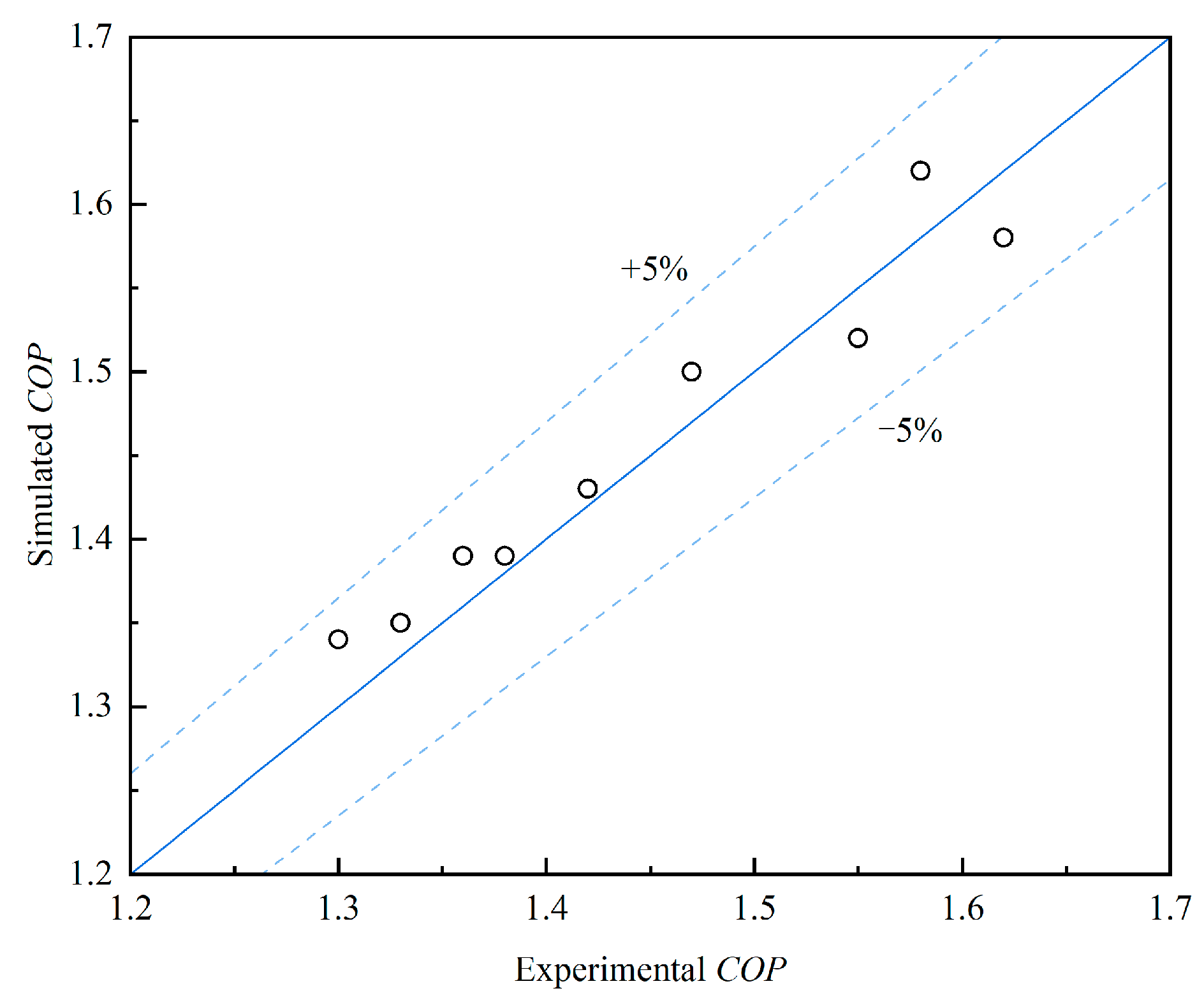

3.4. Model Validation

3.5. Case Study

4. Results and Discussion

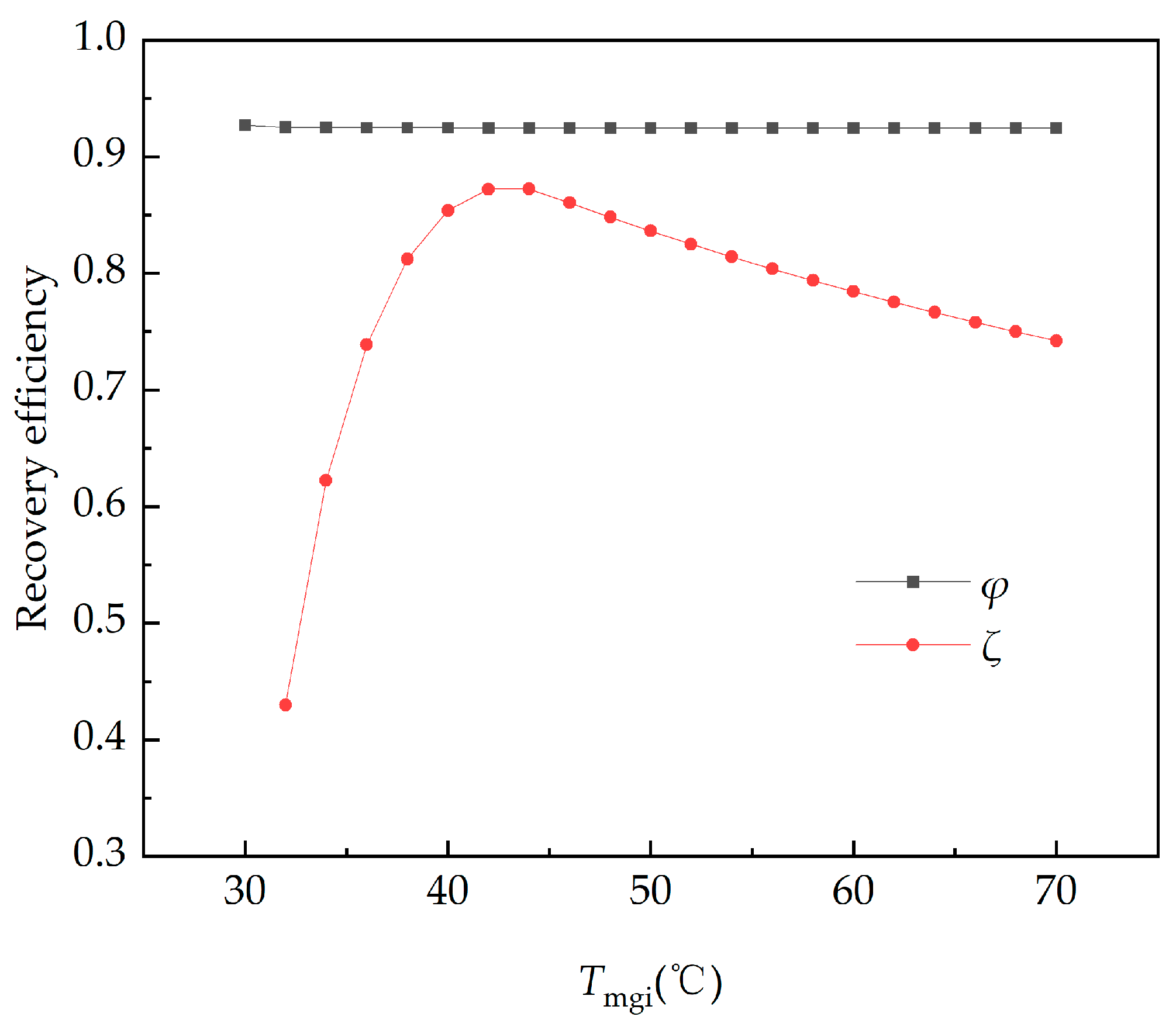

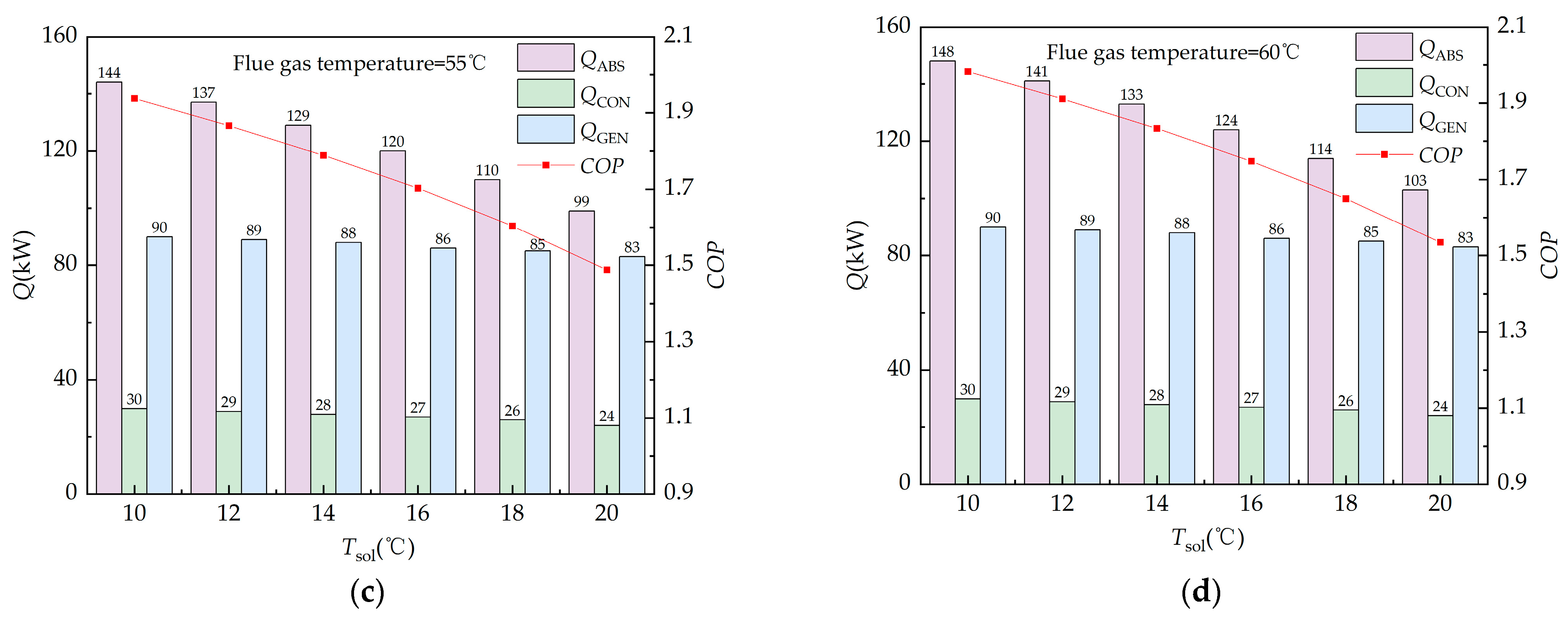

4.1. The Impact of Flue Gas Temperature (Tmgi) on System Performance

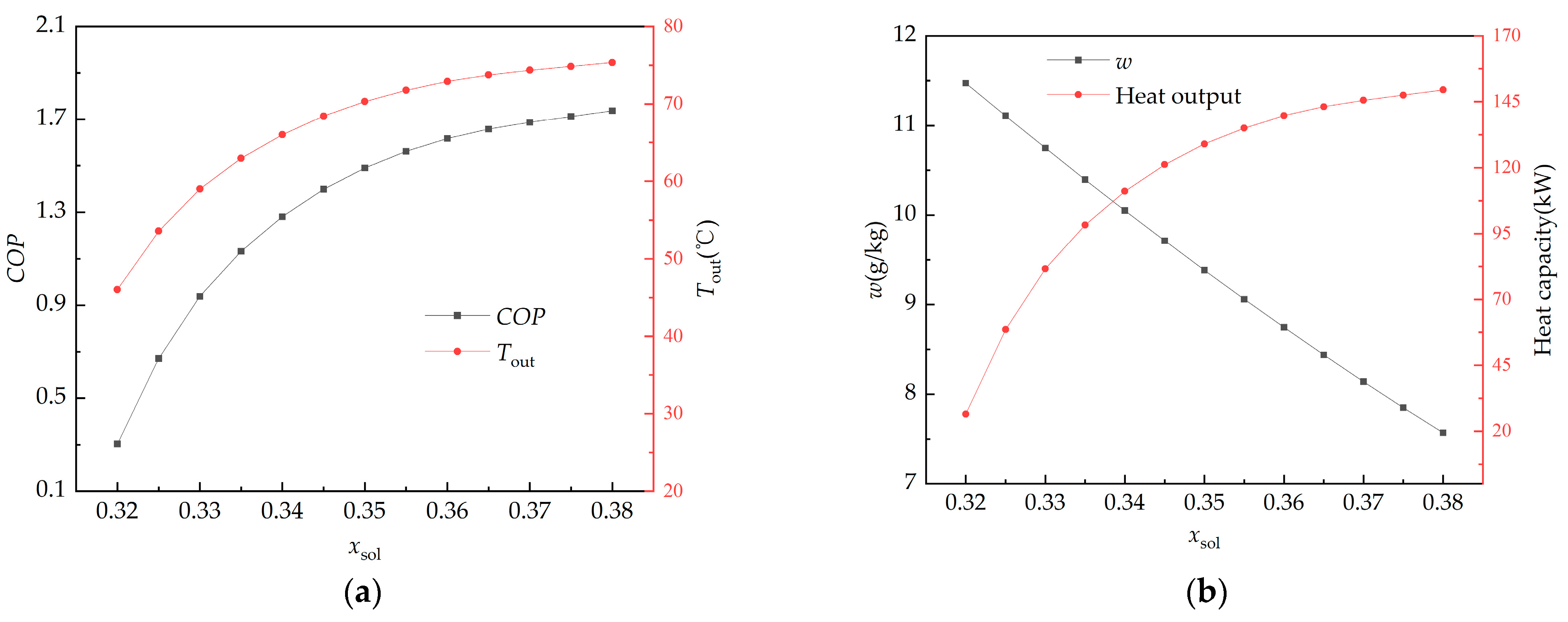

4.2. The Impact of LiCl Solution Concentration (xsol) on System Performance

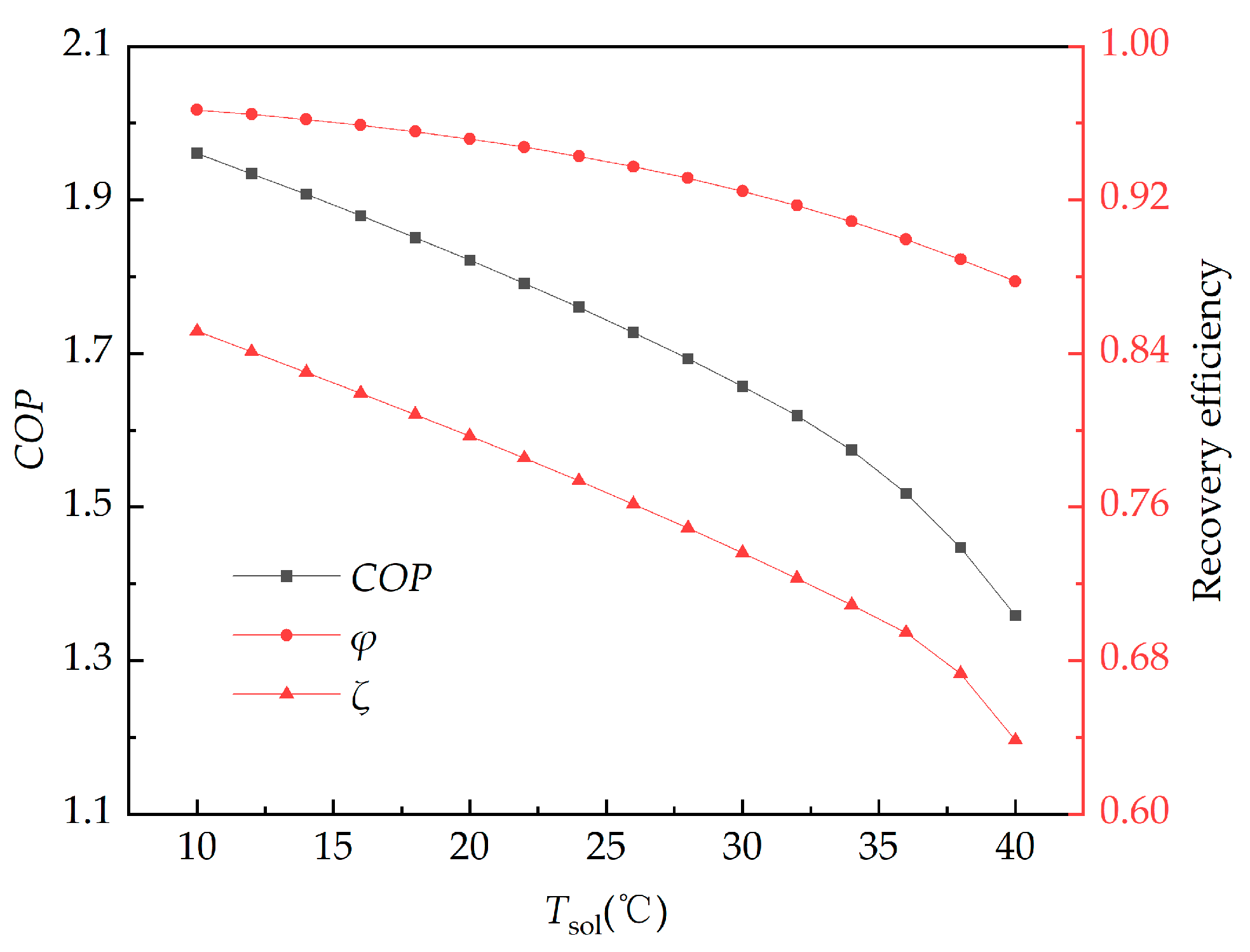

4.3. The Impact of LiCl Solution Temperature (Tsol) on System Performance

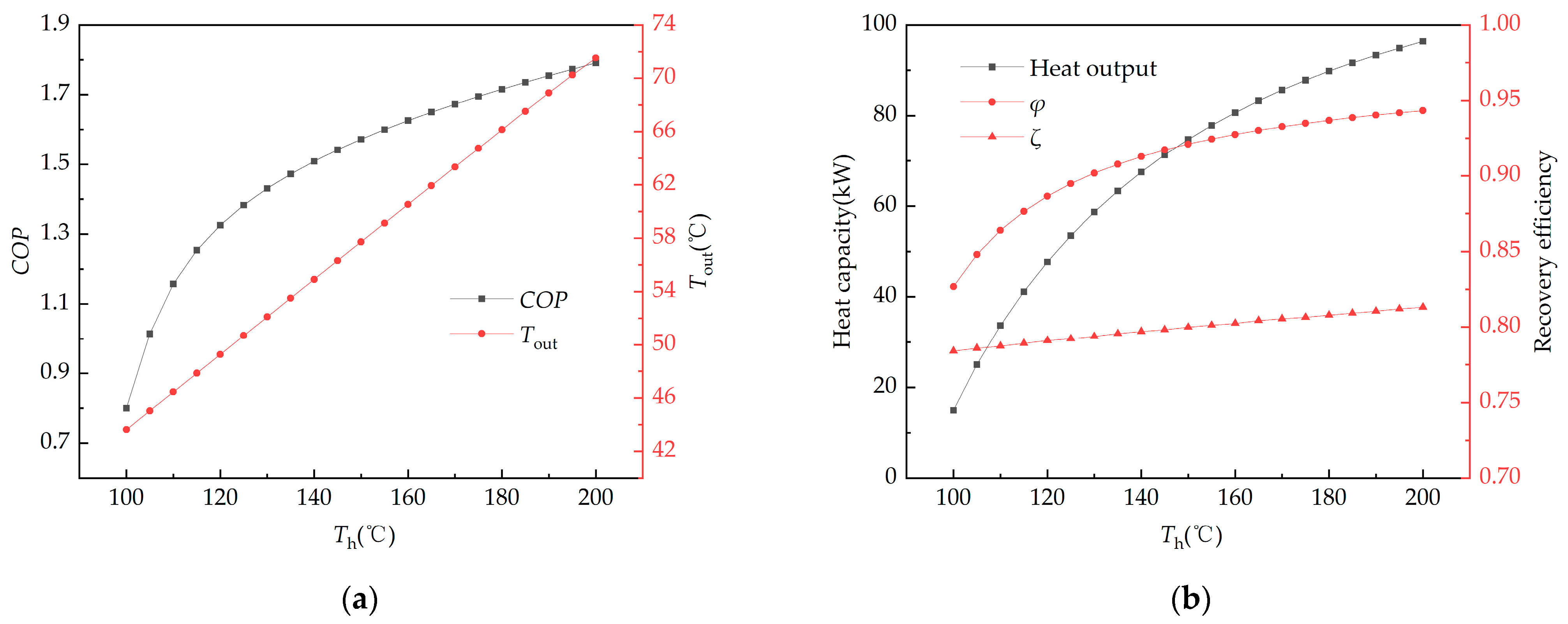

4.4. The Effect of Heat Source Temperature (Th) on the System Performance

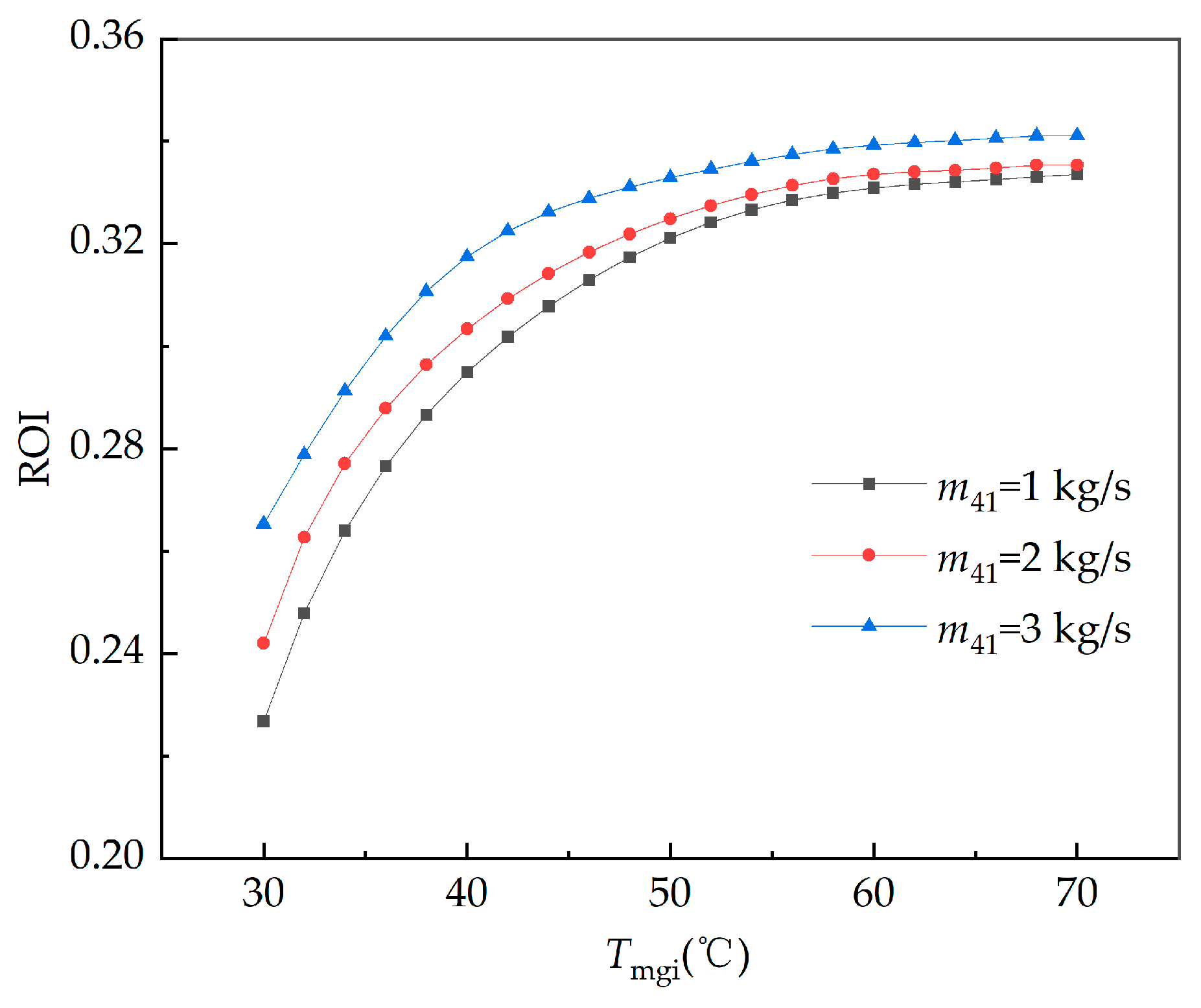

4.5. Economic Analysis

5. Conclusions

- (1)

- The system’s performance will gradually improve with increasing flue gas temperature and flow rate, ultimately stabilizing. At a flue gas temperature of 70 °C and a mass flow rate of 3 kg/s, the system achieves a maximum COP of 1.838 and a heating capacity of up to 158.84 kW. In comparison to traditional open absorption heat pumps, this system demonstrates improved performance. Furthermore, the water recovery efficiency remains stable at approximately 93%, while the thermal recovery efficiency can reach as high as 87.227%.

- (2)

- An increase in the concentration of the LiCl solution at the separator outlet can significantly enhance the system’s performance, resulting in improvements in the COP, heating capacity, and heating temperature. At a concentration of 0.38, the maximum COP reaches 1.736, while the heating temperature attains 75.34 °C. Additionally, the system achieves a peak heating capacity of 149.48 kW, with the lowest flue gas humidity ratio recorded at 7.57 g/kg. These findings indicate that optimizing the LiCl concentration not only improves thermal efficiency but also contributes to more effective heat recovery in the system.

- (3)

- Lowering the solution temperature at the absorber inlet can significantly enhance the system’s thermal recovery capacity and overall performance. At a solution temperature of 10 °C, the system achieves a maximum COP of 1.96, with a water recovery efficiency of 97% and a thermal recovery efficiency of 85%. Notably, this represents a 30.67% improvement in COP compared to a traditional open absorption heat pump. These results highlight the importance of optimizing the solution temperature, as it not only maximizes energy efficiency but also contributes to superior heat recovery capabilities in the system.

- (4)

- As the driving heat source temperature varies from 100 °C to 200 °C, the system performance shows a progressive improvement with increasing Th. Specifically, at Th = 200 °C, the system achieves a COP of 1.79, a heating temperature of 71.52 °C, and a heating capacity of 96.39 kW. This trend indicates that higher driving heat source temperatures significantly enhance the system’s thermal efficiency and capacity, underscoring the importance of optimizing operating conditions to maximize performance.

- (5)

- The return on investment of this system will gradually increase with higher flue gas temperatures and flow rates. When the flue gas temperature is 70 °C and the flow rate is 3 kg/s, the system can achieve a maximum ROI of 34.1%. The results indicate that, although both the initial and operational costs of this system are higher than those of traditional flue gas waste heat recovery systems, it still demonstrates favorable economic viability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature: | |||

| OAHPs | Open absorption heat pumps | r | Latent heat of vaporization of water (kJ/kg) |

| IEA | International Energy Agency | H | Height of the absorber tower (m) |

| VS-OAHP | Multi-stage open absorption heat pump | X | Position along the solution flow path (m) |

| DS-FOAHP | Double-section full-open absorption heat pump | Le | Lewis numbers |

| ABS | Absorber | NTU | Number of mass transfer units |

| SHX | Solution heat exchanger | α | Heat transfer coefficient between the flue gas and LiCl (kW/(m2·oC)) |

| GEN | Generator | c | Specific heat capacity of the flue gas (kJ/(kg·oC)) |

| CON | Condenser | a | Specific area per unit volume of the absorber tower (m2/m3) |

| P | Solution pump | V | Volume of the heat and mass transfer device (m3) |

| V | Throttle valve | C | Cost (CNY/W) |

| COP | Coefficient of performance | M | Molecular weight (kg/kmol) |

| ROI | Return on investment | HP | Average of heat price in China (CNY/kWh) |

| w | Humidity ratio (g/kg) | ||

| Symbols: | |||

| ζ | Thermal recovery efficiency | φ | Water recovery efficiency |

| Mass flow rate (kg/s) | x | Mass fraction (concentration) (kg/kg) | |

| Heat output/input (kW) | Power (kW) | ||

| h | Specific enthalpy (kJ/kg) | Σ | Sum of |

| v | Specific volume (m3/kg) | η | Efficiency (%) |

| ρ | Density (kg/m3) | T | Temperature (oC) |

| P | Pressure (MPa) | ||

| Subscripts: | |||

| i | Isentropic/Inlet | o | Outlet |

| pump | Solution pump | H | High |

| L | Low | f | Flue gas |

| sol | Solution | mgi | Moist gas inlet |

| h | Heat source |

References

- Wu, Z.; Jiang, Y.; Wang, Y.; You, S.; Zhang, H.; Liu, S.; Fan, X.; Pu, J.; Wan, Z.; Sha, L.; et al. Investigating the performance of heat exchangers in ab-sorption heat pump systems using both numerical and experimental methods. Energy Convers. Manag. 2023, 278, 116744. [Google Scholar] [CrossRef]

- Su, W.; Han, Y.; Jin, X.; Liu, Z.; Zhang, X. Energy, economic, and environmental evaluation of a GAX-based cross-type absorption-resorption heat pump. Energy Convers. Manag. 2024, 300, 117952. [Google Scholar] [CrossRef]

- Seyitoglu, S.S.; Dincer, I.; Kilicarslan, A. Assessment of an IGCC based trigeneration system for power, hydrogen and synthesis fuel production. Int. J. Hydrogen Energy 2016, 41, 8168–8175. [Google Scholar] [CrossRef]

- Kashif Shahzad, M.; Ding, Y.; Li, Q.; Xuan, Y.; Gao, N.; Chen, G. Novel multifunctional open absorption heat pump system with compressed air dryer assisted preliminary flash regeneration-An industrial application. Appl. Therm. Eng. 2022, 211, 118526. [Google Scholar] [CrossRef]

- Shahzad, M.K.; Ding, Y.; Xuan, Y.; Gao, N.; Chen, G. Energy efficiency analysis of a multifunctional hybrid open absorption system for dehumidification, heating, and cooling: An industrial waste heat recovery application. Energy Convers. Manag. 2021, 243, 114356. [Google Scholar] [CrossRef]

- Wu, W.; Wang, B.; Shi, W.; Li, X. An overview of ammonia-based absorption chillers and heat pumps. Renew. Sustain. Energy Rev. 2014, 31, 681–707. [Google Scholar] [CrossRef]

- Su, W.; Li, J.; Lu, Z.; Jin, X.; Zhang, J.; Liu, Z.; Xiaosong, Z. Performance analysis and optimization of a solar assisted heat pump-driven vacuum membrane distillation system for liquid desiccant regeneration. Energy Convers. Manag. 2024, 301, 118047. [Google Scholar] [CrossRef]

- Su, W.; Han, Y.; Liu, Z.; Jin, X.; Liu, Z.; Yang, D.; Zhang, X. Absorption heat pumps for low-grade heat utilization: A com-prehensive review on working pairs, classification, system advances and applications. Energy Convers. Manag. 2024, 315, 118760. [Google Scholar] [CrossRef]

- Ye, B.; Ding, Y.; Wang, Z.; Chen, G. Experimental evaluation of a variable-stage open absorption heat pump system utilizing aqueous KCOOH solution as absorbent. Int. J. Refrig. 2023, 148, 83–95. [Google Scholar] [CrossRef]

- Xue, Y.; Zhao, B.; Wang, S.; Yin, P.; Wang, H. Performance analysis of an open absorption heat pump and thermal desalination system for heat and water recovery of coal-fired flue gas based on zero liquid discharge. Energy Convers. Manag. 2022, 273, 116379. [Google Scholar] [CrossRef]

- Ye, B.; Wang, Z.; Yan, X.; Chen, G. Performance analysis of a variable-stage open absorption heat pump combined with a membrane absorber. Energy Convers. Manag. 2019, 184, 290–300. [Google Scholar] [CrossRef]

- Zhang, H.; Dong, Y.; Lai, Y.; Zhang, X. Waste heat recovery from coal-fired boiler flue gas: Performance optimization of a new open absorption heat pump. Appl. Therm. Eng. 2021, 183, 116111. [Google Scholar] [CrossRef]

- Yang, B.; Jiang, Y.; Fu, L.; Zhang, S. Experimental and theoretical investigation of a novel full-open absorption heat pump applied to district heating by recovering waste heat of flue gas. Energy Build. 2018, 173, 45–57. [Google Scholar] [CrossRef]

- Kashif Shahzad, M.; Ding, Y.; Xuan, Y.; Gao, N.; Chen, G. Performance analysis of a novel double stage multifunctional open absorption heat pump system: An industrial moist flue gas heat recovery application. Energy Convers. Manag. 2022, 254, 115224. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, H.; You, T.; Li, X. Performance comparison of absorption heating cycles using various low-GWP and natural refrigerants. Int. J. Refrig. 2017, 82, 56–70. [Google Scholar] [CrossRef]

- Yang, B.; Yuan, W.; Fu, L.; Zhang, S.; Wei, M.; Guo, D. Techno-economic study of full-open absorption heat pump applied to flue gas total heat recovery. Energy 2020, 190, 116429. [Google Scholar] [CrossRef]

- Rosa, M.B.R.; Víctor, M.A.G.; García-Gutiérrez, A. Performance modelling of single and double absorption heat transformers. Curr. Appl. Phys. 2010, 10, 244–248. [Google Scholar]

- Yang, M.; Low, E.; Law, C.L.; Chen, J.; Show, P.L.; Huang, S. Heat and mass transfer in a counter flow parallel plate membrane-based absorption heat pump (PMAHP). Int. J. Therm. Sci. 2022, 171, 107227. [Google Scholar] [CrossRef]

- Herold, K.E.; Radermacher, R.; Klein, S.A. Absorption Chillers and Heat Pumps, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Xie, Y.; Zhang, T.; Liu, X. Performance investigation of a counter-flow heat pump driven liquid desiccant dehumidification system. Energy 2016, 115, 446–457. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, Y.; Xia, J.; Chang, X. Analytical solutions of coupled heat and mass transfer processes in liquid desiccant air dehumidifier/regenerator. Energy Convers. Manag. 2007, 48, 2221–2232. [Google Scholar] [CrossRef]

- Folkedahl, B.C.; Weber, G.F.; Collings, M.E. Water Extraction from Coal-Fired Power Plant Flue Gas; University of North Dakota: Grand Forks, ND, USA, 2006. [Google Scholar]

| Parameter | Inlet Value | Experimental Outlet Data | Calculated Results | Relative Deviation |

|---|---|---|---|---|

| Flue gas temperature | 50 °C | 42.3 °C | 41.02 °C | 3.03% |

| Flue gas humidity ratio | 126 g/kg | 55.4 g/kg | 54.2 g/kg | 2.17% |

| Solution temperature of absorber | 30 °C | 42.3 °C | 40.8 °C | 3.55% |

| Solution concentration | 35% | 34.5% | 34.7% | 0.58% |

| Water supply and return temperature | 35 °C | 56.8 °C | 58.7 °C | 3.35% |

| Power consumption of pump | - | 2.46 kW | 2.37 kW | 3.66% |

| Heat output | - | 80.4 kW | 82.6 kW | 2.67% |

| COP | - | 1.65 | 1.68 | 1.82% |

| Parameters | Unit | Values |

|---|---|---|

| Thermal load | kW | 40–100 |

| Inlet temperature | oC | 50 |

| Outlet temperature | oC | 40 |

| Flue gas mass flow rate | kg/s | 3 |

| Pressure drop | kPa | 0.5 |

| Flue gas diameter (DN) | mm | 400 |

| Parameters | Unit | Values |

|---|---|---|

| Heat output | kW | 80 |

| Return water temperature | °C | 35 |

| Supply water temperature | °C | 45–53 |

| Heating water mass flow rate | kg/s | 1–3 |

| Resistance loss | MPa | 0.08 |

| Heating water diameter (DN) | mm | 450 |

| Drive steam mass flow rate | kg/s | 2.5 |

| Steam pressure drop | MPa | 0.05 |

| Steam diameter (DN) | mm | 400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, X.; Wang, Z.; Han, Y.; Su, W. Study on the Performance of a Novel Double-Section Full-Open Absorption Heat Pump for Flue Gas Waste Heat Recovery. Processes 2024, 12, 2181. https://doi.org/10.3390/pr12102181

Cai X, Wang Z, Han Y, Su W. Study on the Performance of a Novel Double-Section Full-Open Absorption Heat Pump for Flue Gas Waste Heat Recovery. Processes. 2024; 12(10):2181. https://doi.org/10.3390/pr12102181

Chicago/Turabian StyleCai, Xin, Zhanbin Wang, Yuhao Han, and Wei Su. 2024. "Study on the Performance of a Novel Double-Section Full-Open Absorption Heat Pump for Flue Gas Waste Heat Recovery" Processes 12, no. 10: 2181. https://doi.org/10.3390/pr12102181

APA StyleCai, X., Wang, Z., Han, Y., & Su, W. (2024). Study on the Performance of a Novel Double-Section Full-Open Absorption Heat Pump for Flue Gas Waste Heat Recovery. Processes, 12(10), 2181. https://doi.org/10.3390/pr12102181