Study of Helium Irradiation Effect on Al6061 Alloy Fabricated by Additive Friction Stir Deposition

Abstract

1. Introduction

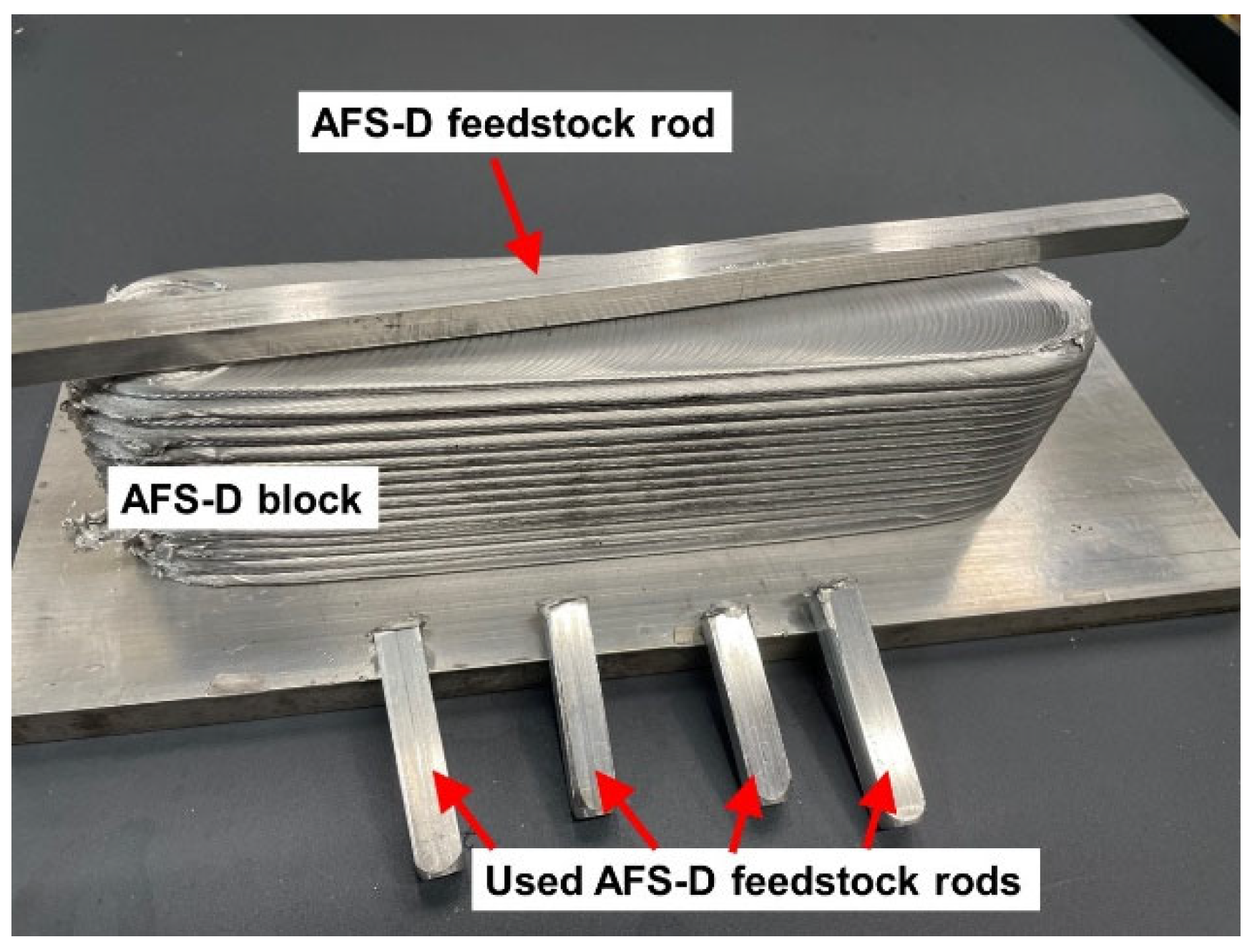

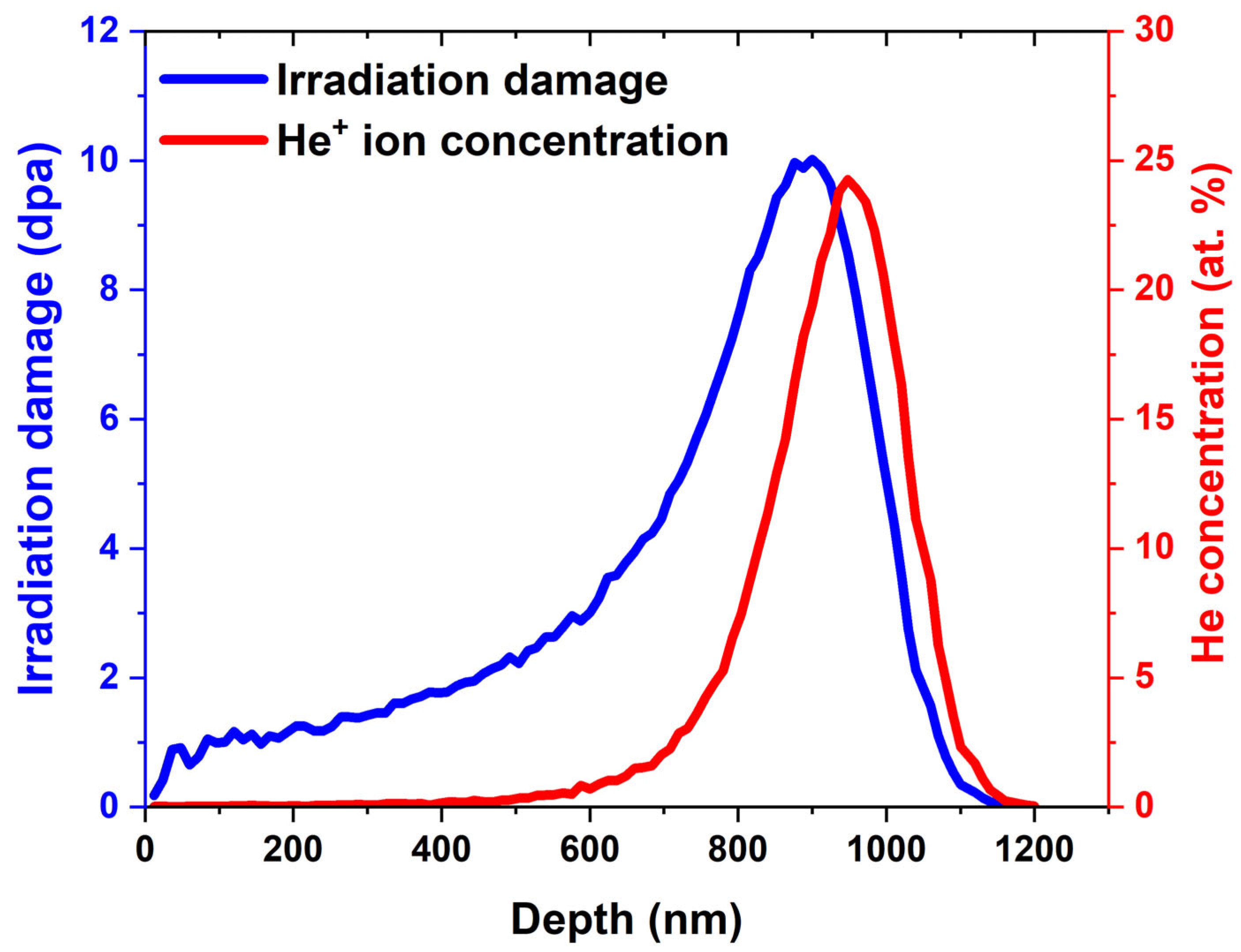

2. Experimental and Simulation Methods

3. Results and Discussions

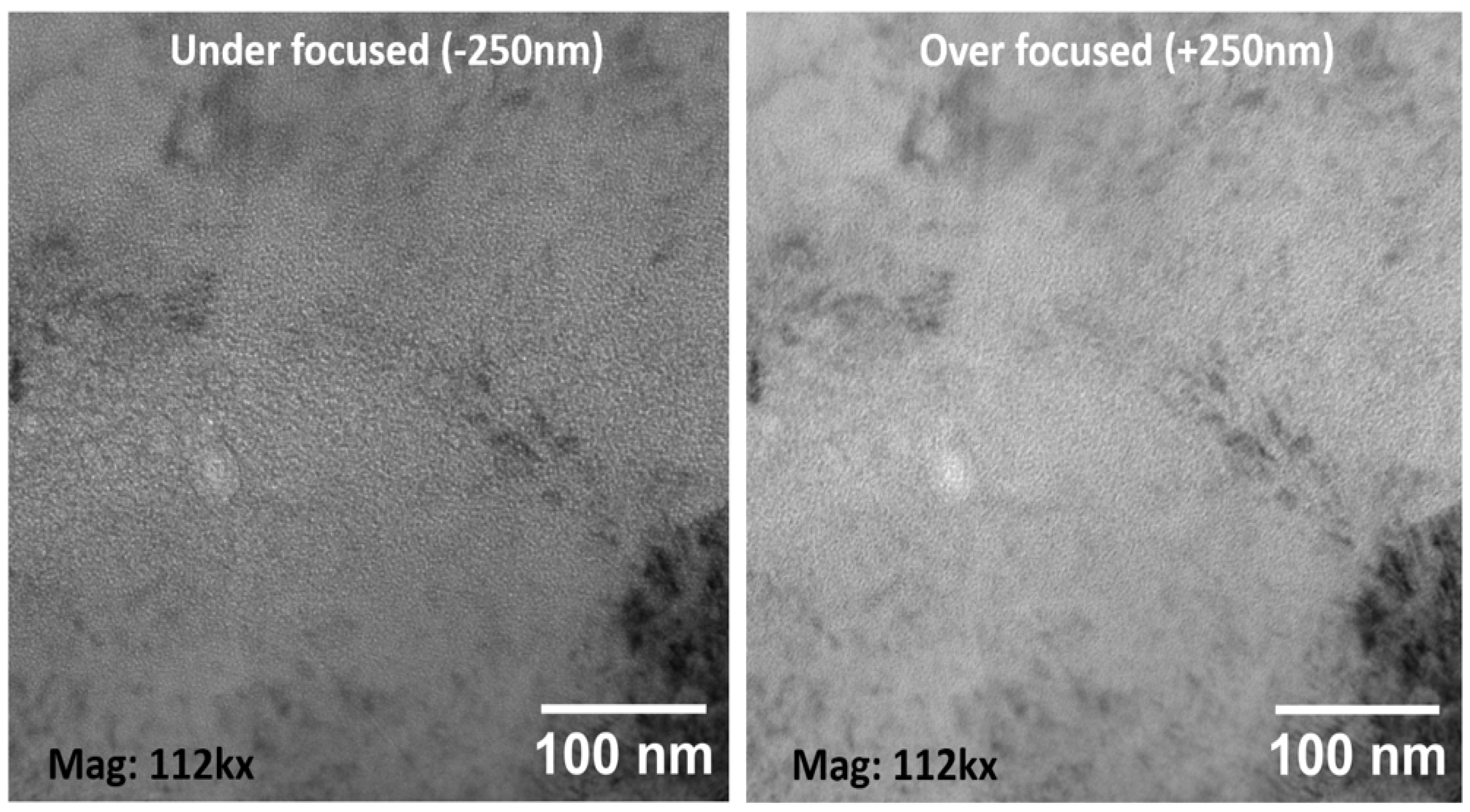

3.1. Surface Morphology and Microstructure Characterization

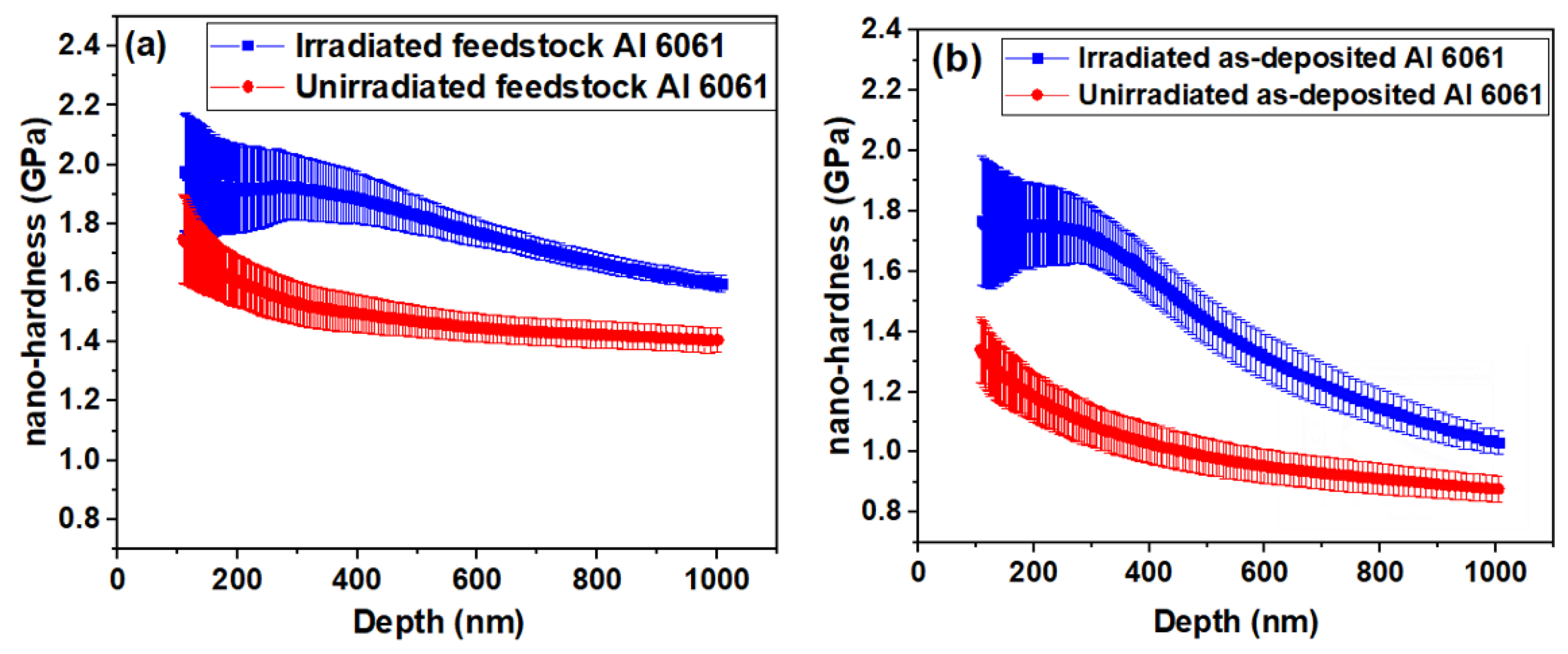

3.2. Nanoindentation Hardness Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, G.B.V.; Pramod, R.; Sekhar, C.G.; Kumar, G.P.; Bhanumurthy, T. Investigation of physical, mechanical and tribological properties of Al6061–ZrO2 nano-composites. Heliyon 2019, 5, e02858. [Google Scholar] [CrossRef] [PubMed]

- Karakoç, H.; Ovalı, İ.; Dündar, S.; Çıtak, R. Wear and mechanical properties of Al6061/SiC/B4C hybrid composites produced with powder metallurgy. J. Mater. Res. Technol. 2019, 8, 5348–5361. [Google Scholar]

- Ogunsanya, O.A.; Akinwande, A.A.; Balogun, O.A.; Romanovski, V. Mechanical and damping behavior of artificially aged Al6061/TiO2 reinforced composites for aerospace applications. Part. Sci. Technol. 2022, 41, 1–13. [Google Scholar]

- Aldwell, B.; Kelly, E.; Wall, R.; Amaldi, A.; O’Donnell, G.E. Machinability of Al6061 deposited with cold spray additive manufacturing. J. Therm. Spray Technol. 2017, 26, 1573–1584. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Gao, H.; Li, H. Friction additive manufacturing technology: A state-of-the-art survey. Adv. Mech. Eng. 2021, 13, 1–29. [Google Scholar] [CrossRef]

- Qu, M.; Guo, Q.; Escano, L.I.; Nabaa, A.; Hojjatzadeh, S.M.H.; Young, Z.A.; Chen, L. Controlling process instability for defect lean metal additive manufacturing. Nat. Commun. 2022, 13, 1079. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Perry, M.E.J.; Sietins, J.M.; Zhu, Y.; Hardwick, N.; Cox, C.D.; Rauch, H.A.; Yu, H.Z. A perspective on solid-state additive manufacturing of aluminum matrix composites using MELD. J. Mater. Eng. Perform. 2019, 28, 648–656. [Google Scholar] [CrossRef]

- Yu, H.Z.; Jones, M.E.; Brady, G.W.; Griffiths, R.J.; Garcia, D.; Rauch, H.A.; Cox, C.D.; Hardwick, N. Non-beam-based metal additive manufacturing enabled by additive friction stir deposition. Scr. Mater. 2018, 153, 122–130. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Petersen, D.T.; Garcia, D.; Yu, H.Z. Additive friction stir-enabled solid-state additive manufacturing for the repair of 7075 aluminum alloy. Appl. Sci. 2019, 9, 3486. [Google Scholar] [CrossRef]

- Perry, M.E.; Rauch, H.A.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Zhu, Y.; Yu, H.Z. Tracing plastic deformation path and concurrent grain refinement during additive friction stir deposition. Materialia 2021, 18, 101159. [Google Scholar] [CrossRef]

- Chaudhary, B.; Jain, N.K.; Murugesan, J.; Patel, V. Exploring temperature-controlled friction stir powder additive manufacturing process for multi-layer deposition of aluminum alloys. J. Mater. Res. Technol. 2022, 20, 260–268. [Google Scholar] [CrossRef]

- Rutherford, B.A.; Avery, D.Z.; Phillips, B.J.; Rao, H.M.; Doherty, K.J.; Allison, P.G.; Brewer, L.N.; Jordon, J.B. Effect of thermomechanical processing on fatigue behavior in solid-state additive manufacturing of Al-Mg-Si alloy. Metals 2020, 10, 947. [Google Scholar] [CrossRef]

- Phillips, B.J.; Avery, D.Z.; Liu, T.; Rodriguez, O.L.; Mason, C.J.T.; Jordon, J.B.; Brewer, L.N.; Allison, P.G. Microstructure-deformation relationship of additive friction stir-deposition Al–Mg–Si. Materialia 2019, 7, 100387. [Google Scholar] [CrossRef]

- Ni, K.; Ma, Q.; Wan, H.; Yang, B.; Ge, J.; Zhang, L.; Si, N. Effect of He+ fluence on surface morphology and ion-irradiation induced defect evolution in 7075 aluminum alloys. Mater. Res. Express 2018, 5, 026514. [Google Scholar] [CrossRef]

- Gussev, M.N.; Sridharan, N.; Babu, S.; Terrani, K.A. Influence of neutron irradiation on Al-6061 alloy produced via ultrasonic additive manufacturing. J. Nucl. Mater. 2021, 550, 152939. [Google Scholar] [CrossRef]

- Kim, Y.S.; Chae, H.; Berghe, S.V.D.; Leenaers, A.; Kuzminov, V.; Yacout, A. Aluminum cladding oxide growth prediction for high flux research reactors. J. Nucl. Mater. 2020, 529, 151926. [Google Scholar] [CrossRef]

- Mehta, A.; Zhou, L.; Huynh, T.; Park, S.; Hyer, H.; Song, S.; Bai, Y.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; et al. Additive manufacturing and mechanical properties of the dense and crack free Zr-modified aluminum alloy 6061 fabricated by the laser-powder bed fusion. Addit. Manuf. 2021, 41, 101966. [Google Scholar] [CrossRef]

- Mehta, A.; Zhou, L.; Schulz, E.A.; Keiser, D.D.; Cole, J.I.; Sohn, Y. Microstructural characterization of AA6061 versus AA6061 HIP bonded cladding–cladding interface. J. Phase Equilibria Diffus. 2018, 39, 246–254. [Google Scholar] [CrossRef]

- Ghadimi, H.; Ding, H.; Emanet, S.; Talachian, M.; Cox, C.; Eller, M.; Guo, S. Hardness Distribution of Al2050 Parts Fabricated Using Additive Friction Stir Deposition. Materials 2023, 16, 1278. [Google Scholar] [CrossRef] [PubMed]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM–The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Zeng, C.; Ghadimi, H.; Ding, H.; Nemati, S.; Garbie, A.; Raush, J.; Guo, S. Microstructure Evolution of Al6061 Alloy Made by Additive Friction Stir Deposition. Materials 2022, 15, 3676. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Wang, X.; Wierschke, J.B.; Wang, L. Helium bubble evolution in ion irradiated Al/B4C metal metrix composite. Scr. Mater. 2015, 109, 28–33. [Google Scholar] [CrossRef]

- Demkowicz, M.; Misra, A.; Caro, A. The role of interface structure in controlling high helium concentrations. Curr. Opin. Solid State Mater. Sci. 2012, 16, 101–108. [Google Scholar] [CrossRef]

- Bai, X.-M.; Voter, A.F.; Hoagland, R.G.; Nastasi, M.; Uberuaga, B.P. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science 2010, 327, 1631–1634. [Google Scholar] [CrossRef]

- Shen, T.D.; Feng, S.; Tang, M.; Valdez, J.A.; Wang, Y.; Sickafus, K.E. Enhanced radiation tolerance in nanocrystalline MgGa2O4. Appl. Phys. Lett. 2007, 90, 263115. [Google Scholar] [CrossRef]

- Bringa, E.M.; Monk, J.D.; Caro, A.; Misra, A.; Zepeda-Ruiz, L.; Duchaineau, M.; Abraham, F.; Nastasi, M.; Picraux, S.T.; Wang, Y.Q.; et al. Are nanoporous materials radiation resistant? Nano Lett. 2012, 12, 3351–3355. [Google Scholar] [CrossRef]

- Zhuo, M.; Fu, E.; Yan, L.; Wang, Y.; Zhang, Y.; Dickerson, R.; Uberuaga, B.; Misra, A.; Nastasi, M.; Jia, Q. Interface-enhanced defect absorption between epitaxial anatase TiO2 film and single crystal SrTiO3. Scr. Mater. 2011, 65, 807–810. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, H.; Millett, P.C.; Tonks, M.; Wolf, D.; Phillpot, S.R. Atomistic study of grain boundary sink strength under prolonged electron irradiation. J. Nucl. Mater. 2012, 422, 69–76. [Google Scholar] [CrossRef]

- Vetterick, G.A.; Gruber, J.; Suri, P.K.; Baldwin, J.K.; Kirk, M.A.; Baldo, P.; Wang, Y.Q.; Misra, A.; Tucker, G.J.; Taheri, M.L. Achieving radiation tolerance through non-equilibrium grain boundary structures. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Wei, Q.; Li, N.; Sun, K.; Wang, L. The shape of bubbles in He-implanted Cu and Au. Scr. Mater. 2010, 63, 430–433. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Kasada, R.; Takayama, Y.; Yabuuchi, K.; Kimura, A. A new approach to evaluate irradiation hardening of ion-irradiated ferritic alloys by nano-indentation techniques. Fusion Eng. Des. 2011, 86, 2658–2661. [Google Scholar] [CrossRef]

- Seeger, A.; Diehl, J.; Mader, S.; Rebstock, H. Work-hardening and work-softening of face-centred cubic metal crystals. Philos. Mag. 1957, 2, 323–350. [Google Scholar] [CrossRef]

- Cui, M.; Wang, J.; Wang, Z.; Shen, T.; Wei, K.; Yao, C.; Sun, J.; Gao, N.; Zhu, Y.; Pang, L.; et al. Helium irradiation induced hardening in MNHS steels. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 406, 611–617. [Google Scholar] [CrossRef]

- Cui, M.; Shen, T.; Pang, L.; Zhu, Y.; Jin, P.; Liu, C.; Fang, X.; Wang, Z. He ion implantation induced He bubbles and hardness in tungsten. Nucl. Mater. Energy 2018, 15, 232–236. [Google Scholar] [CrossRef]

- Kong, F.; Qu, M.; Yan, S.; Zhang, A.; Peng, S.; Xue, J.; Wang, Y. Helium-induced hardening effect in polycrystalline tungsten. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 406, 643–647. [Google Scholar] [CrossRef]

- Cao, P.; Wang, H.; He, J.; Xu, C.; Jiang, S.; Du, J.; Cao, X.; Fu, E.; Lu, Z. Effects of nanosized precipitates on irradiation behavior of CoCrFeNi high entropy alloys. J. Alloys Compd. 2021, 859, 158291. [Google Scholar] [CrossRef]

- Zhang, W.; Han, H.; Dai, J.; Ren, C.; Wang, C.; Yan, L.; Huang, H.; Zhu, Z. Simulation of migration and coalescence of helium bubbles in nickel. J. Nucl. Mater. 2019, 518, 48–53. [Google Scholar] [CrossRef]

- Wang, J.; Gao, X.; Gao, N.; Wang, Z.; Cui, M.; Wei, K.; Yao, C.; Sun, J.; Li, B.; Zhu, Y. Grain size effects on He bubbles distribution and evolution. J. Nucl. Mater. 2015, 457, 182–185. [Google Scholar] [CrossRef]

- Pu, G.; Lin, L.; Ang, R.; Zhang, K.; Liu, B.; Liu, B.; Peng, T.; Liu, S.; Li, Q. Outstanding radiation tolerance and mechanical behavior in ultra-fine nanocrystalline Al1. 5CoCrFeNi high entropy alloy films under He ion irradiation. Appl. Surf. Sci. 2020, 516, 146129. [Google Scholar] [CrossRef]

- Ullmaier, H. The influence of helium on the bulk properties of fusion reactor structural materials. Nucl. Fusion 1984, 24, 1039. [Google Scholar] [CrossRef]

| Alloy | Type | |

|---|---|---|

| Feedstock Al6061 | Unirradiated | 1.36 |

| Feedstock Al6061 | Irradiated | 1.88 |

| AFS-D Al6061 | Unirradiated | 083 |

| AFS-D Al6061 | Irradiated | 1.74 |

| Obstacles | Precipitation | He Bubbles | ||

|---|---|---|---|---|

| Size | Density | Size | Density | |

| Feedstock Al6061 | small | high | large | low |

| AFS-D Al6061 | large | low | small | high |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhandari, U.; Ding, H.; Zeng, C.; Yang, S.; Karoui, A.; Kim, H.; Zhu, P.; Chancey, M.R.; Wang, Y.; Guo, S. Study of Helium Irradiation Effect on Al6061 Alloy Fabricated by Additive Friction Stir Deposition. Processes 2024, 12, 2144. https://doi.org/10.3390/pr12102144

Bhandari U, Ding H, Zeng C, Yang S, Karoui A, Kim H, Zhu P, Chancey MR, Wang Y, Guo S. Study of Helium Irradiation Effect on Al6061 Alloy Fabricated by Additive Friction Stir Deposition. Processes. 2024; 12(10):2144. https://doi.org/10.3390/pr12102144

Chicago/Turabian StyleBhandari, Uttam, Huan Ding, Congyuan Zeng, Shizhong Yang, Abdennaceur Karoui, Hyosim Kim, Pengcheng Zhu, Matthew Ryan Chancey, Yongqiang Wang, and Shengmin Guo. 2024. "Study of Helium Irradiation Effect on Al6061 Alloy Fabricated by Additive Friction Stir Deposition" Processes 12, no. 10: 2144. https://doi.org/10.3390/pr12102144

APA StyleBhandari, U., Ding, H., Zeng, C., Yang, S., Karoui, A., Kim, H., Zhu, P., Chancey, M. R., Wang, Y., & Guo, S. (2024). Study of Helium Irradiation Effect on Al6061 Alloy Fabricated by Additive Friction Stir Deposition. Processes, 12(10), 2144. https://doi.org/10.3390/pr12102144