Low-Carbon Economic Dispatch of Electricity and Cooling Energy System

Abstract

:1. Introduction

2. Method

2.1. Pipeline Characteristic Model

- Heat delay: The heat of the return water is absorbed by the cold source and its temperature decreases, becoming the supply water. The kinetic energy of the circulating water pump in the cooling network drives the flow towards the heat-exchange station. Due to the transportation time required for the supply water, a heat delay occurs, resulting in an imbalance between supply and demand in the heat exchanger. With reference to Ref. [27], the heat delay time of the cooling network is established as follows:

- 2.

- Heat loss: When the supply water temperature is lower than the ambient soil temperature, the supply water temperature increases along the heat transport process, and the inlet temperature supply water of heat-exchange station is higher than the outlet temperature of the cold source, resulting in a loss of cooling capacity. According to Ref. [27], the pipeline heat loss is proposed as follows:

2.2. Flexible Thermal Comfort Model

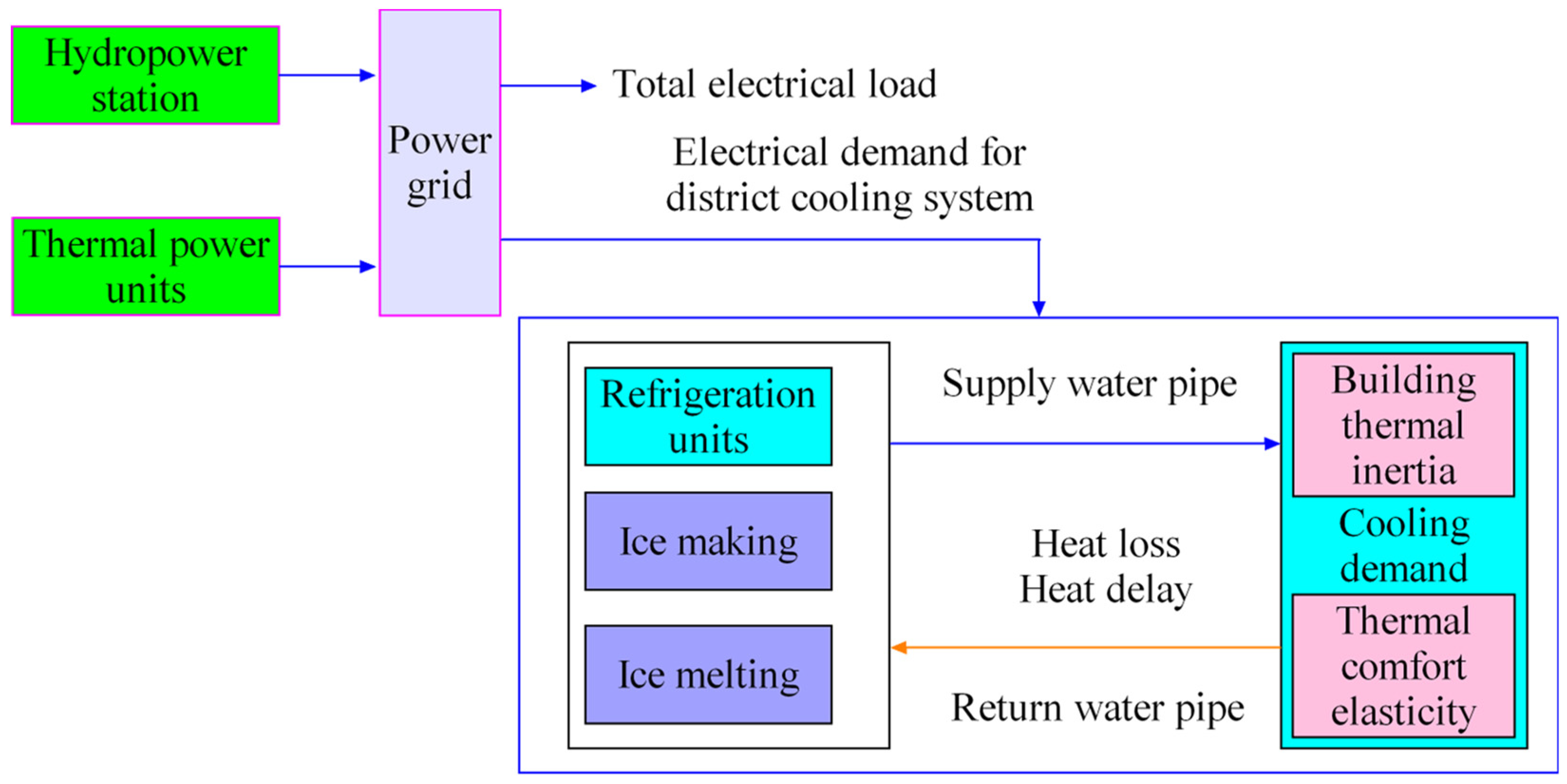

2.3. System Description

2.4. Electric-Cooling Dispatching Model

2.4.1. Goal Function

2.4.2. Constraint Condition

- (1)

- Power balance constraint

- (2)

- Heat transport models of a cooling system

- (3)

- Unit output constraints

- (4)

- Unit ramping constraint

2.5. Basic Data

3. Results and Discussion

4. Conclusions

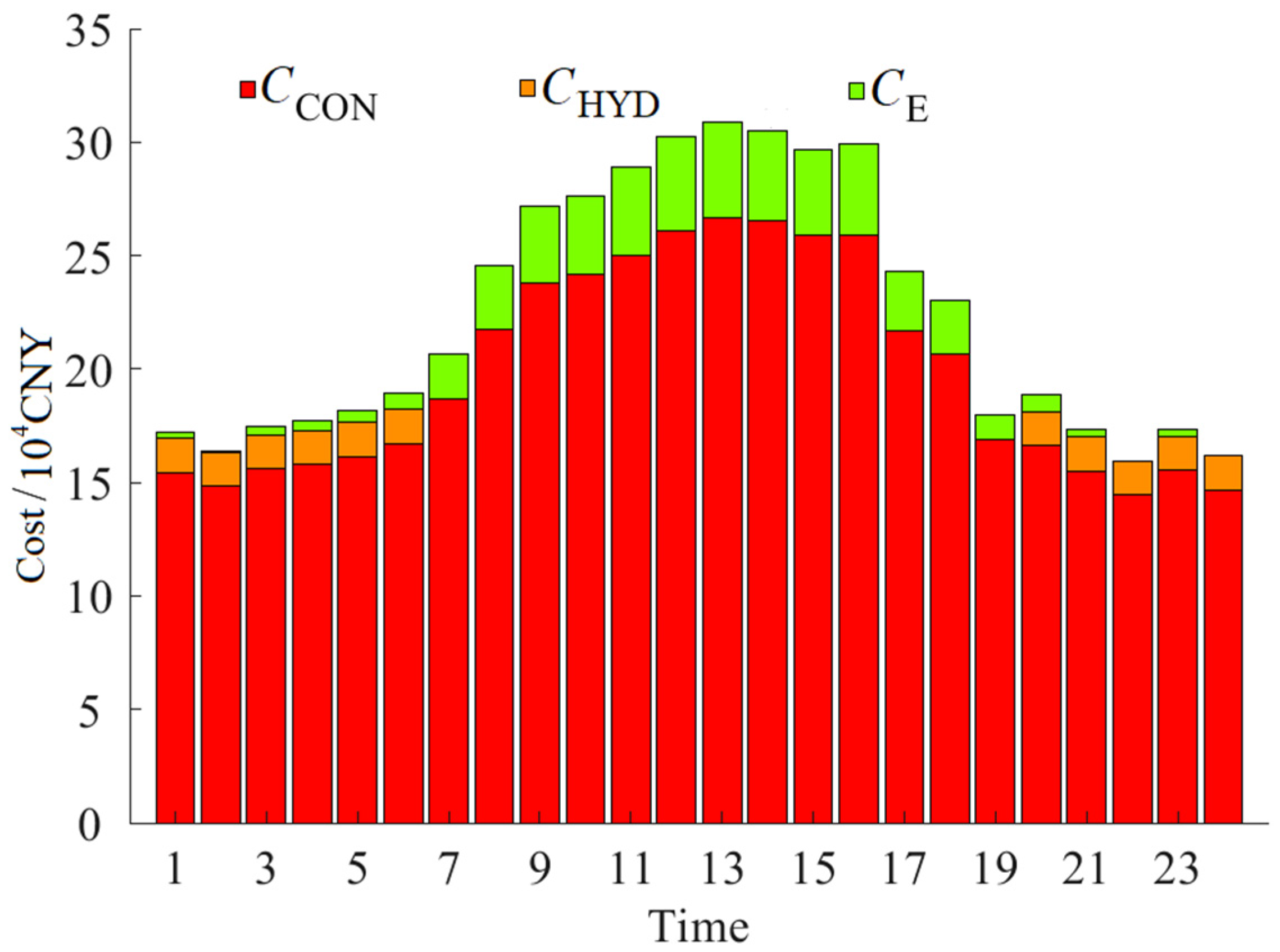

- The electric-cooling joint dispatching is achieved by combining the district cooling and electrical energy to form an integrated energy system. The utilization rates of condensing units are relatively high, and the power generation rates of condensing units are basically higher than 67% without frequent power generation adjustments. The maximum abandoned hydropower rate is below 13.83%.

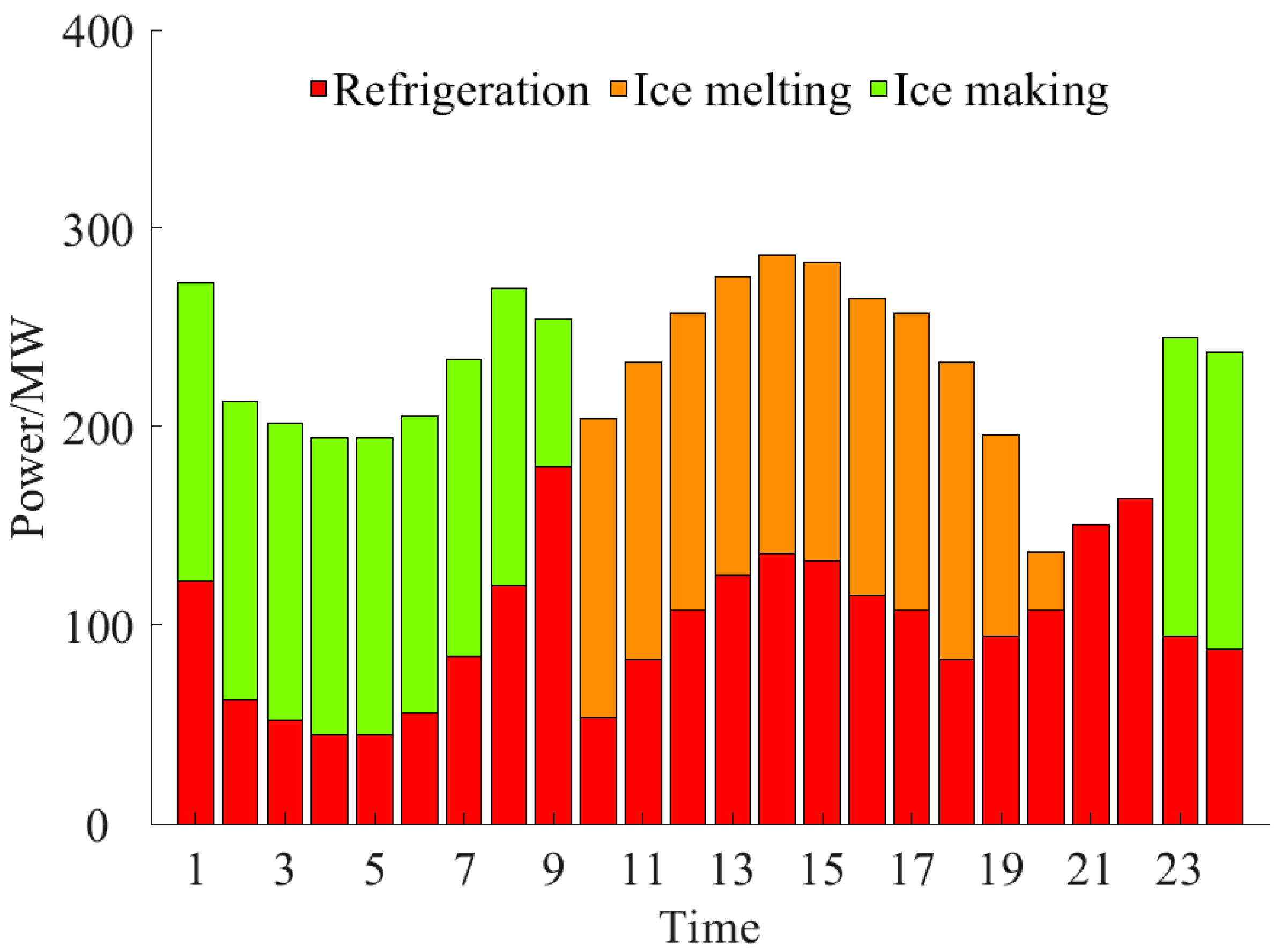

- Refrigeration units and ice storage equipment are adopted to jointly meet the cooling capacity. During the peak period of hydropower at night, the hydropower is used to make ice, and during the peak period of cooling load at daytime, ice melting is used to provide the cooling supply. The ice storage equipment not only supplements the cooling capacity but also effectively promotes the hydropower consumption.

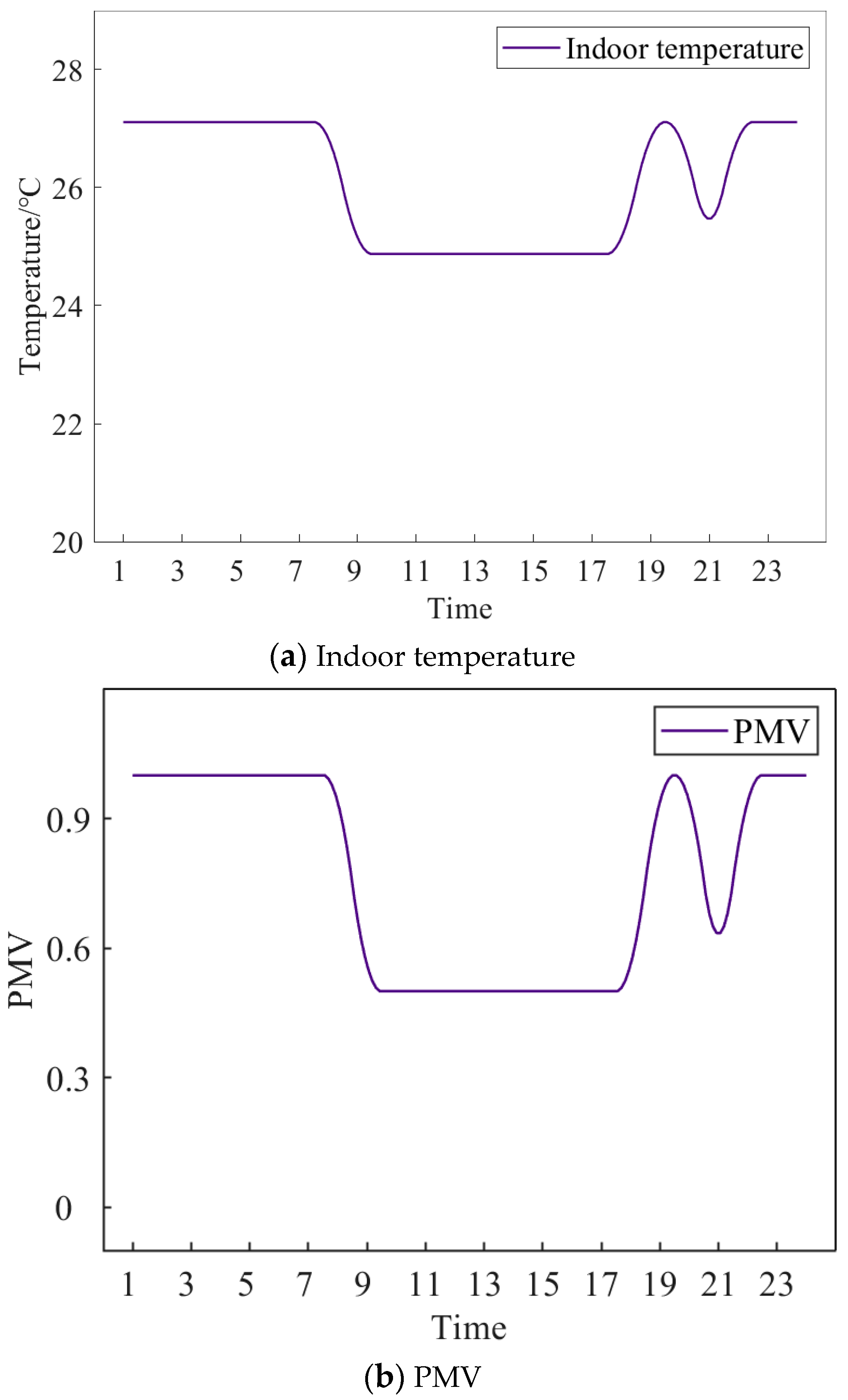

- Most of the time, the inlet supply water temperature is lower than the ambient temperature and the cooling network absorbs heat from the environment, resulting in the heat loss. During the peak period of hydropower at night, the indoor temperature and PMV fluctuate within a certain range. The inlet temperature of the supply water pipe is affected by the constraint of elastic thermal comfort, and an increase in thermal comfort requires a decrease in the supply water temperature to provide a greater cooling capacity. Considering the thermal characteristics of the cooling network, as well as the thermal comfort elasticity, compared to the traditional dispatching model, the carbon trading cost, coal consumption cost, and abandoned hydropower rate were reduced by 4.25%, 4.47%, and 3.66%, respectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, W.; Lund, H.; Mathiesen, B.V. Large-scale integration of wind power into the existing Chinese energy system. Energy 2011, 36, 4753–4760. [Google Scholar] [CrossRef]

- Tveit, T.M.; Savola, T.; Gebremedhin, A.; Fogelholm, C.J. Multi-period MINLP model for optimising operation and structural changes to CHP plants in district heating networks with long-term thermal storage. Energy Convers. Manag. 2009, 50, 639–647. [Google Scholar] [CrossRef]

- Li, Y.; Han, M.; Shahidehpour, M.; Li, J.Z.; Long, C. Data-driven distributionally robust scheduling of community integrated energy systems with uncertain renewable generations considering integrated demand response. Appl. Energy 2023, 335, 120749. [Google Scholar] [CrossRef]

- Hennessy, J.; Li, H.; Wallin, F.; Thorin, E. Flexibility in thermal grids: A review of short-term storage in district heating distribution networks. Energy Procedia 2019, 158, 2430–2434. [Google Scholar] [CrossRef]

- Dahlblom, M.; Nordquist, B.; Jensen, L. Evaluation of a feedback control method for hydronic heating systems based on indoor temperature measurements. Energy Build 2018, 166, 23–34. [Google Scholar] [CrossRef]

- Liu, X.Z.; Wu, J.Z.; Jenkins, N.; Bagdanavicius, A. Combined analysis of electricity and heat networks. Appl. Energy 2016, 162, 1238–1250. [Google Scholar] [CrossRef]

- Arteconi, A.; Mugnini, A.; Polonara, F. Energy flexible buildings: A methodology for rating the flexibility performance of buildings with electric heating and cooling systems. Appl. Energy 2019, 251, 113387. [Google Scholar] [CrossRef]

- Ansari, B.; Aligholami, M.; Khosroshahi, A.R. An experimental and numerical investigation into using hydropower plant on oil transmission lines. Energy Sci. Eng. 2022, 10, 4397–4410. [Google Scholar] [CrossRef]

- Hao, L.; Xu, F.; Chen, Q.; Wei, M.S.; Chen, L.; Min, Y. A thermal-electrical analogy transient model of district heating pipelines for integrated analysis of thermal and power systems. Appl. Therm. Eng. 2018, 139, 213–221. [Google Scholar] [CrossRef]

- Dai, Y.H.; Chen, L.; Min, Y.; Chen, Q.; Zhang, Y.W.; Xu, F.; Hu, K.; Hao, J.H. Active and passive thermal energy storage in combined heat and power plants to promote wind power accommodation. J. Energy Eng. 2017, 143, 04017037. [Google Scholar] [CrossRef]

- Yang, Y.L.; Wu, K.; Long, H.Y.; Gao, J.C.; Yan, X.; Kato, T.; Suzuoki, Y. Integrated electricity and heating demand-side management for wind power integration in China. Energy 2014, 78, 235–246. [Google Scholar] [CrossRef]

- Hassine, I.B.; Eicker, U. Impact of load structure variation and solar thermal energy integration on an existing district heating network. Appl. Therm. Eng. 2013, 50, 1437–1446. [Google Scholar] [CrossRef]

- Li, Z.G.; Wu, W.C.; Shahidehpour, M.; Wang, J.H.; Zhang, B.M. Combined heat and power dispatch considering pipeline energy storage of district heating network. IEEE Trans. Sustain. Energy 2016, 7, 12–21. [Google Scholar] [CrossRef]

- Gu, W.; Wang, J.; Lu, S.; Luo, Z.; Wu, C.Y. Optimal operation for integrated energy system considering thermal inertia of district heating network and buildings. Appl. Energy 2017, 199, 234–246. [Google Scholar] [CrossRef]

- Li, L.; Jia, G.; Qian, W. Optimal dispatching of combined heat-power system considering characteristics of thermal network and thermal comfort elasticity for wind power accommodation. Power Syst. Technol. 2019, 43, 3648–3655. (In Chinese) [Google Scholar]

- Yi, Z.K.; Li, Z.M. Combined heat and power dispatching strategy considering heat storage characteristics of heating network and thermal inertia in heating area. Power Syst. Technol. 2018, 42, 1378–1384. (In Chinese) [Google Scholar]

- Dong, Y.T.; Wang, Y.S.; Ni, C.B.; Yi, J.B. Dispatch of a combined heat-power system considering elasticity with thermal comfort. Power Syst. Prot. Control. 2021, 49, 26–34. (In Chinese) [Google Scholar]

- Yuan, J.J.; Huang, K.; Han, Z.; Zhou, Z.H.; Lu, S.L. A new feedback predictive model for improving the operation efficiency of heating station based on indoor temperature. Energy 2021, 222, 119961. [Google Scholar] [CrossRef]

- Xu, F.; Hao, L.; Chen, L.; Chen, Q.; Wei, M.S.; Min, Y. Discussions on the real potential of district heating networks in improving wind power accommodation with temperature feedback as one consideration. Energy Convers. Manag. 2021, 250, 114907. [Google Scholar] [CrossRef]

- Li, Z.G.; Wu, W.C.; Wang, J.H.; Zhang, B.M.; Zheng, T.Y. Transmission-constrained unit commitment considering combined electricity and district heating networks. IEEE Trans. Sustain. Energy 2016, 7, 480–492. [Google Scholar] [CrossRef]

- Lund, H. Large-scale integration of wind power into different energy systems energy system. Energy 2005, 30, 2402–2412. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.L.; Li, G.Q.; Wang, J.L.; Zhao, D.B.; Chen, C. Improving operational flexibility of integrated energy system with uncertain renewable generations considering thermal inertia of buildings. Energy Convers. Manag. 2020, 207, 112526. [Google Scholar] [CrossRef]

- Guelpa, E.; Sciacovelli, A.; Verda, V. Thermo-fluid dynamic model of large district heating networks for the analysis of primary energy savings. Energy 2019, 184, 34–44. [Google Scholar] [CrossRef]

- Hao, L.; Wei, M.S.; Xu, F.; Yang, X.C.; Meng, J.; Song, P.P.; Min, Y. Study of operation strategies for integrating ice-storage district cooling systems into power dispatch for large-scale hydropower utilization. Appl. Energy 2020, 261, 114477. [Google Scholar] [CrossRef]

- Ghilardi LM, P.; Castelli, A.F.; Moretti, L.; Morini, M.; Martelli, E. Co-optimization of multi-energy system operation, district heating/cooling network and thermal comfort management for buildings. Appl. Energy 2021, 302, 117480. [Google Scholar] [CrossRef]

- Wirtz, M.; Neumaier, L.; Remmen, P.; Müller, D. Temperature control in 5th generation district heating and cooling networks: An MILP-based operation optimization. Appl. Energy 2021, 288, 116608. [Google Scholar] [CrossRef]

- Lin, Z.R.; Zhu, X.D.; Wang, S.X.; Gao, L.X.; Yu, Y.; Wang, S.M. Optimal scheduling of electric-thermal integrated energy system considering dynamic characteristics of heating network and carbon trading. Proc. CSU-EPSA 2022, 34, 64–70. (In Chinese) [Google Scholar]

- ISO 7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. ISO: Geneve, Switzerland, 2005.

| s1 | s2 | s3 | |

|---|---|---|---|

| Minimum power generation capacity/MW | 150 | 175 | 175 |

| Maximum power generation capacity/MW | 300 | 350 | 350 |

| Coal consumption fitting parameter a0 | 0.000171 | 0.000072 | 0.000072 |

| Coal consumption fitting parameter a1 | 0.2705 | 0.2292 | 0.2292 |

| Coal consumption fitting parameter a2 | 11.537 | 14.618 | 14.618 |

| Maximum up-regulation power/(MW/h) | 50 | 70 | 70 |

| Maximum down-regulation power/(MW/h) | 30 | 70 | 70 |

| Time Interval | Electric Load/MW | Cooling Load/MW | Hydropower Forecast Output/MW | Outdoor Air Temperature/°C |

|---|---|---|---|---|

| 1 (0:00–1:00) | 624 | 272.6 | 405 | 29.1 |

| 2 (1:00–2:00) | 655.2 | 212.6 | 405 | 28.9 |

| 3 (2:00–3:00) | 702 | 201.9 | 405 | 28.6 |

| 4 (3:00–4:00) | 717.6 | 194.7 | 405 | 28.4 |

| 5 (4:00–5:00) | 733.2 | 194.7 | 405 | 28.4 |

| 6 (5:00–6:00) | 748.8 | 205.49 | 405 | 28.7 |

| 7 (6:00–7:00) | 764.4 | 234.1 | 306 | 29.5 |

| 8 (7:00–8:00) | 873.6 | 269.8 | 319.5 | 30.5 |

| 9 (8:00–9:00) | 967.2 | 254.55 | 321.75 | 31.5 |

| 10 (9:00–10:00) | 1185.6 | 53.9 | 325.35 | 32.3 |

| 11 (10:00–11:00) | 1170 | 82.5 | 310.05 | 33.1 |

| 12 (11:00–12:00) | 1170 | 107.6 | 301.5 | 33.8 |

| 13 (12:00–13:00) | 1185.6 | 125.5 | 315 | 34.3 |

| 14 (13:00–14:00) | 1185.6 | 136.2 | 330.75 | 34.6 |

| 15 (14:00–15:00) | 1170 | 132.6 | 332.1 | 34.5 |

| 16 (15:00–16:00) | 1170 | 114.7 | 313.65 | 34 |

| 17 (16:00–17:00) | 1014 | 107.6 | 317.7 | 33.8 |

| 18 (17:00–18:00) | 1014 | 82.5 | 323.5 | 33.1 |

| 19 (18:00–19:00) | 842.4 | 94.4 | 324.9 | 32.2 |

| 20 (19:00–20:00) | 842.4 | 107.8 | 405 | 31.3 |

| 21 (20:00–21:00) | 748.8 | 150.3 | 405 | 30.7 |

| 22 (21:00–22:00) | 686.4 | 163.6 | 405 | 30.2 |

| 23 (22:00–23:00) | 655.2 | 244.8 | 405 | 29.8 |

| 24 (23:00–24:00) | 624 | 237.6 | 405 | 29.6 |

| Carbon Trading Cost/104CNY | Abandoned Hydropower Rate/% | Coal Consumption Cost/104CNY | Total Cost/104CNY | |

|---|---|---|---|---|

| Case 1 | 52.96 | 11.03 | 497.29 | 566.71 |

| Case 2 | 45.41 | 7.37 | 475.06 | 536.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Hao, L.; Zheng, L.; Chen, L.; Xu, F.; Chen, Q.; Min, Y. Low-Carbon Economic Dispatch of Electricity and Cooling Energy System. Processes 2023, 11, 2787. https://doi.org/10.3390/pr11092787

Wang Y, Hao L, Zheng L, Chen L, Xu F, Chen Q, Min Y. Low-Carbon Economic Dispatch of Electricity and Cooling Energy System. Processes. 2023; 11(9):2787. https://doi.org/10.3390/pr11092787

Chicago/Turabian StyleWang, Yubo, Ling Hao, Libin Zheng, Lei Chen, Fei Xu, Qun Chen, and Yong Min. 2023. "Low-Carbon Economic Dispatch of Electricity and Cooling Energy System" Processes 11, no. 9: 2787. https://doi.org/10.3390/pr11092787

APA StyleWang, Y., Hao, L., Zheng, L., Chen, L., Xu, F., Chen, Q., & Min, Y. (2023). Low-Carbon Economic Dispatch of Electricity and Cooling Energy System. Processes, 11(9), 2787. https://doi.org/10.3390/pr11092787