1. Introduction

One of the modern applications of automatic control technology in mobile applications is vehicle control (either with or without a driver) that ensures road-handling ability and ride comfort. One of these fascinating applications is the cruise control system that adjusts the car’s speed based on data received by a set of sensors and is implemented with advanced control techniques [

1,

2,

3]. Another interesting area is lane-free control systems that use sensors and cameras to steer vehicles and retain them inside their lane without any action from the driver. Furthermore, the blind-spot-monitoring control system can detect when a car or a random object is out of sight. The latter can be combined with anti-collision warning control systems that warn the driver if such an obstacle is detected within the vehicle direction. Clearly, the above applications have received significant attention from researchers [

4,

5]. Still, however, the suspension control system, which is responsible for controlling and adjusting the ride comfort with an aim of reducing oscillations, is always at the forefront of research and lectures in engineering schools (mainly in undergraduate studies).

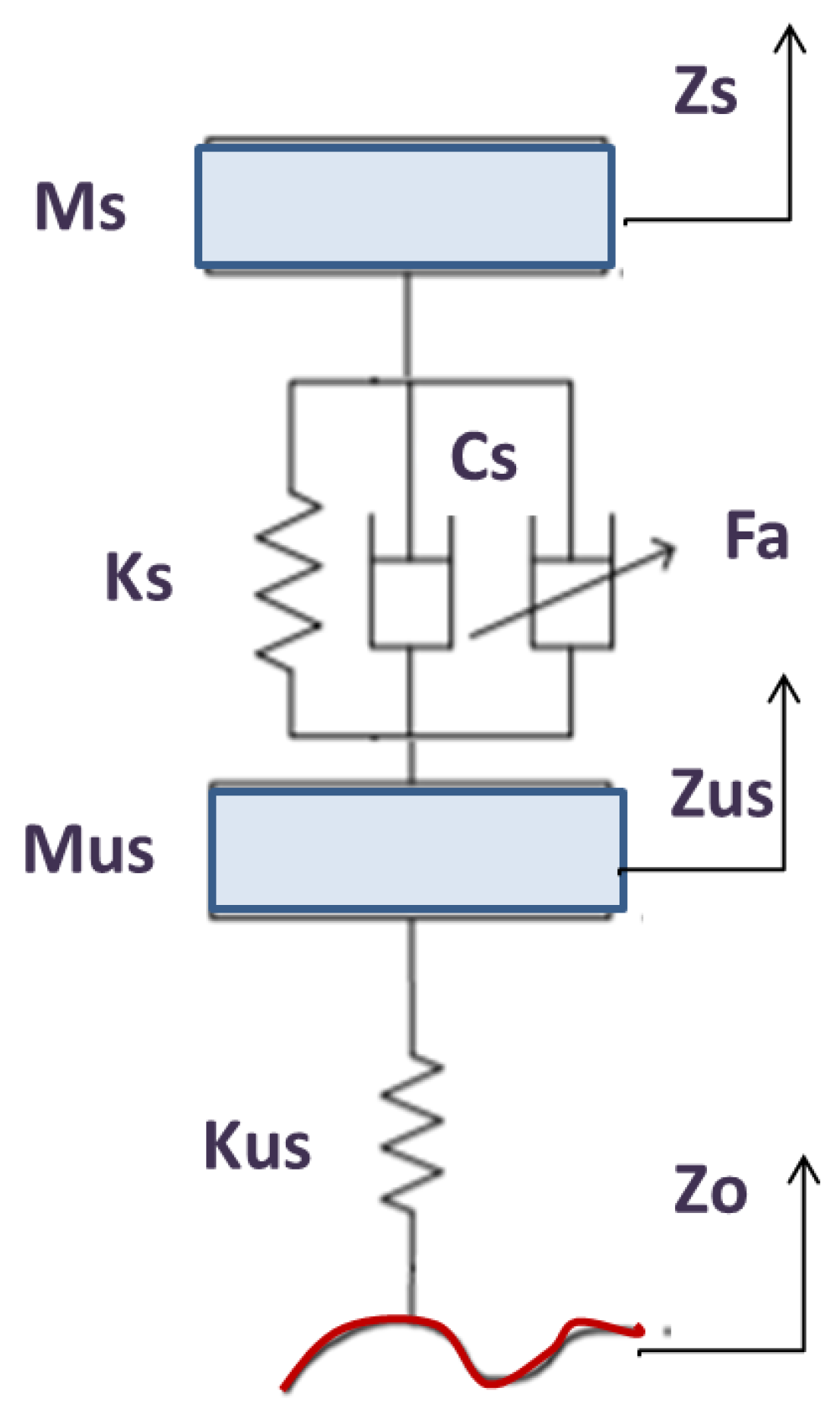

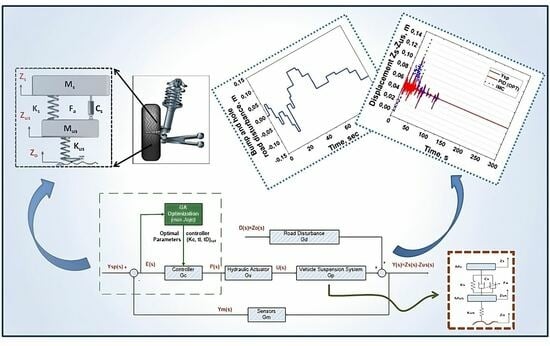

The core aim of the suspension system (see

Figure 1) is to isolate the vehicle’s cabin from external road disturbances (e.g., it separates the car body from the wheels) in order to maximize the driving comfort for the passengers and ensure car stability. Another important role of the suspension system is to keep the wheel in contact with the road surface, as vibrations may be harmful to the passengers and the vehicle itself. These requirements for improved driving comfort and passenger safety have pushed car manufacturers to develop new active suspension systems. This type of suspension has the ability to adapt to harsh road surface conditions and is realized through the ability to store, dissipate and utilize energy within the system. Compared with the passive suspension (open loop without a control action), the active suspension performs better due to the force/power actuator. The actuator is a mechanical control system, which is mounted on the suspension, and can be pneumatic, hydraulic, electromagnetic, etc. The controller collects data from various sensors mounted on the vehicle that can analyze the road profile before any control action.

The design and simulation of a car suspension can be found in various forms in the literature. Most studies take a mathematical model for the active suspension into account and simulate it along with a (properly tuned) PID controller. In most case studies, simulations using a hydraulic actuator and tested in various road surface scenarios (uneven road, potholes and random road entrances) prove to be an established line of work. Such results have proven that the active suspension system with PID control improves driving comfort [

6]. In [

7], a significant effort was made to reduce the motion of a rail car body and the damper. Τhe PID controller was tuned through the Ziegler–Nichols methodology, and the simulated results between the passive and the active suspension system proved that the active suspension system with PID control improves ride comfort, gives a low peak overshoot (amplitude) and a faster settling time. Another group of studies discussed the performance of a PID controller (tuned with the Ziegler–Nichols method or with fuzzy methods) in a semi-active suspension of a vehicle. Again, the results proved that the active suspension system significantly improves driving comfort [

8,

9,

10]. An interesting approach was reported in a study by A. Al-Zughaibi and H. Davies [

11]. The controller was designed using the Routh–Hurwitz stability criterion and the respective simulations were carried out in a system with unknown time delays, different masses and road disturbance. The simulation results showed a significant improvement in performance and disturbance rejection. A quite interesting study using a combination of commercial software (used for extracting vehicle responses) and control design investigated the performance of a K-seat-based PID that is able to enhance motion comfort [

12]. Along the same trend, J. Zhu et al. [

13] worked on the nonlinear modeling and control of emergency rescue vehicles (e.g., active suspension systems in fire trucks) that lack body stability. Their disturbance rejection control design provided a complementary perspective to the results derived from feedback control implementation.

Moving on to modern control techniques, a neural-network-based model predictive controller (NN-MPC), designed for a non-linear servo-hydraulic vehicle suspension system, was compared to a PID controller. The analysis revealed the superior performance of the NN-MPC over the PID, as it showed a better tracking of the set-point, despite the disturbances that emerged [

14]. J. Kim et al. [

15] developed an MPC algorithm for semi-active suspension systems with road preview that managed to improve both the ride comfort and the road-handling performance. In particular, the damping force (input variable) was minimized towards achieving predefined trajectories. A detailed mathematical methodology based on multi-agent communication topology and MPC was presented by N. Zhang et al. [

16] with an aim to minimize the vertical acceleration, pitch acceleration and roll acceleration of the vehicle body. Another meaningful case study dealt with the development of controllers in motors [

17]. The control system was realized and tuned by an artificial intelligence strategy that is based on heuristic optimization techniques (particle swarm optimization, PSO). At first, the development of the mathematical model of the DC motor was carried out. Then, a feedback control system was applied under the adaptive PSO and the conventional Ziegler–Nichols method. The simulation and comparison of the above controller with the PSO and Ziegler–Nichols tuning methods showed that the PSO algorithm can be effectively used to tune the PID controller. In [

18], three tuning methods were used for a PID controller, (heuristic tuning, Ziegler–Nichols tuning and the iterative learning algorithm). Afterwards, the simulation and comparison of the above-mentioned tuning methods, as well as of the comparison between the passive and active suspension system, were carried out for scenarios of three different road disturbances (bump and hole, sinusoidal and random input). The outcome of the study is that the active suspension system performs better than the passive suspension system, whereas the PID controller that was tuned by the iterative learning algorithm performed better than the other two tuning methods. In a more detailed study regarding the development of a full vehicle model, an adaptive PID control was designed [

19]. Specifically, this study is worth mentioning because it developed an adaptive controller for active suspension systems with parameter uncertainties. Their aim was to improve the transient response of the body and to save the communication resources of the in-vehicle network. An interesting study that tried to address problems relating to gain estimation was presented by Y. Jeong et al. [

20]. This group designed a linear-quadratic (LQ) static output feedback with a 2-DOF quarter-car model for an active suspension system. This type of control uses available sensor signals measured in real vehicles and formulates an optimization problem that can be solved via a heuristic optimization method. It was concluded that the proposed controller showed the best performance in terms of ride comfort.

Several other studies can also be found in the literature and include control approaches such as the linear quadratic regulator [

21,

22,

23], adaptive sliding control [

24], H∞ control [

25,

26], advanced fuzzy control [

27,

28], optimal control [

15,

29] and neural-network-based methods for tuning [

30,

31].

Aside from vehicles, specifically those in train suspension systems, the study by X. He et al. in [

32] studied the riding comfort of high-speed trains (which affect the travel experience of passengers) and aimed at reducing the vibrations through the application of a vertical dynamics model of railway vehicles. Furthermore, a unique study with actual implementation scenarios was reported by K. Ikeda et al. [

33]. The purpose of this study was to estimate the psychological state of an occupant based on biometric information. Based on the research findings, the ride quality of occupants while driving can be recorded and control algorithms can be retrofitted in real time.

Since several studies dealing with vehicle suspensions have been carried out in the literature, the focus of this study is not claimed to be unique among such interesting and useful studies. The vision of the present study is to provide a simplified step-by-step approach that can be used as an applied example of modeling and control for engineering students’ lectures. The concept of active suspension systems has significant benefits, as it can be comprehensively taught via the following consecutive educational requirements: (a) the set-up of the mathematical model of a quarter of a car (¼) active suspension in the dual form of differential equations, state-space model and transfer functions, (b) the design and application of a feedback control system based on P, PI and PID controllers, (c) the design and application of a feedback control system based on internal model control (IMC) and (d) the evaluation of the controllers’ performance under different road conditions (including disturbances). The above are accompanied by applied tuning techniques such as the methodologies of Ziegler–Nichols and Tyreus–Luyben and optimal tuning through genetic algorithms (GA).

The structure of the paper is as follows:

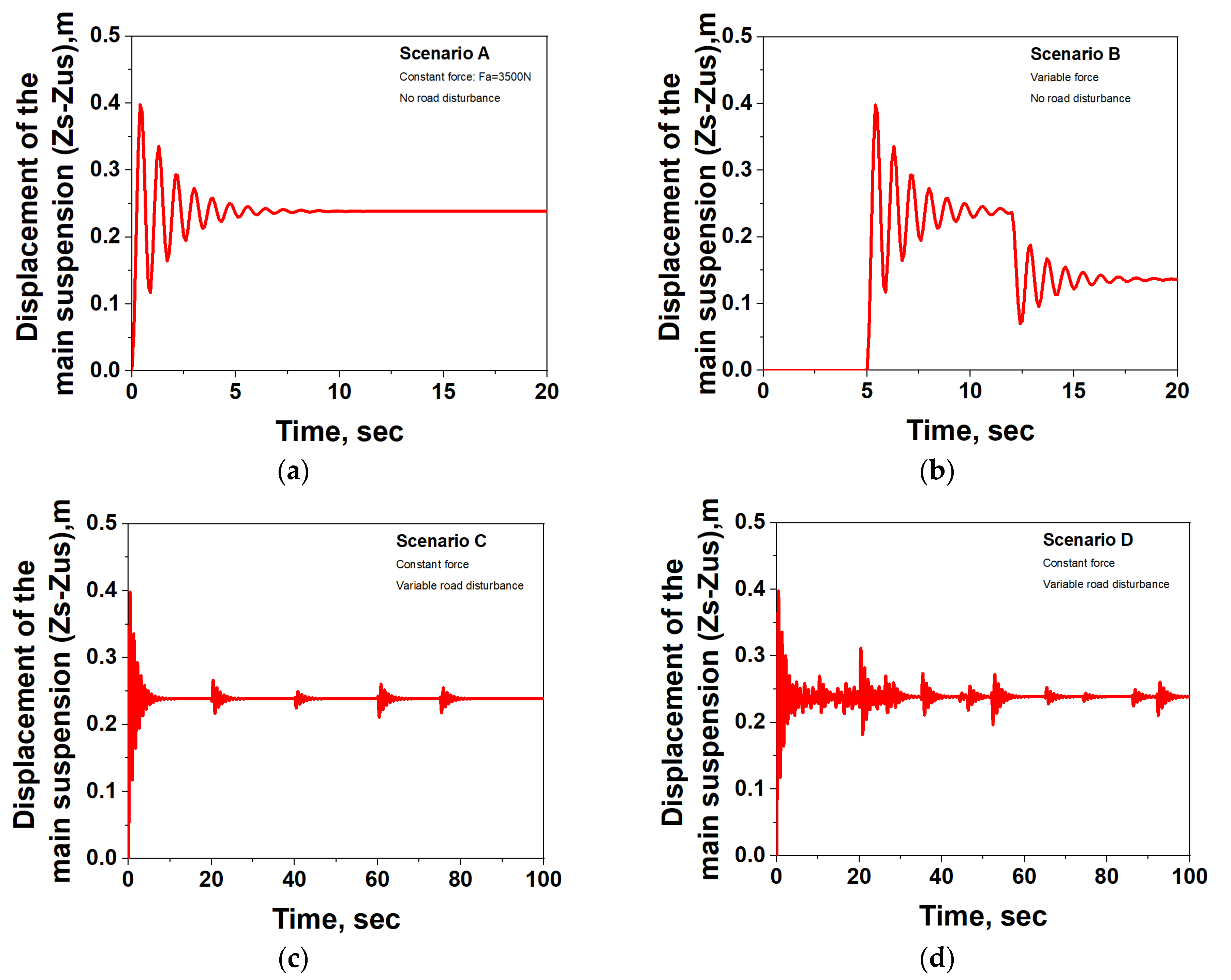

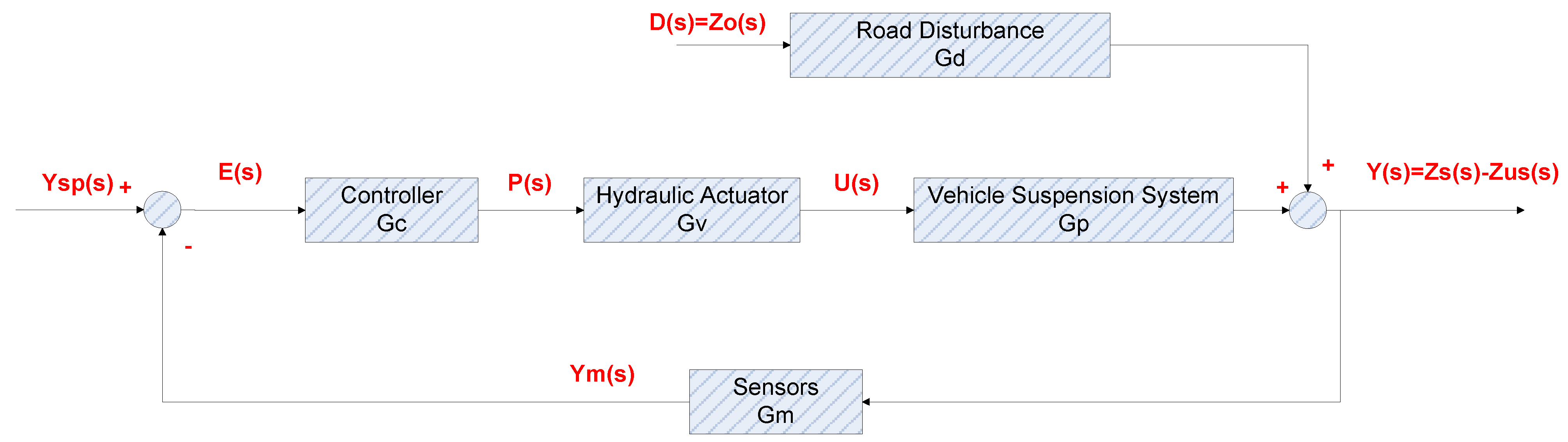

Section 2 presents the mathematical model of the active suspension system. In this section, open loop simulations are used to evaluate the system dynamics under scenarios of varying input force and by applying random disturbances. Next,

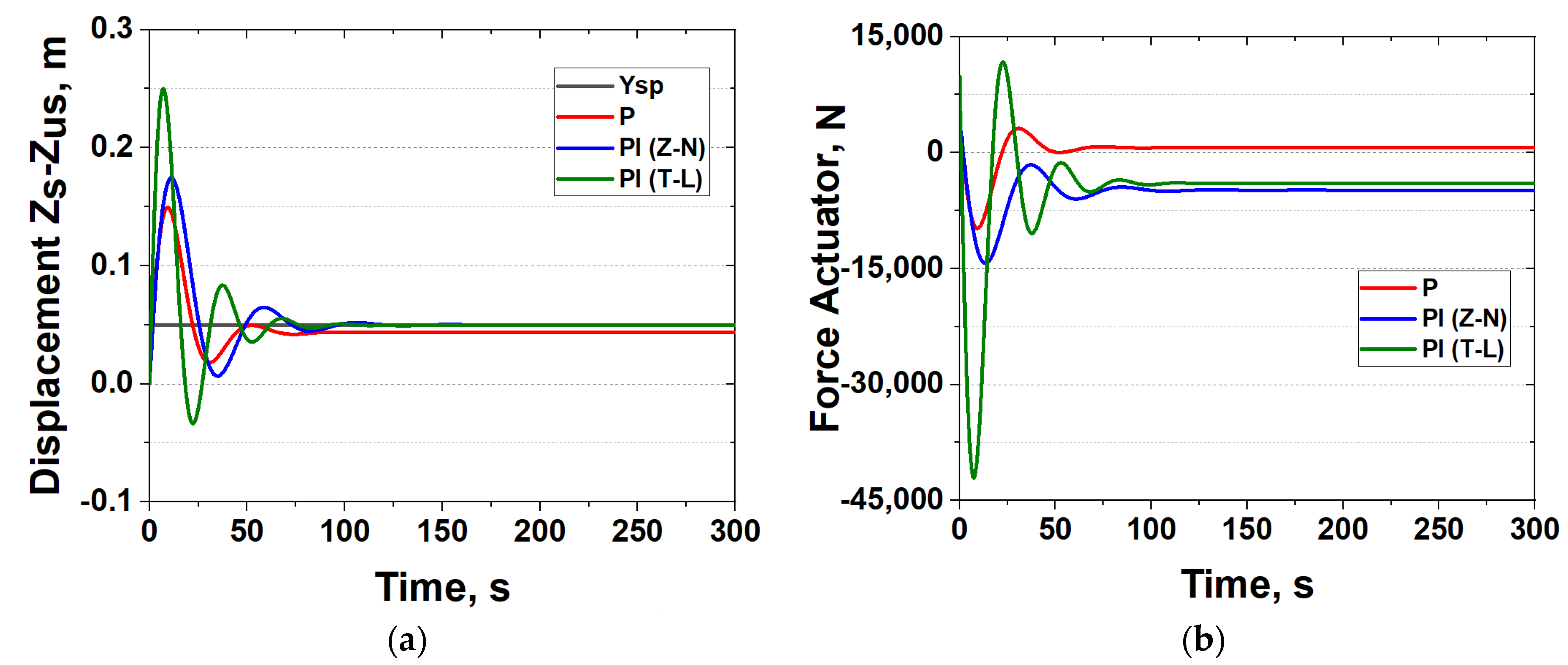

Section 3 designs the feedback control system that is realized in the form of P, PI and PID controllers (tuned via the Ziegler–Nichols and Tyreus–Luyben methodologies), in the form of an optimal PID controller tuned via a GA optimization framework and in the form of a feedback internal model controller. The comparison of the performance of all controllers is evaluated (

Section 4) in different scenarios that include set-point variations with or without the presence of road disturbances.

5. Conclusions

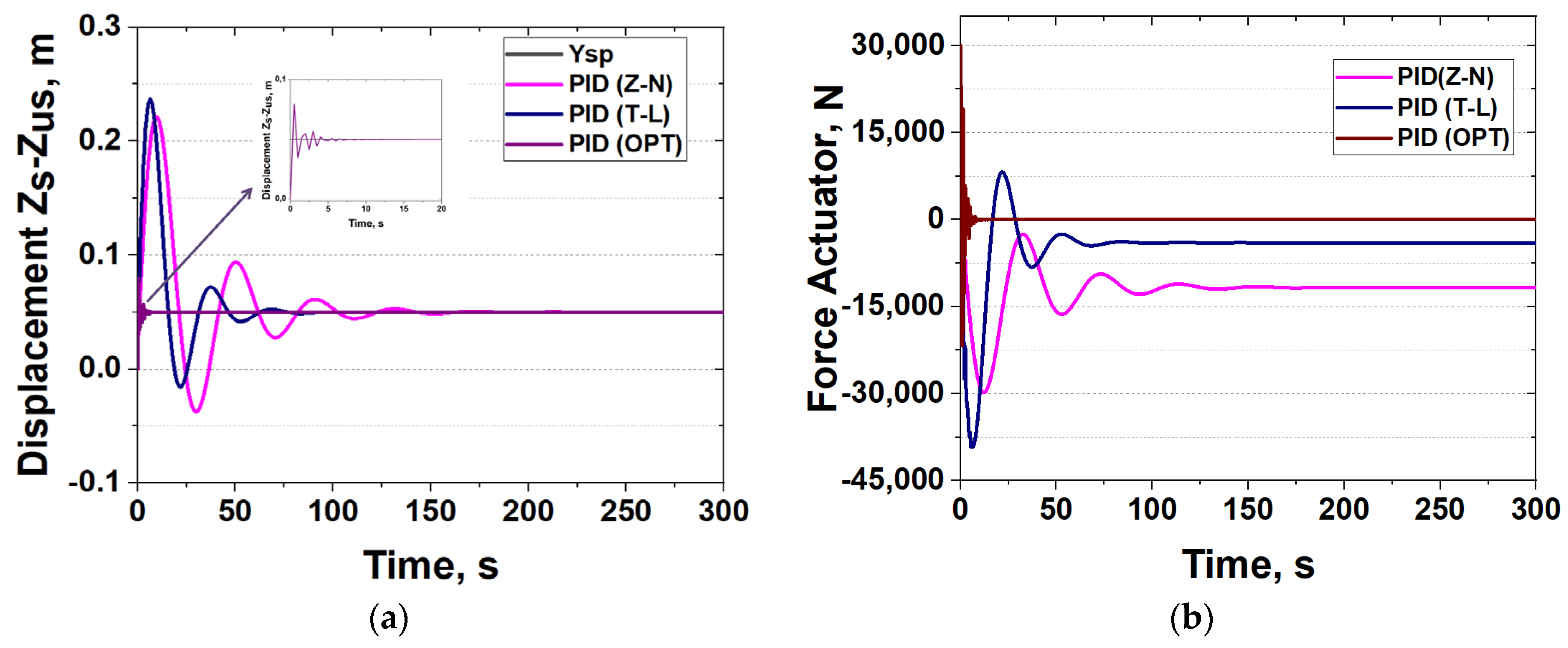

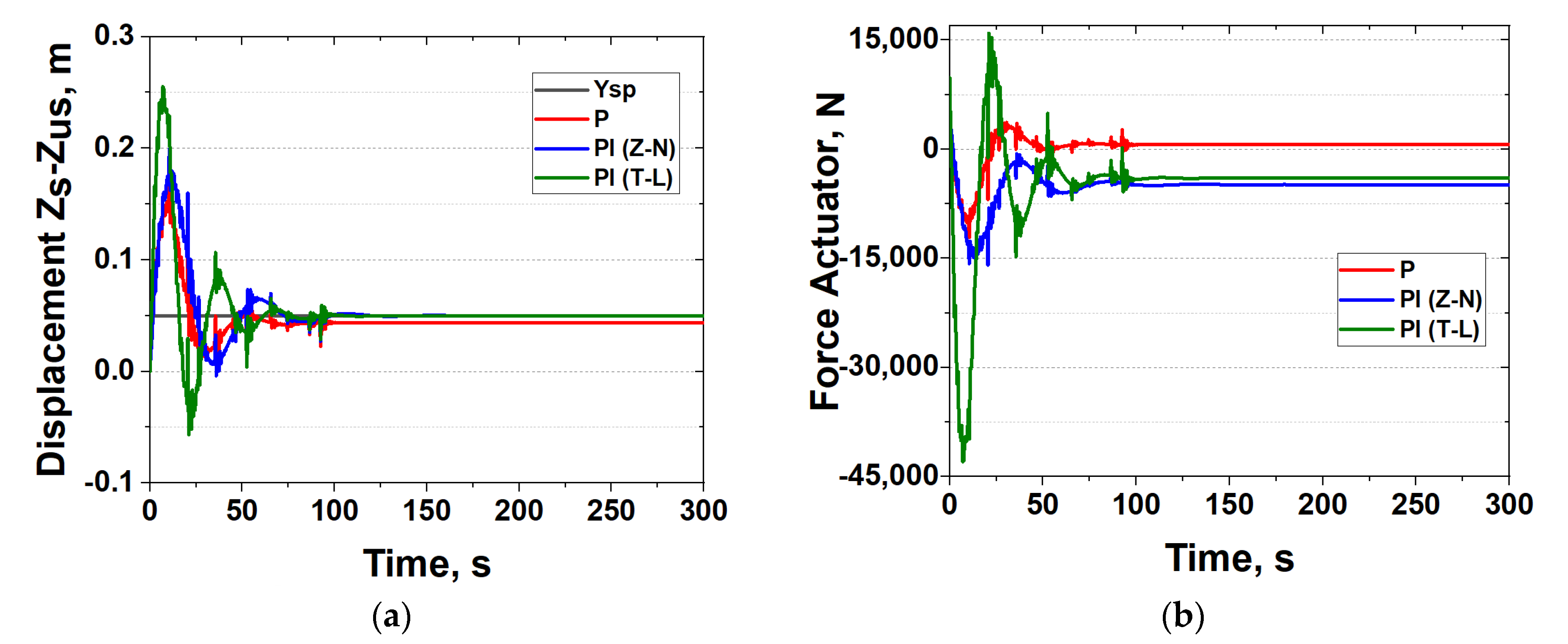

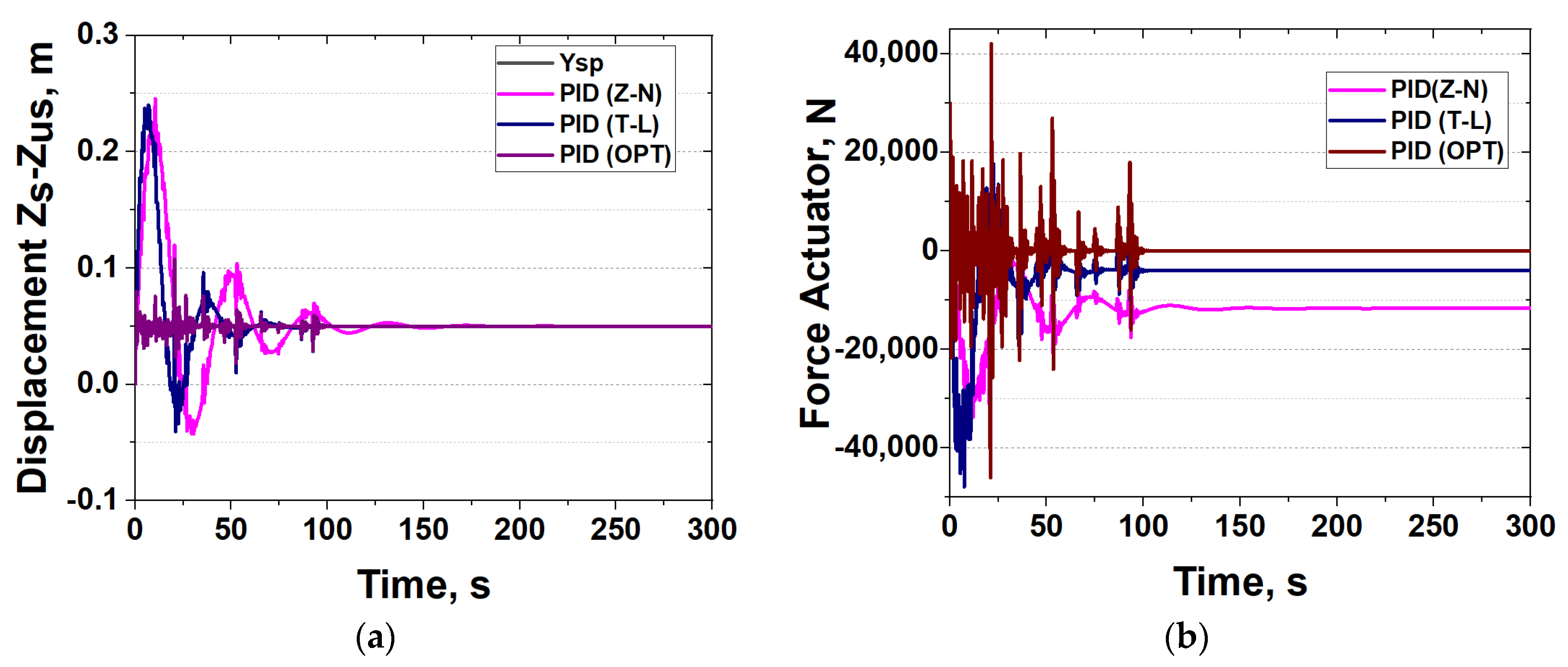

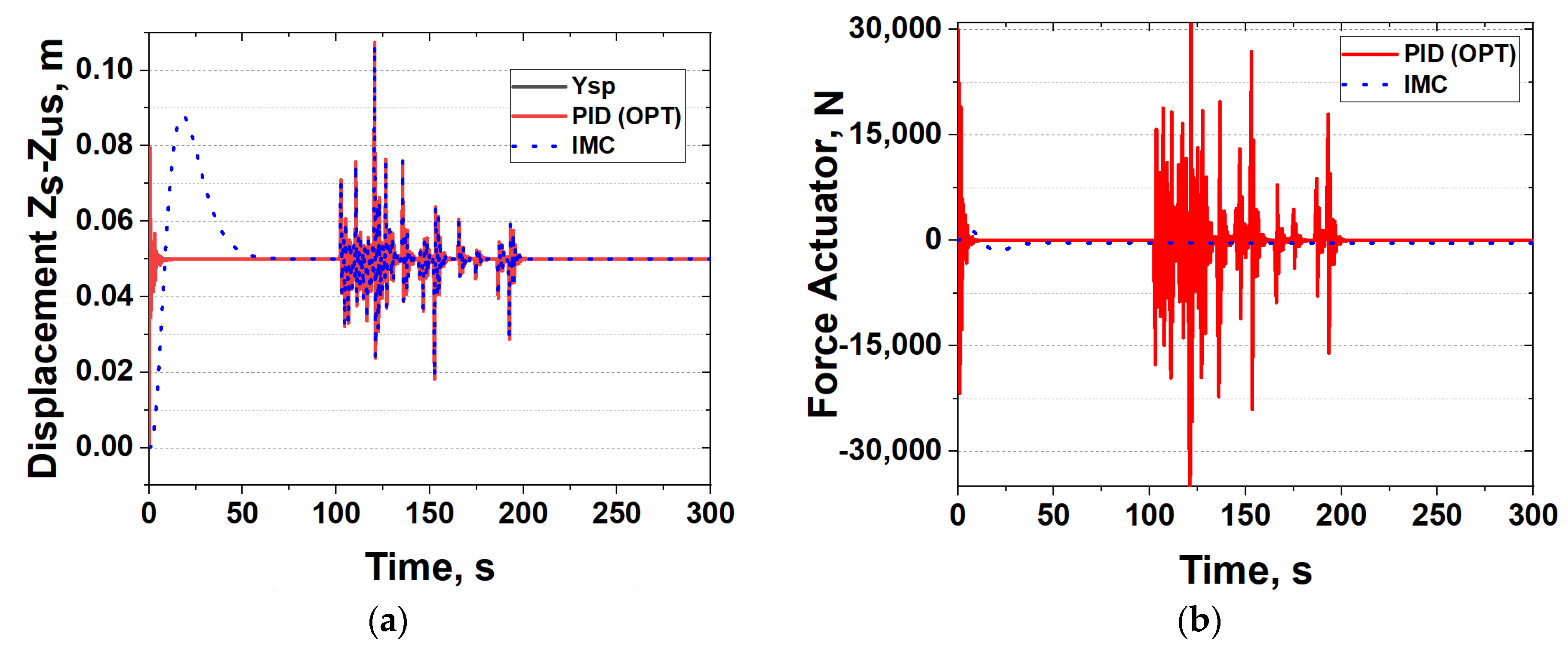

The core aim of this study was the establishment of a feedback control system for an active suspension system. The open loop simulations revealed that the presence of disturbances induces high overshoots and continuous oscillations that are persistent in time. With this indication in mind, the need for a control system design was verified. Next, the evaluation and comparison of three sets of feedback controllers took place: (a) P, PI and PID tuned controllers via the Ziegler–Nichols and Tyreus–Luyben methods, (b) an optimally tuned PID controller via genetic algorithms and (c) an internal model controller. Through a set of simulation scenarios that involved set-point tracking with and without the effect of bumps and holes (road disturbances), it was shown that the optimally tuned PID and IMC controllers exhibit a superior performance in terms of ride comfort and minimum control actions. Among the two, the IMC controller exhibited the lowest (overall) action from the actuator, whereas the optimal PID controller presented the best results for the performance criteria of errors, peak overshoots and settling and rise times, but with extreme mechanical effort from the actuator elements.

Future studies regarding the effective control of active suspension systems should involve the application of advanced methodologies such as model predictive control. This way, the optimal action from the actuator could be applied in order to sustain a predefined trajectory despite emerged disturbances. Furthermore, the application of the most crucial research findings could be implemented using lab hardware equipment, which could involve a similar mechanical structure accompanied by automation utilities.