Evaluation of Hydrogen Addition on Combustion and Emission Characteristics of Dual-Fuel Diesel Engines with Different Compression Ratios

Abstract

:1. Introduction

2. Numerical Method and Modelling Setup

2.1. Calculation Principles

2.1.1. Fluid Dynamics Governing Equations

2.1.2. Modeling and Simulation Flowchart

2.2. Modelling and Numerical Setup

2.2.1. Turbulence Model

2.2.2. Spray Model

2.2.3. Combustion Model

2.2.4. Other Models

2.3. Model Setup and Validation

2.3.1. Model Setup

2.3.2. Computational Mesh Study

3. Experiment Cases and Engine Setup

3.1. Fuel Properties

3.2. Engine Specification

3.3. Experimental and Simulation Plan

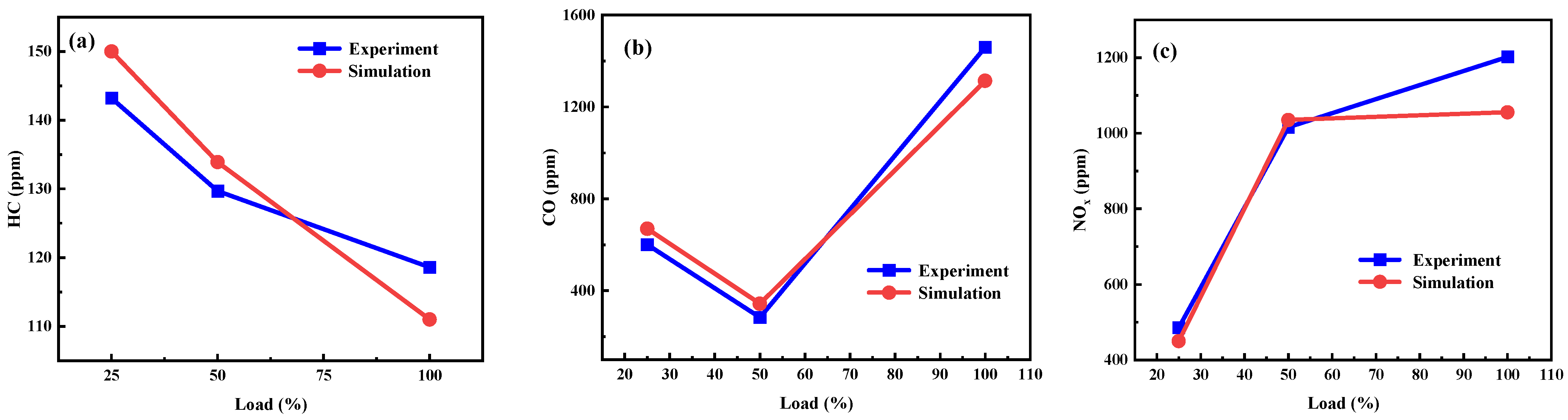

3.4. Model Validation

3.5. Error and Uncertainty Analysis

4. Results and Discussions

4.1. Combustion Characteristics

4.1.1. In-Cylinder Pressure

4.1.2. Heat Release Rate (HRR)

4.1.3. In-Cylinder Temperature

4.2. Emission Characteristic

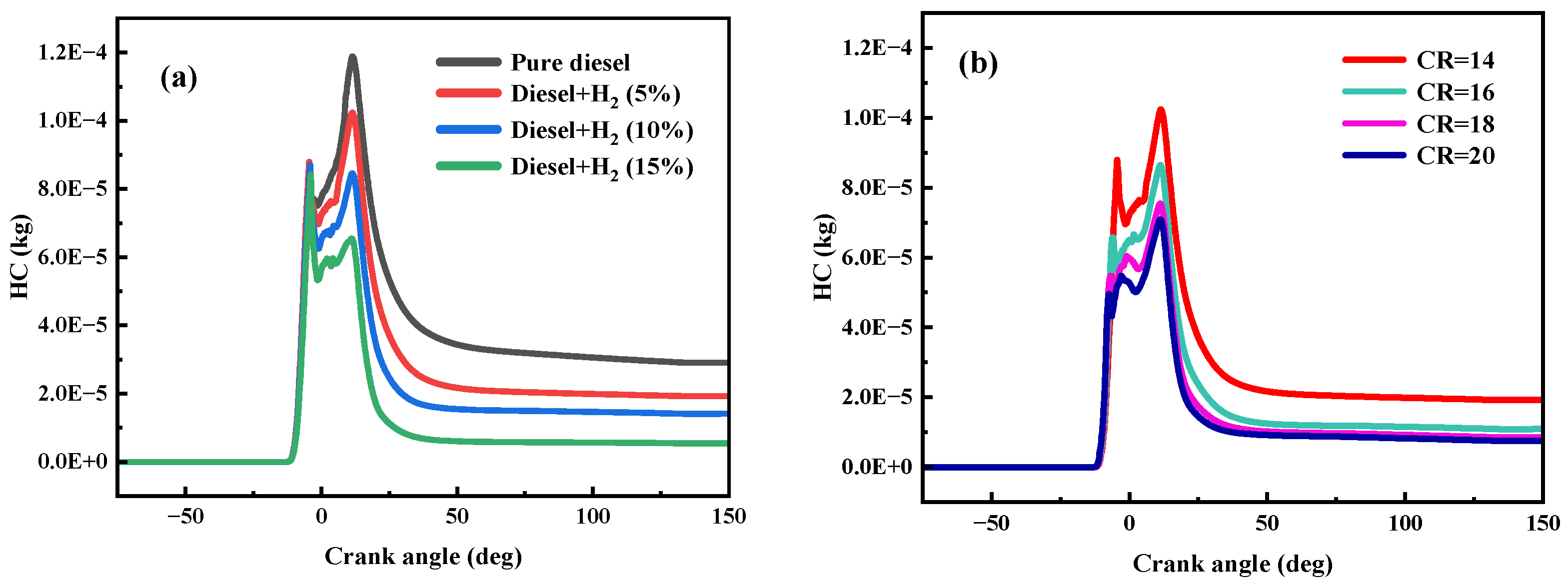

4.2.1. HC Emission

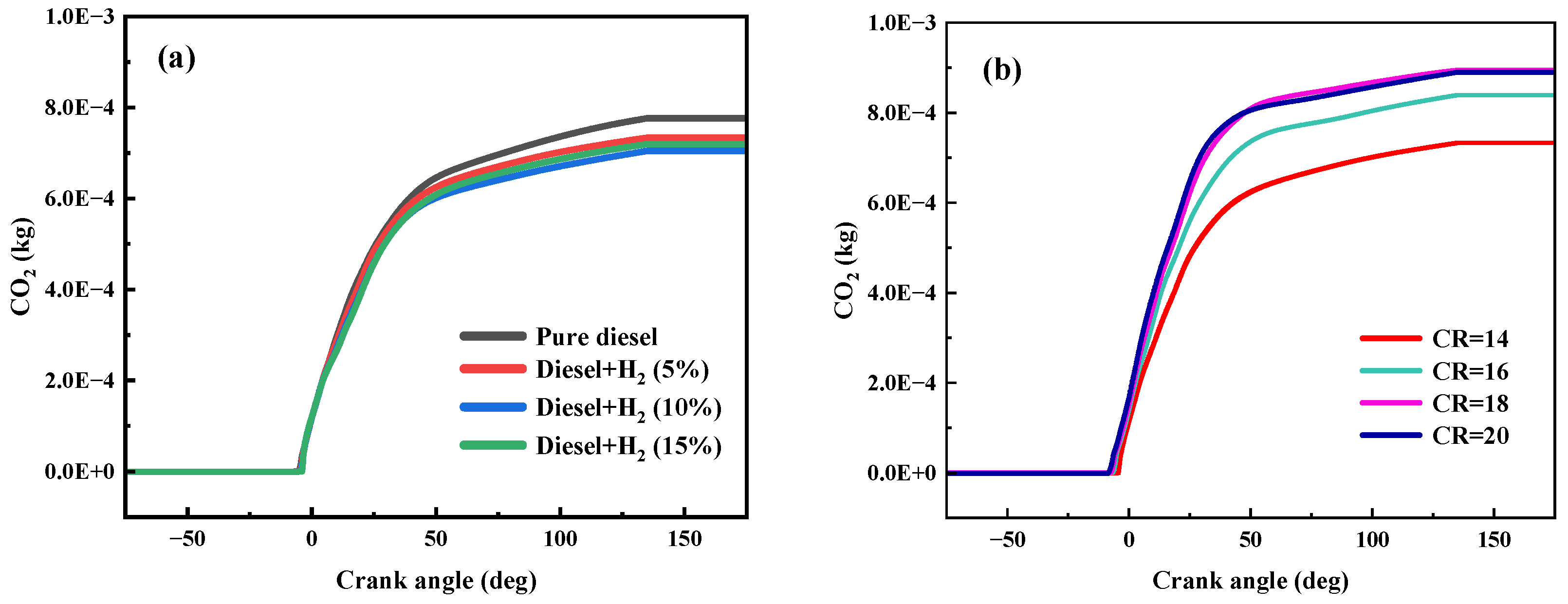

4.2.2. CO and CO2 Emissions

4.2.3. NOx Emission

4.2.4. Soot Emission

5. Conclusions

- (1)

- Hydrogenation improves combustion characteristics. The in-cylinder pressure increased by 10.54% when the HES reached 15% compared to when no hydrogen was added. And, the in-cylinder temperature increased by 15.11%. Hydrogenation is also good for improving emission characteristics. HC emission, CO emission, CO2 emission, and soot emission can be reduced.

- (2)

- Increasing CR has benefits for both combustion characteristics and emission characteristics. The simulation results show that the in-cylinder pressure and in-cylinder temperature increased by 66.10% and 13.09%, respectively, when the CR rose from 14 to 20 at the HES of 5%.

- (3)

- It should be also noted that NOx emission increased after hydrogenation, which is one of the biggest problems after hydrogenation. Higher in-cylinder temperatures and in-cylinder pressures lead to increased NOx emission.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Hassan, Q.; Sameen, A.; Olapade, O.; Alghoul, M.; Salman, H.; Jaszczur, M. Hydrogen fuel as an important element of the energy storage needs for future smart cities. Int. J. Hydrogen Energy 2023, in press. [Google Scholar] [CrossRef]

- Guan, Y.; Zhao, D. Enhancing ammonia combustion with minimum hydrogen blended in presence of self-excited intermittent pulsating oscillations. Phys. Fluids 2023, 35, 054102. [Google Scholar] [CrossRef]

- Muniyappan, M.; Tamil, P.S.; Gopi, P.; Shanmugam, M.; Bhuvendran, A.; Shaisundaram, V.S. Hydrogen behavior in dual fuel mode diesel engine with nano diesel. Mater. Today 2021, 37, 2401–2405. [Google Scholar] [CrossRef]

- Roy, A.; Pramanik, S. A review of the hydrogen fuel path to emission reduction in the surface transport industry. Int. J. Hydrogen Energy 2023, in press. [Google Scholar] [CrossRef]

- Tarafdar, A.; Majumder, P.; Deb, M.; Bera, U.K. Performance-emission optimization in a single cylinder CI-engine with diesel hydrogen dual fuel: A spherical fuzzy MARCOS MCGDM based Type-3 fuzzy logic approach. Int. J. Hydrogen Energy 2023, in press. [Google Scholar] [CrossRef]

- Lalsangi, S.; Yaliwal, V.S.; Banapurmath, N.R.; Soudagar, M.E.M.; Ağbulut, Ü.; Kalam, M.A. Analysis of CRDI diesel engine characteristics operated on dual fuel mode fueled with biodiesel-hydrogen enriched producer gas under the single and multi-injection scheme. Int. J. Hydrogen Energy 2023, in press. [Google Scholar] [CrossRef]

- Shi, Z.; Peng, Q.; E, J.; Xie, B.; Wei, J.; Yin, R.; Wei, J.; Yin, R.; Fu, G. Mechanism, performance and modification methods for NH3-SCR catalysts: A review. Fuel 2023, 331, 125885. [Google Scholar] [CrossRef]

- Ye, J.; Peng, Q. Improved emissions conversion of diesel oxidation catalyst using multifactor impact analysis and neural network. Energy 2023, 271, 127048. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, R.; Tan, D.; Duan, L.; Jiang, F.; Yao, X.; Yang, D.; Hu, J.; Zhong, W.; Zhao, Z. Effect of structural parameters on diesel particulate filter trapping performance of heavy-duty diesel engines based on grey correlation analysis. Energy 2023, 271, 127025. [Google Scholar] [CrossRef]

- Barik, D.; Bora, B.J.; Sharma, P.; Medhi, B.J.; Balasubramanian, D.; Krupakaran, R.L.; Ramegowda, R.; Kavalli, K.; Josephin, F.; Vikneswaran, M.; et al. Exploration of the dual fuel combustion mode on a direct injection diesel engine powered with hydrogen as gaseous fuel in port injection and diesel-diethyl ether blend as liquid fuel. Int. J. Hydrogen Energy 2023, in press. [Google Scholar] [CrossRef]

- Nag, S.; Dhar, A.; Gupta, A. Hydrogen-diesel co-combustion characteristics, vibro-acoustics and unregulated emissions in EGR assisted dual fuel engine. Fuel 2022, 307, 121925. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Tan, D.; Feng, Z.; Luo, J.; Tan, Y.; Hu, Y. The effects of Fe2O3 based DOC and SCR catalyst on the combustion and emission characteristics of a diesel engine fueled with biodiesel. Fuel 2021, 290, 120039. [Google Scholar] [CrossRef]

- Liu, Z.; Luo, J.; Pan, Y.; Li, J.; Li, L.; Wei, X.; Xu, H.; Tie, Y.; Zhang, C.; Yang, D. Multi-objective optimization of the performance and emission characteristics for a dual-fuel engine with hydrogen addition. Fuel 2023, 332, 126231. [Google Scholar] [CrossRef]

- Raju, P.; Masimalai, S.K.; Ganesan, N.; Karthic, S.V. Engine’s behavior on hydrogen addition of waste cooking oil fueled light duty diesel engine—A dual fuel approach. Energy 2020, 194, 116844. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Deng, Y.; MinhHieu, P.; Zuo, W.; Peng, Y.; Yin, Z. Effects of fatty acid methyl esters proportion on combustion and emission characteristics of a biodiesel fueled marine diesel engine. Energy Convers. Manag. 2018, 159, 244–253. [Google Scholar] [CrossRef]

- Tripathi, G.; Sharma, P.; Dhar, A. Computational study of diesel injection strategies for methane-diesel dual fuel engine. Eng. Technol. 2022, 6, 100393. [Google Scholar] [CrossRef]

- Tan, D.; Meng, Y.; Tian, J.; Zhang, C.; Zhang, Z.; Yang, G.; Cui, X.; Hu, J.; Zhao, Z. Utilization of renewable and sustainable diesel/methanol/n-butanol (DMB) blends for reducing the engine emissions in a diesel engine with different pre-injection strategies. Energy 2023, 269, 126785. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/alcohol/ n-butanol blends. Fuel 2022, 314, 123975. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Z.; Hou, X.; Lv, J.; Lan, G.; Yang, G.; Hu, J. The environmental potential of hydrogen addition as complementation for diesel and biodiesel: A comprehensive review and perspectives. Fuel 2023, 342, 127794. [Google Scholar] [CrossRef]

- Kumar, M.V.; Babu, A.V.; Kumar, P.R. Experimental investigation on the effects of diesel and mahua biodiesel blended fuel in direct injection diesel engine modified by nozzle orifice diameters. Renew. Energ. 2018, 119, 388–399. [Google Scholar] [CrossRef]

- Kumar, M.V.; Reddy, T.S.; Reddy, C.R.; Reddy, S.; Alsharef, M.; Alharbi, Y.; Alamri, B. Impact of a Thermal Barrier Coating in Low Heat Rejection Environment Area of a Diesel Engine. Sustainability 2022, 14, 15801. [Google Scholar] [CrossRef]

- Chintala, V.; Subramanian, K.A. Hydrogen energy share improvement along with NOx (oxides of nitrogen) emission reduction in a hydrogen dual-fuel compression ignition engine using water injection. Energy Convers. Manag. 2014, 83, 249–259. [Google Scholar] [CrossRef]

- Nag, S.; Sharma, P.; Gupta, A.; Dhar, A. Experimental study of engine performance and emissions for hydrogen diesel dual fuel engine with exhaust gas recirculation. Energy Convers. Manag. 2019, 44, 12163–12175. [Google Scholar] [CrossRef]

- Suzuki, Y.; Tsujimura, T.; Mita, T. The Performance of Multi-Cylinder Hydrogen/Diesel Dual Fuel Engine. SAE Int. J. Engines 2015, 8, 2240–2252. [Google Scholar] [CrossRef]

- Seelam, N.; Gugulothu, S.K.; Reddy, R.V.; Bhasker, B.; Panda, J.K. Exploration of engine characteristics in a CRDI diesel engine enriched with hydrogen in dual fuel mode using toroidal combustion chamber. Int. J. Hydrogen Energy 2022, 47, 13157–13167. [Google Scholar] [CrossRef]

- Ekin, F.; Ozsoysal, O.A.; Arslan, H. The effect of using hydrogen at partial load in a diesel-natural gas dual fuel engine. Int. J. Hydrogen Energy 2022, 47, 18532–18550. [Google Scholar] [CrossRef]

- Chintala, V.; Subramanian, K.A. CFD analysis on effect of localized in-cylinder temperature on nitric oxide (NO) emission in a compression ignition engine under hydrogen-diesel dual-fuel mode. Energy 2016, 116, 470–488. [Google Scholar] [CrossRef]

- Saravana, N.; Nagarajan, G.; Kalaiselvan, K.M.; Dhanasekaran, C. An experimental investigation on hydrogen as a dual fuel for diesel engine system with exhaust gas recirculation technique. Renew. Energy 2008, 33, 422–427. [Google Scholar] [CrossRef]

- Sathishkumar, S.; Ibrahim, M.M. Investigation on the effect of injection schedule and EGR in hydrogen energy share using common rail direct injection dual fuel engine. Int. J. Hydrogen Energy 2021, 46, 11494–11510. [Google Scholar] [CrossRef]

- Zhang, Z.; Lv, J.; Xie, G.; Wang, S.; Ye, Y.; Huang, G.; Tan, D. Effect of assisted hydrogen on combustion and emission characteristics of a diesel engine fueled with biodiesel. Energy 2022, 254, 124269. [Google Scholar] [CrossRef]

- Dimitriou, P.; Tsujimura, T.; Suzuki, Y. Low-load hydrogen-diesel dual-fuel engine operation—A combustion efficiency improvement approach. Int. J. Hydrogen Energy 2019, 44, 17048–17060. [Google Scholar] [CrossRef]

- Hamdan, M.O.; Selim, M.Y.E.; Al-Omari, S.; Elnajjar, E. Hydrogen supplement co-combustion with diesel in compression ignition engine. Renew. Energy 2015, 82, 54–60. [Google Scholar] [CrossRef]

- Jamrozik, A.; Grab-Rogaliński, K.; Tutak, W. Hydrogen effects on combustion stability, performance and emission of diesel engine. Int. J. Hydrogen Energy 2020, 45, 19936–19947. [Google Scholar] [CrossRef]

- Koten, H. Hydrogen effects on the diesel engine performance and emissions. Int. J. Hydrogen Energy 2018, 43, 10511–10519. [Google Scholar] [CrossRef]

- Juknelevičius, R.; Rimkus, A.; Pukalskas, S.; Matijošius, J. Research of performance and emission indicators of the compression-ignition engine powered by hydrogen—Diesel mixtures. Int. J. Hydrogen Energy 2019, 44, 10129–10138. [Google Scholar] [CrossRef]

- Karagöz, Y.; Sandalcı, T.; Yüksek, L.; Dalkılıç, A.S. Engine performance and emission effects of diesel burns enriched by hydrogen on different engine loads. Int. J. Hydrogen Energy 2015, 40, 6702–6713. [Google Scholar] [CrossRef]

- Rahman, M.A.; Ruhul, A.M.; Aziz, M.A.; Ahmed, R. Experimental exploration of hydrogen enrichment in a dual fuel CI engine with exhaust gas recirculation. Int. J. Hydrogen Energy 2017, 42, 5400–5409. [Google Scholar] [CrossRef]

- Ghazal, O.H. Performance and combustion characteristic of CI engine fueled with hydrogen enriched diesel. Int. J. Hydrogen Energy 2013, 38, 15469–15476. [Google Scholar] [CrossRef]

- Juknelevicius, R.; Szwaja, S.; Pyrc, M.; Gruca, M. Influence of hydrogen co-combustion with diesel fuel on performance, smoke and combustion phases in the compression ignition engine. Int. J. Hydrogen Energy 2019, 44, 19026–19034. [Google Scholar] [CrossRef]

- Kumar, A.; Bhushan, K.C.; Lata, D.B. Effect of hydrogen enrichment on exhaust gas temperature and emission of a dual fuel diesel engine. Mater. Today 2023, 72, 631–635. [Google Scholar] [CrossRef]

- Castro, N.; Toledo, M.; Amador, G. An experimental investigation of the performance and emissions of a hydrogen-diesel dual fuel compression ignition internal combustion engine. Appl. Therm. Eng. 2019, 156, 660–667. [Google Scholar] [CrossRef]

- Verma, S.; Das, L.M.; Kaushik, S.C.; Bhattii, S.S. The effects of compression ratio and EGR on the performance and emission characteristics of diesel-biogas dual fuel engine. Appl. Therm. Eng. 2019, 150, 1090–1103. [Google Scholar] [CrossRef]

- Dahake, M.R.; Malkhede, D.N. Experimental investigation of performance and emissions of CRDI diesel engine in dual fuel mode by hydrogen induction and diesel injection coupled with exhaust gas recirculation. Mater. Today 2021, 46, 2814–2819. [Google Scholar] [CrossRef]

- Tan, D.; Wu, Y.; Lv, J.; Li, J.; Ou, X.; Meng, Y.; Lan, G.; Chen, Y.; Zhang, Z. Performance optimization of a diesel engine fueled with hydrogen/biodiesel with water addition based on the response surface methodology. Energy 2023, 263, 125869. [Google Scholar] [CrossRef]

- Kumar, M.; Bhowmik, S.; Paul, A. Effect of pilot fuel injection pressure and injection timing on combustion, performance and emission of hydrogen-biodiesel dual fuel engine. Int. J. Hydrogen Energy 2022, 47, 29554–29567. [Google Scholar] [CrossRef]

- Karimi, M.; Wang, X.; Hamilton, J.; Negnevitsky, M. Numerical investigation on hydrogen-diesel dual-fuel engine improvements by oxygen enrichment. Int. J. Hydrogen Energy 2022, 47, 25418–25432. [Google Scholar] [CrossRef]

- Dimitriou, P.; Kumar, M.; Tsujimura, T.; Suzuki, Y. Combustion and emission characteristics of a hydrogen-diesel dual-fuel engine. Int. J. Hydrogen Energy 2018, 43, 13605–13617. [Google Scholar] [CrossRef]

- Verma, S.; Suman, A.; Das, L.M.; Kaushik, S.C.; Tyagi, S.K. A renewable pathway towards increased utilization of hydrogen in diesel engines. Int. J. Hydrogen Energy 2020, 45, 5577–5587. [Google Scholar] [CrossRef]

- Kumar, M.; Babu, A.; Reddy, C.; Pandian, A.; Bajaj, M.; Zawbaa, H.; Kamel, S. Investigation of the combustion of exhaust gas recirculation in diesel engines with a particulate filter and selective catalytic reactor technologies for environmental gas reduction. Case Stud. Therm. Eng. 2022, 40, 102557. [Google Scholar] [CrossRef]

- Gürbüz, H. Analysis of the effects of multiple injection strategies with hydrogen on engine performance and emissions in diesel engine. Int. J. Hydrogen Energy 2020, 45, 27969–27978. [Google Scholar] [CrossRef]

- Tripathi, G.; Sharma, P.; Dhar, A.; Sadiki, A. Computational investigation of diesel injection strategies in hydrogen-diesel dual fuel engine. Sustain. Energy Techn. 2019, 36, 100543. [Google Scholar] [CrossRef]

- Yusri, I.M.; Abdul, M.A.; Mamat, R.; Ghazali, M.F.; Awad, O.I.; Azmi, W.H. A review on the application of response surface method and artificial neural network in engine performance and exhaust emissions characteristics in alternative fuel. Renew. Sust. Energ. Rev. 2018, 90, 665–686. [Google Scholar] [CrossRef]

- Goyal, D.; Goyal, T.; Mahla, S.K.; Goga, G.; Dhir, A.; Balasubramanian, D.; Hoang, A.T.; Wae-Hayee, M.; Josephin, J.S.F.; Sonthalia, A.; et al. Application of Taguchi design in optimization of performance and emissions characteristics of n-butanol/diesel/biogas under dual fuel mode. Fuel 2023, 338, 127246. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, A.K. Application of Response Surface Methodology for Optimization of Fuel Injection Parameters of a Dual Fuel Engine Fuelled with Producer Gas-Biodiesel blends. Energ. Source. Part A. 2021. [Google Scholar] [CrossRef]

- Bora, B.J.; Tran, T.D.; Shadangi, K.P.; Sharma, P.; Said, Z.; Kalita, P.; Buradi, A.; Nguyen, V.N.; Niyas, H.; Pham, M.T.; et al. Improving combustion and emission characteristics of a biogas/biodiesel-powered dual-fuel diesel engine through trade-off analysis of operation parameters using response surface methodology. Sustain. Energy Technol. Assess. 2022, 53, 102455. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, J.; Tan, D.; Li, J.; Jiang, F.; Yao, X.; Yang, D.; Ye, Y.; Zhao, Z.; Yang, G. Multi-objective optimization of the three-way catalytic converter on the combustion and emission characteristics for a gasoline engine. Energy 2023, 277, 127634. [Google Scholar] [CrossRef]

- Wang, H.; Gan, H.; Wang, G.; Zhong, G. Emission and Performance Optimization of Marine Four-Stroke Dual-Fuel Engine Based on Response Surface Methodology. Math. Probl. Eng. 2020, 2020, 5268314. [Google Scholar] [CrossRef]

- Lotfan, S.; Ghiasi, R.A.; Fallah, M.; Sadeghi, M.H. ANN-based modeling and reducing dual-fuel engine’s challenging emissions by multi-objective evolutionary algorithm NSGA-II. Appl. Energy 2016, 175, 91–99. [Google Scholar] [CrossRef]

- Yu, W.; Zhao, F. Predictive study of ultra-low emissions from dual-fuel engine using artificial neural networks combined with genetic algorithm. Int. J. Green Energy 2019, 16, 938–946. [Google Scholar] [CrossRef]

- Xiang, L.; Theotokatos, G.; Ding, Y. Parametric investigation on the performance-emissions trade-off and knocking occurrence of dual fuel engines using CFD. Fuel 2023, 340, 127535. [Google Scholar] [CrossRef]

- Zhang, Z.; Lv, J.; Li, W.; Long, J.; Wang, S.; Tan, D.; Yin, Z. Performance and emission evaluation of a marine diesel engine fueled with natural gas ignited by biodiesel-diesel blended fuel. Energy 2022, 256, 124662. [Google Scholar] [CrossRef]

- Zareei, J.; Haseeb, M.; Ghadamkheir, K.; Farkhondeh, S.A.; Yazdani, A.; Ershov, K. The effect of hydrogen addition to compressed natural gas on performance and emissions of a DI diesel engine by a numerical study. Int. J. Hydrogen Energy 2020, 45, 34241–34253. [Google Scholar] [CrossRef]

- Saravanan, N.; Nagarajan, G. Experimental investigation on a DI dual fuel engine with hydrogen injection. Int. J. Energy Res. 2009, 33, 295–308. [Google Scholar] [CrossRef]

- Raza, A.; Arif, M.; Glatz, G.; Mahmoud, M.; Al Kobaisi, M.; Alafnan, S.; Stefan, I. A holistic overview of underground hydrogen storage: Influencing factors, current understanding, and outlook. Fuel 2022, 330, 125336. [Google Scholar] [CrossRef]

- Cernat, A.; Pana, C.; Negurescu, N.; Nutu, C.; Fuiorescu, D.; Lazaroiu, G. Aspects of an experimental study of hydrogen use at automotive diesel engine. Heliyon 2023, 9, e13889. [Google Scholar] [CrossRef]

- Joseph, S.; Shanmugaiah, K.; Sonthalia, A.; Devarajan, Y.; Varuvel, E.G. Application of machine learning algorithms for predicting the engine characteristics of a wheat germ oil–Hydrogen fuelled dual fuel engine. Int. J. Hydrogen Energy 2023, 48, 23308–23322. [Google Scholar] [CrossRef]

- Khandal, S.V.; Ağbulut, Ü.; Afzal, A.; Sharifpur, M.; Abdul Razak, K.; Khalilpoor, N. Influences of hydrogen addition from different dual-fuel modes on engine behaviors. Energy Sci. Eng. 2022, 10, 881–891. [Google Scholar] [CrossRef]

- Sharma, P.; Dhar, A. Compression ratio influence on combustion and emissions characteristic of hydrogen diesel dual fuel CI engine: Numerical Study. Fuel 2018, 222, 852–858. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, S.; Wang, H. Computational investigation of combustion, performance, and emissions of a diesel-hydrogen dual-fuel engine. Sustainability 2023, 15, 3610. [Google Scholar] [CrossRef]

- Bakar, R.A.; Widudo; Kadirgama, K.; Ramasamy, D.; Yusaf, T.; Kamarulzaman, M.K.; Sivaraos; Aslfattahi, N.; Samylingam, L.; Alwayzy, S.H. Experimental analysis on the performance, combustion/emission characteristics of a DI diesel engine using hydrogen in dual fuel mode. Int. J. Hydrogen Energy 2022, in press. [Google Scholar] [CrossRef]

- Serrano, J.; Jiménez-Espadafor, F.J.; López, A. Analysis of the effect of different hydrogen/diesel ratios on the performance and emissions of a modified compression ignition engine under dual-fuel mode with water injection. Hydrogen-diesel dual-fuel mode. Energy 2019, 172, 702–711. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Zhong, Y.; Zou, Z.; Dong, R.; Gao, S.; Xu, W.; Tan, D. The effects of Mn-based catalysts on the selective catalytic reduction of NOx with NH3 at low temperature: A review. Fuel Process. Technol. 2022, 230, 107213. [Google Scholar] [CrossRef]

- Zhou, Y. AVL 415 Filter Paper Smoke Meter Internal Comprehensive Training. 2012. Available online: https://wenku.baidu.com/view/1a28d7174835eefdc8d376eeaeaad1f34793117a.html?_wkts_=1693928158169 (accessed on 17 June 2023).

| Models/Mechanisms | Sub-Model |

|---|---|

| Pilot injection | O′ Rurke |

| Spray break-up | KH-RT model [11] |

| Evaporation | Frossling model |

| Collision model | NTC model |

| Combustion | SAGE model [62] |

| Turbulence | RNG k- [63] |

| NOx formation | Extended Zeldovich Mechanism [64] |

| Soot formation | Hiroyasu-NSC soot model |

| Heat transfer | O’Rurke and Amsden |

| Base Grid Size | 1.25 mm | 2 mm | 4 mm | ||||

|---|---|---|---|---|---|---|---|

| Adaptive mesh refinement | Max embedding level | Sub-grid criterion | |||||

| Velocity | 2 | 2.0 | |||||

| Temperature | 2 | 5 | |||||

| Fixed embedding | Scale | Embed layers | |||||

| Nozzles | 2 | - | |||||

| Piston | 1 | 1 | |||||

| Head | 1 | 1 | |||||

| Parameter | Diesel | H2 [66] |

|---|---|---|

| Density (kg/m3, at 25 °C) | 833–881 | 0.0838 |

| Viscosity (Pa·s, at 25 °C) | 2.419 × 10−3 | 8.915 × 10−6 |

| Octane number (-) | 15–25 | >130 |

| Cetane number | 50 | -- |

| Critical temperature (K) | 736 | 33.19 |

| Critical pressure (Mpa) | -- | 1.313 |

| Auto-ignition temperature (K) | 530 | 858 |

| Theoretical air/fuel ratio (-) | 14.6 | 34.38 |

| Flammability range in the air (%) | 0.5–4.1 | 4.1–75 |

| Flame velocity in the air (cm/s) | 30 | 265–325 |

| Low calorific value (MJ/kg) | 42.8 | 120.1 |

| Parameter | Value |

|---|---|

| Combustion system | Four-stroke diesel with direct injection |

| Number of cylinders | 4 |

| Bore × stroke | 190 mm × 210 mm |

| Connecting rod length | 410 mm |

| Number of injector holes | 8 |

| Injection hole diameter | 0.26 mm |

| Swept volume | 23.82 L |

| Compression ratio | 14 |

| Engine speed | 1000 rpm |

| Torque | 210N·m |

| Effective power | 220 kW |

| Injection pressure | 40 MPa |

| Injection time | −15°CA |

| Exhaust valve opening | 58°BBDC |

| Exhaust valve closing | 56°ATDC |

| Intake valve opening | 66°BTDC |

| Intake valve closing | 54°ABDC |

| Parameter | Value | |||

|---|---|---|---|---|

| Engine speed | 1000 rpm | |||

| Mass of fuel injection | 49 mg | |||

| Intake pressure | 0.157 Mpa | |||

| Intake temperature | 313.15 K | |||

| Hydrogen energy share | 0% | 5% | 10% | 15% |

| Mass flow rate of H2 | 0 | 5.5 kg/h | 11.0 kg/h | 16.5 kg/h |

| Compression ratio | 14 | 16 | 18 | 20 |

| Device | Measured | Precision |

|---|---|---|

| Electric dynamometer | NIDY S22-2/05251BV-1 | Speed: ±2 r/min; Torque: ±0.8% F.S |

| Dynamometer control system | PUMA OPEN1.4.1 | ±0.8% FS |

| Diesel flowmeter | TOCEIL CMFG010 | 0.1% |

| Gas flowmeter | TOCEIL 20 N125 | ±0.8% |

| Temperature sensor | Thermojunction type | ±0.5 °C |

| Emission analyzer (Horiba MEXA-1600DS) | HC, CO, CO2, NOx | ±1.0% F.S |

| Combustion analyzer | DEWE-2010CA | -- |

| AVL GH13P Piezoelectric sensor | 0–25 MPa | ±0.3 kPa |

| AVL 415 S Filter Paper Smoke Measurement | Soot | ±0.1 FSN |

| No. | Parameters | Load % |

|---|---|---|

| 1 | Diesel | 100 |

| 2 | Diesel + H2 (0% 5% 10% 15%), CR = 14 | 100 |

| 3 | Diesel + H2 CR = 14, 16, 18, 20, HES = 5% | 100 |

| Measurements | Measuring Range | Accuracy | Uncertainty (%) |

|---|---|---|---|

| Engine speed | 1–2000 rpm | ±0.2% | ±0.25 |

| Pressure | 0–25 MPa | ±10 MPa | ±0.5 |

| Exhaust temperature | 0–2000 °C | ±0.5 °C | ±0.25 |

| NOx emission | 0–5000 ppm | ±10 ppm | ±0.48 |

| THC emission | 0–20,000 ppm | ±10 ppm | ±0.12 |

| CO emission | 0–10% vol | ±0.03% | ±0.38 |

| Soot emission | 0–9 FSN | ±0.1 FSN | ±3.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Li, Y.; Lv, J.; Liu, Z.; Gao, S.; Hu, J.; Zhang, J.; Zhong, W.; Zhao, Z. Evaluation of Hydrogen Addition on Combustion and Emission Characteristics of Dual-Fuel Diesel Engines with Different Compression Ratios. Processes 2023, 11, 2675. https://doi.org/10.3390/pr11092675

Wang S, Li Y, Lv J, Liu Z, Gao S, Hu J, Zhang J, Zhong W, Zhao Z. Evaluation of Hydrogen Addition on Combustion and Emission Characteristics of Dual-Fuel Diesel Engines with Different Compression Ratios. Processes. 2023; 11(9):2675. https://doi.org/10.3390/pr11092675

Chicago/Turabian StyleWang, Su, Youchang Li, Junshuai Lv, Zhonghang Liu, Sheng Gao, Jingyi Hu, Jian Zhang, Weihuang Zhong, and Ziheng Zhao. 2023. "Evaluation of Hydrogen Addition on Combustion and Emission Characteristics of Dual-Fuel Diesel Engines with Different Compression Ratios" Processes 11, no. 9: 2675. https://doi.org/10.3390/pr11092675

APA StyleWang, S., Li, Y., Lv, J., Liu, Z., Gao, S., Hu, J., Zhang, J., Zhong, W., & Zhao, Z. (2023). Evaluation of Hydrogen Addition on Combustion and Emission Characteristics of Dual-Fuel Diesel Engines with Different Compression Ratios. Processes, 11(9), 2675. https://doi.org/10.3390/pr11092675