Homogeneous Field Measurement and Simulation Study of Injector Nozzle Internal Flow and Near-Field Spray

Abstract

1. Introduction

2. Experimental and Simulation Methods

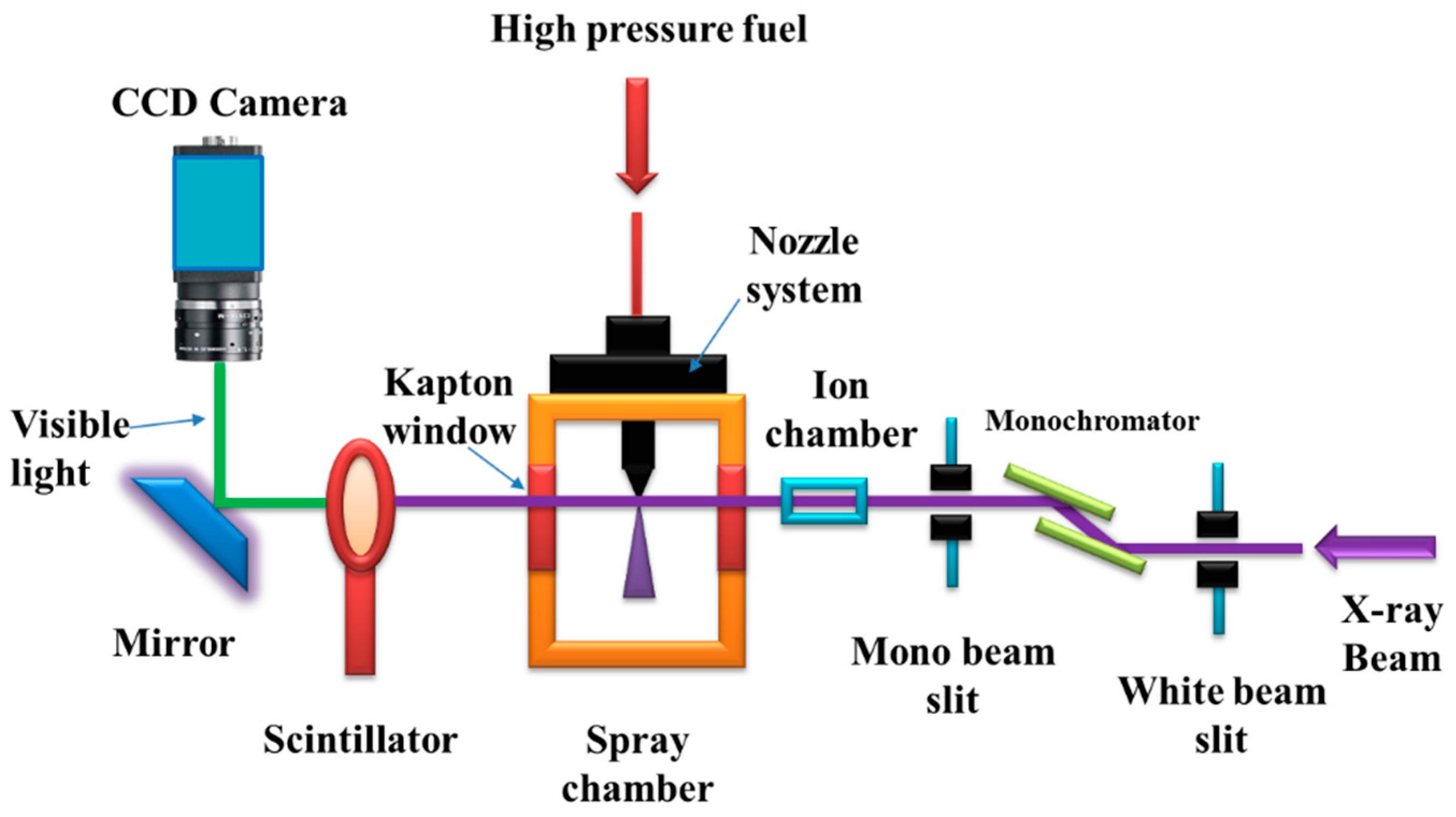

2.1. X-ray Phase Contrast Imaging (XPCI)

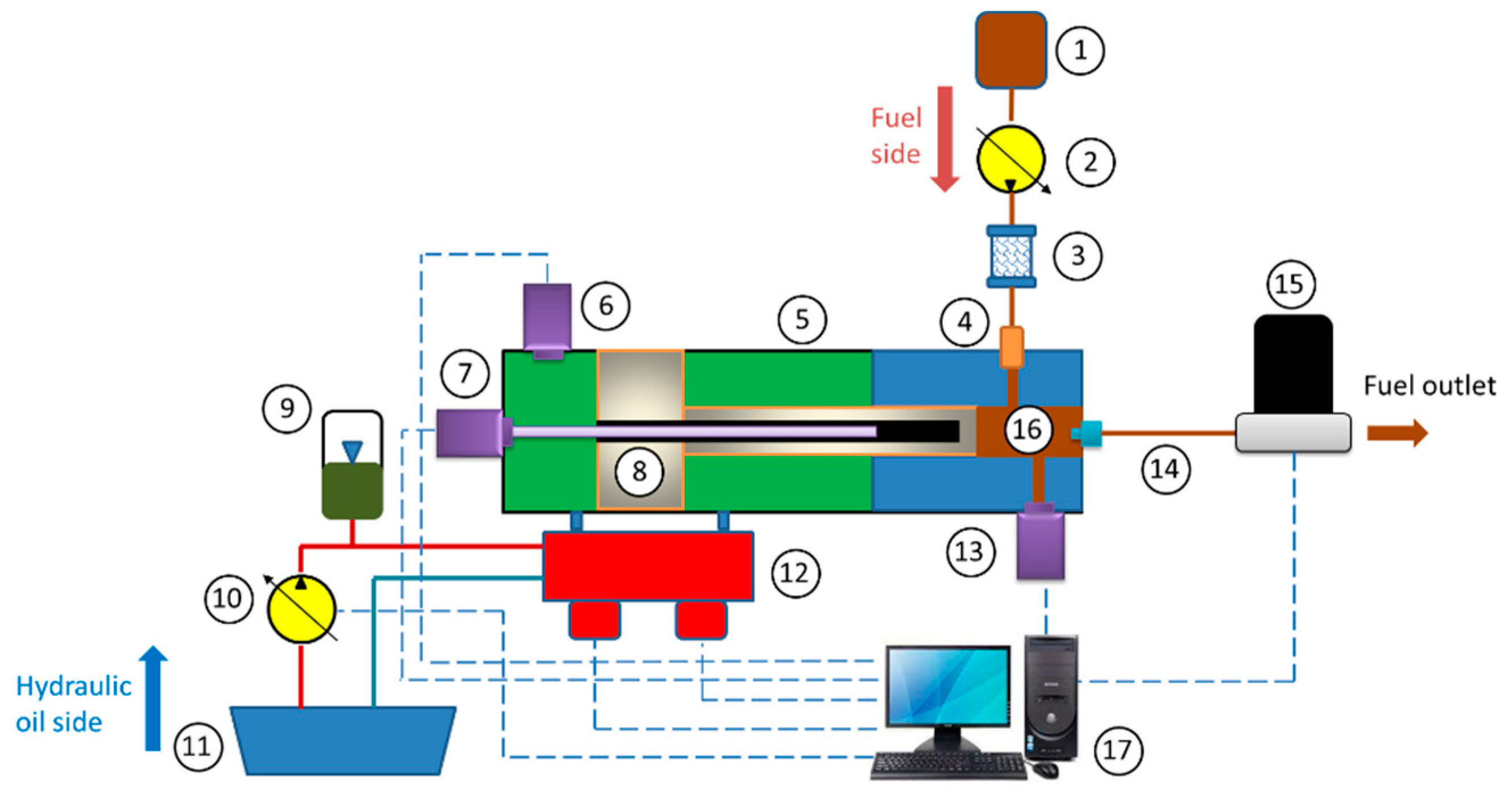

2.2. Aluminum Alloy Nozzle and High-Pressure Injection System

2.3. Simulation Method

3. Experiment Result

3.1. Digital Image Processing

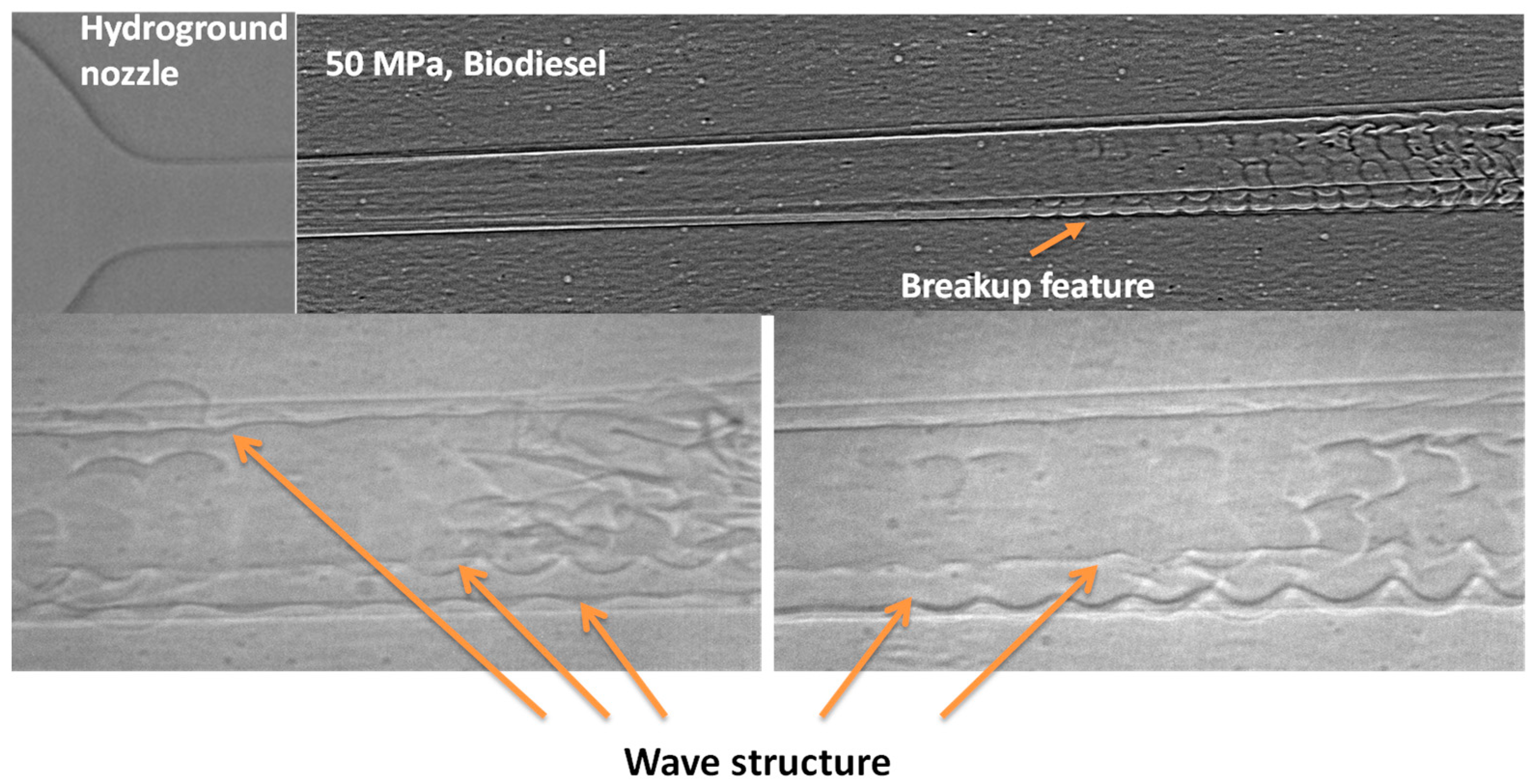

3.2. Internal Flow and Jet Characterization

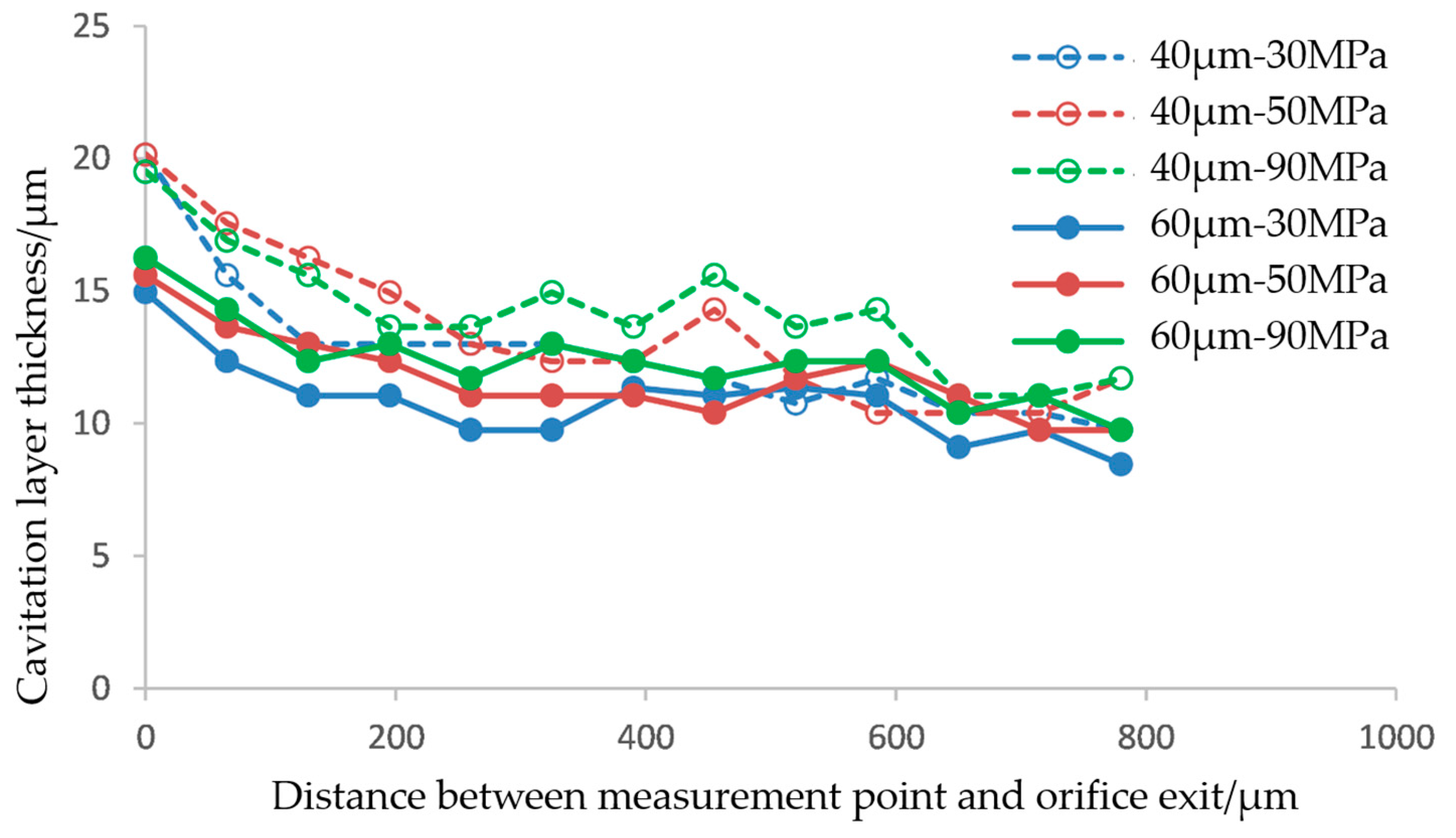

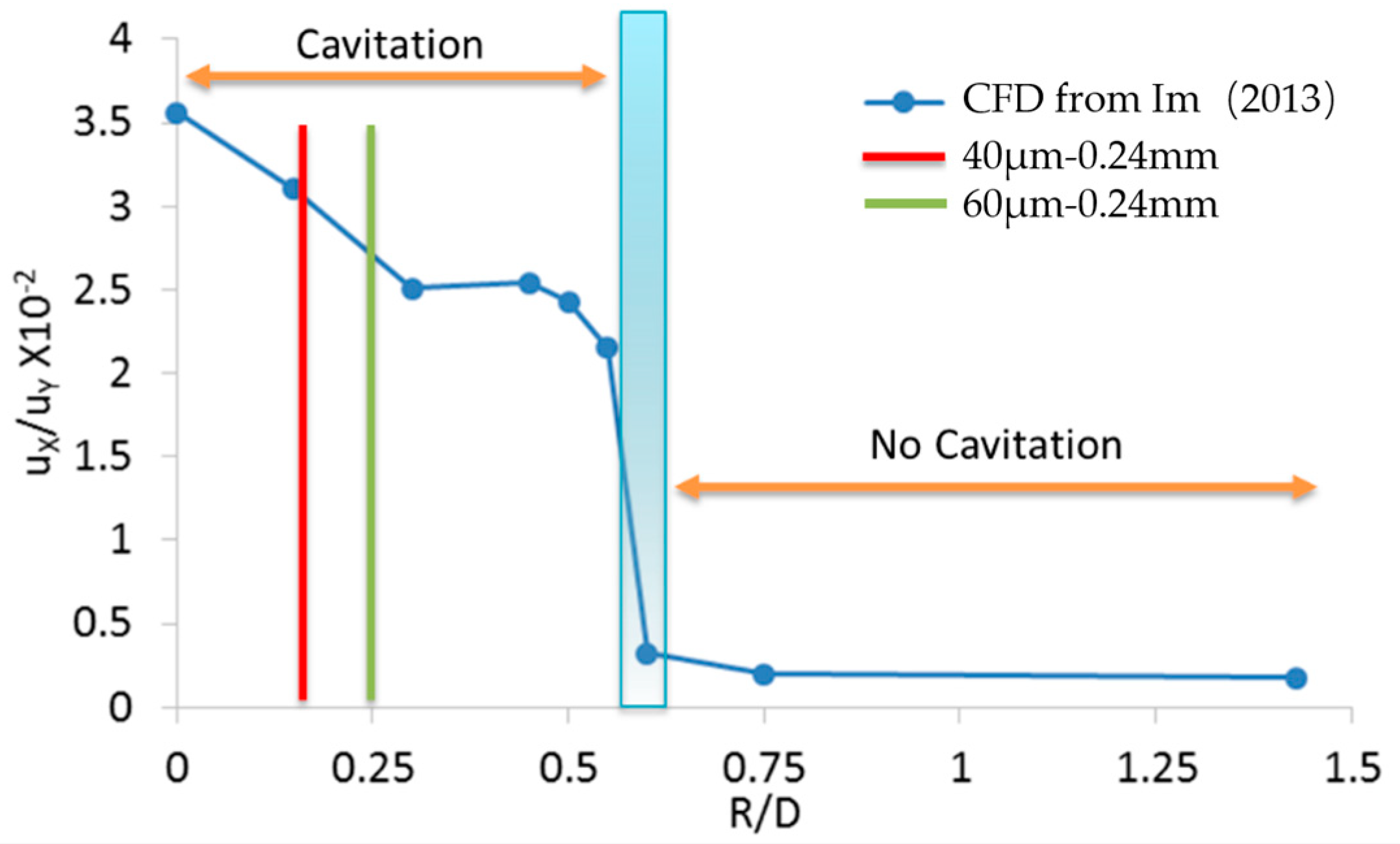

3.3. Quantitative Cavitation Layer Thickness Analysis

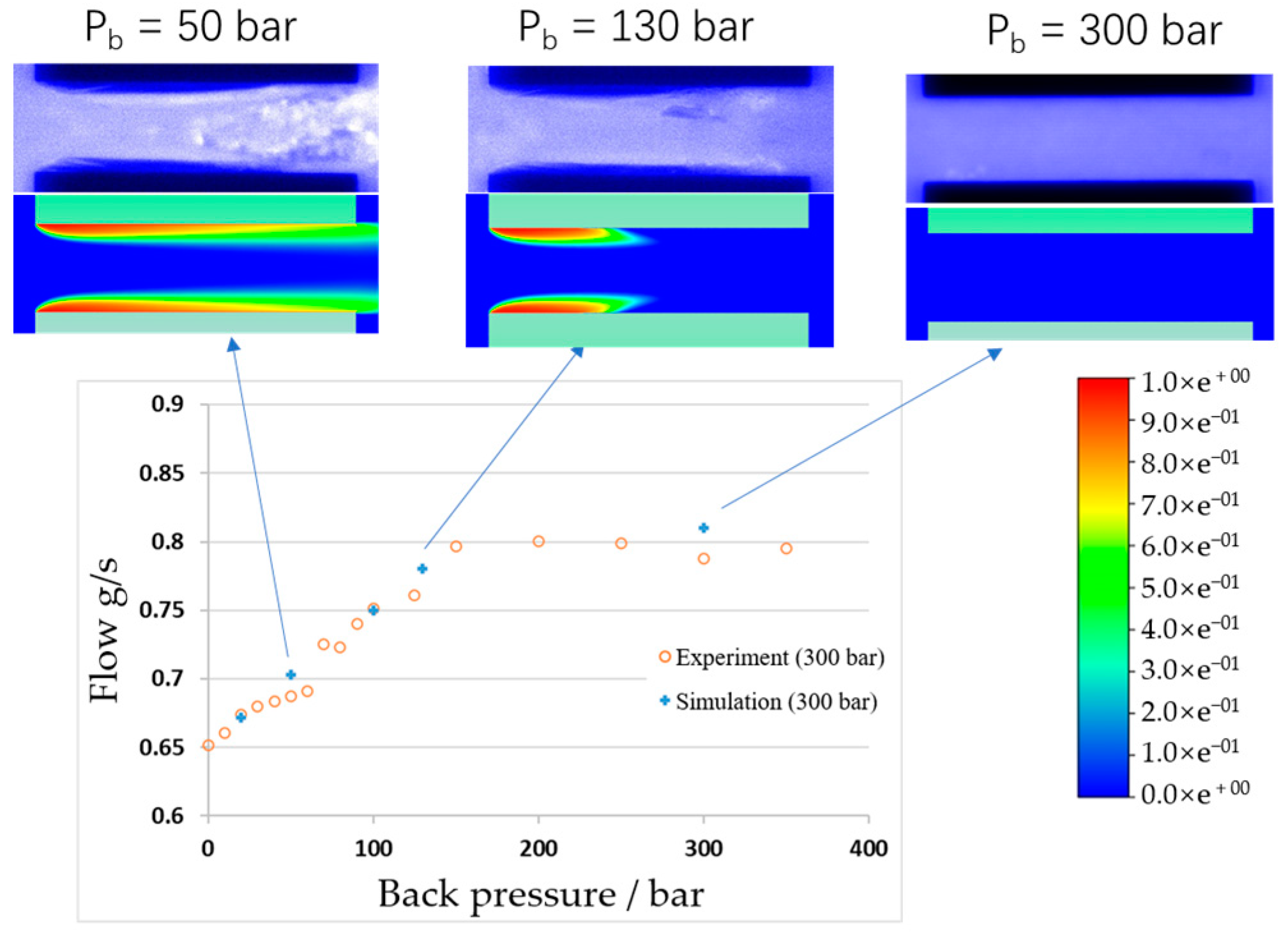

4. Simulation Results

5. Discussion

6. Conclusions

- (1)

- Aluminum nozzles combined with XPCI imaging technology can effectively achieve the same field measurement of internal flow in the orifice and near-field spray at higher injection pressures.

- (2)

- The imaging streak characteristics of the internal flow in the orifice are continuous and coincide with the external spray streak characteristics, indicating that the internal flow strongly influences the near-field spray characteristics.

- (3)

- The thickness of the cavitation layer of the progressively expanding orifice increases along the flow direction, and the cavitation leads to a shrinkage ratio of about 0.70 in the circulation cross-section.

- (4)

- The entrance fillet significantly affects the thickness of the cavitation layer in the orifice, with the larger entrance fillet conducive to reducing the thickness of the cavitation layer in the orifice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| CFD | Computational Fluid Dynamics |

| XPCI | X-ray Phase Contrast Imaging |

| CCD | Charge-Coupled Device |

| ROI | Region of Interest |

| SST | Shear Stress Transport |

References

- Andriotis, A.; Gavaises, M.; Arcoumanis, C. Vortex flow and cavitation in diesel injector nozzles. J. Fluid Mech. 2008, 610, 195–215. [Google Scholar] [CrossRef]

- Sou, A.; Pratama, R.H.; Tomisaka, T.; Kibayashi, Y. Cavitation Flow in Nozzle of Liquid Injector. In Proceedings of the ICLASS 2012, Heidelberg, Germany, 2–6 September 2012. [Google Scholar]

- Sun, S.X. Study on the String Cavitation Characteristics in the Nozzle of Diesel Engine and Its Effect on Fuel Injection and Spray. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2018. [Google Scholar]

- Arcoumanis, C.; Flora, H.; Gavaises, M.; Badami, M. Cavitation in Real-Size Multi-Hole Diesel Injector Nozzles; SAE Technical Paper: Warrendale, PA, USA, 2000. [Google Scholar]

- Payri, R.; Salvador, F.J.; Gimeno, J.; Venegas, O. Study of cavitation phenomenon using different fuels in a transparent nozzle by hydraulic characterization and visualization. Exp. Therm. Fluid Sci. 2013, 44, 235–244. [Google Scholar] [CrossRef]

- Hult, J.; Simmank, P.; Matlok, S.; Mayer, S.; Falgout, Z.; Linne, M. Interior flow and near-nozzle spray development in a marine-engine diesel fuel injector. Exp. Fluids 2016, 57, 49. [Google Scholar] [CrossRef]

- Watanabe, H.; Nishikori, M.; Hayashi, T.; Suzuki, M.; Kakehashi, N.; Ikemoto, M. Visualization analysis of relationship between vortex flow and cavitation behavior in diesel nozzle. Int. J. Engine Res. 2015, 16, 5–12. [Google Scholar] [CrossRef]

- Falgout, Z.; Linne, M. Novel design for transparent high-pressure fuel injector nozzles. Rev. Sci. Instrum. 2016, 87, 085108. [Google Scholar] [CrossRef]

- Chen, Z.; He, Z.; Shang, W.; Duan, L.; Zhou, H.; Guo, G.; Guan, W. Experimental study on the effect of nozzle geometry on string cavitation in real-size optical diesel nozzles and spray characteristics. Fuel 2018, 232, 562–571. [Google Scholar] [CrossRef]

- Manin, J.; Pickett, L.M.; Yasutomi, K. Stereoscopic high-speed microscopy to understand transient internal flow processes in high-pressure nozzles. Exp. Therm. Fluid Sci. 2020, 114, 110027. [Google Scholar] [CrossRef]

- Som, S.; Longman, D.E.; Ramírez, A.I.; Aggarwal, S.K. A comparison of injector flow and spray characteristics of biodiesel with petrodiesel. Fuel 2010, 89, 4014–4024. [Google Scholar] [CrossRef]

- Edelbauer, W.; Strucl, J.; Morozov, A. Large Eddy Simulation of cavitating throttle flow. Adv. Hydroinform. Simhydro 2016, 2014, 501–517. [Google Scholar]

- Balz, R.; Nagy, I.G.; Weisser, G.; Sedarsky, D. Experimental and numerical investigation of cavitation in marine Diesel injectors. Int. J. Heat Mass Transf. 2021, 169, 120933. [Google Scholar] [CrossRef]

- Guo, G.; He, Z.; Wang, Q.; Lai, M.C.; Zhong, W.; Guan, W.; Wang, J. Numerical investigation of transient hole-to-hole variation in cavitation regimes inside a multi-hole diesel nozzle. Fuel 2020, 287, 119457. [Google Scholar] [CrossRef]

- Shi, J.; Lopez Aguado, P.; Guerrassi, N.; Dober, G. Understanding High-pressure Injection Primary Breakup by Using Large Eddy Simulation and X-ray Spray Imaging. Mtz Worldw. 2017, 78, 50–57. [Google Scholar] [CrossRef]

- Winklhofer, E.; Kull, E.; Kelz, E.; Morozov, A. Comprehensive hydraulic and flow field documentation in model throttle experiments under cavitation conditions. In Proceedings of the ILASS-Europe Conference, Zurich, Switzerland, 2–6 September 2001. [Google Scholar]

- Duke, D.J.; Matusik, K.E.; Kastengren, A.L.; Swantek, A.B.; Sovis, N.; Payri, R.; Viera, J.P.; Powell, C.F. X-ray radiography of cavitation in a beryllium alloy nozzle. Int. J. Engine Res. 2017, 18, 39–50. [Google Scholar] [CrossRef]

- Moon, S.; Gao, Y.; Park, S.; Wang, J.; Kurimoto, N.; Nishijima, Y. Effect of the number and position of nozzle holes on in- and near-nozzle dynamic characteristics of diesel injection. Fuel 2015, 150, 112–122. [Google Scholar] [CrossRef]

- Zhang, X.; Moon, S.; Gao, J.; Dufresne, E.M.; Fezzaa, K.; Wang, J. Experimental study on the effect of nozzle hole-to-hole angle on the near-field spray of diesel injector using fast X-ray phase-contrast imaging. Fuel 2016, 185, 142–150. [Google Scholar] [CrossRef]

- Zhang, W.Q.; Wang, Q.; He, Z.X.; Zhang, X.; Guan, W.; Leng, X.Y. Experimental study of cavitation and cavitation characteristic in diesel engine model orifice. Intern. Combust. Engine Eng. 2018, 39, 14–20. [Google Scholar]

- Liu, Y.P.; Sheng, W.F.; Wu, Z.H. Progress of synchrotron radiation and its application in inorganic materials. J. Inorg. Mater. 2021, 36, 901–918. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, G.; Du, G.; Sun, X.; Jiang, G.; Zeng, X.; Sun, P.; Deng, B.; Xie, H.; Wu, Z.; et al. Investigating the microstructures of piston carbon deposits in a large-scale marine diesel engine using synchrotron X-ray microtomography. Fuel 2015, 142, 173–179. [Google Scholar] [CrossRef]

- Liu, C. Numerical Simulation Study of Diesel-Ignited Natural Gas in-Cylinder High-Pressure Direct Injection Dual-Fuel Engine. Master’s Thesis, Jiangsu University of Science and Technology, Zhenjiang, China, 2020. [Google Scholar]

- Gothsch, T.; Schilcher, C.; Richter, C.; Beinert, S.; Dietzel, A.; Büttgenbach, S.; Kwade, A. High-pressure microfluidic systems (HPMS): Flow and cavitation measurements in supported silicon microsystems. Microfluid Nanofluid 2015, 18, 121–130. [Google Scholar] [CrossRef]

- Yu, S.; Yin, B.; Deng, W.; Ye, Z.; Xu, B.; Xu, H. Internal flow and spray characteristics for elliptical orifice with large aspect ratio under typical diesel engine operation conditions. Fuel 2018, 228, 62–73. [Google Scholar] [CrossRef]

- Karrholm, F.P.; Weller, H.; Nordin, N. Modelling injector flow including cavitation effects for diesel. In Proceedings of the FEDSM2007 5th Joint ASME/JSME Fluids Engineering Conference, San Diego, CA, USA, 30 July–2 August 2007. [Google Scholar]

- Wu, P.-K.; Miranda, R.F.; Faeth, G.M. Effects of initial flow conditions on primary breakup of nonturbulent and turbulent round liquid jets. At. Spray 1995, 5, 175–196. [Google Scholar] [CrossRef]

- Bauer, D.; Chaves, H.; Arcoumanis, C. Measurements of void fraction distribution in cavitating pipe flow using x-ray CT. Meas. Sci. Technol. 2012, 23, 055302. [Google Scholar] [CrossRef][Green Version]

- Im, K.S.; Cheong, S.K.; Powell, C.F.; Lai, M.C.D.; Wang, J. Unraveling the Geometry Dependence of In-Nozzle Cavitation in High-Pressure Injectors. Sci. Rep. 2013, 3, 2067. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.; Gimeno, J.; Novella, R. Flow regime effects on non-cavitating injection nozzles over spray behavior. Int. J. Heat Fluid Flow 2011, 32, 273–284. [Google Scholar] [CrossRef]

- Zhang, X.; Moon, S.; Gao, J. Investigation of the spray morphology and primary breakup of biodiesel blends using X-ray ultrafast phase-contrast Imaging. In Proceedings of the 2011 International Conference on Advances in Construction Machinery and Vehicle Engineering, Shanghai, China, 5–7 November 2011. [Google Scholar]

- Miranda, R.; Chaves, H.; Obermeier, F. Imaging of cavitation, hollow jets and jet branching at low lift in a real size VCO nozzle s. In Proceedings of the ILASS-Europe 2002, Zaragoza, Spain, 9–11 September 2002. [Google Scholar]

- Tekawade, A.; Sforzo, B.A.; Matusik, K.E.; Fezzaa, K.; Kastengren, A.L.; Powell, C.F. Time-resolved 3D imaging of two-phase fluid flow inside a steel fuel injector using synchrotron X-ray tomography. Sci. Rep. 2020, 10, 8674. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.; Xu, R.; Liu, Z.; Liu, J.; Zhang, X. Homogeneous Field Measurement and Simulation Study of Injector Nozzle Internal Flow and Near-Field Spray. Processes 2023, 11, 2533. https://doi.org/10.3390/pr11092533

Chen P, Xu R, Liu Z, Liu J, Zhang X. Homogeneous Field Measurement and Simulation Study of Injector Nozzle Internal Flow and Near-Field Spray. Processes. 2023; 11(9):2533. https://doi.org/10.3390/pr11092533

Chicago/Turabian StyleChen, Ping, Rongwu Xu, Zhenming Liu, Jingbin Liu, and Xusheng Zhang. 2023. "Homogeneous Field Measurement and Simulation Study of Injector Nozzle Internal Flow and Near-Field Spray" Processes 11, no. 9: 2533. https://doi.org/10.3390/pr11092533

APA StyleChen, P., Xu, R., Liu, Z., Liu, J., & Zhang, X. (2023). Homogeneous Field Measurement and Simulation Study of Injector Nozzle Internal Flow and Near-Field Spray. Processes, 11(9), 2533. https://doi.org/10.3390/pr11092533