Research on the Positioning Accuracy of the Cutting Head of a Tunneling Machine Based on Ultra-Wideband Positioning Technology

Abstract

:1. Introduction

2. Ultra-WideBand (UWB) Positioning Technology and Simplified Cutting Head Motion Model

2.1. Ultra-WideBand (UWB) Positioning Technology

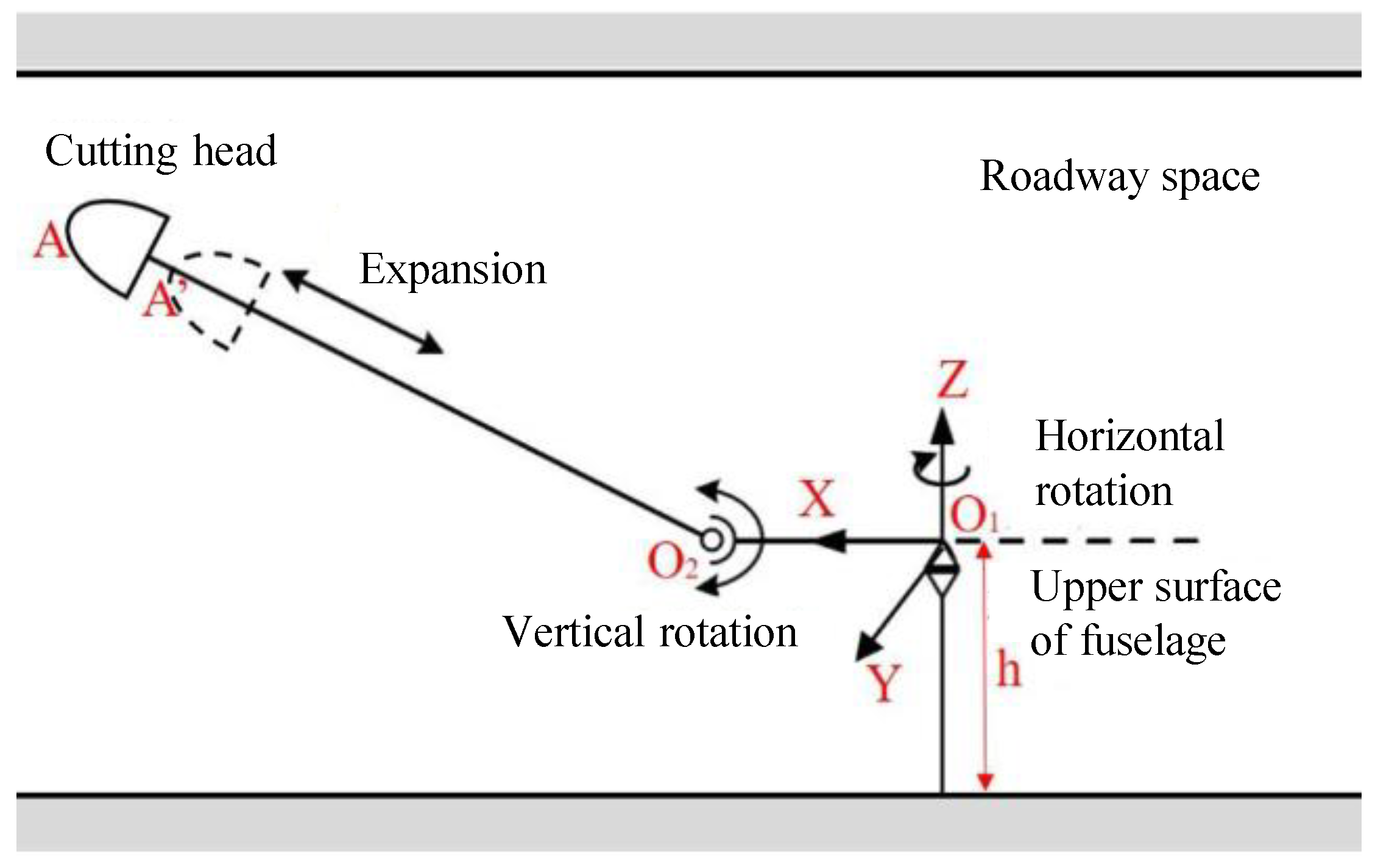

2.2. Simplified Cutting Head of Roadheader Motion Model

3. Cutting Head Ultra-Wideband Positioning System Simulation Experiment

3.1. Experimental Principles

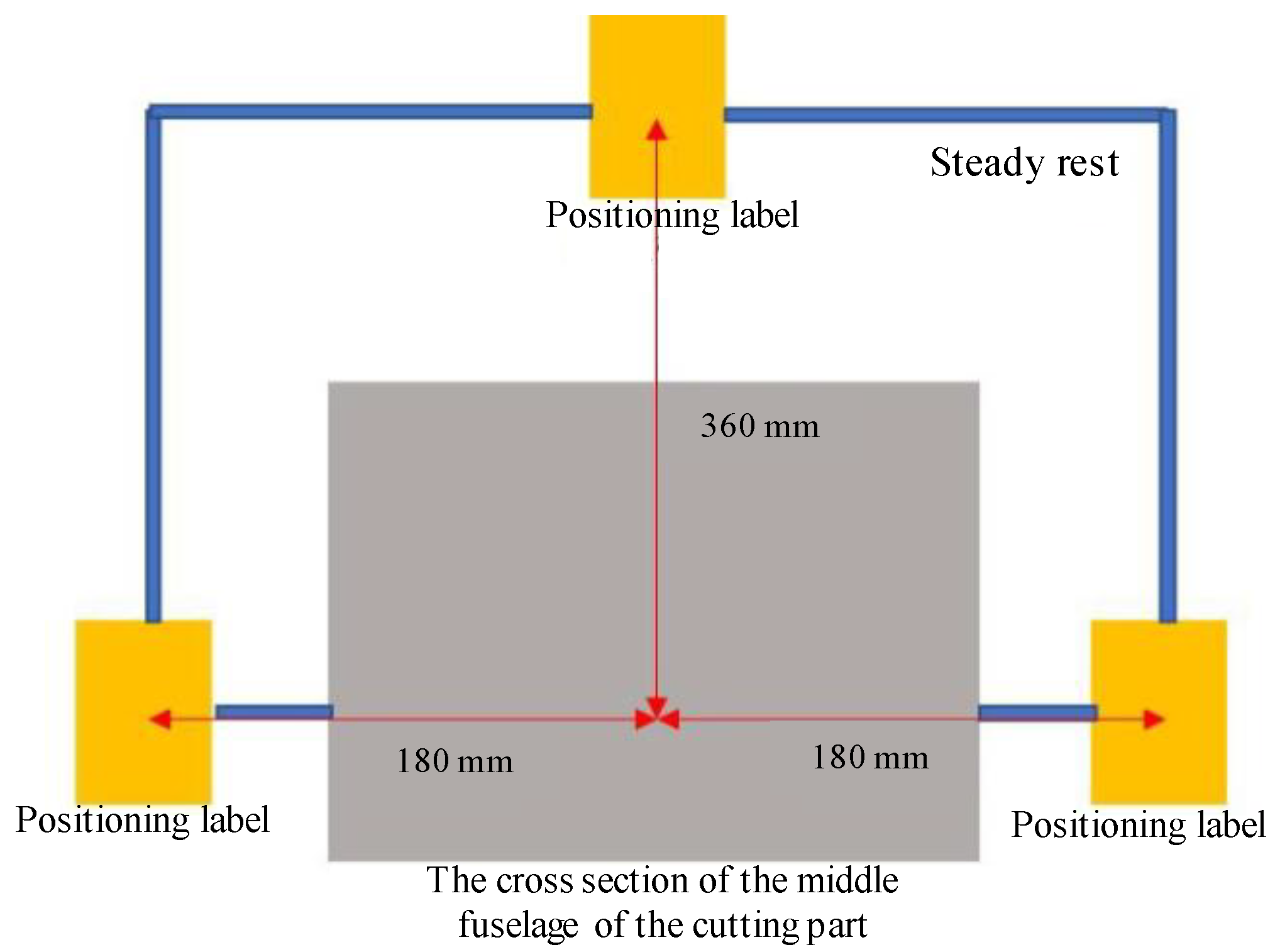

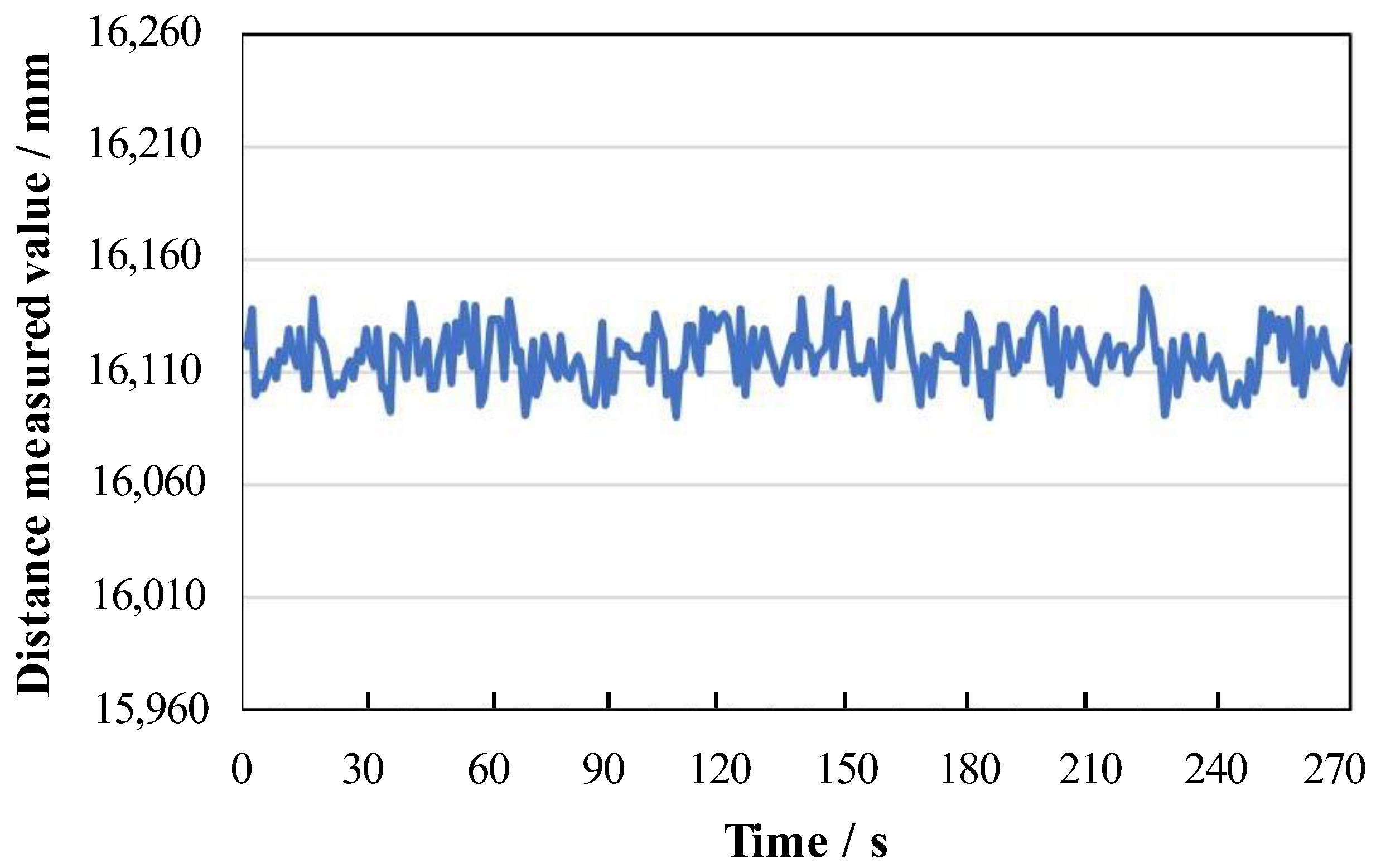

3.2. Components of Positioning System

4. Analysis of Interference Factors of System Positioning Accuracy

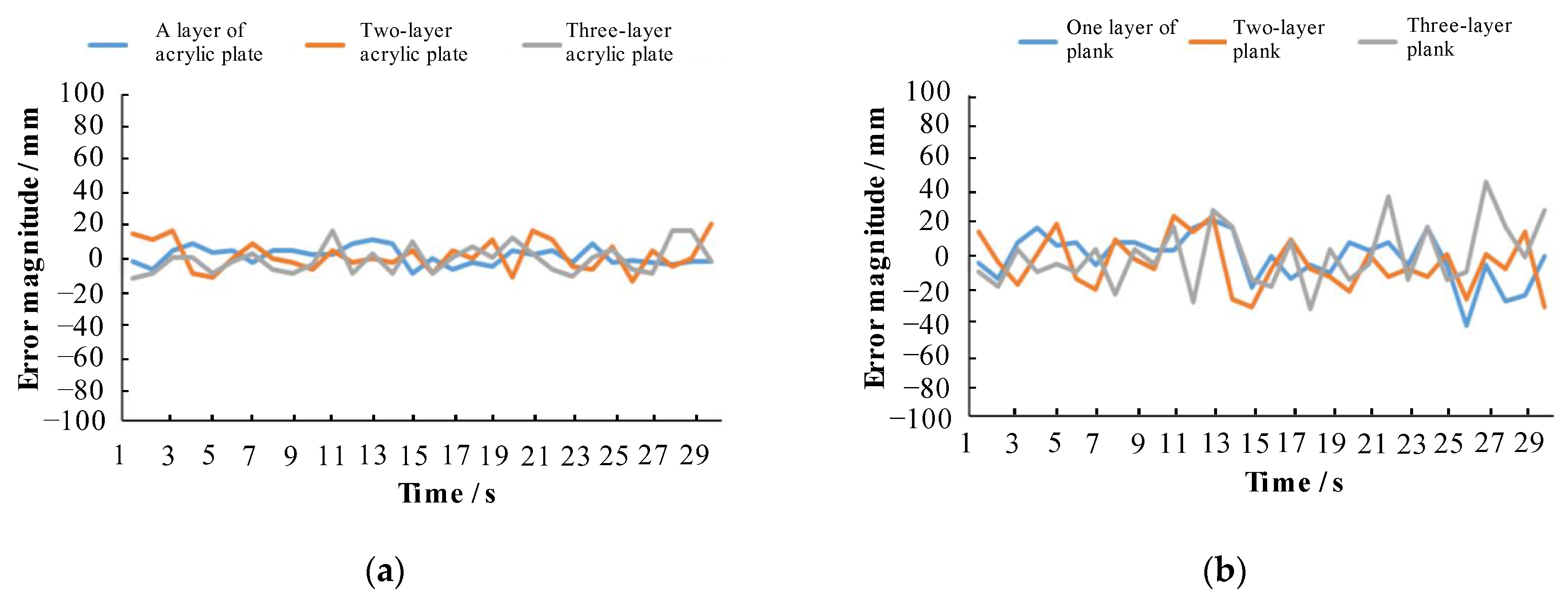

4.1. Direct Occlusion Effects

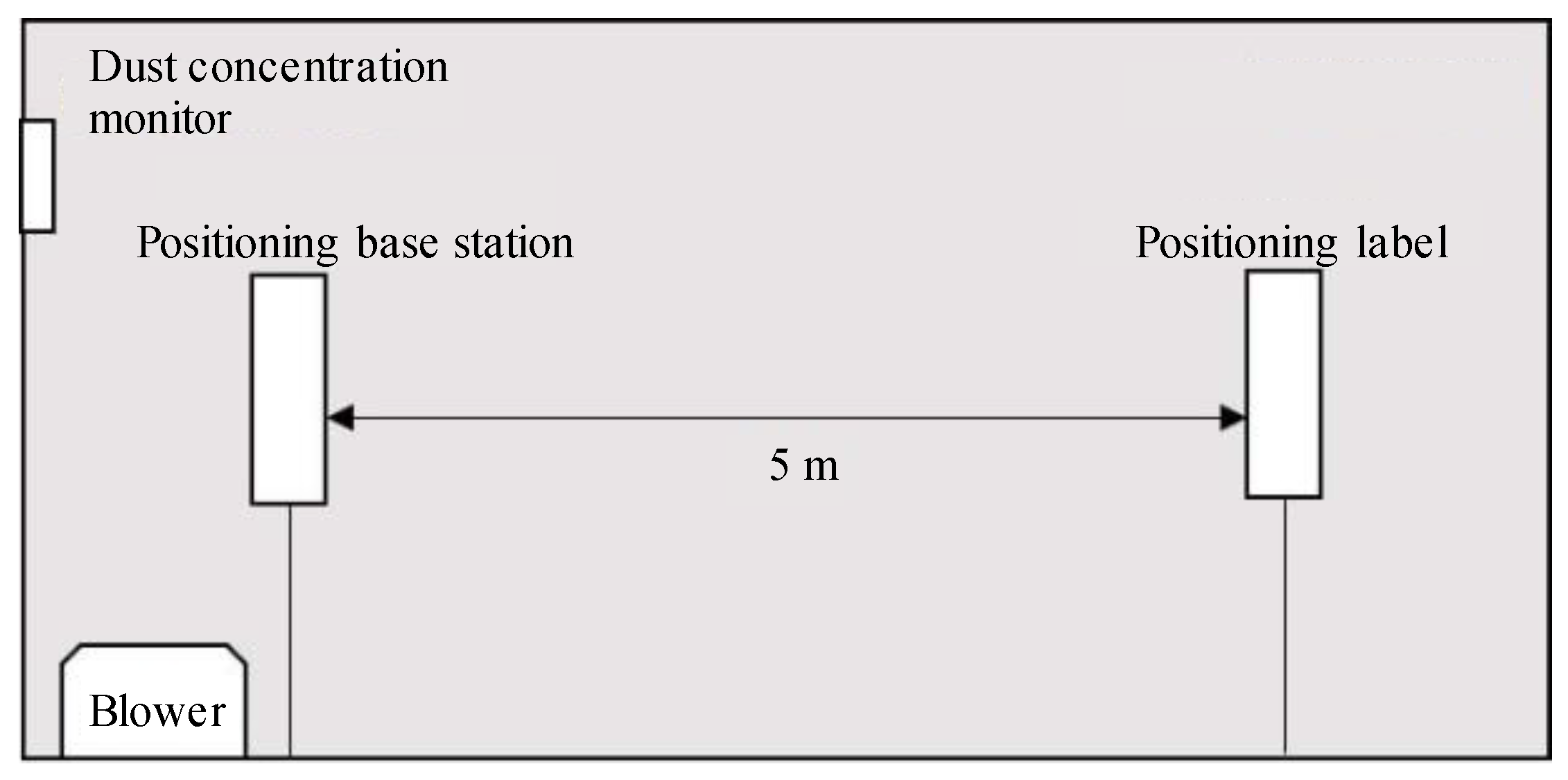

4.2. Effect of Dust Concentration

4.3. Mutual Interference Effects of Ultra-Wideband Equipment

5. Solution Experiment and Accuracy Evaluation

5.1. Positioning System Positioning Accuracy Evaluation Standard

5.2. Dynamic Solution Experiment and Accuracy Evaluation Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, G.F.; Liu, F.; Meng, X.J.; Fan, J.; Wu, Q.; Ren, H.; Pang, Y.; Xu, Y.; Zhao, G.; Zhang, D.; et al. Research and practice on intelligent coal mine construction (primary stage). Coal Sci. Technol. 2019, 47, 1–36. [Google Scholar]

- Wan, J.C.; Zhang, X.H.; Zhang, C.; Yang, W.; Lei, M.; Du, Y.; Dong, Z. Vision and Inertial Navigation Combined-Based Pose Measurement Method of Cantilever Roadheader. Sustainability 2023, 15, 4018. [Google Scholar] [CrossRef]

- Yang, J.J.; Zhang, Q.; Wang, C.; Chang, B.; Wang, X.; Ge, S.; Wu, M. Status and development of robotization research on roadheader for coal mines. J. China Coal Soc. 2020, 45, 2995–3005. [Google Scholar]

- Rycroft, M.J. Understanding GPS. Principles and applications. J. Atmos. Sol. Terr. Phys. 1997, 59, 598–599. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, X.; Ma, H.; Zhang, G. Laser Beams-Based Localization Methods for Boom-Type Roadheader Using Underground Camera Non-Uniform Blur Model. IEEE Access 2020, 8, 190327–190341. [Google Scholar] [CrossRef]

- Adam, H.; Jaroslaw, J. Automatic control of roadheader cutting head speed and load torque. IOP Conf. Ser. Earth Environ. Sci. 2020, 609, 012081. [Google Scholar]

- Bartoszek, S.; Stankiewicz, K.; Kost, G.; Ćwikła, G.; Dyczko, A. Research on Ultrasonic Transducers to Accurately Determine Distances in a Coal Mine Conditions. Energies 2021, 14, 2532. [Google Scholar] [CrossRef]

- Want, R.; Hopper, A.; Falcão, V.; Gibbons, J. The active badge location system. ACM Trans. Inf. Syst. 1992, 10, 91–102. [Google Scholar] [CrossRef]

- Zhao, J.X.; Yang, W.J.; Zhang, X.H.; Du, Y.Y.; Zhang, C. Study on accurate positioning method and its visual measurement technology of cantilever roadheader underground. Coal Sci. Technol. 2021, 49, 192–201. [Google Scholar]

- Zhang, M.; Lyu, F.; Fu, S.; Cai, X.; Zong, K.; Wu, M. Study on the pitch angle control of a robotized hydraulic drive roadheader using different control methods. J. Mech. Sci. Technol. 2018, 32, 4893–4901. [Google Scholar] [CrossRef]

- Cheluszka, P.; Jagiea-Zajc, A. Determining the position of pick holders on the side surface of the working unit of the cutting machine in the robotic technology of their assembly. IOP Conf. Ser. Earth Environ. Sci. 2019, 261, 012003. [Google Scholar] [CrossRef]

- Du, Y.X. Study on the Pose Perception and Positioning Mechanism of Boom-Type Roadheader in Mines; China University of Mining and Technology: Xuzhou, China, 2019. [Google Scholar]

- Wu, M.; Shen, Y.; Ji, X.D.; Wang, P.J.; Jiang, H.; Zheng, W.X.; Li, Y. Trajectory and deviation perception method of boom-type roadheader. J. China Coal Soc. 2021, 46, 2046–2056. [Google Scholar]

- Wang, B.K. Current status and trend analysis of readway driving technology and equipment in coal mine. Coal Sci. Technol. 2020, 48, 1–11. [Google Scholar]

- Yang, W.J.; Zhang, X.H.; Ma, H.W.; Zhang, G.-M. Infrared LEDs-Based Pose Estimation with Underground Camera Model for Boom-Type Roadheader in Coal Mining. IEEE Access 2019, 7, 33698–33712. [Google Scholar] [CrossRef]

- Olivart i Llop, J.M.; Moreno-Salinas, D.; Sánchez, J. Full Real-Time Positioning and Attitude System Based on GNSS-RTK Technology. Sustainability 2020, 12, 9796. [Google Scholar] [CrossRef]

- Eric Calais, J. Bernard Minster, Michelle Hofton. Ionospheric signature of surface mine blasts from Global Positioning System measurements. Geophys. J. Int. 1998, 132. [Google Scholar]

- Wang, S.Y.; Ma, D.C.; Ren, Z.; Wu, M. A multi-objective optimization method for cantilever roadheader section forming trajectory. Chin. J. Sci. Instrum. 2021, 41, 183–192. [Google Scholar]

- Tian, Y.; Yang, X.; Yang, J.; Mao, K.K.; Yao, Y.J. Evolution dynamic of intelligent construction strategy of coal mine enterprises in China. Heliyon 2022, 8, e10933. [Google Scholar] [CrossRef]

- Zang, X.H.; Yang, W.J.; Xue, X.S.; Zhang, C.; Wang, J.; Mao, Q.; Lei, M.; Du, Y.; Ma, H.; Zhao, Y. Challenges and developing of the intelligent remote controlon roadheaders in coal mine. J. China Coal Soc. 2022, 47, 579–597. [Google Scholar]

- Xu, M.G.; Liu, X.K.; Wen, X.Q. Full-mechanized excavation face efficient sprinkler & dust fall system. J. Hunan Univ. Sci. Technol. 2015, 30, 1–7. [Google Scholar]

- Piotr, C. Optimization of the Cutting Process Parameters to Ensure High Efficiency of Drilling Tunnels and Use the Technical Potential of the Boom-Type Roadheader. Energies 2020, 13, 6597. [Google Scholar]

- Yang, J.; Zhang, G.; Huang, Z.; Ye, Y.; Ma, B.; Wang, Y. Research on position and orientation measurement method for roadheader based on vision INS. In Proceedings of the International Conference on Optical Instruments and Technology 2017: Optoelectronic Measurement Technology and System, Beijing, China, 28–30 October 2017. Society of Photo-Optical Instrumentation Engineers Conference Series. [Google Scholar]

- Orteu, J.; Catalina, J.; Devy, M. Perception for a roadheader in automatic selective cutting operation. In Proceedings of the IEEE International Conference on Robotics and Automation, Nice, France, 12–14 May 1992; Volume 5, pp. 626–632. [Google Scholar]

| Experimental Distance (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

|---|---|---|---|---|---|---|

| 4 | 28.32 | 24.65 | 29.65 | 18.62 | 21.54 | 20.04 |

| 8 | 30.65 | 26.93 | 27.84 | 20.65 | 24.66 | 24.25 |

| 12 | 36.21 | 25.63 | 32.79 | 19.45 | 22.63 | 20.06 |

| 16 | 52.31 | 38.62 | 40.63 | 22.78 | 24.23 | 19.47 |

| 20 | 61.36 | 44.57 | 34.23 | 27.86 | 24.54 | 25.45 |

| 24 | 89.62 | 45.69 | 45.32 | 31.42 | 28.31 | 28.00 |

| 28 | 120.34 | 48.32 | 42.32 | 27.12 | 29.62 | 27.61 |

| 32 | 147.95 | 49.52 | 49.34 | 28.01 | 29.46 | 29.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, H.; Zhang, H.; Yang, K.; Hu, Y.; Yang, Z.; Ma, N. Research on the Positioning Accuracy of the Cutting Head of a Tunneling Machine Based on Ultra-Wideband Positioning Technology. Processes 2023, 11, 2534. https://doi.org/10.3390/pr11092534

Ma H, Zhang H, Yang K, Hu Y, Yang Z, Ma N. Research on the Positioning Accuracy of the Cutting Head of a Tunneling Machine Based on Ultra-Wideband Positioning Technology. Processes. 2023; 11(9):2534. https://doi.org/10.3390/pr11092534

Chicago/Turabian StyleMa, Haiyan, Hongkai Zhang, Kunlin Yang, Yingjie Hu, Zeyu Yang, and Nianjie Ma. 2023. "Research on the Positioning Accuracy of the Cutting Head of a Tunneling Machine Based on Ultra-Wideband Positioning Technology" Processes 11, no. 9: 2534. https://doi.org/10.3390/pr11092534

APA StyleMa, H., Zhang, H., Yang, K., Hu, Y., Yang, Z., & Ma, N. (2023). Research on the Positioning Accuracy of the Cutting Head of a Tunneling Machine Based on Ultra-Wideband Positioning Technology. Processes, 11(9), 2534. https://doi.org/10.3390/pr11092534