Optimization of Cost–Carbon Reduction–Technology Solution for Existing Office Parks Based on Genetic Algorithm

Abstract

1. Introduction

2. Optimization Model

2.1. Objective Function

2.2. Constraints

2.2.1. Technical Boundary Constraints

2.2.2. Cost Constraints

2.2.3. Model Solving

3. Case Study

3.1. Park Overview

3.2. Selection of Optimization Variables

3.3. Optimizing Variable Constraints

- (1)

- Low-carbon technologies for building envelopes

- (2)

- Heat-reflective coatings

- (3)

- HAVC Intelligent Control System

- (4)

- Lighting-energy-saving retrofit

- (5)

- PV-paved

3.4. Investment Cost Constraints

| Low-Carbon Technology | Relational Equation for Cost and Parameter Configuration | Equation No. | |

|---|---|---|---|

| Building thermal performance | Roof | (14) | |

| External wall | (15) | ||

| External window | (16) | ||

| Heat-reflective coating technology | (17) | ||

| HVAC intelligent control technology | (18) | ||

| Lighting-energy-saving technology | (19) | ||

| Photovoltaic power technology | (20) | ||

3.5. Quantitative Relationship between Carbon Reduction and Optimization Variables

- (1)

- Enhancement in the insulation performance of the envelope

- (2)

- HVAC intelligent control, heat-reflective coatings, lighting-energy-saving retrofit

- (3)

- Photovoltaic

4. Results and Discussion

4.1. Optimization of the Park under Infinite Cost

4.2. Analysis of Carbon-Reduction Benefits under Infinite Cost

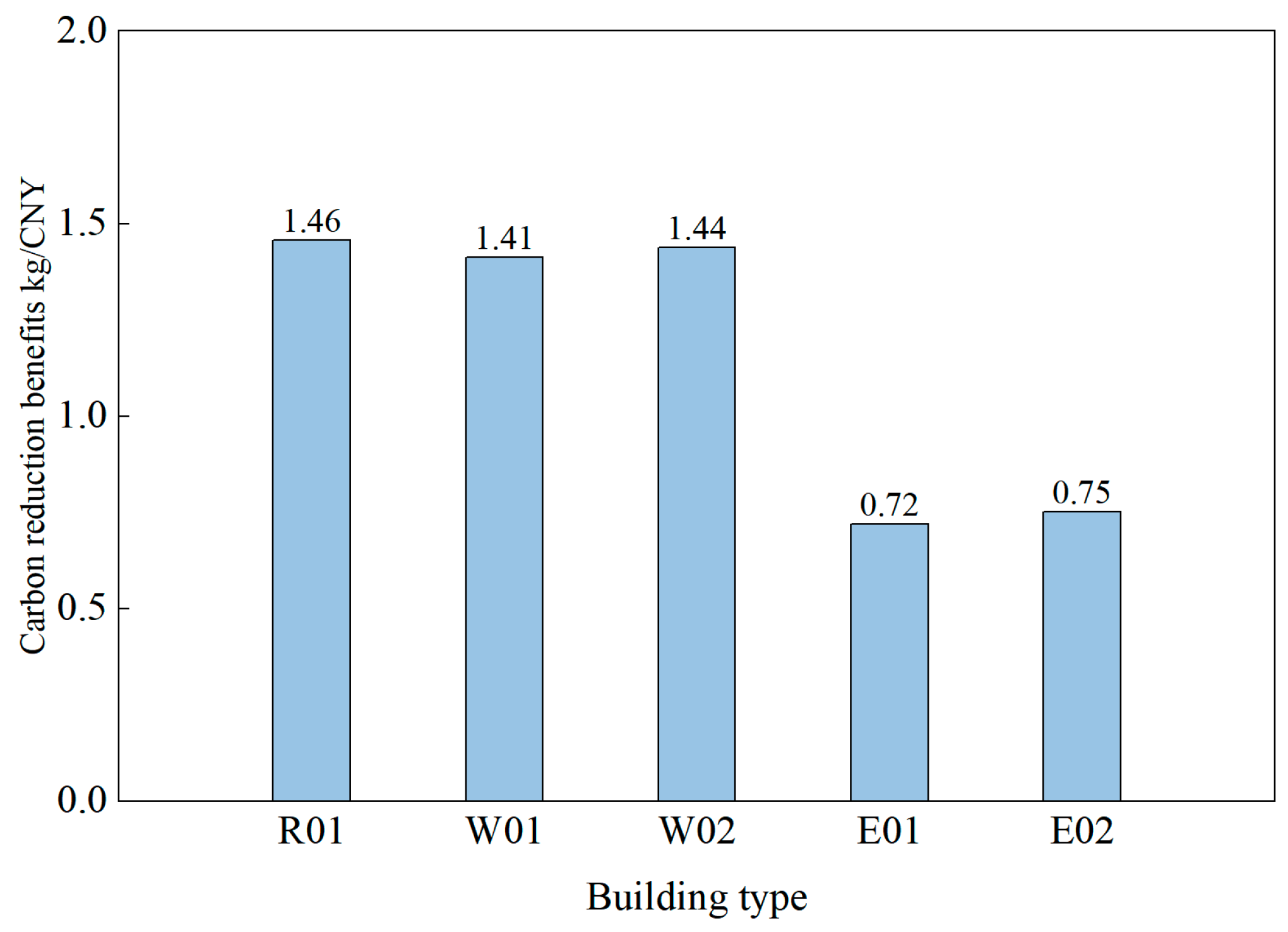

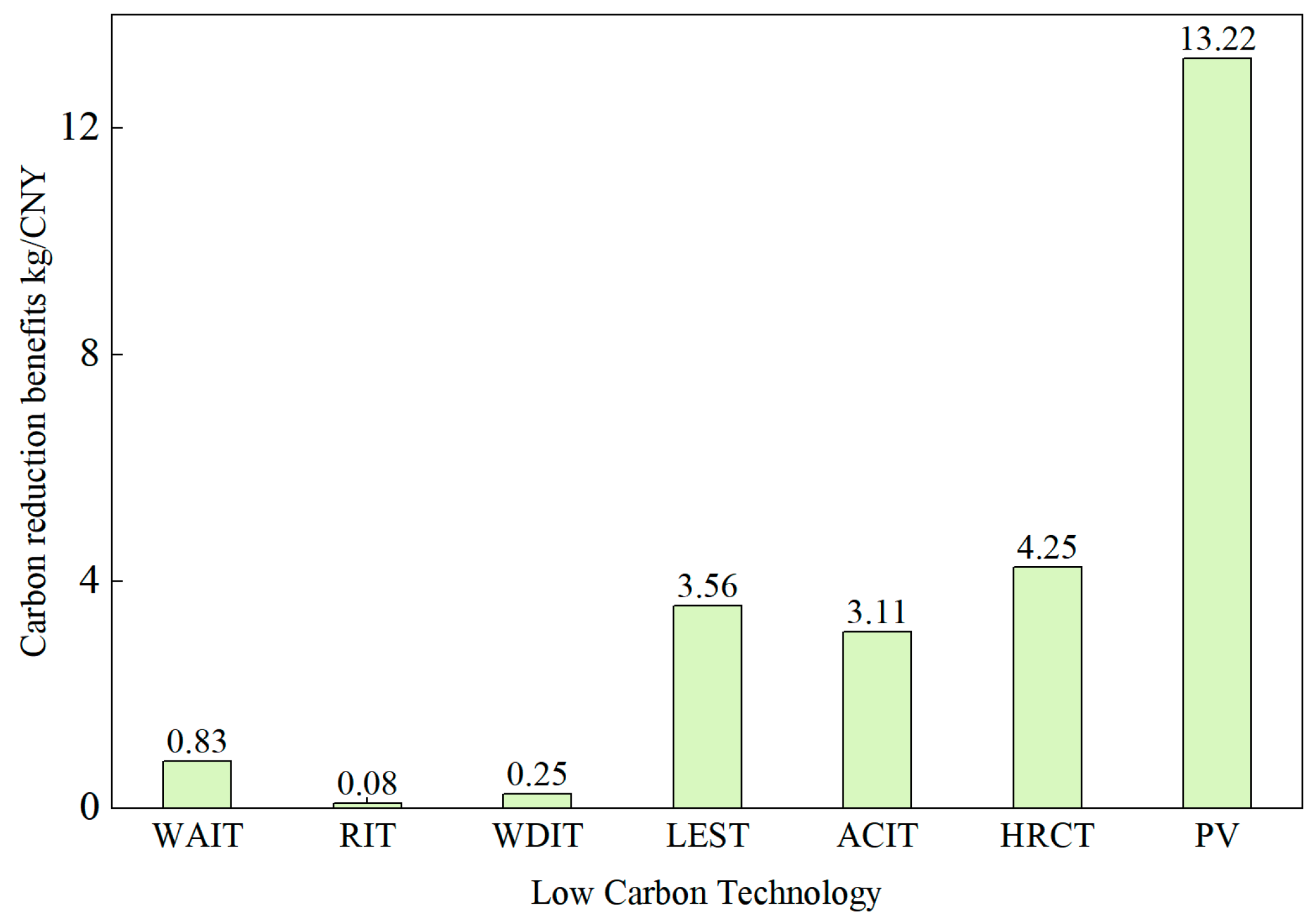

- (1)

- Carbon-reduction benefits of different LCTs in different buildings

- (2)

- Carbon-Reduction Benefits of Various Types of Building and Various Types of LCT

4.3. Optimization of the Park at Limited Cost

- (1)

- Variation in total carbon reduction in the park with the total investment cost

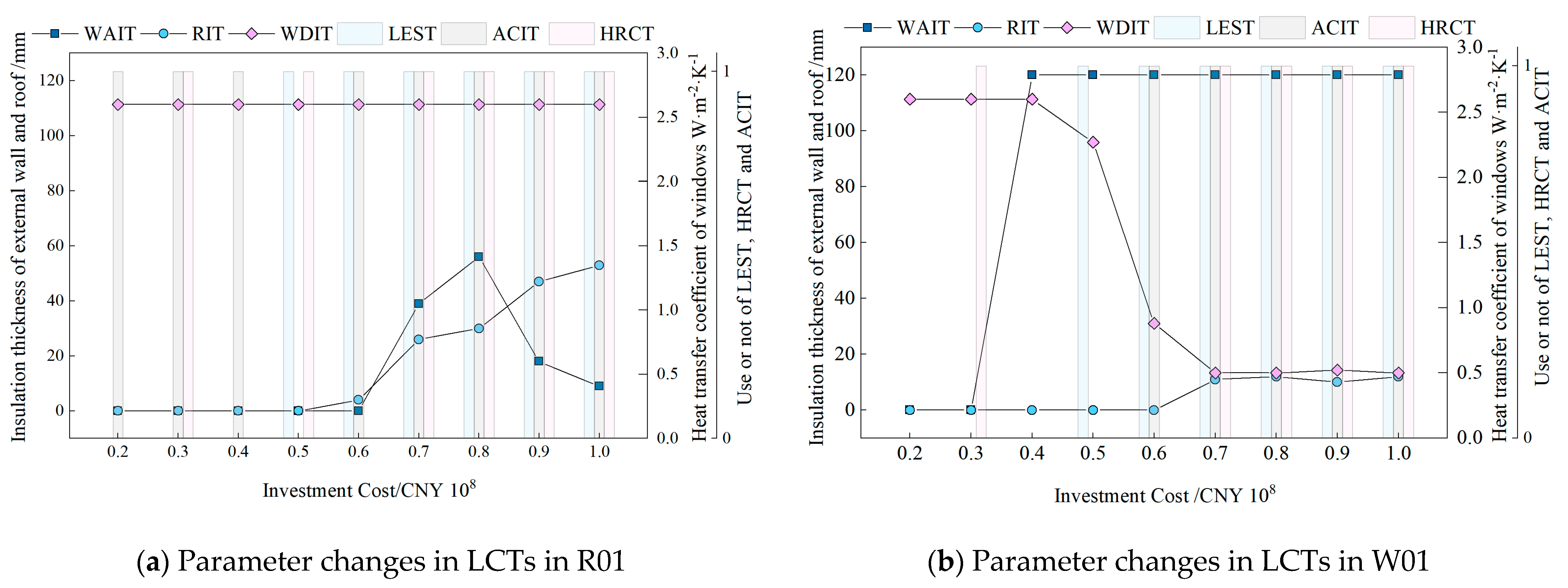

- (2)

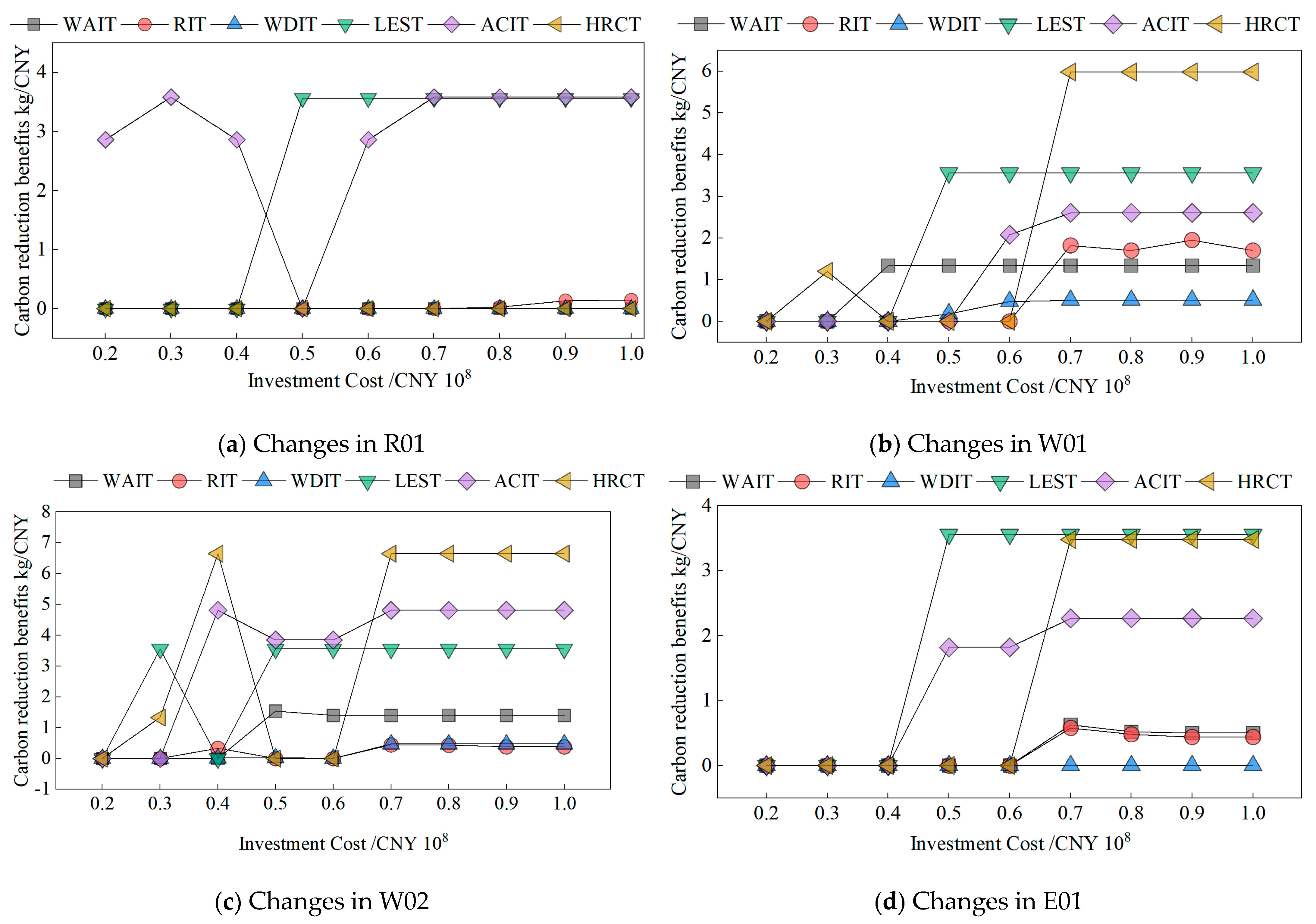

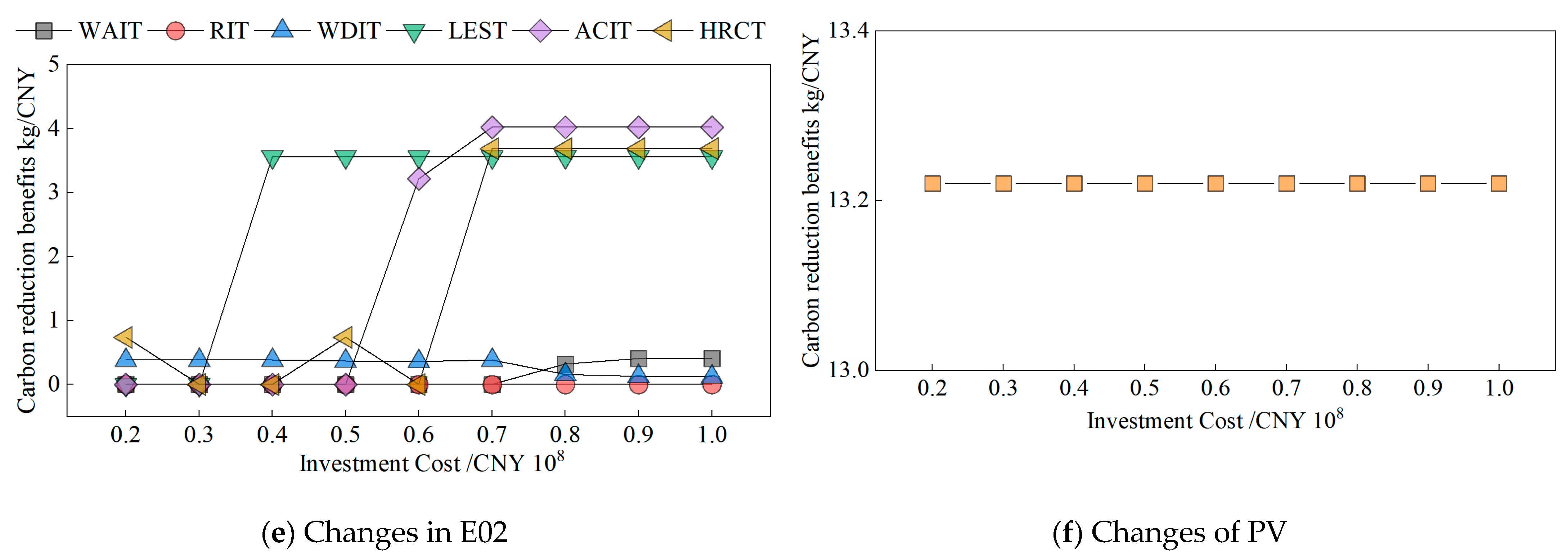

- Variation in parameters with the investment costs for different LCTs in the same building

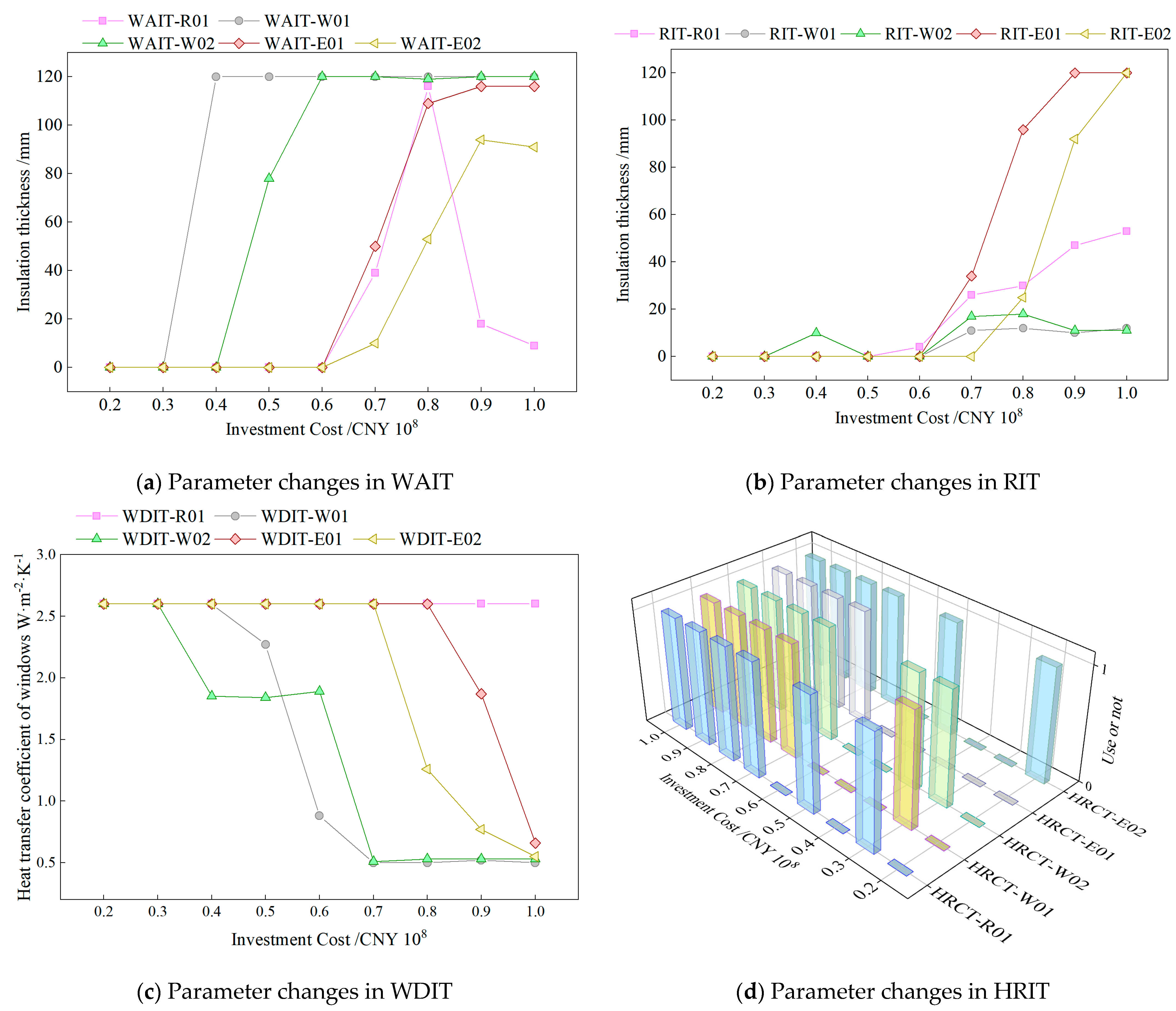

- (3)

- Variation in the configuration parameters of the same LCT in different buildings

4.4. Analysis of Carbon-Reduction Benefits with Limited Cost

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, F.; Yu, B.; Hadachin, T.; Dai, Y.; Wang, Y.; Zhang, S.; Long, R. Drivers of carbon emission intensity change in China. Resour. Conserv. Recycl. 2018, 129, 187–201. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, W.; Yao, M.; Yuan, J. Carbon emissions performance regulation for China’s top generation groups by 2020: Too challenging to realize? Resour. Conserv. Recycl. 2017, 122, 326–334. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, X. Research on Low-Carbon Development Model of Domestic and Overseas Typical Cities and Parks. Shanghai Energy Sav. 2022, 04, 363–369. [Google Scholar]

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventory; IPCC: Geneva, Switzerland, 2019. [Google Scholar]

- Song, Z.; Liu, T.; Liu, Y.; Jiang, X.; Lin, Q. Study on the optimization and sensitivity analysis of CCHP systems for industrial park facilities. Int. J. Electr. Power Energy Syst. 2020, 120, 105984. [Google Scholar] [CrossRef]

- Wu, D.; Han, S.; Wang, L.; Li, G.; Guo, J. Multi-parameter optimization design method for energy system in low-carbon park with integrated hybrid energy storage. Energy Convers. Manag. 2023, 291, 117265. [Google Scholar] [CrossRef]

- Wang, Y.; Li, R.; Dong, H.; Ma, Y.; Yang, J.; Zhang, F.; Li, S. Capacity planning and optimization of business park-level integrated energy system based on investment constraints. Energy 2019, 189, 116345. [Google Scholar] [CrossRef]

- Guo, W.; Wang, Q.; Liu, H.; Desire, W.A. Multi-energy collaborative optimization of park integrated energy system considering carbon emission and demand response. Energy Rep. 2023, 9, 3683–3694. [Google Scholar] [CrossRef]

- Luo, Z.; Lu, Y.; Cang, Y.; Yang, L. Study on dual-objective optimization method of life cycle energy consumption and economy of office building based on HypE genetic algorithm. Energy Build. 2022, 256, 111749. [Google Scholar] [CrossRef]

- Fesanghary, M.; Asadi, S.; Geem, Z.W. Design of low-emission and energy-efficient residential buildings using a multi-objective optimization algorithm. Build. Environ. 2012, 49, 245–250. [Google Scholar] [CrossRef]

- Ferrara, M.; Fabrizio, E.; Virgone, J.; Filippi, M. A simulation-based optimization method for cost-optimal analysis of nearly Zero Energy Buildings. Energy Build. 2014, 84, 442–457. [Google Scholar] [CrossRef]

- Gerber, D.J.; Pantazis, E.; Wang, A. A multi-agent approach for performance based architecture: Design exploring geometry, user, and environmental agencies in façades. Autom. Constr. 2017, 76, 45–58. [Google Scholar] [CrossRef]

- Yigit, S.; Ozorhon, B. A simulation-based optimization method for designing energy efficient buildings. Energy Build. 2018, 178, 216–227. [Google Scholar] [CrossRef]

- Tuhus-Dubrow, D.; Krarti, M. Genetic-algorithm based approach to optimize building envelope design for residential buildings. Build. Environ. 2010, 45, 1574–1581. [Google Scholar] [CrossRef]

- Carli, R.; Dotoli, M.; Pellegrino, R.; Ranieri, L. Using multi-objective optimization for the integrated energy efficiency improvement of a smart city public buildings’ portfolio. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; IEEE: New York, NY, USA; pp. 21–26. [Google Scholar]

- Chantrelle, F.P.; Lahmidi, H.; Keilholz, W.; El Mankibi, M.; Michel, P. Development of a multicriteria tool for optimizing the renovation of buildings. Appl. Energy 2011, 88, 1386–1394. [Google Scholar] [CrossRef]

- Petkov, I.; Mavromatidis, G.; Knoeri, C.; Allan, J.; Hoffmann, V.H. MANGOret: An optimization framework for the long-term investment planning of building multi-energy system and envelope retrofits. Appl. Energy 2022, 314, 118901. [Google Scholar] [CrossRef]

- Abdou, N.; El Mghouchi, Y.; Hamdaoui, S.; Mhamed, M. Optimal Building Envelope Design and Renewable Energy Systems Size for Net-zero Energy Building in Tetouan (Morocco). In Proceedings of the 2021 9th International Renewable and Sustainable Energy Conference (IRSEC), Tetouan, Morocco, 28 March 2022. [Google Scholar]

- Lin, Y.H.; Lin, M.D.; Tsai, K.T.; Deng, M.J.; Ishii, H. Multi-objective optimization design of green building envelopes and air conditioning systems for energy conservation and CO2 emission reduction. Sust. Cities Soc. 2021, 64, 102555. [Google Scholar] [CrossRef]

- Bichiou, Y.; Krarti, M. Optimization of envelope and HVAC systems selection for residential buildings. Energy Build. 2011, 43, 3373–3382. [Google Scholar] [CrossRef]

- Hashempour, N.; Taherkhani, R.; Mahdikhani, M. Energy performance optimization of existing buildings: A literature review. Sustain. Cities Soc. 2020, 54, 101967. [Google Scholar] [CrossRef]

- Mela, K.; Tiainen, T.; Heinisuo, M. Comparative study of multiple criteria decision making methods for building design. Adv. Eng. Inform. 2012, 26, 716–726. [Google Scholar] [CrossRef]

- Shan, W. Research on Low-Carbon Design of High-Tech Park Office Building under Ecological Concept. Master’s Thesis, Nanchang Hangkong University, Nanchang, China, 2020. [Google Scholar]

- Zhu, J. Study on the Low Carbon Design Strategy of the Office Building of High-Tech Park. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, Chian, 2012. [Google Scholar]

- Huang, B.; Jiang, P.; Wang, S.; Zhao, J.; Wu, L. Low carbon innovation and practice in Caohejing high-tech industrial park of Shanghai. Int. J. Prod. Econ. 2016, 181, 367–373. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, H.; Wang, S.; Meng, F. Analysis of building energy consumption and discussion on energy-saving reform in an office park. Archit. Technol. 2020, 51, 670–672. [Google Scholar]

- Sun, J. Methodology of Integrated Planning Toward Urban Block-Level Carbon Reduction. Urban Plan. Forum 2022, 6, 102–109. [Google Scholar]

- Xiao, H.; Wei, Q.; Wang, H. Marginal abatement cost and carbon reduction potential outlook of key energy efficiency technologies in China’s building sector to 2030. Energy Policy 2014, 69, 92–105. [Google Scholar] [CrossRef]

- Guo, W.; Qiao, X.; Huang, Y.; Fang, M.; Han, X. Study on energy saving effect of heat-reflective insulation coating on envelopes in the hot summer and cold winter zone. Energy Build. 2012, 50, 196–203. [Google Scholar] [CrossRef]

- Ye, X.; Chen, D. Thermal insulation coatings in energy saving. In Energy-Efficient Approaches in Industrial Applications; IntechOpen: London, UK, 2018. [Google Scholar]

- Liu, Z.; Liu, Y.; He, B.J.; Xu, W.; Jin, G.; Zhang, X. Application and suitability analysis of the key technologies in nearly zero energy buildings in China. Sustain. Energy Rev. 2019, 101, 329–345. [Google Scholar] [CrossRef]

- Liu, Y.; Xue, S.; Guo, X.; Zhang, B.; Sun, X.; Zhang, Q.; Dong, Y. Towards the goal of zero-carbon building retrofitting with variant application degrees of low-carbon technologies: Mitigation potential and cost-benefit analysis for a kindergarten in Beijing. J. Clean. Prod. 2023, 393, 136316. [Google Scholar] [CrossRef]

- Tang, J.; Cai, X.; Li, H. Study on development of low-carbon building based on LCA. Energy Procedia 2011, 5, 708–712. [Google Scholar] [CrossRef]

| Building | Number | Individual Building Area/m2 | No. of Floors | Window–Wall Ratio | Roof Area/m2 | External Wall Area/m2 | External Window Area/m2 | The Area of East, West, and South External Wall/m2 |

|---|---|---|---|---|---|---|---|---|

| R01 | 1 | 23,150 | 2 | 0.8 | 11,575 | 1200 | 4800 | 1200 |

| W01 | 4 | 2088 | 6 | 0.3 | 3348 | 5223 | 2712 | 2717 |

| W02 | 1 | 33,480 | 10 | 0.3 | 3348 | 8705 | 4687 | 4528 |

| E01 | 4 | 22,902 | 6 | 0.3 | 3817 | 7160 | 3856 | 4086 |

| E02 | 1 | 38,170 | 10 | 0.3 | 3817 | 11,933 | 6427 | 6809 |

| Building | Building Envelope | Use or Not of Heat Reflective Coating Technology | Use or Not of HVAC Intelligent Control Technology | Use or Not of Lighting Energy-Saving Technology | PV Area | ||

|---|---|---|---|---|---|---|---|

| Thickness of Roof Insulation | Thickness of External Wall Insulation | Heat Transfer Coefficient of Windows | |||||

| R01 | |||||||

| W01 | |||||||

| W02 | |||||||

| E01 | |||||||

| E02 | |||||||

| Building | Optimization Variables | Unit | Range | Step |

|---|---|---|---|---|

| R01, W01, W02, E01, E02 | Thickness of external wall insulation | mm | [0, 120] | 10 |

| Thickness of roof insulation | mm | [0, 120] | 10 | |

| Heat transfer coefficient of windows | W m−2 K−1 | [0.5, 2.6] | 0.5 | |

| Use or not of heat-reflective coating technology | / | 0/1 | \ | |

| Use or not of lighting-energy-saving technology | / | 0/1 | \ | |

| Use or not of HVAC intelligent control technology | / | 0/1 | \ | |

| Park | PV area | m2 | [0, 33, 180] | 1 |

| Building | Low-Carbon Technology | Relationship Equation between Optimization Variables and Carbon Reduction in the Operational Phase | Equation No. |

|---|---|---|---|

| R01 | External wall insulation | (24) | |

| Roof insulation | (25) | ||

| External window insulation | (26) | ||

| W01 | External wall insulation | (27) | |

| Roof insulation | (28) | ||

| External window insulation | (29) | ||

| W02 | External wall insulation | (30) | |

| Roof insulation | (31) | ||

| External window insulation | (32) | ||

| E01 | External wall insulation | (33) | |

| Roof insulation | (34) | ||

| External window insulation | (35) | ||

| E02 | External wall insulation | (36) | |

| Roof insulation | (37) | ||

| External window insulation | (38) |

| Building | R01 | W01 | W02 | E01 | E02 | |

|---|---|---|---|---|---|---|

| Building envelope | The thickness of the roof insulation/mm | 71 | 19 | 19 | 120 | 120 |

| The thickness of the external wall insulation/mm | 0 | 120 | 120 | 120 | 120 | |

| Heat transfer coefficient of the windows/W m−2 K−1 | 2.6 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Use or not of heat-reflective coating technology | 0 | 1 | 1 | 1 | 1 | |

| Use or not of HVAC intelligent control technology | 1 | 1 | 1 | 1 | 1 | |

| Use or not of lighting-energy-saving technology | 1 | 1 | 1 | 1 | 1 | |

| Whole-life carbon reductions for different building types/t | 8462 | 9580 | 16,064 | 7301 | 12,405 | |

| PV area/m2 | 33,180 | |||||

| Whole-life-cycle carbon reduction by PV/t | 131,627 | |||||

| Total life-cycle carbon reduction of the park/t | 236,087 | |||||

| Total investment/CNY 10,000 | 10,300 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, Z.; Jin, L.; Chen, Y.; Huang, Z. Optimization of Cost–Carbon Reduction–Technology Solution for Existing Office Parks Based on Genetic Algorithm. Processes 2023, 11, 2452. https://doi.org/10.3390/pr11082452

Dou Z, Jin L, Chen Y, Huang Z. Optimization of Cost–Carbon Reduction–Technology Solution for Existing Office Parks Based on Genetic Algorithm. Processes. 2023; 11(8):2452. https://doi.org/10.3390/pr11082452

Chicago/Turabian StyleDou, Zhenlan, Lu Jin, Yinhui Chen, and Zishuo Huang. 2023. "Optimization of Cost–Carbon Reduction–Technology Solution for Existing Office Parks Based on Genetic Algorithm" Processes 11, no. 8: 2452. https://doi.org/10.3390/pr11082452

APA StyleDou, Z., Jin, L., Chen, Y., & Huang, Z. (2023). Optimization of Cost–Carbon Reduction–Technology Solution for Existing Office Parks Based on Genetic Algorithm. Processes, 11(8), 2452. https://doi.org/10.3390/pr11082452