Experimental Study on Convection and Heat Conduction Heating of an Air-Conditioned Bed System under Winter Lunch Break Mode

Abstract

1. Introduction

2. Literature Review

3. Experiment Introduction

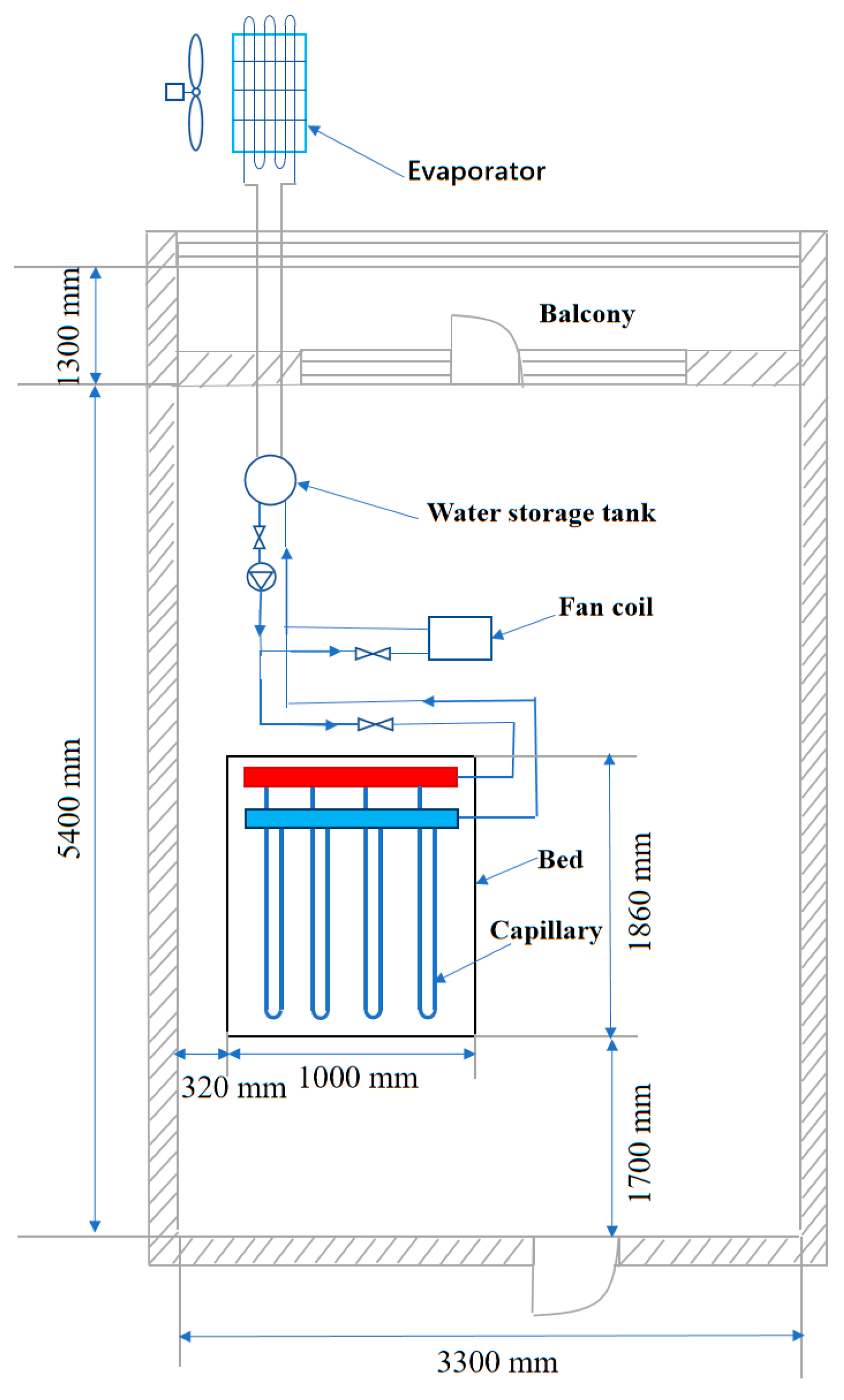

3.1. Experimental Room and Equipment

3.2. Subjects and Measurement Point Arrangement

3.3. Experimental Research Method

4. Results and Analysis

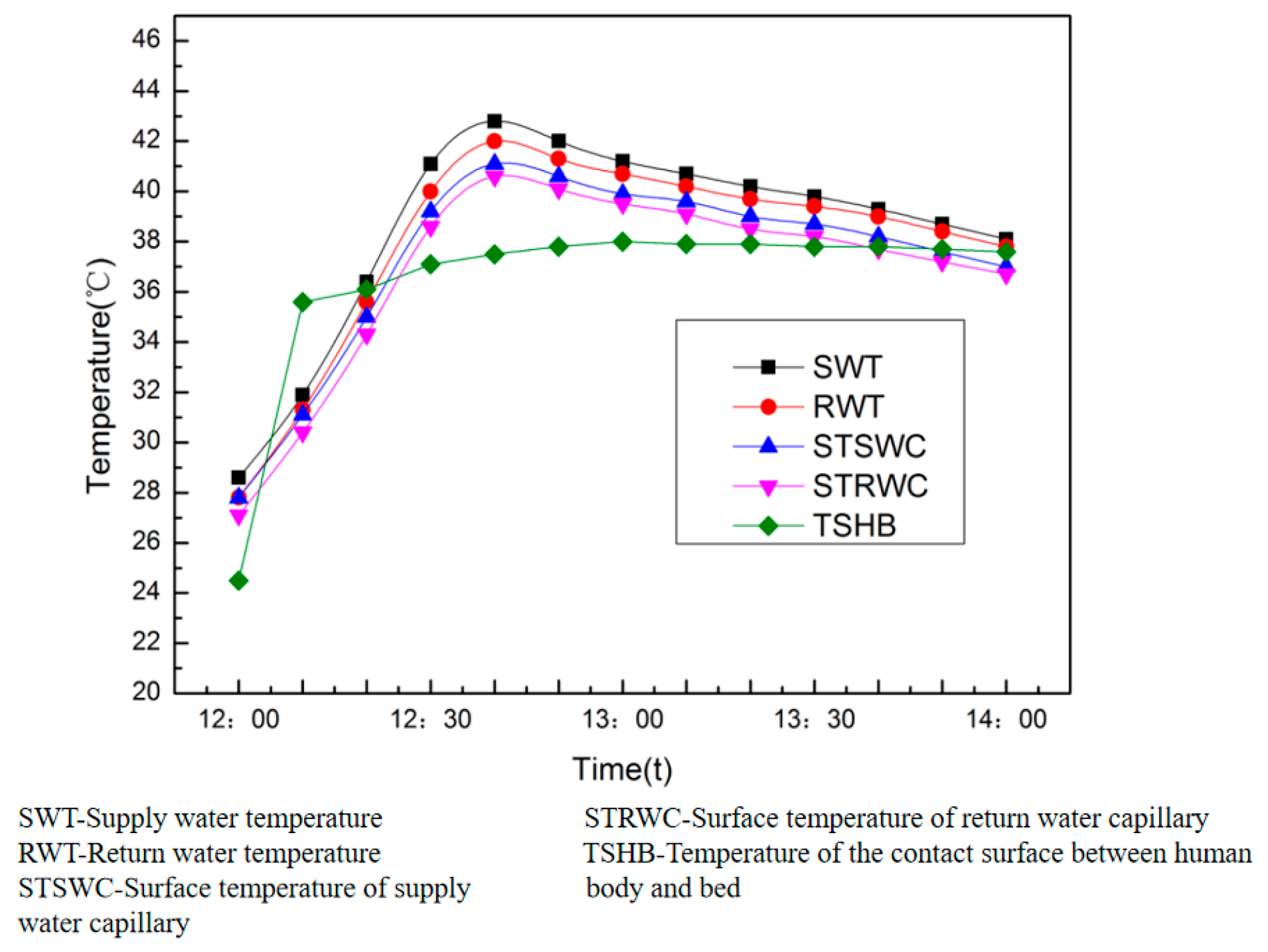

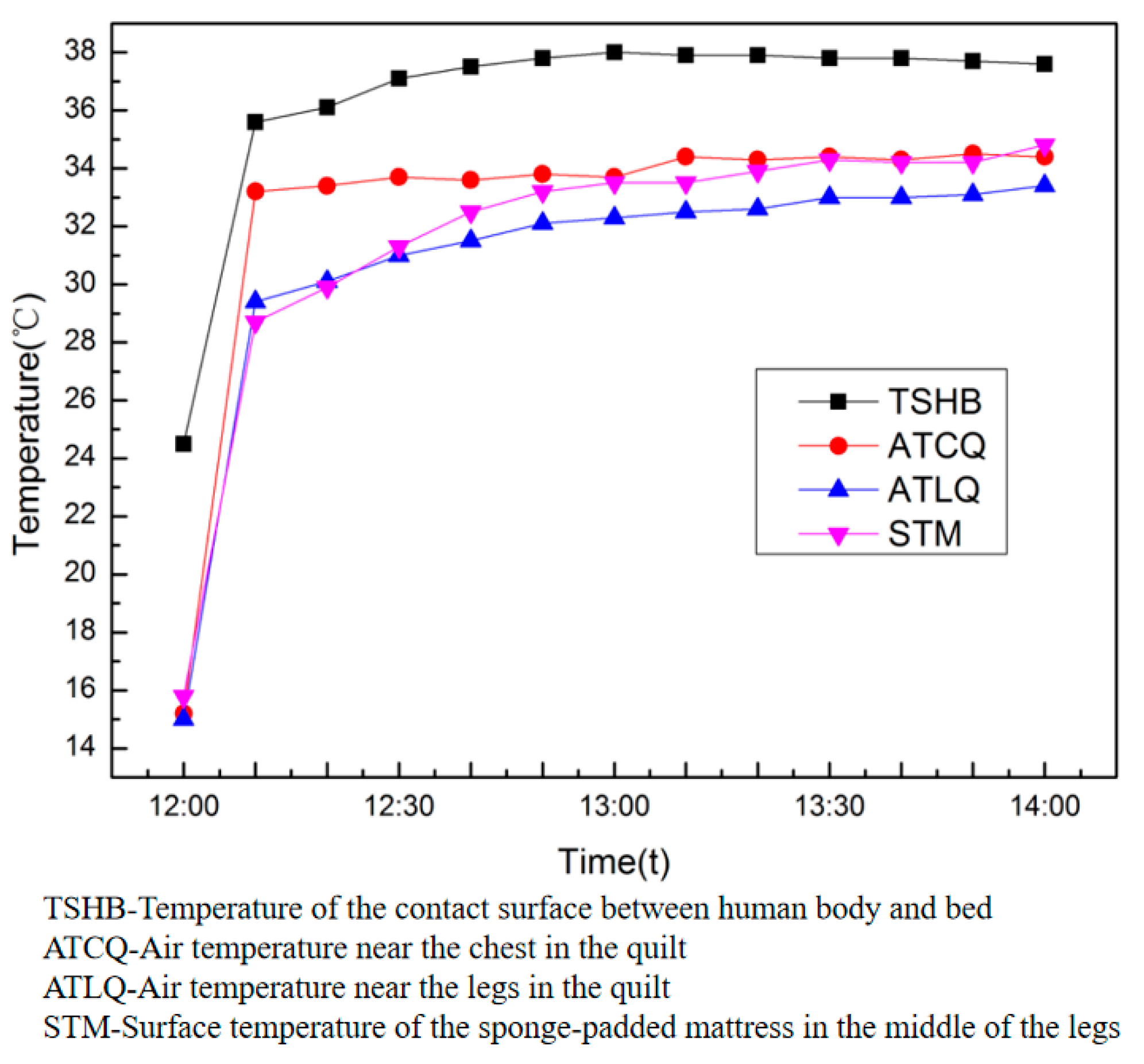

4.1. Experimental Results of Thermally Conductive Heating

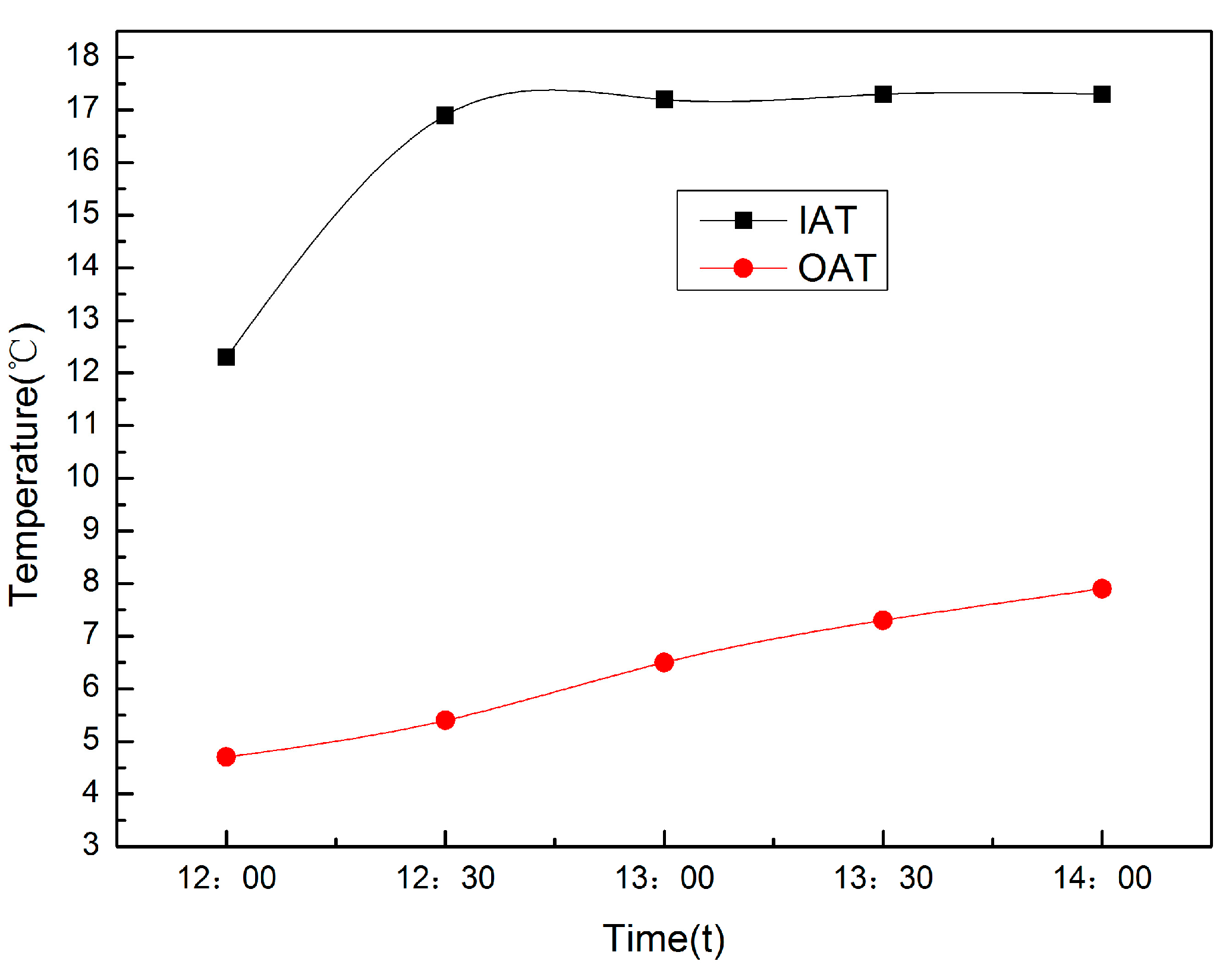

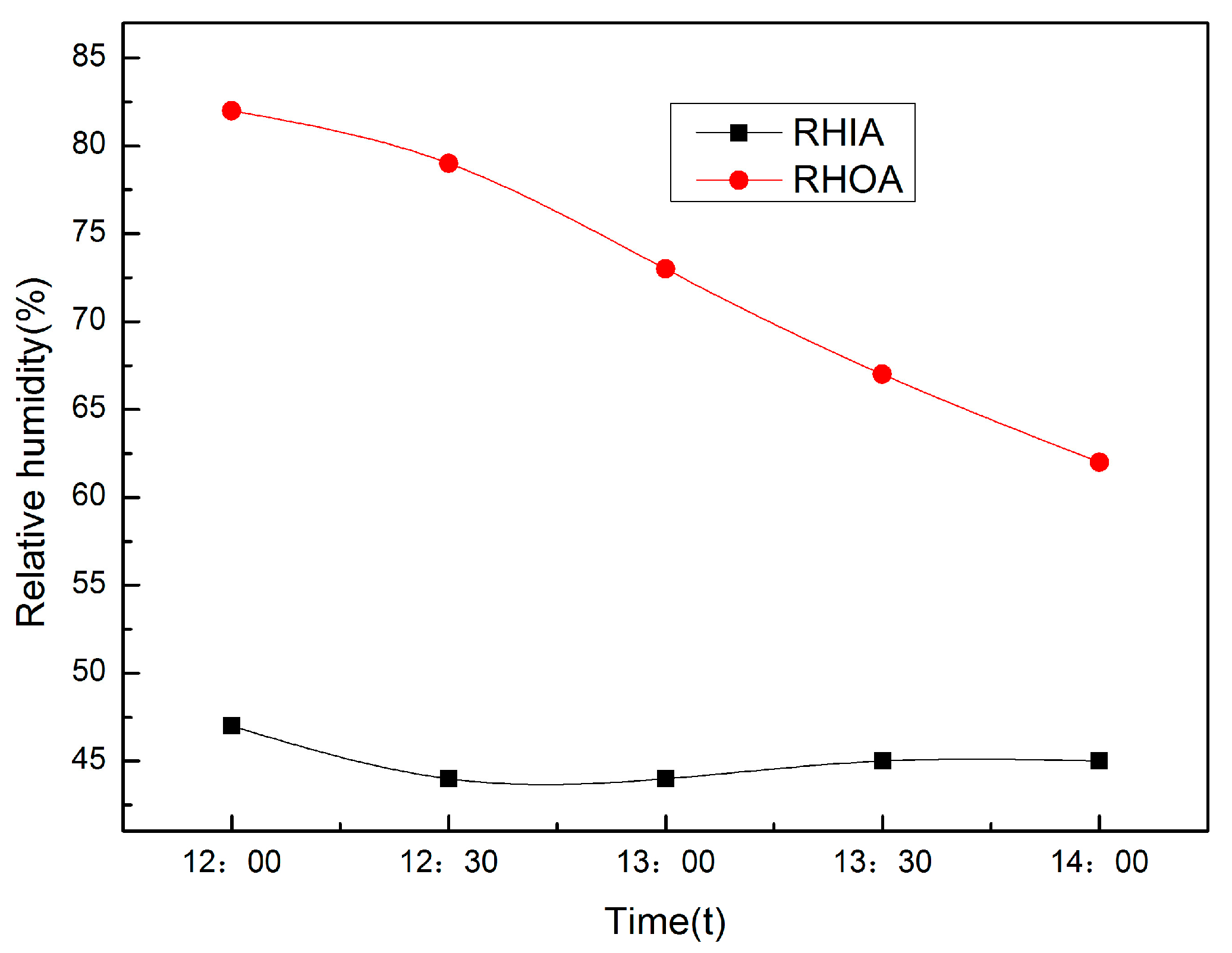

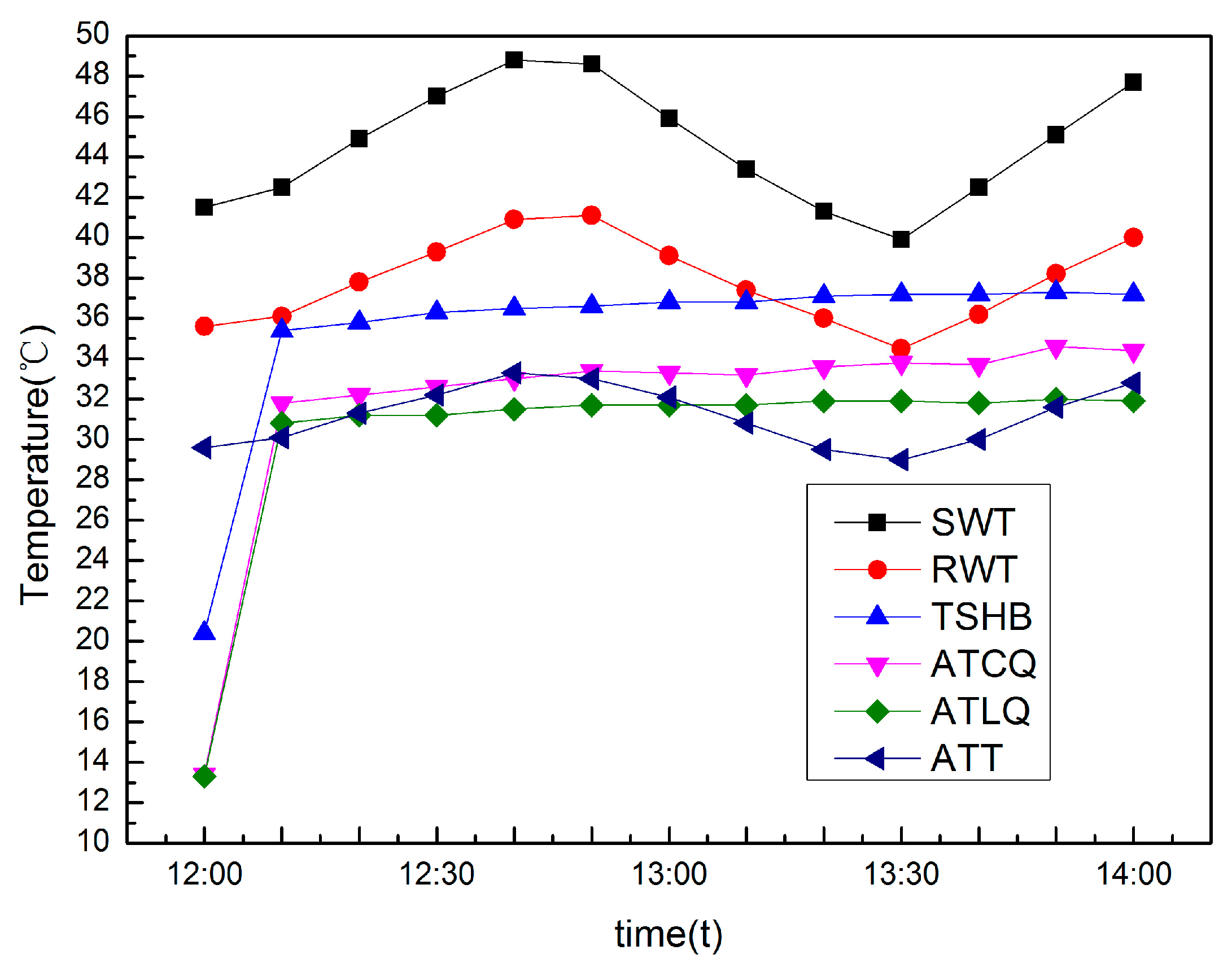

4.1.1. Analysis of Data Changes at Different Measurement Points

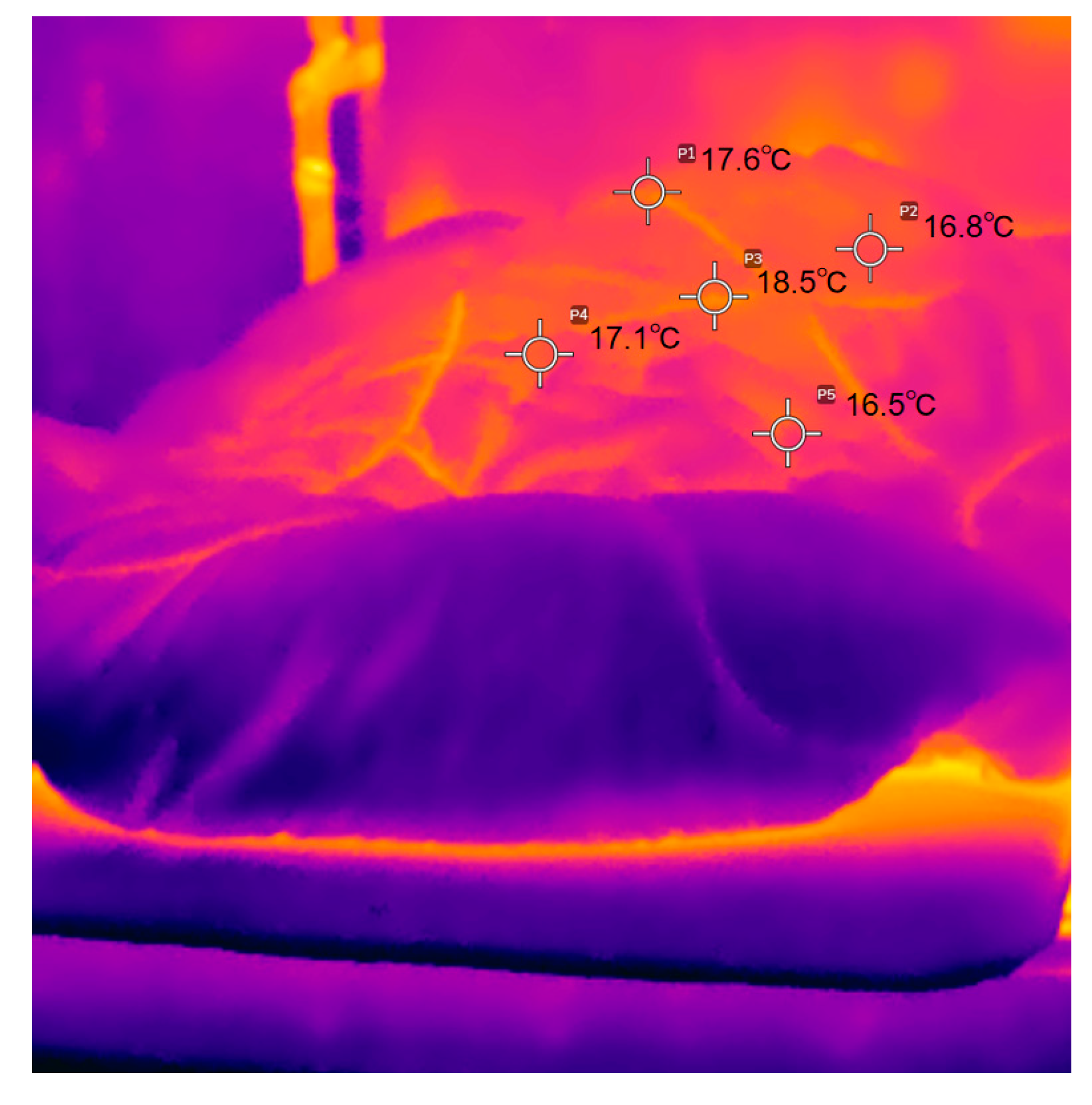

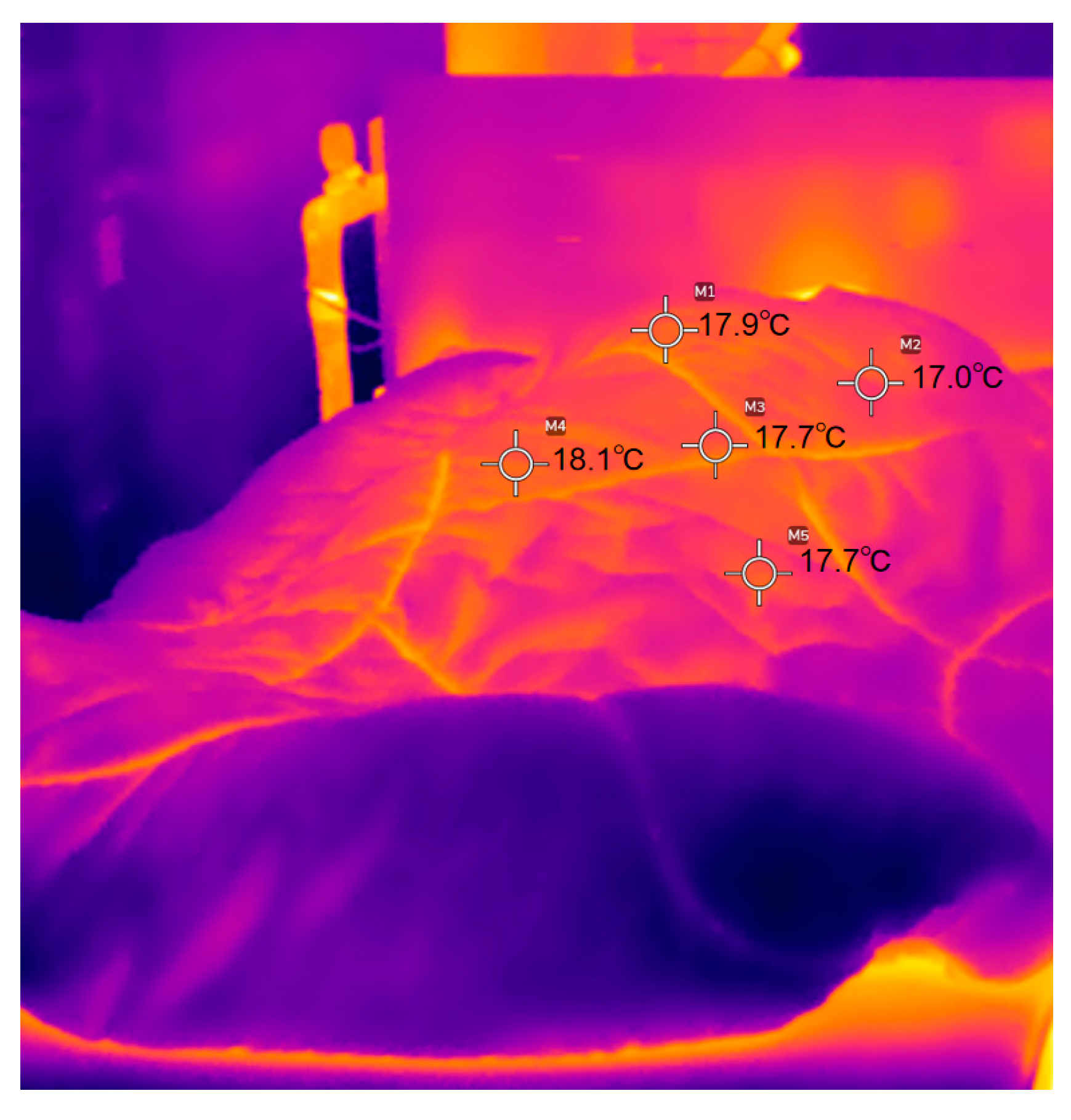

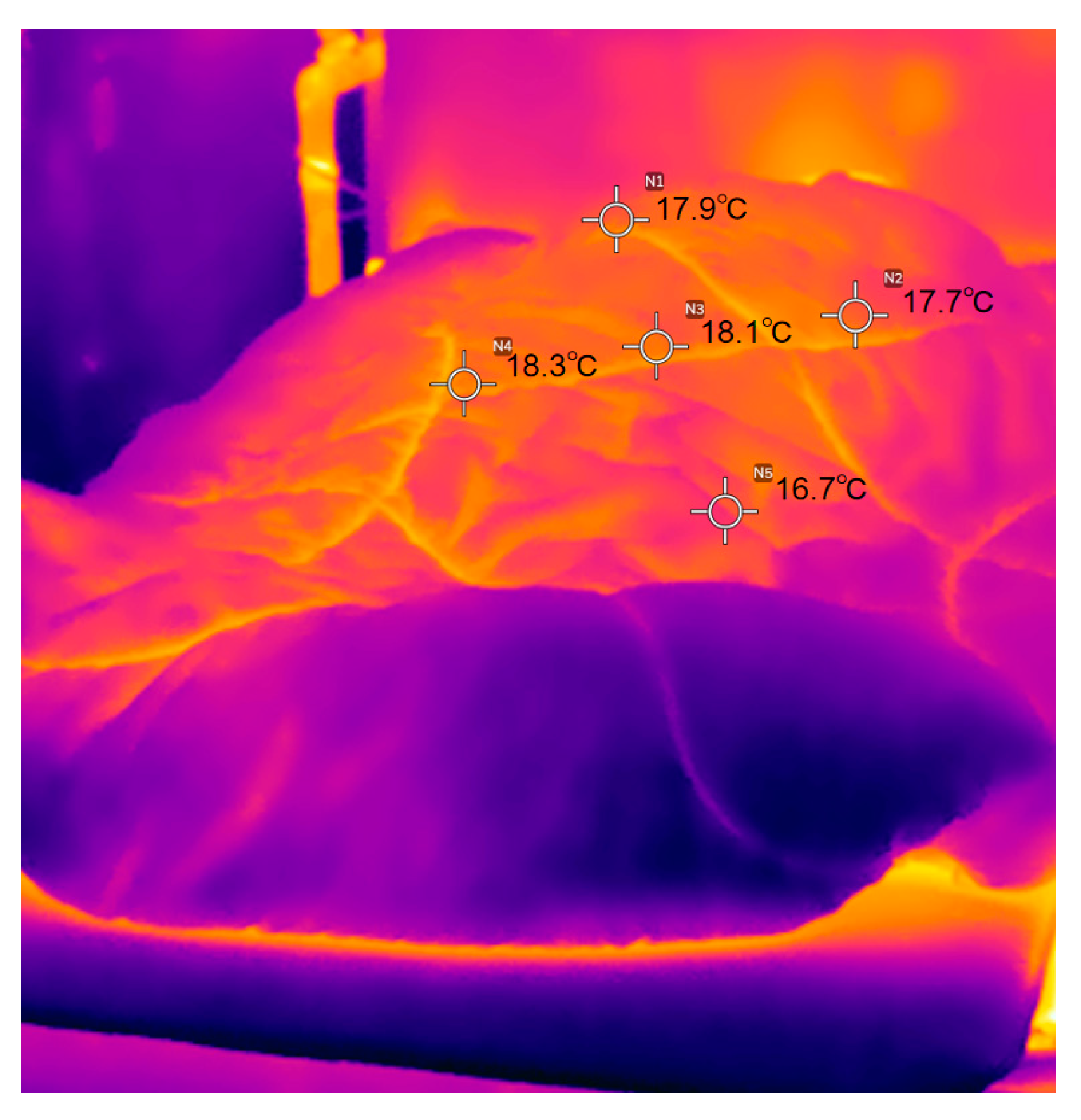

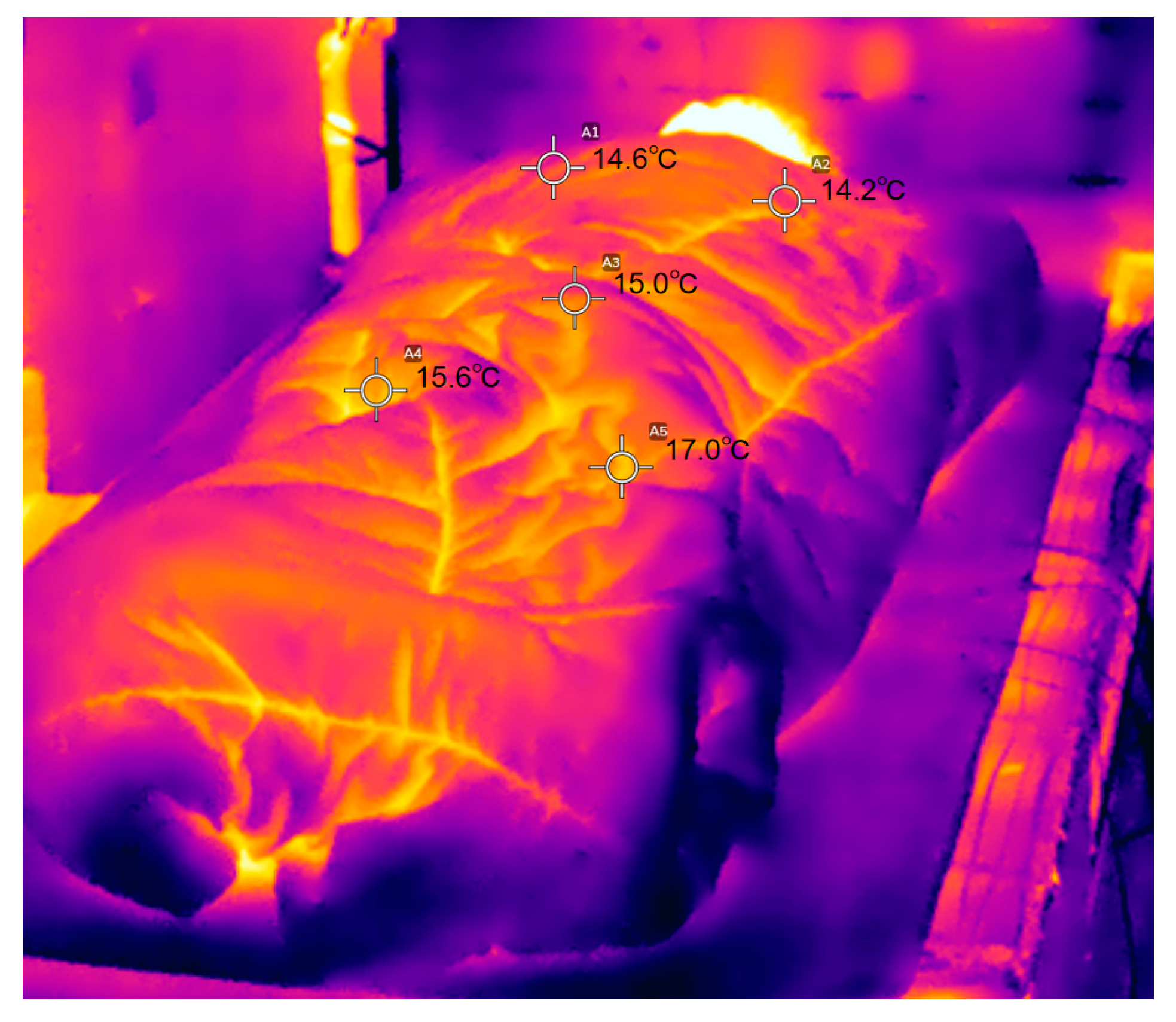

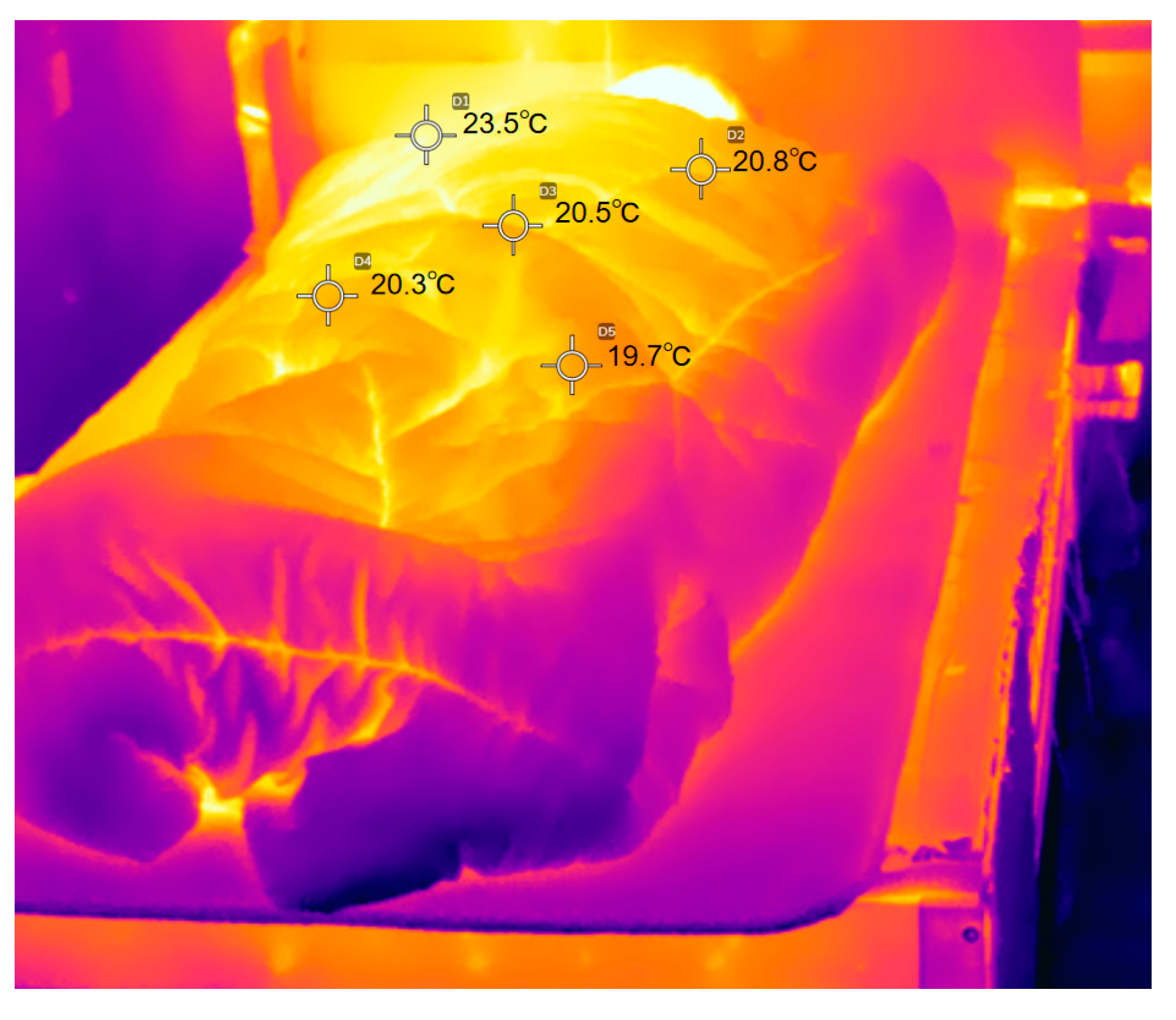

4.1.2. Temperature Analysis of Infrared Thermal Imager

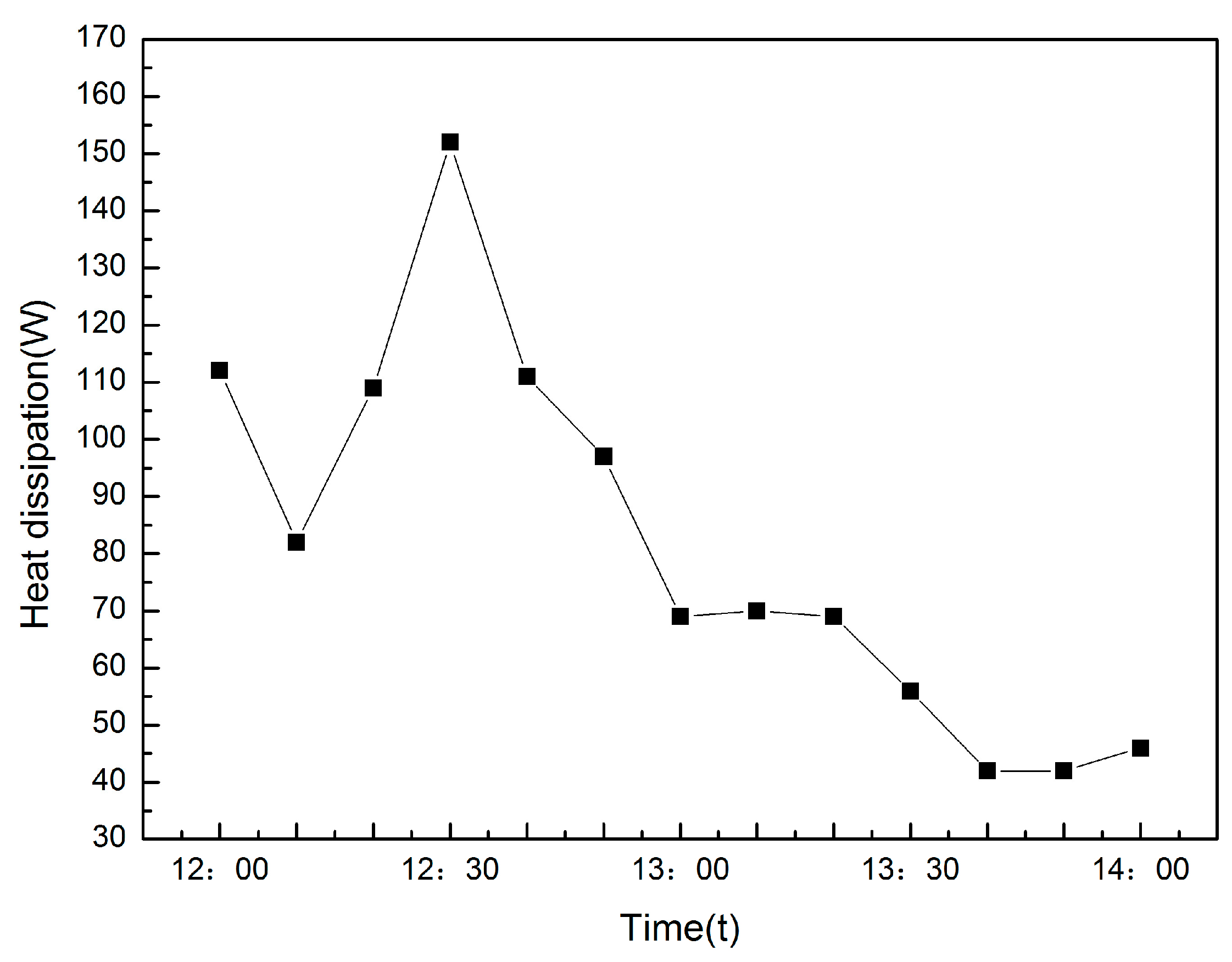

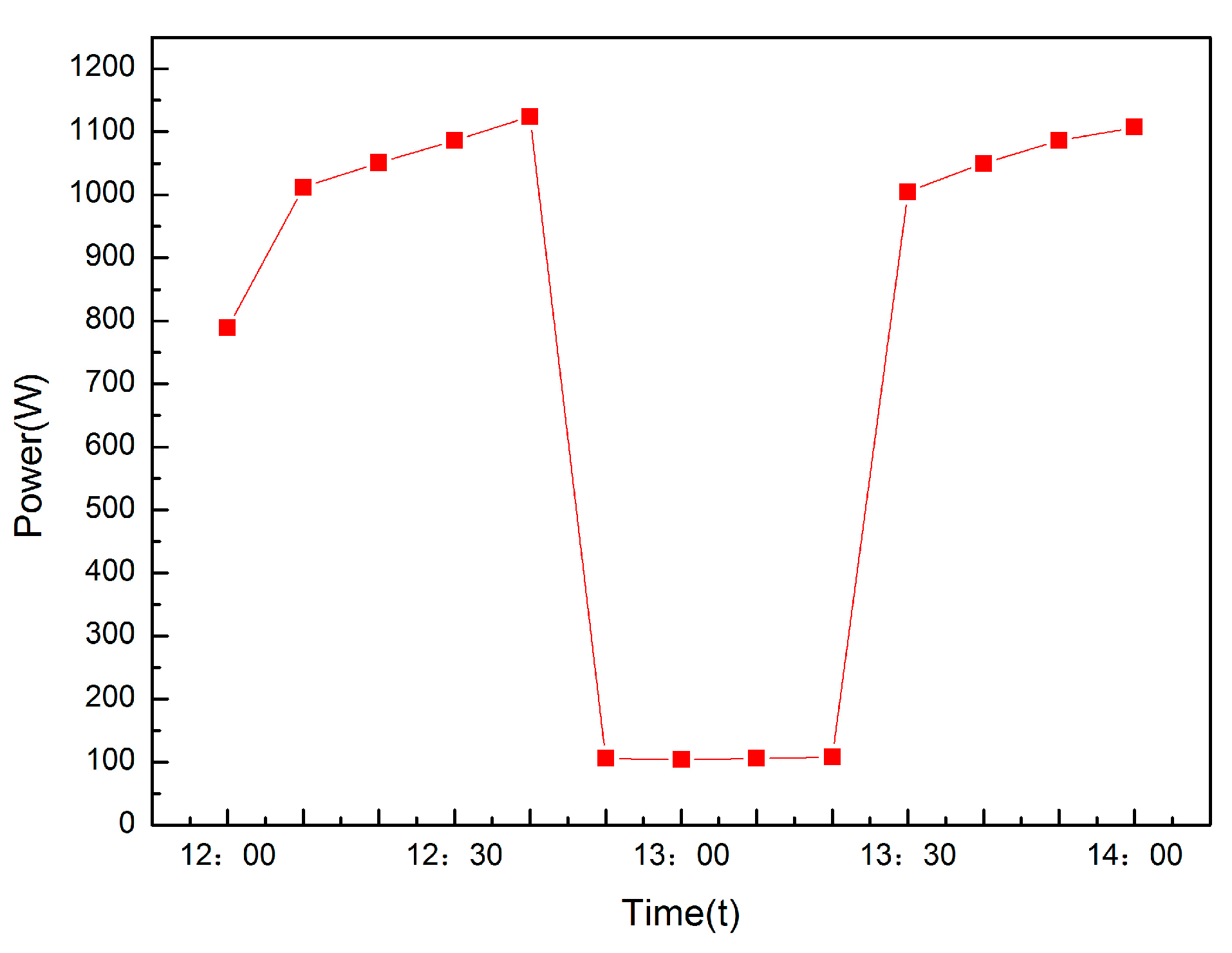

4.1.3. Analysis of Power and Heat Dissipation Data

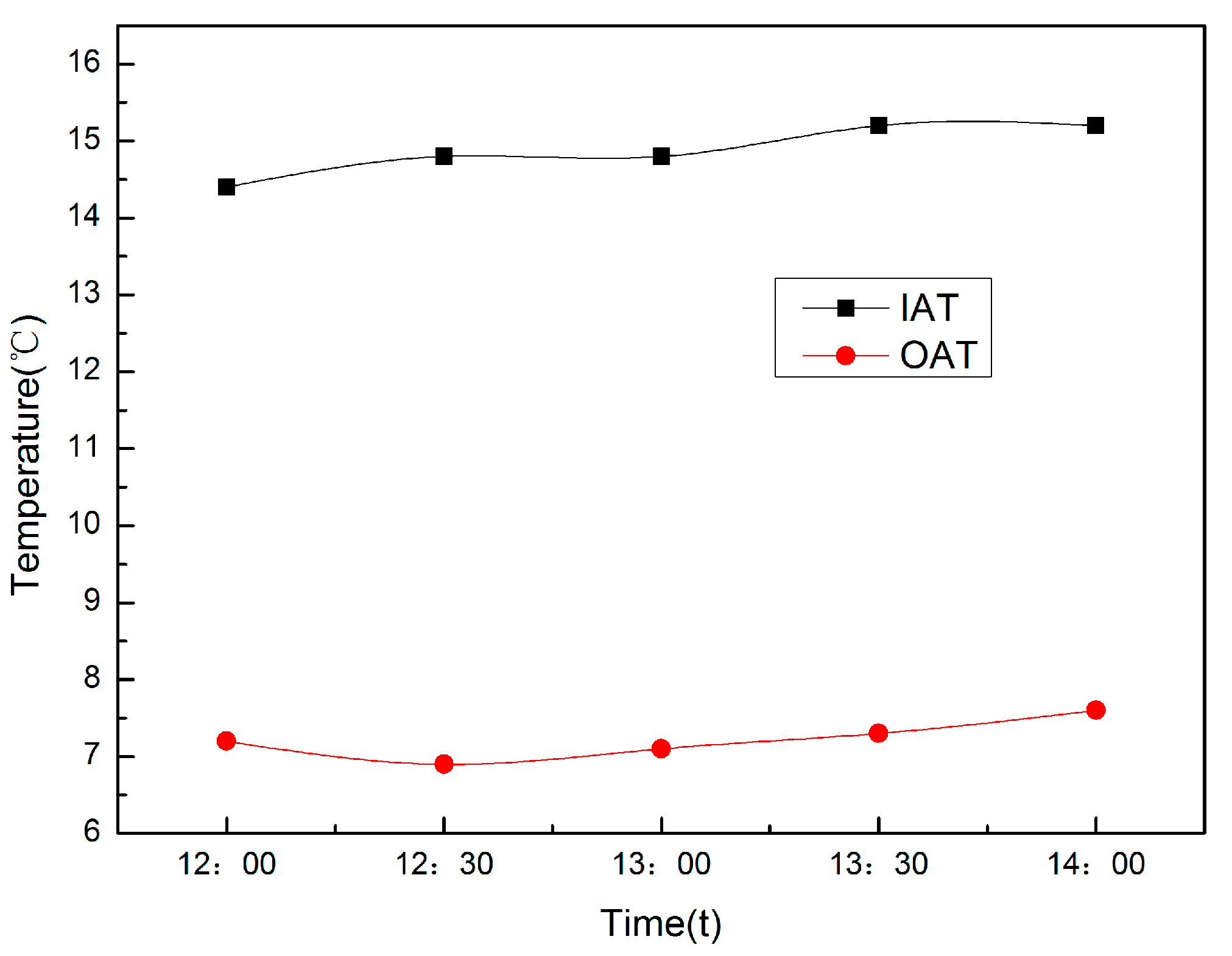

4.2. Experimental Results of Convective Heat Exchange Heating

4.2.1. Analysis of Data Changes at Different Measurement Points

4.2.2. Temperature Analysis of Infrared Thermal Imager

4.2.3. Analysis of Power and Heat Dissipation Data

5. Discussion

5.1. Thermal Comfort Analysis

5.2. Energy Saving Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| IAT | Indoor air temperature (°C) |

| OAT | Outdoor air temperature (°C) |

| RHIA | Relative humidity of indoor air (%) |

| RHOA | Relative humidity of outdoor air (%) |

| SWT | Supply water temperature (°C) |

| RWT | Return water temperature (°C) |

| STSWC | Surface temperature of supply water capillary (°C) |

| STRWC | Surface temperature of return water capillary (°C) |

| TSHB | Temperature of the contact surface between human body and bed (°C) |

| ATCQ | Air temperature near the chest in the quilt (°C) |

| ATLQ | Air temperature near the legs in the quilt (°C) |

| STM | Surface temperature of the sponge-padded mattress in the middle of the legs (°C) |

| ATT | Air temperature of tuyere (°C) |

References

- Zhang, H.; Arens, E.; Zhai, Y. A review of the corrective power of personal comfort systems in non-neutral ambient environments. Build. Environ. 2015, 91, 15–41. [Google Scholar] [CrossRef]

- Tian, X.Y.; Liu, W.W.; Liu, J.W.; Yu, B.; Zhang, J. Effects of personal heating on thermal comfort: A review. J. Cent. South Univ. 2022, 29, 2279–2300. [Google Scholar] [CrossRef]

- Shahzad, S.; Calautit, J.K.; Calautit, K.; Hughes, B.R.; Aquino, A.I. Advanced Personal Comfort System (APCS) for the workplace: A review and case study. Energy Build. 2018, 173, 689–709. [Google Scholar] [CrossRef]

- Godithi, S.B.; Sachdeva, E.; Garg, V.; Brown, R.; Kohler, C.; Rawal, R. A review of advances for thermal and visual comfort controls in personal environmental control (PEC) systems. Intell. Build. Int. 2019, 11, 75–104. [Google Scholar] [CrossRef]

- Warthmann, A.; Wölki, D.; Metzmacher, H.; Van Treeck, C. Personal Climatization Systems—A Review on Existing and Upcoming Concepts. Appl. Sci. 2018, 9, 35. [Google Scholar] [CrossRef]

- Rawal, R.; Schweiker, M.; Kazanci, O.B.; Vardhan, V.; Duanmu, L. Personal Comfort Systems: A review on comfort, energy, and economics. Energy Build. 2020, 214, 109858. [Google Scholar] [CrossRef]

- Li, N.; He, D.; He, Y.; He, M.; Zhang, W. Experimental Study on Thermal Comfort with Radiant Cooling Workstation and Desktop Fan in Hot—Humid Environment. J. Huanan Univ. Nat. Sci. 2017, 44, 198–204. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhang, H.; Zhang, Y.; Pasut, W.; Arens, E.; Meng, Q. Comfort under personally controlled air movement in warm and humid environments. Build. Environ. 2013, 65, 109–117. [Google Scholar] [CrossRef]

- Huang, L.; Ouyang, Q.; Zhu, Y.; Jiang, L. A study about the demand for air movement in warm environment. Build. Environ. 2013, 61, 27–33. [Google Scholar] [CrossRef]

- Zhang, H.; Arens, E.; Kim, D.; Buchberger, E.; Bauman, F.; Huizenga, C. Comfort, perceived air quality, and work performance in a low-power task–ambient conditioning system. Build. Environ. 2010, 45, 29–39. [Google Scholar] [CrossRef]

- He, Y.; Wang, X.; Li, N.; He, M.; He, D. Heating chair assisted by leg-warmer: A potential way to achieve better thermal comfort and greater energy conservation in winter. Energy Build. 2018, 158, 1106–1116. [Google Scholar] [CrossRef]

- Pasut, W.; Zhang, H.; Arens, E.; Zhai, Y. Energy-efficient comfort with a heated/cooled chair: Results from human subject tests. Build. Environ. 2015, 84, 10–21. [Google Scholar] [CrossRef]

- Oi, H.; Yanagi, K.; Tabata, K.; Tochihara, Y. Effects of heated seat and foot heater on thermal comfort and heater energy consumption in vehicle. Ergonomics 2011, 54, 690–699. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Arens, E.; Taub, M.; Dickerhoff, D.; Bauman, F.; Fountain, M.; Pasut, W.; Fannon, D.; Zhai, Y.; Pigman, M. Using footwarmers in offices for thermal comfort and energy savings. Energy Build. 2015, 104, 233–243. [Google Scholar] [CrossRef]

- Foda, E.; Sirén, K. Design strategy for maximizing the energy-efficiency of a localized floor-heating system using a thermal manikin with human thermoregulatory control. Energy Build. 2012, 51, 111–121. [Google Scholar] [CrossRef]

- Zeiler, W.; Boxem, G. Effects of thermal activated building systems in schools on thermal comfort in winter. Build. Environ. 2009, 44, 2308–2317. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, R.; Li, Y.; Miao, Y.; Zhao, J. Human thermal sensation and comfort in a non-uniform environment with personalized heating. Sci. Total Environ. 2017, 578, 242–248. [Google Scholar] [CrossRef]

- Arens, E.; Zhang, H.; Huizenga, C. Partial- and whole-body thermal sensation and comfort—Part II: Non-uniform environmental conditions. J. Therm. Biol. 2006, 31, 60–66. [Google Scholar] [CrossRef]

- Lv, B.; Su, C.; Yang, L.; Wu, T. Effects of stimulus mode and ambient temperature on cerebral responses to local thermal stimulation: An EEG study. Int. J. Psychophysiol. 2017, 113, 17–22. [Google Scholar] [CrossRef]

- Schellen, L.; Loomans, M.G.; de Wit, M.H.; Olesen, B.W.; van Marken Lichtenbelt, W.D. The influence of local effects on thermal sensation under non-uniform environmental conditions--gender differences in thermophysiology, thermal comfort and productivity during convective and radiant cooling. Physiol. Behav. 2012, 107, 252–261. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Chen, P.; Liu, Y.; Wu, C.; Liu, J. Heat transfer characteristics of a novel sleeping bed with an integrated hot water heating system. Appl. Therm. Eng. 2017, 113, 79–86. [Google Scholar] [CrossRef]

- Yu, G.; Gao, S.; Qiang, j. Modeling of heartbeat for sleep in integrated with PCM thermal storage and solar heating. J. Chongqing Univ. 2011, 34, 89–92. [Google Scholar]

- Pan, D.; Chan, M.; Xia, L.; Xu, X.; Deng, S. Performance evaluation of a novel bed-based task/ambient conditioning (TAC) system. Energy Build. 2012, 44, 54–62. [Google Scholar] [CrossRef]

- Mao, N.; Pan, D.; Chan, M.; Deng, S. Experimental and numerical studies on the performance evaluation of a bed-based task/ambient air conditioning (TAC) system. Appl. Energy 2014, 136, 956–967. [Google Scholar] [CrossRef]

- Mao, N.; Song, M.; Deng, S.; Pan, D.; Chen, S. Experimental and numerical study on air flow and moisture transport in sleeping environments with a task/ambient air conditioning (TAC) system. Energy Build. 2016, 133, 596–604. [Google Scholar] [CrossRef]

- Mao, N.; Pan, D.; Li, Z.; Xu, Y.; Song, M.; Deng, S. A numerical study on influences of building envelope heat gain on operating performances of a bed-based task/ambient air conditioning (TAC) system in energy saving and thermal comfort. Appl. Energy 2017, 192, 213–221. [Google Scholar] [CrossRef]

- Mao, N.; Hao, J.; Cui, B.; Li, Y.; Song, M.; Xu, Y.; Deng, S. Energy performance of a bedroom task/ambient air conditioning (TAC) system applied in different climate zones of China. Energy 2018, 159, 724–736. [Google Scholar] [CrossRef]

- Du, J.; Chan, M.; Deng, S. An experimental study on the performances of a radiation-based task/ambient air conditioning system applied to sleeping environments. Energy Build. 2017, 139, 291–301. [Google Scholar] [CrossRef]

- Catalina, T.; Virgone, J.; Kuznik, F. Evaluation of thermal comfort using combined CFD and experimentation study in a test room equipped with a cooling ceiling. Build. Environ. 2009, 44, 1740–1750. [Google Scholar] [CrossRef]

- Mikeska, T.; Svendsen, S. Study of thermal performance of capillary micro tubes integrated into the building sandwich element made of high performance concrete. Appl. Therm. Eng. 2013, 52, 576–584. [Google Scholar] [CrossRef]

- Xin, Y.; Cui, W.; Zeng, J. Experimental study on thermal comfort in a confined sleeping environment heating with capillary radiation panel. Energy Build. 2019, 205, 109540. [Google Scholar] [CrossRef]

- Jiang, P.; Huang, Y.; Wei, X.; Mu, Y. Effect of Local Radiant Heating on Thermal Comfort in Cold Environment. J. BEE 2022, 50, 52–55. [Google Scholar] [CrossRef]

- Fanger, P.O.; Melikov, A.K.; Hanzawa, H.; Ring, J. Air turbulence and sensation of draught. Energy Build. 1988, 12, 21–39. [Google Scholar] [CrossRef]

- He, Y.; Li, N.; Huang, Q. A field study on thermal environment and occupant local thermal sensation in offices with cooling ceiling in Zhuhai, China. Energy Build. 2015, 102, 277–283. [Google Scholar] [CrossRef]

| Temperature Range (°C) | Thermal Sensation (Number of Voters) | ||||

|---|---|---|---|---|---|

| Cold | Cool | Neutral | Warm | Hot | |

| (24.0–33.0) | 8 | 0 | 0 | 0 | 0 |

| (33.0–36.0) | 2 | 6 | 0 | 0 | 0 |

| (36.0–36.6) | 0 | 1 | 7 | 0 | 0 |

| (36.6–37.5) | 0 | 0 | 1 | 7 | 0 |

| (37.5–38.0) | 0 | 0 | 0 | 5 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, J.; Duan, P.; Liu, Y.; Chen, H.; Yu, T. Experimental Study on Convection and Heat Conduction Heating of an Air-Conditioned Bed System under Winter Lunch Break Mode. Processes 2023, 11, 2391. https://doi.org/10.3390/pr11082391

Jin J, Duan P, Liu Y, Chen H, Yu T. Experimental Study on Convection and Heat Conduction Heating of an Air-Conditioned Bed System under Winter Lunch Break Mode. Processes. 2023; 11(8):2391. https://doi.org/10.3390/pr11082391

Chicago/Turabian StyleJin, Junjie, Peiyao Duan, Yu Liu, Honglin Chen, and Tingting Yu. 2023. "Experimental Study on Convection and Heat Conduction Heating of an Air-Conditioned Bed System under Winter Lunch Break Mode" Processes 11, no. 8: 2391. https://doi.org/10.3390/pr11082391

APA StyleJin, J., Duan, P., Liu, Y., Chen, H., & Yu, T. (2023). Experimental Study on Convection and Heat Conduction Heating of an Air-Conditioned Bed System under Winter Lunch Break Mode. Processes, 11(8), 2391. https://doi.org/10.3390/pr11082391