Container Terminal Digital Twin Yard System Construction

Abstract

:1. Introduction

- The process of terminal production and operation cannot be analyzed retrospectively;

- The production and operation of the terminal cannot be visualized;

- The terminal production and operation process cannot be effectively improved;

- The level of terminal intelligence cannot be effectively evaluated;

- The intelligent module of the terminal cannot be effectively iterated;

- The terminal cannot effectively preview the future time state.

2. Related Work

3. Container Terminal Yard Digital Twin Framework

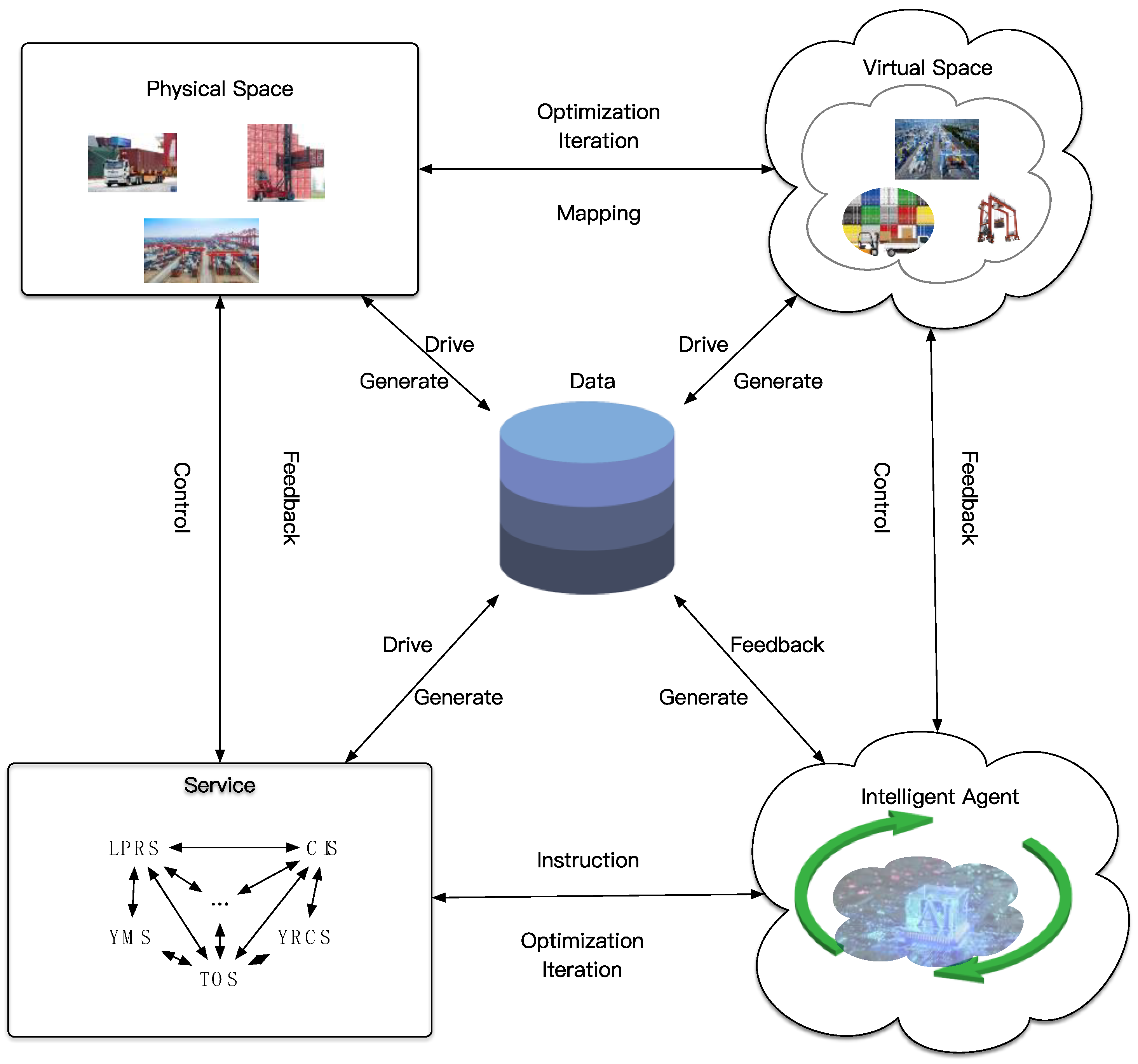

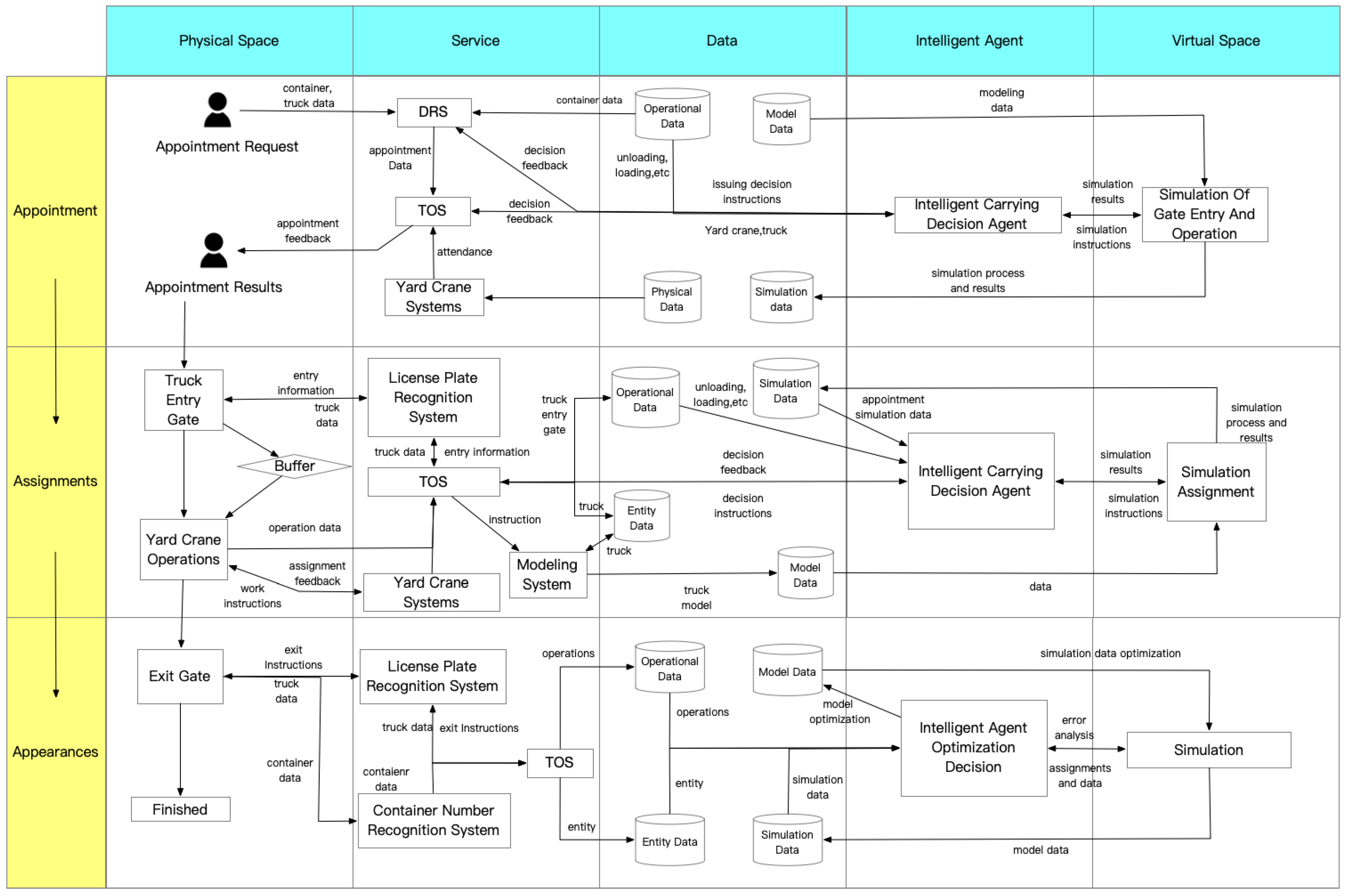

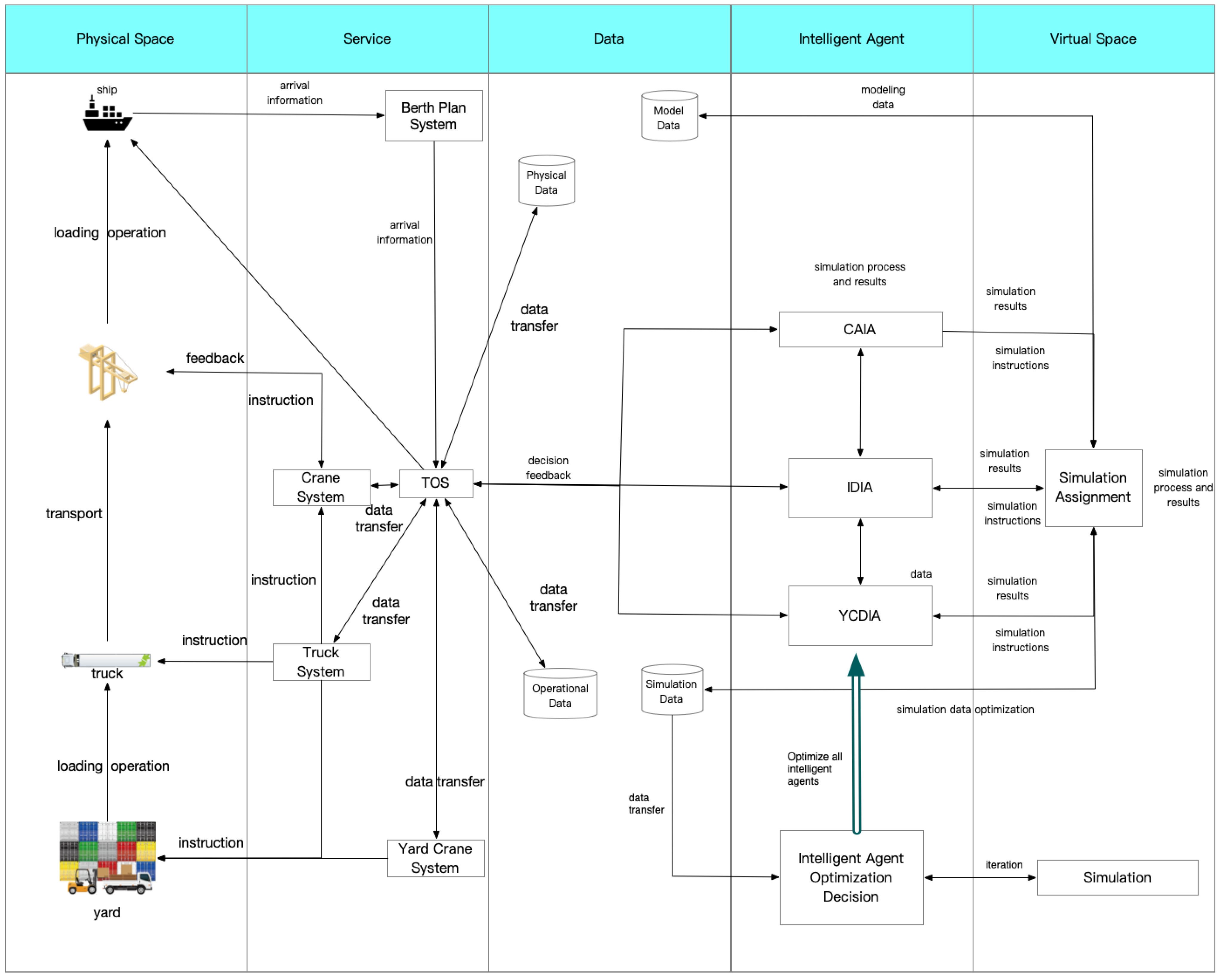

3.1. Architecture System

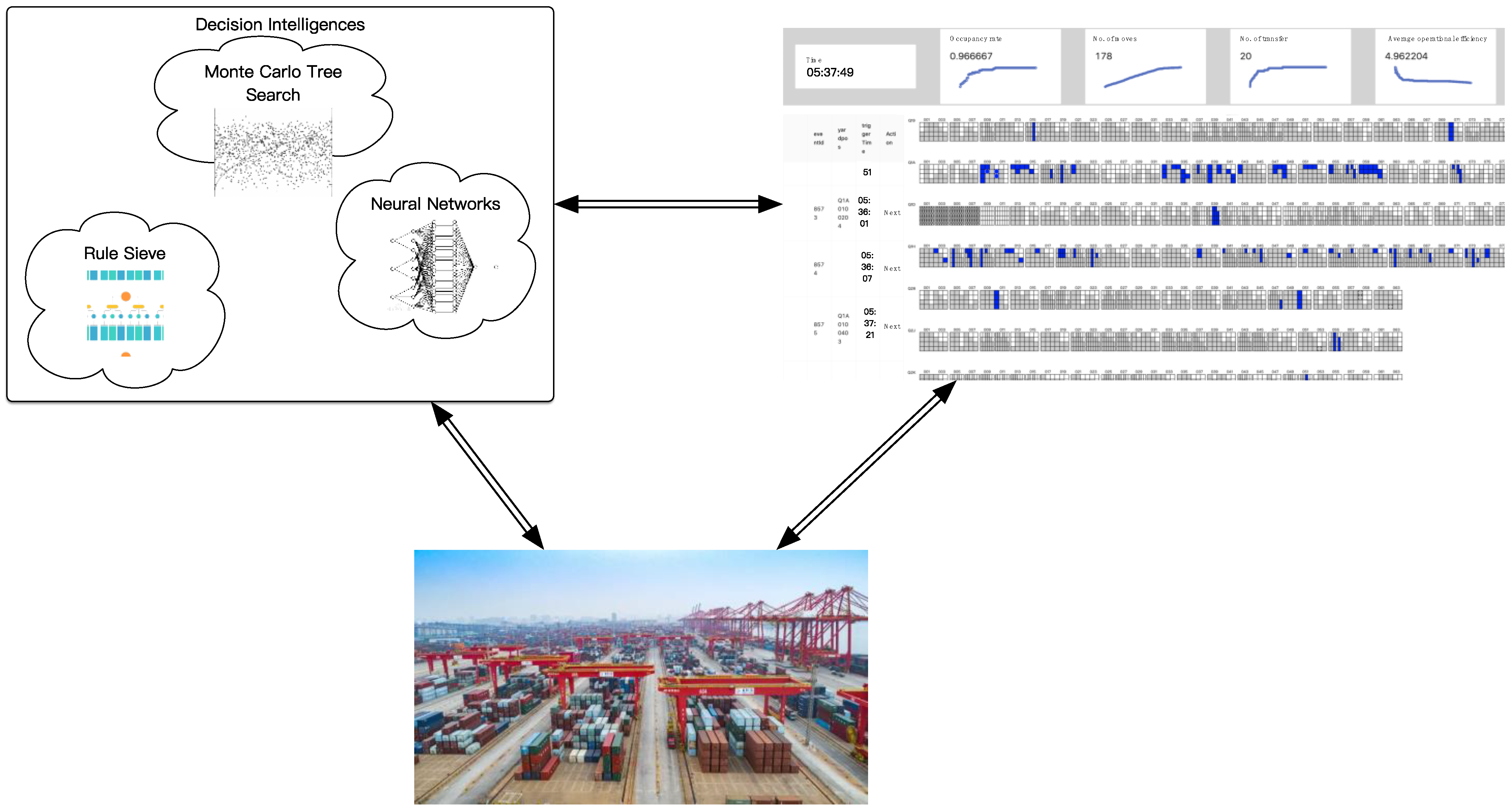

3.2. Core Technology

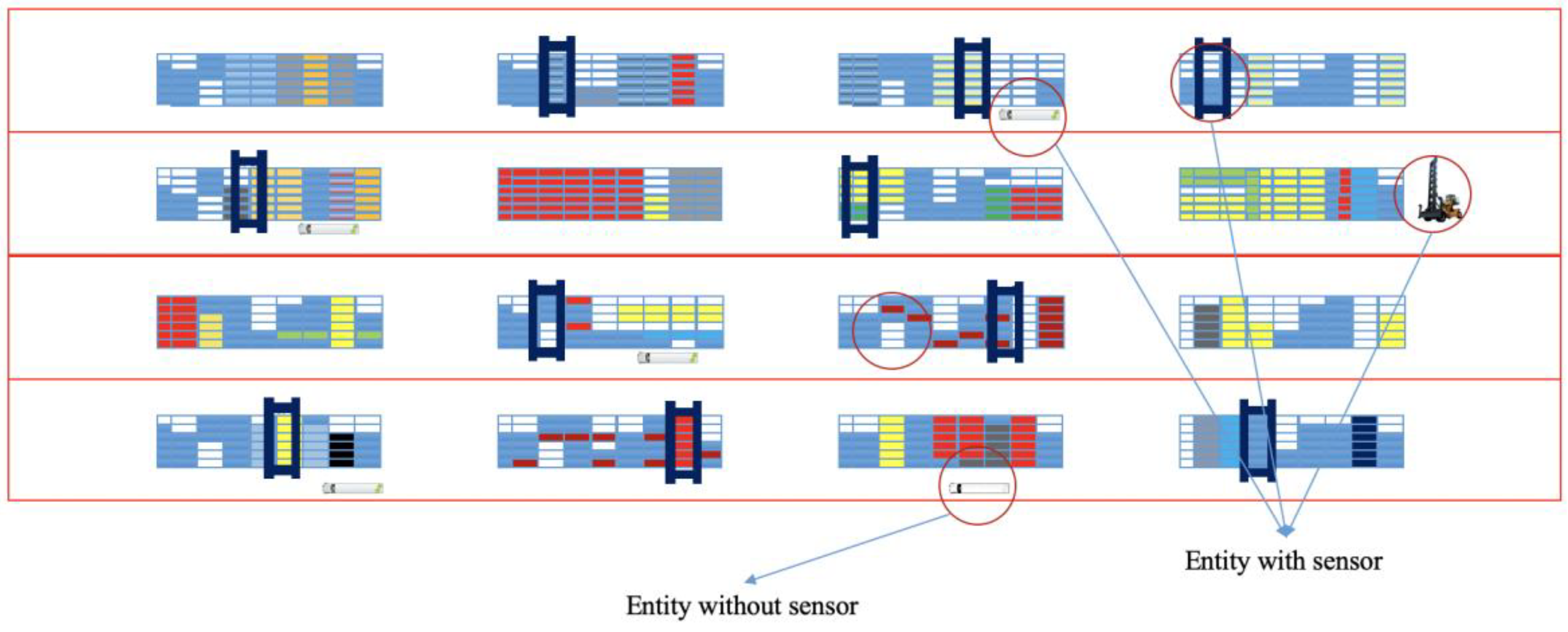

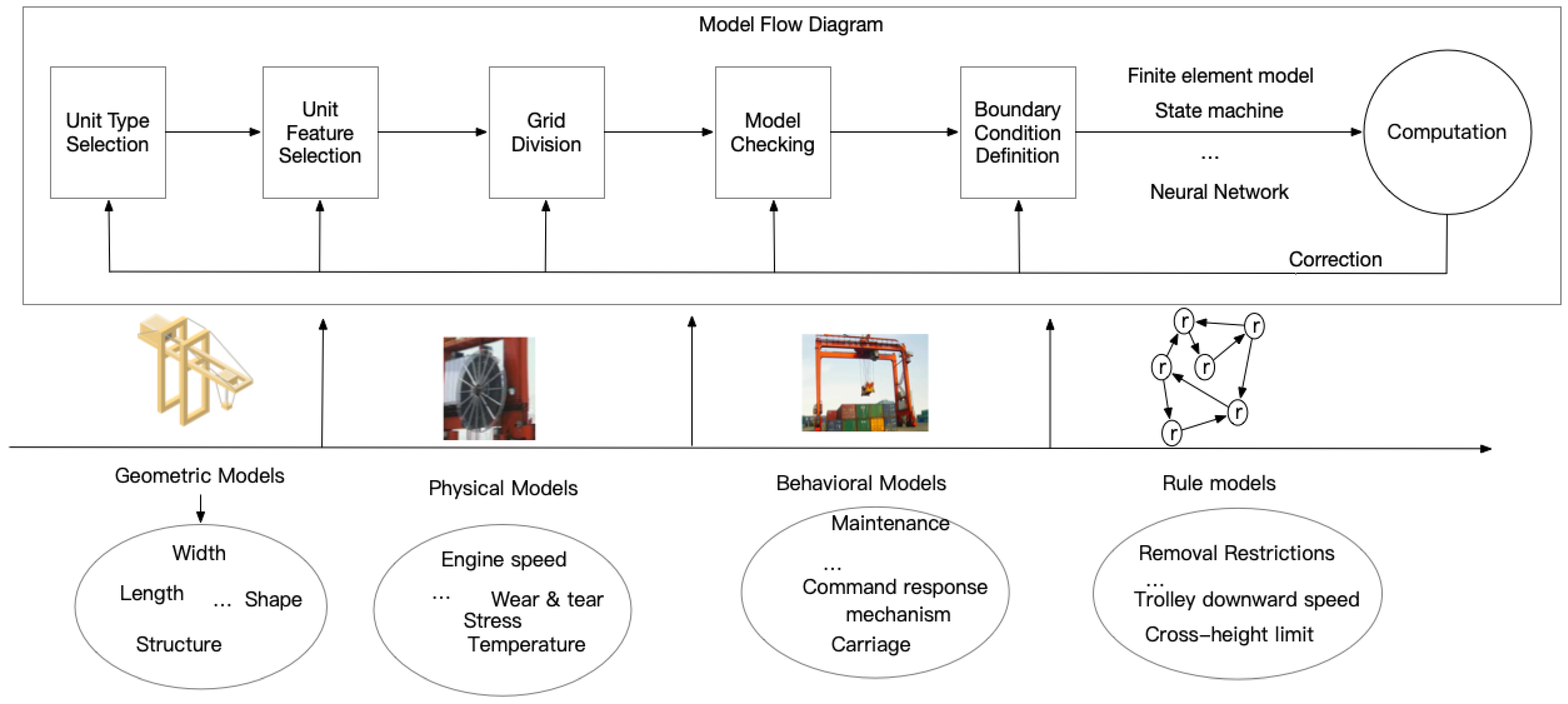

3.2.1. Spatial Model Construction

3.2.2. Dynamic Integration of Service Systems

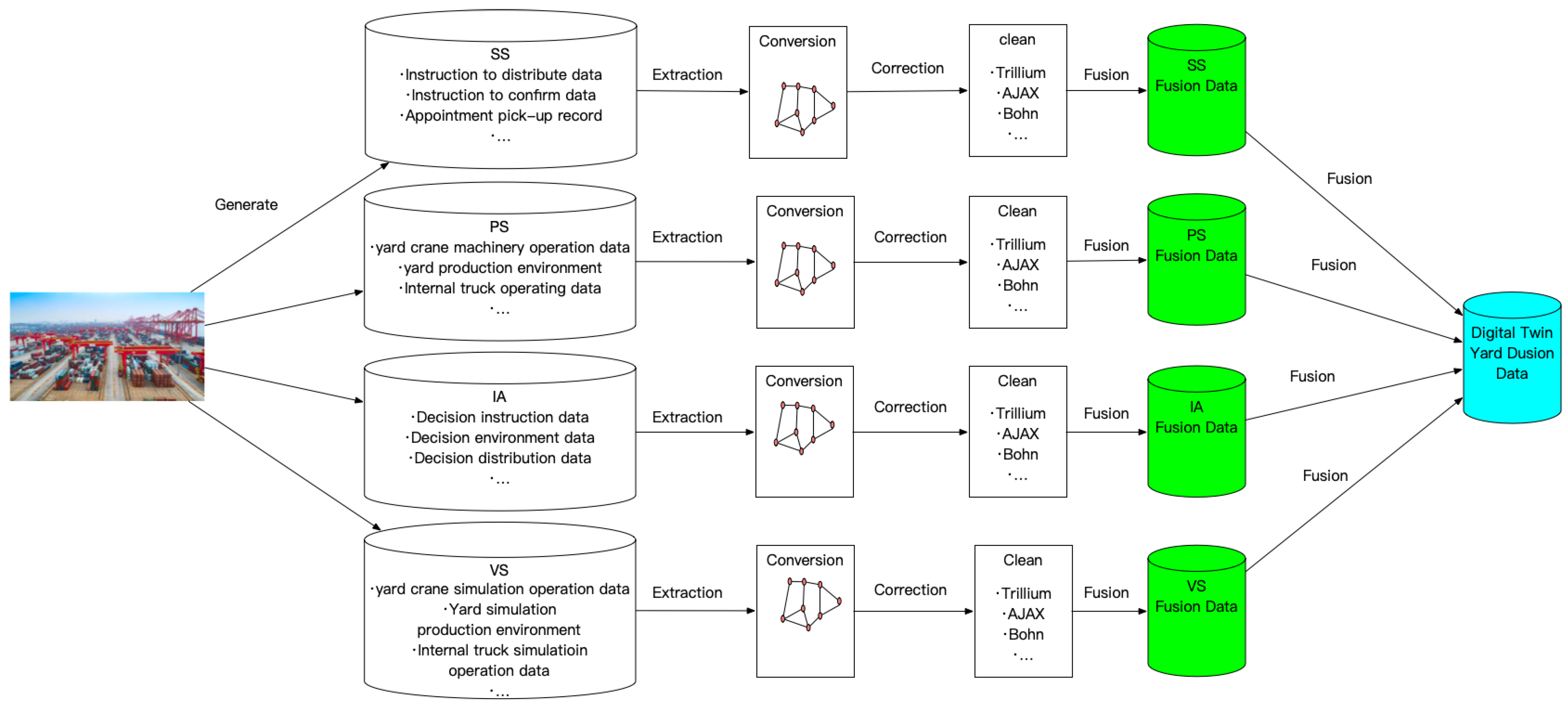

3.2.3. Data Warehouse

3.2.4. Intelligent Agent Decision Optimization

4. Optimization of the Production Process

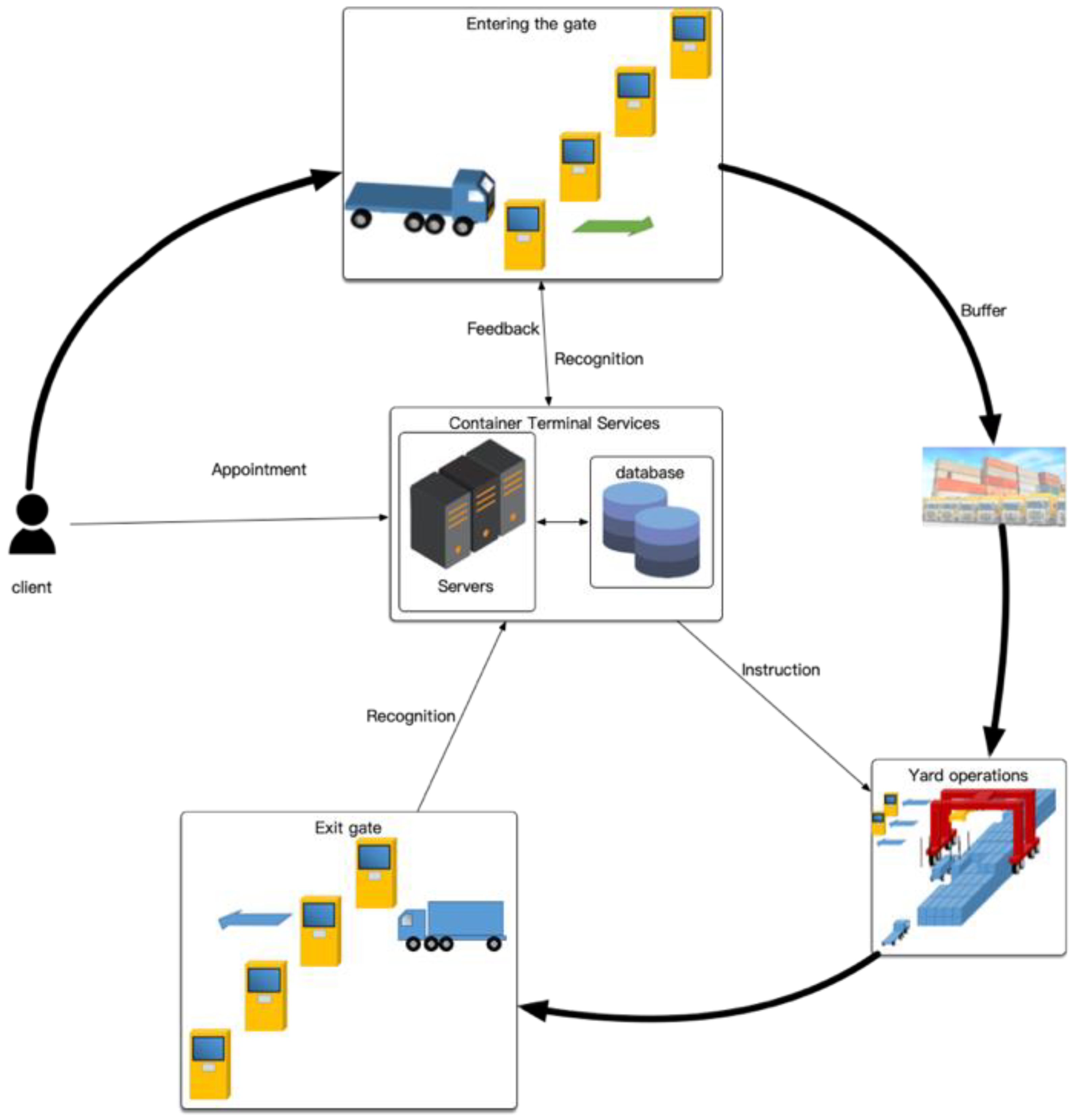

4.1. Optimization of the Container Delivery Operation Process

4.1.1. Existing Container Delivery Process

4.1.2. Delivery Operation under a Digital Twin Yard

4.2. Digital Twin Loading Operation Process

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A.Y.C. Digital twin driven prognostics and health management for complex equipment. Cirp Ann. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Tao, F.; Xiao, B.; Qi, Q.; Cheng, J.; Ji, P. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- Li, Y.; Chang, D.; Gao, Y.; Zou, Y.; Bao, C. Automated container terminal production operation and optimization via an adaboost-based digital twin framework. J. Adv. Transp. 2021, 2021, 1–16. [Google Scholar]

- Wang, K.; Hu, Q.; Liu, J. Digital twin-driven approach for process management and traceability towards ship industry. Processes 2022, 10, 1083. [Google Scholar] [CrossRef]

- Jakovlev, S.; Eglynas, T.; Voznak, M.; Partila, P.; Tovarek, J.; Jusis, M.; Pocevicius, E.; Purlaura, Z. Development of an intelligent digital twins framework for secure container terminal operations. In Proceedings of the 2021 62nd International Scientific Conference on Information Technology and Management Science of Riga Technical University (ITMS), Riga, Latvia, 14–15 October 2021; pp. 1–4. [Google Scholar]

- Oliveira, L.; Castro, M.; Ramos, R.; Santos, J.; Silva, J.; Dias, L. Digital Twin for Monitoring Containerized Hazmat Cargo in Port Areas. In Proceedings of the 2022 17th Iberian Conference on Information Systems and Technologies (CISTI), Madrid, Spain, 22–25 June 2022; pp. 1–4. [Google Scholar]

- Zhao, B.; Li, X.; Sun, W.; Qian, J.; Liu, J.; Gao, M.; Guan, X.; Ma, Z.; Li, J. BioDT: An Integrated Digital-Twin-Based Framework for Intelligent Biomanufacturing. Processes 2023, 11, 1213. [Google Scholar] [CrossRef]

- Li, Y.; Li, M.; Yan, Z.; Li, R.; Tian, A.; Xu, X.; Zhang, H. Application of Life Cycle of Aeroengine Mainshaft Bearing Based on Digital Twin. Processes 2023, 11, 1768. [Google Scholar] [CrossRef]

- Kazała, R.; Luściński, S.; Strączyński, P.; Taneva, A. An Enabling Open-Source Technology for Development and Prototyping of Production Systems by Applying Digital Twinning. Processes 2021, 10, 21. [Google Scholar] [CrossRef]

- Wang, K.; Hu, Q.; Zhou, M.; Zun, Z.; Qian, X. Multi-aspect applications and development challenges of digital twin-driven management in global smart ports. Case Stud. Transp. Policy 2021, 9, 1298–1312. [Google Scholar] [CrossRef]

- Yang, A.; Liu, Y.; Xin, C.; Chen, Q.; Wang, L. Towards intuitive visualisation goals for the operation optimisation of automated container terminal based on digital twin technology. Marit. Policy Manag. 2023, 1–22. [Google Scholar] [CrossRef]

- Yang, W.; Bao, X.; Zheng, Y.; Zhang, L.; Zhang, Z.; Zhang, Z.; Li, L. A digital twin framework for large comprehensive ports and a case study of Qingdao Port. Int. J. Adv. Manuf. Technol. 2022, 1–18. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, W.; Zheng, Y.; Zhang, L.; Zhang, Z. Digital twin modeling method for container terminal in port. In Proceedings of the ASME 2022 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, St. Louis, MO, USA, 14–17 August 2022. V002T02A036. [Google Scholar]

- Zong, C.; Wan, Z. Container ship cell guide accuracy check technology based on improved 3d point cloud instance segmentation. Brodogradnja 2022, 73, 23–35. [Google Scholar] [CrossRef]

- Koroleva, E.; Sokolov, S.; Makashina, I.; Filatova, E. Digital maritime container terminal-An element of digitalization of container transportation systems. In Proceedings of the E3S Web of Conferences, Kenitra, Morocco, 25–27 December 2020; EDP Sciences: Les Ulis, France, 2020; Volume 203, p. 05004. [Google Scholar]

- Bielli, M.; Boulmakoul, A.; Rida, M. Object oriented model for container terminal distributed simulation. Eur. J. Oper. Res. 2006, 175, 1731–1751. [Google Scholar] [CrossRef]

- Mi, C.; Huang, S.; Zhang, Y.; Zhang, Z.; Postolache, O. Design and implementation of 3-D measurement method for container handling target. J. Mar. Sci. Eng. 2022, 10, 1961. [Google Scholar] [CrossRef]

- Szpytko, J.; Duarte, Y.S. Digital twins model for cranes operating in container terminal. IFAC-PapersOnLine 2019, 52, 25–30. [Google Scholar] [CrossRef]

- Derse, O.; Göçmen, E. A simulation modelling approach for analysing the transportation of containers in a container terminal system. Int. Sci. Vocat. Stud. J. 2018, 2, 19–28. [Google Scholar]

- Gao, Y.; Chang, D.; Chen, C.H. A digital twin-based approach for optimizing operation energy consumption at automated container terminals. J. Clean. Prod. 2023, 385, 135782. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, Z.; Chen, K.; Ding, H.; Voss, S.; Heilig, L.; Chen, Y.; Chen, X. Real-time monitoring and optimal resource allocation for automated container terminals: A digital twin application at the Yangshan Port. J. Adv. Transp. 2023, 2023, 6909801. [Google Scholar] [CrossRef]

- Zhao, N.; Fu, Z.; Sun, Y.; Pu, X.; Luo, L. Digital-twin driven energy-efficient multi-crane scheduling and crane number selection in workshops. J. Clean. Prod. 2022, 336, 130175. [Google Scholar] [CrossRef]

- Zhou, Y.; Fu, Z.; Zhang, J.; Li, W.; Gao, C. A digital twin-based operation status monitoring system for port cranes. Sensors 2022, 22, 3216. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Liang, C.; Zhao, N.; Xuan, B. Container Terminal Digital Twin Yard System Construction. Processes 2023, 11, 2223. https://doi.org/10.3390/pr11072223

Du X, Liang C, Zhao N, Xuan B. Container Terminal Digital Twin Yard System Construction. Processes. 2023; 11(7):2223. https://doi.org/10.3390/pr11072223

Chicago/Turabian StyleDu, Xueqiang, Chengji Liang, Ning Zhao, and Beng Xuan. 2023. "Container Terminal Digital Twin Yard System Construction" Processes 11, no. 7: 2223. https://doi.org/10.3390/pr11072223

APA StyleDu, X., Liang, C., Zhao, N., & Xuan, B. (2023). Container Terminal Digital Twin Yard System Construction. Processes, 11(7), 2223. https://doi.org/10.3390/pr11072223