Coffee Pulp: A Sustainable and Affordable Source for Developing Functional Foods

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Zone

2.2. Product Characterization

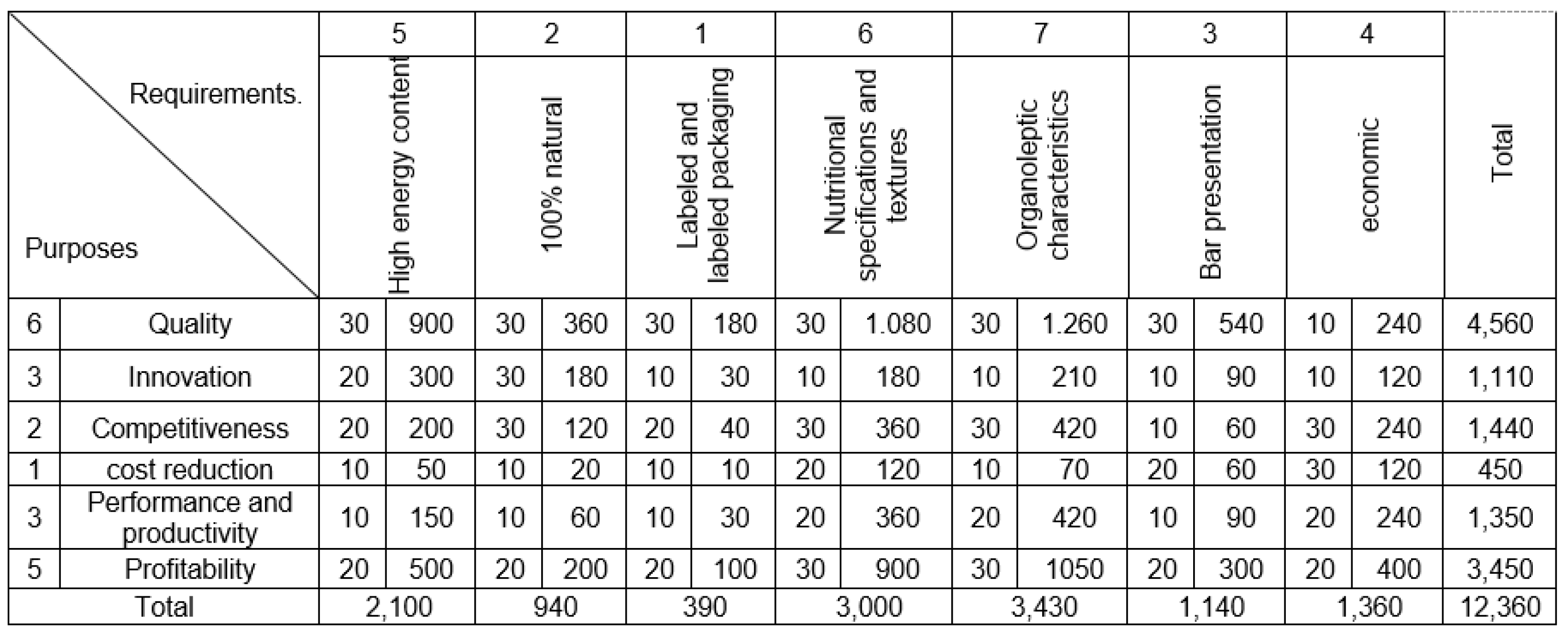

2.3. Quality Plan

2.4. Experimental Design

2.5. Proximal and Microbiological Analysis

3. Results and Discussion

3.1. Location of the Study Population and Characteristics of Inputs

3.2. Production Process Characteristics

3.3. Statistical Analysis of Experimental Design

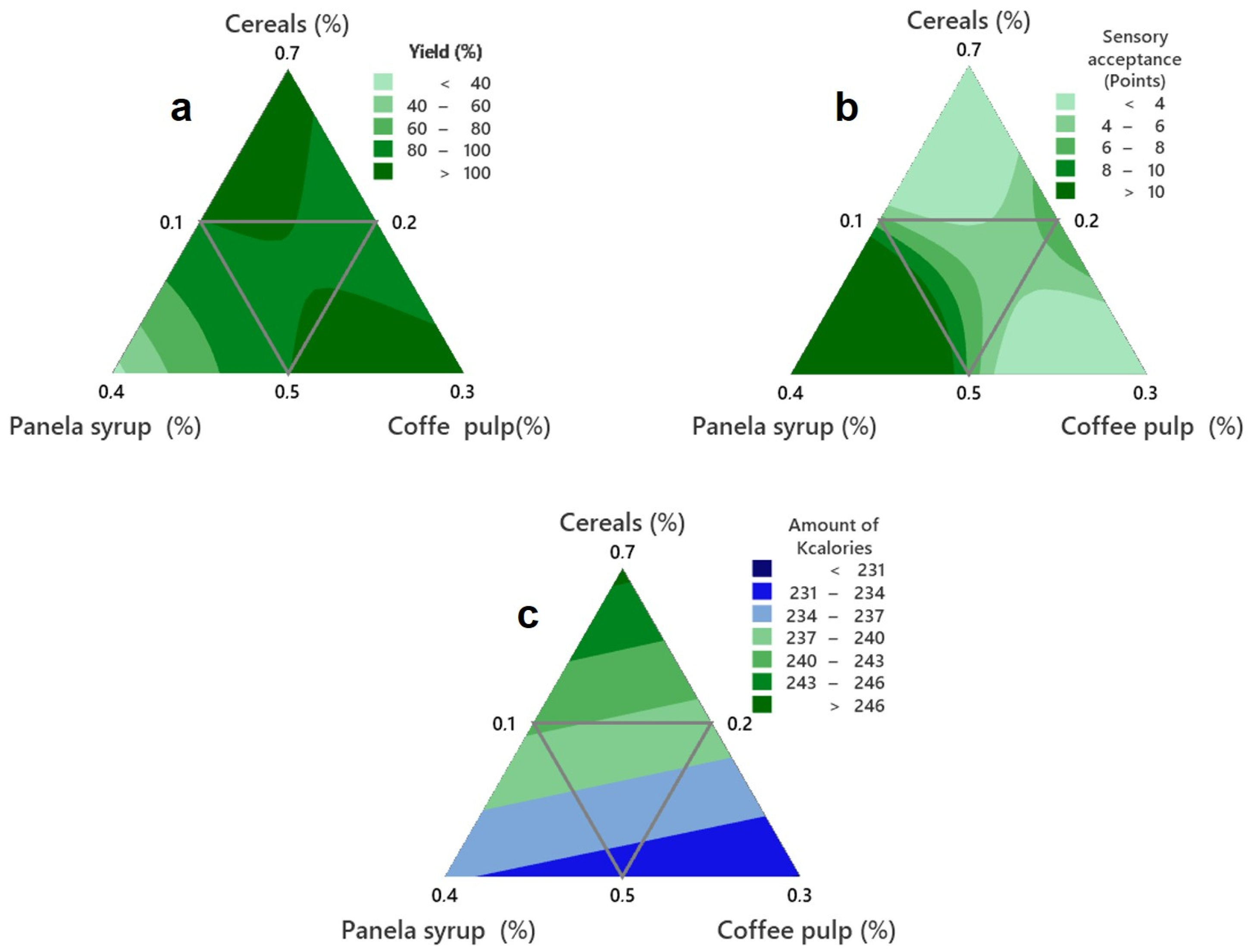

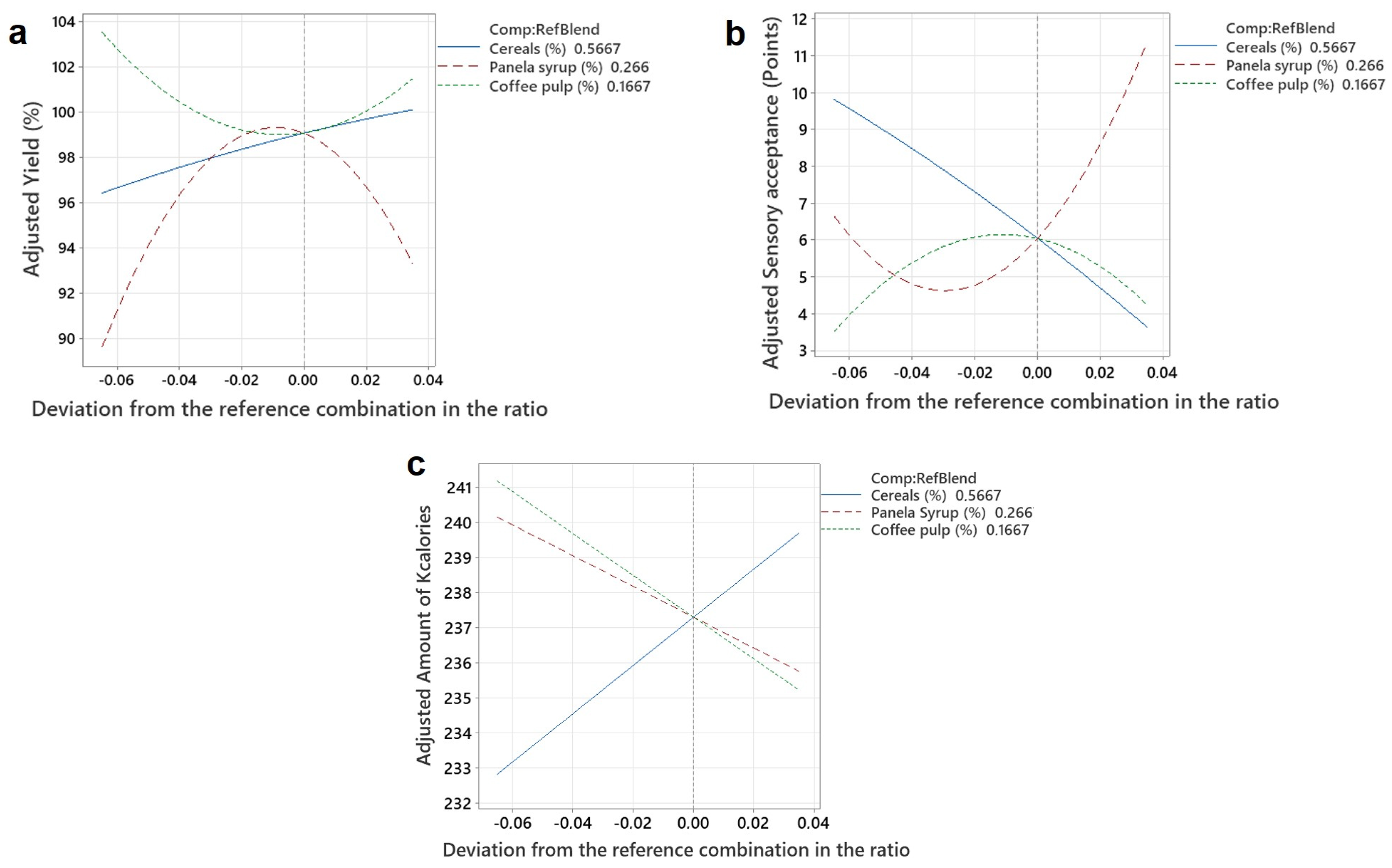

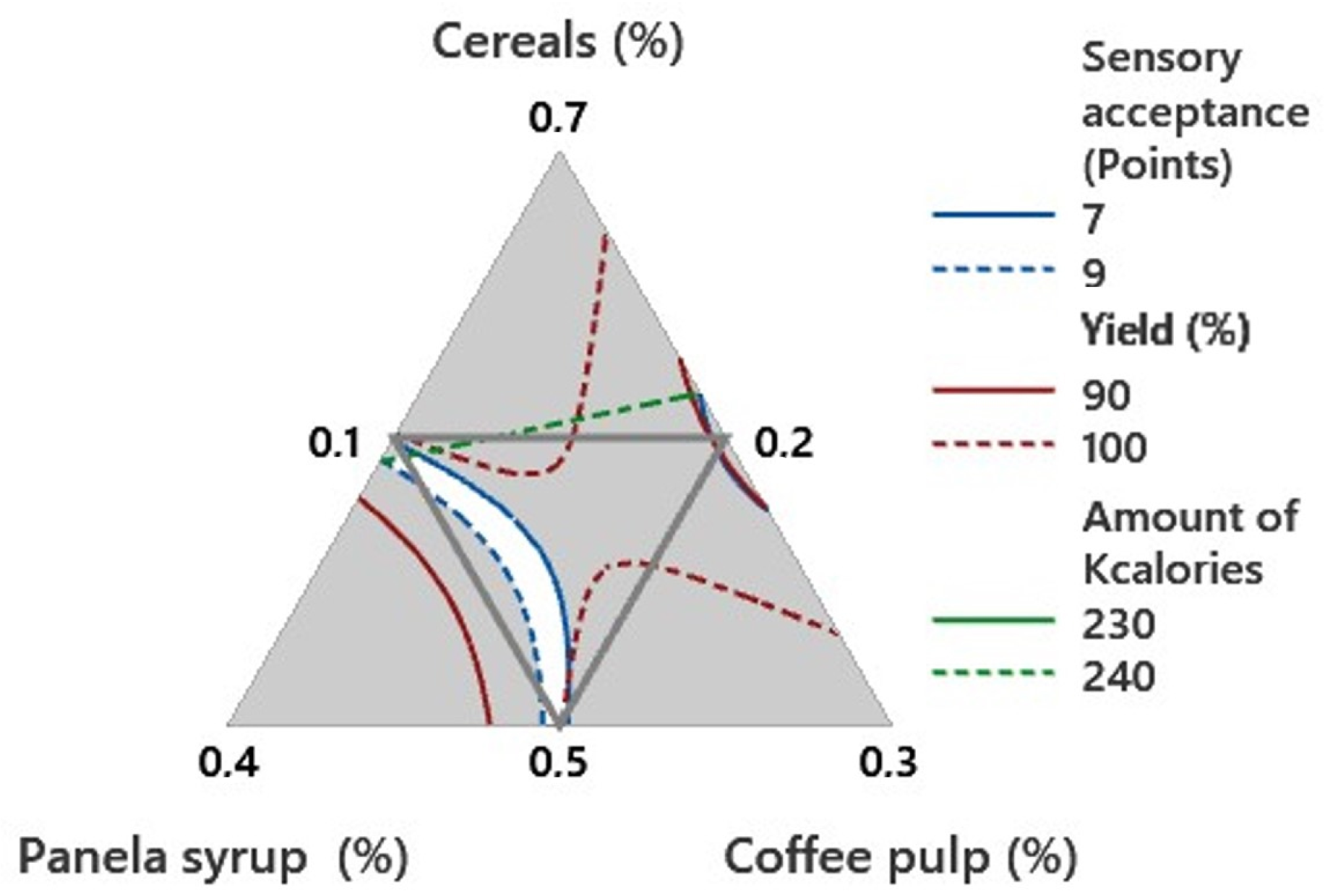

3.4. Microbiological and Nutritional Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Federación Nacional de Cafeteros de Colombia. Ensayos Sobre Economía Cafetera; La Federación: Caracas, Venezuela, 2019. [Google Scholar]

- Cafeteros del Cauca, C. Informe de Gestión Cauca 2020. 2020. Available online: https://cauca.federaciondecafeteros.org/app/uploads/sites/2/2021/04/INFORME-DE-GESTIÓN-con-enlaces.pdf (accessed on 18 July 2022).

- Rathinavelu, R.; Graziosi, G. Posibles Usos Alternativos de los Residuos y Subproductos del Café. 2005. Available online: http://www.ico.org/documents/ed1967c.pdf (accessed on 18 July 2022).

- Gouvea, B.M.; Torres, C.; Franca, A.S.; Oliveira, L.S.; Oliveira, E.S. Feasibility of ethanol production from coffee husks. Biotechnol. Lett. 2009, 31, 1315–1319. [Google Scholar] [CrossRef]

- Caipo, Y.; Gutiérrez, A.; Julca, A. Optimization by mixtures design of the acceptability of an energy bar from quinoa (Chenopodium quinoa), amaranth (Amaranthus caudatus) and cañihua (Chenopodium pallidicaule) evaluated in children. Agroind. Sci. 2015, 5, 61–67. [Google Scholar] [CrossRef]

- Rodríguez, N.; Zambrano, D. Los subproductos del cafe: Fuente de energia renovable. Cenicafé 2010. [Google Scholar]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Greenfield, H.; Southgate, D.A.T. Datos de Composición de Alimentos. Roma. 2003. Available online: https://www.fao.org/3/y4705s/y4705s.pdf (accessed on 18 July 2022).

- Gryna, F.M.; Chua, R.C.; Defeo, J.A. Método Juran. Análisis y Planteamiento de la Calidad, 5th ed.; McGraw Hill Interamericana: Ciudad Victoria, Mexico, 2007. [Google Scholar]

- Ramirez, L.; Torres, P. Documentación del Sistema de Gestión de Calidad Bajo la Norma ISO 9001:2015 en la Distribuidora Bombicol S.A.S de Pereira; Universidad Tecnológica de Pereira: Risaralda, Colombia, 2017. [Google Scholar]

- Betancourt, J. Estudio de Factibilidad Para la Elaboración y Comercialización de un Nuevo Producto Energizante a Base de Panela orgáNica del Municipio de Cajibio (Cauca); Universidad EAFIT: Medellín, Colombia, 2019. [Google Scholar]

- Verduga, K.; Santamaría, J.L.; Gordillo, G.; Montero, C. Barras energéticas de sacha inchi: Optimización de la formulación mediante diseño estadístico de mezclas. Enfoque UTE 2022, 13, 58–72. [Google Scholar] [CrossRef]

- Gutiérrez, H.; la Vara, R.D. Control Estadístico de Calidad y Seis Sigma, 2nd ed.; McGraw Hill Interamericana: Ciudad Victoria, Mexico, 2009. [Google Scholar]

- Nicolau, J.; Gozalbes, M. Juran y la Planeación Para la Calidad, 1st ed.; Ediciones Díaz de Santos: Madrid, Spain, 1990. [Google Scholar]

- Márquez, L.F.; Pretell, C.C. Evaluación de características de calidad en barras de cereales con alto contenido de fibra y proteína. Biotecnoloía En El Sect. Agropecu. Y Agroind. 2018, 16, 67. [Google Scholar] [CrossRef]

- Fernández, I.; García, E.; Fuentes, A. Aplicación de las Escalas de Punto Ideal o Just-About-Right (JAR) en Análisis Sensorial de Alimentos. 2018. Available online: https://riunet.upv.es/bitstream/handle/10251/104054/Fernández%3BGarcía%3BFuentes-AplicacióndelasescalasdepuntoidealoJust-About-Right%28JAR%29ena....pdf?sequence=1 (accessed on 18 July 2022).

- Nikzade, V.; Tehrani, M.M.; Saadatmand, M. Optimization of low-cholesterol-low-fat mayonnaise formulation: Effect of using soy milk and some stabilizer by a mixture design approach. Food Hydrocoll. 2012, 28, 344–352. [Google Scholar] [CrossRef]

- Sanínl, A.; Calderón, M.; Serna, A.J.; Torres, L.S.; Ladino, N. Desarrollo de alimento funcional a partir de productos promisorios andinos. Aliment. Hoy 2016, 24, 73–84. [Google Scholar]

- Chávez, J.J.; Miranda, B.S. Elaboración de una Barra Energética y Alimenticia a Base de Quinua y Amaranto Como Alternativa EconóMica Para una Microempresa Agroindustrial en el Cantón Riobamba, Provincia del Chimborazo; Universidad de las Amerricas: Ciudad de México, Mexico, 2008. [Google Scholar]

- Fierro, N.; Contreras, A.; González, O.; Rosas, E.S.; Morales, V. Caracterización química y nuntrimental de la pulpa de café(Coffea arabica L.). Agroproductividad 2018, 11, 9–13. [Google Scholar]

- De Agricultura, M. Evaluaciones Agropecuarias Municipales. Bogotá, 2020. Available online: https://www.agronet.gov.co/estadistica/Paginas/home.aspx?cod=59 (accessed on 18 July 2022).

- Navarrete, M.; Mascietti, M. Panela: Propiedades, Información y Aceptación. Bachelor’s Thesis, Universidad Fasta, Mar del Plata, Argentina, 2014. [Google Scholar]

- Davila, A.; Davila, L. Influencia de la Composición Químico Proximal de la Chía (Salvia hispánica L.) y Quinua (Chenopodium quinoa w.) Sobre las Características Bromatológicas de una Barra Energética; Universidad Nacional de Huancavelica: Paturpampa, Peru, 2018. [Google Scholar]

- FAO. La Quinua: Cultivo Milenario para Contribuir a la Seguridad Alimentaria Mundial. 2011. Available online: https://www.fao.org/3/aq287s/aq287s.pdf (accessed on 15 February 2022).

- Siles, L.; Guido, E. Barra Energética a Partir de Cereales y Frutos Secos de alto Valor Nutricional y Aporte Energético, Departamento de Química, UNAN-Managua, Septiembre—Diciembre 2019; Universidad Nacional Autónoma de Nicaragua: Managua, Nicaragua, 2019. [Google Scholar]

| Formulation | Cereals (%) | Panela Syrup (%) | Coffee Pulp (%) |

|---|---|---|---|

| 1 | 0.53333 | 0.28333 | 0.18333 |

| 2 | 0.50000 | 0.30000 | 0.20000 |

| 3 | 0.58333 | 0.23333 | 0.18333 |

| 4 | 0.60000 | 0.20000 | 0.20000 |

| 5 | 0.56667 | 0.26667 | 0.16667 |

| 6 | 0.60000 | 0.30000 | 0.10000 |

| 7 | 0.58333 | 0.28333 | 0.13333 |

| LABORATORY TEST | ANALYSIS: | METHOD |

|---|---|---|

| Total mesophilic aerobic count CFU/g-mL | AOAC 966.23ED. 21:2019 | |

| Molds and yeasts count CFU/g-mL | ISO 21527-2: 2008 | |

| Total content MPN/g-mL | ICMSF:2000 Method 1, Volume 1, Ed. 2:2000 | |

| MICROBIOLOGICAL ANALYSIS | Fecal Content MPN 45 °C/g-mL | ICMSF:2000 Method 1, Volume 1 Ed. 2:2000 |

| Coagulase-positive Staphylococcus count CFU/g-mL | UNE EN ISO 6888-1 2000 | |

| Detection of Salmonella in 25 g | Norma ISO 6579-1:2017 | |

| Mold and yeast counts UFC/g-mL | SO 21527-2: 2008 | |

| Humedad y materia volátil | PRO-AYS-057 V0 2021-07- 19 Determination of total solids and drying losses at 103 °C y 130 °C | |

| ASH | PRO-AYS-067 V0 2021-07- 19 Ash Determination 550 °C | |

| Total grasses | PRO-AYS-067 V0 2021-07- 19 Ash Determination 550 °C | |

| PROXIMAL ANALYSIS | Protein total (%N x 6.25) | PRO-AYS-055 V0 2021-07- 19 Protein determination according to ISO 1871 |

| Total carbohydrates | Calculation | |

| Total calories |

| Municipality | Area Cultivated Hectares | Tree Production | Production in Kilograms | Jobs Generated | Harvest Value in Millions of Pesos |

|---|---|---|---|---|---|

| Cajibío | 6.873 | 660,000 | 8,250,000 | 4.811 | 66,000 |

| Caldono | 4.789 | 640,000 | 8,000,000 | 3.353 | 64,000 |

| El Tambo | 8.155 | 820,000 | 10,250,000 | 5.708 | 82,000 |

| Inzá | 5.095 | 570,000 | 7,125,000 | 3.566 | 57,000 |

| Morales | 6.827 | 840,000 | 10,500,000 | 4.779 | 84,000 |

| Páez | 5.242 | 630,000 | 7,875,000 | 3.669 | 63,000 |

| Piendamó | 7.721 | 1,000,000 | 12,500.000 | 5.405 | 100,000 |

| Timbío | 4.095 | 540,000 | 6,750,000 | 2.866 | 54,000 |

| Components | Contents |

|---|---|

| Proteins (g) | 10.63 |

| Fats (g) | 5.78 |

| Carbohydrates (g) | 45.67 |

| Ash (g) | 9.58 |

| Crude fiber (g) | 36.07 |

| Caffeine % | 2.26 |

| Humidity % | 12.05 |

| Components | Contents |

|---|---|

| Energy value (kcal) | 110–462 |

| Carbohydrates (g) | 11.80 |

| Proteins (g) | 10.30 |

| Greases (g) | 3 |

| fiber (g) | 4.50 |

| water (g) | 9.80 |

| Ashes (g) | 0.04 |

| Formulation | Cereals (%) | Syrup of Panela (%) | Coffee Pulp (%) | Yield (%) | Quantity Kcalories | Sensory Analysis (Points) |

|---|---|---|---|---|---|---|

| 1 | 0.533 | 0.283 | 0.183 | 99.000 | 234.940 | 7.219 |

| 2 | 0.500 | 0.300 | 0.200 | 99.500 | 232.580 | 7.688 |

| 3 | 0.583 | 0.233 | 0.183 | 97.600 | 238.040 | 4.750 |

| 4 | 0.600 | 0.200 | 0.200 | 88.300 | 238.780 | 7.656 |

| 5 | 0.567 | 0.267 | 0.167 | 98.500 | 237.300 | 6.344 |

| 6 | 0.600 | 0.300 | 0.100 | 99.400 | 240.530 | 6.719 |

| 7 | 0.583 | 0.283 | 0.133 | 98.900 | 238.910 | 6.688 |

| Model | ES | R-Squared | R-Square— Adjusted Square |

|---|---|---|---|

| Lineal | 2.37925 | 76.71 | 65.07 |

| Quadratic | 0.72243 | 99.46 | 96.78 |

| Special cubic | 100 | 0 |

| Source | Sum of Squares | GL | Mean Square | Reason F | p-Value |

|---|---|---|---|---|---|

| Average | 66.2905 | 1 | 66.2905 | ||

| Lineal | 74.5852 | 2 | 37.2926 | 6.59 | 0.0542 |

| Quadratic | 22.1215 | 3 | 7.37383 | 14.13 | 0.1899 |

| Special cubic | 0.5219 | 1 | 0.5219 | ||

| Error | 4.0099 × 10 | 0 | |||

| Total | 66.3877 | 7 |

| Model | ES | R-Squared | R-Square— Adjusted Square |

|---|---|---|---|

| Lineal | 0.0024119 | 100 | 100 |

| Quadratic | 0.0026969 | 100 | 100 |

| Special cubic | 100 | 0 |

| Source | Sum of Squares | GL | Mean Square | Reason F | p-Value |

|---|---|---|---|---|---|

| Average | 394.170 | 1 | 394.170 | ||

| Lineal | 43.6109 | 2 | 21.8055 | 3.7484 | 0 |

| Quadratic | 1.600 × 10 | 3 | 5.33191 × 10 | 0.73 | 0.6728 |

| Special cubic | 7.27328 × 10 | 1 | 7.27328 × 10 | ||

| Error | −3.69552 × 10 | 0 | 0 | ||

| Total | 394.213 | 7 |

| Model | ES | R-Squared | R-Square— Adjusted Square |

|---|---|---|---|

| Lineal | 1.14576 | 13.7 | 0 |

| Quadratic | 0.3943 | 97.44 | 84.67 |

| Special cubic | 100 | 0 |

| Source | Sum of Squares | GL | Mean Square | Reason F | p-Value |

|---|---|---|---|---|---|

| Average | 316.411 | 1 | 316.411 | ||

| Lineal | 0.833739 | 2 | 0.41687 | 0.32 | 0.7447 |

| Quadratic | 5.09561 | 3 | 1.69854 | 10.93 | 0.215 |

| Special cubic | 0.155572 | 1 | 0.155472 | ||

| Error | 4.9063 × 10 | 0 | 0 | ||

| Total | 322.496 | 7 |

| SAMPLE | ANALYSIS | METHOD | SPECIFICATION | RESULT | |

|---|---|---|---|---|---|

| Total mesophilic aerobic count CFU/g-mL | AOAC 966.23 ED. 21:2019 | 5.000 (m)–10.000 (M) | 30 (±1 UFC) | ||

| Molds and yeasts count CFU/g-mL | ISO 21527-2: 2008 | 1.000 (m)–2.000 (M) | <100 (±1 UFC) | ||

| EN- ERGY BAR | Total coliforms MPN/g-mL | ICMSF:2000 Method 1, Volume 1, Ed. 2:2000 | 9 (m)–110 (M) | 3 | |

| Fecal Coliforms MPN 45 °C/g-mL | ICMSF:2000 Method 1, Volume 1 Ed. 2:2000 | 3 | 3 | ||

| Coagulase-positive Staphylococcus count CFU/g-mL | UNE EN ISO 6888-1 2000 | 100 | 100 (±1 UFC) | ||

| Detection of Salmonella in 25 g | ISO 6579-1: 2017 | AUSENCIA | AUSENCIA | ||

| COFFEE RAISINS | PULP | Mold and yeast counts UFC/g-mL | SO 21527-2: 2008 | 10 (m)–100 (M) | 10 (±1 UFC) |

| SAMPLE | ANALYSIS | UNIT | SPECIFICATION | RESULT | METHOD |

|---|---|---|---|---|---|

| MOISTURE AND VOLATILE MATTER | g/100 g | N/A | 8.57 | PRO-AYS-057 V0 2021-07- 19 Determi- nation of total solids and drying losses at 103 °C y 130 °C | |

| EN- ERGY BAR | ASH | g/100 g | N/A | 0.89 | PRO-AYS-067 V0 2021-07- 19 Ash Determination 550 °C |

| TOTAL GRASES | g/100 g | N/A | 0.61 | PRO-AYS-113 V0 2021-07- 19 Determination of fat by ethereal extract | |

| TOTAL PROTEIN (%N x 6.25) | g/100 g | N/A | 5.88 | PRO-AYS-055 V0 2021-07- 19 Protein determination according to ISO 1871 | |

| TOTAL CARBOHY- DRATES | g/100 g | N/A | 84.05 | Calculation | |

| TOTAL CALORIES | kcal/100 g | N/A | 365.21 | Calculation | |

| MOISTURE AND VOLATILE MATTER | g/100 g | N/A | 26.13 | PRO-AYS-057 V0 2021-07- 19 Determination of total solids and drying losses at 103 °C y 130 °C | |

| COF- FEE PULP RAISINS | ASH | g/100 g | N/A | 1.38 | PRO-AYS-067 V0 2021-07- 19 Ash Determination 550 °C |

| TOTAL GRASES | g/100 g | N/A | 0.32 | PRO-AYS-113 V0 2021-07- 19 Determination of fat by ethereal extract | |

| TOTAL PROTEIN | g/100 g | N/A | 2.12 | PRO-AYS-055 V0 2021-07- 19 Protein determination according to ISO 1871 | |

| TOTAL CARBOHY- DRATES | g/100 g | N/A | 70.05 | Calculation | |

| TOTAL CALORIES | kcal/100 g | N/A | 291.56 | Calculation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez Calvo, A.; Paz Ruiz, N.; Delgado Espinoza, Z. Coffee Pulp: A Sustainable and Affordable Source for Developing Functional Foods. Processes 2023, 11, 1693. https://doi.org/10.3390/pr11061693

Pérez Calvo A, Paz Ruiz N, Delgado Espinoza Z. Coffee Pulp: A Sustainable and Affordable Source for Developing Functional Foods. Processes. 2023; 11(6):1693. https://doi.org/10.3390/pr11061693

Chicago/Turabian StylePérez Calvo, Angélica, Nelson Paz Ruiz, and Zuly Delgado Espinoza. 2023. "Coffee Pulp: A Sustainable and Affordable Source for Developing Functional Foods" Processes 11, no. 6: 1693. https://doi.org/10.3390/pr11061693

APA StylePérez Calvo, A., Paz Ruiz, N., & Delgado Espinoza, Z. (2023). Coffee Pulp: A Sustainable and Affordable Source for Developing Functional Foods. Processes, 11(6), 1693. https://doi.org/10.3390/pr11061693