Influence of Sputtering Pressure on the Micro-Topography of Sputtered Cu/Si Films: Integrated Multiscale Simulation

Abstract

1. Introduction

2. Simulation Method

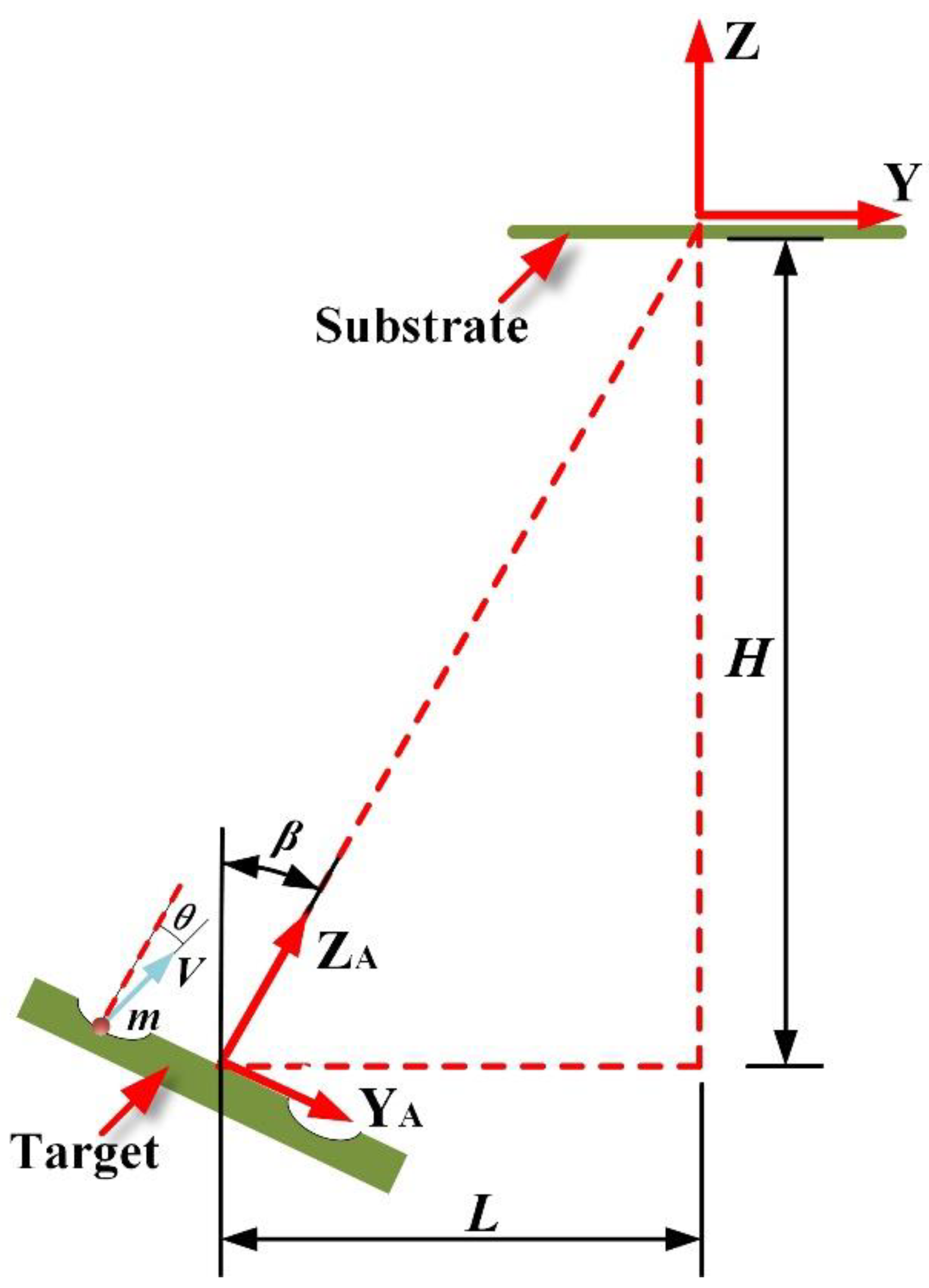

2.1. MC-MD Simulation of the Transport of Sputtered Cu Atoms

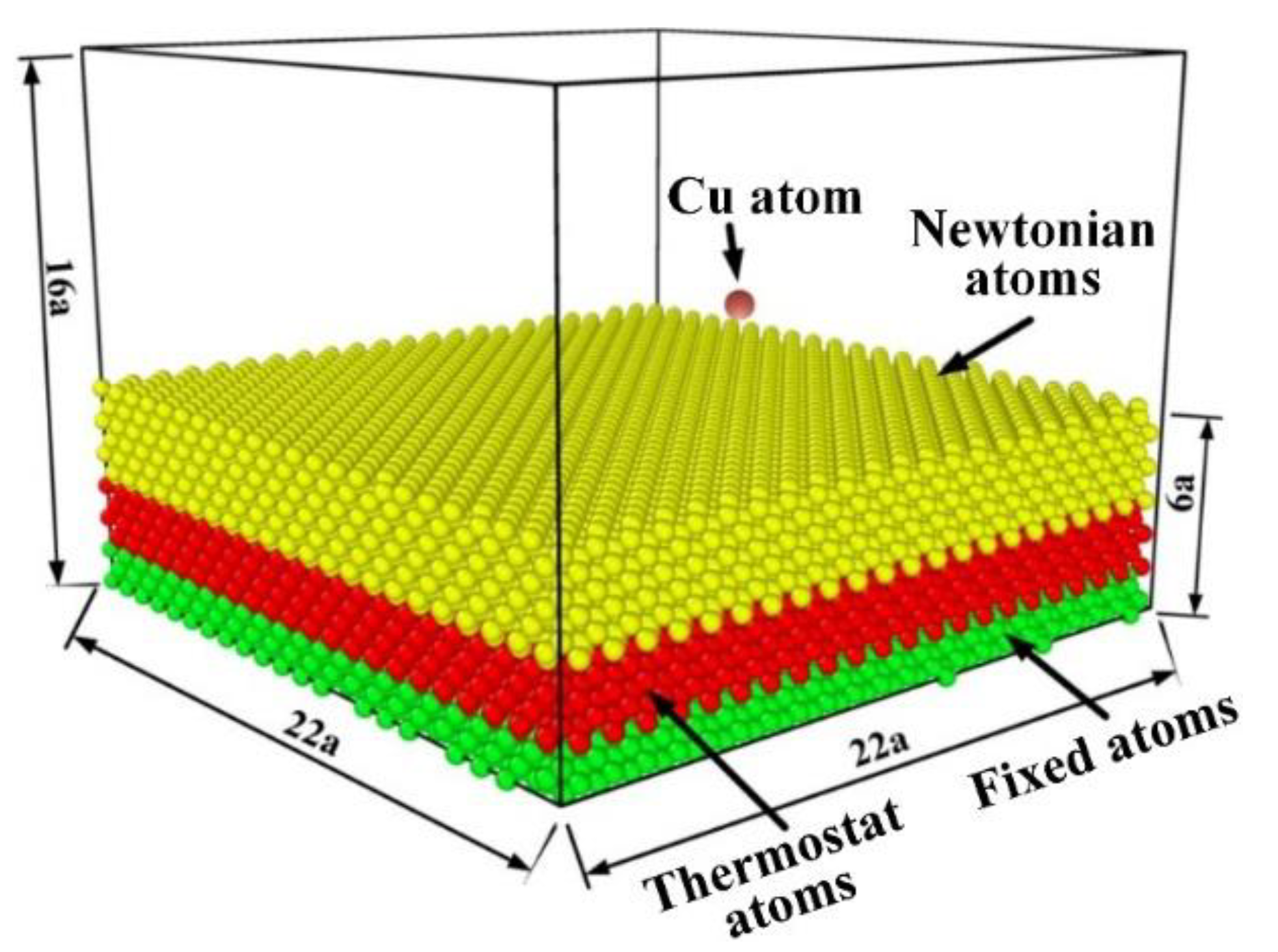

2.2. MD Simulation of the Growth of Sputtered Cu Film on Si Substrate

3. Results

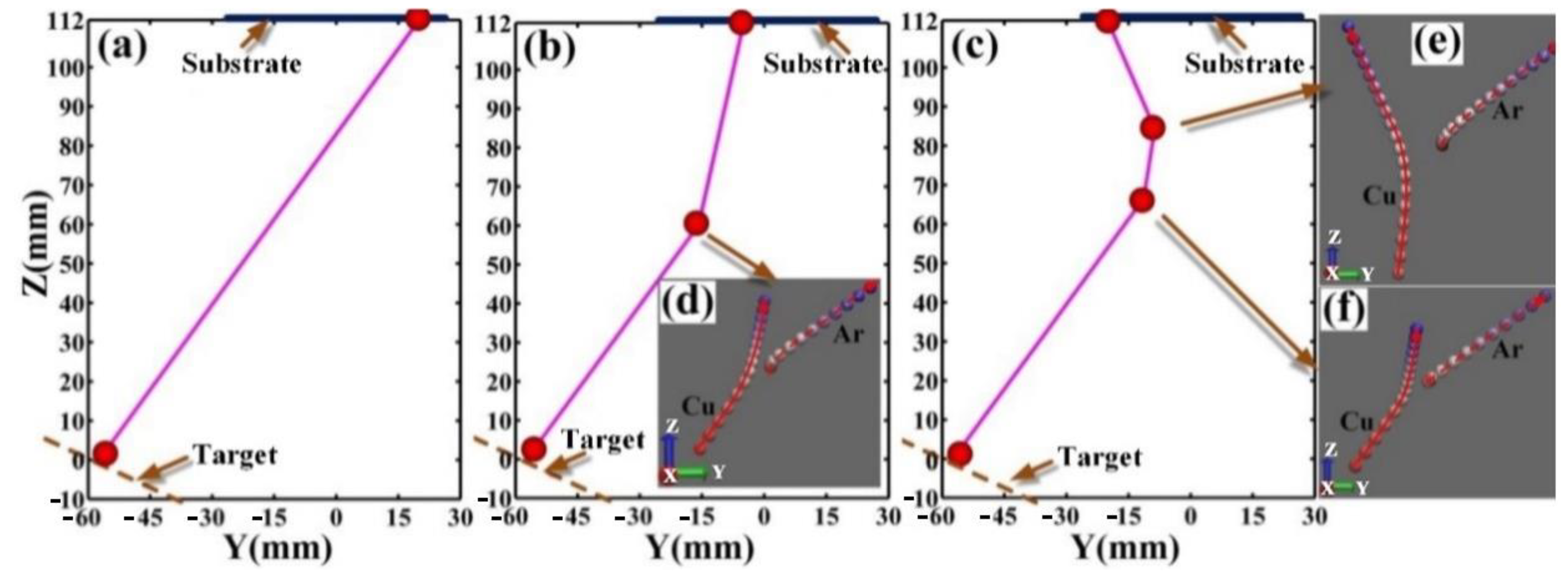

3.1. Transport Processes of One Cu Atom in Maro and Micro Sacles

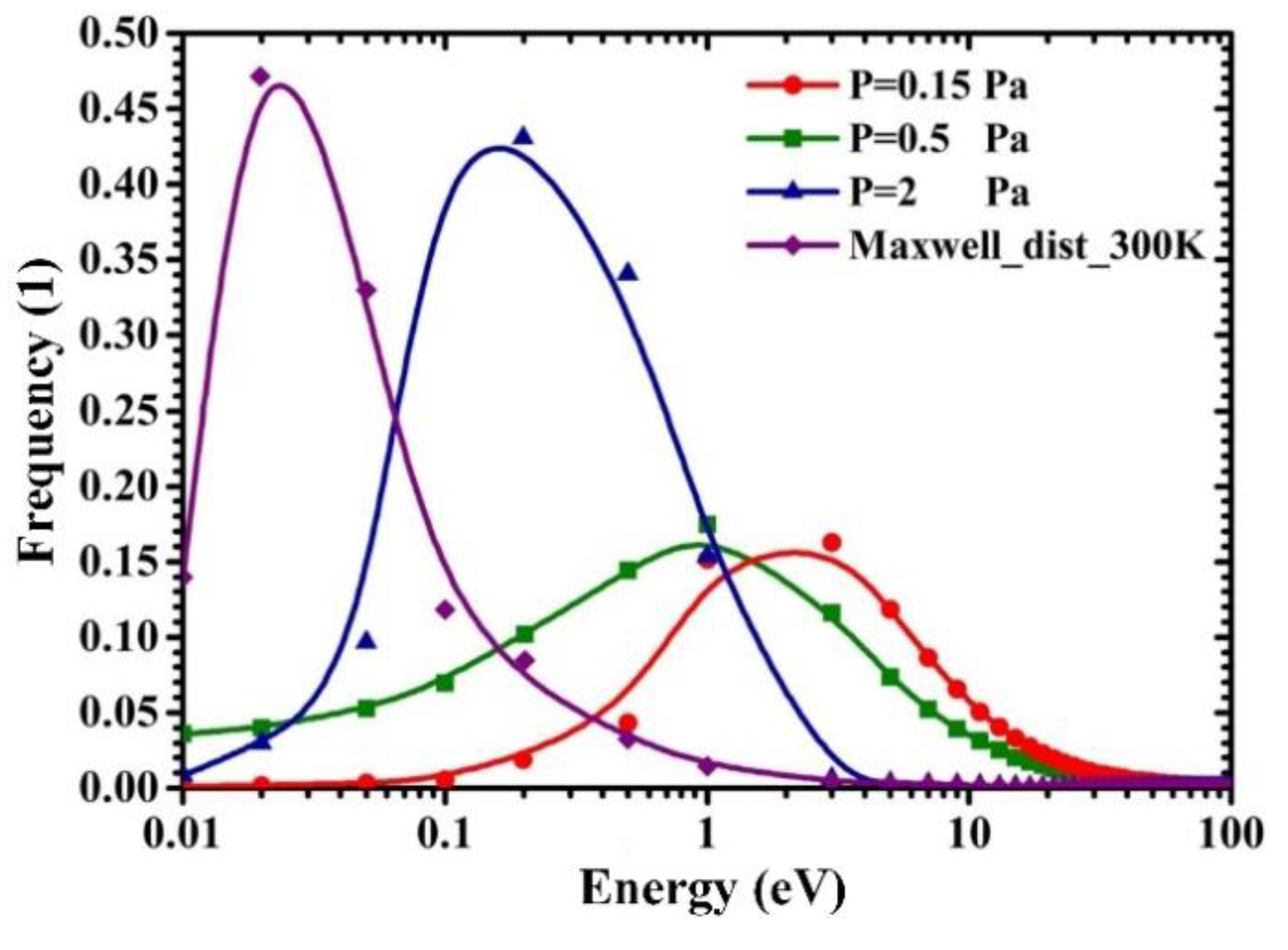

3.2. Incident Energy Distribution of Deposited Cu Atoms

3.3. Incident Polar Angle Distribution of Deposited Cu Atoms

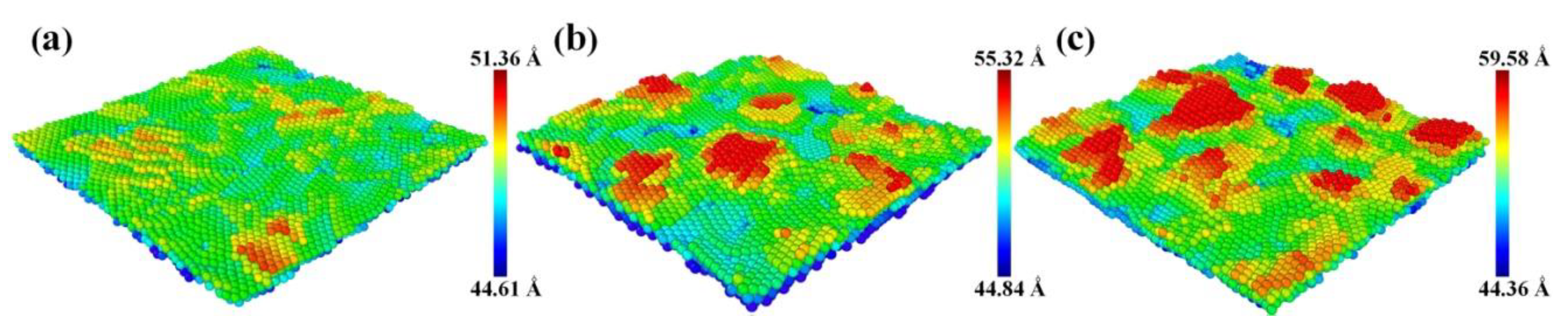

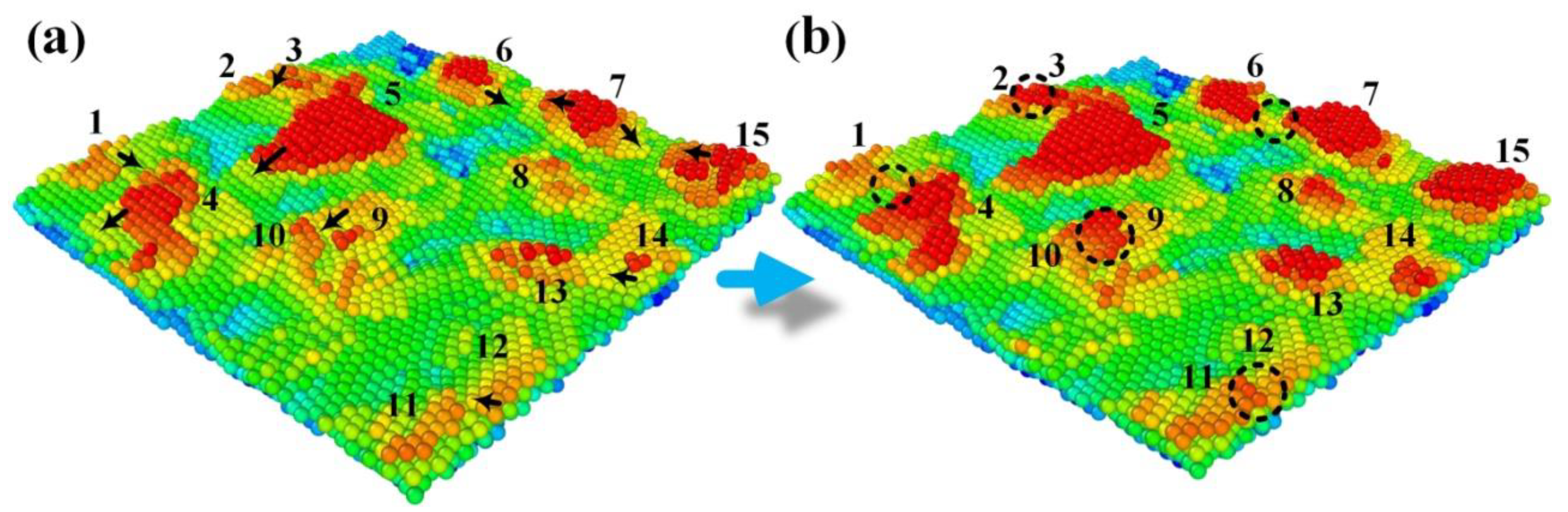

3.4. Surface Morphology of Deposited Cu Film

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, K.; Hu, Q.F.; Xu, X.; Chen, S.H.; Ma, J.; Dong, W.W. Excellent diffusion barrier property of amorphous NbMoTaW medium entropy alloy thin films used in Cu/Si Connect System. Vacuum 2022, 202, 111195. [Google Scholar] [CrossRef]

- Lee, J.; Park, S.; Kim, K.; Jo, H.; Lee, D. Combined effects of residual stress and microstructure on degradation of Cu thin films on Si. Thin Solid Film. 2023, 764, 139607. [Google Scholar] [CrossRef]

- Theerthagiri, J.; Karuppasamy, K.; Lee, S.J.; Shwetharani, R.; Kim, H.-S.; Pasha, S.K.K.; Ashokkumar, M.; Choi, M.Y. Fundamentals and comprehensive insights on pulsed laser synthesis of advanced materials for diverse photo-and electrocatalytic applications. Light Sci. Appl. 2022, 11, 250. [Google Scholar] [CrossRef]

- Zhu, H.H.; Ye, X.J.; Liu, C.S.; Yan, X.H. Monolayer Cu2Si as a potential gas sensor for NOx and Cox (x = 1, 2): A first-principles study. Surf. Sci. 2018, 668, 42–46. [Google Scholar] [CrossRef]

- Roslan, N.A.; Supangat, A.; Sagadevan, S. Investigation of Charge Transport Properties in VTP: PC71BM Organic Schottky Diode. Electronics 2022, 11, 3777. [Google Scholar] [CrossRef]

- Venkatesan, R.; Sheik KadarMaideen, S.M.T.; Chandhiran, S.; Kushvaha, S.S.; Sagadevan, S.; Venkatachalapathy, V.; Mayandi, J. Fabrication and Characterization of Si/PEDOT: PSS-Based Heterojunction Solar Cells. Electronics 2022, 11, 4145. [Google Scholar] [CrossRef]

- Xiang, S.Q.; Gao, S.T.; Shi, J.L.; Zhang, W.; Zhao, L.B. Developing micro-kinetic model for electrocatalytic reduction of carbon dioxide on copper electrode. J. Catal. 2021, 393, 11–19. [Google Scholar] [CrossRef]

- Lee, S.J.; Theerthagiri, J.; Nithyadharseni, P.; Arunachalam, P.; Balaji, D.; Kumar, A.M.; Madhavan, J.; Mittal, V.; Choi, M.Y. Heteroatom-doped graphene-based materials for sustainable energy applications: A review. Renew. Sustain. Energy Rev. 2021, 143, 110849. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhou, H.; Lu, Q.; Gao, H.; Lu, L. Extra strengthening and work hardening in gradient nanotwinned metals. Science 2018, 362, eaau1925. [Google Scholar] [CrossRef]

- Cheng, Z.; Bu, L.; Zhang, Y.; Wu, H.; Zhu, T.; Gao, H.; Lu, L. Unraveling the origin of extra strengthening in gradient nanotwinned metals. Proc. Natl. Acad. Sci. USA 2022, 119, e2116808119. [Google Scholar] [CrossRef]

- Kreuzpaintner, W.; Schmehl, A.; Book, A.; Mairoser, T.; Ye, J.; Wiedemann, B.; Mayr, S.; Moulin, J.F.; Stahn, J.; Gilbert, D.A.; et al. Reflectometry with Polarized Neutrons on In Situ Grown Thin Films. Phys. Status Solidi (B) 2022, 259, 2100153. [Google Scholar] [CrossRef]

- Vautrin, C.; Lacour, D.; Tiusan, C.; Lu, Y.; Montaigne, F.; Chshiev, M.; Weber, W.; Hehn, M. Low-Energy Spin Precession in the Molecular Field of a Magnetic Thin Film. Ann. Phys. 2021, 533, 2000470. [Google Scholar] [CrossRef]

- Flokstra, M.G.; Stewart, R.; Satchell, N.; Burnell, G.; Luetkens, H.; Prokscha, T.; Suter, A.; Morenzoni, E.; Langridge, S.; Lee, S.L. Manifestation of the electromagnetic proximity effect in superconductor-ferromagnet thin film structures. Appl. Phys. Lett. 2019, 115, 072602. [Google Scholar] [CrossRef]

- Chen, L.; Andrea, L.; Timalsina, Y.P.; Wang, G.C.; Lu, T.M. Engineering Epitaxial-Nanospiral Metal Films Using Dynamic Oblique Angle Deposition. Cryst. Growth Des. 2013, 13, 2075–2080. [Google Scholar] [CrossRef]

- Hull, C.M.; Switzer, J.A. Electrodeposited Epitaxial Cu(100) on Si(100) and Lift-Off of Single-Crystal-Like Cu(100) Foils. ACS Appl. Mater. Interfaces 2018, 10, 38596–38602. [Google Scholar] [CrossRef] [PubMed]

- Polat, B.D.; Keles, O. Multi-layered Cu/Si nanorods and its use for lithium ion batteries. J. Alloys Compd. 2015, 622, 418–425. [Google Scholar] [CrossRef]

- Boo, J.H.; Jung, M.J.; Park, H.K.; Nam, K.H.; Han, J.G. High-rate deposition of copper thin films using newly designed high-power magnetron sputtering source. Surf. Coat. Technol. 2004, 188, 721–727. [Google Scholar] [CrossRef]

- Cemin, F.; Lundin, D.; Furgeaud, C.; Michel, A.; Amiard, G.; Minea, T.; Abadias, G. Epitaxial growth of Cu(001) thin films onto Si(001) using a single-step HiPIMS process. Sci. Rep. 2017, 7, 1655. [Google Scholar] [CrossRef]

- Zhu, G.; Xiao, B.; Chen, G.; Gan, Z. Study on the Deposition Uniformity of Triple-Target Magnetron Co-Sputtering System: Numerical Simulation and Experiment. Materials 2022, 15, 7770. [Google Scholar] [CrossRef]

- Yanguas-Gil, A. Growth and Transport in Nanostructured Materials; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Wu, B.; Haehnlein, I.; Shchelkanov, I.; McLain, J.; Patel, D.; Uhlig, J.; Jurczyk, B.; Leng, Y.; Ruzic, D.N. Cu films prepared by bipolar pulsed high power impulse magnetron sputtering. Vacuum 2018, 150, 216–221. [Google Scholar] [CrossRef]

- Turner, G.M.; Falconer, I.S.; James, B.W.; McKenzie, D.R. Monte Carlo calculation of the thermalization of atoms sputtered from the cathode of a sputtering discharge. J. Appl. Phys. 1989, 65, 3671–3679. [Google Scholar] [CrossRef]

- Nakano, T.; Mori, I.; Baba, S. The effect of ‘warm’ gas scattering on the deceleration of energetic atoms: Monte Carlo study of the sputter-deposition of compounds. Appl. Surf. Sci. 1997, 113, 642–646. [Google Scholar] [CrossRef]

- Yamamura, Y.; Ishida, M. Monte Carlo simulation of the thermalization of sputtered atoms and reflected atoms in the magnetron sputtering discharge. J. Vac. Sci. Technol. A 1995, 13, 101–112. [Google Scholar] [CrossRef]

- Van Aeken, K.; Mahieu, S.; Depla, D. The metal flux from a rotating cylindrical magnetron: A Monte Carlo simulation. J. Phys. D Appl. Phys. 2008, 41, 205307. [Google Scholar] [CrossRef]

- Depla, D.; Leroy, W.P. Magnetron sputter deposition as visualized by Monte Carlo modeling. Thin Solid Films 2012, 520, 6337–6354. [Google Scholar] [CrossRef]

- Trieschmann, J.; Mussenbrock, T. Transport of sputtered particles in capacitive sputter sources. J. Appl. Phys. 2015, 118, 033302. [Google Scholar] [CrossRef]

- Revel, A.; el Farsy, A.; de Poucques, L.; Robert, J.; Minea, T. Transition from ballistic to thermalized transport of metal-sputtered species in a DC magnetron. Plasma Sources Sci. Technol. 2021, 30, 125005. [Google Scholar] [CrossRef]

- Zhu, G.; Du, Q.; Xiao, B.; Chen, G.; Gan, Z. Influence of Target-Substrate Distance on the Transport Process of Sputtered Atoms: MC-MD Multiscale Coupling Simulation. Materials 2022, 15, 8904. [Google Scholar] [CrossRef]

- Chu, C.J.; Chen, T.C. Surface properties of film deposition using molecular dynamics simulation. Surf. Coat. Technol. 2006, 201, 1796–1804. [Google Scholar] [CrossRef]

- Taguchi, M.; Hamaguchi, S. MD simulations of amorphous SiO2 thin film formation in reactive sputtering deposition processes. Thin Solid Films 2007, 515, 4879–4882. [Google Scholar] [CrossRef]

- Georgieva, V.; Voter, A.F.; Bogaerts, A. Understanding the Surface Diffusion Processes during Magnetron Sputter-Deposition of Complex Oxide Mg–Al–O Thin Films. Cryst. Growth Des. 2011, 11, 2553–2558. [Google Scholar] [CrossRef]

- Ibrahim, S.; Lahboub, F.Z.; Brault, P.; Petit, A.; Caillard, A.; Millon, E.; Sauvage, T.; Fernández, A.; Thomann, A.L. Influence of helium incorporation on growth process and properties of aluminum thin films deposited by DC magnetron sputtering. Surf. Coat. Technol. 2021, 426, 127808. [Google Scholar] [CrossRef]

- Brault, P.; Neyts, E.C. Molecular dynamics simulations of supported metal nanocatalyst formation by plasma sputtering. Catal. Today 2015, 256, 3–12. [Google Scholar] [CrossRef]

- Meyer, K.; Schuller, I.K.; Falco, C.M. Thermalization of sputtered atoms. J. Appl. Phys. 1981, 52, 5803–5805. [Google Scholar] [CrossRef]

- Zhu, G.; Sun, J.; Zhang, L.; Gan, Z. Molecular dynamics simulation of temperature effects on deposition of Cu film on Si by magnetron sputtering. J. Cryst. Growth 2018, 492, 60–66. [Google Scholar] [CrossRef]

- Thompson, M.W., II. The energy spectrum of ejected atoms during the high energy sputtering of gold. Philos. Mag. 1968, 18, 377–414. [Google Scholar] [CrossRef]

- Yamamura, Y.; Takiguchi, T.; Ishida, M. Energy and angular distributions of sputtered atoms at normal incidence. Radiat. Eff. Defect. Solids 1991, 118, 237–261. [Google Scholar] [CrossRef]

- Thompson, A.P.; Aktulga, H.M.; Berger, R.; Bolintineanu, D.S.; Brown, W.M.; Crozier, P.S.; in ’t Veld, P.J.; Kohlmeyer, A.; Moore, S.G.; Nguyen, T.D.; et al. LAMMPS—A flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Comput. Phys. Commun. 2022, 271, 108171. [Google Scholar] [CrossRef]

- Tersoff, J. Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B. 1989, 39, 5566–5568. [Google Scholar] [CrossRef]

- Foiles, S.M.; Baskes, M.I.; Daw, M.S. Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B 1986, 33, 7983–7991. [Google Scholar] [CrossRef]

- Yasukawa, A. Static Fatigue Strength Analysis of SiO2 under Atmospheric Influence Using Extended Tersoff Interatomic Potential. Trans. Jpn. Soc. Mech. Eng. A 1995, 61, 913–920. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, C.; Shu, Y.; Fan, J. Growth and properties of Cu thin film deposited on Si(001) substrate: A molecular dynamics simulation study. Appl. Surf. Sci. 2012, 261, 690–696. [Google Scholar] [CrossRef]

- Kadlec, S.; Quaeyhaegens, C.; Knuyt, G.; Stals, L.M. Energy-resolved mass spectrometry and Monte Carlo simulation of atomic transport in magnetron sputtering. Surf. Coat. Technol. 1997, 97, 633–641. [Google Scholar] [CrossRef]

- Lu, J.; Lee, C.G. Numerical estimates for energy of sputtered target atoms and reflected Ar neutrals in sputter processes. Vacuum 2012, 86, 1134–1140. [Google Scholar] [CrossRef]

- Settaouti, A.; Settaouti, L. Simulation of the transport of sputtered atoms and effects of processing conditions. Appl. Surf. Sci. 2008, 254, 5750–5756. [Google Scholar] [CrossRef]

- Sambandam, S.N.; Bhansali, S.; Bhethanabotla, V.R.; Sood, D.K. Studies on sputtering process of multicomponent Zr–Ti–Cu–Ni–Be alloy thin films. Vacuum 2006, 80, 406–414. [Google Scholar] [CrossRef]

- Reif, F.; Scott, H.L. Fundamentals of Statistical and Thermal Physics. Am. J. Phys. 1998, 66, 164–167. [Google Scholar] [CrossRef]

- Turner, G.M.; Falconer, I.S.; James, B.W.; McKenzie, D.R. Monte Carlo calculations of the properties of sputtered atoms at a substrate surface in a magnetron discharge. J. Vac. Sci. Technol. A 1992, 10, 455–461. [Google Scholar] [CrossRef]

- Volmer, M.; Weber, A. Nucleus formation in supersaturated systems. Z. Phys. Chem. 1926, 119, 277–301. [Google Scholar] [CrossRef]

- Pletea, M.; Brückner, W.; Wendrock, H.; Kaltofen, R. Stress evolution during and after sputter deposition of Cu thin films onto Si (100) substrates under various sputtering pressures. J. Appl. Phys. 2005, 97, 054908. [Google Scholar] [CrossRef]

- Thornton, J.A. Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings. J. Vac. Sci. Technol. A. 1974, 11, 666. [Google Scholar] [CrossRef]

- Anders, A. A structure zone diagram including plasma-based deposition and ion etching. Thin Solid Films 2010, 518, 4087–4090. [Google Scholar] [CrossRef]

- Evans, J.W.; Sanders, D.E.; Thiel, P.A.; DePristo, A.E. Low-temperature epitaxial growth of thin metal films. Phys. Rev. B 1990, 41, 5410–5413. [Google Scholar] [CrossRef]

- Stoltze, P.; Norskov, J.K. Accommodation and diffusion of Cu deposited on flat and stepped Cu(111) surfaces. Phys. Rev. B 1993, 48, 5607–5611. [Google Scholar] [CrossRef]

- Villarba, M.; Jónsson, H. Atomic exchange processes in sputter deposition of Pt on Pt(111). Surf. Sci. 1995, 324, 35–46. [Google Scholar] [CrossRef]

- Kürpick, U.; Rahman, T.S. Diffusion processes relevant to homoepitaxial growth on Ag(100). Phys. Rev. B 1998, 57, 2482–2492. [Google Scholar] [CrossRef]

- Mes-adi, H.; Saadouni, K.; Mazroui, M. Effect of incident angle on the microstructure proprieties of Cu thin film deposited on Si (001) substrate. Thin Solid Films 2021, 721, 138553. [Google Scholar] [CrossRef]

- Hanson, D.E.; Kress, J.D.; Voter, A.F.; Liu, X.Y. Trapping and desorption of energetic Cu atoms on Cu(111) and (001) surfaces at grazing incidence. Phys. Rev. B 1999, 60, 11723–11729. [Google Scholar] [CrossRef]

- Liu, X.Y.; Daw, M.S.; Kress, J.D.; Hanson, D.E.; Arunachalam, V.; Coronell, D.G.; Liu, C.L.; Voter, A.F. Ion solid surface interactions in ionized copper physical vapor deposition. Thin Solid Films 2002, 422, 141–149. [Google Scholar] [CrossRef]

- Wu, H.; Anders, A. Energetic deposition of metal ions: Observation of self-sputtering and limited sticking for off-normal angles of incidence. J. Phys. D Appl. Phys. 2010, 43, 065206. [Google Scholar] [CrossRef]

- Eckstein, W.; Garciá-Rosales, C.; Roth, J.; László, J. Threshold energy for sputtering and its dependence on angle of incidence. Nucl. Instrum. Methods Phys. Res. B 1993, 83, 95–109. [Google Scholar] [CrossRef]

- Kress, J.D.; Hanson, D.E.; Voter, A.F.; Liu, C.L.; Liu, X.Y.; Coronell, D.G. Molecular dynamics simulation of Cu and Ar ion sputtering of Cu (111) surfaces. J. Vac. Sci. Technol. A 1999, 17, 2819–2825. [Google Scholar] [CrossRef]

- Abrams, C.F.; Graves, D.B. Cu sputtering and deposition by off-normal, near-threshold Cu+ bombardment: Molecular dynamics simulations. J. Appl. Phys. 1999, 86, 2263–2267. [Google Scholar] [CrossRef]

- Insepov, Z.; Norem, J.; Veitzer, S. Atomistic self-sputtering mechanisms of rf breakdown in high-gradient linacs. Nucl. Instrum. Methods Phys. Res. B 2010, 268, 642–650. [Google Scholar] [CrossRef]

- Liu, C.L.; Cohen, J.M.; Adams, J.B.; Voter, A.F. EAM study of surface self-diffusion of single adatoms of fcc metals Ni, Cu, Al, Ag, Au, Pd, and Pt. Surf. Sci. 1991, 253, 334–344. [Google Scholar] [CrossRef]

- Boisvert, G.; Lewis, L.J. Self-diffusion of adatoms, dimers, and vacancies on Cu(100). Phys. Rev. B 1997, 56, 7643–7655. [Google Scholar] [CrossRef]

- Karimi, M.; Tomkowski, T.; Vidali, G.; Biham, O. Diffusion of Cu on Cu surfaces. Phys. Rev. B 1995, 52, 5364–5374. [Google Scholar] [CrossRef]

- Mehl, H.; Biham, O.; Furman, I.; Karimi, M. Models for adatom diffusion on fcc (001) metal surfaces. Phys. Rev. B 1999, 60, 2106–2116. [Google Scholar] [CrossRef]

- Yu, B.D.; Scheffler, M. Ab initio study of step formation and self-diffusion on Ag(100). Phys. Rev. B 1997, 55, 13916–13924. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, G.; Han, M.; Xiao, B.; Gan, Z. Influence of Sputtering Pressure on the Micro-Topography of Sputtered Cu/Si Films: Integrated Multiscale Simulation. Processes 2023, 11, 1649. https://doi.org/10.3390/pr11061649

Zhu G, Han M, Xiao B, Gan Z. Influence of Sputtering Pressure on the Micro-Topography of Sputtered Cu/Si Films: Integrated Multiscale Simulation. Processes. 2023; 11(6):1649. https://doi.org/10.3390/pr11061649

Chicago/Turabian StyleZhu, Guo, Mengxin Han, Baijun Xiao, and Zhiyin Gan. 2023. "Influence of Sputtering Pressure on the Micro-Topography of Sputtered Cu/Si Films: Integrated Multiscale Simulation" Processes 11, no. 6: 1649. https://doi.org/10.3390/pr11061649

APA StyleZhu, G., Han, M., Xiao, B., & Gan, Z. (2023). Influence of Sputtering Pressure on the Micro-Topography of Sputtered Cu/Si Films: Integrated Multiscale Simulation. Processes, 11(6), 1649. https://doi.org/10.3390/pr11061649