Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component

Abstract

1. Introduction

- The actual use of the bicycle (mountain bike, road bike, etc.).

- Restrictions on certain dimensions in order for the bicycle to be compatible with the majority of components offered on the market.

- The correct dimensioning of the frame in order to comply with the UCI regulations.

- The choice of the appropriate materials and the corresponding design in order to make the frame compliant with international standards (iso, din, ebfe) and exhibit low weight and optimal mechanical behaviors.

- The correct aerodynamic behavior of the bicycle in frontal and lateral wind impacts.

- The ergonomics of the frame, so that the rider can exert the optimum force on the bike in order to achieve the best possible performance at all times.

- Cost constraints.

2. Materials and Methods

3. Results

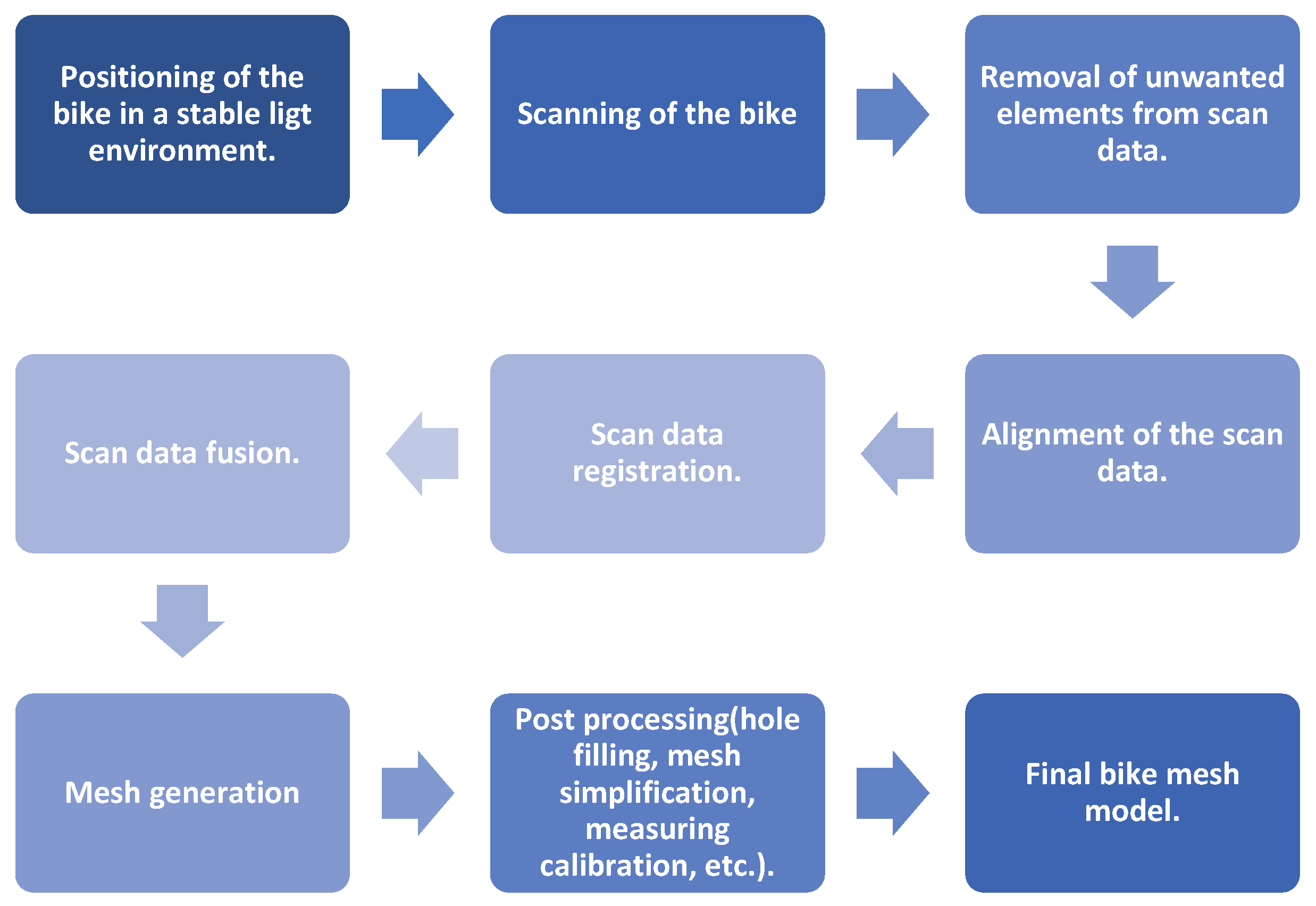

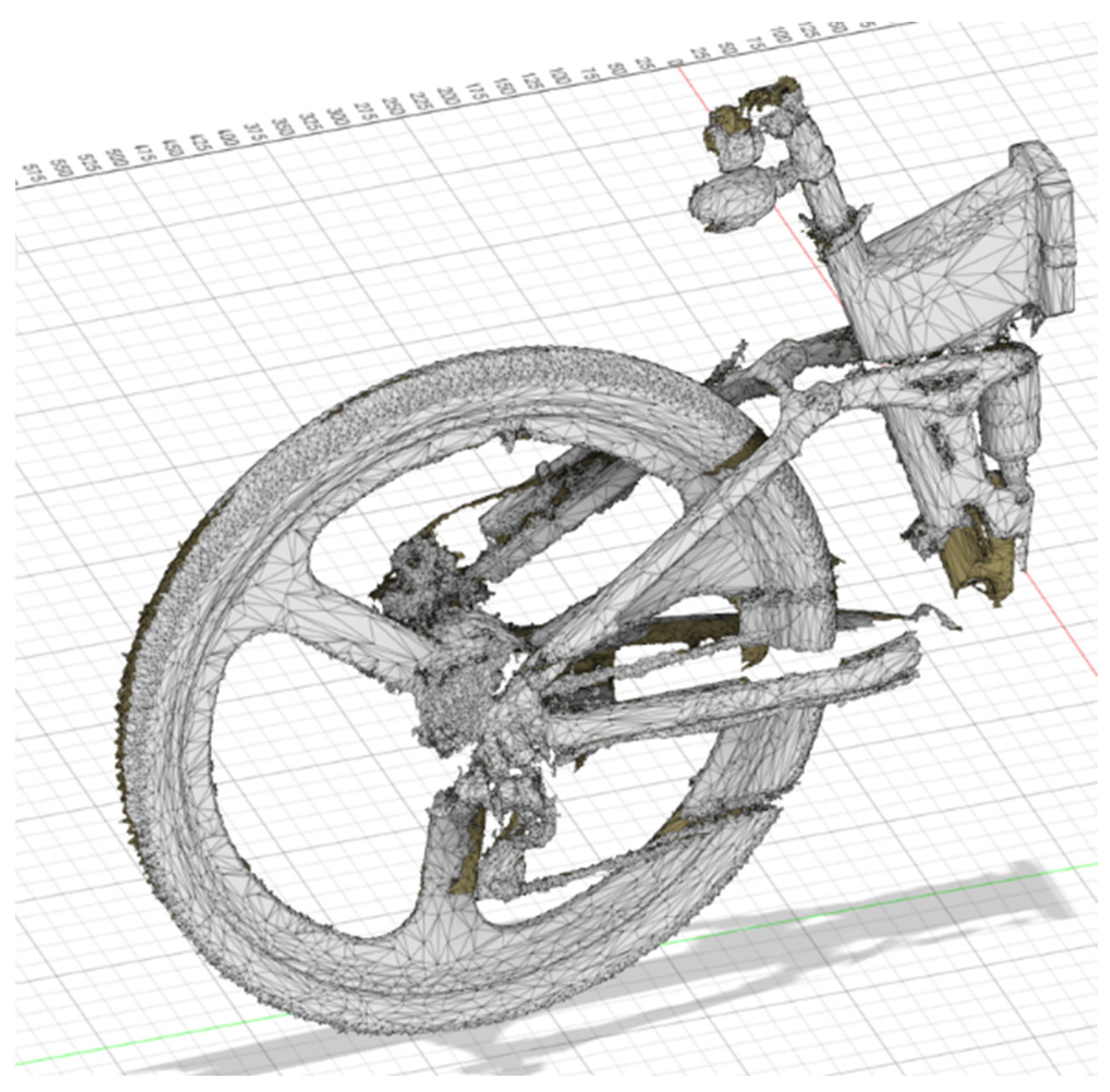

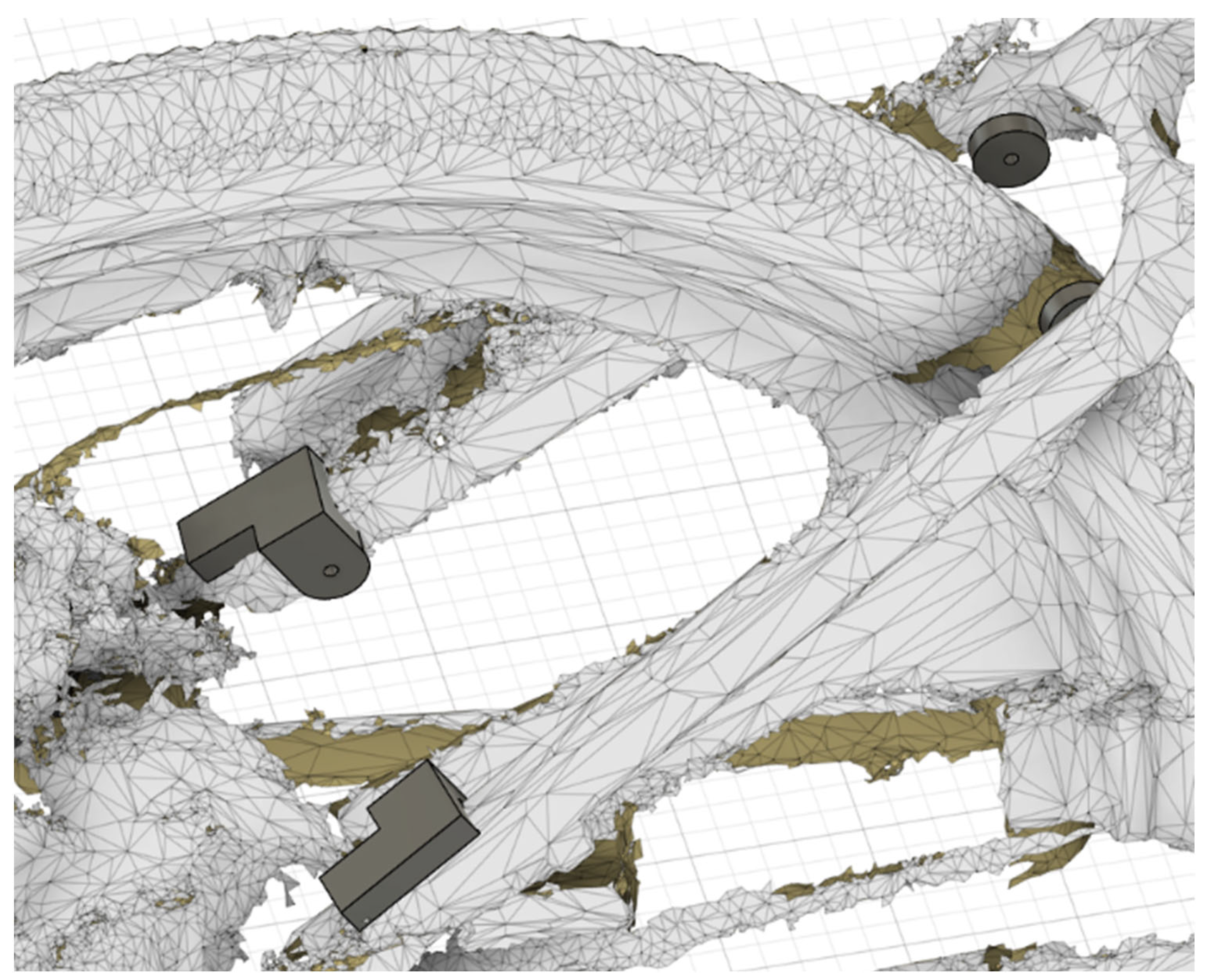

3.1. The 3D Scanning Process

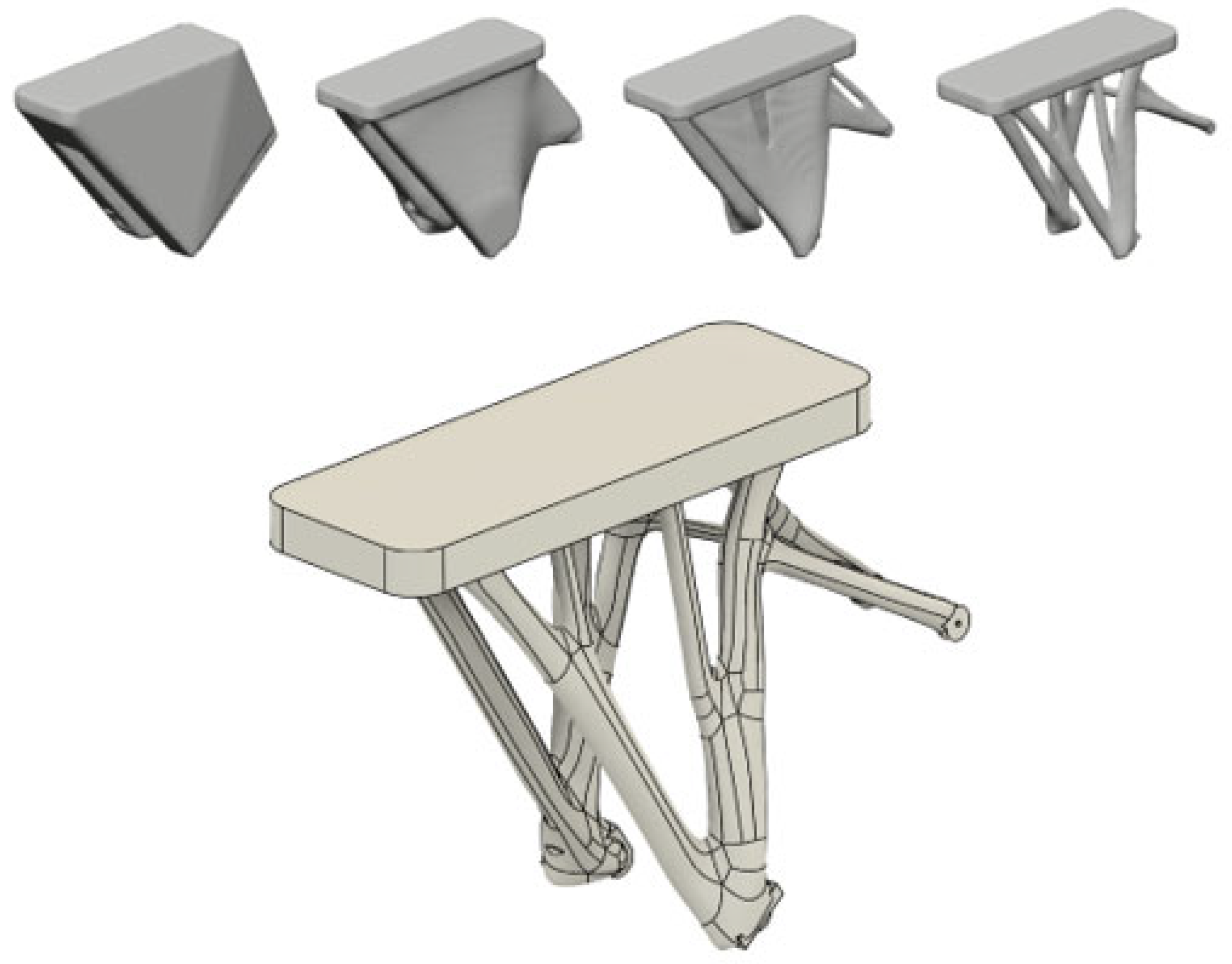

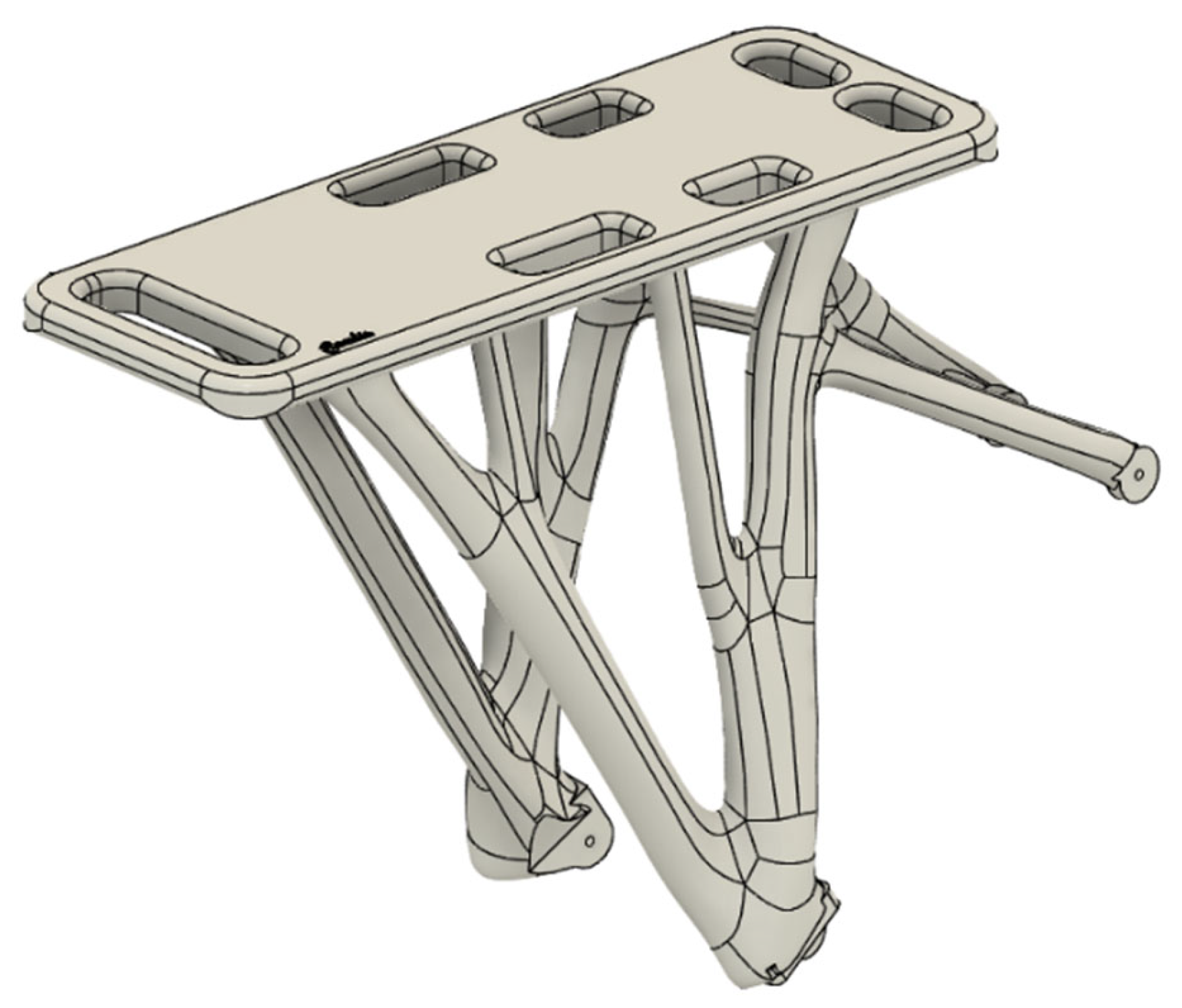

3.2. Generative Design Process

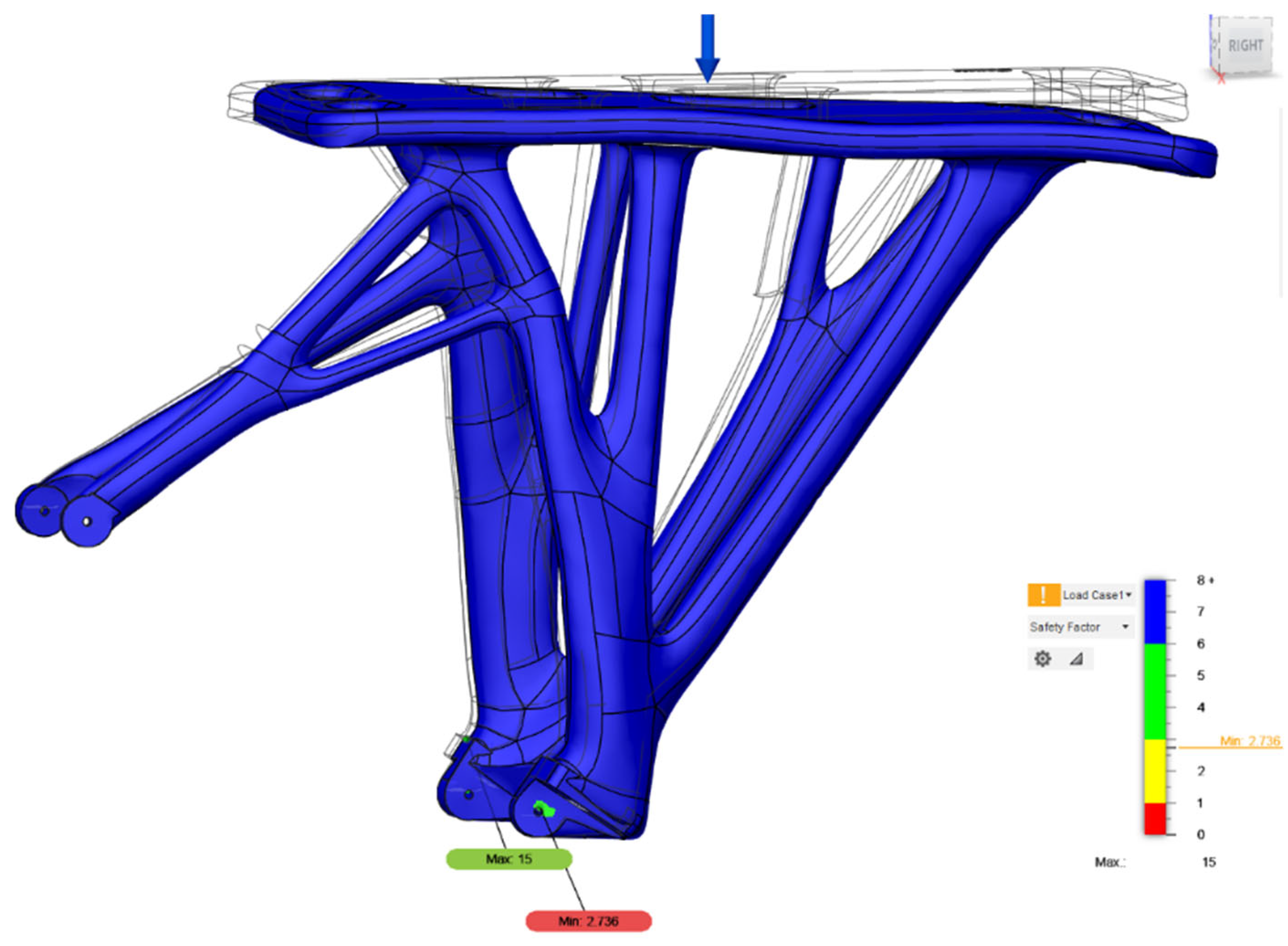

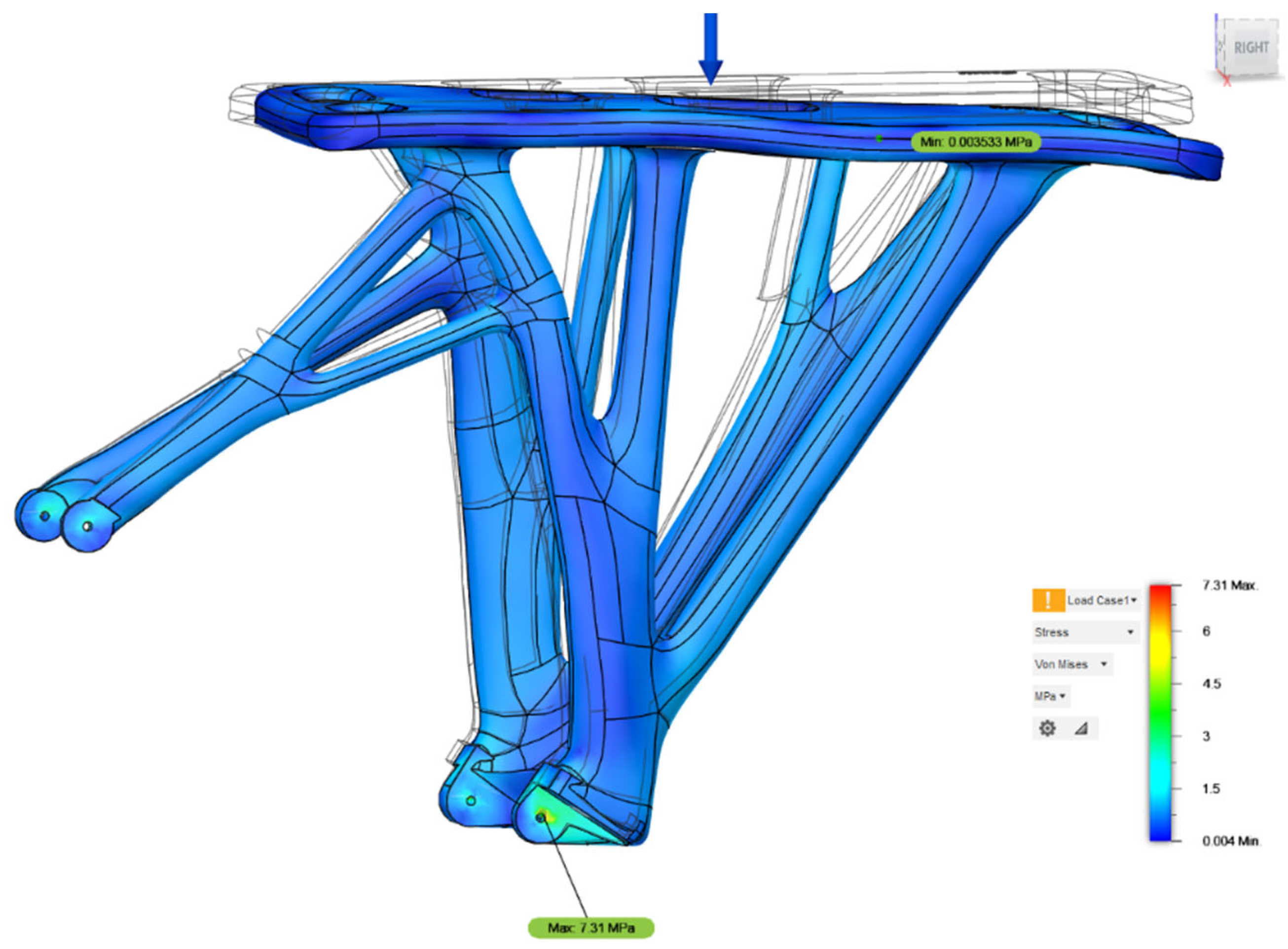

3.3. Simulation Process

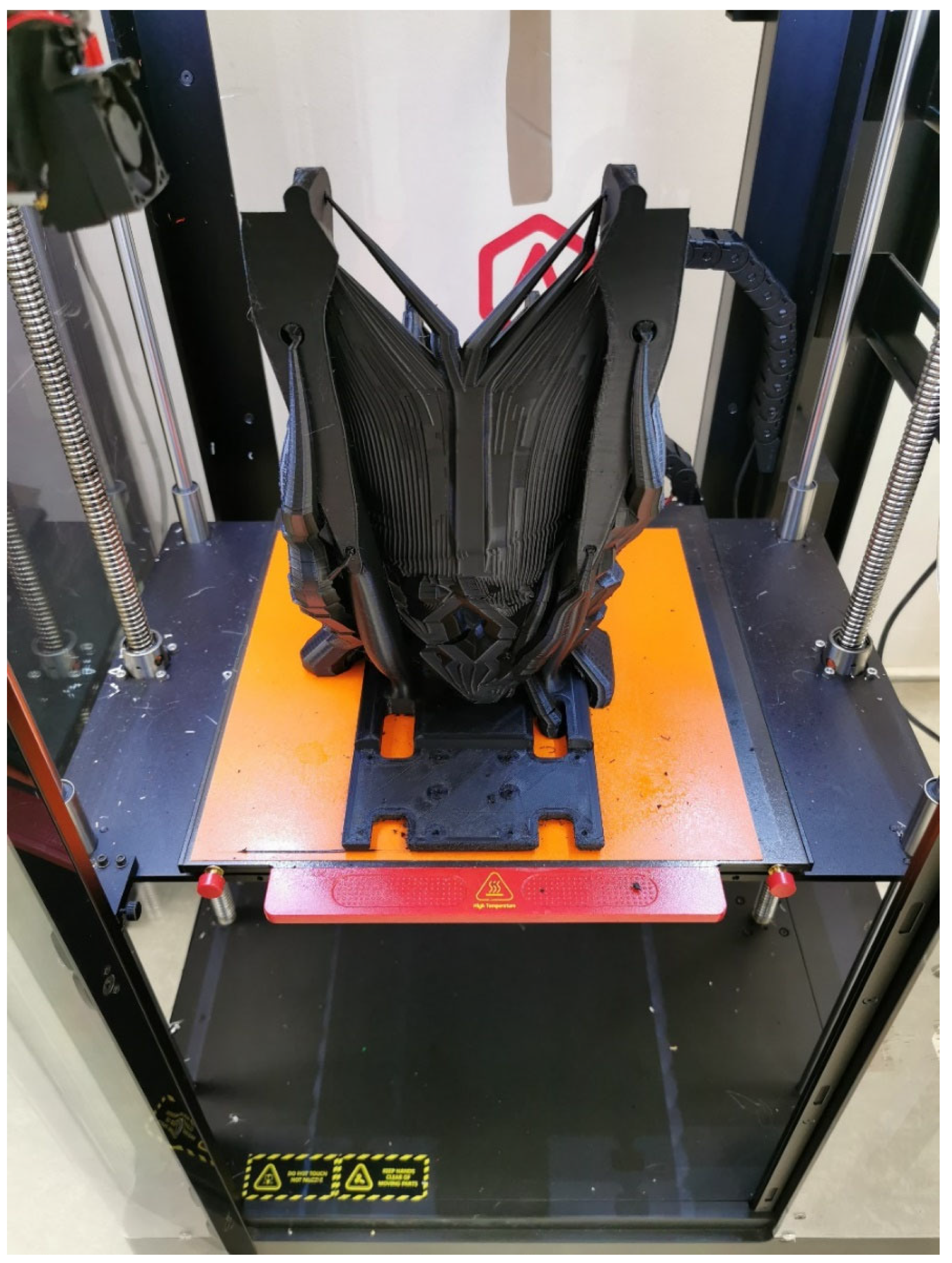

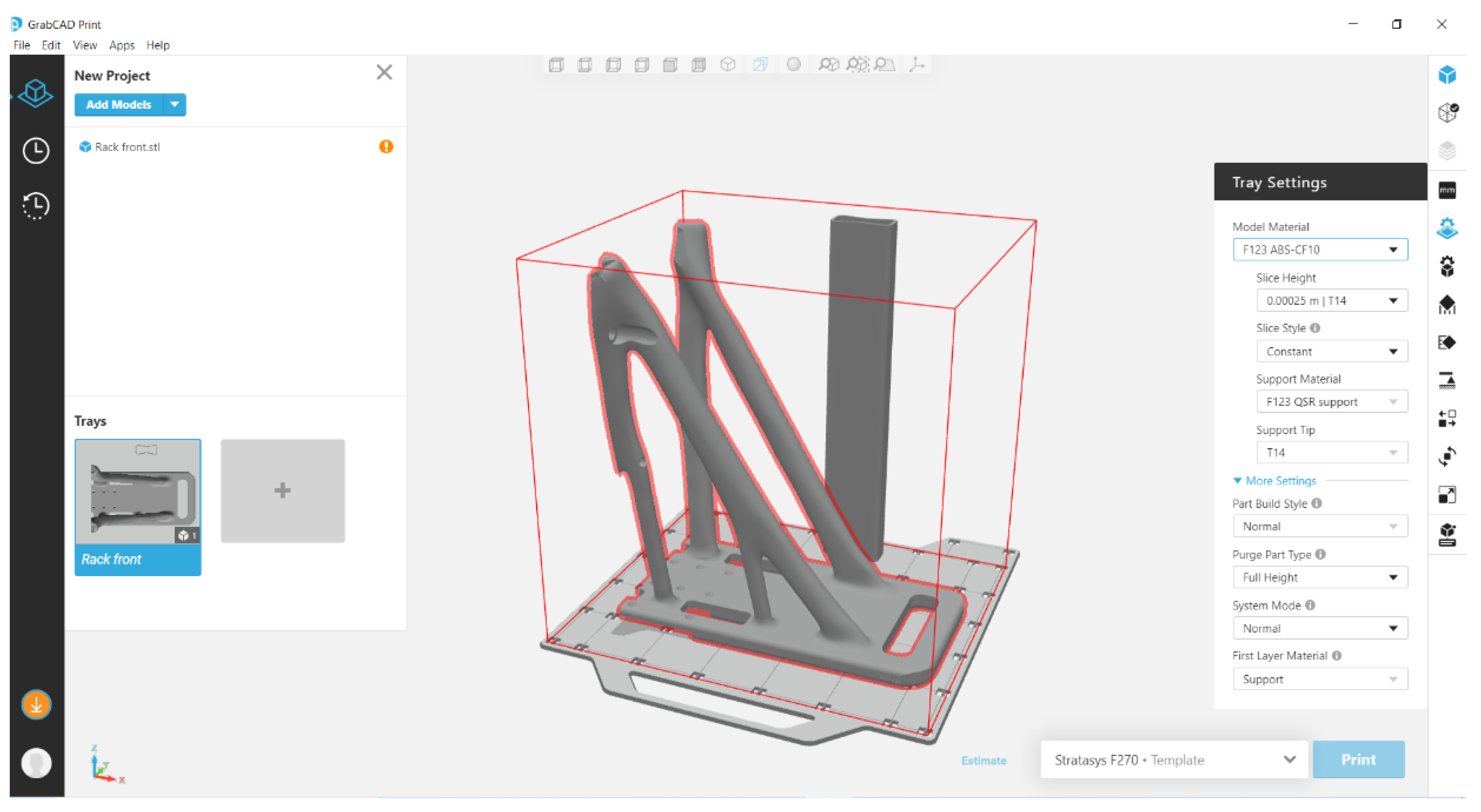

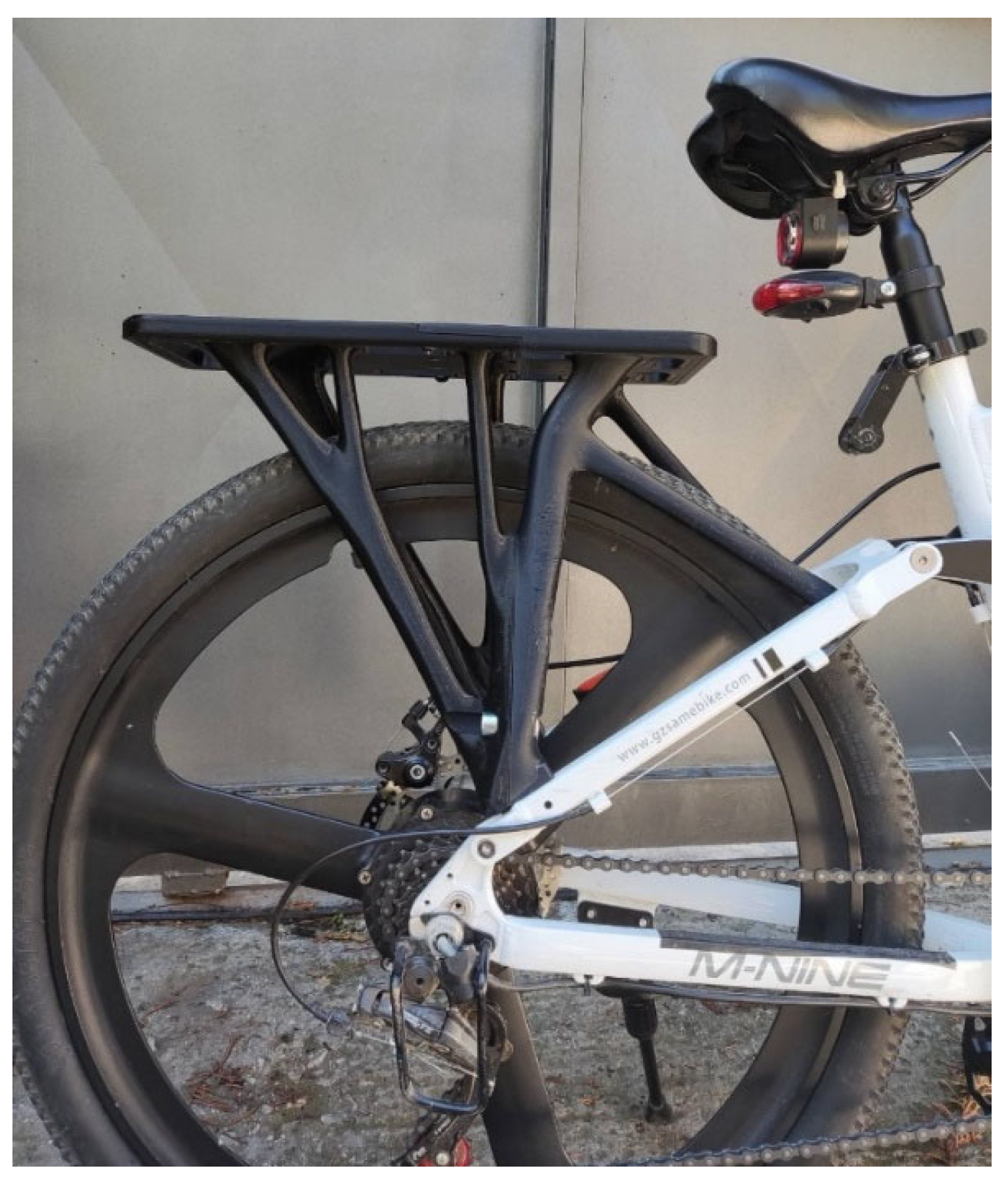

3.4. 3D Printing Process

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jeong, E.; Kim, Y.; Hong, S.; Yoon, K.; Lee, S. Innovative Injection Molding Process for the Fabrication of Woven Fabric Reinforced Thermoplastic Composites. Polymers 2022, 14, 1577. [Google Scholar] [CrossRef] [PubMed]

- Petráček, P.; Fojtů, P.; Kozlok, T.; Sulitka, M. Effect of CNC Interpolator Parameter Settings on Toolpath Precision and Quality in Corner Neighborhoods. Appl. Sci. 2022, 12, 9496. [Google Scholar] [CrossRef]

- Elverum, C.W.; Welo, T. On the use of directional and incremental prototyping in the development of high novelty products: Two case studies in the automotive industry. J. Eng. Technol. Manag. 2015, 38, 71–88. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L.; Darlington, J. Co-creation and user innovation: The role of online 3D printing platforms. J. Eng. Technol. Manag. 2015, 37, 90–102. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D printing: Making an innovative technology widely accessible through makerspaces and outsourced services. Mater. Today Proc. 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Mersand, S. The State of Makerspace Research: A Review of the Literature. TechTrends 2021, 65, 174–186. [Google Scholar] [CrossRef]

- Lettl, C. User involvement competence for radical innovation. J. Eng. Technol. Manag. 2007, 24, 53–75. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D. Fabricating Lattice Structures via 3D Printing: The Case of Porous Bio-Engineered Scaffolds. Appl. Mech. 2021, 2, 289–302. [Google Scholar] [CrossRef]

- Kantaros, A.; Laskaris, N.; Piromalis, D.; Ganetsos, T. Manufacturing Zero-Waste COVID-19 Personal Protection Equipment: A Case Study of Utilizing 3D Printing While Employing Waste Material Recycling. Circ. Econ. Sustain. 2021, 1, 851–869. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D. Employing a Low-Cost Desktop 3D Printer: Challenges, and How to Overcome Them by Tuning Key Process Parameters. Int. J. Mech. Appl. 2021, 10, 11–19. [Google Scholar] [CrossRef]

- Kantaros, A.; Chatzidai, N.; Karalekas, D. 3D printing-assisted design of scaffold structures. Int. J. Adv. Manuf. Technol. 2016, 82, 559–571. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. FBG based in situ characterization of residual strains in FDM process. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems; Springer: Cham, Switzerland, 2014; Volume 8, pp. 333–337. [Google Scholar] [CrossRef]

- Kantaros, A.; Giannatsis, J.; Karalekas, D. A novel strategy for the incorporation of optical sensors in Fused Deposition Modeling parts. In Proceedings of the International Conference on Advanced Manufacturing Engineering and Technologies, Stockolm, Sweden, 27–30 October 2013; Universitets Service US AB, KTH Royal Institite of Technology: Stockholm, Sweden, 2013. ISBN 978-91-7501-893-5. [Google Scholar]

- Kantaros, A.; Karalekas, D. Fiber Bragg grating based investigation of residual strains in ABS parts fabricated by fused deposition modeling process. Mater. Des. 2013, 50, 44–50. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Singh, R.P.; Rab, S.; Suman, R.; Kumar, L.; Khan, I.H. Exploring the potential of 3D scanning in Industry 4.0: An overview. Int. J. Cogn. Comput. Eng. 2022, 3, 161–171. [Google Scholar] [CrossRef]

- Bugeja, A.; Bonanno, M.; Garg, L. 3D scanning in the art & design industry. Mater. Today Proc. 2022, 63, 718–725. [Google Scholar] [CrossRef]

- Derusova, D.A.; Vavilov, V.P.; Druzhinin, N.V.; Shpil’noi, V.Y.; Pestryakov, A.N. Detecting Defects in Composite Polymers by Using 3D Scanning Laser Doppler Vibrometry. Materials 2022, 15, 7176. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Sigmund, O. Topology Optimization: Theory, Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 3-540-42992-1. [Google Scholar]

- Liu, Y.; Li, Z.; Wei, P.; Chen, S. Generating support structures for additive manufacturing with continuum topology optimization methods. Rapid Prototyp. J. 2019, 25, 232–246. [Google Scholar] [CrossRef]

- Jiang, L.; Ye, H.; Zhou, C.; Chen, S. Parametric Topology Optimization Toward Rational Design and Efficient Prefabrication for Additive Manufacturing. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 041007. [Google Scholar] [CrossRef]

- Jiang, D.; Hoglund, R.; Smith, D.E. Continuous Fiber Angle Topology Optimization for Polymer Composite Deposition Additive Manufacturing Applications. Fibers 2019, 7, 14. [Google Scholar] [CrossRef]

- Zhu, D.; Zhan, W.; Wu, F.; Simeone, A. Topology Optimization of Spatially Compliant Mechanisms with an Isomorphic Matrix of a 3-UPC Type Parallel Prototype Manipulator. Micromachines 2018, 9, 184. [Google Scholar] [CrossRef]

- Garaigordobil, A.; Ansola, R.; Veguería, E.; Fernandez, I. Overhang constraint for topology optimization of self-supported compliant mechanisms considering additive manufacturing. Comput. Aided Des. 2019, 110, 33–48. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Sigmund, O. Topology optimization by distribution of isotropic material. In Topology Optimization; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Junk, S.; Klerch, B.; Nasdala, L.; Hochberg, U. Topology optimization for additive manufacturing using a component of a humanoid robot. Procedia CIRP 2018, 70, 102–107. [Google Scholar] [CrossRef]

- Orme, M.; Madera, I.; Gschweitl, M.; Ferrari, M. Topology Optimization for Additive Manufacturing as an Enabler for Light Weight Flight Hardware. Designs 2018, 2, 51. [Google Scholar] [CrossRef]

- Sadri, M.; Kavandi, M.; Jozepiri, A.; Teimouri, S.; Abbasi, F. Bionic Architecture, Forms and Constructions. Res. J. Recent Sci. 2014, 3, 93–98. [Google Scholar]

- Ding, Y.; Zhou, Z.; Wang, Z.; Liu, H.; Wang, K. Bionic Stiffener Layout Optimization with a Flexible Plate in Solar-Powered UAV Surface Structure Design. Appl. Sci. 2019, 9, 5196. [Google Scholar] [CrossRef]

- Christiansen, A.N.; Bærentzen, J.A.; Nobel-Jørgensen, M.; Aage, N.; Sigmund, O. Combined shape and topology optimization of 3D structures. Comput. Graph. 2015, 46, 25–35. [Google Scholar] [CrossRef]

- Wang, L.; Du, W.; He, P.; Yang, M. Topology Optimization and 3D Printing of Three-Branch Joints in Treelike Structures. J. Struct. Eng. 2020, 146, 04019167. [Google Scholar] [CrossRef]

- Primo, T.; Calabrese, M.; Del Prete, A.; Anglani, A. Additive manufacturing integration with topology optimization methodology for innovative product design. Int. J. Adv. Manuf. Technol. 2017, 93, 467–479. [Google Scholar] [CrossRef]

- Significant Weight Reduction by Using Topology Optimization in Volkswagen Design Development. Available online: https://www.altair.com/resource/significant-weight-reduction-by-using-topology-optimization-in-volkswagen-design-development (accessed on 3 December 2022).

- BMW 3D Printing Superbike Components at the Track|3D-Prints. Available online: https://3d-prints.com/2020/11/04/bmw-3d-printing-superbike-components-at-the-track/ (accessed on 3 December 2022).

- Airbus APWorks Launches the ‘Light Rider’: The World’s First 3D-Printed Motorcycle. Available online: https://www.airbus.com/newsroom/press-releases/en/2016/05/APWorks-Launch-Light-Rider.html (accessed on 3 December 2022).

- Topology Optimization of Aircraft Wing Box Ribs. Available online: https://www.altair.com/resource/topology-optimization-of-aircraft-wing-box-ribs (accessed on 8 February 2022).

- Felipe-Falgas, P.; Madrid-Lopez, C.; Marquet, O. Assessing Environmental Performance of Micromobility Using LCA and Self-Reported Modal Change: The Case of Shared E-Bikes, E-Scooters, and E-Mopeds in Barcelona. Sustainability 2022, 14, 4139. [Google Scholar] [CrossRef]

- Pazzini, M.; Cameli, L.; Lantieri, C.; Vignali, V.; Dondi, G.; Jonsson, T. New Micromobility Means of Transport: An Analysis of E-Scooter Users’ Behaviour in Trondheim. Int. J. Environ. Res. Public Health 2022, 19, 7374. [Google Scholar] [CrossRef]

- Park, J.; Honda, Y.; Fujii, S.; Kim, S.E. Air Pollution and Public Bike-Sharing System Ridership in the Context of Sustainable Development Goals. Sustainability 2022, 14, 3861. [Google Scholar] [CrossRef]

- Harrou, F.; Dairi, A.; Zeroual, A.; Sun, Y. Forecasting of Bicycle and Pedestrian Traffic Using Flexible and Efficient Hybrid Deep Learning Approach. Appl. Sci. 2022, 12, 4482. [Google Scholar] [CrossRef]

- Wysling, L.; Purves, R.S. Where to improve cycling infrastructure? Assessing bicycle suitability and bikeability with open data in the city of Paris. Transp. Res. Interdiscip. Perspect. 2022, 15, 100648. [Google Scholar] [CrossRef]

- Santos, B.; Passos, S.; Gonçalves, J.; Matias, I. Spatial Multi-Criteria Analysis for Road Segment Cycling Suitability Assessment. Sustainability 2022, 14, 9928. [Google Scholar] [CrossRef]

- Reggiani, G.; van Oijen, T.; Hamedmoghadam, H.; Daamen, W.; Vu, H.L.; Hoogendoorn, S. Understanding bikeability: A methodology to assess urban networks. Transportation 2022, 49, 897–925. [Google Scholar] [CrossRef]

- Kellstedt, D.K.; Spengler, J.O.; Foster, M.; Lee, C.; Maddock, J.E. A Scoping Review of Bikeability Assessment Methods. J. Community Health 2021, 46, 211–224. [Google Scholar] [CrossRef]

- Krenn, P.J.; Oja, P.; Titze, S. Development of a Bikeability Index to Assess the Bicycle-Friendliness of Urban Environments. Open J. Civ. Eng. 2015, 5, 451–459. [Google Scholar] [CrossRef]

- Schmid-Querg, J.; Keler, A.; Grigoropoulos, G. The Munich Bikeability Index: A Practical Approach for Measuring Urban Bikeability. Sustainability 2021, 13, 428. [Google Scholar] [CrossRef]

- Karanikola, P.; Panagopoulos, T.; Tampakis, S.; Tsantopoulos, G. Cycling as a Smart and Green Mode of Transport in Small Touristic Cities. Sustainability 2018, 10, 268. [Google Scholar] [CrossRef]

- Grisé, E.; El-Geneidy, A. If we build it, who will benefit? A multi-criteria approach for the prioritization of new bicycle lanes in Quebec City, Canada. J. Transp. Land Use 2018, 11, 217–235. [Google Scholar] [CrossRef]

- Rietveld, P. Biking and Walking: The Position of Non-Motorized Transport Modes in Transport Systems. In Handbook of Transport Systems and Traffic Control; Button, K.J., Hensher, D.A., Eds.; Emerald Group Publishing Limited: Bingley, UK, 2001. [Google Scholar]

- Hardinghaus, M.; Papantoniou, P. Evaluating Cyclists’ Route Preferences with Respect to Infrastructure. Sustainability 2020, 12, 3375. [Google Scholar] [CrossRef]

- Prato, C.G.; Halldórsdóttir, K.; Nielsen, O.A. Evaluation of land-use and transport network effects on cyclists’ route choices in the Copenhagen Region in value-of-distance space. Int. J. Sustain. Transp. 2018, 12, 770–781. [Google Scholar] [CrossRef]

- McKinsey & Company. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/why-micromobility-is-here-to-stay (accessed on 15 November 2022).

- Carroll, P. Perceptions of Electric Scooters Prior to Legalisation: A Case Study of Dublin, Ireland, the ‘Final Frontier’ of Adopted E-Scooter Use in Europe. Sustainability 2022, 14, 11376. [Google Scholar] [CrossRef]

- Hamzani, Y.; Demtriou, H.; Zelnik, A.; Cohen, N.; Drescher, M.J.; Chaushu, G.; Yahya, B.H. Age as a Predictive Factor in Severity of Injuries in Riders of Electric Bikes and Powered Scooters: A Retrospective Cross-Sectional Study. Healthcare 2022, 10, 1689. [Google Scholar] [CrossRef] [PubMed]

- Meir, A. Can Complete-Novice E-Bike Riders Be Trained to Detect Unmaterialized Traffic Hazards in the Urban Environment? An Exploratory Study. Sustainability 2022, 14, 10869. [Google Scholar] [CrossRef]

- Noh, E.; Hong, S. Finite Element Analysis and Support Vector Regression-Based Optimal Design to Minimize Deformation of Indoor Bicycle Handle Frame Equipped with Monitor. Appl. Sci. 2022, 12, 2999. [Google Scholar] [CrossRef]

- Khutal, K.; Kathiresan, G.; Ashok, K.; Simhachalam, B.; Jebaseelan, D.D. Design Validation Methodology for Bicycle Frames Using Finite Element Analysis. Mater. Today Proc. 2020, 22, 1861–1869. [Google Scholar] [CrossRef]

- Devaiah, B.; Purohit, R.; Rana, R.; Parashar, V. Stress Analysis of A Bicycle Frame. Int. J. Eng. Sci. Technol. 2018, 5, 18920–18926. [Google Scholar] [CrossRef]

- Covill, D.; Begg, S.; Elton, E.; Milne, M.; Morris, R.; Katz, T. Parametric Finite Element Analysis of Bicycle Frame Geometries. Procedia Eng. 2014, 72, 441–446. [Google Scholar] [CrossRef]

- Khade, H.A.; Narwade, P.A. Structural Analysis of Two Wheeler Handlebar. Int. J. Adv. Sci. Technol. 2014, 68, 65–76. [Google Scholar] [CrossRef]

- Zdravkovich, M. Aerodynamics of bicycle wheel and frame. J. Wind. Eng. Ind. Aerodyn. 1992, 40, 55–70. [Google Scholar] [CrossRef]

- Tomaszewski, T. Fatigue life analysis of steel bicycle frame according to ISO 4210. Eng. Fail. Anal. 2021, 122, 105195. [Google Scholar] [CrossRef]

- Hsiao, S.-W.; Chen, R.-Q.; Leng, W.-L. Applying riding-posture optimization on bicycle frame design. Appl. Ergon. 2015, 51, 69–79. [Google Scholar] [CrossRef]

- Liu, T.J.-C.; Wu, H.-C. Fiber direction and stacking sequence design for bicycle frame made of carbon/epoxy composite laminate. Mater. Des. 2010, 31, 1971–1980. [Google Scholar] [CrossRef]

- Lépine, J.; Champoux, Y.; Drouet, J.-M. The relative contribution of road bicycle components on vibration induced to the cyclist. Sport. Eng. 2015, 18, 79–91. [Google Scholar] [CrossRef]

- Covill, D.; Allard, P.; Drouet, J.-M.; Emerson, N. An Assessment of Bicycle Frame Behaviour under Various Load Conditions Using Numerical Simulations. Procedia Eng. 2016, 147, 665–670. [Google Scholar] [CrossRef]

- Malizia, F.; Blocken, B. Bicycle aerodynamics: History, state-of-the-art and future perspectives. J. Wind. Eng. Ind. Aerodyn. 2020, 200, 104134. [Google Scholar] [CrossRef]

- Mesicek, J.; Jancar, L.; Ma, Q.-P.; Hajnys, J.; Tanski, T.; Krpec, P.; Pagac, M. Comprehensive View of Topological Optimization Scooter Frame Design and Manufacturing. Symmetry 2021, 13, 1201. [Google Scholar] [CrossRef]

- Callens, A.; Bignonnet, A. Fatigue design of welded bicycle frames using a multiaxial criterion. Procedia Eng. 2012, 34, 640–645. [Google Scholar] [CrossRef]

- Behnam, H.; Kuang, J.S.; Samali, B. Parametric Finite Element Analysis of RC Wide Beam-Column Connections. Comput. Struct. 2018, 205, 28–44. [Google Scholar] [CrossRef]

- Covill, D.; Blayden, A.; Coren, D.; Begg, S. Parametric Finite Element Analysis of Steel Bicycle Frames: The Influence of Tube Selection on Frame Stiffness. Procedia Eng. 2015, 112, 34–39. [Google Scholar] [CrossRef]

- Choosing the Right Adhesive to Bond ABS Plastic: What You Need to Know. Available online: https://forgeway.com/choose-glue-to-bond-abs-plastic/ (accessed on 7 February 2022).

- Petrescu, R.V.V.; Petrescu, F.I.T. The current stage in aerospace at the end of 2020. Indep. J. Manag. Prod. 2022, 13, 405–478. [Google Scholar] [CrossRef]

- Aversa, R.; Petrescu, R.V.V.; Petrescu, F.I.T.; Apicella, A. Smart-Factory: Optimization and Process Control of Composite Centrifuged Pipes. Am. J. Appl. Sci. 2016, 13, 1330–1341. [Google Scholar] [CrossRef]

| Printing Process Parameters | Value |

|---|---|

| Extrusion hot end temperature | 250 °C |

| Platform/bed temperature | 100 °C |

| Printing speed | 60 mm/s |

| Infill percentage | 100% |

| Layer height (resolution) | 0.2 mm |

| Material (at zx Orientation and 0.010 mm Layer Height) | ABS Fusion | ABS-CF10 |

|---|---|---|

| Young’s Modulus (GPa) | 1.106 | 1.958 |

| Tensile Strength (MPa) | 17.9 | 21.2 |

| Flexural Strength (GPa) | 23.1 | 29.2 |

| Flexural Modulus (GPa) | 0.878 | 1.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes 2023, 11, 1385. https://doi.org/10.3390/pr11051385

Kantaros A, Soulis E, Ganetsos T, Petrescu FIT. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes. 2023; 11(5):1385. https://doi.org/10.3390/pr11051385

Chicago/Turabian StyleKantaros, Antreas, Evangelos Soulis, Theodore Ganetsos, and Florian Ion Tiberiu Petrescu. 2023. "Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component" Processes 11, no. 5: 1385. https://doi.org/10.3390/pr11051385

APA StyleKantaros, A., Soulis, E., Ganetsos, T., & Petrescu, F. I. T. (2023). Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes, 11(5), 1385. https://doi.org/10.3390/pr11051385