Abstract

This work focuses on introducing new sustainable chemicals in the wool grease removal processes by aiming to understand the effect of an eco-friendly solvent, cyclopentyl methyl ether (CPME), in solvent-based wool grease extraction and, in addition, the impact of the wool protein hydrolyzate (WPH) as a biosurfactant derived from green hydrolysis in the wool scouring process. In the green solvent extraction process assisted using solvent CPME, the effect of CPME on grease extraction and the presence of four primary fatty acids were evaluated and compared with conventional solvents. The quantity of grease extracted using green solvent CPME was more significant than the conventional solvents. An extraction using green solvent CPME resulted in 11.95% extracted wool grease, which is more when compared with 8.19% hexane and 10.28% diethyl ether. The total quantity of four fatty acids was analyzed and found to be ~15% for CPME ~17% for Hexan compared with ~20% for commercial lanolin. FTIR of CPME-extracted wool grease exhibits primary and distinguishing bands similar to pure wool grease. Wool cleanliness efficiency was morphologically analyzed using SEM, resulting in no fiber degradation or surface alterations. These analyzes indicated that CPME has the potential to be claimed as an effective green alternative to conventional solvents for the extraction of grease and fatty acids. In a sustainable scouring process, WPH was used as a biosurfactant, an eco-friendly alternative. Furthermore, scouring process parameters such as temperature, material-to-liquor ratio, and WPH concentration were optimized for efficient scouring. The wool samples scoured using WPH biosurfactant exhibited nearly similar whiteness and yellowness and washing yield compared with Biotex AL. These results comply with SEM analysis, which showed that WPH-scoured wool had an intact scale structure, a smooth fiber surface, and no wool grease layer. At optimum conditions, WPH reduced the residual grease content of Sopravissana wool from 22.29% to 0.30%, comparable to the commercial biosurfactant Biotex AL. Compared with conventional wool grease removal processes, the green solvent CPME and biosurfactant WPH were considered viable, sustainable, and environmentally friendly alternatives.

1. Introduction

Sheep and wool-producing animals secrete a waxy, yellow substance called “wool grease” from their sebaceous glands [1]. Depending on the sheep breed and wool quality, wool grease makes up 5–25% of the weight of the shorn fleece [2]. It is extracted from the scouring liquid using high-speed centrifugation. This process is carried out to obtain crude lanolin or reduce the chemical oxygen demand (COD) and the biological oxygen demand (BOD) of effluents. Wool grease extracted from wool scouring liquors is refined into value-added products ranging from rust-proof coatings, lubricants, and personal and healthcare creams [3,4,5]. Lanolin is a mixture of esters, diesters, and hydroxy esters of high molecular weight, free fatty alcohols, and fatty acids [2,6,7,8]. Lanolin was proposed in the textile sector as a binder in pigment printing of wool, polyester, polyester/wool, and polyester/cotton fabrics, as a nonionic softener on wool fabrics, and as a durable hydrophobic coating on viscose fibers [4,9,10].

Conventional wool grease extraction is carried out using soxhlet with the help of solvents consisting of dichloromethane [11], acetone, hexane, toluene, and ethanol [12]. These solvents were volatile organic compounds (VOCs) obtained from non-renewable resources, and now, most of them are suspected to be harmful to human health and the environment [13,14]. In particular, hexane is of petroleum origin and a neurotoxic substance. It is toxic for the aquatic environment under the European Directives and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation [15].

In order to avoid the health and environmental risks associated with traditional hazardous solvents, it is vital to conduct research into sustainable alternatives. Cyclopentyl methyl ether (CPME), a greener option, is employed in the current work to evaluate its impact on wool grease solvent extraction and compare it with conventional solvents. It is already applicable in pharmaceuticals, aroma chemicals, electronic material as a process solvent, and as a sustainable green alternative to hazardous solvents in chemical synthesis [16]. CPME is a suitable solvent for various processes due to its hydrophobicity, good stability in acidic and basic environments, low toxicity, high boiling, and low melting temperatures, and very low latent heat of vaporization [17]. CPME is not classified as ‘banned’ or ‘undesirable’ in the most recent solvent selection guides rating solvents’ greenness [18]. It leads to no genotoxicity or mutagenicity and is approved by the Toxic Substances Control Act and the European List of Notified Chemical Substances (ELINCS) [19].

The production of CPME currently relies on petrochemical-based techniques, such as the methylation of cyclopentanol in the presence of a salt (substitution reaction) or the addition of methanol to cyclopentene in the presence of an acid. As the process based on substitution reactions results in the generation of waste byproducts, the addition reaction is preferable from an environmental safety perspective [20]. Potential biomass-based routes have focused on producing chemical precursors for CPME, such as cyclopentanone and cyclopentanol. These precursors can be synthesized from furfural, produced by the dehydration of pentoses, preferably xylose. Cyclopentanone can be synthesized in classic petroleum refineries by decarboxylation of adipic acid. Adipic acid can also be derived from biomass using fermentative pathways involving sugars or lignin as the substrate. These biobased alternative routes have recently become available, paving the way for a future biogenic supply of the solvent [21,22]. However, it perfectly fits the principles of green chemistry to establish sustainable processes with low environmental impact while being economically feasible [23].

Recently, a study has been carried out for the valorization of fat biomass, such as wool grease, by the conversion of fatty acids (FAs), which are their primary constituents, into α-hydroxy FAs (α-HFAs) [5]. The conversion was accomplished by an efficient two-step procedure relying on the intermediate α-chlorination of FAs with tricloroisocyanuric acid (TCCA), a green and inexpensive organohalogen used for regioselective C- and N-halogenation of a wide variety of substrates [24,25,26].

Nowadays, conventional wool scouring is also raising environmental concerns similar to conventional solvent extraction because conventional aqueous wool scouring generates a very high pollution level [27]. In recent years, the need for pollution reduction from wool scouring has increased, and effective dirt removal, the replacement of hazardous chemicals, and subsequent water treatment to ensure minimal environmental contamination are major focus areas. The first step in processing wool is scouring the fleece to remove both the animal’s inherent impurities (grease and perspiration) and the acquired impurities (soil and vegetable debris) that the animal picked up while grazing [28]. The conventional scouring process is scouring in the suint, and emulsion scouring consists of a surfactant and alkali [29]. This process successfully emulsifies wool waxes into water-soluble emulsified wool waxes and removes dirt from fibers, but the effluents generated from the process are environmentally undesirable due to the presence of significant amounts of wool contaminants and washing additives. The BOD in scouring wastewater ranges from 20,000 to 40,000 mg/L, while the COD reaches 100,000 mg/L [12,30]. In addition, synthetic detergents and chemicals used in wool scouring have negative environmental impacts such as environmental pollution, toxicity, slow or no degradability, and endocrine hormone disruption [31,32,33]. Due to these limitations, eco-friendly wool scouring alternatives have been developed. Ultrasonication, microwaves, and enzymes have been investigated as eco-friendly techniques [34,35,36,37]. The use of eco-friendly biosurfactants is an alternate approach for lowering environmental impact. Studies on the application of biosurfactants in scouring are limited, mainly consisting of the plant-based biosurfactant saponin from Quillaja Saponara, and oat extract [38,39].

Protein-based surfactants have attracted renewed interest due to their biodegradability, non-toxicity, biocompatibility, and being environmentally friendly surfactants derived from sustainable renewable sources as well as an effective solution for the disposal of animal and vegetable protein wastes [40]. Proteins are comprised of hydrophobic and hydrophilic, anionic, and cationic amino acids that give them a certain degree of surface activity, and they are similar to amphiphilic synthetic surfactants [41,42]. Fibrous proteins called keratins are the major component of wool fibers. In nature, keratin is available in large quantities as a byproduct in the wool and leather industries, slaughterhouses, and poultry farms [43]. Keratin protein hydrolyzates are used as a foaming agent in firefighting foams [44]. Shan Li et al. reported the possible use of keratin-based quaternary ammonium salt as a biosurfactant in hair care and related products owing to its antibacterial and biodegradable qualities [45]. Bhavsar et al. showed that low molecular weight hydrolyzed keratin resulted in low surface tension, outstanding surface activity, and a potential foaming agent for wool and cotton’s sustainable green dyeing process [46].

In this research, for the first time, wool protein hydrolyzate (WPH) derived from superheated water hydrolysis is used as a biosurfactant in sustainable wool scouring. Applying WPH as a biosurfactant is better than synthetic surfactants in terms of biodegradability and lower toxicity, but it will also be beneficial in treating effluents in wastewater [47]. Several techniques, such as hydrolysis (with acids, bases, and enzymes), steam explosion, acoustic cavitation, sulfitolysis, microwaves, and ionic liquids, were used to extract keratin from wool [48,49,50,51,52,53,54]. This research produces WPH by superheated water hydrolysis, a solvent-free, chemical-free, cost-effective, and environmentally friendly sustainable method. Wool is sterilized during hydrolysis, making it more water-soluble, biodegradable, and useful for various applications. Studies have shown that WPH, produced by superheated water hydrolysis, by heating only water under pressure, is particularly effective for hydrolyzing proteins and contains low molecular weight oligopeptides and amino acids that further require no neutralization or filtration for subsequent application [46,55,56].

No study has been reported using CPME as a green solvent for wool grease extraction or wool hydrolyzate as a biosurfactant in the wool scouring process. Hence, the main objective of this research is to study the influence of CPME green solvent on wool grease extraction and compare it with conventional solvents. In addition, four primary fatty acids in the greasy wool solvent extract were evaluated using gas chromatography and compared with commercial lanolin, anticipating the potential of CPME for sustainable green solvent extraction for industrial applications. Moreover, in the sustainable scouring process, a novel biosurfactant derived from the green hydrolysis of wool was presented, and its impact on wool grease removal was evaluated and compared with a commercial surfactant. Using eco-friendly surfactants derived from wool hydrolyzate will assist in reducing the use of synthetic chemicals while also benefiting the environment.

2. Materials and Methods

2.1. Materials

2.1.1. Wool Grease Solvent Extraction

Three types of wool: Sarda, Biellese, and Sopravissana, were supplied by a local wool supplier in the Piedmont area of Italy (Biella The Wool Company, Miagliano, Italy) Table 1. The solvents cyclopentyl methyl ether (CPME), hexane, diethyl ether, and all the chemicals used in this study were acquired from Sigma-Aldrich unless otherwise specified.

Table 1.

Wool of three types used for solvent extraction and their properties.

2.1.2. Wool Scouring

Sopravissana wool (Biella The Wool Company, Miagliano, Italy), commercial surfactant Biotex AL (Prochimica Novarese, San Pietro Mosezzo, Novara, Italy), dichloromethane, and all the other chemicals used in this study were acquired from Sigma-Aldrich unless otherwise specified

2.2. Methods

2.2.1. Wool Grease Solvent Extraction

Raw wool from the Sarda, Biellese, and Sopravissana breeds was used to compare the grease extraction efficacy of the eco-friendly solvent CPME with conventional hexane and diethyl ether solvents. According to IWTO-10-01, 10 g of wool was subjected to continuous extraction as a function of continuous siphoning per hour with 200 mL of solvent in a Soxhlet apparatus in order to determine the residual grease concentration. Each time, a solvent of analytical grade was utilized, and extractions were carried out for four hours. The amount of grease extracted was determined and referred to as the dry weight of wool samples after grease extraction [57,58]. Every reference measurement was the average of three assessments made on separate batches of 10 g of wool.

2.2.2. Wool Scouring

Preparation of WPH Biosurfactant

In a laboratory-scale hydrolysis reactor (A2513, Amar Equipments Pvt. Ltd., Mumbai, India), wool was hydrolyzed with superheated water to yield wool protein hydrolyzate, which was then used as a protein-based biosurfactant for wool scouring. In hydrolysis, wool and water as a chemical were fed to the hydrolysis reactor. Based on our prior research, in order to get water-soluble hydrolyzed wool, hydrolysis was performed at optimal process conditions of 170 °C (pressure 7 bar) and 60 min [28]. The hydrolysis reactor was outfitted with an electrical system. One kilogram of wool was hydrolyzed using an estimated 4 kWh of energy. In the hydrolysis reactor, wool was uniformly impregnated with water, which made it totally soluble in water. The resulting hydrolyzed solution was centrifuged three times to remove any precipitated solid particles before being utilized as a biosurfactant.

Wool Scouring

Sopravissana raw wool was scoured in the laboratory-scale Lauda hydro shaking water baths H 20 S (Lauda Germany)using parameters shown in Table 2. A conical flask comprising 10 g of a greasy raw wool sample was heated in a water bath to a specific temperature and material-to-liquor ratio while being shaken at 120 rpm. The wool samples were manually pressed to remove excess water at each stage and then returned to the subsequent step flask. The process parameters were optimized to comprehend the impact of temperature, WPH concentration, and material-to-liquor ratio on biosurfactant-based scouring.

Table 2.

Wool scouring process.

Scouring was carried out in the following five steps: first soaking, fourth rinsing, and fifth rinsing of wool in water for five minutes. In the second step, wool was scoured in a flask containing X% surfactant and 5% sodium carbonate by fiber weight (o.w.f.) for 10 min. Similarly, in the third step, raw wool was scoured in a flask containing X% surfactant and 5% sodium carbonate by fiber weight (o.w.f.) for 5 min.

Wool scouring using the commercial surfactant Biotex AL was carried out at a recommended concentration of 2 g/L for the optimal time and temperature. After scouring, dichloromethane was used to analyze the scoured wool’s residual grease content [58].

2.3. Characterisation

2.3.1. Wool Grease Solvent Extraction

Wool grease was analyzed by FTIR (fourier transform infrared spectroscopy), DSC (differential scanning calorimetry), and GC-FID (gas chromatography with flame-ionization detection) spectroscopy.

FT-IR Analysis

Using FTIR, the structural conformation of wool grease was investigated. FT-IR spectra were obtained by a Nexus Thermo Nicolet Spectrometer in attenuated total reflectance (ATR) using microcrystal diamond ATR mode with 100 scans in the range 4000–650 cm−1, with a resolution of 4 cm−1 and gain of 8.0. After completing wool grease extraction experiments using solvents CPME, hexane, and diethyl ether, the extracted wool grease samples were analyzed using FT-IR. The FT-IR spectra of extracted grease samples were compared with the original lanolin sample. FTIR was primarily utilized to investigate qualitative changes in the structure of wool grease.

DSC Analysis

DSC measurements of wool grease samples extracted from solvent scouring were analyzed by a Mettler Toledo DSC 821e (Mettler Toledo GmbH, Schwerzenbach, Switzerland). The apparatus was calibrated with an indium standard in a nitrogen atmosphere. About 3 mg of sample were heated from 25 to 300 °C at a heating rate of 10 °C min−1, flushing the crucible with 100 mL min−1 nitrogen. The data was processed using the Mettler Toledo STAR System.

GC-FID Analysis

- Lanolin saponification

Twenty grams of lanolin were hydrolyzed using 17 g of KOH in 250 mL of distilled water by refluxing for 48 h. Alcohols and unsaponifiable materials were then removed from the aqueous phase by extraction with AcOEt (200 mL × 2). The pH of the aqueous phase was adjusted to 1–2 and free fatty acids were extracted using AcOEt. The organic phases were collected, dried, and concentrated to obtain 10 g of mixed free fatty acids (FA). The recovery of fatty acids was about 50% of the weight of the starting material. The saponification was performed on three different samples of lanolin: lanolin purchased from Sigma Aldrich (LA), lanolin obtained by the extraction of greasy wool with hexane (LB), and lanolin obtained by the extraction of greasy wool with CPME (LC).

- Derivatization of fatty acids

In three different glass tubes, 100 mg c.a., accurately weighed, of LA, LB, and LC were added. The samples were solubilized with 250 µL of methanol, added 500 µL of 3 M HCl methanol solution, and 250 µL of 8 mg/mL solution of C17 in MeOH (ISTD). The glass tubes were placed in a stove at 55 °C overnight and then extracted with 2.50 mL of hexane. 1 mL of each solution was transferred into a 2 mL vial and analyzed in a single step.

- Preparation of standard compounds for calibration graph

The STD mixture of myristic, palmitic, and stearic acid was prepared by adding 100 mg c.a. of C14, 200 mg c.a. of C16 and 100 mg c.a. of C18 and methanol to capacity in a 25 mL volumetric flask. The resulting solution of 250 µL was added to a glass tube along with 500 µL of 3 M HCl methanol solution and 250 µL of 8 mg/mL solution of C17 in MeOH (ISTD). The glass tube was placed in a stove at 55 °C overnight and then extracted with 2.50 mL of hexane. The obtained solution of 1 mL was transferred to a 2 mL vial and analyzed. The STD solution was prepared and analyzed in triple.

The STD solution of αOH-palmitic acid was prepared, solubilizing 40 mg c.a. of the compound in 1 mL of MeOH. A 250 µL of this solution was added to a glass tube along with 500 µL of 3 M HCl methanol solution, and 250 µL of 8 mg/mL solution of C17 in MeOH (ISTD). The glass tube was placed in a stove at 55 °C overnight and then extracted with 2.50 mL of hexane. The obtained solution of 1 mL was transferred to a 2 mL vial and analyzed. The STD solution was prepared and analyzed in triple.

- GC-FID analysis

The amount of four fatty acids (FAs) (i.e., myristic acid, palmitic acid, stearic acid, and αOH-palmitic acid) in two Sopravissana wool grease extracts and in a commercial sample of lanolin were determined by GC-FID analysis. Before the analysis, the samples were submitted to hydrolysis, and the obtained mixed fatty acids were derivatized as methyl esters using a 3 M HCl methanol solution. Samples were analyzed using a gas chromatograph Trace GC with a Flame Ionization Detector (FID) and autosampler 2000 (Thermo Fischer, Monza, Italy). Fused silica capillary column DB-5MS UI, (30 m × 0.25 mm ID, 0.25 μm film from Agilent, Milan, Italy) was used, and separation was performed as follows: 180 °C to 300 °C with a 5 °C/min temperature gradient and a final isotherm at 300 °C for 6 min using helium as the carrier gas at a constant flow of 1.0 mL/min. One microliter of the sample was injected, and the split was set to 30:1. The injector temperature was 280 °C, while the FID was operated at 300 °C.

2.3.2. Wool Scouring

Molecular Weight Distribution of Wool Protein Hydrolyzate

Sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE), a method developed by Laemmli, was used to determine the molecular weight distribution of the proteins in the wool and wool protein hydrolyzate samples [59]. In a nitrogen environment, the wool and wool protein hydrolyzate was dissolved in a solution of Tris/HCl (550 mM, pH 8.6), dithiothreitol (140 mM), ethylenediaminetetraacetic acid (EDTA), and urea (8 M) [60]. The Bradford protein assay technique (BioRad) uses bovine serum albumin as the standard applied to determine the solutions’ protein concentration. As stated by the Invitrogen procedure, samples were dissolved into a buffer comprising NuPAGE LDS sample buffer and NuPAGE sample reducing agent. The SDS PAGE electrophoresis was carried out with Xcell SureLock Mini-Cell (Invitrogen) on a 4–12% polyacrylamide precast gel (Invitrogen) using NuPAGE MES SDS running buffer, appropriate for proteins having molecular weights between 188 and 3 kDa, including myosin, bovine serum albumin, glutamate dehydrogenase, alcohol dehydrogenase, carbonic anhydrase, myoglobin, lysozyme, aprotinin, and insulin B chain. (blue prestained standard, Invitrogen).

Scanning Electron Microscopy

The morphology analysis of raw greasy, biosurfactant-scoured, and solvent-extracted wool samples was carried out using a scanning electron microscope, the LEO 135 VP (Leica Electron Optics) (LEO Electron Microscopy Ltd., Cambridge, UK) at a 15 kV acceleration voltage, a current probe of 50 pA, and a working distance of 30 mm. The samples were adhered to aluminum specimen stubs using double-sided adhesive tape and coated with a 20–30 nm thick layer of gold in rarefied argon for four minutes using a sputter coater and a current intensity of 20 mA.

Washing Yield

The washing yield was evaluated following a scouring procedure. Prior to weighing, each sample was dried for four hours at 105 °C to achieve a constant weight, and the washing yield was calculated as follows:

where:

Wiw = Initial weight of the dried wool sample

Wfw = Final weight of the dried wool sample

Color Measurement

The scoured wool sample was prepared for color assessment in three replicates. A spectrophotometer Datacolor (spectra flash SF600x) was then used to measure the samples (Datacolor International, Lawrenceville, NJ, USA). Whiteness and Yellowness Index values were determined using a D65 standard illumination lamp as per the International Commission of Illumination and accepted by the IWTO-56 (International Wool Textile Organisation, Brussels, Belgium) test method [61].

3. Results and Discussion

3.1. Wool Grease Extraction

3.1.1. Amount of Grease Extracted

In order to quantify the wool grease extraction efficacy of CPME as an eco-friendly solvent with hexane and diethyl ether solvent, wool from three different breeds, Sarda, Biellese, and Sopravissana, was used to perform soxhlet extraction.

According to Table 3, the findings from three replicas have a significant standard of deviation because different species of sheep and their body parts have varied quantities of contaminants such as dirt, vegetable matter, etc., and grease content.

Table 3.

Solvent extraction of grease from three different wool using three different solvents.

Wool grease extraction resulted in a significant difference between the wool grease content of coarse wool utilized for milk and meat production (Sarda and Biellese) and fine wool (Sorpravissana) from sheep breeds used for wool and meat production. The results obtained for mean grease extraction were 4.01% w/w for Sarda, 4.13% w/w for Biellese, and 22.29% for Sopravissana wool.

These results are in accordance with results obtained by a previous study carried out by Kaur et al. [62]. The difference in wool grease content occurs as a result of the fact that the finer the diameter of wool fibers, the greater the amount of grease present in comparison with the coarse and long fibers.

This CPME solvent extraction study showed that the quantity of grease removed using the environmentally friendly solvent CPME was greater than the amount of grease extracted using diethyl ether and hexane. The results obtained for mean grease extraction were 8.19% w/w for hexane, 10.28% w/w for diethyl ether, and 11.95% for CPME. The ranking for maximum grease extraction using solvents was found to be CPME > diethyl ether > hexane.

This impact may be related to the unique characteristics of CPME in comparison to diethyl ether and hexane (nonpolar). CPME is significantly more hydrophobic than diethyl ether, as shown in Table 4, for properties related to solubility in water, the solubility of water in the solvent, and logP, respectively. However, it is notably more polar than hexane and just moderately more polar than diethyl ether, as shown in Table 4 for properties related to the dipole moment [19].

Table 4.

Physical properties of CPME, diethyl ether, and hexane.

Hence, it is possible that more compounds can be extracted from the matrix. A higher dissolving ability of CPME for polar extracted compounds may also be indicated by the higher boiling temperature of this solvent (Table 4), which can result in a lower viscosity of the extracted material in the matrix and, consequently, a better diffusion rate of the solute from the solid phase to the solvent.

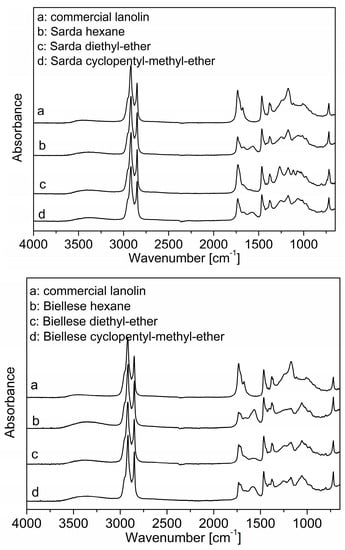

3.1.2. FT-IR Analysis

Figure 1 shows the FT-IR spectra of the wool grease obtained by solvent extraction using hexane, diethyl ether, and CPME from three distinct varieties of wool, including Sarda, Biellese, and Sopravissana. The infrared spectrum of pure wool wax (lanolin) from a commercial source (Sigma Aldrich) was collected, and the principal absorption peaks discovered in this investigation, consisting of absorption bands in the range of 2900–2800 cm−1 were attributed to CH3 and CH2 asymmetric stretching. The peak at 1740 cm−1 corresponds to C=O stretching. The absorbance peaks at 1462 and 1372 cm−1 were attributed to CH2 and CH3 bending vibrations, respectively. The peaks observed in this FT-IR study were also reported in prior studies [63,64,65]. FT-IR spectra show that the pure wool grease spectrum’s principal and characteristic bands were also found in the extracted grease, consisting of organic acids, organic acid esters, and tertiary alcohols, the principal substances often present in the grease of this type. This analysis indicated that no substantial chemical changes were observed in the functional groups of wool grease extracted with the eco-friendly solvent CPME.

Figure 1.

FT-IR spectra of wool grease extracted using solvent extraction of three different types of wool: Sarda, Biellese and Sopravissana.

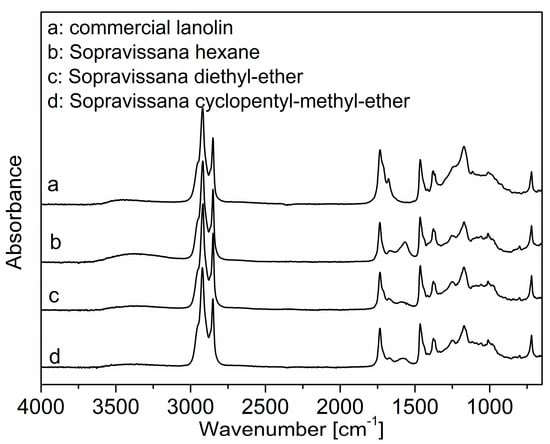

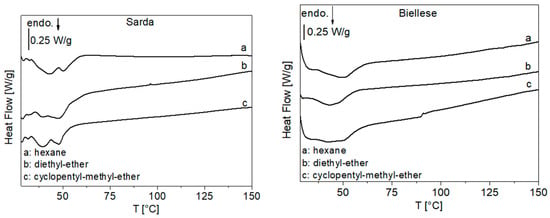

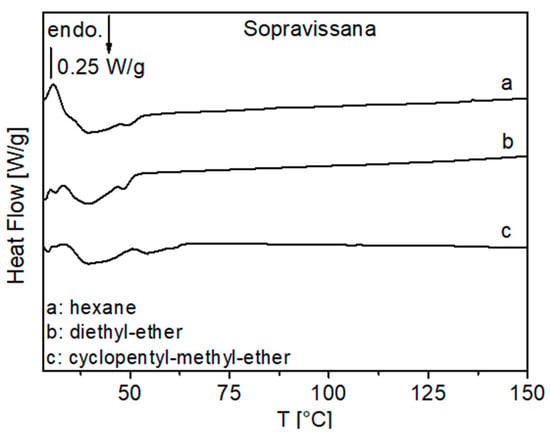

3.1.3. DSC Analysis

The DSC thermograms of the wool grease extracted using three different solvents from three different types of wool Sarda, Biellese, and Sopravissana, are shown in Figure 2. Figure 2 shows exothermic and endothermic curves. Apart from the Tm and Tg, the lanolin thermogram showed distinct exothermic and endothermic transitions at 25.7 °C and 46.0 °C. These increases in endothermic transition temperatures in wool may be correlated with increases in a polar characteristic of the solvent-extracted wool grease lipid composition. As wool grease consists of many sterols, these peaks may be due to the lanolin’s nonpolar lipid component and diol fractions. A DSC pattern with similar endothermic transition temperatures was seen in the lanolin fraction, lanolin oil, which has a more significant percentage of esters, branched-chain compounds, and hydroxyl compounds than the anhydrous lanolin wax, which is associated with higher polarity [66].

Figure 2.

DSC thermograms of the wool grease extracted using three different solvents from three different types of wool: Sarda, Biellese, and Sopravissana.

3.1.4. GC-FID Analysis

In Table 5, the composition of commercial lanolin (LA) is compared with those of grease extracted from raw wool with hexane (LB) and with CPME (LC) relative to three saturated FAs (myristic, palmitic, and stearic acid) and the predominant α-OH fatty acid, namely 2-hydroxypalmitic acid. The total amount of the four analytes is similar in the three samples, ranging between 15 and 20%. Notably, LB is richer in the three less polar FAs (5.45%) than LA (3.22%) and LC (3.73%) and relatively poorer in more polar 2-hydroxypalmitic acid (69.4% of the total amount) than LA (83.7%) and LC (76.0%). For LB and LC, these data seem consistent with the extraction of the former by nonpolar hexane and of the latter by moderately polar CPME.

Table 5.

Composition of commercial lanolin (LA) and grease extracted from raw wool with hexane (LB) and with CPME (LC) relatively to three saturated FAs and 2-hydroxypalmitic acid.

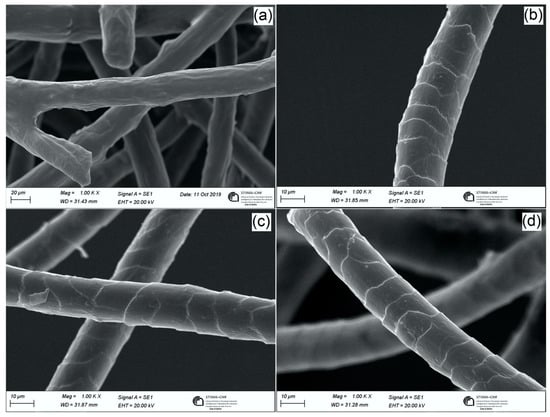

3.1.5. Morphological Characterization by SEM Analysis

A morphological investigation of the wool surface was carried out at 1000× magnification using a scanning electron microscope. For this analysis, wool with a higher wool grease percentage (Sopravissana) was used to study the morphological characteristics of solvent-extracted wool. Figure 3a demonstrates that the raw wool fiber’s surface is covered with wool grease and other contaminants, which mask the fiber’s distinctive scales and cuticular structure. As seen in Figure 3b–d, following solvent extraction with hexane, diethyl ether, and CPME, all SEM images appeared clean without the wool grease layer, and scales were visible on the wool surface. CPME solvent extraction, such as hexane and diethyl ether, has not caused any topographical alterations or fiber damage. After extraction, surface scales are deemed intact, and no surface cracking is seen in Figure 3b–d. Consequently, this morphological study shows that CPME can be utilized as an ecologically friendly solvent in wool grease extraction to extract wool grease without damaging the wool’s surface.

Figure 3.

Scanning Electron Microscopy images of wool fibers—(a) Raw wool, (b) Solvent extracted wool-hexane, (c) diethyl ether, and (d) CPME.

3.2. Wool Scouring Using WPH as Biosurfactant

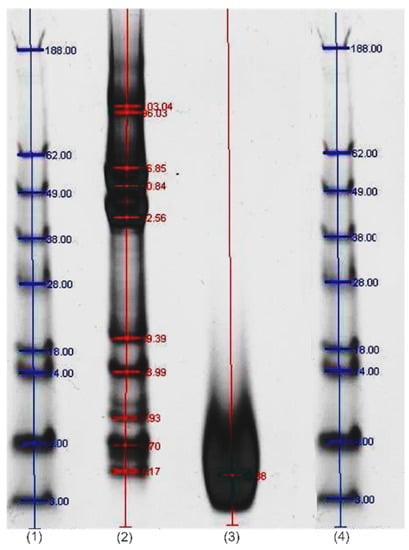

3.2.1. Molecular Weight Distribution

The molecular weight distribution of the WPH produced by superheated water hydrolysis was compared with that of Sopravissana wool. As seen in lane 2 of Figure 4, the electrophoresis pattern of the original wool sample comprises significant protein fractions of molecular weight 43–67 kDa, which correspond to low sulfur proteins of intermediate filaments in cortical cells, whereas molecular weights in the range of 11–28 kDa correspond to the high sulfur content proteins [48]. The effect of superheated water hydrolysis on wool is visible in lane 3 of Figure 4, where WPH shows the absence of high molecular weight proteins. In WPH, degraded proteins with varying molecular weights were observed in the 3–14 kDa range. In this analysis, 3 kDa is the lowest limit of detection, and as shown in lane 3, most of the molecular weights lie below the relevant line, close to this limit. Superheated water hydrolysis of wool resulted in the loss of molecular weight and peptide bond hydrolysis into short-chain peptide units. Proteins can be subjected to chemical, thermal, or enzymatic treatments that alter their composition and size to increase performance characteristics, such as emulsification and foam formation, and decrease their molecular weight [67]. The molecular weight is a significant factor in surface activity; according to Bhavsar et al., low molecular weight protein hydrolyzate exhibited great surface activity with reduced surface tension [46]. Hence, this study used WPH comprising low molecular weight proteins as a biosurfactant, resulting in effective wool grease removal characteristics.

Figure 4.

Electrophoresis pattern of wool and wool protein hydrolyzate: (1) and (4) standard reference proteins of different molecular weights, (2) wool, and (3) wool protein hydrolyzate.

3.2.2. Optimization of Wool Scouring

Effect of Temperature

Scouring Sopravissana wool with biosurfactant WPH shows that increasing the scouring temperature from 35 to 65 °C removes wool grease from raw wool effectively. The effect of temperature in combination with WPH biosurfactant on wool scouring resulted in wool grease removal from raw Sorpravissina wool, from 22.29% to 1.5–4%, in a temperature range between 35 and 65 °C. Wool grease has a melting point of 36–42 °C [68,69]; hence, greater temperatures than the melting point will cause more grease to remain in the liquid phase, resulting in less grease on scoured wool fibers. Wool grease can be further emulsified in water with the help of WPH. The material-to-liquor ratio was kept constant (1:20) throughout the optimization study, and WPH was maintained at 3%. Up to 45 °C, the washing yield increased from 42% to 53%; at 55 °C and 65 °C, it was comparable. Based on the results in Table 6, the overall best scouring performance was observed at 55 °C compared with the other process temperatures. This suggests that WPH has the potential to be used as a surfactant in the traditional scouring method at 55 °C.

Table 6.

Effect of temperature during scouring in terms of grease content, whiteness and yellowness indexes, and washing yield.

Material to Liquor Ratio

The influence of the material-to-liquid ratio on scouring was studied, and the results are shown in Table 7. The optimization was carried out by increasing the liquor ratio while maintaining a WPH concentration of 3% and an optimized temperature of 55 °C. The impact of the material-to-liquor ration on wool grease removal was seen to be more significant for liquor rations of 1:20 and 1:40, where less than 1% residual wool grease content was observed. Regarding washing yield, the influence of the material-to-liquor ratio on wool cleaning was comparable in the 50–52% range for all liquor ratios used in this study. The whiteness and yellowness indexes were lower at 1:40 compared with the other liquor ratios, indicating that scouring was more effective. Thus, for further optimization, a material-to-liquor ratio of 1:40 was implemented.

Table 7.

Effect of material to liquor ratio during scouring in terms of grease content, whiteness and yellowness indexes and washing yield.

WPH Concentration

The efficacy of WPH as a biosurfactant and the influence of its concentrations on sustainable wool scouring were investigated to reach an acceptable level of residual wool grease content. The optimization of WPH was carried out between 1–5% concentration while maintaining an optimal temperature of 55 °C and a material-to-liquor ratio of 1:40. A commercial surfactant, Biotex AL, was utilized as a reference for the results obtained using WPH at various concentrations, as indicated in Table 8.

Table 8.

Effect of WPH during scouring in terms of grease content, whiteness and yellowness indexes, and washing yield. Commercial surfactant Biotex AL was used as a comparison with WPH biosurfactant.

The residual grease concentration must be less than 1% for the wool to be processed easily during carding and dyeing [57]. The residual grease content after scouring with a 2–5% WPH concentration was less than 1%. These residual wool grease content results in the 0.30–0.36% range for 2–4% WPH concentration were comparable to the 0.38% residual wool grease content of commercial surfactants Biotex AL. Similarly, Leigh et al. reported that using saponin as a biosurfactant in wool scouring residual grease levels was found to be below 0.50% [39]. The results achieved utilizing WPH as a biosurfactant were consistent with a previous study on the application of biosurfactants in wool scouring.

The grease content of wool was decreased by increasing the WPH concentration in the beginning, indicating that proteins are similar to amphiphilic synthetic surfactants in that they contain hydrophobic and hydrophilic, anionic, and cationic amino acids, which give them a certain degree of surface activity [41,42]. Due to good water solubility, a low CMC, and the capacity to lower the interfacial tension between the oil and the water, amino acid-based surfactants found their application in enhanced oil recovery and are considered alternatives to conventional surfactants [70,71].

Using alkali sodium carbonate in wool scouring leads to the swelling of wool fiber, loosening the bond between wool and grease, and preventing grease redeposition [72]. It neutralizes free fatty acids and aids in emulsifying wool grease in water in the presence of WPH, enhancing wool fiber grease removal.

The impact of WPH on washing yield was consistent for all 1–5% concentrations in the range of 49–52%. The efficiency of washing yield using WPH was also in accordance with the commercial surfactant Biotex AL. Wool has a natural creamy color, but raw wool fibers were contaminated by the sheep farming environment, which gave them a soiled and dirty appearance. The chemicals used in the scouring process are designed to remove these contaminants, improving whiteness. The whiteness and yellowness index of 4% WPH were equivalent to those of commercially available surfactants. Considering that wool whiteness and yellowness indices depend not only on wool scouring but also on wool color, the results obtained for grease content and whiteness and yellowness indices are comparable to or even superior to those obtained by Li et al., who introduced an ultrasonic device into the wool scouring process [73].

Based on these results, WPH has the potential to be used as a surfactant for sustainable scouring under optimal conditions consisting of a protein hydrolyzate concentration of 4%, a temperature of 55 °C, and a material-to-liquid ratio of 1:40. At these optimal conditions, WPH biosurfactant scoured samples exhibited nearly similar whiteness and yellowness indexes, washing yield, and residual grease content as the commercial biosurfactant Biotex AL.

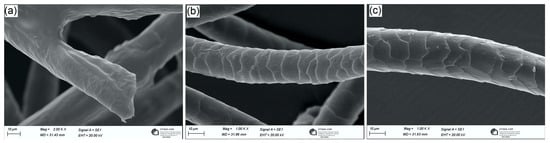

3.2.3. Morphological Characterization by SEM Analysis

The morphological study was carried out using SEM on wool fibers after scouring to determine the efficacy of wool protein hydrolyzate in removing wool grease compared with the commercial biosurfactant Biotex AL. As demonstrated in Figure 5a, the protective layer of wool grease coating is visible on the raw wool surface, concealing the scale-like structure of the wool’s surface. As seen in Figure 5b,c, after wool was scoured under optimum conditions with both WPH and Biotex AL biosurfactants, a scale-like surface composed of a microsized layer of flat, overlapping cuticle cells surrounding the interior part of the fiber was appeared. As reported by Bozaci et al. SEM analysis of conventionally scoured wool resulted in surface morphology of fibers with fractures, minute-size particles on their surface, and damaged and peeled cuticle structures with sharp edges responsible for the friction and shrinking of wool subjected to washing. In the case of wool scoured with Biotex AL biosurfactant, the wool surface emerged without a wool grease layer or any significant surface modification or damage; only a few minute particles on the wool surface could be attributed to surface contamination or parts of cuticles. WPH scouring does not cause any topographical changes consisting of fractures or damage to the cuticular structure but instead contributes to a smooth fiber surface and an intact scale structure. The fiber’s smoothness and intact scale structure contribute to the wool’s low friction and antifelting properties throughout washing [38,74]. Hence, this morphological analysis leads us to conclude that WPH scouring can be used as a biosurfactant in the sustainable wool scouring process that has a lesser impact on the wool surface.

Figure 5.

Scanning Electron Microscopy images (1000×) of wool fibers—(a) Raw Sopravissana wool, (b) Sopravissana wool scoured with WPH biosurfactant, and (c) commercial surfactant Biotex AL at optimized wool scouring conditions.

3.3. Cost-Effectiveness

In the case of solvents, de Jesus et al. showed that hexane cost around $0.84/kg, while the industrial bulk production cost for CPME was reported to be $4.55–7.00/kg [75,76]. These environmentally favorable solvents remain uncompetitive in price compared with their fossil-based alternatives. The price reduction for these solvents depends on increased demand and annual output growth. International regulations have prohibited using hazardous solvents in extraction systems, demanding the development of new eco-friendly solvents. Among the studied solvents, cyclopentyl methyl ether (CPME) has garnered the most interest due to its high efficiency in extracting fatty acids, proteins, and biodiesel [77]. Future studies should focus on bio-based CPME manufacturing to expand their scope, create ecologically friendly procedures, and assure sustainability in industrial settings.

Based on our predictive cost analysis for the production of a wool protein hydrolyzate using a sustainable superheated water hydrolysis process, which accounted for electricity, water, oil, raw material, equipment, personnel, and operating costs (parameters calculated based on Italian territory), the cost for the annual processing of 150 ton of raw material was found to be approximately between 0.30 and 0.50 euros per kilogram. A separate, concise cost-effectiveness study on the comparative wool scouring process must be carried out to obtain a comprehensive perspective.

4. Conclusions

This study investigates two sustainable routes for wool grease removal: solvent extraction and sustainable wool scouring. The green, non-toxic solvent proposed in the sustainable solvent extraction route is CPME. Extraction using CPME resulted in 11.95% extracted wool grease, which is more than conventional solvents hexane and diethyl ether. GC-FID analysis of a CPME-extracted wool grease composition resulted in higher 2-hydroxy palmitic acid than conventional solvents. The FTIR of wool grease extracted using CPME reveals principal and distinctive bands for organic acids, esters of organic acids, and tertiary alcohols similar to pure wool grease. The FTIR results revealed that CPME-extracted wool grease functional groups undergo no chemical changes. SEM analysis revealed that the wool that undergoes CPME solvent extraction has not resulted in any topographical alterations or fiber damage.

A sustainable wool scouring study was proposed by applying WPH as a non-hazardous biosurfactant in scouring. The results obtained from the sustainable wool scouring process confirmed its efficacy as a biosurfactant. The best scouring results were obtained at 55 °C temperature, a 1:40 material-to-liquor ratio, and a 4% WPH concentration. The residual grease content in Sopravissana wool was reduced from 22.29% to 0.30% at the optimal condition using WPH, comparable to the commercial biosurfactant Biotex AL. The wool samples scoured using WPH demonstrated a smooth fiber surface, the absence of a wool grease layer, and an intact scale structure without fiber damage. These findings indicate that the proposed sustainable routes for wool grease removal using green solvent CPME and wool protein hydrolyzate as an eco-friendly biosurfactant have the potential to be used as a sustainable alternative.

Author Contributions

Conceptualization, M.Z. and M.P.; methodology, P.B., G.D.F., G.R.; software, P.B., G.D.F., G.R.; validation, P.B., G.D.F. and G.R.; formal analysis, P.B., G.D.F. and G.R.; investigation, P.B., G.D.F. and G.R.; resources, M.Z., M.P., C.B.; data curation, P.B., G.D.F. and G.R.; writing—original draft preparation, P.B.; writing—review and editing, M.Z., M.P., C.B.; visualization, P.B., G.D.F.; supervision, M.Z., C.B. and M.P.; project administration, M.Z., C.B. and M.P.; funding acquisition, M.Z. and M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by cariplo foundation for the financial support—project Falstaff 2018-2781-Lanolin and valuable hydroxyl fatty acids from raw wool processing: integrating sustainable chemical methods and biocatalysis.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to express appreciation to the Cariplo Foundation for the financial support—project Falstaff 2018-2781-Lanolin and valuable hydroxyl fatty acids from raw wool processing: integrating sustainable chemical methods and biocatalysis.

Conflicts of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

References

- Korjenic, A.; Klarić, S.; Hadžić, A.; Korjenic, S. Sheep Wool as a Construction Material for Energy Efficiency Improvement. Energies 2015, 8, 5765–5781. [Google Scholar] [CrossRef]

- Schlossman, M.L.; McCarthy, J.P. Lanolin and Its Derivatives. J. Am. Oil Chem. Soc. 1978, 55, 447–450. [Google Scholar] [CrossRef]

- Sengupta, A.; Behera, J. Comprehensive View on Chemistry, Manufacturing & Applications of Lanolin Extracted from Wool Pretreatment. Am. J. Eng. Res. 2014, 3, 33–43. [Google Scholar]

- Hussien, A. Utilization of Lanolin in Microwave-Assisted Pigment Printing of Textiles. Egypt. J. Chem. 2020, 63, 3259–3269. [Google Scholar] [CrossRef]

- Bertolini, V.; Pallavicini, M.; Tibhe, G.; Roda, G.; Arnoldi, S.; Monguzzi, L.; Zoccola, M.; Di Nardo, G.; Gilardi, G.; Bolchi, C. Synthesis of α-Hydroxy Fatty Acids from Fatty Acids by Intermediate α-Chlorination with TCCA under Solvent-Free Conditions: A Way to Valorization of Waste Fat Biomasses. ACS Omega 2021, 6, 31901–31906. [Google Scholar] [CrossRef]

- Thewlis, J. Lanolin for Cosmetics Application. Agro Food Ind. Hi-Tech 1997, 8(5), 37–40. [Google Scholar]

- Thewlis, J. Lanolin for Cosmetics Application. Agro Food Ind. Hi-Tech 1997, 8(3), 14–20. [Google Scholar]

- Thewlis, J. Lanolin for Cosmetics Application. Agro Food Ind. Hi-Tech 1997, 8(4), 10–15. [Google Scholar]

- Taleb, M.A.; El-Sayed, H. Preparation and Characterization of Lanolin-Based Condensate and Its Utilization as a Nonionic Softener for Wool Fabric Surface. J. Appl. Res. Technol. 2021, 19, 508–520. [Google Scholar] [CrossRef]

- Khattab, T.A.; Mowafi, S.; El-Sayed, H. Development of Mechanically Durable Hydrophobic Lanolin/Silicone Rubber Coating on Viscose Fibers. Cellulose 2019, 26, 9361–9371. [Google Scholar] [CrossRef]

- Stewart, R.G. Woolscouring and Allied Technology; WRONZ: Christchurch, New Zealand, 1985; ISBN 978-0-908699-03-2. [Google Scholar]

- López-Mesas, M.; Carrillo, F.; Gutiérrez, M.C.; Crespi, M. Alternative Methods for the Wool Wax Extraction from Wool Scouring Wastes. Grasas Aceites 2007, 58, 402–407. [Google Scholar] [CrossRef]

- Choudhury, A.K.R. Green Chemistry and Textile Industry. J. Text. Eng. Fash. Technol. 2017, 2, 1–12. [Google Scholar] [CrossRef]

- Kassim, M.A.; Meng, T.K.; Serri, N.A.; Yusoff, S.B.; Shahrin, N.A.M.; Seng, K.Y.; Bakar, M.H.A.; Keong, L.C. Sustainable Biorefinery Concept for Industrial Bioprocessing. In Biorefinery Production Technologies for Chemicals and Energy; Kuila, A., Mukhopadhyay, M., Eds.; Wiley: Hoboken, NJ, USA, 2020; pp. 15–39. ISBN 978-1-119-59142-9. [Google Scholar]

- Rapinel, V.; Claux, O.; Abert-Vian, M.; McAlinden, C.; Bartier, M.; Patouillard, N.; Jacques, L.; Chemat, F. 2-Methyloxolane (2-MeOx) as Sustainable Lipophilic Solvent to Substitute Hexane for Green Extraction of Natural Products. Properties, Applications, and Perspectives. Molecules 2020, 25, 3417. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, K. The Toxicological Assessment of Cyclopentyl Methyl Ether (CPME) as a Green Solvent. Molecules 2013, 18, 3183–3194. [Google Scholar] [CrossRef] [PubMed]

- Azzena, U.; Carraro, M.; Pisano, L.; Monticelli, S.; Bartolotta, R.; Pace, V. Cyclopentyl Methyl Ether: An Elective Ecofriendly Ethereal Solvent in Classical and Modern Organic Chemistry. ChemSusChem 2019, 12, 40–70. [Google Scholar] [CrossRef] [PubMed]

- Henderson, R.K.; Jiménez-González, C.; Constable, D.J.C.; Alston, S.R.; Inglis, G.G.A.; Fisher, G.; Sherwood, J.; Binks, S.P.; Curzons, A.D. Expanding GSK’s Solvent Selection Guide—Embedding Sustainability into Solvent Selection Starting at Medicinal Chemistry. Green Chem. 2011, 13, 854. [Google Scholar] [CrossRef]

- Watanabe, K.; Yamagiwa, N.; Torisawa, Y. Cyclopentyl Methyl Ether as a New and Alternative Process Solvent. Org. Process Res. Dev. 2007, 11, 251–258. [Google Scholar] [CrossRef]

- Watanabe, K.; Goto, K. Cyclopentyl Methyl Ether. J. Synth. Org. Chem. Jpn. 2003, 61, 806–808. [Google Scholar] [CrossRef]

- de Gonzalo, G.; Alcántara, A.R.; Domínguez de María, P. Cyclopentyl Methyl Ether (CPME): A Versatile Eco-Friendly Solvent for Applications in Biotechnology and Biorefineries. ChemSusChem 2019, 12, 2083–2097. [Google Scholar] [CrossRef]

- de Jesus, S.S.; Filho, R.M. Recent Advances in Lipid Extraction Using Green Solvents. Renew. Sustain. Energy Rev. 2020, 133, 110289. [Google Scholar] [CrossRef]

- Anastas, P.T.; Kirchhoff, M.M. Origins, Current Status, and Future Challenges of Green Chemistry. Acc. Chem. Res. 2002, 35, 686–694. [Google Scholar] [CrossRef]

- Mendonca, G.; Mattos, M. Green Chlorination of Organic Compounds Using Trichloroisocyanuric Acid (TCCA). Curr. Org. Synth. 2014, 10, 820–836. [Google Scholar] [CrossRef]

- Bolchi, C.; Valoti, E.; Straniero, V.; Ruggeri, P.; Pallavicini, M. From 2-Aminomethyl-1,4-Benzodioxane Enantiomers to Unichiral 2-Cyano- and 2-Carbonyl-Substituted Benzodioxanes via Dichloroamine. J. Org. Chem. 2014, 79, 6732–6737. [Google Scholar] [CrossRef]

- Pallavicini, M.; Bolchi, C.; Fumagalli, L.; Piccolo, O.; Valoti, E. Highly Efficient Racemisation of a Key Intermediate of the Antibiotic Moxifloxacin. Tetrahedron Asymmetry 2011, 22, 379–380. [Google Scholar] [CrossRef]

- Hassan, M.M.; Shao, J.Z. Chemical Processing of Wool: Sustainability Considerations. Key Eng. Mater. 2015, 671, 32–39. [Google Scholar] [CrossRef]

- Bhavsar, P.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Mossotti, R.; Rovero, G.; Giansetti, M.; Tonin, C. Superheated Water Hydrolysis of Waste Wool in a Semi-Industrial Reactor to Obtain Nitrogen Fertilizers. ACS Sustain. Chem. Eng. 2016, 4, 6722–6731. [Google Scholar] [CrossRef]

- Halliday, L.A. Woolscouring, Carbonising and Effluent Treatment. In Wool; Elsevier: Amsterdam, The Netherlands, 2002; pp. 21–59. ISBN 978-1-85573-574-3. [Google Scholar]

- Yordanov, D.; Betcheva, R.; Yotova, L. Biotechnological Treatment of Effluent from the Combined Enzymatic-Ultrasound Scouring of Raw Wool. Eur. J. Chem. 2010, 1, 12–14. [Google Scholar] [CrossRef]

- Priac, A.; Morin-Crini, N.; Druart, C.; Gavoille, S.; Bradu, C.; Lagarrigue, C.; Torri, G.; Winterton, P.; Crini, G. Alkylphenol and Alkylphenol Polyethoxylates in Water and Wastewater: A Review of Options for Their Elimination. Arab. J. Chem. 2017, 10, S3749–S3773. [Google Scholar] [CrossRef]

- Maguire, R.J. Review of the Persistence of Nonylphenol and Nonylphenol Ethoxylates in Aquatic Environments. Water Qual. Res. J. 1999, 34, 37–78. [Google Scholar] [CrossRef]

- Talmage, S.S. Environmental and Human Safety of Major Surfactants: Alcohol Ethoxylates and Alkylphenol Ethoxylates; Lewis Publishers: Boca Raton, FL, USA, 1994; ISBN 978-1-56670-017-7. [Google Scholar]

- Pan, Y.; Wang, W.; Gong, K.; Hurren, C.J.; Li, Q. Ultrasonic Scouring as a Pretreatment of Wool and Its Application in Low-Temperature Dyeing. Text. Res. J. 2019, 89, 1975–1982. [Google Scholar] [CrossRef]

- Das, T.; Ramaswamy, G.N. Enzyme Treatment of Wool and Specialty Hair Fibers. Text. Res. J. 2006, 76, 126–133. [Google Scholar] [CrossRef]

- López-Mesas, M.; Carrillo, F.; Crespi, M. Microwave Enhanced Extraction of Wool Wax from Solid Wool Scour Wastes. Anal. Chim. Acta 2003, 494, 255–260. [Google Scholar] [CrossRef]

- Bahtiyari, M.İ.; Duran, K. A Study on the Usability of Ultrasound in Scouring of Raw Wool. J. Clean. Prod. 2013, 41, 283–290. [Google Scholar] [CrossRef]

- Bozaci, E. Investigation of Biosurfactant Usage in Raw Wool Scouring by Response Surface Methodology. Tekst. Ve Konfeksiyon 2017, 27, 382–392. [Google Scholar]

- Leighs, S.J.; McNeil, S.J.; Ranford, S.L. The Application of Biosurfactants for Scouring Wool. Color. Technol. 2019, 135, 48–52. [Google Scholar] [CrossRef]

- Dimitrijev Dwyer, M.; Brech, M.; Yu, L.; Middelberg, A.P.J. Intensified Expression and Purification of a Recombinant Biosurfactant Protein. Chem. Eng. Sci. 2014, 105, 12–21. [Google Scholar] [CrossRef]

- Xia, J. Protein-Based Surfactants; CRC Press: Boca Raton, FL, USA, 2001; ISBN 978-1-4822-6971-0. [Google Scholar]

- Takehara, M. Properties and Applications of Amino Acid Based Surfactants. Colloids Surf. 1989, 38, 149–167. [Google Scholar] [CrossRef]

- Zoccola, M.; Aluigi, A.; Patrucco, A.; Tonin, C. Extraction, Processing and Applications of Wool Keratin. In Keratin Structure, Properties and Applications; Series: Protein Biochemistry, Synthesis, Structure, and Cellular Functions Series; Nova Publishers: New York, NY, USA, 2012; ISBN 1-62100-392-2. [Google Scholar]

- Hoshino, M. Foam Fire Extinguishing Agent. J. Jpn. Oil Chem. Soc. 1993, 42, 856–867. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Z.; Liu, Y.; Wang, J.; Yang, K.; Chen, D.; Liang, Z.; Li, Z. Antibacterial and Biodegradable Keratin-Based Quaternary Ammonium Salt Surfactant Potential as Hair Care Additive. J. Dispers. Sci. Technol. 2022, 1–10. [Google Scholar] [CrossRef]

- Bhavsar, P.S.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Mossotti, R.; Giansetti, M.; Rovero, G.; Maier, S.S.; Muresan, A.; Tonin, C. Superheated Water Hydrolyzed Keratin: A New Application as a Foaming Agent in Foam Dyeing of Cotton and Wool Fabrics. ACS Sustain. Chem. Eng. 2017, 5, 9150–9159. [Google Scholar] [CrossRef]

- Peiravi-Rivash, O.; Mashreghi, M.; Baigenzhenov, O.; Hosseini-Bandegharaei, A. Producing Bacterial Nano-Cellulose and Keratin from Wastes to Synthesize Keratin/Cellulose Nanobiocomposite for Removal of Dyes and Heavy Metal Ions from Waters and Wastewaters. Colloids Surf. Physicochem. Eng. Asp. 2023, 656, 130355. [Google Scholar] [CrossRef]

- Tonin, C.; Zoccola, M.; Aluigi, A.; Varesano, A.; Montarsolo, A.; Vineis, C.; Zimbardi, F. Study on the Conversion of Wool Keratin by Steam Explosion. Biomacromolecules 2006, 7, 3499–3504. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Y.; Li, J.; Zhao, Z.; Liu, X.; Li, Z.; Han, Y.; Hu, J.; Chen, A. Isolation and Characterization of Biofunctional Keratin Particles Extracted from Wool Wastes. Powder Technol. 2013, 246, 356–362. [Google Scholar] [CrossRef]

- Berechet, M.D.; Niculescu, M.D.; Gaidau, C.; Ignat, M.; Epure, D.G. Alkaline-Enzymatic Hydrolysis of Wool Waste for Different Applications. Rev. Chim. 2018, 69, 1649–1654. [Google Scholar] [CrossRef]

- Dias, G.J.; Haththotuwa, T.N.; Rowlands, D.S.; Gram, M.; Bekhit, A.E.-D.A. Wool Keratin—A Novel Dietary Protein Source: Nutritional Value and Toxicological Assessment. Food Chem. 2022, 383, 132436. [Google Scholar] [CrossRef]

- Tonin, C.; Aluigi, A.; Vineis, C.; Varesano, A.; Montarsolo, A.; Ferrero, F. Thermal and Structural Characterization of Poly(Ethylene-Oxide)/Keratin Blend Films. J. Therm. Anal. Calorim. 2007, 89, 601–608. [Google Scholar] [CrossRef]

- Okoro, O.V.; Jafari, H.; Hobbi, P.; Nie, L.; Alimoradi, H.; Shavandi, A. Enhanced Keratin Extraction from Wool Waste Using a Deep Eutectic Solvent. Chem. Pap. 2022, 76, 2637–2648. [Google Scholar] [CrossRef]

- Holkar, C.R.; Jadhav, A.J.; Bhavsar, P.S.; Kannan, S.; Pinjari, D.V.; Pandit, A.B. Acoustic Cavitation Assisted Alkaline Hydrolysis of Wool Based Keratins to Produce Organic Amendment Fertilizers. ACS Sustain. Chem. Eng. 2016, 4, 2789–2796. [Google Scholar] [CrossRef]

- Yin, J.; Rastogi, S.; Terry, A.E.; Popescu, C. Self-Organization of Oligopeptides Obtained on Dissolution of Feather Keratins in Superheated Water. Biomacromolecules 2007, 8, 800–806. [Google Scholar] [CrossRef]

- Bhavsar, P.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Rovero, G.; Tonin, C. Comparative Study on the Effects of Superheated Water and High Temperature Alkaline Hydrolysis on Wool Keratin. Text. Res. J. 2017, 87, 1696–1705. [Google Scholar] [CrossRef]

- Innocenti, R.; Zoccola, M. Near Infrared Reflectance Spectroscopy as a Tool for the Determination of Dichloromethane Extractable Matter and Moisture Content in Combed Wool Slivers. J. Infrared Spectrosc. 2003, 11, 333–340. [Google Scholar] [CrossRef]

- Method for the Determination of Dichloromethane Soluble Matter in Combed Wool and Commercially Scoured or Carbonised Wool; Test Method IWTO-10; International Wool Textile Organization: Brussels, Belgium.

- Laemmli, U.K. Cleavage of Structural Proteins during the Assembly of the Head of Bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef] [PubMed]

- Zoccola, M.; Aluigi, A.; Tonin, C. Characterisation of Keratin Biomass from Butchery and Wool Industry Wastes. J. Mol. Struct. 2009, 938, 35–40. [Google Scholar] [CrossRef]

- Method for the Measurement of the Colour of Raw Wool; Test Method IWTO-56; International Wool Textile Organization: Brussels, Belgium.

- Kaur, D.; Singh, O.P. Fleece Composition of Wool of Different Breeds of Sheep. Text. Trends 2005, 48, 39–43. [Google Scholar]

- Sagiri, S.S.; Behera, B.; Pal, K.; Basak, P. Lanolin-Based Organogels as a Matrix for Topical Drug Delivery. J. Appl. Polym. Sci. 2013, 128, 3831–3839. [Google Scholar] [CrossRef]

- Shanmugavel, M.; Lakshmi, J.N.; Vasantharaj, S.; Anu, C.; Paul, L.E.; Kumar, R.P.; Gnanamani, A. Wealth from Waste: Recovery of the Commercially Important Waxy Ester from Enzymatic Dehaired Sheep Wool. Biocatal. Agric. Biotechnol. 2019, 20, 101255. [Google Scholar] [CrossRef]

- Okpuwhara, R.O.; Oboirien, B.O.; Sadiku, E.R. The Lanolin-based Oil Plasticized Polylactide: Thermal and Chemical Characteristics. Polym. Eng. Sci. 2022, 62, 1571–1581. [Google Scholar] [CrossRef]

- Barba Albanell, C.; Carrer, V.; Marti, M.; Iglesias, J.; Iglesias, J.; Coderch, L. Solvent-Extracted Wool Wax: Thermotropic Properties and Skin Efficacy. Skin Pharmacol. Physiol. 2018, 31, 198–205. [Google Scholar] [CrossRef]

- e Silva, N.M.P.R.; Meira, H.M.; Almeida, F.C.G.; de Silva, R.d.C.F.S.; Almeida, D.G.; Luna, J.M.; Rufino, R.D.; Santos, V.A.; Sarubbo, L.A. Natural Surfactants and Their Applications for Heavy Oil Removal in Industry. Sep. Purif. Rev. 2019, 48, 267–281. [Google Scholar] [CrossRef]

- Das, D.; Das, S. Wool Structure and Morphology. In Wool Fiber Reinforced Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2022; pp. 13–32. ISBN 978-0-12-824056-4. [Google Scholar]

- Valverde, A.; Recasens, F. Extraction of Solid Lanoline from Raw Wool with Near-Critical Ethanol-Modified CO2—A Mass Transfer Model. J. Supercrit. Fluids 2019, 145, 151–161. [Google Scholar] [CrossRef]

- Morán, M.C.; Pinazo, A.; Pérez, L.; Clapés, P.; Angelet, M.; García, M.T.; Vinardell, M.P.; Infante, M.R. “Green” Amino Acid-Based Surfactants. Green Chem 2004, 6, 233–240. [Google Scholar] [CrossRef]

- Madani, M.; Zargar, G.; Takassi, M.A.; Daryasafar, A.; Wood, D.A.; Zhang, Z. Fundamental Investigation of an Environmentally-Friendly Surfactant Agent for Chemical Enhanced Oil Recovery. Fuel 2019, 238, 186–197. [Google Scholar] [CrossRef]

- Rahman, M.; Nur, M.G. Golam Nur Feasible Application of Modern Eco-Friendly Treatment of Wool Fabric before Coloration. Int. J. Sci. Res. Publ. 2014, 4, 1–7. [Google Scholar]

- Li, Q.; Hurren, C.J.; Wang, X. Ultrasonic Assisted Industrial Wool Scouring. Procedia Eng. 2017, 200, 39–44. [Google Scholar] [CrossRef]

- Vujasinović, E.; Tarbuk, A.; Pušić, T.; Dekanić, T. Bio-Innovative Pretreatment of Coarse Wool Fibers. Processes 2022, 11, 103. [Google Scholar] [CrossRef]

- de Jesus, S.S.; Ferreira, G.F.; Moreira, L.S.; Wolf Maciel, M.R.; Maciel Filho, R. Comparison of Several Methods for Effective Lipid Extraction from Wet Microalgae Using Green Solvents. Renew. Energy 2019, 143, 130–141. [Google Scholar] [CrossRef]

- Bijoy, R.; Agarwala, P.; Roy, L.; Thorat, B.N. Unconventional Ethereal Solvents in Organic Chemistry: A Perspective on Applications of 2-Methyltetrahydrofuran, Cyclopentyl Methyl Ether, and 4-Methyltetrahydropyran. Org. Process Res. Dev. 2022, 26, 480–492. [Google Scholar] [CrossRef]

- de Jesus, S.S.; Ferreira, G.F.; Wolf Maciel, M.R.; Maciel Filho, R. Biodiesel Purification by Column Chromatography and Liquid-Liquid Extraction Using Green Solvents. Fuel 2019, 235, 1123–1130. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).