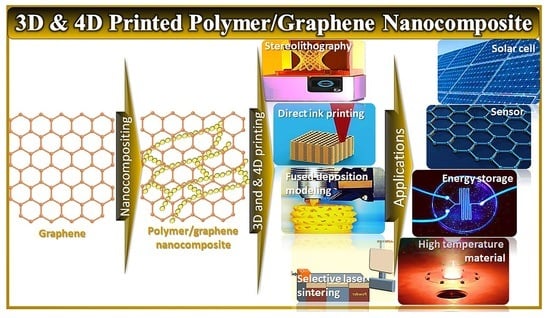

Polymer/Graphene Nanocomposites via 3D and 4D Printing—Design and Technical Potential

Abstract

1. Introduction

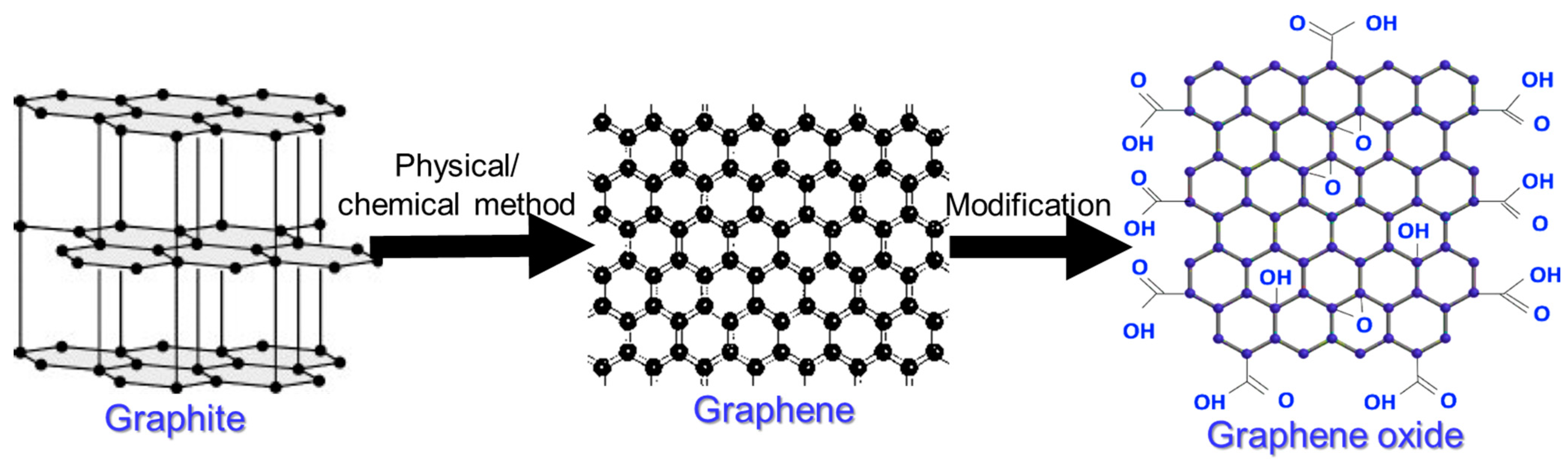

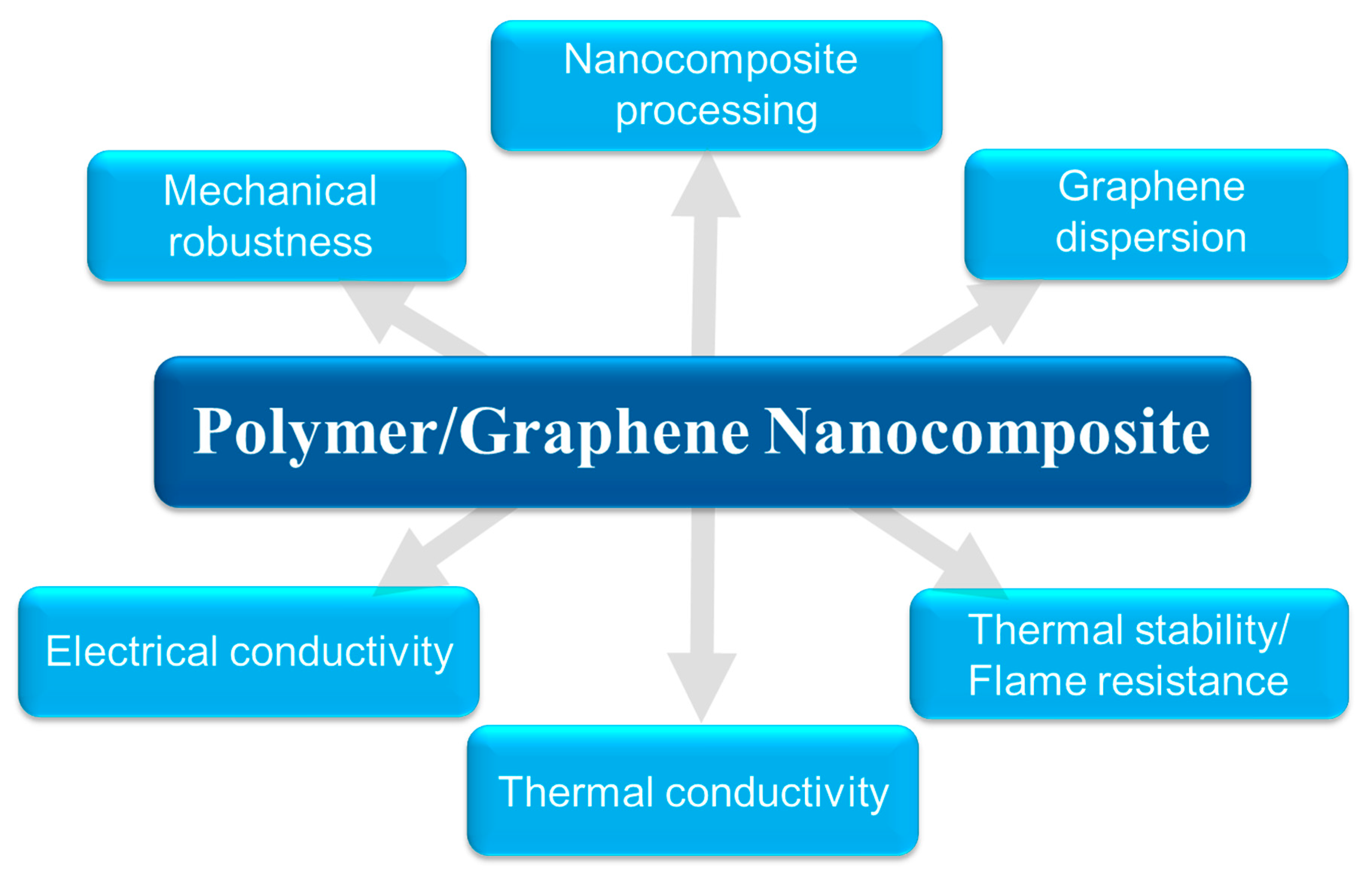

2. Graphene and Polymer–Graphene Nanocomposites

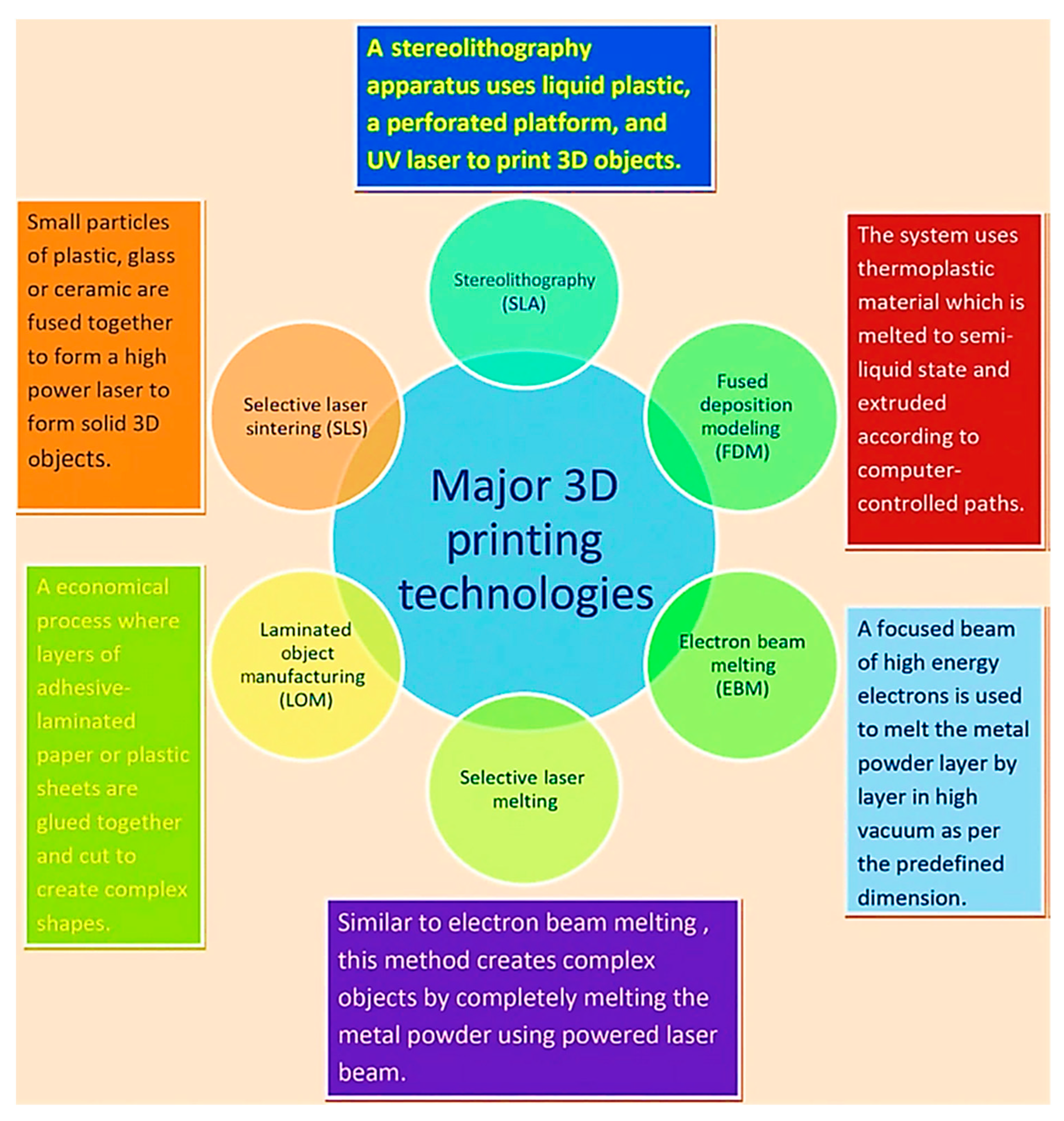

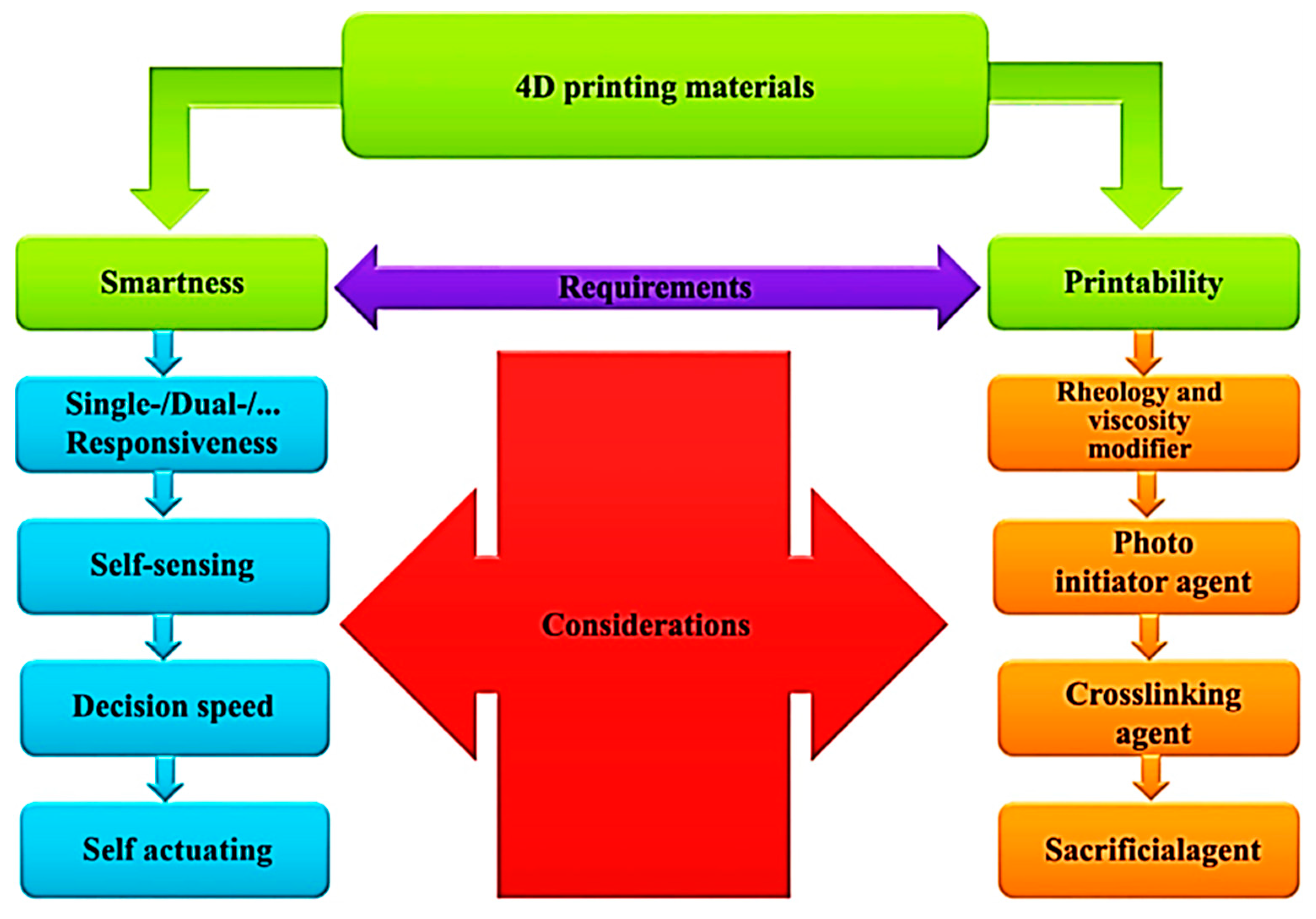

3. Features of 3D and 4D Printing Techniques

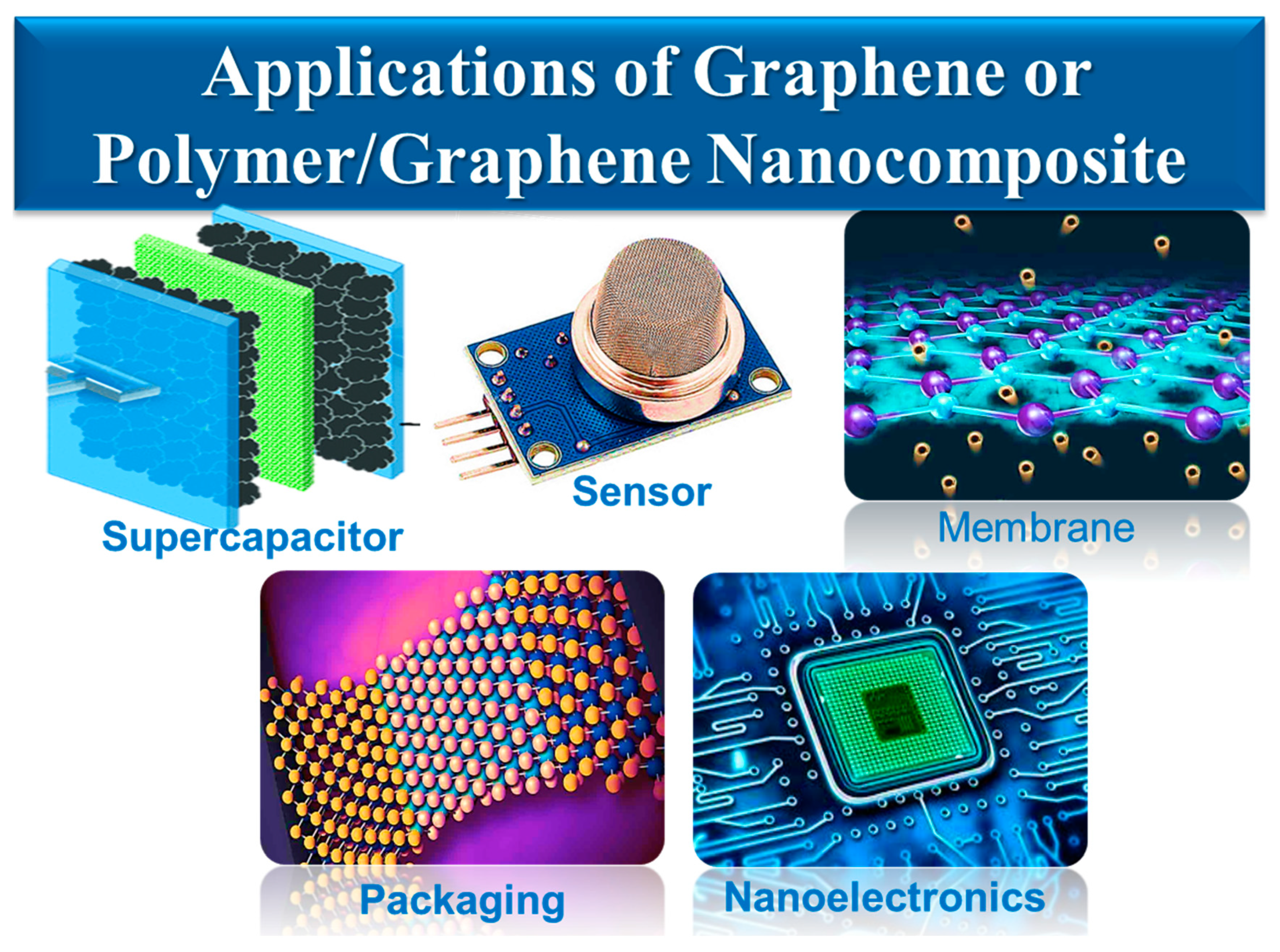

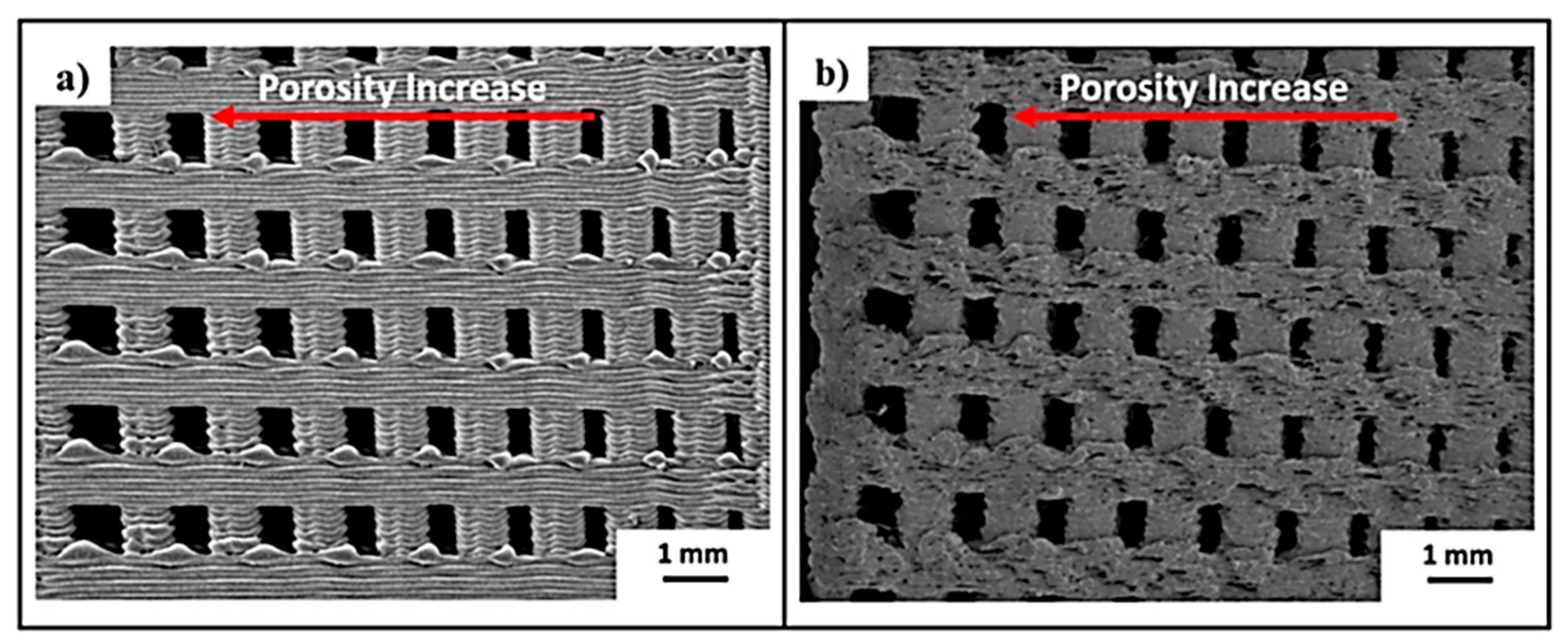

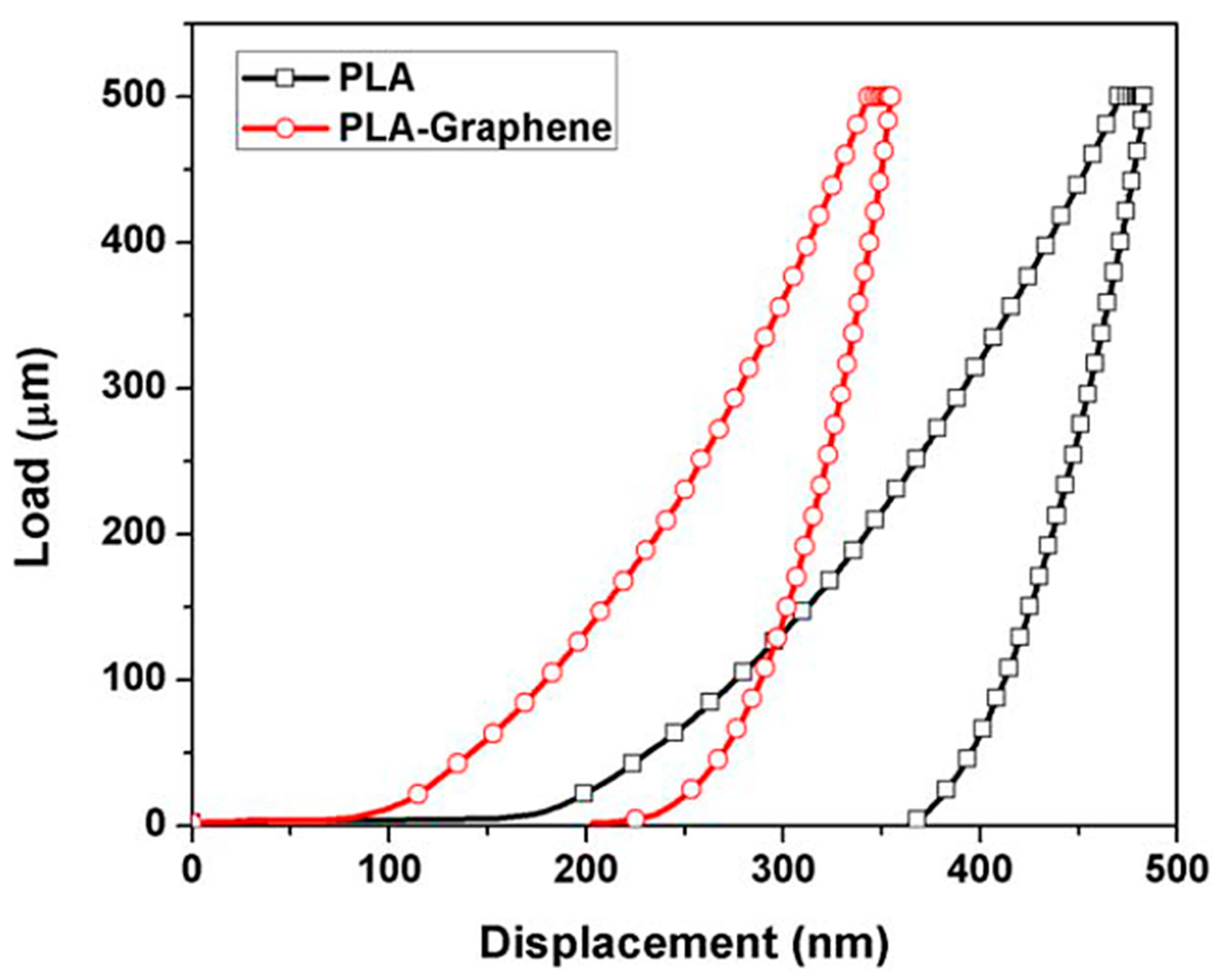

4. 3D–4D Printing Polymeric–Graphene Nanocomposites

5. Working Principle or Mechanism of 3D–4D Printing Technology for Polymeric–Graphene Nanocomposites

6. Potential of 3D–4D Printing Polymeric–Graphene Nanocomposites

7. Viewpoint and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kausar, A. Shape memory polymer/graphene nanocomposites: State-of-the-art. E-Polymers 2022, 22, 165–181. [Google Scholar] [CrossRef]

- Gopal, J.; Muthu, M.; Sivanesan, I. A Comprehensive Compilation of Graphene/Fullerene Polymer Nanocomposites for Electrochemical Energy Storage. Polymers 2023, 15, 701. [Google Scholar] [CrossRef] [PubMed]

- De Angelis, F.; Vadini, M.; Buonvivere, M.; Valerio, A.; Di Cosola, M.; Piattelli, A.; Biferi, V.; D’Arcangelo, C. In Vitro Mechanical Properties of a Novel Graphene-Reinforced PMMA-Based Dental Restorative Material. Polymers 2023, 15, 622. [Google Scholar] [CrossRef]

- Kausar, A. Graphene to Polymer/Graphene Nanocomposites: Emerging Research and Opportunities; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Morales, M.A.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Colombian Sustainability Perspective on Fused Deposition Modeling Technology: Opportunity to Develop Recycled and Biobased 3D Printing Filaments. Polymers 2023, 15, 528. [Google Scholar] [CrossRef]

- Silvestre, R.; Garcia-Breijo, E.; Ferri, J.; Montava, I.; Bou-Belda, E. The Influence of the Structure of Cotton Fabrics on the Adhesion of Conductive Polymer Printed with 3D Printing Technology. Polymers 2023, 15, 668. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.; Shi, J.; Qiu, R.; Lei, W.; Yu, W. Comparative Investigations on Properties of Three Kinds of FDM 3D-Printed Natural Plant Powder/Poly(lactic acid) Biocomposites. Polymers 2023, 15, 557. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Zhou, W.; Qiao, Z.; Zare, E.N.; Huang, J.; Zheng, X.; Sun, X.; Shao, M.; Wang, H.; Wang, X.; Chen, D.; et al. 4D-Printed Dynamic Materials in Biomedical Applications: Chemistry, Challenges, and Their Future Perspectives in the Clinical Sector. J. Med. Chem. 2020, 63, 8003–8024. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, W.; Cao, K.; Hu, X.; Gao, L.; Lu, Y. Architectured graphene and its composites: Manufacturing and structural applications. Compos. Part Appl. Sci. Manuf. 2021, 140, 106177. [Google Scholar] [CrossRef]

- Hartings, M.R.; Ahmed, Z. Chemistry from 3D printed objects. Nat. Rev. Chem. 2019, 3, 305–314. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Razaq, A.; Bibi, F.; Zheng, X.; Papadakis, R.; Jafri, S.H.M.; Li, H. Review on Graphene-, Graphene Oxide-, Reduced Graphene Oxide-Based Flexible Composites: From Fabrication to Applications. Materials 2022, 15, 1012. [Google Scholar] [CrossRef]

- Li, F.; Long, L.; Weng, Y. A Review on the Contemporary Development of Composite Materials Comprising Graphene/Graphene Derivatives. Adv. Mater. Sci. Eng. 2020, 2020, 7915641. [Google Scholar] [CrossRef]

- Xu, M.; Liang, T.; Shi, M.; Chen, H. Graphene-Like Two-Dimensional Materials. Chem. Rev. 2013, 113, 3766–3798. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.K.; Grigorieva, I.V. Van der Waals heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Martinez, A.; Wang, F. Optical modulators with 2D layered materials. Nat. Photon 2016, 10, 227–238. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Wang, J.; Li, J.; Lin, Y. Graphene and graphene oxide: Biofunctionalization and applications in biotechnology. Trends Biotechnol. 2011, 29, 205–212. [Google Scholar] [CrossRef]

- Casero, E.; Parra-Alfambra, A.; Domínguez, M.D.P.; Pariente, F.; Lorenzo, E.; Alonso, F.P. Differentiation between graphene oxide and reduced graphene by electrochemical impedance spectroscopy (EIS). Electrochem. Commun. 2012, 20, 63–66. [Google Scholar] [CrossRef]

- Chen, J.; Chi, F.; Huang, L.; Zhang, M.; Yao, B.; Li, Y.; Li, C.; Shi, G. Synthesis of graphene oxide sheets with controlled sizes from sieved graphite flakes. Carbon 2016, 110, 34–40. [Google Scholar] [CrossRef]

- Dua, V.; Surwade, S.P.; Ammu, S.; Agnihotra, S.R.; Jain, S.; Roberts, K.E.; Park, S.; Ruoff, R.S.; Manohar, S.K. All-Organic Vapor Sensor Using Inkjet-Printed Reduced Graphene Oxide. Angew. Chem. Int. Ed. 2010, 49, 2154–2157. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yang, C.; Mai, Y.-W.; Zhang, Y. Effect of non-covalent functionalisation on thermal and mechanical properties of graphene-polymer nanocomposites. Carbon 2016, 102, 311–318. [Google Scholar] [CrossRef]

- Criado, A.; Melchionna, M.; Marchesan, S.; Prato, M. The covalent functionalization of graphene on substrates. Angew. Chem. Int. Ed. 2015, 54, 10734–10750. [Google Scholar] [CrossRef] [PubMed]

- Fechine, G.J.M.; Martin-Fernandez, I.; Yiapanis, G.; Bentini, R.; Kulkarni, E.S.; Bof de Oliveira, R.V.; Hu, X.; Yarovsky, I.; Castro Neto, A.H.; Oezyilmaz, B. Direct dry transfer of chemical vapor deposition graphene to polymeric substrates. Carbon 2015, 83, 224–231. [Google Scholar] [CrossRef]

- Raccichini, R.; Varzi, A.; Passerini, S.; Scrosati, B. The role of graphene for electrochemical energy storage. Nat. Mater. 2015, 14, 271–279. [Google Scholar] [CrossRef]

- Cui, C.; Huang, J.; Huang, J.; Chen, G. Size separation of mechanically exfoliated graphene sheets by electrophoresis. Electrochim. Acta 2017, 258, 793–799. [Google Scholar] [CrossRef]

- Sun, L.; Wang, L.; Tian, C.; Tan, T.; Xie, Y.; Shi, K.; Li, M.; Fu, H. Nitrogen-doped graphene with high nitrogen level via a one-step hydrothermal reaction of graphene oxide with urea for superior capacitive energy storage. RSC Adv. 2012, 2, 4498–4506. [Google Scholar] [CrossRef]

- Ji, L.; Xin, H.L.; Kuykendall, T.R.; Wu, S.-L.; Zheng, H.; Rao, M.; Cairns, E.J.; Battaglia, V.; Zhang, Y. SnS2 nanoparticle loaded graphene nanocomposites for superior energy storage. Phys. Chem. Chem. Phys. 2012, 14, 6981–6986. [Google Scholar] [CrossRef]

- Kausar, A. Strategies in Polymeric Nanoparticles and Hybrid Polymer Nanoparticles. NanoWorld J. 2019, 5, 1–5. [Google Scholar] [CrossRef]

- Garlow, J.A.; Barrett, L.K.; Wu, L.; Kisslinger, K.; Zhu, Y.; Pulecio, J.F. Large-Area Growth of Turbostratic Graphene on Ni(111) via Physical Vapor Deposition. Sci. Rep. 2016, 6, 19804. [Google Scholar] [CrossRef]

- Pirkle, A.; Chan, J.; Venugopal, A.; Hinojos, D.; Magnuson, C.W.; McDonnell, S.; Colombo, L.; Vogel, E.M.; Ruoff, R.S.; Wallace, R.M. The effect of chemical residues on the physical and electrical properties of chemical vapor deposited graphene transferred to SiO2. Appl. Phys. Lett. 2011, 99, 122108. [Google Scholar] [CrossRef]

- Burattini, S.; Greenland, B.W.; Merino, D.H.; Weng, W.; Seppala, J.; Colquhoun, H.M.; Hayes, W.; Mackay, M.E.; Hamley, I.W.; Rowan, S.J. A healable supramolecular polymer blend based on aromatic π−π stacking and hydrogen-bonding interactions. J. Am. Chem. Soc. 2010, 132, 12051–12058. [Google Scholar] [CrossRef] [PubMed]

- Björk, J.; Hanke, F.; Palma, C.-A.; Samori, P.; Cecchini, M.; Persson, M. Adsorption of aromatic and anti-aromatic systems on graphene through π−π stacking. J. Phys. Chem. Lett. 2010, 1, 3407–3412. [Google Scholar] [CrossRef]

- Li, H.; Rothberg, L. Colorimetric detection of DNA sequences based on electrostatic interactions with unmodified gold nanoparticles. Proc. Natl. Acad. Sci. USA 2004, 101, 14036–14039. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, J.; Huang, X.; Zhou, X.; Wu, H.; Guo, S. Assembly of Graphene Oxide-Enzyme Conjugates through Hydrophobic Interaction. Small 2012, 8, 154–159. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.X.; Zhou, K.G.; Xie, Y.L.; Zeng, J.; Chai, N.N.; Li, J.; Zhang, H.L. Photoactive graphene sheets prepared by “click” chemistry. Chem. Commun. 2011, 47, 5747–5749. [Google Scholar] [CrossRef]

- Eigler, S.; Hirsch, A. Chemistry with Graphene and Graphene Oxide—Challenges for Synthetic Chemists. Angew. Chem. Int. Ed. 2014, 53, 7720–7738. [Google Scholar] [CrossRef]

- Fang, L.; Xue, L.; Yang, P.; Li, X.; Wang, Z. A Facile Route to 4-Polyfluoroarylquinolin-2(1H)-ones and 4-Polyfluoroarylcoumarins via C–H Bond Activation. Chem. Lett. 2017, 46, 1223–1226. [Google Scholar] [CrossRef]

- Shi, M.; Shen, J.; Ma, H.; Li, Z.; Lu, X.; Li, N.; Ye, M. Preparation of graphene–TiO2 composite by hydrothermal method from peroxotitanium acid and its photocatalytic properties. Colloids Surfaces A Physicochem. Eng. Asp. 2012, 405, 30–37. [Google Scholar] [CrossRef]

- Khan, M.; Tahir, M.N.; Adil, S.F.; Khan, H.U.; Siddiqui, M.R.H.; Al-Warthan, A.A.; Tremel, W. Graphene based metal and metal oxide nanocomposites: Synthesis, properties and their applications. J. Mater. Chem. A 2015, 3, 18753–18808. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, T.; Zhou, X.; Zhang, Y.; Lou, X.W.; Chen, X.; Zhang, H.; Hng, H.H.; Yan, Q. Facile synthesis of metal oxide/reduced graphene oxide hybrids with high lithium storage capacity and stable cyclability. Nanoscale 2011, 3, 1084–1089. [Google Scholar] [CrossRef]

- Mohan, V.B.; Lau, K.-T.; Hui, D.; Bhattacharyya, D. Graphene-based materials and their composites: A review on production, applications and product limitations. Compos. Part B Eng. 2018, 142, 200–220. [Google Scholar] [CrossRef]

- Prolongo, S.; Jiménez-Suárez, A.; Moriche, R.; Ureña, A. Graphene nanoplatelets thickness and lateral size influence on the morphology and behavior of epoxy composites. Eur. Polym. J. 2014, 53, 292–301. [Google Scholar] [CrossRef]

- Nasir, A.; Kausar, A.; Younus, A. Polymer/Graphite Nanocomposites: Physical Features, Fabrication and Current Relevance. Polym. Technol. Eng. 2015, 54, 750–770. [Google Scholar] [CrossRef]

- Szeluga, U.; Kumanek, B.; Trzebicka, B. Synergy in hybrid polymer/nanocarbon composites. A review. Compos. Part A Appl. Sci. Manuf. 2015, 73, 204–231. [Google Scholar] [CrossRef]

- Rokaya, D.; Skallevold, H.E.; Srimaneepong, V.; Marya, A.; Shah, P.K.; Khurshid, Z.; Zafar, M.S.; Sapkota, J. Shape Memory Polymeric Materials for Biomedical Applications: An Update. J. Compos. Sci. 2023, 7, 24. [Google Scholar] [CrossRef]

- Johnson, D.W.; Dobson, B.P.; Coleman, K.S. A manufacturing perspective on graphene dispersions. Curr. Opin. Colloid Interface Sci. 2015, 20, 367–382. [Google Scholar] [CrossRef]

- Ghasemi, I.; Gomari, S. Polymeric Nanocomposites Including Graphene Nanoplatelets. In Handbook of Graphene; Celasco, E., Chaika, A.N., Stauber, T., Zhang, M., Ozkan, C., Ozkan, C., Ozkan, U., Palys, B., Harun, S.W., Eds.; Wiley, Scrivener Publishing LLC: Beverly, MA, USA, 2019; pp. 481–515. [Google Scholar]

- Zhang, S.; Xiong, P.; Yang, X.; Wang, X. Novel PEG functionalized graphene nanosheets: Enhancement of dispersibility and thermal stability. Nanoscale 2011, 3, 2169–2174. [Google Scholar] [CrossRef]

- Liu, C.; Ye, S.; Feng, J. Promoting the dispersion of graphene and crystallization of poly (lactic acid) with a freezing-dried graphene/PEG masterbatch. Compos. Sci. Technol. 2017, 144, 215–222. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Z.; Lu, Z.; Shen, H.; Huang, J.; Zhao, Q.; Liu, M.; He, N.; Zhang, Z. PEGylated reduced graphene oxide as a superior ssRNA delivery system. J. Mater. Chem. B 2013, 1, 749–7555. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.L.; Zhao, X.S.; Wu, J. Graphene/Polyaniline Nanofiber Composites as Supercapacitor Electrodes. Chem. Mater. 2010, 22, 1392–1401. [Google Scholar] [CrossRef]

- Singh, K.; Ohlan, A.; Saini, P.; Dhawan, S. Poly (3, 4-ethylenedioxythiophene) γ-Fe2O3 polymer composite–super paramagnetic behavior and variable range hopping 1D conduction mechanism–synthesis and characterization. Polym. Adv. Technol. 2008, 19, 229–236. [Google Scholar] [CrossRef]

- Saeb, M.R.; Zarrintaj, P. Polyaniline/graphene-based nanocomposites. In Fundamentals and Emerging Applications of Polyaniline; Elsevier: Amsterdam, The Netherlands, 2019; pp. 165–175. [Google Scholar]

- Sawangphruk, M.; Suksomboon, M.; Kongsupornsak, K.; Khuntilo, J.; Srimuk, P.; Sanguansak, Y.; Klunbud, P.; Suktha, P.; Chiochan, P. High-performance supercapacitors based on silver nanoparticle–polyaniline–graphene nanocomposites coated on flexible carbon fiber paper. J. Mater. Chem. A 2013, 1, 9630–9636. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, Y.; Zhao, Y.; Tsang, Y.H.; Lau, S.P.; Huang, H.; Chai, Y. Stretchable all-solid-state supercapacitor with wavy shaped polyaniline/graphene electrode. J. Mater. Chem. A 2014, 2, 9142–9149. [Google Scholar] [CrossRef]

- Bo, P.; Yunbin, X.; Jiabao, G.; Zijun, C.; Yanhuang, T.; Gang, Z.; Huanxiang, X.U. Research progress in preparation and properties of polymer/graphene composites. China Plast. 2022, 36, 190. [Google Scholar]

- Deshmukh, K.; Houkan, M.T.; AlMaadeed, M.A.; Sadasivuni, K.K. Introduction to 3D and 4D printing technology. In State of the Art and Recent Trends. 3D and 4D Printing of Polymer Nanocomposite Materials; Sadasivuni, K.K., Deshmukh, K., Almaadeed, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–24. [Google Scholar]

- Gokhare, V.G.; Raut, D.; Shinde, D. A review paper on 3D-printing aspects and various processes used in the 3D-printing. Int. J. Eng. Res. Technol. 2017, 6, 953–958. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Xu, W.; Jambhulkar, S.; Zhu, Y.; Ravichandran, D.; Kakarla, M.; Vernon, B.; Lott, D.G.; Cornella, J.L.; Shefi, O.; Miquelard-Garnier, G.; et al. 3D printing for polymer/particle-based processing: A review. Compos. Part B Eng. 2021, 223, 109102. [Google Scholar] [CrossRef]

- Chahal, V.; Taylor, R.M. A review of geometric sensitivities in laser metal 3D printing. Virtual Phys. Prototyp. 2020, 15, 227–241. [Google Scholar] [CrossRef]

- Ford, S.; Minshall, T. Invited review article: Where and how 3D printing is used in teaching and education. Addit. Manuf. 2019, 25, 131–150. [Google Scholar] [CrossRef]

- Lesage, P.; Dembinski, L.; Lachat, R.; Roth, S. Mechanical characterization of 3D printed samples under vibration: Effect of printing orientation and comparison with subtractive manufacturing. Results Eng. 2022, 13, 100372. [Google Scholar] [CrossRef]

- Joharji, L.; Mishra, R.B.; Alam, F.; Tytov, S.; Al-Modaf, F.; El-Atab, N. 4D printing: A detailed review of materials, techniques, and applications. Microelectron. Eng. 2022, 265, 111874. [Google Scholar] [CrossRef]

- Costa, L.A.; Carvalho, B.R.; Alves, J.L.; Marques, A.T.; da Silva, A.F.B.; Esfandiari, P.; da Silva, J.F.M.; Silva, A.R.; Parente, M. 4D structures for the short-time building of emergency shelters. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 1869–1894. [Google Scholar] [CrossRef]

- Shen, B.; Erol, O.; Fang, L.; Kang, S.H. Programming the time into 3D printing: Current advances and future directions in 4D printing. Multifunct. Mater. 2020, 3, 012001. [Google Scholar] [CrossRef]

- Rayate, A.; Jain, P.K. A review on 4D printing material composites and their applications. Mater. Today Proc. 2018, 5, 20474–20484. [Google Scholar] [CrossRef]

- Li, X.; Shang, J.; Wang, Z. Intelligent materials: A review of applications in 4D printing. Assem. Autom. 2017, 37, 170–185. [Google Scholar] [CrossRef]

- Agarwal, R.; Malhotra, S.; Gupta, V.; Jain, V. The application of Three-dimensional printing on foot fractures and deformities: A mini-review. Ann. 3D Print. Med. 2022, 5, 100046. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W. 4D Printing: Technological and Manufacturing Renaissance. Macromol. Mater. Eng. 2022, 307, 2200003. [Google Scholar] [CrossRef]

- Van Manen, T.; Dehabadi, V.M.; Saldívar, M.C.; Mirzaali, M.J.; Zadpoor, A.A. Theoretical stiffness limits of 4D printed self-folding metamaterials. Commun. Mater. 2022, 3, 43. [Google Scholar] [CrossRef]

- Tejada-Ortigoza, V.; Cuan-Urquizo, E. Towards the Development of 3D-Printed Food: A Rheological and Mechanial Approach. Foods 2022, 11, 1191. [Google Scholar] [CrossRef]

- Khorsandi, D.; Fahimipour, A.; Abasian, P.; Saber, S.S.; Seyedi, M.; Ghanavati, S.; Ahmad, A.; De Stephanis, A.A.; Taghavinezhaddilami, F.; Leonova, A.; et al. 3D and 4D printing in dentistry and maxillofacial surgery: Printing techniques, materials, and applications. Acta Biomater. 2021, 122, 26–49. [Google Scholar] [CrossRef] [PubMed]

- Quanjin, M.; Rejab, M.; Idris, M.; Kumar, N.M.; Abdullah, M.; Reddy, G.R. Recent 3D and 4D intelligent printing technologies: A comparative review and future perspective. Procedia Comput. Sci. 2020, 167, 1210–1219. [Google Scholar] [CrossRef]

- Wu, J.-J.; Huang, L.-M.; Zhao, Q.; Xie, T. 4D Printing: History and Recent Progress. Chin. J. Polym. Sci. 2018, 36, 563–575. [Google Scholar] [CrossRef]

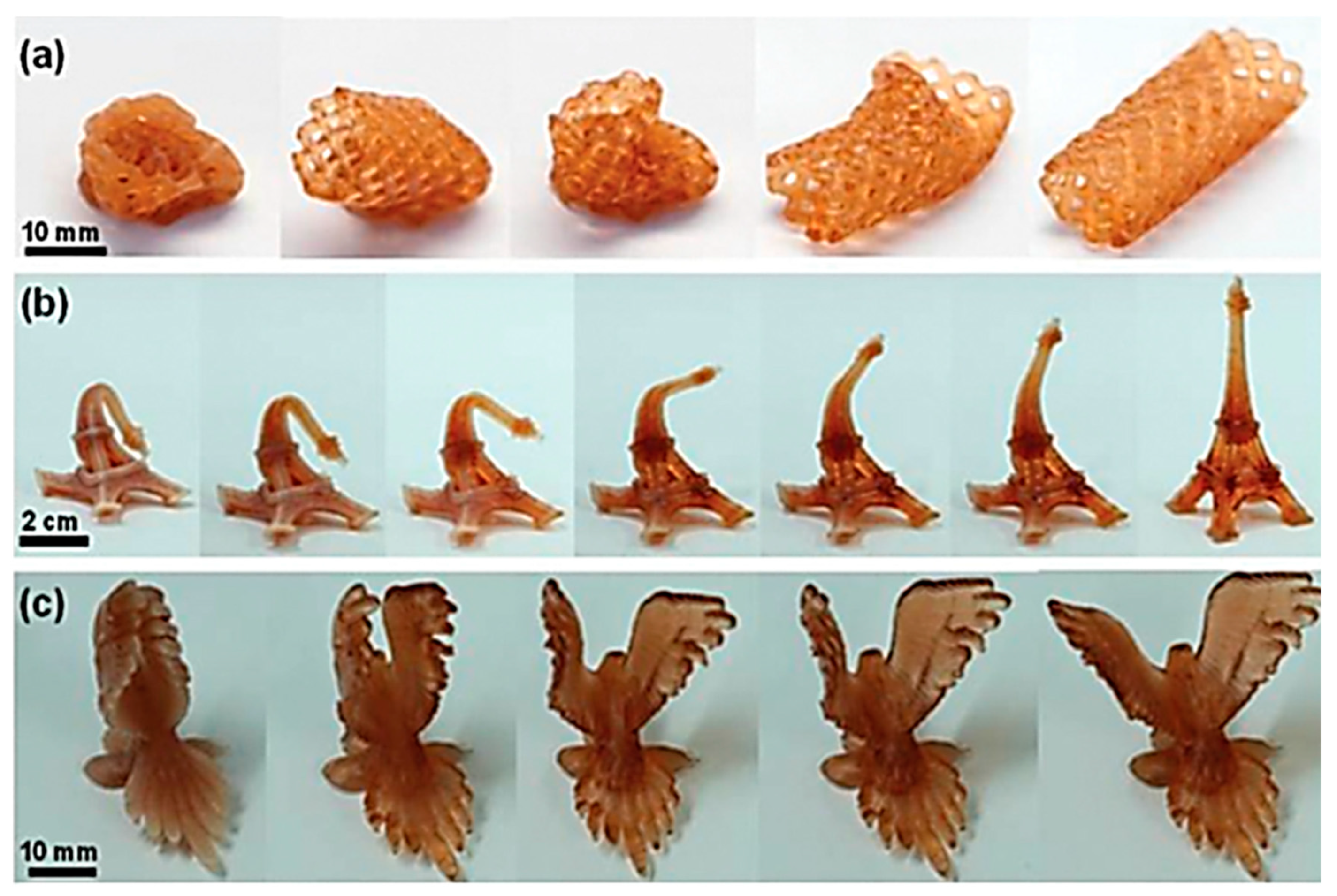

- Yang, D.; Mei, H.; Yao, L.; Yang, W.; Yao, Y.; Cheng, L.; Zhang, L.; Dassios, K.G. 3D/4D printed tunable electrical metamaterials with more sophisticated structures. J. Mater. Chem. C 2021, 9, 12010–12036. [Google Scholar] [CrossRef]

- Wan, X.; Luo, L.; Liu, Y.; Leng, J. Direct Ink Writing Based 4D Printing of Materials and Their Applications. Adv. Sci. 2020, 7, 2001000. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Patanwala, H.S.; Bognet, B.; Ma, A.W. Inkjet and inkjet-based 3D printing: Connecting fluid properties and printing performance. Rapid Prototyp. J. 2017, 23, 562–576. [Google Scholar] [CrossRef]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Kadri, N.A.; ABU Osman, N.A. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef] [PubMed]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

- Ponnamma, D.; Yin, Y.; Salim, N.; Parameswaranpillai, J.; Thomas, S.; Hameed, N. Recent progress and multifunctional applications of 3D printed graphene nanocomposites. Compos. Part B Eng. 2021, 204, 108493. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.L.; Viktorova, J.; Bennett, C.W.; Connal, L.A. Extrusion 3D Printing of Polymeric Materials with Advanced Properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.; Mahapatra, S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Zhang, Z.; Corrigan, N.; Bagheri, A.; Jin, J.; Boyer, C. A versatile 3D and 4D printing system through photocontrolled RAFT polymerization. Angew. Chem. 2019, 131, 18122–18131. [Google Scholar] [CrossRef]

- Pan, H.M. Advanced Materials in 3D/4D Printing Technology. Polymers 2022, 14, 3255. [Google Scholar] [CrossRef]

- Qian, Y.; Li, C.; Qi, Y.; Zhong, J. 3D printing of graphene oxide composites with well controlled alignment. Carbon 2021, 171, 777–784. [Google Scholar] [CrossRef]

- Markandan, K.; Seetoh, I.P.; Lai, C.Q. Mechanical anisotropy of graphene nanocomposites induced by graphene alignment during stereolithography 3D printing. J. Mater. Res. 2021, 36, 4262–4274. [Google Scholar] [CrossRef]

- Zuo, Y.; Yao, Z.; Lin, H.; Zhou, J.; Lu, J.; Ding, J. Digital light processing 3D printing of graphene/carbonyl iron/polymethyl methacrylate nanocomposites for efficient microwave absorption. Compos. Part B Eng. 2019, 179, 107533. [Google Scholar] [CrossRef]

- Mangal, U.; Min, Y.J.; Seo, J.-Y.; Kim, D.-E.; Cha, J.-Y.; Lee, K.-J.; Kwon, J.-S.; Choi, S.-H. Changes in tribological and antibacterial properties of poly(methyl methacrylate)-based 3D-printed intra-oral appliances by incorporating nanodiamonds. J. Mech. Behav. Biomed. Mater. 2020, 110, 103992. [Google Scholar] [CrossRef]

- Salgado, H.; Gomes, A.T.P.C.; Duarte, A.S.; Ferreira, J.M.F.; Fernandes, C.; Figueiral, M.H.; Mesquita, P. Antimicrobial Activity of a 3D-Printed Polymethylmethacrylate Dental Resin Enhanced with Graphene. Biomedicines 2022, 10, 2607. [Google Scholar] [CrossRef] [PubMed]

- Aati, S.; Chauhan, A.; Shrestha, B.; Rajan, S.M.; Aati, H.; Fawzy, A. Development of 3D printed dental resin nanocomposite with graphene nanoplatelets enhanced mechanical properties and induced drug-free antimicrobial activity. Dent. Mater. 2022, 38, 1921–1933. [Google Scholar] [CrossRef] [PubMed]

- Jing, J.; Xiong, Y.; Shi, S.; Pei, H.; Chen, Y.; Lambin, P. Facile fabrication of lightweight porous FDM-Printed polyethylene/graphene nanocomposites with enhanced interfacial strength for electromagnetic interference shielding. Compos. Sci. Technol. 2021, 207, 108732. [Google Scholar] [CrossRef]

- Mohan, V.B.; Bhattacharyya, D. Mechanical, electrical and thermal performance of hybrid polyethylene-graphene nanoplatelets-polypyrrole composites: A comparative analysis of 3D printed and compression molded samples. Polym. Plast. Technol. Mater. 2020, 59, 780–796. [Google Scholar] [CrossRef]

- Younes, H.; Kuang, X.; Lou, D.; DeVries, B.; Rahman, M.M.; Hong, H. Magnetic-field-assisted DLP stereolithography for controlled production of highly aligned 3D printed polymer-Fe3O4@ graphene nanocomposites. Mater. Res. Bull. 2022, 154, 111938. [Google Scholar] [CrossRef]

- Li, Z.; Young, R.J.; Wilson, N.R.; Kinloch, I.A.; Vallés, C.; Li, Z. Effect of the orientation of graphene-based nanoplatelets upon the Young’s modulus of nanocomposites. Compos. Sci. Technol. 2016, 123, 125–133. [Google Scholar] [CrossRef]

- Peng, R.D.; Zhou, H.W.; Wang, H.W.; Mishnaevsky, L., Jr. Modeling of nano-reinforced polymer composites: Microstructure effect on Young’s modulus. Comput. Mater. Sci. 2012, 60, 19–31. [Google Scholar] [CrossRef]

- Sun, R.; Li, L.; Feng, C.; Kitipornchai, S.; Yang, J. Tensile behavior of polymer nanocomposite reinforced with graphene containing defects. Eur. Polym. J. 2018, 98, 475–482. [Google Scholar] [CrossRef]

- Jing, J.; Chen, Y.; Shi, S.; Yang, L.; Lambin, P. Facile and scalable fabrication of highly thermal conductive polyethylene/graphene nanocomposites by combining solid-state shear milling and FDM 3D-printing aligning methods. Chem. Eng. J. 2020, 402, 126218. [Google Scholar] [CrossRef]

- Camargo, J.C.; Machado, R.; Almeida, E.C.; Silva, E.F.M.S. Mechanical properties of PLA-graphene filament for FDM 3D printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT Composites with Improved Electrical and Thermal Properties Suitable for FDM 3D Printing Applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef]

- Bustillos, J.; Montero, D.; Nautiyal, P.; Loganathan, A.; Boesl, B.; Agarwal, A. Integration of graphene in poly(lactic) acid by 3D printing to develop creep and wear-resistant hierarchical nanocomposites. Polym. Compos. 2018, 39, 3877–3888. [Google Scholar] [CrossRef]

- 1Kim, H.; Lee, S. Characterization of Electrical Heating of Graphene/PLA Honeycomb Structure Composite Manufactured by CFDM 3D Printer. Fash. Text. 2020, 7, 1–18. [Google Scholar]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A.S. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

- Wei, X.; Li, D.; Jiang, W.; Gu, Z.; Wang, X.; Zhang, Z.; Sun, Z. 3D Printable Graphene Composite. Sci. Rep. 2015, 5, 11181. [Google Scholar] [CrossRef]

- Zarek, M.; Layani, M.; Cooperstein, I.; Sachyani, E.; Cohn, D.; Magdassi, S. 3D Printing: 3D Printing of Shape Memory Polymers for Flexible Electronic Devices (Adv. Mater. 22/2016). Adv. Mater. 2016, 28, 4166. [Google Scholar] [CrossRef]

- Chang, Y.; Cao, Q.; Venton, B. 3D printing for customized carbon electrodes. Curr. Opin. Electrochem. 2023, 9, 101228. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, S.; Luque, R.; Han, S.; Hu, L.; Xu, G. Recent development of carbon electrode materials and their bioanalytical and environmental applications. Chem. Soc. Rev. 2016, 45, 715–752. [Google Scholar] [CrossRef]

- Chyan, Y.; Ye, R.; Li, Y.; Singh, S.P.; Arnusch, C.J.; Tour, J.M. Laser-Induced Graphene by Multiple Lasing: Toward Electronics on Cloth, Paper, and Food. ACS Nano 2018, 12, 2176–2183. [Google Scholar] [CrossRef] [PubMed]

- Ludvigsen, E.; Pedersen, N.; Zhu, X.; Marie, R.; Mackenzie, D.; Emnéus, J.; Petersen, D.; Kristensen, A.; Keller, S. Selective Direct Laser Writing of Pyrolytic Carbon Microelectrodes in Absorber-Modified SU-8. Micromachines 2021, 12, 564. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh, K.; Muzaffar, A.; Kovářík, T.; Křenek, T.; Ahamed, M.B.; Pasha, S.K. Fundamentals and applications of 3D and 4D printing of polymers: Challenges in polymer processing and prospects of future research. In 3D and 4D Printing of Polymer Nanocomposite Materials; Sadasivuni, K.K., Deshmukh, K., Almaadeed, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 527–560. [Google Scholar]

- Zhou, X.; Ren, L.; Song, Z.; Li, G.; Zhang, J.; Li, B.; Wu, Q.; Li, W.; Ren, L.; Liu, Q. Advances in 3D/4D printing of mechanical metamaterials: From manufacturing to applications. Compos. Part B Eng. 2023, 254, 110585. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- Li, M.; Zhou, S.; Cheng, L.; Mo, F.; Chen, L.; Yu, S.; Wei, J. 3D Printed Supercapacitor: Techniques, Materials, Designs, and Applications. Adv. Funct. Mater. 2023, 33, 2208034. [Google Scholar] [CrossRef]

- Xiong, C.; Zhang, Y.; Ni, Y. Recent progress on development of electrolyte and aerogel electrodes applied in supercapacitors. J. Power Sources 2023, 560, 232698. [Google Scholar] [CrossRef]

- Channegowda, M.; Kp, S.; Athreya, Y.; Kumar, S.G.; Mk, S.K. Perspective—Supercapacitor-Powered Flexible Wearable Strain Sensors. ECS Sensors Plus 2023, 2, 017002. [Google Scholar] [CrossRef]

- Wei, Q.; Zhou, J.; An, Y.; Li, M.; Zhang, J.; Yang, S. Modification, 3D printing process and application of sodium alginate based hydrogels in soft tissue engineering: A review. Int. J. Biol. Macromol. 2023, 232, 123450. [Google Scholar] [CrossRef]

- Wang, Z.; Xiang, L.; Lin, F.; Tang, Y.; Cui, W. 3D bioprinting of emulating homeostasis regulation for regenerative medicine applications. J. Control. Release 2023, 353, 147–165. [Google Scholar] [CrossRef]

- Kameoka, M.; Watanabe, Y.; Shiblee, N.I.; Kawakami, M.; Ogawa, J.; Khosla, A.; Furukawa, H.; Zhang, S.; Hirai, S.; Wang, Z. 4D Printing of Hydrogels Controlled by Hinge Structure and Spatially Gradient Swelling for Soft Robots. Machines 2023, 11, 103. [Google Scholar] [CrossRef]

- Kuang, X.; Yue, L.; Qi, H.J. Introduction to 4D Printing: Concepts and Material Systems. In Additive Manufacturing Technology: Design, Optimization, and Modeling; Zhou, K., Ed.; Wiley-VCH: Weinheim, Germany, 2023; pp. 1–42. [Google Scholar] [CrossRef]

- Singh, S.; Mali, H.S. 4D printing for product development: State of the art and future scope. Innov. Process. Mater. Addit. Manuf. 2023, 1, 293–306. [Google Scholar] [CrossRef]

- Sloutski, A.; Cohn, D. Reverse thermo-responsive biodegradable shape memory-displaying polymers. Polymer 2023, 267, 125640. [Google Scholar] [CrossRef]

- Pourmasoumi, P.; Moghaddam, A.; Mahand, S.N.; Heidari, F.; Moghaddam, Z.S.; Arjmand, M.; Kühnert, I.; Kruppke, B.; Wiesmann, H.-P.; Khonakdar, H.A. A review on the recent progress, opportunities, and challenges of 4D printing and bioprinting in regenerative medicine. J. Biomater. Sci. Polym. Ed. 2023, 34, 108–146. [Google Scholar] [CrossRef] [PubMed]

- Kocharyan, H.; Karanjgaokar, N. Development of adaptive granular metamaterials for impact mitigation. Extreme Mech. Lett. 2023, 58, 101943. [Google Scholar] [CrossRef]

- Fu, X.; Lin, J.; Liang, Z.; Yao, R.; Wu, W.; Fang, Z.; Zou, W.; Wu, Z.; Ning, H.; Peng, J. Graphene oxide as a promising nanofiller for polymer composite. Surf. Interfaces 2023, 37, 102747. [Google Scholar] [CrossRef]

- Meng, Z. Effects of Chemical and Physical Features of 2D Nanofillers on the Mechanical and Viscoelastic Properties of Polymer Nanocomposites. Bull. Am. Phys. Soc. 2023, 1, 20–22. [Google Scholar]

- Bazhanov, D.A.; Poteryaev, A.A.; Shapagin, A.V.; Shcherbina, A.A. Ethylene-Vinyl Acetate Copolymers as Potential Thermoplastic Modifiers of Photopolymer Compositions. Polymers 2023, 15, 131. [Google Scholar] [CrossRef]

- Idowu, A.; Thomas, T.; Boesl, B.; Agarwal, A. Cryo-Assisted Extrusion Three-Dimensional Printing of Shape Memory Polymer–Graphene Composites. J. Manuf. Sci. Eng. 2023, 145, 041003. [Google Scholar]

- Thongchom, C.; Refahati, N.; Saffari, P.R.; Saffari, P.R.; Niyaraki, M.N.; Sirimontree, S.; Keawsawasvong, S. An Experimental Study on the Effect of Nanomaterials and Fibers on the Mechanical Properties of Polymer Composites. Buildings 2021, 12, 7. [Google Scholar] [CrossRef]

- Nikita, K.; Patel, D.; Patel, G. Additive Manufacturing of Multifunctional Polymer Nanocomposites: From 3 D to 4 D. In Nanotechnology-Based Additive Manufacturing: Product Design, Properties and Applications; Wiley: Hoboken, NJ, USA, 2023; Volume 1, pp. 277–313. [Google Scholar] [CrossRef]

- Du, J.; Fu, G.; Xu, X.; Elshahawy, A.M.; Guan, C. 3D Printed Graphene-Based Metamaterials: Guesting Multi-Functionality in One Gain. Small 2023, 2207833. [Google Scholar] [CrossRef]

- Pugliese, R.; Regondi, S. Artificial Intelligence-Empowered 3D and 4D Printing Technologies toward Smarter Biomedical Materials and Approaches. Polymers 2022, 14, 2794. [Google Scholar] [CrossRef]

- Ahmed, A.; Arya, S.; Gupta, V.; Furukawa, H.; Khosla, A. 4D printing: Fundamentals, materials, applications and challenges. Polymer 2021, 228, 123926. [Google Scholar] [CrossRef]

- Ren, L.; Wu, W.; Ren, L.; Song, Z.; Liu, Q.; Li, B.; Wu, Q.; Zhou, X. 3D Printing of Auxetic Metamaterials with High-Temperature and Programmable Mechanical Properties. Adv. Mater. Technol. 2022, 7, 2101546. [Google Scholar] [CrossRef]

- Farzinazar, S.; Wang, Y.; Owens, C.A.-H.; Yang, C.; Lee, H.; Lee, J. Thermal transport in 3D printed shape memory polymer metamaterials. APL Mater. 2022, 10, 081105. [Google Scholar] [CrossRef]

- Muthe, L.P.; Pickering, K.; Gauss, C. A Review of 3D/4D Printing of Poly-Lactic Acid Composites with Bio-Derived Reinforcements. Compos. Part C Open Access 2022, 8, 100271. [Google Scholar] [CrossRef]

- Liang, Z.; Yao, Y.; Jiang, B.; Wang, X.; Xie, H.; Jiao, M.; Liang, C.; Qiao, H.; Kline, D.; Zachariah, M.R.; et al. 3D Printed Graphene-Based 3000 K Probe. Adv. Funct. Mater. 2021, 31, 2102994. [Google Scholar] [CrossRef]

- Chen, W.; Wang, Z.; Bets, K.V.; Luong, D.X.; Ren, M.; Stanford, M.G.; McHugh, E.A.; Algozeeb, W.A.; Guo, H.; Gao, G.; et al. Millisecond conversion of metastable 2D materials by flash Joule heating. ACS Nano 2021, 15, 1282–1290. [Google Scholar] [CrossRef]

- Xia, T.; Zeng, D.; Li, Z.; Young, R.J.; Vallés, C.; Kinloch, I.A. Electrically conductive GNP/epoxy composites for out-of-autoclave thermoset curing through Joule heating. Compos. Sci. Technol. 2018, 164, 304–312. [Google Scholar] [CrossRef]

- Chowdhury, J.; Anirudh, P.V.; Karunakaran, C.; Rajmohan, V.; Mathew, A.T.; Koziol, K.; Alsanie, W.F.; Kannan, C.; Balan, A.S.S.; Thakur, V.K. 4D Printing of Smart Polymer Nanocomposites: Integrating Graphene and Acrylate Based Shape Memory Polymers. Polymers 2021, 13, 3660. [Google Scholar] [CrossRef]

- Xiao, Y.Y.; Jiang, Z.C.; Zhao, Y. Liquid Crystal Polymer-Based Soft Robots. Adv. Intell. Syst. 2020, 2, 2000148. [Google Scholar] [CrossRef]

- Chen, G.; Seo, J.; Yang, C.; Prasad, P.N. Nanochemistry and nanomaterials for photovoltaics. Chem. Soc. Rev. 2013, 42, 8304–8338. [Google Scholar] [CrossRef]

- Yang, W.; Xu, X.; Gao, Y.; Li, Z.; Li, C.; Wang, W.; Chen, Y.; Ning, G.; Zhang, L.; Yang, F.; et al. High-surface-area nanomesh graphene with enriched edge sites as efficient metal-free cathodes for dye-sensitized solar cells. Nanoscale 2016, 8, 13059–13066. [Google Scholar] [CrossRef] [PubMed]

- Inshakova, E.; Inshakova, A.; Goncharov, A. Engineered Nanomaterials for Energy Sector: Market Trends, Modern Applications and Future Prospects. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032031. [Google Scholar] [CrossRef]

- Li, Y.; Gao, T.; Yang, Z.; Chen, C.; Kuang, Y.; Song, J.; Jia, C.; Hitz, E.M.; Yang, B.; Hu, L. Graphene oxide-based evaporator with one-dimensional water transport enabling high-efficiency solar desalination. Nano Energy 2017, 41, 201–209. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Liu, G.; Rong, Y.; Yang, Y.; Wang, H.; Ku, Z.; Xu, M.; Zhong, C.; Han, H. Efficient Dye-Sensitized Solar Cells with Potential-Tunable Organic Sulfide Mediators and Graphene-Modified Carbon Counter Electrodes. Adv. Funct. Mater. 2013, 23, 3344–3352. [Google Scholar] [CrossRef]

- Jung, S.; Sou, A.; Banger, K.; Ko, D.H.; Chow, P.C.; McNeill, C.R.; Sirringhaus, H. All-inkjet-printed, all-air-processed solar cells. Adv. Energy Mater. 2014, 4, 1400432. [Google Scholar] [CrossRef]

- Vak, D.; Hwang, K.; Faulks, A.; Jung, Y.-S.; Clark, N.; Kim, D.-Y.; Wilson, G.J.; Watkins, S.E. 3D Printer Based Slot-Die Coater as a Lab-to-Fab Translation Tool for Solution-Processed Solar Cells. Adv. Energy Mater. 2015, 5, 1401539. [Google Scholar] [CrossRef]

- Finn, M., III; Martens, C.J.; Zaretski, A.V.; Roth, B.; Søndergaard, R.R.; Krebs, F.C.; Lipomi, D.J. Mechanical stability of roll-to-roll printed solar cells under cyclic bending and torsion. Sol. Energy Mater. Sol. Cells 2018, 174, 7–15. [Google Scholar] [CrossRef]

- Wu, X.; Mu, F.; Lin, Z. Three-dimensional printing of graphene-based materials and the application in energy storage. Mater. Today Adv. 2021, 11, 100157. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Shao, Y.; Kaner, R.B. Graphene for batteries, supercapacitors and beyond. Nat. Rev. Mater. 2016, 1, 16033. [Google Scholar] [CrossRef]

- Armelin, E.; Pérez-Madrigal, M.M.; Alemán, C.; Díaz, D.D. Current status and challenges of biohydrogels for applications as supercapacitors and secondary batteries. J. Mater. Chem. A 2016, 4, 8952–8968. [Google Scholar] [CrossRef]

- Elder, B.; Neupane, R.; Tokita, E.; Ghosh, U.; Hales, S.; Kong, Y.L. Nanomaterial Patterning in 3D Printing. Adv. Mater. 2020, 32, e1907142. [Google Scholar] [CrossRef]

- Lyu, Z.; Lim, G.J.; Koh, J.J.; Li, Y.; Ma, Y.; Ding, J.; Wang, J.; Hu, Z.; Wang, J.; Chen, W.; et al. Design and Manufacture of 3D-Printed Batteries. Joule 2021, 5, 89–114. [Google Scholar] [CrossRef]

- Chu, T.; Park, S.; Fu, K. 3D printing-enabled advanced electrode architecture design. Carbon Energy 2021, 3, 424–439. [Google Scholar] [CrossRef]

- Le, L.T.; Ervin, M.H.; Qiu, H.; Fuchs, B.E.; Zunino, J.; Lee, W.Y. Inkjet-printed graphene for fleible micro-supercapacitors. In Proceedings of the 2011 11th IEEE International Conference on Nanotechnology, Portland, OR, USA, 15–18 August 2011; pp. 67–71. [Google Scholar]

- Tang, K.; Ma, H.; Tian, Y.; Liu, Z.; Jin, H.; Hou, S.; Zhou, K.; Tian, X. 3D printed hybrid-dimensional electrodes for flexible micro-supercapacitors with superior electrochemical behaviours. Virtual Phys. Prototyp. 2020, 15, 511–519. [Google Scholar] [CrossRef]

- Zhou, Y.; Parker, C.B.; Joshi, P.; Naskar, A.K.; Glass, J.T.; Cao, C. 4D Printing of Stretchable Supercapacitors via Hybrid Composite Materials. Adv. Mater. Technol. 2021, 6, 2001055. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, T.; Qian, F.; Han, T.Y.-J.; Duoss, E.B.; Kuntz, J.D.; Spadaccini, C.M.; Worsley, M.A.; Li, Y. Supercapacitors Based on Three-Dimensional Hierarchical Graphene Aerogels with Periodic Macropores. Nano Lett. 2016, 16, 3448–3456. [Google Scholar] [CrossRef]

- Shen, K.; Mei, H.; Li, B.; Ding, J.; Yang, S. 3D Printing Sulfur Copolymer-Graphene Architectures for Li-S Batteries. Adv. Energy Mater. 2018, 8, 1701527. [Google Scholar] [CrossRef]

- Wu, B.; Guo, B.; Chen, Y.; Mu, Y.; Qu, H.; Lin, M.; Bai, J.; Zhao, T.; Zeng, L. High Zinc Utilization Aqueous Zinc Ion Batteries Enabled by 3D Printed Graphene Arrays. Energy Storage Mater. 2023, 54, 75–84. [Google Scholar] [CrossRef]

- Fu, K.; Wang, Y.; Yan, C.; Yao, Y.; Chen, Y.; Dai, J.; Lacey, S.; Wang, Y.; Wan, J.; Li, T.; et al. Graphene Oxide-Based Electrode Inks for 3D-Printed Lithium-Ion Batteries. Adv. Mater. 2016, 28, 2587–2594. [Google Scholar] [CrossRef]

- Qiao, Y.; Liu, Y.; Chen, C.; Xie, H.; Yao, Y.; He, S.; Ping, W.; Liu, B.; Hu, L. 3D-Printed Graphene Oxide Framework with Thermal Shock Synthesized Nanoparticles for Li-CO2 Batteries. Adv. Funct. Mater. 2018, 28, 1805899. [Google Scholar] [CrossRef]

- Wen, N.; Zhang, L.; Jiang, D.; Wu, Z.; Li, B.; Sun, C.; Guo, Z. Emerging flexible sensors based on nanomaterials: Recent status and applications. J. Mater. Chem. A 2020, 8, 25499–25527. [Google Scholar] [CrossRef]

- Christ, J.F.; Aliheidari, N.; Ameli, A.; Pötschke, P. 3D printed highly elastic strain sensors of multiwalled carbon nanotube/thermoplastic polyurethane nanocomposites. Mater. Des. 2017, 131, 394–401. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, E.; Hao, S.; Yang, X.; Li, T.; Lou, C.; Run, M.; Song, H. 3D Printable, ultra-stretchable, Self-healable, and self-adhesive dual cross-linked nanocomposite ionogels as ultra-durable strain sensors for motion detection and wearable human-machine interface. Chem. Eng. J. 2022, 431, 133949. [Google Scholar] [CrossRef]

- Xiang, D.; Zhang, X.; Harkin-Jones, E.; Zhu, W.; Zhou, Z.; Shen, Y.; Li, Y.; Zhao, C.; Wang, P. Synergistic effects of hybrid conductive nanofillers on the performance of 3D printed highly elastic strain sensors. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105730. [Google Scholar] [CrossRef]

- Cardoso, R.M.; Kalinke, C.; Rocha, R.G.; Dos Santos, P.L.; Rocha, D.P.; Oliveira, P.R.; Janegitz, B.C.; Bonacin, J.A.; Richter, E.M.; Munoz, R.A. Additive-manufactured (3D-printed) electrochemical sensors: A critical review. Anal. Chim. Acta 2020, 1118, 73–91. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, R.; Ahuja, I.P. 3D printed graphene-reinforced polyvinylidene fluoride composite for piezoelectric properties. In 4D Printing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 51–66. [Google Scholar]

- Maurya, D.; Khaleghian, S.; Sriramdas, R.; Kumar, P.; Kishore, R.A.; Kang, M.G.; Kumar, V.; Song, H.-C.; Lee, S.-Y.; Yan, Y.; et al. 3D printed graphene-based self-powered strain sensors for smart tires in autonomous vehicles. Nat. Commun. 2020, 11, 5392. [Google Scholar] [CrossRef]

- Mahmud, M.A.P.; Tat, T.; Xiao, X.; Adhikary, P.; Chen, J. Advances in 4D-printed physiological monitoring sensors. Exploration 2021, 1, 210033. [Google Scholar] [CrossRef]

- Sun, J.; Sun, Y.; Jia, H.; Bi, H.; Chen, L.; Que, M.; Xiong, Y.; Han, L.; Sun, L. A novel pre-deposition assisted strategy for inkjet printing graphene-based flexible pressure sensor with enhanced performance. Carbon 2022, 196, 85–91. [Google Scholar] [CrossRef]

- Li, Q.; Wu, T.; Zhao, W.; Li, Y.; Ji, J.; Wang, G. 3D printing stretchable core-shell laser scribed graphene conductive network for self-powered wearable devices. Compos. Part B Eng. 2022, 240, 110000. [Google Scholar] [CrossRef]

- Tan, H.W.; Choong, Y.Y.C.; Kuo, C.N.; Low, H.Y.; Chua, C.K. 3D printed electronics: Processes, materials and future trends. Prog. Mater. Sci. 2022, 127, 100945. [Google Scholar] [CrossRef]

- Wang, F.; Xu, Z. Graphene and graphene oxide-reinforced 3D and 4D printable composites. In 3D and 4D Printing of Polymer Nanocomposite Materials; Sadasivuni, K.K., Deshmukh, K., Almaadeed, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 259–296. [Google Scholar]

| Advantages | Challenges |

|---|---|

| Formation of customized products from small batches, as compared to traditional mass production methods |

|

| Possibility to produce 3D models directly without using any tools and molds is not required. |

|

| Can be designed in the form of digital files to easily share and facilitate the modification and customization of components and products |

|

| Material can be saved due to the additive nature of the process. The waste materials (powder, resin) during manufacturing can be reused. |

|

| Possibility to achieve novel and complex structures |

|

| Very low porosity of final products |

|

| Due to the distribution, the direct interaction between local consumer or client and producer is possible. |

|

| Efficient printing processes, such as FDM, SLA, SLS, etc. |

|

| Sample | Tg (C) | Tm (C) |

|---|---|---|

| PLA filament | 59.3 | 168.7 |

| PLA-graphene filament | 45.9 | 164.1 |

| 3D-printed PLA | 60.7 | 168.5 |

| 3D-printed PLA-graphene | 51.2 | 165.5 |

| Sample | Digital Images | ×6.5 Magnification |

|---|---|---|

| PLA |  |  |

| PLA/GR |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I.; Zhao, T.; Aldaghri, O.; Eisa, M.H. Polymer/Graphene Nanocomposites via 3D and 4D Printing—Design and Technical Potential. Processes 2023, 11, 868. https://doi.org/10.3390/pr11030868

Kausar A, Ahmad I, Zhao T, Aldaghri O, Eisa MH. Polymer/Graphene Nanocomposites via 3D and 4D Printing—Design and Technical Potential. Processes. 2023; 11(3):868. https://doi.org/10.3390/pr11030868

Chicago/Turabian StyleKausar, Ayesha, Ishaq Ahmad, Tingkai Zhao, O. Aldaghri, and M. H. Eisa. 2023. "Polymer/Graphene Nanocomposites via 3D and 4D Printing—Design and Technical Potential" Processes 11, no. 3: 868. https://doi.org/10.3390/pr11030868

APA StyleKausar, A., Ahmad, I., Zhao, T., Aldaghri, O., & Eisa, M. H. (2023). Polymer/Graphene Nanocomposites via 3D and 4D Printing—Design and Technical Potential. Processes, 11(3), 868. https://doi.org/10.3390/pr11030868