Abstract

The aim of this study was to compare the aromatic profile of plum spirits, obtained from the Požegača and Stanley varieties, as affected by different combinations of pre-distillation steps used in traditional and six modified production methods that are common in Serbian distilleries. Traditional plum spirits (produced from spontaneously fermented mashes of crushed plums with stones distilled after two months of storage) had the highest contents of ethyl acetate, benzaldehyde, and total acids, which resulted in the occurrence of an unpleasant solvent-like and stone-like odour and acidic taste. These sensory defects were overcome by the distillation of fermented mashes immediately after the completion of alcoholic fermentation. Depending on the combination of the pre-distillation steps, plum spirits from mashes distilled immediately after alcoholic fermentation were characterized by different aromatic profiles: closer to traditional (from spontaneously fermented crushed plums with/without stones) or with a more pronounced fruity character (from pulped plums without stones regardless of the way of fermentation). These differences in aroma profiles have arisen mostly because of the significantly different contents and OAVs of ethyl esters and volatile fatty acids. The appropriate combination of the pre-distillation steps, which is adapted to the variety, can significantly improve the quality of the plum spirit compared to the traditionally produced spirit.

1. Introduction

Plum spirit is a traditional spirit drink found mostly in the Balkans, but also in other plum-growing regions of Eastern, Central, and Western European countries [1]. The countries differ in the share of the annual plum crop that is processed into plum spirit. Serbia has ranked as one of the world’s leading plum producers, with an average annual production of about 500,000 tons, out of which about 80% is processed into plum spirit (šljivovica, šljivova prepečenica), considered the Serbian national spirit drink [2,3,4].

Until the 1970s, plum spirits in Serbia were produced almost exclusively in a traditional manner, both in small household distilleries and in most of the commercial distilleries. In addition to double distillation in a simple alembic (pot still), the traditional production method includes the processing of plums with stones, crushing of fruits, spontaneous alcoholic fermentation, and long storage of fermented mash until distillation (even up to 2–3 months, most commonly in open vessels, with a constant mash surface/air contact). Therefore, traditional plum spirits often have increased contents of volatile acids, HCN, and benzaldehyde, which affect the acidic taste and unpleasant odour as well as the appearance of a pronounced aroma of bitter almond. In addition, traditionally produced plum spirits may have increased contents of methanol that may be even higher (>1200 g/hL 100% vol. ethanol) than legally allowed [5].

In recent decades, there has been a change in the consumers’ taste towards consuming lighter fruit spirits without any defects in odour and taste (an acidic profile of the odour and taste are especially undesirable). In addition, modern legislation is very restrictive in terms of the content of potentially toxic ingredients [6]. Therefore, in many countries, including Serbia, a modification of plum spirit production methods has mainly aimed at reducing the contents of volatile acids [7], HCN, benzaldehyde and ethyl carbamate [8,9,10,11,12,13], and methanol [7,14,15,16]. However, the influence of these production methods on the aromatic profile of plum brandies has not been investigated.

Some authors have also suggested the application of certain pre-distillation steps to enhance the aroma of the plum spirit [17]. There are very few studies comparing the aroma profiles of plum spirits produced by the traditional and modified methods [18,19,20,21]. The pre-distillation steps (pH adjustment of mash, addition of pectolytic enzymes, and separation the solid and liquid part of the mash) studied in these works are rarely applied in Serbian distilleries, whilst some of them were applied only to local plum varieties not grown in Serbia.

In modern distilleries, the production methods should be chosen so that the obtained plum spirits contain less undesirable ingredients (methanol and HCN) than legally allowed, and, at the same time, contain the “optimal” content of the congeners (higher alcohols, esters, volatile acids, aldehydes, and benzaldehyde), which directly affect sensory characteristics. The chosen method affects whether the traditional character of the plum spirit will be preserved (as the EU regulative insists [22]) or a product with a modified aromatic profile will be obtained.

There are different modification levels of the traditional production method in Serbian distilleries that produce plum spirit. They depend on distillery capacity and its equipment [3], and on the manufacturer’s knowledge and experience as well. The shortening of the fermented mash storage time is the simplest and most widely used modification in distilleries, aimed at improving plum spirit quality, so the mash is distilled immediately after fermentation. Furthermore, in a number of distilleries, stones are removed from plums before fermentation. In small, household distilleries, stones can be removed manually. Better-equipped distilleries use different types of fruit-stone-removing machines (destoner and pitting machine); the resulting crushed mash without stones contains large pieces of plum fruits, similar to that after the manual removal of stones. Nowadays, many manufacturers use fruit-pulping machines for simultaneously removing the stones and obtaining the pulped mash of fluid consistency that can be easily transported by pumps. Spontaneous alcoholic fermentation of the plum mash is commonly employed by Serbian distilleries. Only a few distilleries use commercial yeasts, mostly wine strains that are more prevalent on the market than the strains intended for fruit mash fermentation. Therefore, the production methods of plum spirit in Serbia, today, differ in combinations of the following pre-distillation steps: processing of plums with or without stones, crushing or pulping of fruits, spontaneous mash fermentation or fermentation by added commercial yeast strains, and distillation of fermented mash after long storage or immediately after completed alcoholic fermentation.

The aim of this work was to determine the influence of traditional and six modified production methods used in Serbian distilleries on the aromatic profile of plum spirits from the most common varieties in the plum assortment—Požegača and Stanley.

2. Materials and Methods

2.1. Raw Material

For processing, 500 kg of fully ripe fruits of Požegača and Stanley plum varieties were picked at the same orchard (Preljina, Serbia, 43°92′41″ N, 20°44′75″ E). The fruits had the following characteristics: Požegača (P), soluble solid content—21.00%, total sugars—11.52%, and pH—3.72; Stanley (S), soluble solid content—17.80%, total sugars—11.76%, and pH—3.66.

2.2. Plum Spirit Production Methods

Plums were processed on a pilot scale immediately after picking. The production methods (variants) of plum spirit are shown in Table 1. Production method 1 (M1) is considered traditional, whereas variants 2–7 (M2–M7) are modified methods.

Table 1.

Traditional (M1) and modified (M2–M7) plum spirit production methods.

In variants M1 to M4, plums were crushed. When processing plums with stones (methods M1 and M3), the fruits were crushed in toothed roller crusher so that the stones remained unbroken. In the processing of plums without stones (methods M2 and M4), removing of stones (destoning) was performed manually; the resulting mashes (consisting of the whole plum halves without stones) had similar characteristics as the mash of the crushed plums with stones, and very similar physical characteristics as the mash without stones obtained by using fruit-pitting machine. In variants M5 to M7, fruit pulping and destoning were performed simultaneously using a pilot-scale pulping machine (capacity, 350 kg h−1; perforations of the sieve, 8 mm) whereby a pulped plum mash without stones was obtained. All variants were performed in triplicate; that is, 60 kg of mash for each variant was divided in 3 equal parts and placed into three 30 L polyethylene vessels (20 kg of mash in each vessel) for alcoholic fermentation (Supplementary Materials, Figures S1 and S2).

In all variants, alcoholic fermentation was carried out in open vessels at 20 ± 2 °C, with constant mash-surface–air contact (Supplementary Materials, Figure S3). The plum mashes were spontaneously fermented in variants M1 to M5. In variants M6 and M7, the mashes were inoculated (20 g/100 kg mash) with two commercial yeast strains (Enologica Vason, San Pietro in Cariano, Italy), previously rehydrated according to manufacturer’s instructions: Saccharomyces cerevisiae Premium Blanc 12V (M6) and Saccharomyces cerevisiae Montrachet (M7). The kinetics of plum mashes fermentation (Supplementary Materials, Figure S4) were monitored daily based on a decrease in the soluble solids content (using 3828 Carl Zeiss manual refractometer). Duration of alcoholic fermentation was similar (11–12 days) in all processing methods (variants M1–M7) of Požegača variety. Fermentation of the Stanley variety lasted shorter (maximum 9 days); it was completed 2–3 days earlier in the pulped plum mashes with added selected yeasts (variants M6 and M7) than in the mashes fermented spontaneously (variants M1–M5).

In variants M1 and M2, fermented mashes were stored for 2 months at 10 ± 3 °C (in a room under the influence of outside temperature), which is common way of mash storage in the traditional plum spirit production. These mashes were distilled on the 71st day (Požegača) and on 69th day (Stanley) from the moment of crushed plum distribution in fermentation vessels. Mashes from variants M3 to M7 were distilled immediately after finished alcoholic fermentation.

Distillation of the fermented mashes was carried out using a copper pilot pot still—alembic (volume 25 L) of traditional construction, heated by a gas burner. In all variants, the same traditional double distillation regime was applied. By distillation of fermented mashes, the distillates (raw soft plum spirits) with ethanol content of 28.0 ± 0.3% v/v were obtained. These distillates were redistilled in the same apparatus with the fraction separation as follows: the first fraction—head (1% of the volume of the first distillate which was poured into the pot still boiler for redistillation), middle fraction—heart (with ethanol content 60.0 ± 0.3% v/v) and the last fraction—tail. For further analyses, only middle fractions (hearts) were used.

2.3. Analysis of Volatile Compounds

Official methods were used to determine contents of total acid (titration with 0.1 M NaOH) and HCN (Wurzinger and Bandion method) in plum spirits [23].

Methanol, 1-propanol, 1-butanol, 2-butanol, 2-methyl-1-propanol, 2-methyl-1-butanol, 3-methyl-1-butanol, ethyl acetate, ethyl butyrate, ethyl octanoate, isoamyl acetate, acetaldehyde, and benzaldehyde in plum spirits were quantified using the method described by Senn [24] and Schehl et al. [6]. Headspace gas chromatograph (HS 40, GC 8420 Perkin Elmer, Uberlingen, Germany) equipped with a packed crossbondphenylmethyl-polysiloxane column (Rtx volatiles; 60 m × 0.32 mm id, film thickness 1.5 μm, Restecks GmbH, Bad Homburg, Germany), a flame ionisation detector (FID), and a CLASS VP 4.2 integrator (Shimadzu, Duisburg, Germany) were used. The internal standard was 2-pentanol.

The method described by Senn [24] was used for quantitative analysis of 2-phenylethanol, 1-hexanol, ethyl decanoate, ethyl dodecanoate, ethyl tetradecanoate, ethyl lactate, diethyl succinate, hexanoic acid, octanoic acid, and decanoic acid. Gas chromatograph Shimazu (AOC-20, GC 17) fitted with the HP-INNOWax column (30 m × 0.32 mm id, film thickness 0.25 μm, Agilent Technologies, Santa Clara, California, United States), a flame ionisation detector (FID), and a CLASS VP 4.2 integrator (Shimadzu, Duisburg, Germany) were used. The internal standard was 2-ethyl butyric acid.

The plum spirits were analysed in triplicate and the results were expressed as mean values ± standard deviation.

Based on gas chromatographic analyses, total amounts of higher alcohols, esters, volatile fatty acids, and aldehydes were calculated. Total volatile substances are presented as the sum of the concentrations of these four groups of compounds. In addition to the content of total esters, the content of total esters reduced by the content of ethyl acetate (total esters-EtAc) and total esters reduced by the content of ethyl acetate and ethyl lactate (total esters-EtAc-EtLac) were calculated.

2.4. Odour Activity Values

Odour activity values (OAVs) were calculated dividing concentrations of 23 analysed volatile compounds (eight higher alcohols, ten esters, three fatty acids. and two aldehydes) by values of their odour threshold [25].

2.5. Sensory Analysis

Before sensory analysis, ethanol content in the middle fractions obtained by redistillation was diluted with deionized water from 60.0 ± 0.3% v/v to 45.0 ± 0.3% v/v. A 5-member expert panel conducted sensory evaluation. Panel members had 10–30 years of experience in the sensory evaluation of plum spirits. The 20-point Buxbaum method [26,27] was used to evaluate four parameters of the plum spirit quality: clearness (maximum 1 point), colour (maximum 2 points), odour (maximum 7 points), and flavour (maximum 10 points).

2.6. Statistical Analysis

Statistical analyses were performed using Statistica 7 (StatSoft Inc., Tulsa, OK, USA). Significant differences among concentrations of volatile compounds and sensory assessments of plum spirits produced by different methods were determined using one-way ANOVA, for each plum variety. Using the Dunnett’s test (p < 0.05), these characteristics of plum spirits produced by modified methods (M2–M7) were compared with same characteristics in control plum spirit produced by the traditional method (M1). Principal component analysis (PCA) based on the content of 23 volatile compounds (eight higher alcohols, ten esters, three fatty acids, and two aldehydes) was carried out, and cluster analysis based on the content of 23 volatile compounds and based on sensory quality were carried out.

3. Results

Production methods significantly influenced (p < 0.001) the content of most analysed volatile components and the sensory quality of plum spirits from the same variety (Požegača or Stanley, respectively) (results of ANOVA are shown in (Supplementary Materials, Table S1)).

3.1. Components of Plum Spirits Prescribed by Regulation

The contents of the components prescribed by the EU [22] and Serbian [28] regulation were within the permitted limits (methanol ≤ 1200 g/hL 100% vol. ethanol, HCN ≤ 7 g/hL 100% vol. ethanol, and volatile substances ≥ 200 g/hL 100% vol. ethanol), regardless of the method of plum spirit production (the results are shown in Supplementary Materials, Figure S5b–d). All plum spirits, even those from long-stored fermented mashes, contain lower total acids (Supplementary Materials, Figure S5a) than the maximal content (250 g/hL 100% vol. ethanol) prescribed by the last Serbian regulation from 2004 [29], adopted before the harmonization with EU regulations in 2015. However, the contents of methanol and total volatile substances were significantly lower in all varietal plum brandies obtained from the mashes distilled immediately after finishing fermentation (P3–P7 and S3–S7) compared to the control plum spirits (P1 and S1). The same was found for the content of total acids.

3.2. Aromatic Profile of Plum Spirits

According to the current regulation, the volatile substances represent the sum of higher alcohols, volatile fatty acids, esters, and aldehydes. The total volatile substances expressed in this way do not explain much about the aromatic profile of tge fruit spirit, but indicate that it comes from the appropriate raw material—in this case, the plum fruits. However, these compounds crucially affect the sensory characteristics of spirit drinks [6,30].

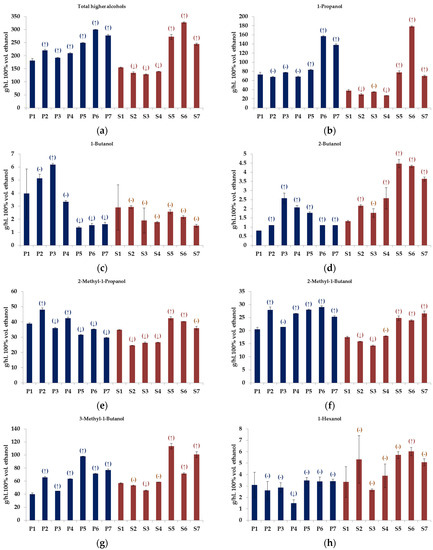

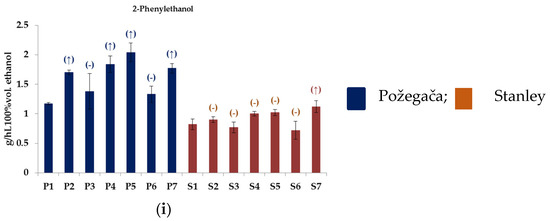

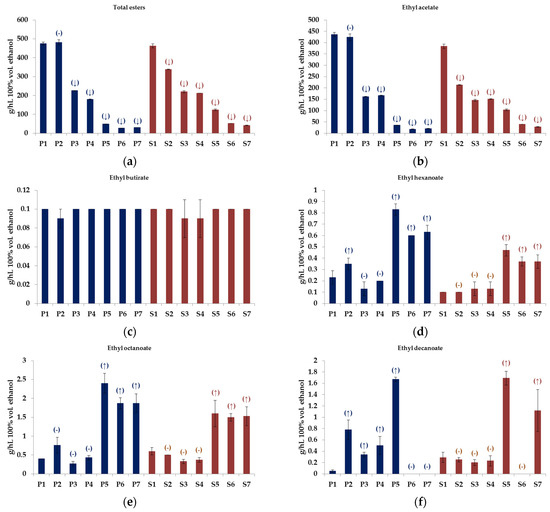

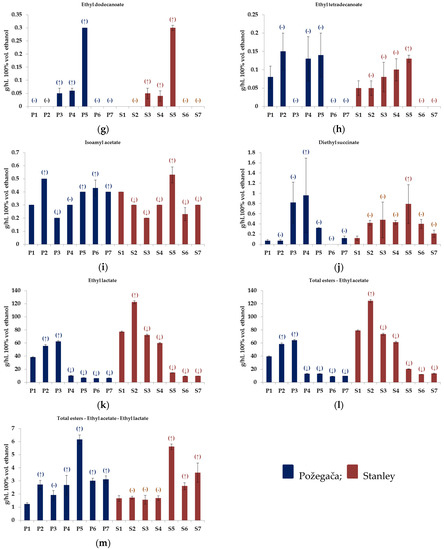

Compared to the traditional method of production (M1), the changes in the content of certain volatile components (Figure 1, Figure 2, Figure 3 and Figure 4), affected by the modification (M2–M7) of the production method of plum spirits, showed the same patterns in both monovarietal spirits.

Figure 1.

Content of higher alcohols (g/hL 100% vol. ethanol) in plum spirits of Požegača (P) and Stanley (S) varieties produced by traditional method (P1 and S1) and modified methods (P2–P7 and S2–S7): (a) TA, (b) A1, (c) A2, (d) A3, (e) A4, (f) A5, (g) A6, (h) A7, and (i) A8. (Codes are listed in Table S1 of Supplementary Materials.) For each plum variety, different marks indicate differences in the means (p < 0.05), according to Dunnett test: (↑) Statistically significant higher values compared to values in traditionally produced plum spirit, (↓): Statistically significant lower values compared to values in traditionally produced plum spirit, (-): No statistically significant differences in values compared to values in traditionally produced plum spirit. Concentrations of all parameters are shown as mean ± standard deviation.

Figure 2.

Content of esters (g/hL 100% vol. ethanol) in plum spirits of Požegača (P) and Stanley (S) varieties produced by traditional method (P1 and S1) and modified methods (P2–P7 and S2–S7): (a) TE, (b) E1, (c) E2, (d) E3, (e) E4, (f) E5, (g) E6, (h) E7, (i) E8, (j) E9, (k) E10, (l) TE-E1, and (m) TE-E1-E10. (Codes are listed in Table S1 of Supplementary Materials.) For each plum variety, different marks indicate differences in the means (p < 0.05), according to Dunnett test: (↑) Statistically significant higher values compared to values in traditionally produced plum spirit, (↓): Statistically significant lower values compared to values in traditionally produced plum spirit, (-): No statistically significant differences in values compared to values in traditionally produced plum spirit. Concentrations of all parameters are shown as mean ± standard deviation.

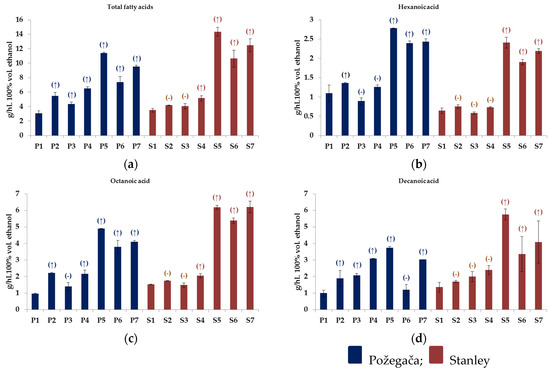

Figure 3.

Content of fatty acids (g/hL 100% vol. ethanol) in plum spirits of Požegača (P) and Stanley (S) varieties produced by traditional method (P1 and S1) and modified methods (P2–P7 and S2–S7): (a) TFA, (b) FA1, (c) FA2, and (d) FA3. (Codes are listed in Table S1 of Supplementary Materials.) For each plum variety, different marks indicate differences in the means (p < 0.05), according to Dunnett test: (↑) Statistically significant higher values compared to values in traditionally produced plum spirit, (↓): Statistically significant lower values compared to values in traditionally produced plum spirit, (-): No statistically significant differences in values compared to values in traditionally produced plum spirit. Concentrations of all parameters are shown as mean ± standard deviation.

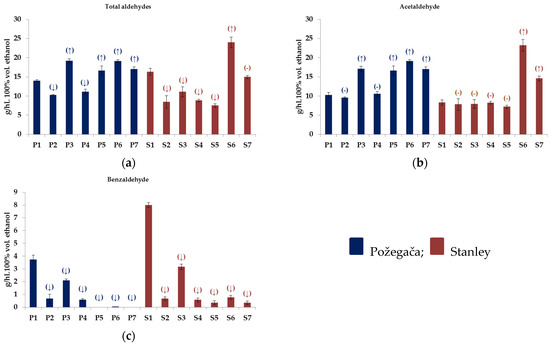

Figure 4.

Content of aldehydes (g/hL 100% vol. ethanol) in plum spirits of Požegača (P) and Stanley (S) varieties produced by traditional method (P1 and S1) and modified methods (P2–P7 and S2–S7): (a) TAd, (b) Ad1, and (c) Ad2. (Codes are listed in Table S1 of Supplementary Materials.) For each plum variety, different marks indicate differences in the means (p < 0.05), according to Dunnett test: (↑) Statistically significant higher values compared to values in traditionally produced plum spirit, (↓): Statistically significant lower values compared to values in traditionally produced plum spirit, (-): No statistically significant differences in values compared to values in traditionally produced plum spirit. Concentrations of all parameters are shown as mean ± standard deviation.

All six modified methods of plum spirit production (M2–M7) resulted in a statistically significant decrease in the benzaldehyde (Figure 4c) content in the plum spirits, compared to control (M1).

Five modifications of the traditional method, which included shortening the storage time of the fermented mash (M3–M7), led to a significant decrease in the contents of ethyl acetate (Figure 2b) and total esters (Figure 2a) in the plum spirits. Plum spirits produced from destoned mashes (M2, M4, M5, M6, and M7) contained significantly higher concentrations of 2-butanol (Figure 1d) than traditionally produced plum spirits (M1). Furthermore, if the plum spirits were obtained from destoned mash distilled immediately after fermentation (M4, M5, M6, and M7), the contents of ethyl lactate (Figure 2k) and total esters-EtAc (Figure 2l) decreased significantly, while their contents increased if the destoned mash is distilled two months after fermentation finished (M2).

Plum spirits obtained from the destoned mash distilled immediately after fermentation (four modifications—M4, M5, M6, and M7) contained significantly higher concentrations of octanoic acid (Figure 3c) and total fatty acids (Figure 3a) than traditional plum spirits (M1).

It is interesting that only plum spirits produced from spontaneously fermented mashes, distilled immediately after fermentation (three modifications—M3, M4, and M5) contained more ethyl dodecanoate (Figure 2g) than those produced by the traditional method. Compared to traditional plum spirits (M1), all plum spirits produced from pulped mashes without stones (modifications M5, M6, and M7), regardless of the microbial flora causing alcoholic fermentation, contained more 1-propanol, 2-methyl-1-butanol, 3-methyl-1-butanol, and total higher alcohols (Figure 1a,b,f,g), as well as ethyl hexanoate, ethyl octanoate, total esters-EtAc-EtLac (Figure 2d,e,m), and hexanoic acid (Figure 3b).

By using commercial yeast strains for the fermentation of pulped mashes (two modifications—M6 and M7), plum spirits with a significantly higher concentration of acetaldehyde (Figure 4b) than in the traditional methods were obtained. Furthermore, during the processing of pulped plums, the spontaneous fermentation or inoculation of mash with commercial strain S. cerevisiae Montrachet (M5 and M7) resulted in a significantly higher concentration of decanoic acid (Figure 3d) in the plum spirits than in traditionally produced ones. In the case of isoamyl acetate, a lower concentration of this ester was found in plum spirits produced by modification M3, but higher concentrations were found in plum spirits obtained using M5 method, compared to traditionally produced plum spirits (M1).

Only the M3 modification led to a significant decrease in the concentration of 2-methyl-1-propanol (Figure 1e) in both monovarietal plum spirits, compared to the traditionally produced plum spirits. Method M5 influenced an increase in the concentration of ethyl decanoate (Figure 2f), while method M7 resulted in an increase in the concentration of 2-phenylethanol (Figure 1i).

Among the 23 analysed compounds (eight higher alcohols, ten esters, three fatty acids, and two aldehydes), different patterns of concentration changes in the monovarietal plum spirits produced by the same method from the two plum varieties were found only for four compounds: 1-butanol and 1-hexanol (Figure 1c,h), as well as ethyl tetradecanoate and diethyl succinate (Figure 2h,j). Only the content of ethyl butyrate (Figure 2c) in the plum spirits was not significantly affected by modifications of the traditional production method.

3.3. OAV of Volatiles in Plum Spirits

Regardless of the production method, the concentrations of four higher alcohols (2-methyl-1-propanol, 2-methyl-1-butanol, 3-methyl-1-butanol, and 2-phenylethanol), five esters (ethyl acetate, ethyl butyrate, ethyl hexanoate, ethyl octanoate, and isoamyl acetate), decanoic acid, and acetaldehyde in plum spirits were higher than their odour thresholds (Table 2). Hence, they had OAVs > 1 and contributed to the sensory characteristics of all plum spirits. The processing method highly influenced the occurrence of multiple differences in OAVs of certain volatiles. The OAVs of ethyl acetate (characterized by a fresh, fruity odour at lower concentrations, i.e., solvent-like and glue-like odour at higher concentrations) were up to 20 times higher in plum spirits from mashes distilled two months after fermentation finishing (M1 and M2) than in plum spirits obtained from methods M3–M7. In addition, the OAVs of ethyl hexanoate and ethyl octanoate (both are characterized by a fruity, brandy-like odour) were several times higher in plum spirits obtained from pulped plum mashes (M5–M7), especially from spontaneously fermented pulped mashes (M5), than in plum spirits from crushed plum mashes.

Table 2.

Odour activity values (OAVs) of volatile compounds in plum spirits obtained by traditional (M1) and modified (M2–M7) production methods.

On the other hand, the OAVs of some volatiles in plum spirits can be higher than 1 only if certain pre-distillation steps in their production were applied. Thus, he OAVs of ethyl lactate (fruity, butter-like odour) were higher than 1 in most of plum spirits obtained from spontaneously fermented crushed plum mashes (methods M1–M4). On the contrary, if plum spirits were produced from pulped plum mashes (methods M5–M7), the OAVs of hexanoic acid (fresh odour at lower concentrations, and rancid, stable-like odour at higher concentrations) and octanoic acid (fresh odour, and if excessive, a rancid, goat-like odour) were always higher than 1, and several times higher than in plum spirits obtained from crushed plums. The OAVs of benzaldehyde were always greater than 1 in plum spirits obtained from mashes with stones (methods M1 and M3); in addition, the OAVs of this compound were two times higher in plum spirits obtained from M1 (longer storage of the fermented mash with stones) than in samples from M3.

Volatiles, such as 1-propanol and 1-hexanol, had OAVs between 0.2 and 1.0 in most plum spirits, so they only partially contributed to the aroma. The 1-Butanol, 2-butanol and ethyl tetradecanoate did not contribute to the plum spirits’ aroma because their OAVs < 0.2 in all samples.

3.4. Sensory Evaluation

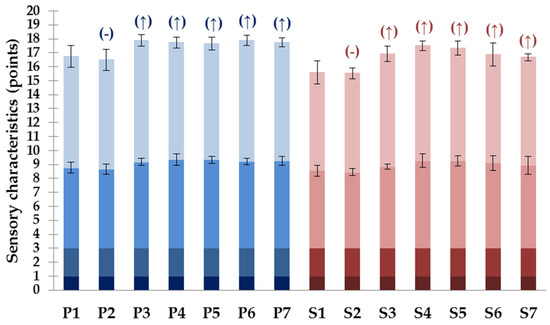

All plum spirits produced from mashes distilled immediately after fermentation (M3–M7) had significantly higher sensory scores than traditional plum spirits produced from long-stored mashes (M1) (Figure 5). Among them, all five plum spirits of the Požegača variety (P3–P7) and only two plum spirits of the Stanley variety (S4 and S5) can be described as products of very good sensory quality, considering that they had sensory scores in the range of 17.0–18.4. Other plum spirits (S3, S6, and S7), graded with less than 17.0 points, had an average quality.

Figure 5.

Sensory analysis of plum spirits of Požegača (P) and Stanley (S) varieties produced by traditional process (P1 and S1) and modified process (P2–P7 and S2–S7). Four rectangles from the darkest to the lightest shades of blue (Požegača) and red (Stanley) represent the clearness, colour, odour, and taste of plum spirits. For each plum variety, different marks indicate differences in the means of total sensory quality (p < 0.05), according to Dunnett test: (↑) Statistically significant higher values compared to values in traditionally produced plum spirit, (↓): Statistically significant lower values compared to values in traditionally produced plum spirit, (-): No statistically significant differences in values compared to values in traditionally produced plum spirit. Values of all sensory characteristics are shown as mean ± standard deviation.

It should be emphasized that the two best-graded plum spirits from both varieties were obtained by different processing methods: by methods M6 (grade 17.90) and M3 (17.88) from Požegača; and by M4 (17.50) and M5 (17.33) from Stanley. Three of them were obtained from a spontaneously fermented mash (P3, S4, and S5), whereas one from the mash fermented by commercial yeast (P6). Furthermore, three plum spirits were obtained from the mash without stones (P6, S4, and S5), and one from the mash with stones (P3). In addition to the effects of stones and yeasts, among these best-graded brandies of both varieties, two were produced from crushed (P3 and S4) and two from pulped plums (P6 and S5).

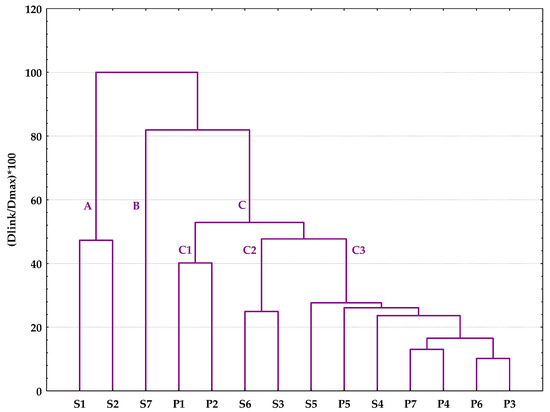

3.5. Cluster Analysis

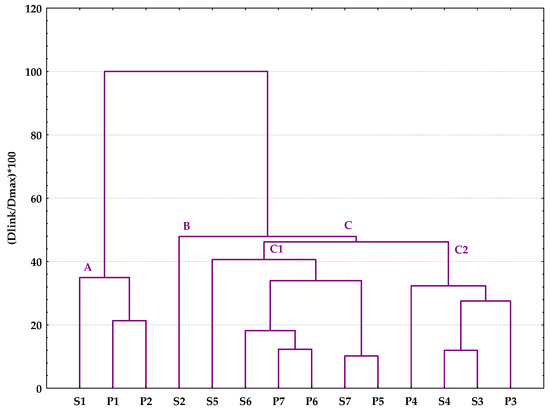

The cluster analysis based on the concentrations of the 23 volatile substances (Figure 6) showed that the plum spirits were separated into three main clusters (A, B, and C). Cluster A contained plum spirits obtained by the distillation of long-stored mashes (P1, P2, and S1), characterized by the concentration of ethyl acetate > 350 g/hL 100% vol. ethanol. The second (B) and third (C) clusters included plum spirits with a concentration of ethyl acetate less than 250 g/hL 100% vol. ethanol. Cluster B only contained plum spirit S2. Within cluster C, divided into two sub-clusters (C1 and C2), there were plum spirits obtained from the mash distilled immediately after fermentation. C1 included all plum spirits from pulped fruits of both varieties (P5–P7 and S5–S7). Sub-cluster C2 contained plum spirits produced from crushed fruits (P3–P4 and S3–S4).

Figure 6.

Dendrogram obtained by the cluster analysis for all 14 plum spirits based on the contents of 23 examined volatile components.

The cluster analysis based on the plum spirits’ sensory grade (Figure 7) gave a somewhat different grouping. Clusters A (samples S1 and S2) and B (sample S7) included plum spirits made of the Stanley variety with sensory scores < 17.00. Cluster C was divided into three sub-clusters. C1 included Požegača spirits (P1 and P2) made of plum mashes distilled 2 months after fermentation. Cluster C2 included Stanley plum spirits (S3 and S6) with sensory grades less than 17.00, but close to this value. In a separate sub-cluster (C3) were grouped the plum spirits from mashes distilled immediately after fermentation with sensory grades > 17.00 (P3, P4, P5, P6, P7, S4, and S5).

Figure 7.

Dendrogram obtained by the cluster analysis based on the sensory assessment of 14 plum spirits.

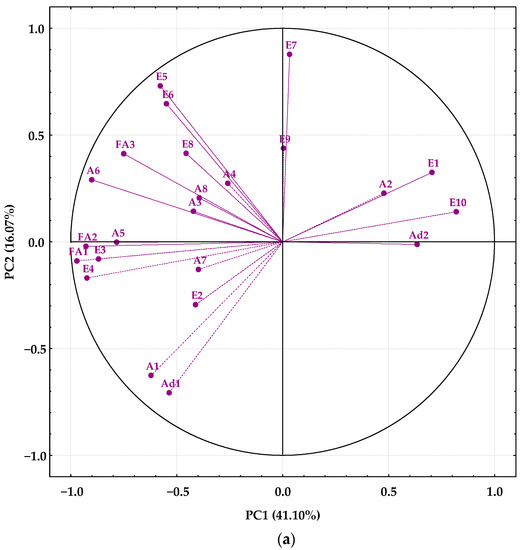

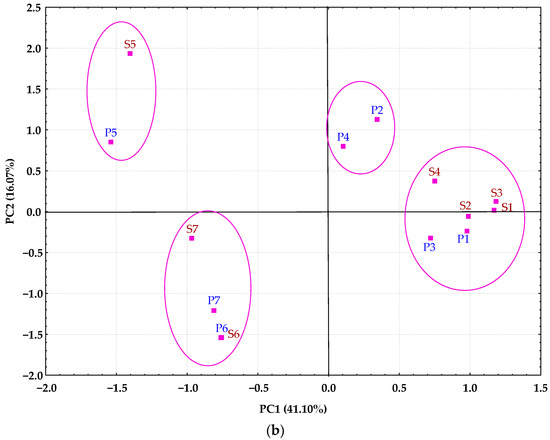

3.6. Principal Component Analysis

The PCA was applied to determine how plum spirits obtained by different methods are grouped based on the concentration of the 23 volatiles. The first two principal components explain 57.17% (41.10% and 16.07%, respectively) of the total variance (Figure 8).

Figure 8.

Principal component analysis (PCA) calculated on 23 volatile compounds. (a) Variable loadings. Codes of components are shown in Table S1; (b) Sample scores. Plum spirits of Požegača (P) and Stanley (S) varieties produced by traditional process (P1 and S1) and modified methods (P2–P7 and S2–S7).

The PC1 was characterized by higher concentrations of 1-butanol (Code A2; codes of volatile components are shown in the Supplementary Materials, Table S1), ethyl acetate (Code E1), ethyl lactate (Code E10), and benzaldehyde (Code Ad2) in the positive loading of this axis, and by higher concentrations of most of the other volatiles in the negative loading of the same axis (Figure 8a). A good separation among plum spirits was observed (Figure 8b). Plum spirits obtained from spontaneously fermented crushed plums (P1–P4 and S1–S4), regardless of mash distillation moment, forms the first group, situated on the positive side of PC1. A second group, situated on the negative side of PC1, is formed by the plum spirits obtained from pulped plums (P5–P7 and S5–S7).

On the negative side of PC1, the second principal component (PC2) showed ethyl decanoate (Code E5), ethyl dodecanoate (Code E6), and ethyl tetradecanoate (Code E7) in the positive loading of axis PC2, and 1-propanol (Code A1) and acetaldehyde (Code Ad1) in the negative loading of the same axis (Figure 8a). Based on this, it follows that two groups can be visualized: plum spirits obtained from the pulped plum mash fermented by commercial yeast strains (P6–P7 and S6–S7) formed one group and plum spirits from the spontaneously fermented pulped plums (P5 and S5) formed the second group (Figure 8b).

4. Discussion

The effect of the processing method on the concentrations of the components that are prescribed by regulation (methanol, HCN, and volatile substances), and concentrations of total acids in plum spirits were in accordance with the results of our previous works [5,12]. Fruit pectin demethylation begins during plum fruit mashing and continues during alcoholic fermentation and the storage of fermented plum mash until distillation [7,15]. Therefore, a long-term storage of the fermented mash, that is characteristic of the traditional way of plum spirit production, leads to a significant increase in the content of methanol in the final product. All modifications of the traditional method that involved the shortening of the fermented mash storage time consenquently lowered the concentration of methanol in the plum spirit. In the plum spirit production, HCN is formed from cyanogenic glycosides—mainly from amygdalin (present in the stone kernel) and prunasin (present in the fruit pulp). The removing of stones in the processing of crushed plums had a statistically significant effect on the reduction of the HCN content in plum spirits obtained from the Požegača variety, which is in agreement with the results of other authors [9]. However, the removing of stones in the processing of the Stanley variety did not significantly affect the decrease in HCN content in the plum spirits compared to the traditionally produced one. A similar finding was reported by Schehl et al. [6] for the variety Ersinger.

The plum processing method affected the contents of most congeners that contribute to the aromatic profile and specific sensory characteristics of spirits. The traditional method of plum spirit production was dominant in Serbia and former Yugoslavia even in the last decades of the 20th century [19,36]. Similar technological methods are used in the traditional production of plum spirit in other European countries [27,37]. In these studies, traditionally produced plum spirits met the legal regulations, but they had high concentrations of total acids, ethyl acetate, and benzaldehyde. It is interesting that the plum spirit of the Požegača variety, produced by the traditional method (P1) in our study, had similar contents of most volatile components such as the traditional home-made plum spirits of the same variety analysed by Filajdić and Djuković [36].

Benzaldehyde in plum spirit originated mostly from cyanogenic glycoside—amygdalin present in stone. This can explain the significantly lower content of this compound in the plum spirits obtained from the mashes without stones. In addition, if the plums were processed without removing the stones, the longer the storage of the mashes with stones until distillation, the higher the concentrations of benzaldehyde in the plum spirits [38].

A continuous contact of the mash surface layers with air during the traditional plum fermentation and long storage in open vessels creates favourable conditions for the massive growth of acetic acid bacteria and larger formation of volatile acids than during the use of closed vessels [39]. A similar result was found during the inadequate and long-lasting storage of wine and cider intended for distillation [40,41]. Filajdić and Djuković [36] found that acetic acid is the most abundant volatile acid in plum spirits produced traditionally. It was previously observed that traditional plum spirits contained high concentrations (>170 g/hL 100% vol. ethanol) of total acids (with a dominant share of acetic acid) and had a pronounced acidic flavour [5,36,42,43]. By mash distillation immediately after fermentation (methods M3–M7), these problems have been overcome. Furthermore, the pulping of plum fruits and addition of selected commercial yeast probably led to the rapid establishment of ellipsoidal yeast dominance over wild yeasts and bacteria in the mash, and the obtained plum spirits contain significantly lower total acid content than plum spirits from spontaneously fermented mashes.

The most abundant ester in the obtained plum spirits was ethyl acetate. Similar to the total acids, the content of this ester was particularly high in traditional plum spirits produced from fermented plum mashes long-stored in aerobic conditions. As previously reported [39,40], this storage way of fermented plum mash or wine intended for distillation resulted in high concentations of these compounds in the fermented medium, due to the massive growth and activity of acetic acid bacteria. Ethyl lactate was the second most abundant ester in plum spirits. In wine spirit production, this ester is formed by lactic acid bacteria simultaneously with alcoholic fermentation and especially during malolactic fermentation in long-stored wines [44]. A similar result was found in long-stored ciders intended for the production of apple cider spirits [41]. Based on the concentrations of ethyl lactate in the plum spirit samples, it was obvious that plum processing methods that involved fruit crushing and spontaneous alcoholic fermentation created favorable conditions for the growth and activity of lactic acid bacteria, both during alcoholic fermentation and fermented mash storage. However, it remains unclear to what degree the high ethyl lactate concentration can be attributed to the long storage of the plum mash, because plum spirits produced from crushed fruits distilled imediatelly after alcoholic fermentation had a high concentration of this ester, similar to plum spirits distilled two months after alcoholic fermentation finished. The lowest contents of ethyl lactate in the plum spirits, compared to traditional ones, were obtained from pulped plum mashes with added selected yeasts, which were distilled immediately after fermentation. These findings coincide with those found by Battaglia et al. [8], who observed that more ethyl lactate was formed in the spontaneously fermenting plum mash than in the mashes fermented by added commercial yeast.

The pulping of plums, as a pre-distillation step, led to significant increases in the concentration of the largest number of compounds in plum spirits compared to the traditionally produced ones. These were mostly compounds (higher alcohols, fatty acids, and ethyl esters of fatty acids) that are formed primarily by the metabolic activity of yeasts. By the fermentation of grape must with the increased content of suspended solid particles, wine spirits with an increased level of higher alcohols have been obtained [44]. Due to a complete disintegration of the plum fruits during pulping, the content of suspended solid particles in the liquid phase of the pulped plum mashes increased (methods M5–M7) compared to the liquid phase of the crushed plum mashes obtained by the traditional method (M1). This could partly explain the higher content of 1-propanol, 3-methyl-1-butanol, and total higher alcohols in the plum spirits from pulped fruits. As previously reported, the inoculation of plum mashes with commercial Saccharomyces cerevisiae strains significantly influenced the higher content of 3-methyl-1-butanol, 1-propanol, and total higher alcohols in fermented plum mashes [8] and plum spirits [20] compared to those obtained by spontaneous fermentation. However, it should be kept in mind that different indigenous Saccharomyces cerevisiae strains isolated from plum mashes can produce certain higher alcohols in a very wide range of concentrations; some strains synthesize in the model fermentation solutions up to four times higher concentrations of 2-methyl-1-propanol and two times higher concentrations of 2/3-methyl-1-butanol than other strains [45]. This could be the explanation for why the contents of 3-methyl-1-butanol were higher in the plum spirits from spontaneously fermented pulped plum mashes than in the plum spirits obtained from pulped plum mashes with added commercial yeast strains. Plum processing methods that include destoning (especially by pulping) and the addition of selected yeasts most likely led to the early dominance of the Saccharomyces cerevisiae strain over the apiculate yeasts in the mash. Saccharomyces cerevisiae strains produce more fatty acid ethyl esters (especially ethyl hexanoate and ethyl octanoate) and volatile fatty acids than apiculate yeasts [30]. With regard to acetaldehyde, the contents of this component that were signifficantly higher in the plum spirits from pulped plums with added commercial yeast strains than in the traditional ones could be explained by the ability of these strains to produce relatively high concentrations of acetaldehyde.

Ethyl acetate, ethyl hexanoate, and ethyl octanoate are volatiles that most commonly exceed their odour threshold in spirit drinks [31]. Ethyl acetate at higher concentrations has a negative effect on the sensory quality of the spirits, so the lowest sensory-graded plum spirits were produced by methods M1 (traditional method) and M2. These samples, with ethyl acetate OAVs mostly >200, had a pronounced solvent-like aroma, and due to the increased content of total volatile acids, they had a very acidic and unpleasant taste. By processing plums with stones, the expressiveness of the stone-like aroma depended not only on the fermented mash storage time, but also on the variety of plum. A pronounced stone-like tone was found in plum spirit S1 (benzaldehyde OAV = 8.57), and a discretely pronounced stone-like odour in P1 (benzaldehyde OAV = 4.00) and S3 (benzaldehyde OAV = 3.40), whereas panelists registered only a slightly expressed stone-like tone in P3 (benzaldehyde OAV = 2.25).

Correlation analysis showed (all data not shown) that, among all analysed components, there was a statistically significant negative correlation between the sensory grade and concentrations of few plum spirit congeners, such as total acids (r = −0.57), ethyl acetate (r = −0.58), ethyl lactate (r = −0.67), and benzaldehyde (r = −0.54), and a significant positive correlation only between sensory grade and 2-phenylethanol content (r = 0.54). The disadvantage of the Buxbaum method used for sensory assessment is that it only allows the classification of plum spirits into several quality groups, but does not allow us to define their aromatic profiles. For producers of plum spirits, it is of crucial importance that they know how to adapt the method of processing plum varieties in order to obtain the best sensory quality of the plum spirit. Although the plum spirits produced by methods M3–M7 were rated better than the traditional ones, the fine nuances in their sensory quality could be the decisive factor that determines the final choice of the production method.

Four best-graded plum spirits of both varieties (P3 and P6, as well as S4 and S5), produced using different combinations of the pre-distillation steps, had very similar sensory grades but very different aroma profiles. The ethyl acetate and ethyl lactate OAVs were several times higher in plum spirits obtained from crushed fruits (P3 and S4) than in plum spirits from pulped fruits (P6 and S5). Among them, the highest benzaldehyde OAV was in sample P3, produced from mash with stones. These findings are consistent with research showing that ethyl lactate and benzaldehyde are important aroma components of traditionally produced plum spirits [46]. At the same time, plum spirits obtained from crushed plum mashes (P3 and S4) contain lower concentrations of ethyl hexanoate and ethyl octanoate than plum spirits produced from pulped plum mashes (P6 and S5). Gao et al. [35] found that, regardless of the high OAV of ethyl octanoate, its contribution to the fruity note of spirit drinks’ aroma is not so important as the contribution of ethyl acetate and ethyl lactate. Samples P3 and S4 were characterized by a varietal, fresh, rich, and pleasant fruity odour, with a well-balanced stone-like aroma (only in P3 sample), that is close to the sensory character of traditional plum spirit. The spirits from pulped fruits (P6 and S5) had multiple higher OAVs for some fatty acid ethyl esters (fruity odour) and isoamyl acetate (banana-like odour), giving them a light fruity character. The tastes of the four best-graded samples were harmonious and pleasantly fresh, and in the case of the Požegača samples (P3 and P6), full-bodied, rounded, and sweet-ish.

The grouping of samples based on the cluster analysis and PCA confirmed the previous chemical and sensory analysis of plum spirits. In other words, based on these analyses, it is possible to distinguish between plum spirits produced using different technological procedures. The lowest sensory-graded samples had the highest contents of total acids and ethyl acetate, as well as benzaldehyde, if the plums were processed without removing stones. Furthermore, the addition of commercial wine yeast strains did not contribute to a better sensory quality in spirits from the Stanley variety, whereas in Požegača, it had a positive effect. In the samples of the Stanley variety, obtained from mashes without stones, spontaneous fermentation (S4 and S5) caused a somewhat higher content of ethyl acetate, ethyl lactate, and some fatty acid ethyl esters, which probably resulted in a softer and more pleasant aroma tone compared to the aroma of samples S6 and S7. If the commercial yeast strains are used for fermentation, the compatibility of the yeast strain and plum variety should be experimentally determined.

5. Conclusions

Compared to the plum spirits distilled from traditionally long-stored mashes (methods M1 and M2), all processing methods that involve a reduced storage time of the fermented mash (methods M3–M7) caused a significant reduction in total volatile acids, methanol, ethyl acetate, total esters, benzaldehyde and total volatile substances in plum spirits. By this simple modification, the obtained plum spirits had better sensory characteristics (odour and taste) than plum spirits produced by the traditional method.

Plum spirits obtained by processing plums without stones (methods M2 and M4–M7) always had significantly lower benzaldehyde contents than traditional plum spirits produced of plums with stones (methods M1 and M3). In processing plums without stones, by the distillation of mashes immediately after the completed fermentation (methods M4–M7), the obtained plum spirits contained less ethyl lactate and total ester-EtAc than spirits from traditionally mashes stored for two months.

Pulping as a common pre-distillation step used in modern plum spirit production (methods M5–M7) resulted in spirits with higher contents of 1-propanol, 2-methyl-1-butanol, 3-methyl-1-butanol, total higher alcohols, hexanoic acid, ethyl hexanoate, ethyl octanoate, and total esters-EtAc-EtLac compared to plum spirits traditionally obtained from crushed plums.

The PCA based on the concentration of the 23 volatiles had shown that the plum spirits produced from pulped fruits without stones can be clearly distinguished from the plum spirits produced from crushed fruits with or without stones.

Based on sensory differences between the spirits, it can be generally concluded that, for obtaining plum spirits with the most pleasant sensory characteristics, a processing method must be adapted according to the variety. In terms of the sensory evaluations of plum spirits, the best results for the Požegača variety were obtained with modifications M3 and M6, while for the Stanley variety, they were modifications M4 and M5. This shows that with a carefully selected production method, high-quality plum spirits with an aromatic profile close to traditional plum spirits (P3 and S4) can be obtained, on the one hand; or high-quality plum spirits with a lighter, fruity character (P6 and S5) can be obtained, on the other. In this way, it would be possible for distilleries, using small changes in the production method, to offer the market different types of plum spirits that could satisfy the tastes of consumers with different preferences.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/pr11030863/s1, Figure S1: Plum processing; Figure S2: Plum mash without stones; Figure S3: Alcoholic fermentation of plum mash; Figure S4: Kinetics of alcoholic fermentation of plum mashes; Table S1: Results of one-way ANOVA (production method) performed for each parameter; Figure S5: Content of total acids and ingredients prescribed by legal regulations (HCN, methanol, total volatile ingredients) in plum spirits of Požegača (P) and Stanley (S) varieties produced by traditional process (P1 and S1) and modified process (P2–P7 and S2–S7).

Author Contributions

Conceptualization, B.P. and N.N.; methodology, B.P. and V.T.; validation, O.M., N.M. and S.M.; formal analysis, B.P. and I.U.; investigation, B.P., I.U. and S.M.; resources, B.P., V.T., O.M. and I.U.; data curation, N.M.; writing—original draft preparation, B.P., S.M. and N.M.; writing—review and editing, N.N. and V.T.; visualization, N.M.; supervision, N.N. and B.P.; project administration, S.M. and O.M.; funding acquisition, S.M. and B.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Ministry of Science, Technological Development, and Innovation of the Republic of Serbia (grant number 451-03-47/2023-01/200215).

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank the technical support of Mirjana Pajić and Aleksandra Korićanac. The authors also thank the members of the tasting panel.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pieper, H.J.; Bruchmann, E.W.; Kolb, E. Technologie der Obstbrennerei, 2nd ed.; Eugen Ulmer GmbH & Co.: Stuttgart, Germany, 1993; pp. 118–123. [Google Scholar]

- Mišić, P.D.; Ranković, M. Šljivarstvo Jugoslavije. Jugosl. Voćar. 2002, 36, 89–100. [Google Scholar]

- Nikićević, N. Srpska šljivovica; Univerzitet u Beogradu Poljoprivredni Fakultet: Beograd, Serbia, 2014; pp. 207–274. [Google Scholar]

- Milatović, D. Šljiva; Naučno Voćarsko Društvo Srbije: Čačak, Serbia, 2019; pp. 15–49. [Google Scholar]

- Popović, B.; Nikićević, N.; Gavrilović-Damnjanović, J.; Mitrović, O.; Srećković, M.; Ogašanović, D. Uticaj momenta destilacije prevrelog kljuka šljive na kvalitet šljivovice. Voćarstvo 2009, 43, 107–118. [Google Scholar]

- Schehl, B.; Lachenmeier, D.; Senn, T.; Heinisch, J.J. Effect of the stone content on the quality of plum and cherry spirits produced from mash fermentations with commercial and laboratory yeast strains. J. Agric. Food Chem. 2005, 53, 8230–8238. [Google Scholar] [CrossRef] [PubMed]

- Paunović, R. Uticaj izazivača i uslova izvođenja alkoholne fermentacije voćnog kljuka na sastav voćnih rakija. Arh. Poljopr. Nauke 1991, 52, 171–183. [Google Scholar]

- Battaglia, R.; Beck, R.; Kenel, A. Die bildung von ethylcarbamat bei der vergärung von zwetschgenmaischen. Mitt. Gebiete Lebensm. Hyg. 1988, 79, 343–353. [Google Scholar]

- Ljekočević, M. Effects of stone-fruit species and cultivars on potential content of prussic acid and benzaldehyde in brandies. Rev. Res. Work. Fac. Agric. 1993, 38, 119–127. [Google Scholar]

- Lachenmeier, D.; Schehl, B.; Kuballa, T.; Frank, W.; Senn, T. Retrospective trends and current status of ethyl carbamate in German stone-fruit spirits. Food Addit. Contam. 2005, 22, 397–405. [Google Scholar] [CrossRef]

- Weltring, A.; Rupp, M.; Arzberger, U.; Rothenbücher, L.; Koch, H.; Sproll, C.; Lachenmeier, D. Ethylcarbamat: Auswertung von Fragebögen zur Erhebung von Steinobsbränden bei Kleinbrennereien. Deut. Lebensm. Rundsch. 2006, 102, 97–101. [Google Scholar]

- Popović, B.; Nikićević, N.; Gavrilović-Damnjanović, J.; Mitrović, O.; Ogašanović, D. Uticaj izazivača alkoholnog vrenja kljuka šljive bez koštica na kvalitet šljivovice. Voćarstvo 2007, 41, 165–172. [Google Scholar]

- Balcerek, M.; Szopa, J. Ethanol biosynthesis and hydrocyanic acid liberation during fruit mashes fermentation. Czech J. Food Sci. 2012, 30, 144–152. [Google Scholar] [CrossRef]

- Bindler, F.; Laugel, P. Le probleme de la limitation du methanol dans les eaux-de-vie de fruits. Ann. Fals. Exp. Chim. 1989, 82, 423–434. [Google Scholar]

- Nikićević, N.; Tešević, V. Possibilities for methanol content reduction in plum brandy. J. Agric. Sci. 2005, 50, 49–60. [Google Scholar]

- Zhang, H.; Woodadams, E.E.; Hang, Y.D. Factor affecting the methanol content and yield of plum brandy. J. Food Sci. 2012, 77, 79–82. [Google Scholar] [CrossRef] [PubMed]

- Dürr, P. Einmaischen zum Brennen. Schweiz. Z. Obs. -Weinbau 2000, 14, 333–336. [Google Scholar]

- Tupajić, P.; Čmelik, Z.; Boljat, M.; Družić, J. Uticaj uvjeta vrenja na kakvoću rakije od šljive cv Elena (Prunus domestica L.). Pomol. Croat. 2007, 13, 31–40. [Google Scholar]

- Nikićević, N. Aromatični Sastojci šljive Požegače i šljivove Prepečenice Proizvedene od Istoimene Sorte; Univerzitet u Beogradu Poljoprivredni Fakultet: Beograd, Srbija, 2010; pp. 181–285. [Google Scholar]

- Satora, P.; Tusziński, T. Influence of indigenous yeasts on the fermentation and volatile profile of plum brandies. Food Microbiol. 2010, 27, 418–424. [Google Scholar] [CrossRef]

- Ivanović, S.; Simić, K.; Tešević, V.; Vujisić, L.; Ljekočević, M.; Gođevac, D. GC-FID-MS Based Metabolomics to Access Plum Brandy Quality. Molecules 2021, 26, 1391. [Google Scholar] [CrossRef]

- Regulation (EC) No 110/2008 of the European Parliament and of the Council of 15 January 2008 on the Definition, Description, Presentation, Labelling and Protection of Geographical Indications of Spirit Drinks and Repealing Council Regulation (EEC) No 1576/89. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008R0110&from=EN (accessed on 11 February 2023).

- Pravilnik o metodama uzimanja uzoraka i vršenja hemijskih i fizičkih analiza alkoholnih pića No 70/87. Službeni List. SFRJ 1987, 70, 1646–1663.

- Senn, T. Der Einfluß der Filtration auf das Aroma von Spirituosen. Getränkeindustrie 1998, 4, 220–226. [Google Scholar]

- Salo, P.; Nykänen, L.; Suomalainen, H. Odor thresholds and relative intensities of volatile aroma components in an artificial beverage imitating whisky. J. Food Sci. 1972, 37, 394–398. [Google Scholar] [CrossRef]

- Tešević, V.; Nikićević, N.; Jovanović, A.; Djoković, D.; Vujisić, L.J.; Vučković, I.; Bonić, M. Volatile components from old plum brandies. Food Technol. Biotechnol. 2005, 43, 367–372. [Google Scholar]

- Satora, P.; Tuszyński, T. Chemical characteristics of Śliwowica Łącka and other plum brandies. J. Sci. Food Agric. 2008, 88, 167–174. [Google Scholar] [CrossRef]

- Zakon o jakim alkoholnim pićima No 92/15. Službeni List. RS 2015, 92, 1–45.

- Pravilnik o kvalitetu i drugim zahtevima za alkoholna pića No 24/04. Službeni List. SCG 2004, 24, 3–9.

- Nykänen, L.; Nykänen, I. Distilled beverages. In Volatile Compounds in Foods and Beverages; Marse, H., Ed.; Marcel Dekker, Inc.: New York, NY, USA, 1991; pp. 547–580. [Google Scholar]

- Christoph, N.; Bauer-Christoph, C. Flavour of spirit drinks: Raw materials, fermentation, distillation, and aging. In Flavour and Fragrances; Berger, R.D., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 219–239. [Google Scholar]

- Willner, B.; Granvogl, M.; Schieberle, P. Characterization of the key aroma compounds in Bartlett pear brandies by means of the sensomics concept. J. Agric. Food Chem. 2013, 61, 9583–9593. [Google Scholar] [CrossRef] [PubMed]

- Pino, J.A.; Tolle, S.; Gök, R.; Winterhalter, P. Characterisation of odour-active compounds in aged rum. Food Chem. 2012, 132, 1436–1441. [Google Scholar] [CrossRef] [PubMed]

- Pino, J.A.; Fajardo, M. Volatile composition and key flavour compounds of spirits from unifloral honeys. Int. J. Food Sci. Technol. 2011, 46, 994–1000. [Google Scholar] [CrossRef]

- Gao, W.; Fan, W.; Xu, Y. Characterization of the key odorants in light aroma type Chinese liquor by gas chromatography−olfactometry, quantitative measurements, aroma recombination, and omission studies. J. Agric. Food Chem. 2014, 62, 5796–5804. [Google Scholar] [CrossRef]

- Filajdić, M.; Djuković, J. Gas-chromatographic determination of volatile constituents in Yugoslav plum brandies. J. Sci. Food Agric. 1973, 24, 835–842. [Google Scholar] [CrossRef]

- Rusu Coldea, T.E.; Socaciu, S.; Parv, M.; Vodnar, D. Gas-Chromatographic Analysis of Major Volatile Compounds found in Traditional Fruit Brandies from Transylvania, Romania. Not. Bot. Horti. Agrobot. 2011, 39, 109–116. [Google Scholar] [CrossRef]

- Paunović, R.; Nikićević, N. Poreklo cijanovodonične kiseline, benzaldehida i etil karbamata u voćnim rakijama. Zbornik Radova Poljoprivrednog Fakulteta 1988, 34, 109–124. [Google Scholar]

- Rašić, J. Prilog izučavanju alkoholne fermentacije šljiva pri njihovoj preradi u šljivovicu. Zbornik Radova Poljoprivrednog Fakulteta 1954, 1, 33–48. [Google Scholar]

- Benda, I. Wine and brandy. In Prescott and Dunn’s Industrial Microbiology, 4th ed.; Reed, G., Ed.; AVI Technical Books Inc.: Westport, CT, USA, 1982; pp. 293–402. [Google Scholar]

- Rodrigues-Madrera, R.; Picinelli-Lobo, A.; Mangas-Alonso, J.J. Effect of cider maturation on the chemical and sensory characteristics of fresh cider spirits. Food Res. Int. 2010, 43, 70–78. [Google Scholar] [CrossRef]

- Majstorović, G. Prerada šljive u Rakiju; Zavod za Izdavanje Udžbenika SRS: Beograd, Srbija, 1969; pp. 91–95. [Google Scholar]

- Gavrilović-Damnjanović, J.; Mitrović, O.; Mitrović, V. Prilog proučavanju kvaliteta rakije od šljive. Jugosl. Voćar. 1997, 31, 381–386. [Google Scholar]

- Cantagrel, R.; Lurton, L.; Vidal, J.P.; Galy, B. From vine to Cognac. In Fermented Beverage Production; Lea, A.G.H., Piggott, J.R., Eds.; Springer Science + Business Media: Dordrecht, The Netherlands, 1995; pp. 208–228. [Google Scholar]

- Satora, P.; Tusziński, T.; Tomczyk, E. Enological profile of Saccharomyces cerevisiae yeast isolated from fermenting plum mashes. Acta Sci. Pol. Technol. Aliment. 2010, 9, 33–44. [Google Scholar]

- Crowell, E.A.; Guymon, J.F. Aroma constituents of plum brandy. Am. J. Enol. Vitic. 1973, 24, 159–165. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).