Shear Strength Performance of Electrokinetic Geosynthetics Treated Soft Clay after Water Immersion

Abstract

:1. Introduction

2. Materials and Test Schemes

2.1. Materials

2.2. Test Schemes

3. Results

3.1. Electric Current, Vacuum Degree and Water Discharge

3.2. Effect of Water Immersion on Soil Water Content

3.3. Effect of Water Immersion on Soil Shear Strength

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tant, K.; Craig, W.H. Bearing capacity of circular foundations on soft clay of strength increasing with depth. Soils Found. 1995, 35, 21–35. [Google Scholar] [CrossRef]

- Cai, Y.Q.; Guo, L.; Jardine, R.J.; Yang, Z.X.; Wang, J. Stress–strain response of soft clay to traffic loading. Geotechnique 2017, 67, 446–451. [Google Scholar] [CrossRef]

- Hinchberger, S.D.; Rowe, R.K. Geosynthetic reinforced embankments on soft clay foundations: Predicting reinforcement strains at failure. Geotext. Geomembr. 2003, 21, 151–175. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Z.; Zhang, Y.; El Naggar, M.H.; Wu, T.; Wen, M. Semi-analytical solution for negative skin friction development on deep foundations in coastal reclamation areas. Int. J. Mech. Sci. 2023, 241, 107981. [Google Scholar] [CrossRef]

- Cui, C.; Meng, K.; Xu, C.; Wang, B.; Xin, Y. Vertical vibration of a floating pile considering the incomplete bonding effect of the pile-soil interface. Comput. Geotech. 2022, 150, 104894. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, Y. A Review of Pile Foundations in Viscoelastic Medium: Dynamic Analysis and Wave Propagation Modeling. Energies 2022, 15, 9432. [Google Scholar] [CrossRef]

- Saowapakpiboon, J.; Bergado, D.T.; Youwai, S.; Chai, J.C.; Wanthong, P. Measured and predicted performance of prefabricated vertical drains (PVDs) with and without vacuum preloading. Geotext. Geomembr. 2010, 28, 1–11. [Google Scholar] [CrossRef]

- Casagrande, I.L. Electro-osmosis in soils. Geotechnique 1949, 1, 159–177. [Google Scholar] [CrossRef]

- Burnotte, F.; Lefebvre, G.; Grondin, G. A case record of electroosmotic consolidation of soft clay with improved soil electrode contact. Can. Geotech. J. 2004, 41, 1038–1053. [Google Scholar] [CrossRef]

- Wang, D.Y.; Tang, C.S.; Cui, Y.J.; Shi, B.; Li, J. Effects of wetting–drying cycles on soil strength profile of a silty clay in micro-penetrometer tests. Eng Geol. 2016, 206, 60–70. [Google Scholar] [CrossRef]

- Martin, L.; Alizadeh, V.; Meegoda, J. Electro-osmosis treatment techniques and their effect on dewatering of soils, sediments, and sludge: A review. Soils Found. 2019, 59, 407–418. [Google Scholar] [CrossRef]

- Xiao, F.; Guo, K.; Zhuang, Y. Study on electroosmotic consolidation of sludge using EKG. Int. J. Geosynth. Groun. 2021, 7, 1–11. [Google Scholar] [CrossRef]

- Wu, Y.; Xu, Y.; Zhang, X.; Lu, Y.; Chen, G.; Wang, X.; Song, B. Experimental study on vacuum preloading consolidation of landfill sludge conditioned by Fenton’s reagent under varying filter pore size. Geotext. Geomembr. 2021, 49, 109–121. [Google Scholar] [CrossRef]

- Wang, J.; Cai, Y.; Fu, H.; Hu, X.; Cai, Y.; Lin, H. Experimental study on a dredged fill ground improved by a two-stage vacuum preloading method. Soils Found. 2018, 58, 766–775. [Google Scholar] [CrossRef]

- Leonards, G.A. Investigation of failures. J. Geotech. Eng. Div. 1982, 108, 187–246. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, J.-Q.; Bian, K.; Wu, Y. Thermodynamic-based cross-scale model for structural soil with emphasis on bond dissolution. Can. Geotech. J. 2022, 59, 1–11. [Google Scholar] [CrossRef]

- Stark, T.D.; Duncan, J.M. Mechanisms of strength loss in stiff clays. J. Geotech. Eng. 1991, 117, 139–154. [Google Scholar] [CrossRef]

- Estabragh, A.R.; Parsaei, B.; Javadi, A.A. Laboratory investigation of the effect of cyclic wetting and drying on the behaviour of an expansive soil. Soils Found. 2015, 55, 304–314. [Google Scholar] [CrossRef]

- An, P.; Zhang, A.; Xing, Y.; Zhang, B.; Ni, W.; Ren, W. Experimental study on settling characteristics of thick self-weight collapsible loess in Xinjiang lli region in China using field immersion test. Soils Found. 2018, 58, 1476–1491. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Wang, S.; Wang, Q.; Ding, J. Shear strength and mesoscopic character of undisturbed loess with sodium sulfate after dry-wet cycling. Bull. Eng. Geol. Environ. 2020, 79, 1523–1541. [Google Scholar] [CrossRef]

- Lu, Q.; Liu, Y.; Peng, J.; Li, L.; Fan, W.; Liu, N.; Sun, K.; Liu, R. Immersion test of loess in ground fissures in Shuanghuaishu, Shaanxi Province, China. Bull. Eng. Geol. Environ. 2020, 79, 2299–2312. [Google Scholar] [CrossRef]

- Weng, X.; Zhou, R.; Rao, W.; Wang, D. Research on subway shield tunnel induced by local water immersion of collapsible loess. Nat. Hazards 2021, 108, 1197–1219. [Google Scholar] [CrossRef]

- Razouki, S.S.; El-Janabi, O.A. Decrease in the CBR of a gypsiferous soil due to long-term soaking. Q. J. Eng. Geol. Hydrogeol. 1999, 32, 87–89. [Google Scholar] [CrossRef]

- Gasmo, J.M.; Rahardjo, H.; Leong, E.C. Infiltration effects on stability of a residual soil slope. Comput Geotech. 2000, 26, 145–165. [Google Scholar] [CrossRef]

- Hadi, B.A.; Noor, M.J.M.; Ibrahim, A.; Ismail, B.N.; Ahmad, J.; Zakariah, Z. The effect of soaking on shear strength of a Malaysian granitic residual soil. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012049. [Google Scholar] [CrossRef]

- Ying, C.; Hu, X.; Zhou, C.; Siddiqua, S.; Makeen, G.M.H.; Wang, Q.; Xu, C. Analysis of chemo-mechanical behavior of silty soil under long-term immersion in saline reservoir water. Bull. Eng. Geol. Environ. 2021, 80, 627–640. [Google Scholar] [CrossRef]

- Aziz, M.; Sheikh, F.N.; Qureshi, M.U.; Rasool, A.M.; Irfan, M. Experimental study on endurance performance of lime and cement-treated cohesive soil. KSCE J. Civ. Eng. 2021, 25, 3306–3318. [Google Scholar] [CrossRef]

- Sun, Z.; Gao, M.; Yu, X. Vacuum preloading combined with electro-osmotic dewatering of dredger fill using electric vertical drains. Dry. Technol. 2015, 33, 847–853. [Google Scholar]

- Chu, J.; Yan, S.W.; Yang, H. Soil improvement by the vacuum preloading method for an oil storage station. Geotechnique 2000, 50, 625–632. [Google Scholar] [CrossRef]

- Sun, Z.; Yao, K.; Yang, C.; Liang, M. Improvement of soft clay by vacuum preloading incorporated with electroosmosis using electric vertical drains. Mar. Georesour Geotec. 2021, 39, 1339–1349. [Google Scholar] [CrossRef]

- Shang, J.Q.; Lo, K.Y.; Quigley, R.M. Quantitative determination of potential distribution in Stern–Gouy double-layer mode. Can. Geotech. J. 1994, 31, 624–636. [Google Scholar] [CrossRef]

- Van Olphen, H. An introduction to clay colloid chemistry. Soil Sci. 1964, 97, 290. [Google Scholar] [CrossRef]

- Ou, C.Y.; Chien, S.C.; Wang, Y.G. On the enhancement of electroosmotic soil improvement by the injection of saline solutions. Appl. Clay Sci. 2009, 44, 130–136. [Google Scholar] [CrossRef]

| Soil | Specific Gravity a | Water Content (%) b | Liquid Limit (%) c | Plastic Limit (%) c | Chemical Composition (%) d | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | K2O, Na2O | CaO, MgO | Others | |||||

| Clay soil | 2.74 | 4.2 | 45 | 20 | 51 | 24 | 1.6 | 2.8 | 1.3 | 19.3 |

| Treatment Method | Test Number | Initial Soil Water Content (%) | Electrode/Drainage Body | Voltage/Vacuum Degree | Immersion Duration (d) |

|---|---|---|---|---|---|

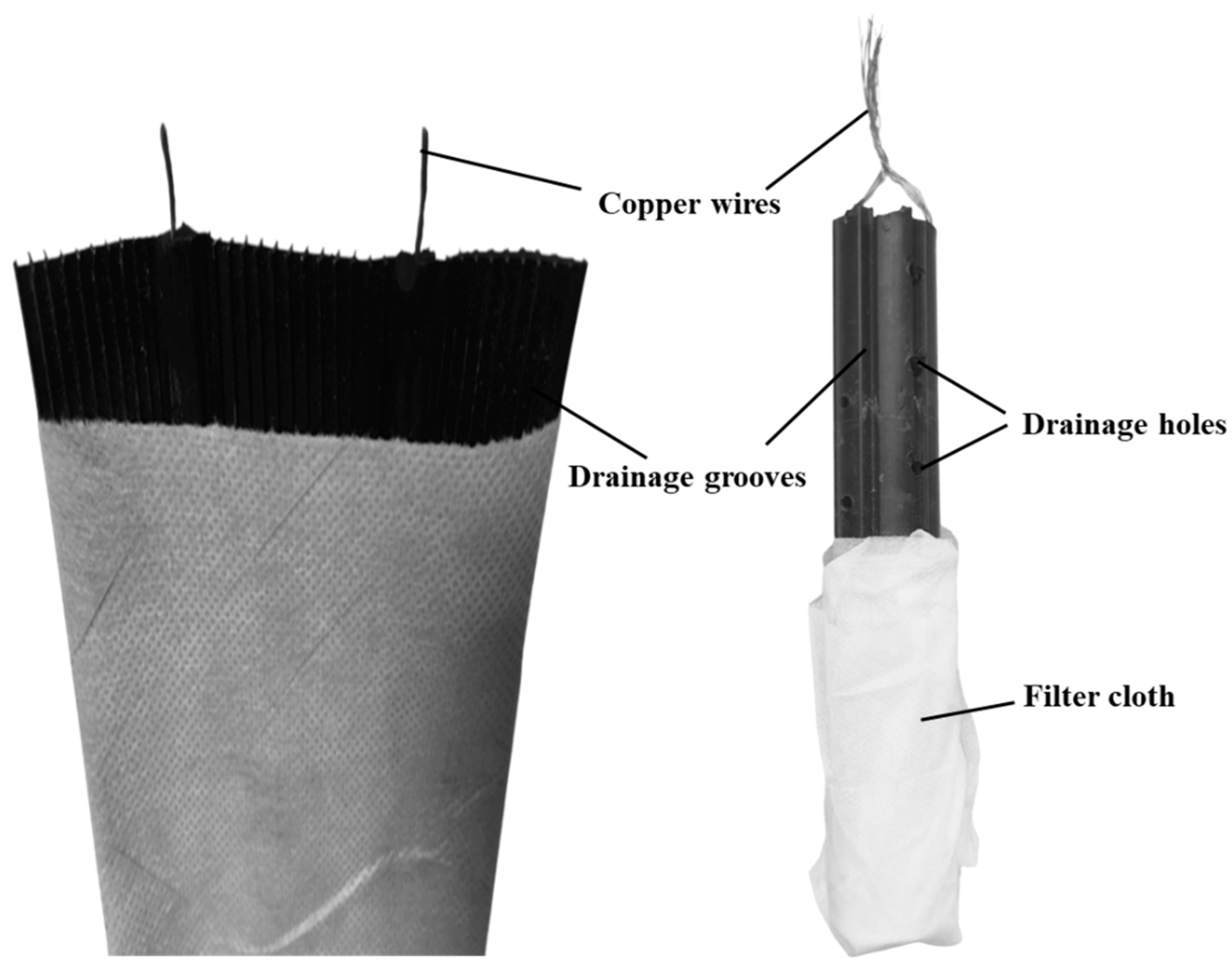

| Electroosmosis | E0 | 48.4 | Flat EKG | 10 V-20 V-30 V-40 V-50 V | 0 |

| E1 | 45.7 | Tubular EKG | 0 | ||

| E2 | 45 | 1 | |||

| E3 | 45 | 5 | |||

| E4 | 46.4 | 10 | |||

| Vacuum preloading | V1 | 46.2 | PVD | 75 kPa | 0 |

| V2 | 43.6 | 80 kPa | 1 | ||

| V3 | 47.6 | 75 kPa | 5 |

| Test Number | No. of Data | Range (%) | Mean (%) | COV (%) |

|---|---|---|---|---|

| E0 | 18 | 27–44 | 36.5 | 13 |

| E1 | 18 | 17–43 | 30.5 | 21 |

| E2 | 18 | 23–43 | 32.6 | 20 |

| E3 | 18 | 25–42 | 33.3 | 17 |

| E4 | 18 | 20–47 | 32.6 | 20 |

| V1 | 21 | 35–42 | 39.4 | 6 |

| V2 | 21 | 36–46 | 39.9 | 7 |

| V3 | 21 | 38–48 | 41.5 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Lu, L.; Gong, J.; Wei, G.; Ye, W. Shear Strength Performance of Electrokinetic Geosynthetics Treated Soft Clay after Water Immersion. Processes 2023, 11, 529. https://doi.org/10.3390/pr11020529

Sun Z, Lu L, Gong J, Wei G, Ye W. Shear Strength Performance of Electrokinetic Geosynthetics Treated Soft Clay after Water Immersion. Processes. 2023; 11(2):529. https://doi.org/10.3390/pr11020529

Chicago/Turabian StyleSun, Zhaohua, Lei Lu, Jian Gong, Guowei Wei, and Wenfeng Ye. 2023. "Shear Strength Performance of Electrokinetic Geosynthetics Treated Soft Clay after Water Immersion" Processes 11, no. 2: 529. https://doi.org/10.3390/pr11020529

APA StyleSun, Z., Lu, L., Gong, J., Wei, G., & Ye, W. (2023). Shear Strength Performance of Electrokinetic Geosynthetics Treated Soft Clay after Water Immersion. Processes, 11(2), 529. https://doi.org/10.3390/pr11020529