Prediction of Clean Coal Ash Content in Coal Flotation through a Convergent Model Unifying Deep Learning and Likelihood Function, Incorporating Froth Velocity and Reagent Dosage Parameters

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Flotation Reagent

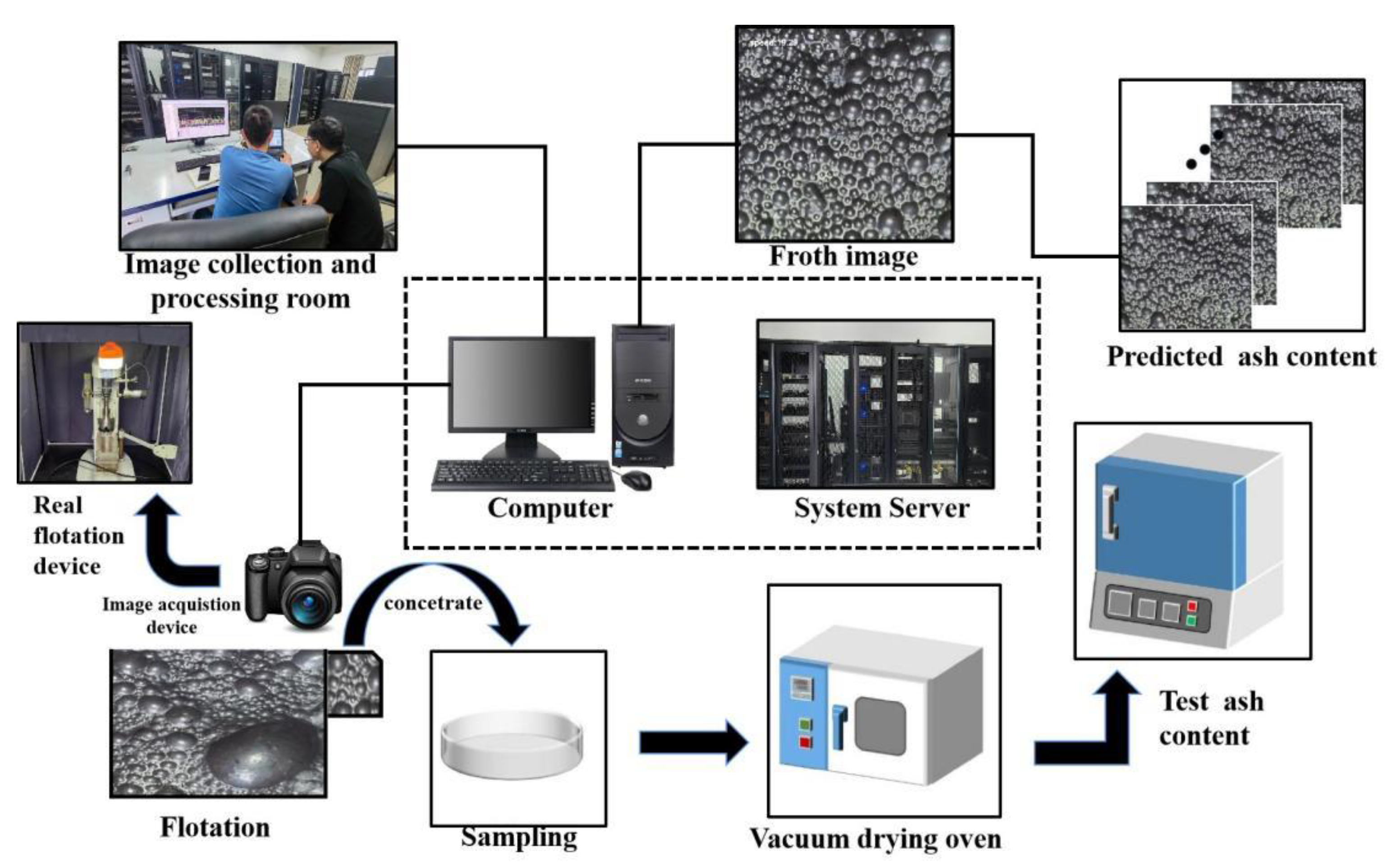

2.3. Data Gathering

3. Methodology and Modeling

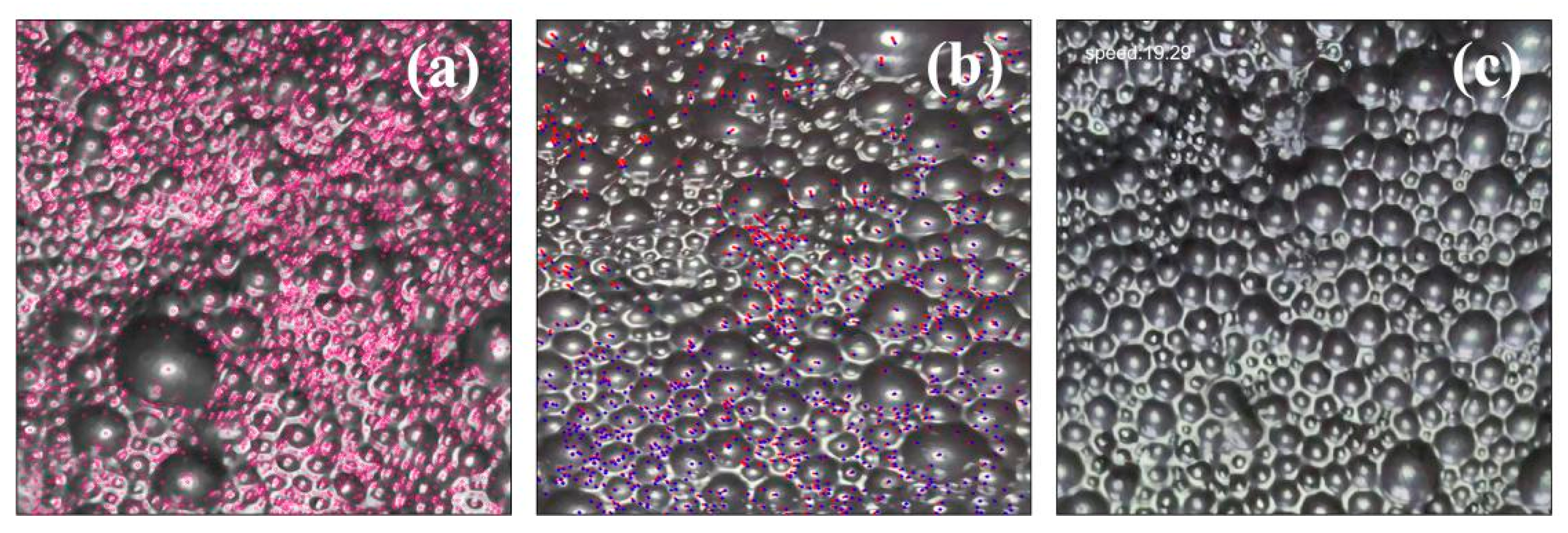

3.1. Modeling of Froth Velocity Feature Extraction

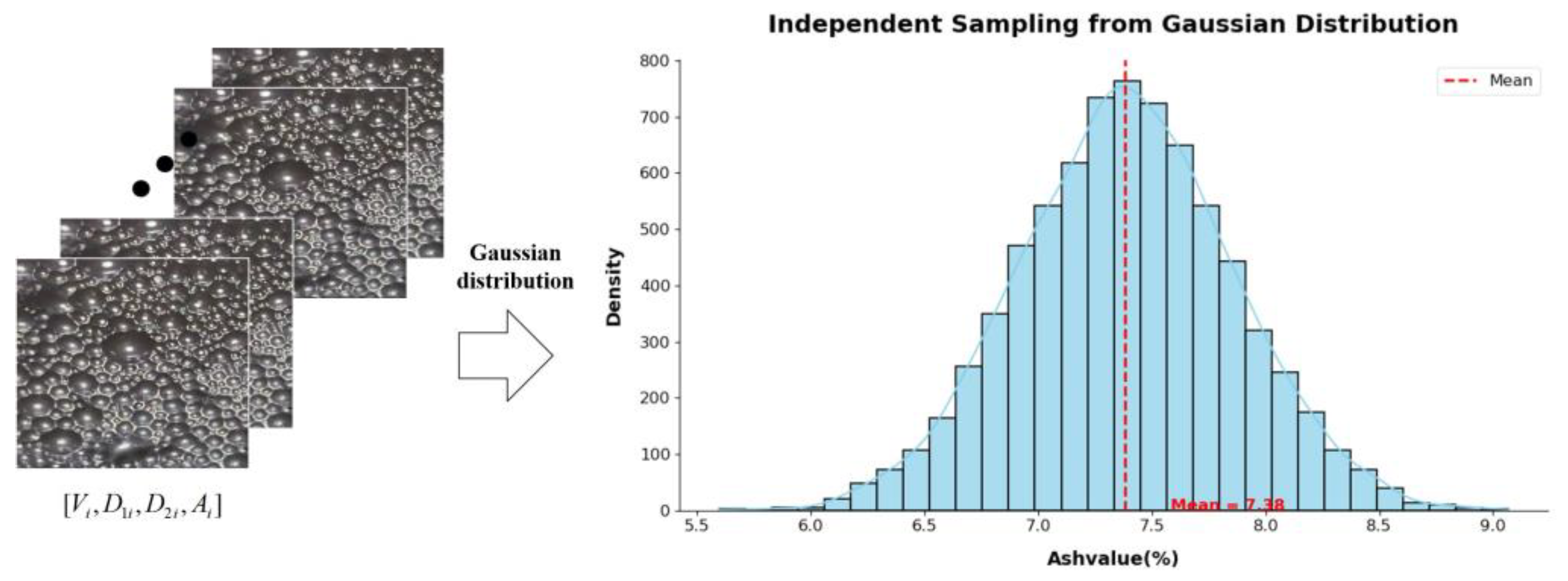

3.2. Likelihood Function Modeling of Froth Velocity and Chemical Additions

3.3. Deep Neural Network Prediction Model with Multi-Feature Input and Hybrid Data Input Using Keras

4. Results and Analysis

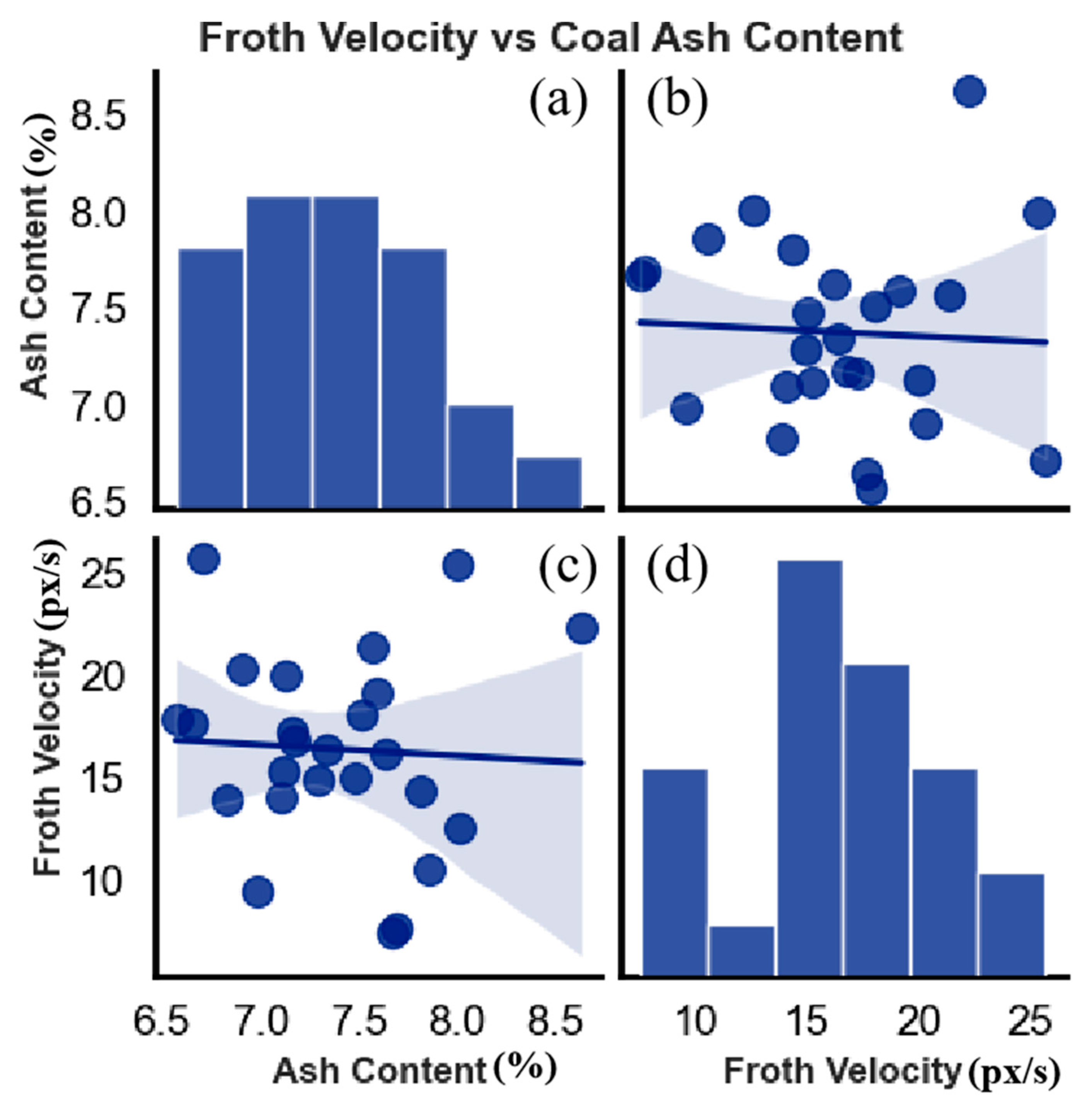

4.1. Dynamic Characterization Parameters of Froth Flotation in Relation to Coal Ash Content

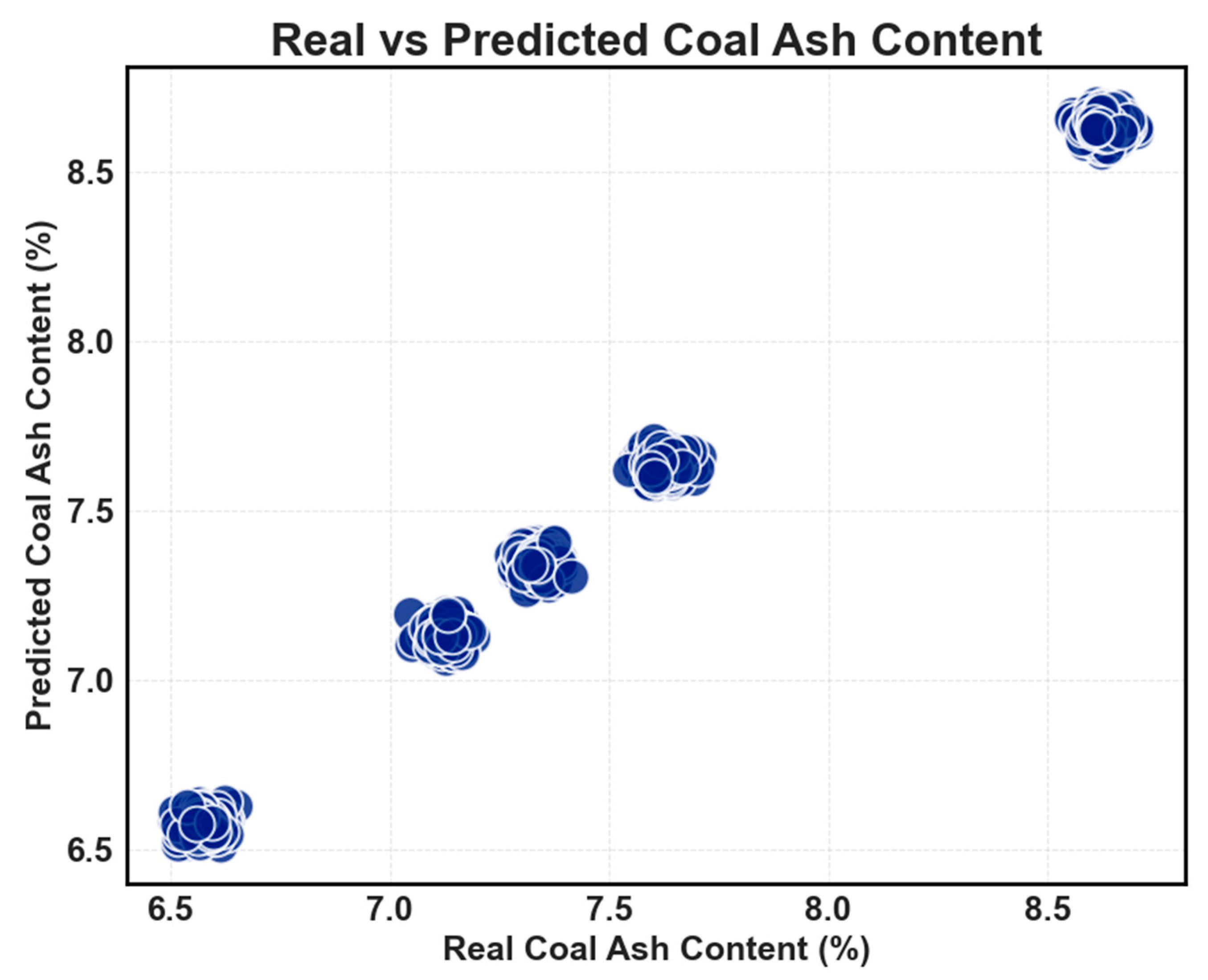

4.2. Froth Flotation Concentrate Coal Ash Content Prediction and Result Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Connotation |

| SIFT | Scale-Invariant Feature Transform |

| XRF | X-ray fluorescence |

| BP | Back Propagation |

| RSM | Response surface methodology |

| ANN | Artificial neural network |

| DNN | Deep neural network |

| CFD | Computational fluid dynamics |

| CNN | Convolutional neural network |

| FRRN | Feature Reconstruction–Regression Network |

| MLE | Maximum likelihood estimation |

| MIBC | 4-Methylpentan-2-ol |

| R2 | Coefficient of Determination |

| RMSE | Root Mean Square Error |

| MAE | Mean Absolute Error |

| MAPE | Mean Absolute Percentage Error |

| RRSE | Relative Root Squared Error |

| MAAPE | Mean Arctangent Absolute Percentage Error |

| PX/S | Pixel/Second |

References

- Jahedsaravani, A.; Marhaban, M.H.; Massinaei, M. Prediction of the metallurgical performances of a batch flotation system by image analysis and neural networks. Miner. Eng. 2014, 69, 137–145. [Google Scholar] [CrossRef]

- Liu, J.; Gao, Q.; Tang, Z.; Xie, Y.; Gui, W.; Ma, T.; Niyoyita, J.P. Online Monitoring of Flotation Froth Bubble-Size Distributions via Multiscale Deblurring and Multistage Jumping Feature-Fused Full Convolutional Networks. IEEE Trans. Instrum. Meas. 2020, 69, 9618–9633. [Google Scholar] [CrossRef]

- Sutherland, J.L.; Dickinson, J.E.; Galvin, K.P. Flotation of coarse coal particles in the Reflux™ Flotation Cell. Miner. Eng. 2020, 149, 106224–106235. [Google Scholar] [CrossRef]

- Yan, Y.; Yang, W.; Fang, X.; Yan, P.; Tu, J. Experimental investigation of multi-phase hydrodynamics and bubble-particle interactions in a Wemco 56 flotation cell. Miner. Eng. 2021, 172, 107115–107126. [Google Scholar] [CrossRef]

- Ni, C.; Bu, X.; Xia, W.; Peng, Y.; Xie, G. Effect of slimes on the flotation recovery and kinetics of coal particles. Fuel 2018, 220, 159–166. [Google Scholar] [CrossRef]

- Tao, D.; Sobhy, A. Nanobubble effects on hydrodynamic interactions between particles and bubbles. Powder Technol. 2019, 346, 385–395. [Google Scholar] [CrossRef]

- Uysal, T.; Guven, O.; Ozdemir, O.; Karaagaclioglu, İ.E.; Tunç, B.; Çelik, M.S. Contribution of particle morphology on flotation and aggregation of sphalerite particles. Miner. Eng. 2021, 165, 106860–106869. [Google Scholar] [CrossRef]

- Cheng, Y.; Min, F.; Li, H.; Chen, J.; Fu, X. Effect of reagent interaction on froth stability of coal flotation. Fuel 2022, 318, 123417–123429. [Google Scholar] [CrossRef]

- Lu, M.; Liu, D.; Deng, Y.; Wu, L.; Xie, Y.; Chen, Z. R-K algorithm: A novel Dynamic Feature Matching Method of flotation froth. Measurement 2020, 156, 107581–107590. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, L.; Li, T.; Tan, J.; Liang, X.; Xie, G. Coal Ash Content Measurement Based on Pseudo-Dual Energy X-ray Transmission. Minerals 2021, 11, 1433–1446. [Google Scholar] [CrossRef]

- Rizk, R.; EI-kateb, A.; Abdul-kader, A.M. On-line nuclear ash gauge for coal based on gamma-ray transmission techniques. J. Radioanal. Nucl. Chem. 1999, 242, 139–145. [Google Scholar] [CrossRef]

- Wen, Z.; Zhou, C.; Pan, J.; Nie, T.; Jia, R.; Yang, F. Froth image feature engineering-based prediction method for concentrate ash content of coal flotation. Miner. Eng. 2021, 170, 107023–107033. [Google Scholar] [CrossRef]

- Pinto, A.M.; Rocha, L.F.; Paulo Moreira, A. Object recognition using laser range finder and machine learning techniques. Robot CIM-INT Manuf. 2013, 29, 12–22. [Google Scholar] [CrossRef]

- Bai, Q.; Li, S.; Yang, J.; Song, Q.; Li, Z.; Zhang, X. Object Detection Recognition and Robot Grasping Based on Machine Learning: A Survey. IEEE Access 2020, 8, 181855–181879. [Google Scholar] [CrossRef]

- Nateghi, H.; Sodeifian, G.; Razmimanesh, F.; Mohebbi Najm Abad, J. A machine learning approach for thermodynamic modeling of the statically measured solubility of nilotinib hydrochloride monohydrate (anti-cancer drug) in supercritical CO2. Sci. Rep. 2023, 13, 12906–12923. [Google Scholar] [CrossRef]

- Jia, R.; Yan, Y.; Lang, D.; He, D.; Li, K. Compression and reconstruction of flotation foam images based on generative adversarial networks. Miner. Eng. 2023, 202, 108299–108311. [Google Scholar] [CrossRef]

- He, M.; Sun, B. On-Line Froth Depth Estimation for Sulphur Flotation Process with Multiple Working Conditions. IEEE Access. 2019, 7, 124774–124784. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Wang, Y.; Dou, D.; Xia, W. Ash content prediction of coarse coal by image analysis and GA-SVM. Powder Technol. 2014, 268, 429–435. [Google Scholar] [CrossRef]

- Aldrich, C.; Avelar, E.; Liu, X. Recent advances in flotation froth image analysis. Miner. Eng. 2022, 188, 107823–107839. [Google Scholar] [CrossRef]

- Massinaei, M.; Jahedsaravani, A.; Taheri, E.; Khalilpour, J. Machine vision based monitoring and analysis of a coal column flotation circuit. Powder Technol. 2019, 343, 330–341. [Google Scholar] [CrossRef]

- Kistner, M.; Jemwa, G.T.; Aldrich, C. Monitoring of mineral processing systems by using textural image analysis. Miner Eng. 2013, 52, 169–177. [Google Scholar] [CrossRef]

- Massinaei, M.; Jahedsaravani, A.; Mohseni, H. Recognition of process conditions of a coal column flotation circuit using computer vision and machine learning. Int. J. Coal Prep. Util. 2020, 42, 2204–2218. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Shirazi, H.H.A.; Massinaei, M.; Mehrshad, N. Modeling the Relationship between Froth Bubble Size and Flotation Performance Using Image Analysis and Neural Networks. Chem. Eng. Commun. 2014, 202, 911–919. [Google Scholar] [CrossRef]

- Wen, Z.; Zhou, C.; Pan, J.; Nie, T.; Zhou, C.; Lu, Z. Deep learning-based ash content prediction of coal flotation concentrate using convolutional neural network. Miner. Eng. 2021, 174, 107251–107260. [Google Scholar] [CrossRef]

- Kalyani, V.K.; Pallavika; Chaudhuri, S.; Gouri Charan, T.; Haldar, D.D.; Kamal, K.P.; Badhe, Y.P.; Tambe, S.S.; Kulkarni, B.D. Study of a Laboratory-Scale Froth Flotation Process Using Artificial Neural Networks. Miner. Process. Extr. Metall. Rev. 2007, 29, 130–142. [Google Scholar] [CrossRef]

- Tang, M.; Zhou, C.; Zhang, N.; Liu, C.; Pan, J.; Cao, S. Prediction of the Ash Content of Flotation Concentrate Based on Froth Image Processing and BP Neural Network Modeling. Int. J. Coal Prep. Util. 2018, 41, 191–202. [Google Scholar] [CrossRef]

- Sodeifian, G.; Sajadian, S.A.; Saadati Ardestani, N. Evaluation of the response surface and hybrid artificial neural network-genetic algorithm methodologies to determine extraction yield of Ferulago angulata through supercritical fluid. J. Taiwan Inst. Chem. Eng. 2016, 60, 165–173. [Google Scholar] [CrossRef]

- Montes-Atenas, G.; Seguel, F.; Valencia, A.; Bhatti, S.M.; Khan, M.S.; Soto, I.; Becerra Yoma, N. Predicting bubble size and bubble rate data in water and in froth flotation-like slurry from computational fluid dynamics (CFD) by applying deep neural networks (DNN). Int. Commun. Heat Mass. Trans. 2016, 76, 197–201. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, Z.; Xie, Y.; Chen, Q.; Gao, X.; Gui, W. Feature Reconstruction-Regression Network: A Light-Weight Deep Neural Network for Performance Monitoring in the Froth Flotation. IEEE Trans. Ind. Inform. 2021, 17, 8406–8417. [Google Scholar] [CrossRef]

- Zhang, P.; Zhu, R.; Chen, J.; Kang, B. A generalized soft likelihood function in combining multi-source belief distribution functions. Appl. Intell. 2021, 52, 3748–3765. [Google Scholar] [CrossRef]

- Tian, Y.; Mi, X.; Liu, L.; Kang, B. A New Soft Likelihood Function Based on D Numbers in Handling Uncertain Information. Int. J. Fuzzy Syst. 2020, 22, 2333–2349. [Google Scholar] [CrossRef]

- Erem, A.; Bilgehan, B.; Özyapıcı, A.; Boratas Sensoy, Z. Further theories on application of new generalized probability density function and its applications. Qual. Reliab. Eng. Int. 2022, 38, 2405–2419. [Google Scholar] [CrossRef]

- Alfonsi, A.; Kebaier, A.; Rey, C. Maximum likelihood estimation for Wishart processes. Stoch. Proc. Appl. 2016, 126, 3243–3282. [Google Scholar] [CrossRef]

- Gong, X.; Jiang, W.; Hu, S.; Yang, Z.; Liu, X.; Fan, Z. Comprehensive utilization of foundry dust: Coal powder and clay minerals separation by ultrasonic-assisted flotation. J. Hazard. Mater. 2021, 402, 124124. [Google Scholar] [CrossRef]

- Jahedsaravani, A.; Massinaei, M.; Zarie, M. Measurement of bubble size and froth velocity using convolutional neural networks. Miner. Eng. 2023, 204, 108400–108414. [Google Scholar] [CrossRef]

- Holtham, P.N.; Nguyen, K.K. On-line analysis of froth surface in coal and mineral flotation using JKFrothCam. Int. J. Miner. Process. 2002, 64, 163–180. [Google Scholar] [CrossRef]

- Yianatos, J.; Panire, I.; Vinnett, L. A new method for flotation rate characterization using top-of-froth grades and the froth discharge velocity. Miner. Eng. 2016, 92, 242–247. [Google Scholar] [CrossRef]

- Hossein-Nejad, Z.; Agahi, H.; Mahmoodzadeh, A. Image matching based on the adaptive redundant keypoint elimination method in the SIFT algorithm. Pattern Anal. Appl. 2020, 24, 669–683. [Google Scholar] [CrossRef]

- Wu, K.-L.; Yang, M.-S. Mean shift-based clustering. Pattern Recogn. 2007, 40, 3035–3052. [Google Scholar] [CrossRef]

- He, Y.; Deng, G.; Wang, Y.; Wei, L.; Yang, J.; Li, X.; Zhang, Y. Optimization of SIFT algorithm for fast-image feature extraction in line-scanning ophthalmoscope. Optik 2018, 152, 21–28. [Google Scholar] [CrossRef]

- Pedrosa, G.V.; Batista, M.A.; Barcelos, C.A.Z. Image feature descriptor based on shape salience points. Neurocomputing 2013, 120, 156–163. [Google Scholar] [CrossRef]

- Li, Z.; Shu, H.; Zheng, C. Multi-Scale Single Image Dehazing Using Laplacian and Gaussian Pyramids. IEEE Trans. Image Process. 2021, 30, 9270–9279. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.-M.; Kao, P.-H. Multiattribute decision making based on nonlinear programming methodology, the Euclidean distance between IVIFVs, and new score function of IVIFVs. Inf. Sci. 2023, 646, 119403–119428. [Google Scholar] [CrossRef]

- Ren, K.; Sun, W.; Meng, X.; Yang, G.; Peng, J.; Huang, J.; Li, J. CDFSL: Image Registration for Spaceborne Hyperspectral and Multispectral Data Having Large Spatial-Resolution Difference. IEEE Trans. Geosci. Remote Sens. 2023, 61, 5515415. [Google Scholar] [CrossRef]

- Chicho, B.T.; Bibo Sallow, A. A Comprehensive Survey of Deep Learning Models Based on Keras Framework. JSCDM 2021, 2, 49–62. [Google Scholar] [CrossRef]

- Conlin, R.; Erickson, K.; Abbate, J.; Kolemen, E. Keras2c: A library for converting Keras neural networks to real-time compatible C. Eng. Appl. Artif. Intel. 2021, 100, 104182–104188. [Google Scholar] [CrossRef]

- Jiang, Z.; Shen, G. Prediction of House Price Based on The Back Propagation Neural Network in The Keras Deep Learning Framework. In Proceedings of the 2019 6th International Conference on Systems and Informatics, Shanghai, China, 2–4 November 2019; pp. 1–5. [Google Scholar]

- Zhang, D.; Wang, S.; Liang, Y.; Du, Z. A novel combined model for probabilistic load forecasting based on deep learning and improved optimizer. Energy 2023, 264, 126172–126187. [Google Scholar] [CrossRef]

| Flotation Machine Operating Parameters | Setting |

|---|---|

| Aeration Rate (m3/(m2·min) | 0.25 |

| Impeller Rotation (r/min) | 1800 |

| Impeller Diameter (mm) | 60 |

| Group | Collector (µL) | Frother (µL) | Initial Bubble Number | Initial Average Bubble Diameter (mm) |

|---|---|---|---|---|

| 1 | 110.63 | 28.98 | 565 | 46 |

| 2 | 33.12 | 312 | 46 | |

| 3 | 37.26 | 534 | 44 | |

| 4 | 41.41 | 763 | 42 | |

| 5 | 45.55 | 645 | 42 | |

| 1 | 119.85 | 28.98 | 705 | 40 |

| 2 | 33.12 | 612 | 45 | |

| 3 | 37.26 | 621 | 41 | |

| 4 | 41.41 | 711 | 42 | |

| 5 | 45.55 | 478 | 48 | |

| 1 | 129.07 | 28.98 | 565 | 48 |

| 2 | 33.12 | 781 | 42 | |

| 3 | 37.26 | 745 | 43 | |

| 4 | 41.41 | 964 | 38 | |

| 5 | 45.55 | 939 | 39 | |

| 1 | 138.29 | 28.98 | 533 | 45 |

| 2 | 33.12 | 514 | 45 | |

| 3 | 37.26 | 477 | 46 | |

| 4 | 41.41 | 777 | 43 | |

| 5 | 45.55 | 750 | 41 | |

| 1 | 147.51 | 28.98 | 265 | 41 |

| 2 | 33.12 | 372 | 47 | |

| 3 | 37.26 | 201 | 38 | |

| 4 | 41.41 | 262 | 47 | |

| 5 | 45.55 | 221 | 36 |

| Delineation Criteria | Number of Pictures |

|---|---|

| Training set | 7500 |

| Validation set | 1500 |

| Collector (µL) | Frother (µL) | Id | Froth Velocity (px/s) | Ash Value (%) |

|---|---|---|---|---|

| 110.63 | 28.98 | 00001.jpg | 8.636 | 6.83 |

| 00002.jpg | 8.723 | 6.83 | ||

| 00003.jpg | 8.683 | 6.83 | ||

| 00004.jpg | 8.785 | 6.83 | ||

| 00005.jpg | 12.669 | 6.83 | ||

| … | … | … | ||

| 00299.jpg | 22.221 | 6.83 | ||

| 00300.jpg | 18.468 | 6.83 | ||

| 33.12 | 00001.jpg | 24.318 | 6.9 | |

| 00002.jpg | 22.261 | 6.9 | ||

| … | … | … | ||

| 00300.jpg | 11.046 | 6.9 | ||

| … | … | … | … | |

| 45.55 | 00001.jpg | 19.31 | 6.65 | |

| 00002.jpg | 17.436 | 6.65 | ||

| … | … | … | ||

| 00300.jpg | 19.691 | 6.65 | ||

| … | … | … | … | … |

| 147.51 | 28.98 | 00001.jpg | 23.493 | 7.13 |

| 00002.jpg | 27.762 | 7.13 | ||

| … | … | … | ||

| 00300.jpg | 12.248 | 7.13 | ||

| … | … | … | … | |

| 45.55 | 00001.jpg | 10.634 | 8.63 | |

| 00002.jpg | 12.151 | 8.63 | ||

| … | … | … | ||

| 00300.jpg | 19.678 | 8.63 |

| Evaluation Criteria | R2 | RMSE | MAE | MAPE | RRSE | MAAPE |

|---|---|---|---|---|---|---|

| Training set | 0.99997 | 0.00218 | 0.00170 | 0.02329 | 0.00994 | 0.00067 |

| Validation set | 0.99992 | 0.00557 | 0.00397 | 0.05552 | 0.00848 | 0.00055 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, F.; Liu, H.; Lv, W. Prediction of Clean Coal Ash Content in Coal Flotation through a Convergent Model Unifying Deep Learning and Likelihood Function, Incorporating Froth Velocity and Reagent Dosage Parameters. Processes 2023, 11, 3425. https://doi.org/10.3390/pr11123425

Lu F, Liu H, Lv W. Prediction of Clean Coal Ash Content in Coal Flotation through a Convergent Model Unifying Deep Learning and Likelihood Function, Incorporating Froth Velocity and Reagent Dosage Parameters. Processes. 2023; 11(12):3425. https://doi.org/10.3390/pr11123425

Chicago/Turabian StyleLu, Fucheng, Haizeng Liu, and Wenbao Lv. 2023. "Prediction of Clean Coal Ash Content in Coal Flotation through a Convergent Model Unifying Deep Learning and Likelihood Function, Incorporating Froth Velocity and Reagent Dosage Parameters" Processes 11, no. 12: 3425. https://doi.org/10.3390/pr11123425

APA StyleLu, F., Liu, H., & Lv, W. (2023). Prediction of Clean Coal Ash Content in Coal Flotation through a Convergent Model Unifying Deep Learning and Likelihood Function, Incorporating Froth Velocity and Reagent Dosage Parameters. Processes, 11(12), 3425. https://doi.org/10.3390/pr11123425