A New Experimental Method for Acid Pretreatment in Perforated Horizontal Wells: A Case Study of Mahu Conglomerate Reservoir

Abstract

:1. Introduction

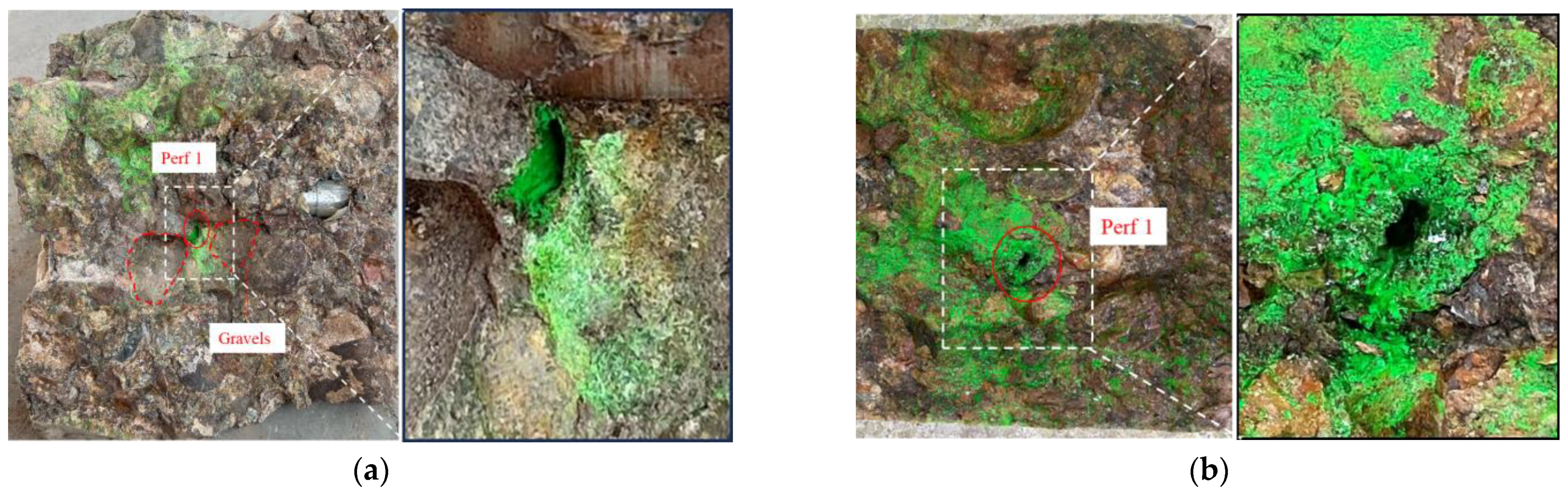

2. New Perforation Method in Rock Samples

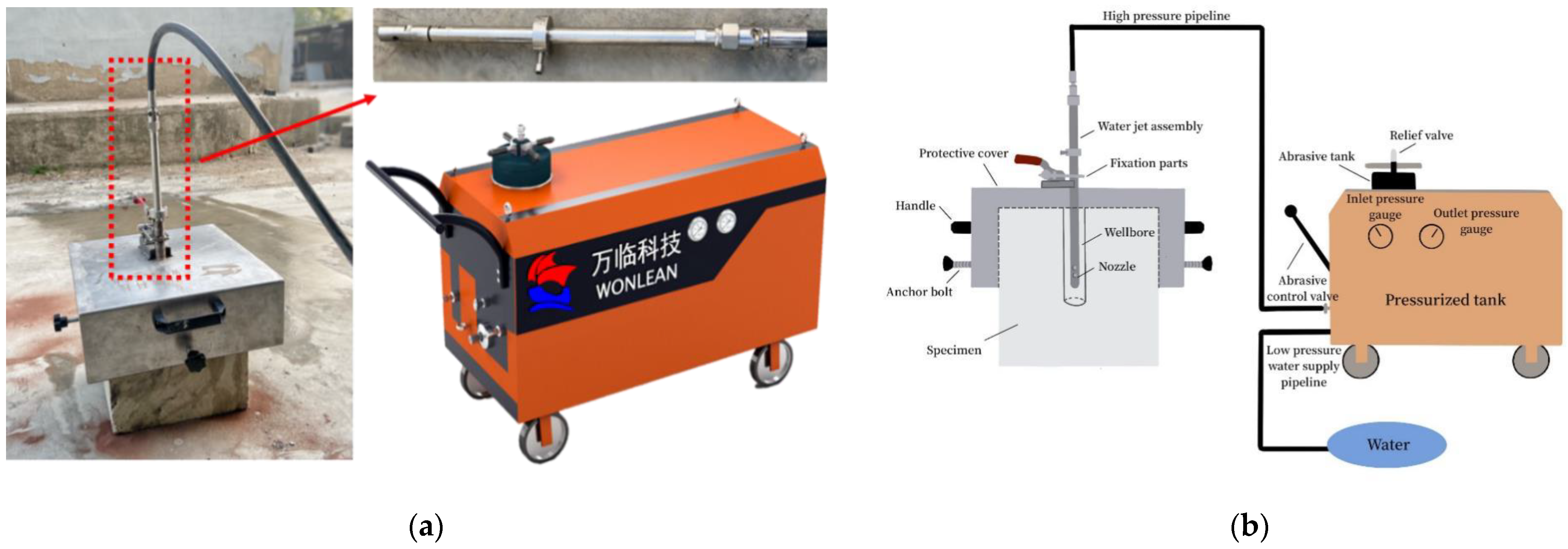

2.1. Perforation Simulation Apparatus

2.2. Reservoir Information

2.3. Specimen Preparation

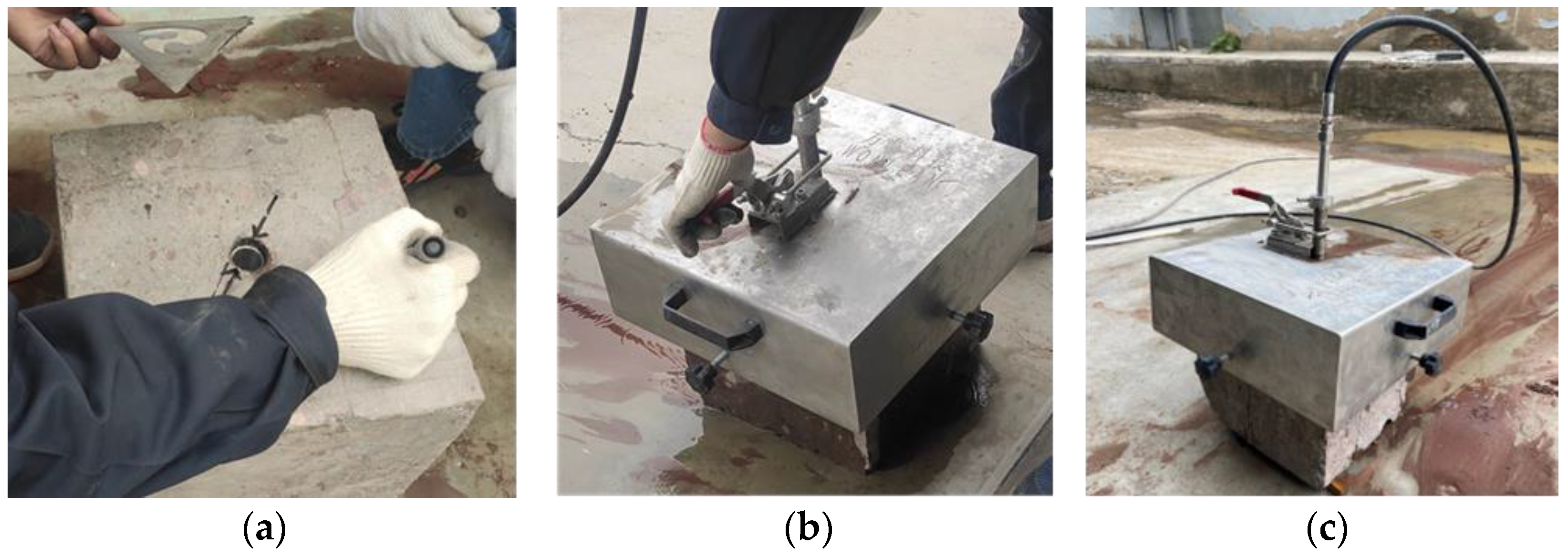

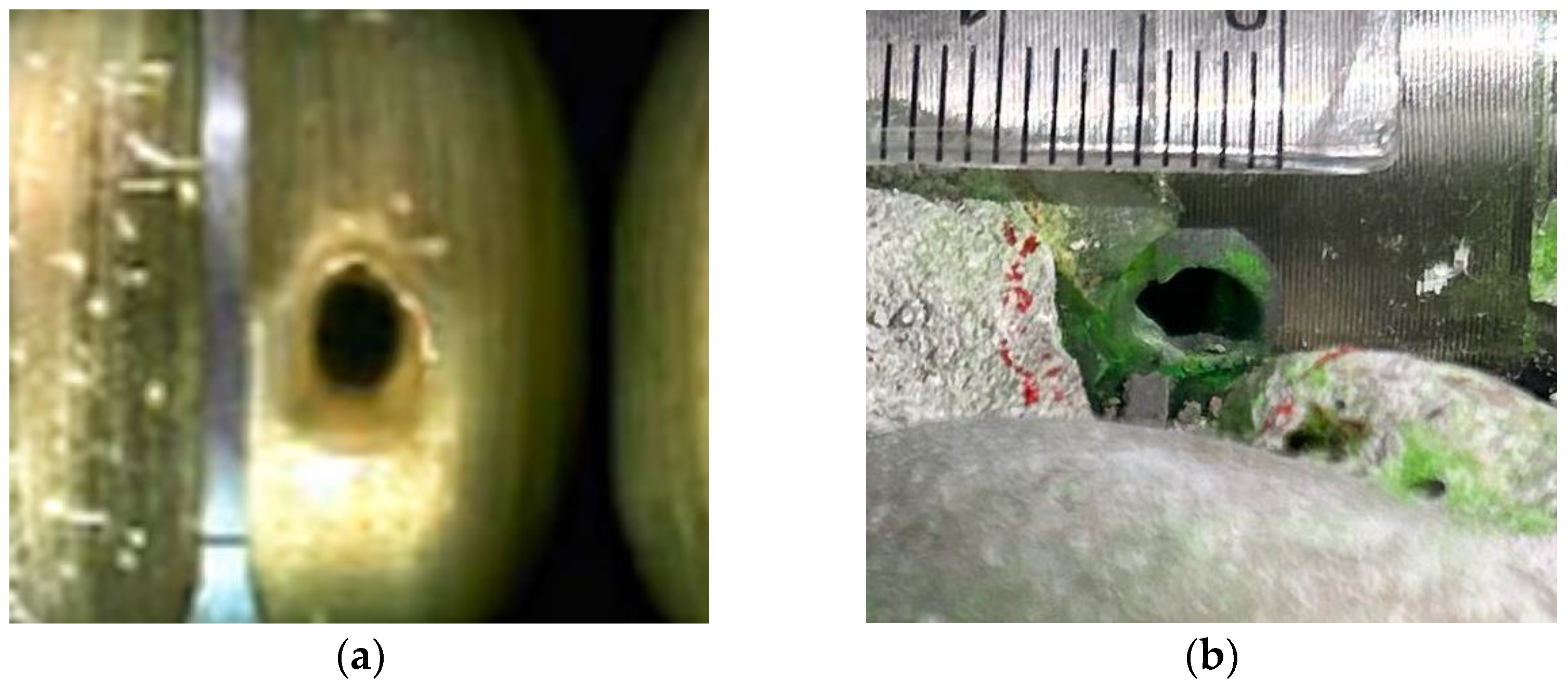

2.4. Perforating Process

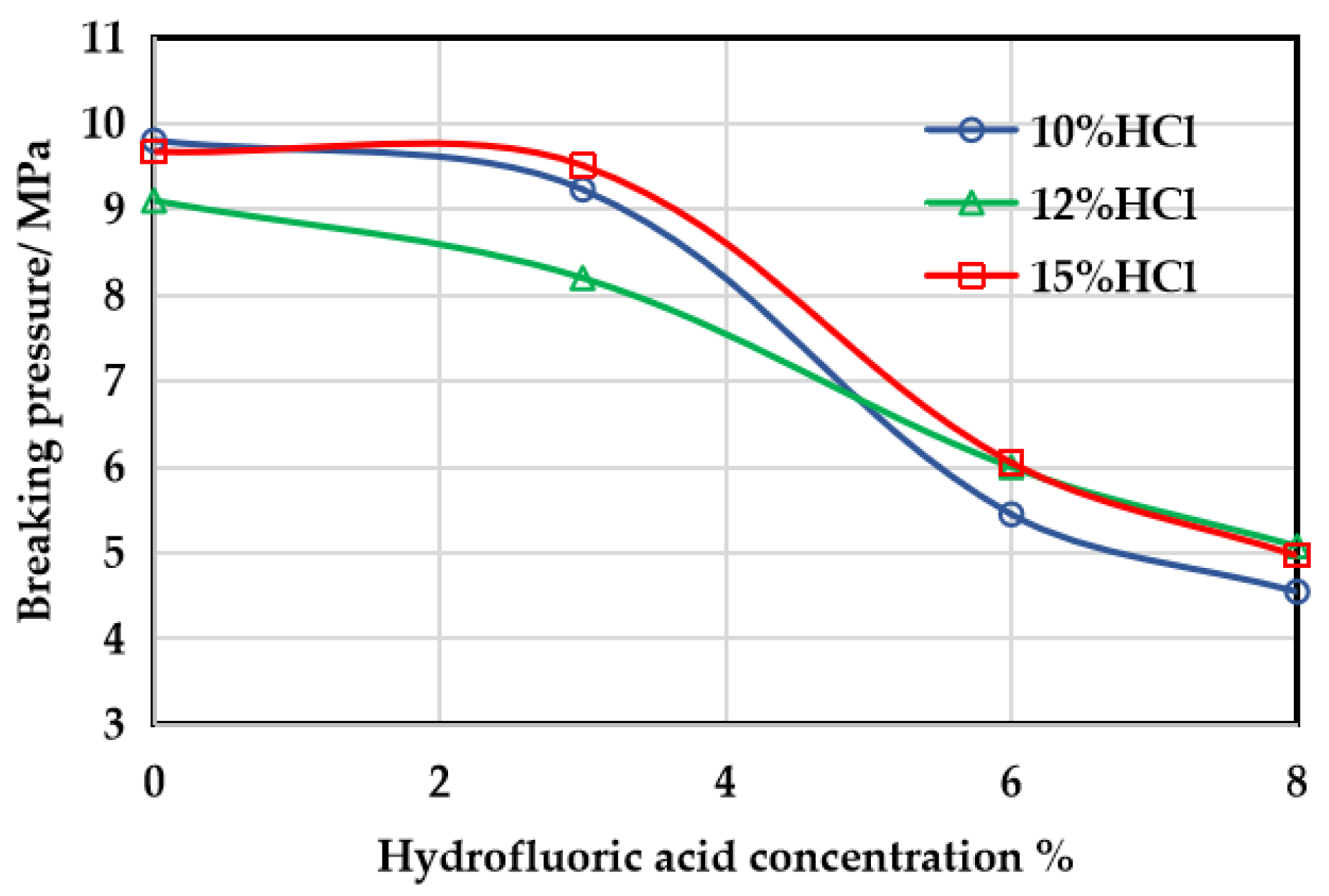

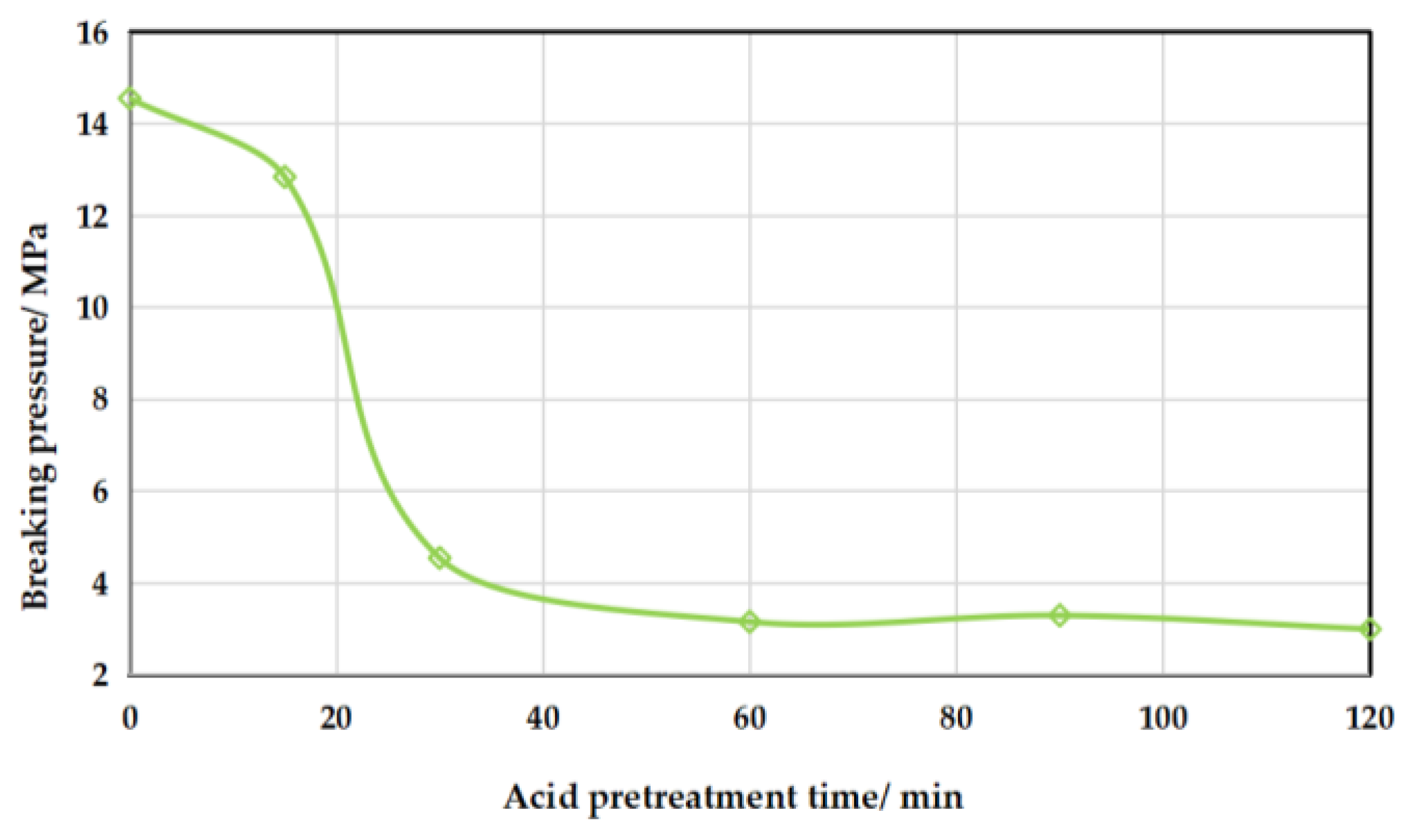

3. Acid Pretreatment for Fracturing

4. Triaxial Hydraulic Fracturing Experiment

4.1. Mineral Composition and Rock Mechanical Properties of Rock Samples

4.2. Triaxial Fracturing Experimental Procedures

4.2.1. Experimental Apparatus

4.2.2. Experimental Procedure

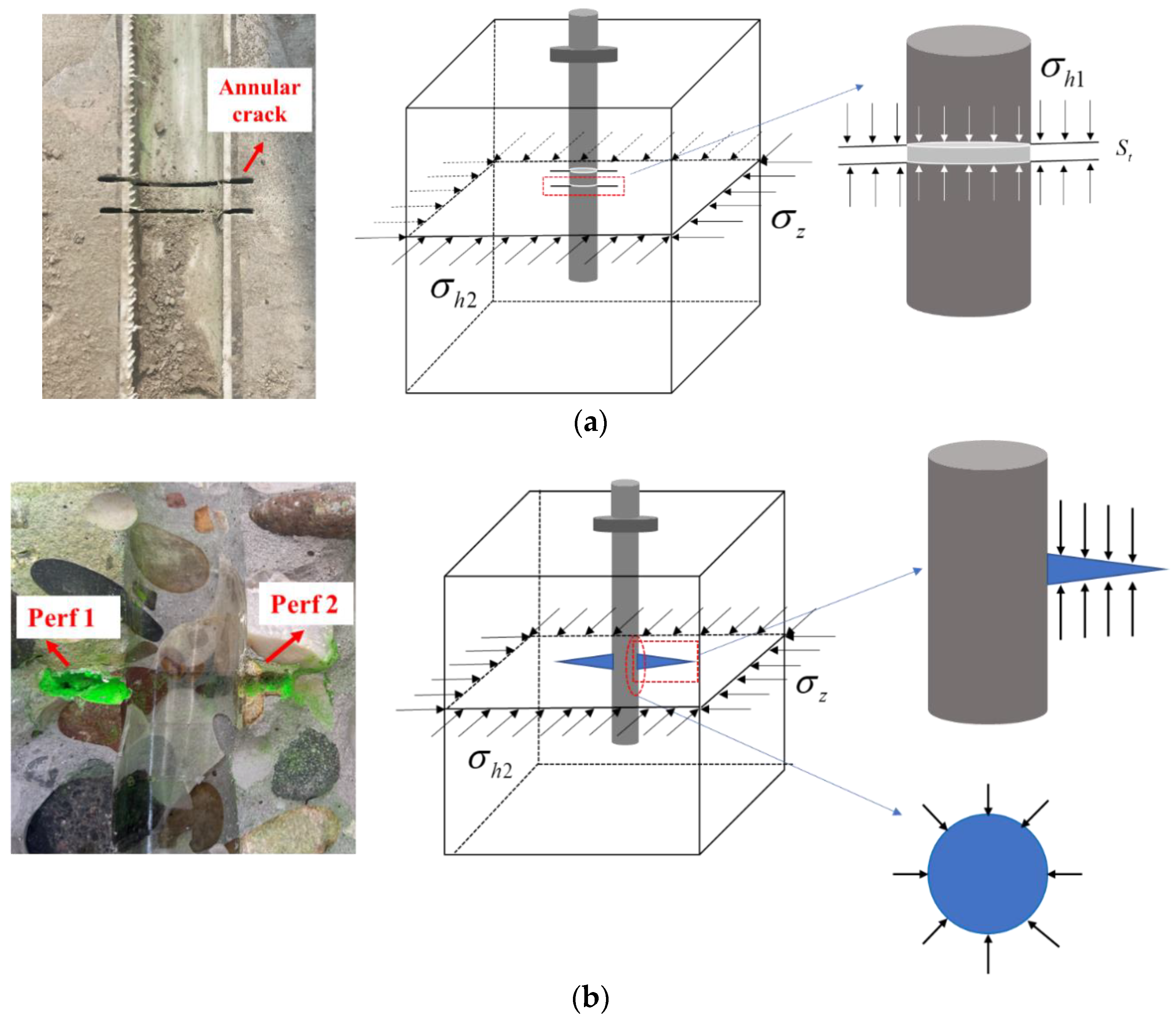

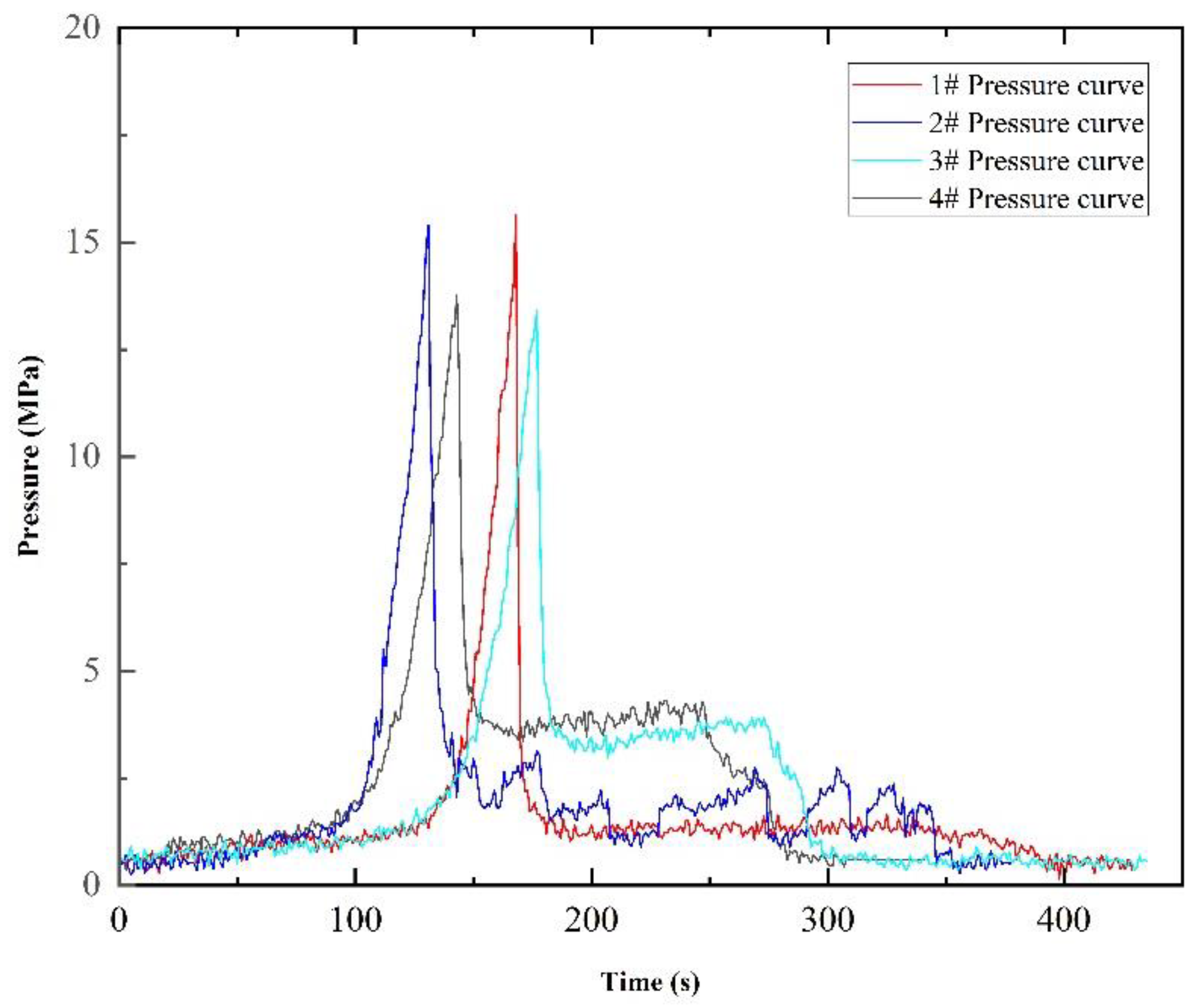

4.3. Experimental Results and Analysis

4.3.1. Effect of Acidizing

4.3.2. Effect of Perforation Angle

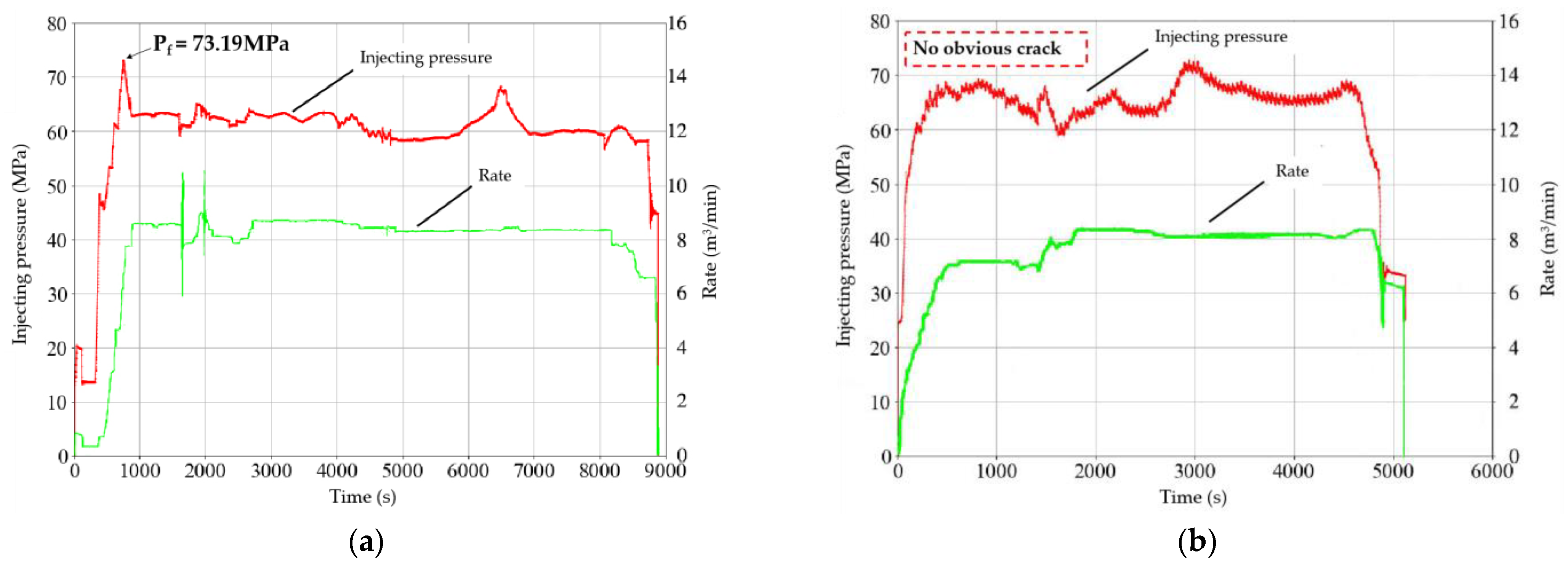

5. Field Application of Acid Pretreatment

6. Conclusions

- The novel perforation method by water jetting in fracturing specimens can better simulate perforation conditions such as the perforation length and angle for the acid pretreatment and triaxial fracturing experiments.

- The perforation angle has a significant effect on the breakdown pressure. A 0° perforation angle results in the minimum breakdown pressure. It is necessary to ensure there are perforation holes with a 0° perforation angle relative to the maximum horizontal stress for a low breakdown pressure.

- Acid pretreatment can effectively decrease the breakdown pressure down to 7.7 MPa under experimental conditions. The mechanism of the acid pretreatment to decrease the breakdown pressure is that rock dissolution by the acid reduces the rock tensile strength and increases its permeability. The raised permeability increases the fluid pressure of the reservoir near the wellbore so as to reduce the breakdown pressure of the formation.

- For the Mahu conglomerate reservoir with a low carbonate content, an acid system of 6%HF + 10%HCl with 60 min plus acid contact time is recommended for the acid pretreatment.

- The field application of the acid pretreatment to horizontal well fracturing in the Mahu conglomerate reservoirs showed that the acid pretreatment was successful and the breakdown pressure was lowered by 10.5%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.; Dong, Y.; Zhu, Y.; Zhang, D.; Hui, J.; Wang, W. Sedimentary reservoir evolution characteristics of lower Triassic Baikouquan formation in Ma18 well area of Mahu sag. J. Hebei Geo Univ. 2022, 45, 32–41. [Google Scholar]

- Yun, J.; Qin, G.J.; Xu, F.Y.; Li, X.; Zhong, N.; Wu, W. Development and utilization prospects of unconventional natural gas in China from a low-carbon perspective. Acta Pet. Sin. 2012, 33, 526–532. [Google Scholar]

- Tan, P.; Jin, Y.; Han, L.; Shan, Q.; Zhang, Y.; Chen, G.; Zhou, Y. Influencing mechanism of acidification pretreatment on hydraulic fracture for deep fractured shale reservoirs. Chin. J. Geotech. Eng. 2018, 40, 384–390. [Google Scholar]

- Wang, Q.; Wen, J.Q.; Yang, Z.C. Application effect analysis of acid fracturing technology in low permeability oilfield development. Oil Gas Prod. 2022, 48, 32–34+51. [Google Scholar]

- Zhang, J.F. The Research on Potential Damage and Acid System of Ultra-Low Permeability Sandstone Reservoir in Shanshan Oilfield. Master’s Thesis, Yangtze University, Hubei, China, 2023. [Google Scholar]

- Zhang, J.; Li, T.; Wu, J.; Guan, Y.; Xu, M.; Dan, Z.; Zhou, M. Sensitivity evaluation of ultra-low permeability sandstone reservoir and development of acidizing stimulation fluid. Spec. Oil Gas Reserv. 2022, 29, 166–174. [Google Scholar]

- Xiong, T. Geological Characteristics of Carbonated Sandstone Reservoir and Acidification Optimization Technology. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2018. [Google Scholar]

- Chen, M.; Pang, F.; Jin, Y. Experiments and analysis on hydraulic fracturing by a large-size triaxial simulator. Chin. J. Rock Mech. Eng. 2000, 19, 868–872. [Google Scholar]

- Yao, F.; Chen, M.; Wu, X.; Zhang, G. Physical simulation of hydraulic fracture propagation in naturally fractured formations. Oil Drill. Prod. Technol. 2008, 3, 83–86. [Google Scholar]

- Hou, B.; Tan, P.; Chen, M.; Yuan, L.; Xiong, Z.; Xu, C. Experimental investigation on propagation geometry of hydraulic fracture in compact limestone reservoirs. Chin. J. Geotech. Eng. 2016, 38, 219–225. [Google Scholar]

- Wang, Y.Z.; Hou, B.; Zhang, K.P.; Zhou, C.L.; Liu, F. Laboratory true triaxial acid fracturing experiments for carbonate reservoirs. Pet. Sci. Bull. 2020, 3, 412–419. [Google Scholar]

- Shan, Q.L.; Jin, Y.; Han, L.; Zhang, R.X. Influence of spiral perforation parameters on fracture geometry near horizontal wellbores. Pet. Sci. Bull. 2017, 1, 44–52. [Google Scholar]

- Feng, F.; Yang, L.S.; Liu, Z.H.; Shen, K. Experimental study on initiation and propagation law of sandstone with axial prefabricated cracks. Saf. Coal Mines 2018, 49, 18–21. [Google Scholar]

- Zhang, R.X.; Hou, B.; Shan, Q.L.; Tan, P.; Wu, Y.; Guo, X.F. Parameter optimization of spiral perforations in horizontal well with tight sandstone reservoir. Chin. J. Geotech. Eng. 2018, 40, 2143–2147. [Google Scholar]

- Wu, Y.; Hou, B.; Han, H.F.; Zhou, X. Study on the optimization of helical perforation parameters for horizontal wells in the condition of high horizontal stress difference. Chin. J. Undergr. Space Eng. 2019, 15, 226–231. [Google Scholar]

- Yu, R.; Zhang, Y.; Zheng, B.; Yang, W.; Tian, Y.; Liu, B. Experimental study on the effects of perforation phasing on fracturing pressure and fracture propagation of thin interbeds. Drill. Fluid Complet. Fluid 2020, 37, 110–115. [Google Scholar]

- Hou, Z.K.; Yang, C.H.; Wang, L.; Liu, P.J.; Guo, Y.T.; Wei, Y.L.; Li, Z. Hydraulic fracture propagation of shale horizontal well by large-scale true triaxial physical simulation test. Rock Soil Mech. 2016, 37, 407–414. [Google Scholar]

- Liu, N.Z.; Zhang, Z.P.; Zou, Y.S.; Ma, X.F.; Zhang, Y.N. Propagation law of hydraulic fractures during multi-staged horizontal well fracturing in a tight reservoir. Pet. Explor. Dev. 2018, 45, 1059–1068. [Google Scholar] [CrossRef]

- Liang, J.; Liu, J.; Xu, Q.Y.; Zhang, L. Study on rock fracture initiation pressure under different hydraulic fracturing parameters. Coal Technol. 2020, 39, 87–89. [Google Scholar]

- Zhang, S.C.; Li, S.H.; Zou, Y.S.; Li, J.M.; Ma, X.F.; Zhang, X.H.; Wang, Z.F.; Wu, S. Experimental study on fracture height propagation during multi-stage fracturing of horizontal wells in shale oil reservoirs. J. China Univ. Pet. (Ed. Nat. Sci.) 2021, 45, 77–86. [Google Scholar]

- Fu, H.F.; Huang, L.K.; Zhang, F.S.; Xu, Y.; Cai, B.; Liang, T.C.; Wang, X. Effect of perforation technologies on the initiation and propagation of hydraulic fracture. Chin. J. Rock Mech. Eng. 2021, 40, 3163–3173. [Google Scholar]

- Wang, Y.H.; Fu, H.F.; Liang, T.C.; Wang, X.; Liu, Y.Z.; Peng, Y.; Yang, L.F.; Tian, Z.H. Large-scale physical simulation experiment research for hydraulic fracturing in shale. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 8 March 2015. [Google Scholar]

- Bai, J.; Martysevich, V.; Walters, H.; Dusterhoft, R.; Matzar, L.; Sansil, M. Laboratory-scale hydraulic fracturing: Experiment and numerical modeling. In Proceedings of the U.S. Symposium on Rock Mechanics, Houston, TX, USA, 26 June 2016. [Google Scholar]

- Fu, H.F.; Zhang, Y.M.; Wang, X.; Yan, Y.Z.; Guan, B.S.; Liu, Y.Z.; Liang, T.C.; Weng, D.W. New stimulation technology research based on impulse fracturing reservoir. Chin. J. Rock Mech. Eng. 2017, 36, 4008–4017. [Google Scholar]

- Lei, D.W.; Chen, G.Q.; Liu, H.L.; Liu, X.; Abrimiti, T.K.; Cao, J. Study on the forming conditions and exploration fields of the Mahu giant oil (gas) province, Junggar Basin. Acta Geol. Sin. 2017, 91, 1604–1619. [Google Scholar]

- Kang, X.; Hu, W.; Cao, J.; Wu, H. Controls on reservoir quality in fan-deltaic conglomerate: Insight from the Lower Triassic Baikouquan Formation, Junggar Basin, China. Mar. Pet. Geol. 2019, 103, 55–75. [Google Scholar] [CrossRef]

- Sang, L.X.; Liu, J.; Wang, G.W.; Wang, S.T.; Li, Q.; Zhang, Y.L. High-quality reservoirs prediction of fan delta in the Triassic Baikouquan Formation in west slope of Mahu sag, Junggar Basin. J. Palaeogeogr. (Chin. Ed.) 2020, 22, 1053–1064. [Google Scholar]

- Jiang, Q.P.; Kong, C.X.; Li, W.F.; Qiu, Z.G.; Lu, Z.Y.; Chang, T.Q.; Liu, K.; Chen, D.L.; Li, S.; Yuan, X.G. Sedimentary characteristics and evolution law of a lacustrine large-scale fan delta: A case study from the Triassic Baikouquan formation on the west slope of Mahu sag. Acta Sedimentol. Sin. 2020, 38, 923–932. [Google Scholar]

- Waters, G.; Weng, X. The Impact of Geomechanics and Perforations on Hydraulic Fracture Initiation and Complexity in Horizontal Well Completions. In Proceedings of the Spe Technical Conference & Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar]

- Detournay, E. Mechanics of hydraulic fractures. Annu. Rev. Fluid Mech. 2016, 48, 311–339. [Google Scholar] [CrossRef]

- Dontsov, E.V. An approximate solution for a plane strain hydraulic fracture that accounts for fracture toughness, fluid viscosity, and leak-off. Int. J. Fract. 2017, 205, 221–237. [Google Scholar] [CrossRef]

- Madyarov, A.; Prioul, R.; Zutshi, A.; Seprodi, N.; Groves, D.; Pei, J.; Wong, S.W. Understanding the impact of completion designs on multi-stage fracturing via block test experiments. In Proceedings of the 55th U.S. Rock Mechanics/Geomechanics Symposium, Houston, TX, USA, 20–23 June 2021. [Google Scholar]

- Bunger, A.P.; Jeffrey, R.G.; Detournay, E. Application of scaling laws to laboratory-scale hydraulic fractures. In Proceedings of the 40th U.S. Symposium on Rock Mechanics (USRMS), Anchorage Alaska, Alaska, 25–29 June 2005. [Google Scholar]

- Zou, Y.S.; Shi, S.Z.; Zhang, S.C.; Li, J.M.; Wang, F.; Wang, J.C.; Zhang, X.H. Hydraulic fracture geometry and proppant distribution in thin interbedded shale oil reservoirs. Pet. Explor. Dev. 2022, 49, 1025–1032. [Google Scholar] [CrossRef]

- Xue, L.; Zhu, J.G.; Guo, C.F.; Ni, X.M.; Li, Y.; Cao, Y.X. Experimental optimization of concentration ratio of buffering acid used for removing plugging of coal seam. Saf. Coal Mines 2021, 52, 72–77. [Google Scholar]

- Deng, Y.; Xue, R.J.; Guo, J.C. The mechanism of high-pressure high-temperature and low permeability acid pretreatment to reduce fracturing pressure. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2011, 33, 125–129+199. [Google Scholar]

- Wang, S.L.; Dong, K.X.; Dong, H.Y. Effect analysis of perforating parameters upon initiation pressure in low permeability reservoir. Oil Drill. Prod. Technol. 2009, 31, 85–89. [Google Scholar]

- Yu, J.Y.; Shen, F.; Gu, Q.H.; Ren, S.S. Influence of perforation parameters on hydraulic fracturing of fracture pressure in horizontal well. Pet. Geol. Recovery Effic. 2011, 18, 105–107. [Google Scholar]

- Xue, S.F.; Sun, C.H.; Yu, H.B.; Sun, F. Effect of spiral perforation parameters on formation fracture pressure. Well Test. 2015, 24, 11–13+73. [Google Scholar]

- Yang, Y.M.; Li, X.; Wang, Z.; Ju, Y. Influence of perforation parameters on propagation laws of hydraulic fracture in heterogeneous sandstones. China Civ. Eng. J. 2022, 55, 1–9. [Google Scholar]

- Andreas, B.; Chavez, F.J.; Sergey, N.; Nihat, G.; Olga, A.; Sergey, C.; Dmitry, K.; Vasily, L. Impact of Perforation Tunnel Orientation and Length in Horizontal Wellbores on Fracture Initiation Pressure in Maximum Tensile Stress Criterion Model for Tight Gas Fields in the Sultanate of Oman. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 8–11 March 2015. [Google Scholar]

- Liu, X.J.; Xiong, J.; Liang, L.X.; You, X. Rock mechanics characteristics and fracture propagation mechanism of glutenite reservoir in Baikouquan Formation of Mahu Sag. Xinjiang Pet. Geol. 2018, 39, 83–91. [Google Scholar]

- Tang, Y.; Xu, Y.; Li, Y.Z.; Wang, L.B. Sedimentation model and exploration significance of large-scaled shallow retrogradation fan delta in Mahu Sag. Xinjiang Pet. Geol. 2018, 39, 16–22. [Google Scholar]

- Qin, J.H.; Wang, J.G.; Li, S.Y.; Li, S.; Dou, Z.; Peng, S.M. Characteristics and formation mechanism of hydraulic fractures in tight conglomerate reservoirs of Triassic Baikouquan formation in Mahu Sag. Lithol. Reserv. 2023, 35, 29–36. [Google Scholar]

| Number | Perforation Length | Jetting Time |

|---|---|---|

| 1 | 1.8 cm | 4 min |

| 2 | 2 cm | 7 min |

| 3 | 2.5 cm | 7 min 30 s |

| 4 | 3 cm | 10 min |

| 5 | 4 cm | 18 min 14 s |

| 6 | 5 cm | 20 min |

| Number | Perforation Angle | Acid System | Acidizing Time (min) | Breakdown Pressure (MPa) |

|---|---|---|---|---|

| 1 | 60° | - | - | 15.65 |

| 2 | 45° | - | - | 15.4 |

| 3 | 30° | - | - | 13.42 |

| 4 | 0° | - | - | 13.77 |

| 5 | 0° | 10%HCl | 30 | 9.8 |

| 6 | 0° | 3%HF + 10%HCl | 30 | 9.23 |

| 7 | 0° | 6%HF + 10%HCl | 30 | 5.45 |

| 8 | 0° | 8%HF + 10%HCl | 30 | 4.55 |

| 9 | 0° | 12%HCl | 30 | 9.1 |

| 10 | 0° | 3%HF + 12%HCl | 30 | 8.2 |

| 11 | 0° | 6%HF + 12%HCl | 30 | 6 |

| 12 | 0° | 8%HF + 12%HCl | 30 | 5.08 |

| 13 | 0° | 15%HCl | 30 | 9.67 |

| 14 | 0° | 3%HF + 15%HCl | 30 | 9.51 |

| 15 | 0° | 6%HF + 15%HCl | 30 | 6.05 |

| 16 | 0° | 8%HF + 15%HCl | 30 | 4.97 |

| 17 | 0° | 6%HF + 10%HCl | 15 | 12.85 |

| 18 | 0° | 6%HF + 10%HCl | 60 | 3.16 |

| 19 | 0° | 6%HF + 10%HCl | 90 | 3.3 |

| 20 | 0° | 6%HF + 10%HCl | 120 | 3 |

| Number | Acid System | Acidizing Time (min) | Quartz (%) | Clay (%) | Feldspar (%) | Calcite (%) | Other (%) |

|---|---|---|---|---|---|---|---|

| 4 | - | - | 35.29 | 21.22 | 25.12 | 9.52 | 8.85 |

| 5 | 10%HCl | 30 | 34.55 | 18.91 | 26.89 | 8.05 | 11.6 |

| 17 | 6%HF + 10%HCl | 15 | 32.5 | 18.13 | 25.75 | 9.18 | 14.44 |

| 8 | 6%HF + 10%HCl | 30 | 37.5 | 16.33 | 22.09 | 8.17 | 17.91 |

| 18 | 6%HF + 10%HCl | 60 | 37.8 | 15.19 | 21.86 | 7.85 | 17.3 |

| 19 | 6%HF + 10%HCl | 90 | 38.48 | 14.67 | 21.36 | 7.67 | 17.82 |

| 20 | 6%HF + 10%HCl | 120 | 38.26 | 14.55 | 21.15 | 7.55 | 18.49 |

| Number | Tensile Strength (Before) (MPa) | Number | Acid System | Contact Time (min) | Tensile Strength (After) (MPa) |

|---|---|---|---|---|---|

| (1)a | 4.72 | (1)b | 6%HF + 10%HCl | 10 | 4.53 |

| (2)a | 4.33 | (2)b | 6%HF + 10%HCl | 20 | 3.59 |

| (3)a | 6.83 | (3)b | 6%HF + 10%HCl | 30 | 4.64 |

| (4)a | 5.39 | (4)b | 6%HF + 10%HCl | 60 | 3.13 |

| (5)a | 6.42 | (5)b | 6%HF + 10%HCl | 120 | 3.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, W.; Mou, J.; Wang, G.; Li, X.; Wang, X.; Ma, X. A New Experimental Method for Acid Pretreatment in Perforated Horizontal Wells: A Case Study of Mahu Conglomerate Reservoir. Processes 2023, 11, 3353. https://doi.org/10.3390/pr11123353

Jia W, Mou J, Wang G, Li X, Wang X, Ma X. A New Experimental Method for Acid Pretreatment in Perforated Horizontal Wells: A Case Study of Mahu Conglomerate Reservoir. Processes. 2023; 11(12):3353. https://doi.org/10.3390/pr11123353

Chicago/Turabian StyleJia, Wenting, Jianye Mou, Guifu Wang, Xiaowei Li, Xinliang Wang, and Xinfang Ma. 2023. "A New Experimental Method for Acid Pretreatment in Perforated Horizontal Wells: A Case Study of Mahu Conglomerate Reservoir" Processes 11, no. 12: 3353. https://doi.org/10.3390/pr11123353

APA StyleJia, W., Mou, J., Wang, G., Li, X., Wang, X., & Ma, X. (2023). A New Experimental Method for Acid Pretreatment in Perforated Horizontal Wells: A Case Study of Mahu Conglomerate Reservoir. Processes, 11(12), 3353. https://doi.org/10.3390/pr11123353