Optimization of Extrusion Conditions for an Extruded Food Enriched with Mango By-Products (Mangifera indica var. Tommy Atkins) via Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Flour

2.3. Extrusion Conditions

2.4. Physical Properties

2.4.1. Expansion Index (EI)

2.4.2. Hardness

2.4.3. Water Solubility Index (WSI) and Water Absorption Index (WAI)

2.5. Chemical Properties

2.5.1. Extraction Method

2.5.2. Total Polyphenol Content (TPC)

2.5.3. Antioxidant Capacity Assay

DPPH Radical Scavenging Capacity

ABTS Radical Scavenging Capacity

2.6. Experimental Design and Statistical Analysis

3. Results and Discussion

3.1. Effects of Extrusion Conditions on Physical Properties

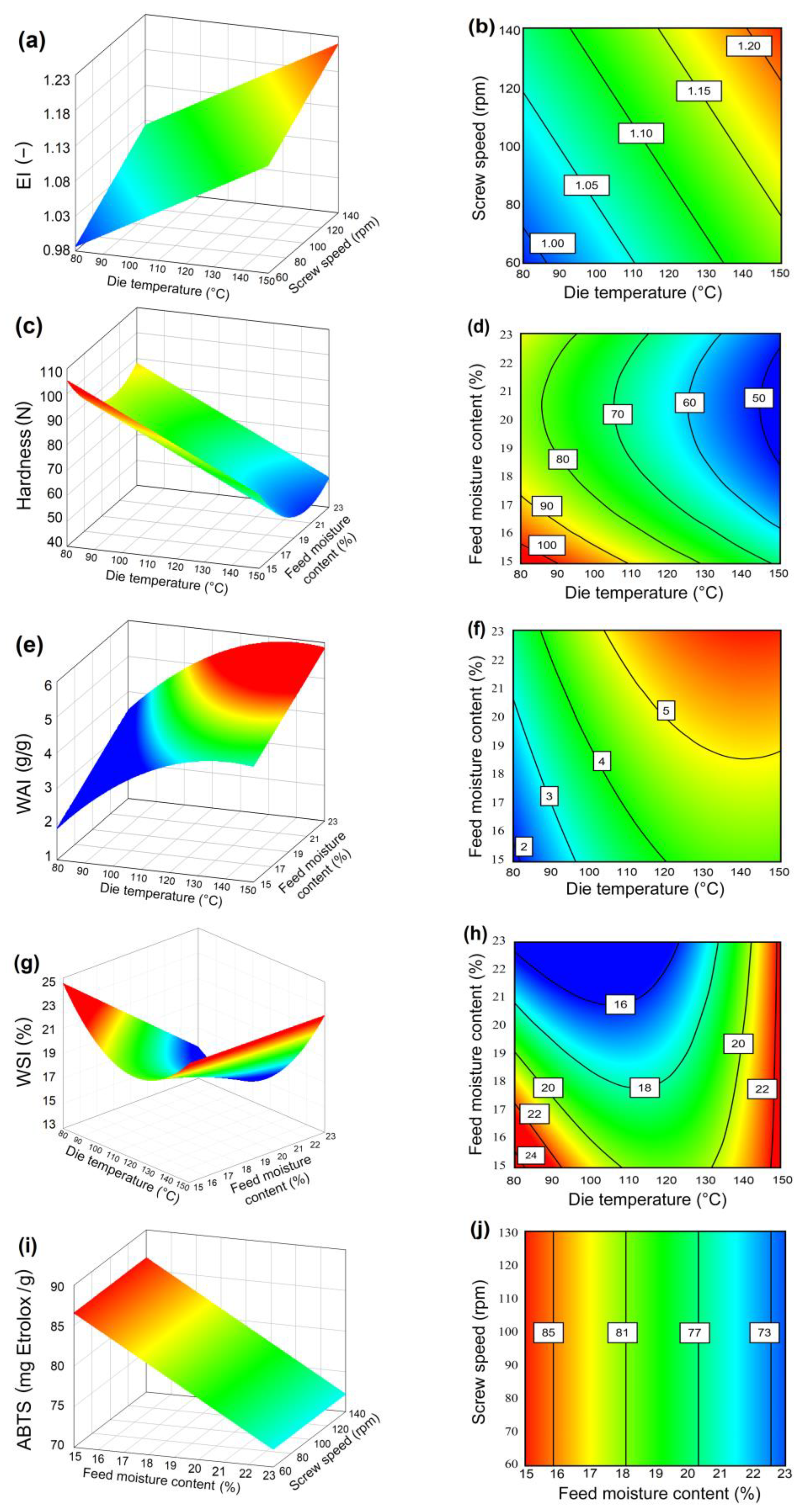

3.1.1. Expansion Index

3.1.2. Hardness

3.1.3. Water Absorption Index

3.1.4. Water Solubility Index

3.2. Effects of Extrusion Conditions on Chemical Properties

3.2.1. Total Polyphenol Content

3.2.2. Antioxidant Capacity Measured by ABTS

3.2.3. Antioxidant Capacity Measured by DPPH

3.3. Optimization and Validation

3.4. Bromatological Composition of the Optimized Extruded Food

3.5. Comparison of Techno-Functional Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oliver-Simancas, R.; Labrador-Fernández, L.; Díaz-Maroto, M.C.; Pérez-Coello, M.S.; Alañón, M.E. Comprehensive Research on Mango By-Products Applications in Food Industry. Trends Food Sci. Technol. 2021, 118, 179–188. [Google Scholar] [CrossRef]

- Villanueva-Rodríguez, S.J. Materia Prima. In Introducción a la Tecnología del Mango; Larios Medrano, I., Campos Serrano, M.d.J.K., Padilla Sahgún, M.d.C., Villanueva-Rodríguez, S.J., Eds.; Centro de Investigación y Asistencia en Tecnología y Diseño del Estado de Jalisco A.C.: Guadalajara, Mexico, 2016; ISBN 978-607-97421-1-9. [Google Scholar]

- Estrada-López, H.H.; Restrepo-Flórez, C.E.; Iglesias-Navas, M.A. Sensorial Acceptability of Bakery and Pastry Products with Incorporation of Dehydrated Fruits and Vegetables as Functional Ingredients. Inf. Tecnol. 2018, 29, 13–20. [Google Scholar] [CrossRef]

- Pacheco-Jiménez, A.A.; Heredia, J.B.; Gutiérrez-Grijalva, E.P.; Quintana-Obregón, E.A.; Muy-Rangel, M.D. Potencial Industrial de La Cáscara de Mango (Mangifera indica L.) Para La Obtención de Pectina En México. TIP Rev. Espec. Cienc. Químico-Biológicas 2022, 25, 1–13. [Google Scholar] [CrossRef]

- Salgado, N.; Giraldo, G.I.; Orrego, C.E. Influence of the Extrusion Operating Conditions on the Antioxidant, Hardness and Color Properties of Extruded Mango. LWT Food Sci. Technol. 2017, 86, 209–218. [Google Scholar] [CrossRef]

- Mazlan, M.M.; Talib, R.A.; Mail, N.F.; Taip, F.S.; Chin, N.L.; Sulaiman, R.; Shukri, R.; Mohd Nor, M.Z. Effects of Extrusion Variables on Corn-Mango Peel Extrudates Properties, Torque and Moisture Loss. Int. J. Food Prop. 2019, 22, 54–70. [Google Scholar] [CrossRef]

- Castañeda-Valbuena, D.; Ayora-Talavera, T.; Luján-Hidalgo, C.; Álvarez-Gutiérrez, P.; Martínez-Galero, N.; Meza-Gordillo, R. Ultrasound Extraction Conditions Effect on Antioxidant Capacity of Mango By-Product Extracts. Food Bioprod. Process. 2021, 127, 212–224. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Commission Regulation (EU) No 68/2013 of 16 January 2013 on the Catalogue of Feed Materials Text with EEA Relevance; European Commission: Brussels, Belgium, 2013. [Google Scholar]

- Choton, S.; Gupta, N.; Bandral, J.D.; Anjum, N.; Choudary, A. Extrusion Technology and Its Application in Food Processing: A Review. Pharma Innov. J. 2020, 9, 162–168. [Google Scholar] [CrossRef]

- Sandhu, R.S.; Singh, N.; Kaler, R.; Singh, B. Optimization of Process Parameters for Preparation of Rice Extrudates from Short and Long Indica Rice Cultivars Milled to Varying Degree of Milling. J. Food Sci. Technol. 2019, 56, 2467–2479. [Google Scholar] [CrossRef]

- Pardhi, S.D.; Singh, B.; Nayik, G.A.; Dar, B.N. Evaluation of Functional Properties of Extruded Snacks Developed from Brown Rice Grits by Using Response Surface Methodology. J. Saudi Soc. Agric. Sci. 2019, 18, 7–16. [Google Scholar] [CrossRef]

- Samyor, D.; Deka, S.C.; Das, A.B. Effect of Extrusion Conditions on the Physicochemical and Phytochemical Properties of Red Rice and Passion Fruit Powder Based Extrudates. J. Food Sci. Technol. 2018, 55, 5003–5013. [Google Scholar] [CrossRef]

- Altaf, U.; Hussain, S.Z.; Qadri, T.; Iftikhar, F.; Naseer, B.; Rather, A.H. Investigation on Mild Extrusion Cooking for Development of Snacks Using Rice and Chickpea Flour Blends. J. Food Sci. Technol. 2021, 58, 1143–1155. [Google Scholar] [CrossRef]

- Pensamiento-Niño, C.A.; Gómez-Aldapa, C.A.; Hernández-Santos, B.; Juárez-Barrientos, J.M.; Herman-Lara, E.; Martínez-Sánchez, C.E.; Torruco-Uco, J.G.; Rodríguez-Miranda, J. Optimization and Characterization of an Extruded Snack Based on Taro Flour (Colocasia esculenta L.) Enriched with Mango Pulp (Mangifera indica L.). J. Food Sci. Technol. 2018, 55, 4244–4255. [Google Scholar] [CrossRef]

- Korkerd, S.; Wanlapa, S.; Puttanlek, C.; Uttapap, D.; Rungsardthong, V. Expansion and Functional Properties of Extruded Snacks Enriched with Nutrition Sources from Food Processing By-Products. J. Food Sci. Technol. 2016, 53, 561–570. [Google Scholar] [CrossRef]

- Gupta, A.K.; Gurjar, P.S.; Beer, K.; Pongener, A.; Ravi, S.C.; Singh, S.; Verma, A.; Singh, A.; Thakur, M.; Tripathy, S.; et al. A Review on Valorization of Different Byproducts of Mango (Mangifera indica L.) for Functional Food and Human Health. Food Biosci. 2022, 48, 101783. [Google Scholar] [CrossRef]

- Medina-Rendon, E.A.; Guatemala-Morales, G.M.; Padilla-Camberos, E.; Corona-González, R.I.; Arriola-Guevara, E.; García-Fajardo, J.A. Production of Extrudate Food with Mango By-Products (Mangifera indica): Analysis of Physical, Chemical, and Sensorial Properties. Processes 2021, 9, 1660. [Google Scholar] [CrossRef]

- Worku Kidane, S. Application of Response Surface Methodology in Food Process Modeling and Optimization. In Response Surface Methodology in Engineering Science; IntechOpen: London, UK, 2021; pp. 1–20. [Google Scholar]

- Secretaría de Economía. NMX-F-608-NORMEX-2011 Alimentos–Determinación de Proteínas En Alimentos–Método de Prueba. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 2011. [Google Scholar]

- Secretaría de Economía. NMX-F-083-1986 Alimentos-Determinación de Humedad En Productos Alimenticios. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 1986. [Google Scholar]

- Secretaría de Salud. NOM-086-SSA1-1994 Alimentos y Bebidas No Alcohólicas Con Modificaciones En Su Composición. Determinación de Extracto Etéreo En Alimentos. Método de Prueba. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 1994. [Google Scholar]

- Secretaría de Economía. NMX-F-613-NORMEX-2003 Determinación de Fibra Cruda En Alimentos–Método de Prueba. In Diario Oficial de la Federación; Dirección General de Normas: México City, México, 2003. [Google Scholar]

- Secretaría de Economía. NMX-F-607-NORMEX-2013 Alimentos–Determinación de Cenizas En Alimentos–Método de Prueba. In Diario Oficial de la Federación; Direccion General de Normas: México City, México, 2013. [Google Scholar]

- AOAC (Association of Official Analytical Chemists). Method 986.25 Carbohydrates, Determination by Difference, a Proximate Analysis. In Official Methods of Analysis Volume I, 15th ed.; Association of Official Analytical Chemist: Arlington, VA, USA, 1990. [Google Scholar]

- Falfán Cortés, R.N.; Verdalet Guzmán, I.; Martínez-Bustos, F. Effects of Some Extrusion Variables on Physicochemical Characteristics of Extruded Corn Starch-Passion Fruit Pulp (Passiflora edulis) Snacks. Plant Foods Hum. Nutr. 2014, 69, 365–371. [Google Scholar] [CrossRef]

- Raleng, A.; Singh, A.; Singh, B.; Attkan, A.K. Response Surface Methodology for Development and Characterization of Extruded Snack Developed from Food-by-Products. Int. J. Bio-Resour. Stress Manag. 2016, 7, 1321–1329. [Google Scholar] [CrossRef]

- Bandyopadhyay, K.; Chakraborty, C.; Bhattacharyya, S. Fortification of Mango Peel and Kernel Powder in Cookies Formulation. J. Acad. Ind. Res. 2014, 2, 661. [Google Scholar]

- Basilio-Atencio, J.; Condezo-Hoyos, L.; Repo-Carrasco-Valencia, R. Effect of Extrusion Cooking on the Physical-Chemical Properties of Whole Kiwicha (Amaranthus caudatus L.) Flour Variety Centenario: Process Optimization. LWT 2020, 128, 109426. [Google Scholar] [CrossRef]

- Polat, H.; Dursun Capar, T.; Inanir, C.; Ekici, L.; Yalcin, H. Formulation of Functional Crackers Enriched with Germinated Lentil Extract: A Response Surface Methodology Box-Behnken Design. LWT Food Sci. Technol. 2020, 123, 109065. [Google Scholar] [CrossRef]

- Lizárraga-Velázquez, C.E.; Hernández, C.; González-Aguilar, G.A.; Heredia, J.B. Effect of Hydrophilic and Lipophilic Antioxidants from Mango Peel (Mangifera indica L. Cv. Ataulfo) on Lipid Peroxidation in Fish Oil. CyTA J. Food 2018, 16, 1095–1101. [Google Scholar] [CrossRef]

- Gümüşay, Ö.A.; Şeker, M. Effects of Extrusion Parameters on Physicochemical Properties of Third Generation Corn Snacks Expanded by Microwave Heating. J. Food Process. Preserv. 2021, 45, e15630. [Google Scholar] [CrossRef]

- Natabirwa, H.; Nakimbugwe, D.; Lung’aho, M.; Muyonga, J.H. Optimization of Roba1 Extrusion Conditions and Bean Extrudate Properties Using Response Surface Methodology and Multi-Response Desirability Function. LWT Food Sci. Technol. 2018, 96, 411–418. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Application of Extrusion Technology in Plant Food Processing Byproducts: An Overview. Compr. Rev. Food Sci. Food Saf. 2020, 19, 218–246. [Google Scholar] [CrossRef] [PubMed]

- Calderón-Castro, A.; Vega-García, M.O.; de Jesús Zazueta-Morales, J.; Fitch-Vargas, P.R.; Carrillo-López, A.; Gutiérrez-Dorado, R.; Limón-Valenzuela, V.; Aguilar-Palazuelos, E. Effect of Extrusion Process on the Functional Properties of High Amylose Corn Starch Edible Films and Its Application in Mango (Mangifera indica L.) Cv. Tommy Atkins. J. Food Sci. Technol. 2018, 55, 905–914. [Google Scholar] [CrossRef]

- Karun, G.; Sukumar, A.; Nagamaniammai, G.; Preetha, R. Development of Multigrain Ready-to-Eat Extruded Snack and Process Parameter Optimization Using Response Surface Methodology. J. Food Sci. Technol. 2023, 60, 947–957. [Google Scholar] [CrossRef] [PubMed]

- Anunciação, P.C.; Cardoso, L.d.M.; Gomes, J.V.P.; Della Lucia, C.M.; Carvalho, C.W.P.; Galdeano, M.C.; Queiroz, V.A.V.; Alfenas, R.d.C.G.; Martino, H.S.D.; Pinheiro-Sant’Ana, H.M. Comparing Sorghum and Wheat Whole Grain Breakfast Cereals: Sensorial Acceptance and Bioactive Compound Content. Food Chem. 2017, 221, 984–989. [Google Scholar] [CrossRef]

- Şensoy, Í.; Rosen, R.T.; Ho, C.T.; Karwe, M.V. Effect of Processing on Buckwheat Phenolics and Antioxidant Activity. Food Chem. 2006, 99, 388–393. [Google Scholar] [CrossRef]

- Rani, P.; Kumar, A.; Purohit, S.R.; Rao, P.S. Extrusion of Fermented Rice-Black Gram Flour for Development of Functional Snacks: Characterization, Optimization and Sensory Analysis. J. Food Sci. Technol. 2021, 58, 494–509. [Google Scholar] [CrossRef]

- Ainsworth, P.; İbanoğlu, Ş.; Plunkett, A.; Ibanoğlu, E.; Stojceska, V. Effect of Brewers Spent Grain Addition and Screw Speed on the Selected Physical and Nutritional Properties of an Extruded Snack. J. Food Eng. 2007, 81, 702–709. [Google Scholar] [CrossRef]

- Dey, D.; Richter, J.K.; Ek, P.; Gu, B.J.; Ganjyal, G.M. Utilization of Food Processing By-Products in Extrusion Processing: A Review. Front. Sustain. Food Syst. 2021, 4, 304. [Google Scholar] [CrossRef]

- Altan, A.; McCarthy, K.L.; Maskan, M. Evaluation of Snack Foods from Barley-Tomato Pomace Blends by Extrusion Processing. J. Food Eng. 2008, 84, 231–242. [Google Scholar] [CrossRef]

| Coded Level | Actual Level | |||||

|---|---|---|---|---|---|---|

| Run | DT | FMC | SS | DT | FMC | SS |

| (°C) | (%) | (rpm) | (°C) | (%) | (rpm) | |

| 1 | 0 | 0 | 0 | 115 | 19 | 100 |

| 2 | −1 | −1 | −1 | 100 | 17 | 80 |

| 3 | 1 | −1 | −1 | 130 | 17 | 80 |

| 4 | −1 | 1 | −1 | 100 | 21 | 80 |

| 5 | 1 | 1 | −1 | 130 | 21 | 80 |

| 6 | −1 | −1 | 1 | 100 | 17 | 120 |

| 7 | 1 | −1 | 1 | 130 | 17 | 120 |

| 8 | −1 | 1 | 1 | 100 | 21 | 120 |

| 9 | 0 | 0 | 0 | 115 | 19 | 100 |

| 10 | 1 | 1 | 1 | 130 | 21 | 120 |

| 11 | −1.68179 | 0 | 0 | 90 a | 19 | 100 |

| 12 | 1.68179 | 0 | 0 | 140 a | 19 | 100 |

| 13 | 0 | −1.68179 | 0 | 115 | 15.5 a | 100 |

| 14 | 0 | 1.68179 | 0 | 115 | 22.5 a | 100 |

| 15 | 0 | 0 | −1.68179 | 115 | 19 | 66 a |

| 16 | 0 | 0 | 1.68179 | 115 | 19 | 134 a |

| 17 | 0 | 0 | 0 | 115 | 19 | 100 |

| Run | EI 1 | Hardness 1 | WAI 1 | WSI 1 | Total Polyphenol 1 | DPPH 1 | ABTS 1 |

|---|---|---|---|---|---|---|---|

| (-) | N | g Wet/g Sample | % | mg GAE/100 g Sample | mg Etrolox/g Sample | mg Etrolox/g Sample | |

| 1 | 1.17 ± 0.02 a,b | 61.88 ± 12.30 a,b,c | 4.65 ± 0.07 **** | 17.75 ± 0.39 ns | 4445 ± 49.27 *** | 119.84 ± 6.10 **** | 83.29 ± 4.48 ns |

| 2 | 1.05 ± 0.02 h,i | 91.79 ± 15.56 f,g | 3.77 ± 0.17 ns | 18.41 ± 0.19 ns | 4938 ± 43.02 ** | 115.39 ± 4.36 **** | 79.76 ± 4.72 ns |

| 3 | 1.02 ± 0.04 i | 65.12 ± 16.44 b,c,d | 4.70 ± 0.25 **** | 18.61 ± 0.21 ns | 3627 ± 23.35 * | 81.46 ± 2.79 ns | 84.87 ± 4.84 ns |

| 4 | 1.03 ± 0.02 h,i | 79.04 ± 21.96 d,e,f | 4.26 ± 0.09 ns | 16.28 ± 1.30 ns | 3238 ± 32.87 ns | 69.53 ± 6.08 ** | 83.72 ± 4.24 ns |

| 5 | 1.12 ± 0.07 b,c,d,e,f | 48.84 ± 13.54 a,h | 5.34 ± 0.21 **** | 18.23 ± 1.74 ns | 4534 ± 51.42 ** | 65.89 ± 2.05 **** | 76.76 ± 4.06 ** |

| 6 | 1.06 ± 0.02 f,g,h,i | 98.65 ± 21.37 g | 4.45 ± 0.10 *** | 16.58 ± 1.50 ns | 2747 ± 20.26 ** | 62.05 ± 2.10 **** | 79.61 ± 4.09 ns |

| 7 | 1.14 ± 0.08 b,c,d | 48.25 ± 14.40 a,h | 5.02 ±0.29 **** | 17.97 ± 1.13 ns | 3305 ± 40.01 ns | 98.76 ± 7.27 ns | 81.49 ± 3.48 ns |

| 8 | 1.04 ± 0.02 h,i | 86.40 ± 19.83 e,f,g | 4.45 ± 0.09 *** | 16.20 ± 0.78 ns | 4619 ± 52.60 **** | 64.64 ± 1.40 **** | 71.87 ± 3.79 **** |

| 9 | 1.15 ± 0.03 b,c | 72.37 ± 12.90 c,d,e | 4.94 ± 0.15 **** | 17.17 ± 0.51 ns | 3136 ± 37.63 ns | 63.30 ± 2.62 **** | 84.25 ± 4.60 ns |

| 10 | 1.21 ± 0.13 a | 45.60 ± 14.53 h | 5.08 ± 0.09 **** | 19.66 ± 0.32 * | 4272 ± 44.50 * | 74.37 ± 3.37 * | 80.38 ± 3.79 ns |

| 11 | 1.06 ± 0.02 g,h,i | 86.49 ± 15.62 e,f,g | 4.09 ± 0.04 ns | 17.36 ± 0.68 ns | 2210 ± 19.98 *** | 120.34 ± 8.01 **** | 76.91 ± 2.67 ** |

| 12 | 1.13 ± 0.10 b,c,d,e | 52.96 ± 17.17 a,b,h | 4.91 ± 0.04 **** | 21.88 ± 0.42 **** | 3024 ± 18.57 * | 100.15 ± 7.13 ns | 80.70 ± 2.33 ns |

| 13 | 1.11 ± 0.02 c,d,e,f,g | 82.87 ± 21.85 e,f,g | 4.52 ± 0.07 **** | 18.45 ± 0.97 ns | 2889 ± 12.18 * | 100.37 ± 4.21 ns | 89.28 ± 4.21 ns |

| 14 | 1.09 ± 0.04 d,e,f,g,h | 74.14 ± 15.29 c,d,e | 5.28 ± 0.10 **** | 16.32 ± 0.60 ns | 2487 ± 24.45 **** | 129.04 ± 12.30 **** | 67.86 ± 1.01 **** |

| 15 | 1.13 ± 0.02 b,c,d | 60.11 ± 15.37 a,b,c,h | 4.83 ± 0.10 **** | 17.31 ± 0.67 ns | 3857 ± 28.32 * | 81.57 ± 5.93 ns | 77.49 ± 2.73 ** |

| 16 | 1.17 ± 0.03 a,b | 73.16 ± 15.48 c,d,e | 5.13 ± 0.16 **** | 17.70 ± 0.62 ns | 1707 ± 12.64 **** | 95.28 ± 7.39 ns | 81.00 ± 2.38 ns |

| 17 | 1.07 ± 0.03 e,f,g,h,i | 78.26 ± 11.79 d,e,f | 4.79 ± 0.23 **** | 17.28 ± 0.69 ns | 2803 ± 20.43 * | 89.61 ± 6.18 ns | 70.15 ± 3.16 **** |

| NEM | N.A. | N.A. | 3.92 ± 0.12 | 17.27 ± 0.80 | 3475 ± 32.96 | 88.82 ± 5.69 | 88.08 ± 4.33 |

| Parameters | EI (-) | Hardness (N) | WAI (g of Gel/g Sample) | WSI (%) | Total Polyphenol (mg EAG/100 g Sample) | DPPH (mg Etrolox/g Sample) | ABTS (mg Etrolox/g Sample) |

|---|---|---|---|---|---|---|---|

| Intercept | 1.10 | 68.53 | 4.84 | 17.25 | 3380.07 | 92.61 | 79.38 |

| Linear | |||||||

| X1 | 0.0313 * | −14.97 *** | 0.3360 *** | 1.07 *** | 114.59 | −1.84 | 1.09 |

| X2 | 0.0071 | −4.29 * | 0.1807 ** | −0.3502 * | 100.31 | −2.56 | −3.59 * |

| X3 | 0.0218 | 1.18 | 0.1050 * | −0.0340 | −366.84 | −0.6878 | −0.4289 |

| Interactions | |||||||

| X1X2 | 0.0262 | 0.7600 | 0.0262 | 0.4775 * | 212.75 | 0.4138 | −0.6800 |

| X1X3 | 0.0237 | −4.29 | −0.1013 | 0.3375 | 28.25 | 10.50 | 1.53 |

| X2X3 | −0.0038 | 1.77 | −0.1338 * | 0.4775 * | 454.00 | 4.95 | −0.5875 |

| Quadratic | |||||||

| X12 | −0.0191 | −0.6611 | −0.1466 ** | 0.7204 ** | −18.62 | 1.00 | 0.0619 |

| X22 | −0.0173 | 2.99 | 0.0023 | −0.1106 | 6.48 | 2.58 | −0.0212 |

| X32 | 0.0003 | −1.75 | 0.0306 | −0.0682 | 39.72 | −6.71 | 0.2175 |

| Model (p-value) | 0.0282 | 0.0002 | <0.0001 | 0.0004 | N.S. | N.S. | 0.0107 |

| Importance | Target | Experimental Value | Optimum Value | Experimental Value a | Desirability | ||

|---|---|---|---|---|---|---|---|

| Min | Max | ||||||

| Experimental Factor | |||||||

| DT (°C) | 3 | Optimum | 89.7731 | 140.227 | 120.66 | 0.870 | |

| FMC (%) | 3 | Optimum | 15.6364 | 22.3636 | 21.8844 | ||

| SS (rpm) | 3 | Optimum | 66.3641 | 133.636 | 66.3642 | ||

| Response Variable | Predicted values | ||||||

| EI (-) NS | 3 | Range | 1.02 | 1.21 | 1.10 | 1.16 ± 0.06 | |

| Hardness (N) | 3 | Minimize | 45.60 | 98.65 | 63.66 | 66.92 ± 5.51 | |

| WAI (g/g) | 3 | Maximize | 3.77 | 5.34 | 5.41 | 5.00 ± 0.43 | |

| WSI (%) | 3 | Minimize | 16.20 | 21.88 | 16.20 | 15.93 ±0.55 | |

| Total Polyphenol (mg GAE/100 g sample) NS | 3 | Range | 1707 | 4938 | 3402 | 3317 ± 308 | |

| DPPH (mg Etrolox/g) NS | 3 | Range | 62.05 | 129.04 | 90.09 | 85.19 ± 10.96 | |

| ABTS (mg Etrolox/g) NS | 3 | Range | 67.86 | 89.28 | 79.38 | 76.70 ± 4.00 | |

| Sample | Moisture (%) | Protein, Nx6.25 (%) | Fat (%) | Carbohydrate (%) | Ash (%) | Crude Fiber (%) |

|---|---|---|---|---|---|---|

| Non-extruded flour mixture (NEM) 1 | 9.95 | 5.90 | 2.63 | 75.18 | 1.47 | 4.87 |

| Optimized extruded food | 3.10 | 6.50 | 3.84 | 81.46 | 1.70 | 3.40 |

| Sample | EI 1 | Hardness 1 | WAI 1 | WSI 1 | Total Polyphenol 1 | DPPH 1 | ABTS 1 |

|---|---|---|---|---|---|---|---|

| (-) | N | g Wet/g Sample | % | mg GAE/100 g Sample | mg Etrolox/g Sample | mg Etrolox/g Sample | |

| Extruded 100% white corn flour (WCF) 1 | 1.42 ± 0.07 | 50.85 ± 5.66 | 3.85 ± 0.26 | 11.49 ± 0.78 | 3966 ± 356 | 82.06 ± 9.86 | 110.92 ± 12.40 |

| Extruded 100% mango peel flour (MPF) 1 | 0.93 ± 0.04 | 102.86 ± 11.16 | 5.08 ± 0.27 | 27.65 ± 1.06 | 6357 ± 270 | 118.71 ± 6.32 | 187.11 ± 15.34 |

| Extruded 100% mango kernel flour (MKF) 1 | 1.42 ± 0.08 | 52.88 ± 5.51 | 2.82 ± 0.17 | 17.29 ± 0.81 | 6163 ± 292 | 175.17 ± 15.59 | 318.38 ± 25.39 |

| Optimized extruded food (58.33% WCF, 33.33% MPF, 8.34% MKF) | 1.16 ± 0.06 | 66.92 ± 5.51 | 5.00 ± 0.43 | 15.93 ± 0.55 | 3317 ± 308 | 85.19 ± 10.96 | 76.70 ± 4.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina-Rendon, E.; Beltran-Medina, E.; Guatemala-Morales, G.; Padilla-Camberos, E.; Corona-González, R.; Mondragón-Cortez, P.; Arriola-Guevara, E. Optimization of Extrusion Conditions for an Extruded Food Enriched with Mango By-Products (Mangifera indica var. Tommy Atkins) via Response Surface Methodology. Processes 2023, 11, 3182. https://doi.org/10.3390/pr11113182

Medina-Rendon E, Beltran-Medina E, Guatemala-Morales G, Padilla-Camberos E, Corona-González R, Mondragón-Cortez P, Arriola-Guevara E. Optimization of Extrusion Conditions for an Extruded Food Enriched with Mango By-Products (Mangifera indica var. Tommy Atkins) via Response Surface Methodology. Processes. 2023; 11(11):3182. https://doi.org/10.3390/pr11113182

Chicago/Turabian StyleMedina-Rendon, Esther, Elisa Beltran-Medina, Guadalupe Guatemala-Morales, Eduardo Padilla-Camberos, Rosa Corona-González, Pedro Mondragón-Cortez, and Enrique Arriola-Guevara. 2023. "Optimization of Extrusion Conditions for an Extruded Food Enriched with Mango By-Products (Mangifera indica var. Tommy Atkins) via Response Surface Methodology" Processes 11, no. 11: 3182. https://doi.org/10.3390/pr11113182

APA StyleMedina-Rendon, E., Beltran-Medina, E., Guatemala-Morales, G., Padilla-Camberos, E., Corona-González, R., Mondragón-Cortez, P., & Arriola-Guevara, E. (2023). Optimization of Extrusion Conditions for an Extruded Food Enriched with Mango By-Products (Mangifera indica var. Tommy Atkins) via Response Surface Methodology. Processes, 11(11), 3182. https://doi.org/10.3390/pr11113182