Model and Analysis of Pump-Stopping Pressure Drop with Consideration of Hydraulic Fracture Network in Tight Oil Reservoirs

Abstract

:1. Introduction

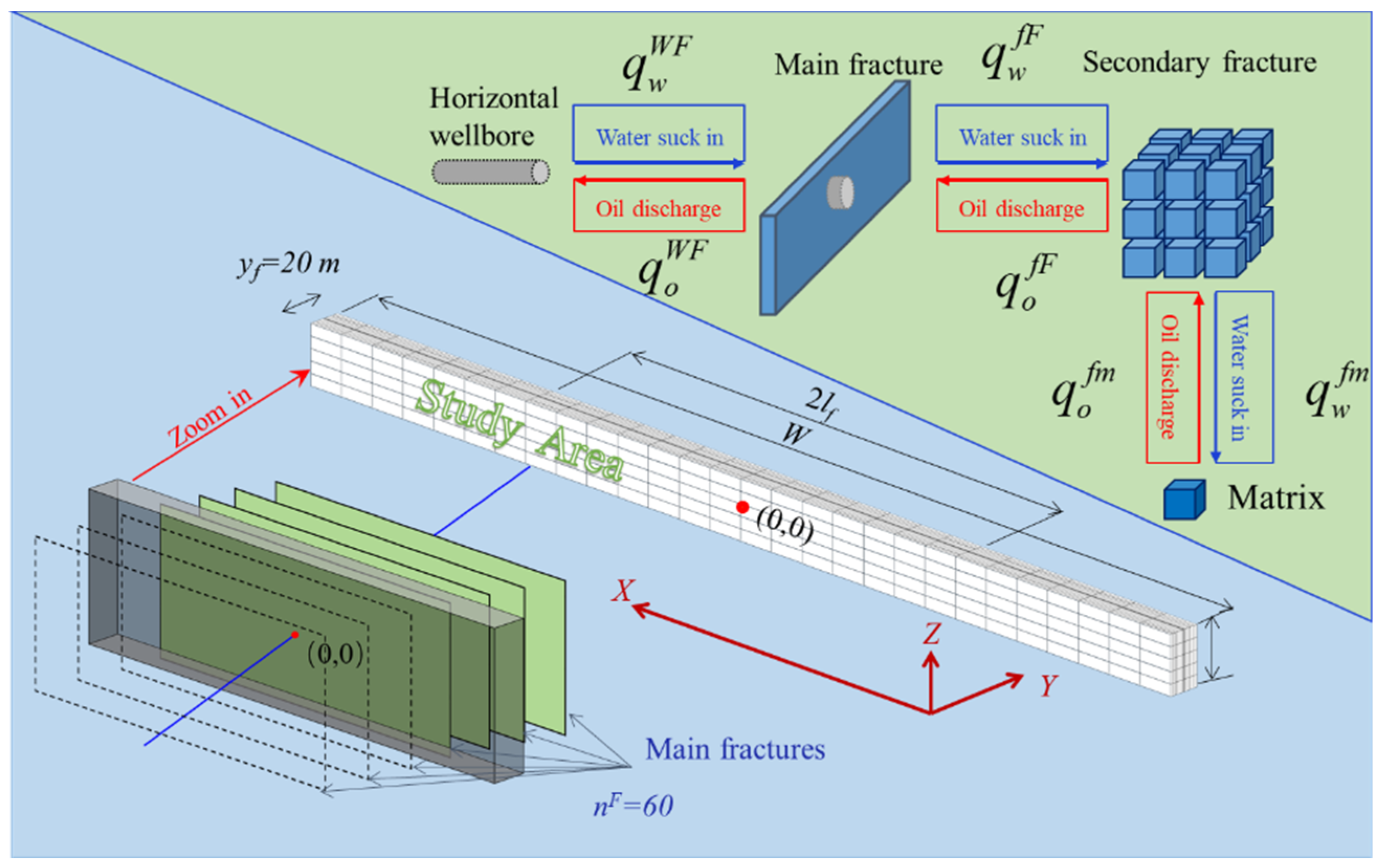

2. The Pump-Stopping Pressure Drop Model

2.1. Assumptions and Physical Model

2.2. Mathematical Model

2.3. The Initial and Boundary Conditions

2.4. Solving Method

3. Numerical Simulation of Pump-Stopping Pressure Drop

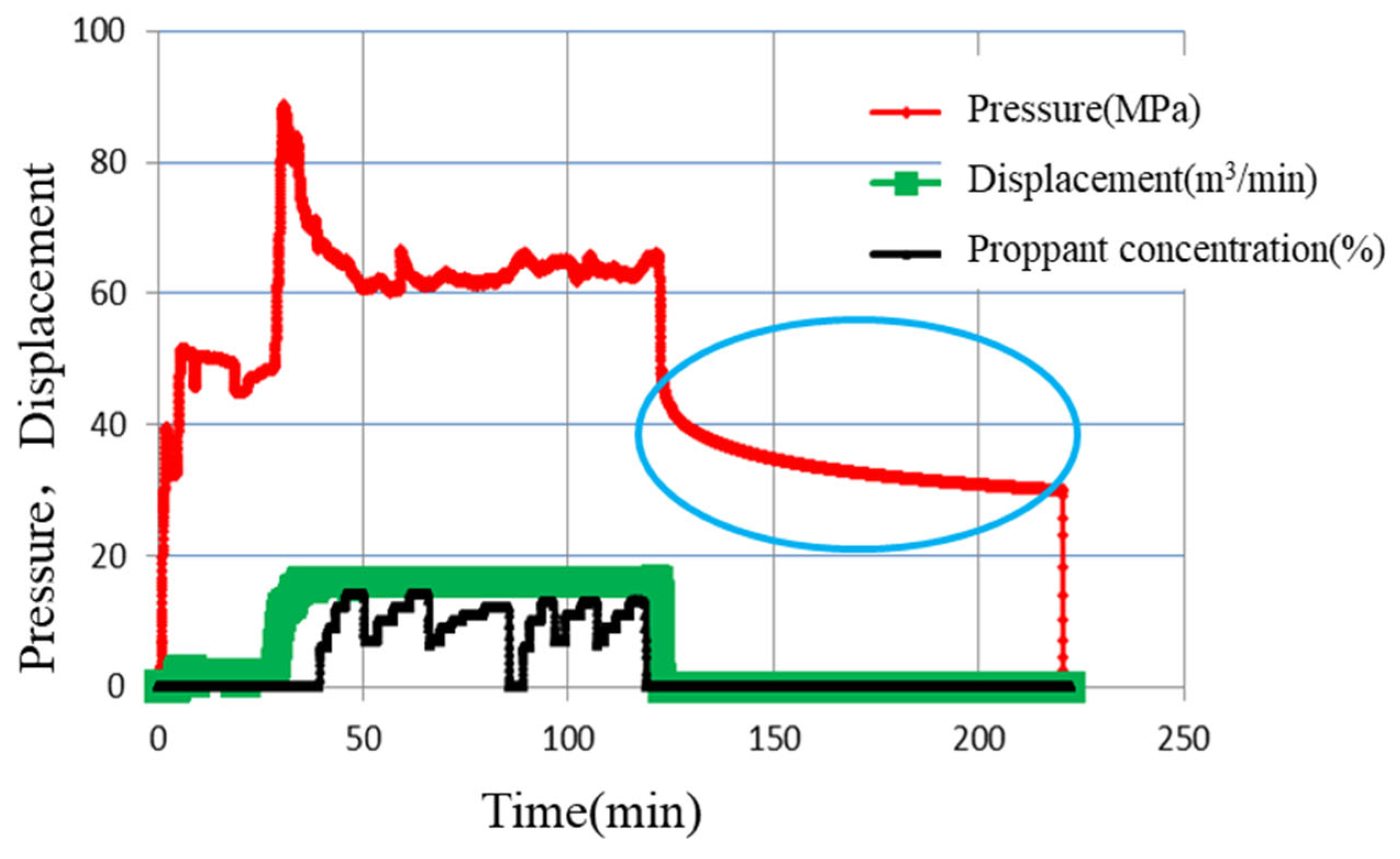

3.1. The Description of Simulated Fracturing Stage

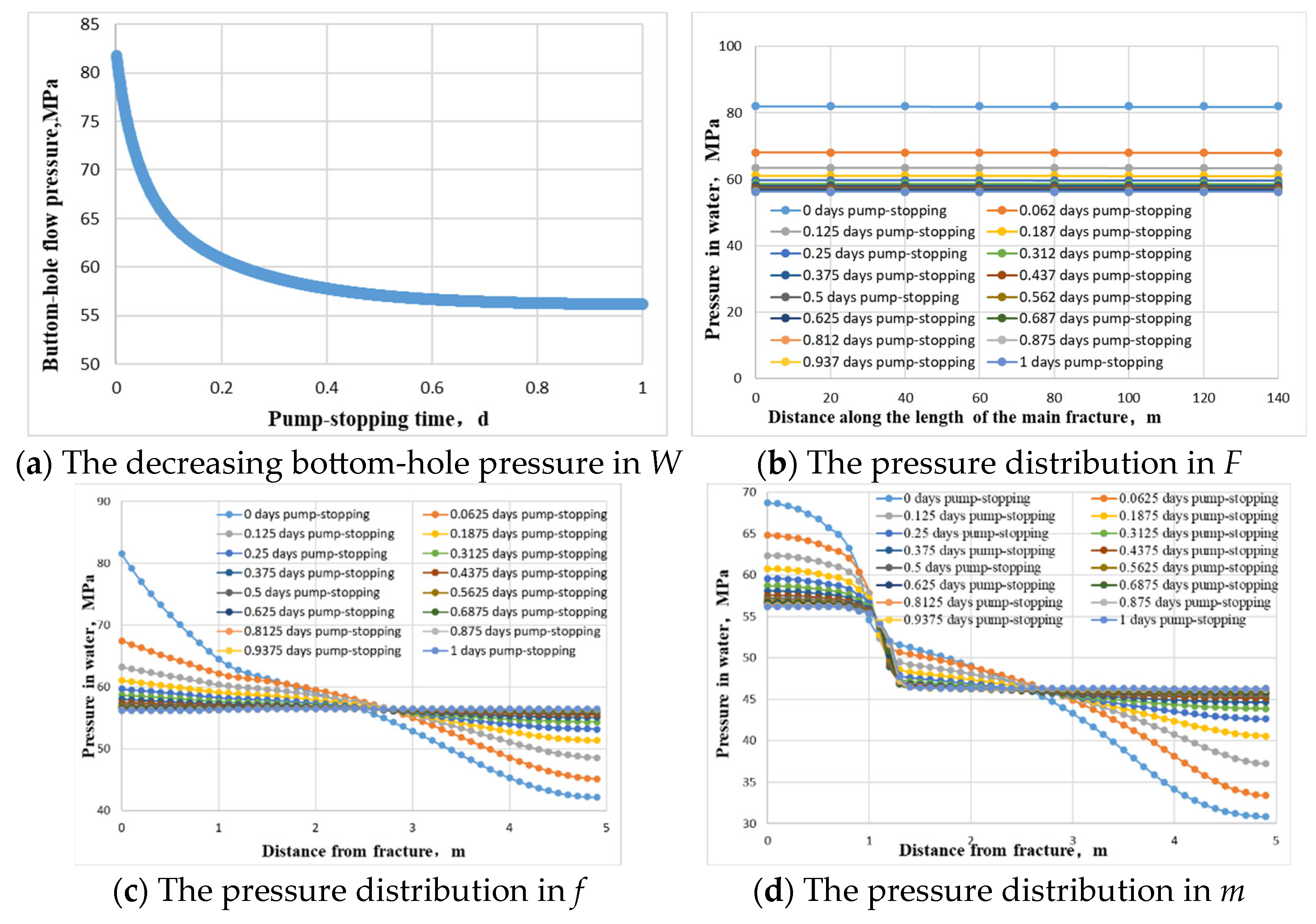

3.2. Simulated Pressure Dynamics

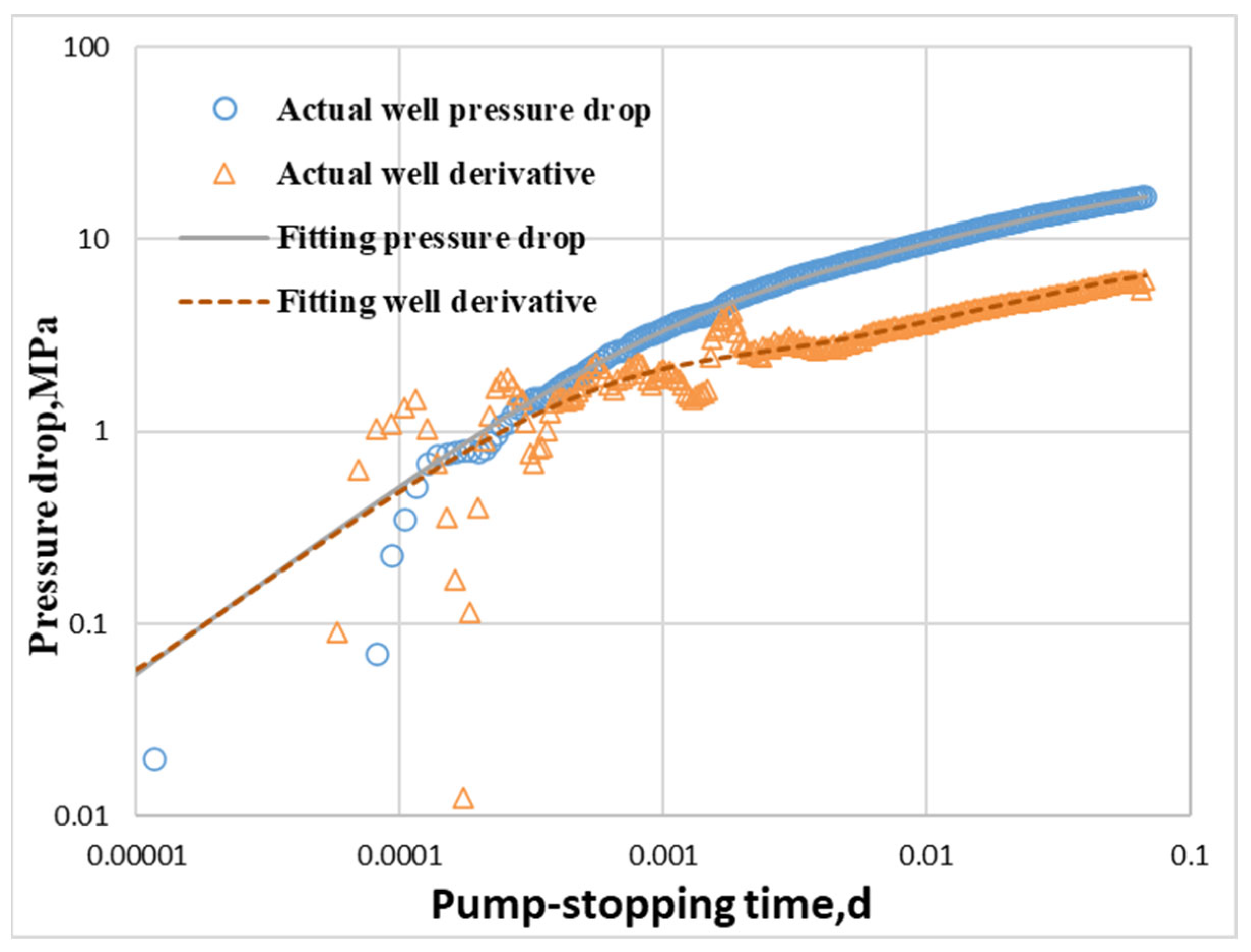

3.3. Simulated Bottom-Hole Pressure Drop

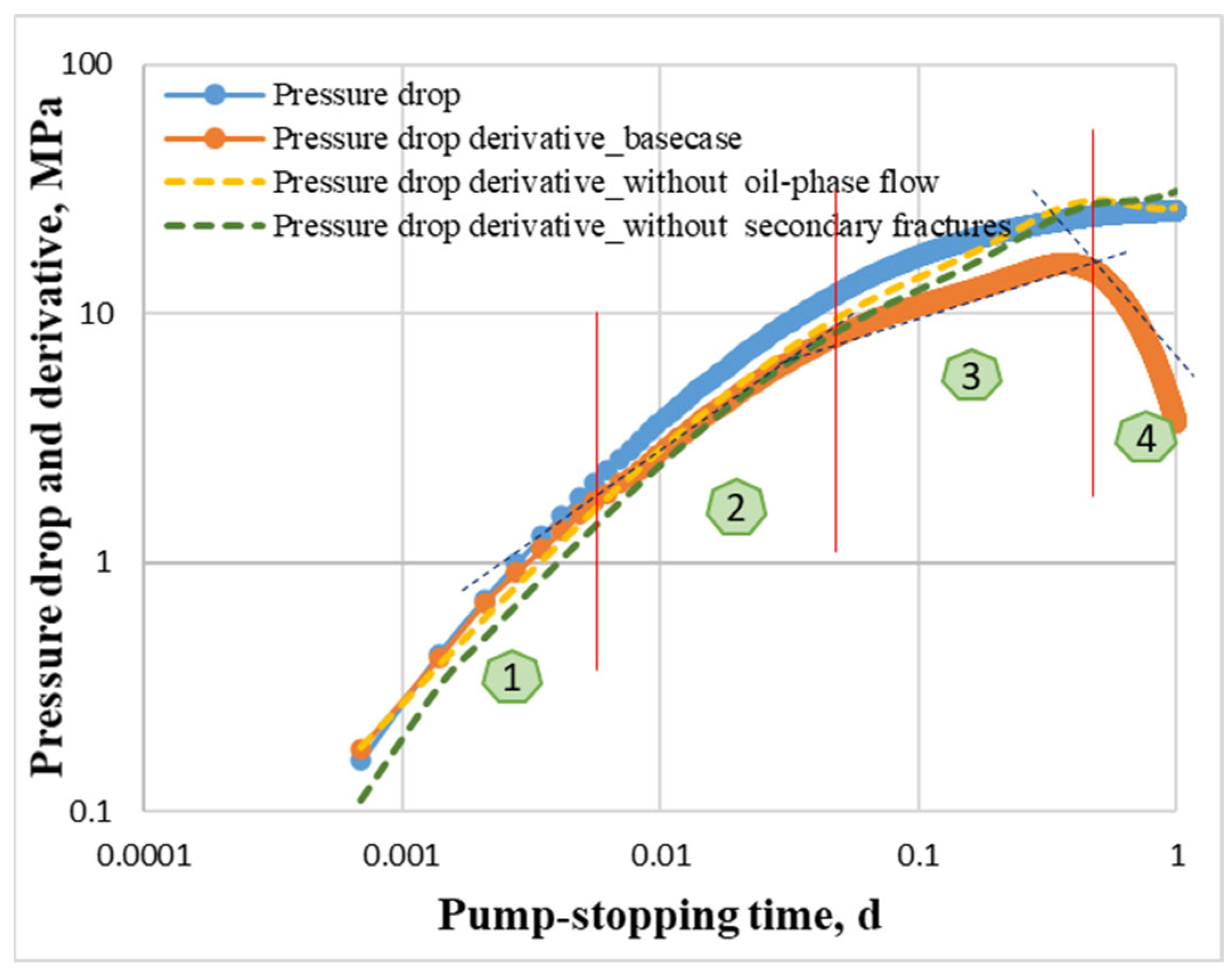

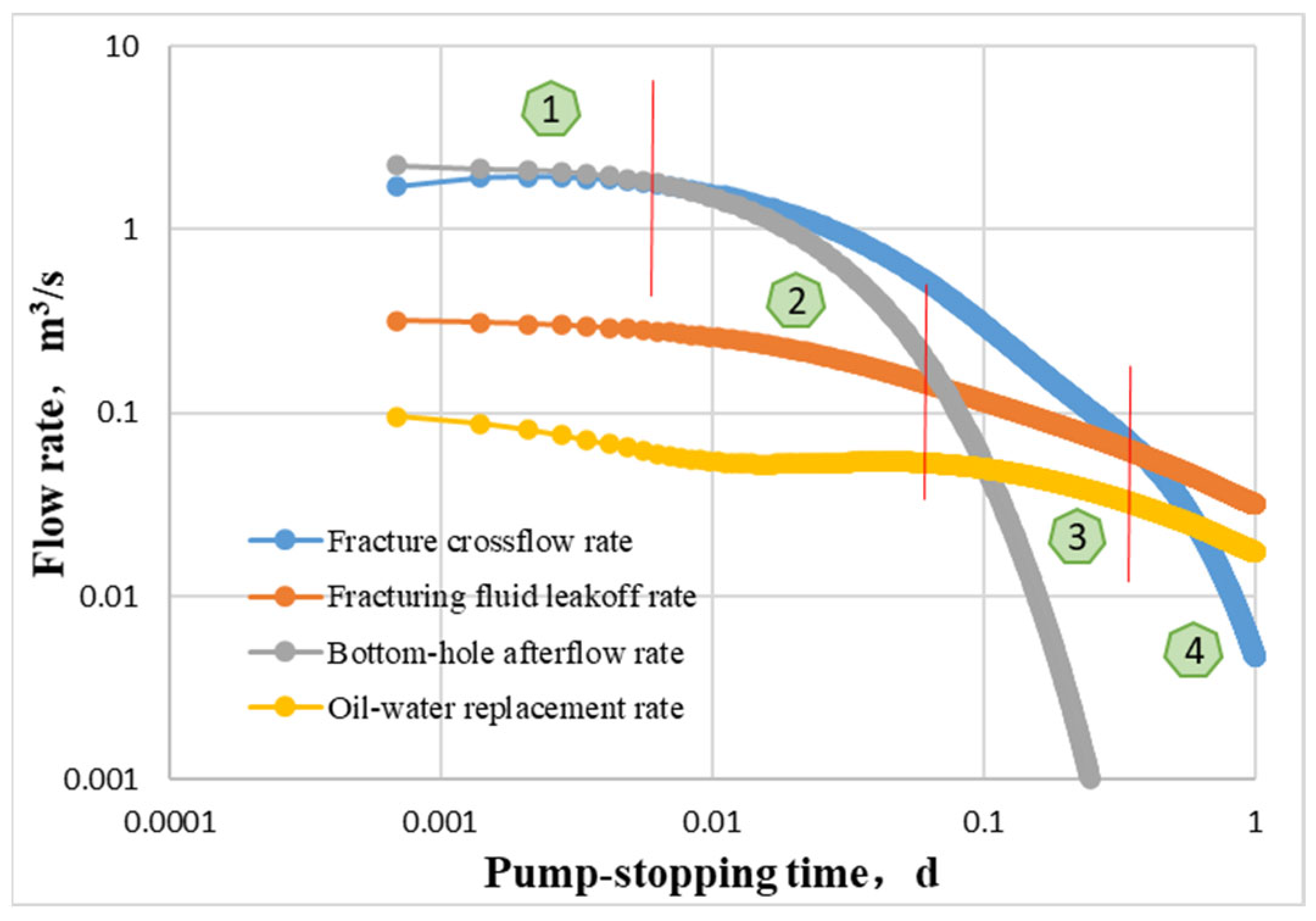

- Main fracture reservoir control stage: the fracturing fluid in the wellbore enters the main fracture after termination of pumping, showing that the pressure drop and derivative curves coincide and the slope is 1;

- Inter-fracture crossflow control stage: the fracturing fluid in the fracture system is crossflow between the main fracture and the secondary fracture, the crossflow speed exceeds the bottom hole after flow speed, and the main fracture begins to close, showing that the slope of the pressure drop derivative curve is 1/2;

- The leak-off control stage of the seam net: the rate of the bottom hole after flow and crossflow between the seams decreased rapidly, and the leak-off rate of the seam net to the substrate began to exceed the bottom hole after flow, showing that the slope of the pressure drop derivative curve was 1/4;

- Substrate imbibition and displacement control stage: the leak-off rate of the slot network begins to exceed the crossflow rate between slots, the secondary fractures begin to close, and the substrate oil change rate and the leak-off rate of slot network begin to show a synchronous downward trend, showing that the slope of pressure drop derivative curve is −1. The closing pressure can be calculated from the pressure drop corresponding to the start time of this stage.

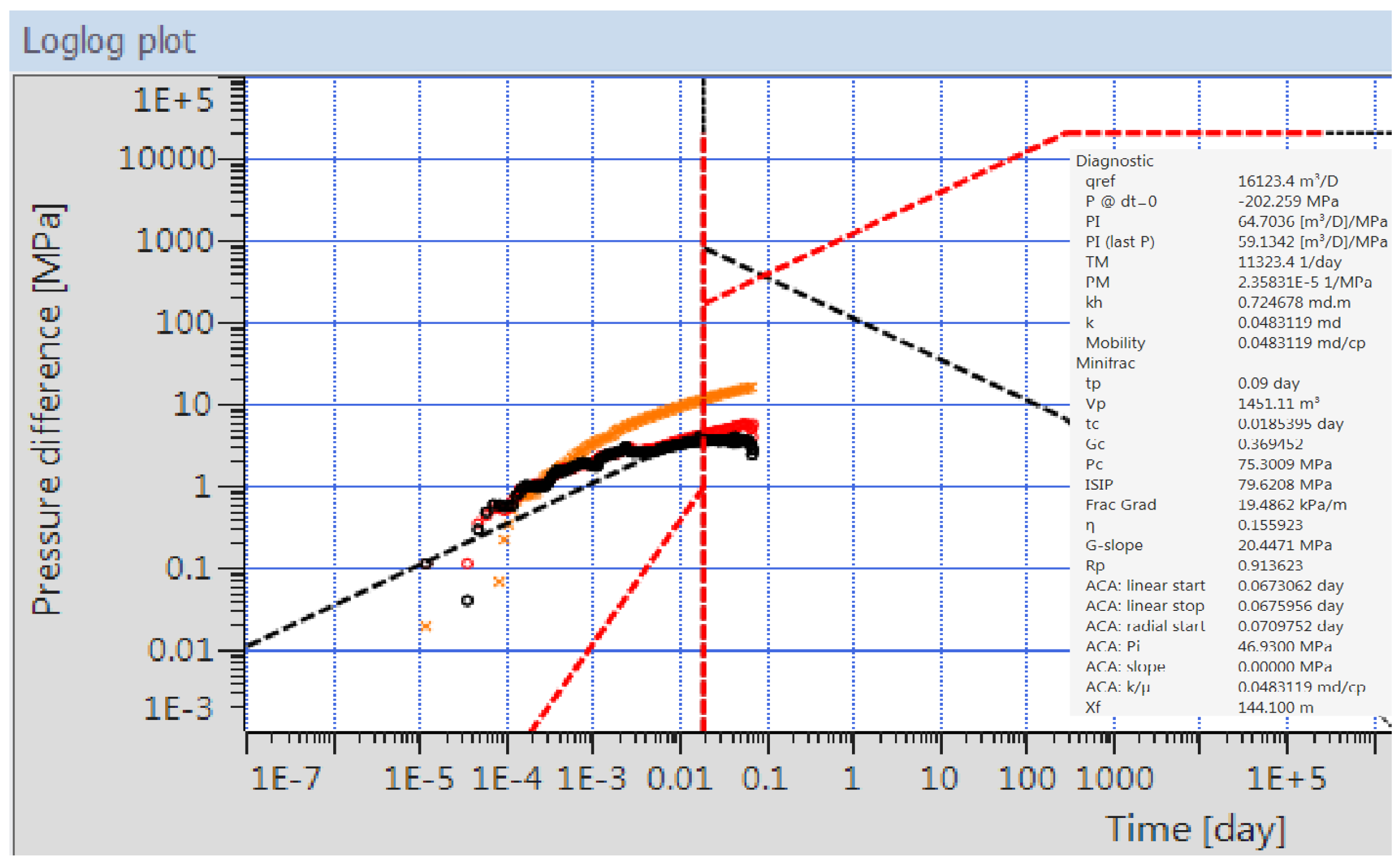

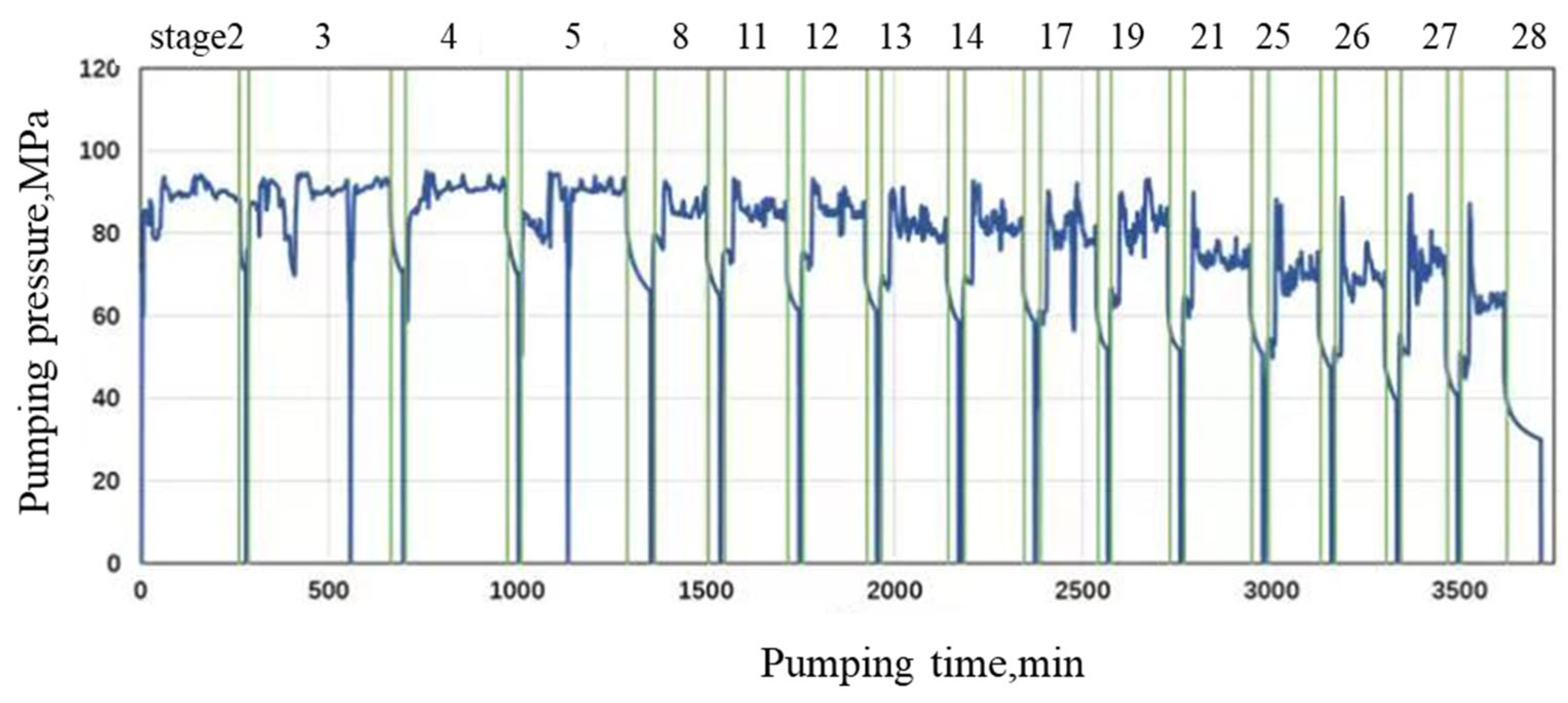

4. Field Applications

5. Conclusions

- (1)

- It is found by numerical simulation that the rate of wellbore afterflow is the largest at the initial time of pump stop, which is dominant in all flows, and then drops rapidly to a very low value. The fracturing fluid in the main fracture will further cross-flow to the secondary fracture and filter to the substrate during the pump stops. With the extension of pump stop time, the leak-off rate of fracturing fluid in the later stage will surpass other flow rates and become the dominant factor. Crude oil in the substrate will be displaced into the fracture from the initial moment when the pump is stopped, and the oil replacement rate is very low but steadily declining, and will be synchronized with the leak-off rate in the later stage.

- (2)

- According to the correlation with the flow rate among media during the pump shutdown, the pressure drop during the pump shutdown in fracturing operation is divided into four main control flow stages, which are: main fracture reservoir control stage, inter-fracture crossflow control stage, fracture net leak-off control stage and substrate imbibition and replacement control stage according to the sequence of pump stop time.

- (3)

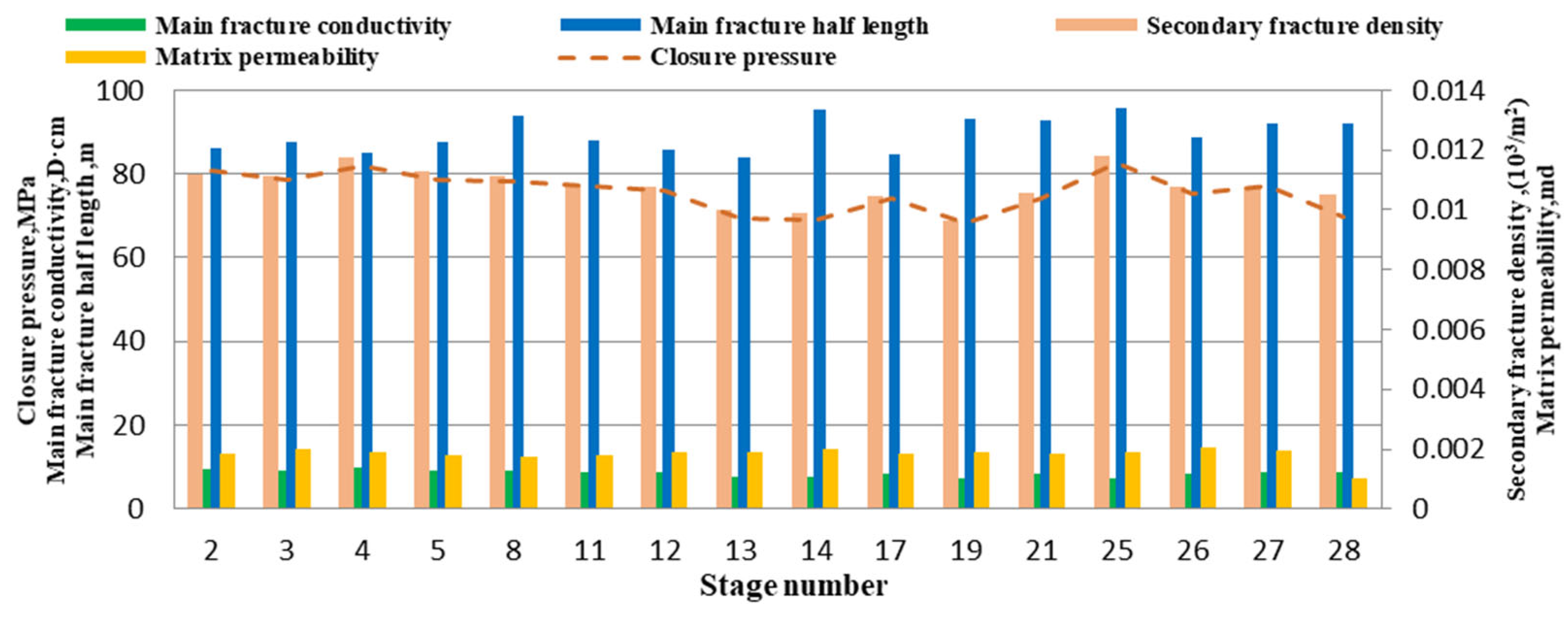

- By fitting the actual fracturing data with the proposed pressure drop model, the key parameters such as fracture network parameters (including half-length of main fracture, conductivity and density of secondary fracture), and closure pressure of each fracturing stage can be obtained by inversion. Compared with the commercial software Saphir–Minifrac model which does not consider the secondary fracture and oil exchange effect, the interpretation results of the proposed model are more accurate and reasonable. In addition, the practical application of well X1 shows that the pressure drop model proposed in this paper can be used to finely evaluate the effect of heterogeneous reoperation in each fracturing stage of horizontal wells.

Author Contributions

Funding

Conflicts of Interest

References

- Nolte, K.G. Determination of proppant and fluid schedules from fracturing-pressure decline. SPE Prod. Eng. 1986, 1, 255–265. [Google Scholar] [CrossRef]

- Valko′, P.P.; Economides, M.J. Fluid-leakoff delineation in high-permeability fracturing. SPE Prod. Facil. 1999, 14, 110–116. [Google Scholar] [CrossRef]

- Talley, G.R.; Swindell, T.M.; Waters, G.A.; Nolte, K.G. Field application of after-closure analysis of fracture calibration tests. In Proceedings of the SPE Mid-Continent Operations Symposium, Oklahoma City, OK, USA, 28–31 March 1999. [Google Scholar]

- Denney, D. Estimating pore pressure and permeability in massively stacked lenticular reservoirs. J. Pet. Technol. 1999, 51, 52–53. [Google Scholar] [CrossRef]

- Mohamed, I.M.; Azmy, R.M.; Sayed, M.; Marongiu-Porcu, M.; Ehlig-Economides, C.A. Evaluation of after-closure analysis techniques for tight and shale gas formations. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

- Marongiu-Porcu, M.; Ehlig-Economides, C.A.; Economides, M.J. Global model for fracture falloff analysis. In Proceedings of the SPE North American Unconventional Gas Conference and Exhibition, The Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

- Ma, J.; Zhao, J.; Lin, Y.; Liang, J.; Chen, J.; Chen, W.; Huang, L. Study on Tamped Spherical Detonation-Induced Dynamic Responses of Rock and PMMA Through Mini-chemical Explosion Tests and a Four-Dimensional Lattice Spring Model. Rock Mech. Rock Eng. 2023, 10, 7357–7375. [Google Scholar] [CrossRef]

- Ma, J.; Chen, J.; Chen, W.; Huang, L. A coupled thermal-elastic-plastic-damage model for concrete subjected to dynamic loading. Int. J. Plast. 2022, 153, 103279. [Google Scholar] [CrossRef]

- Ma, J.; Chen, J.; Guan, J.; Lin, Y.; Chen, W.; Huang, L. Implementation of Johnson-Holmquist-Beissel model in four-dimensional lattice spring model and its application in projectile penetration. Int. J. Impact Eng. 2022, 170, 104340. [Google Scholar] [CrossRef]

- Soliman, M.Y. Technique for considering fluid compressibility and temperature changes in mini-frac analysis. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 5–8 October 1986. [Google Scholar]

- Soliman, M.Y.; Miranda, C.; Wang, H.M. Application of after-closure analysis to a dual-porosity formation, to CBM, and to a fractured horizontal well. SPE Prod. Oper. 2010, 25, 472–483. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Kodura, A.; Kubrak, M.; Malesińska, A.; Bury, P.; Stosiak, M. Modeling Transient Pipe Flow in Plastic Pipes with Modified Discrete Bubble Cavitation Model. Energies 2021, 14, 6756. [Google Scholar] [CrossRef]

- Wang, Y.P.; Sun, L.; Zhang, S.C.; Chen, L.; Liu, P.; Chen, Z. Pressure-decline curve analysis method and its application in fracture reservoir. J. China Univ. Pet. 2004, 28, 55–57. [Google Scholar]

- Mao, G.Y.; Yang, H.C.; Zhang, W.Z. Pressure drowdown analysis method and its application in fractured reservoir. J. Oil Gas Technol. 2011, 33, 116–118+122. [Google Scholar]

- Liu, S.J.; Cai, J.J.; Wang, F.; Lv, X.R.; Wang, W. Application of improved pressure decline analysis for fracturing in offshore low permeability gas field. Fault-Block Oil Gas Field 2015, 22, 369–373. [Google Scholar]

- Liu, G.; Ehlig-Economides, C. Interpretation methodology for fracture calibration test before-closure analysis of normal and abnormal leakoff mechanisms. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 9–11 February 2016. [Google Scholar]

- Liu, G.; Ehlig-Economides, C. Practical considerations for diagnostic fracture injection test (DFIT) analysis—ScienceDirect. J. Pet. Sci. Eng. 2018, 171, 1133–1140. [Google Scholar] [CrossRef]

- Karpenko, M.; Stosiak, M.; Šukevičius, Š.; Skačkauskas, P.; Urbanowicz, K.; Deptuła, A. Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive. Machines 2023, 11, 355. [Google Scholar] [CrossRef]

- Yan, B.; Mi, L.; Wang, Y.; Tang, H.; An, C.; Killough, J.E. Mechanistic simulation workflow in shale gas reservoirs. In Proceedings of the SPE Reservoir Simulation Conference, Montgomery, TX, USA, 20–22 February 2017. [Google Scholar]

- Eshkalak, M.O.; Aybar, U.; Sepehrnoori, K. An integrated reservoir model for unconventional resources, coupling pressure dependent phenomena, SPE-171008-MS. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 21–23 October 2014. [Google Scholar] [CrossRef]

- Raghavan, R.; Chin, L.Y. Productivity changes in reservoirs with stress-dependent permeability, SPE-77535-MS. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002. [Google Scholar] [CrossRef]

- Petro, D.R.; Chu, W.; Burk, M.K.; Rogers, B.A. Benefits of pressure transient testing in evaluating compaction effects: Gulf of Mexico deepwater turbidite sands, SPE-38938-MS. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar] [CrossRef]

- Wang, F.; Pan, Z.; Zhang, Y.; Zhang, S. Simulation of coupled hydro-mechanical-chemical phenomena in hydraulically fractured gas shale during fracturing-fluid flowback. J. Pet. Sci. Eng. 2018, 163, 16–26. [Google Scholar] [CrossRef]

- Huang, X.; Wang, J.; Chen, S.N.; Gates, I.D. A simple dilation-recompaction model for hydraulic fracturing. J. Unconv. Oil Gas Resour. 2016, 16, 62–75. [Google Scholar] [CrossRef]

- Maxwell, S.; Deere, J. An introduction to this special section: Microseismic. Lead. Edge 2010, 29, 277. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Zhu, J.; Wang, J.; Wei, Z.; Sun, Y.; Li, Y.; Wu, J.; Wang, F. Model and Analysis of Pump-Stopping Pressure Drop with Consideration of Hydraulic Fracture Network in Tight Oil Reservoirs. Processes 2023, 11, 3145. https://doi.org/10.3390/pr11113145

Wang M, Zhu J, Wang J, Wei Z, Sun Y, Li Y, Wu J, Wang F. Model and Analysis of Pump-Stopping Pressure Drop with Consideration of Hydraulic Fracture Network in Tight Oil Reservoirs. Processes. 2023; 11(11):3145. https://doi.org/10.3390/pr11113145

Chicago/Turabian StyleWang, Mingxing, Jian Zhu, Junchao Wang, Ziyang Wei, Yicheng Sun, Yuqi Li, Jiayi Wu, and Fei Wang. 2023. "Model and Analysis of Pump-Stopping Pressure Drop with Consideration of Hydraulic Fracture Network in Tight Oil Reservoirs" Processes 11, no. 11: 3145. https://doi.org/10.3390/pr11113145

APA StyleWang, M., Zhu, J., Wang, J., Wei, Z., Sun, Y., Li, Y., Wu, J., & Wang, F. (2023). Model and Analysis of Pump-Stopping Pressure Drop with Consideration of Hydraulic Fracture Network in Tight Oil Reservoirs. Processes, 11(11), 3145. https://doi.org/10.3390/pr11113145