Flow Control in Multiphase Pumps Based on Separated Trailing Edge Flap

Abstract

:1. Introduction

2. Numerical Models and Methods

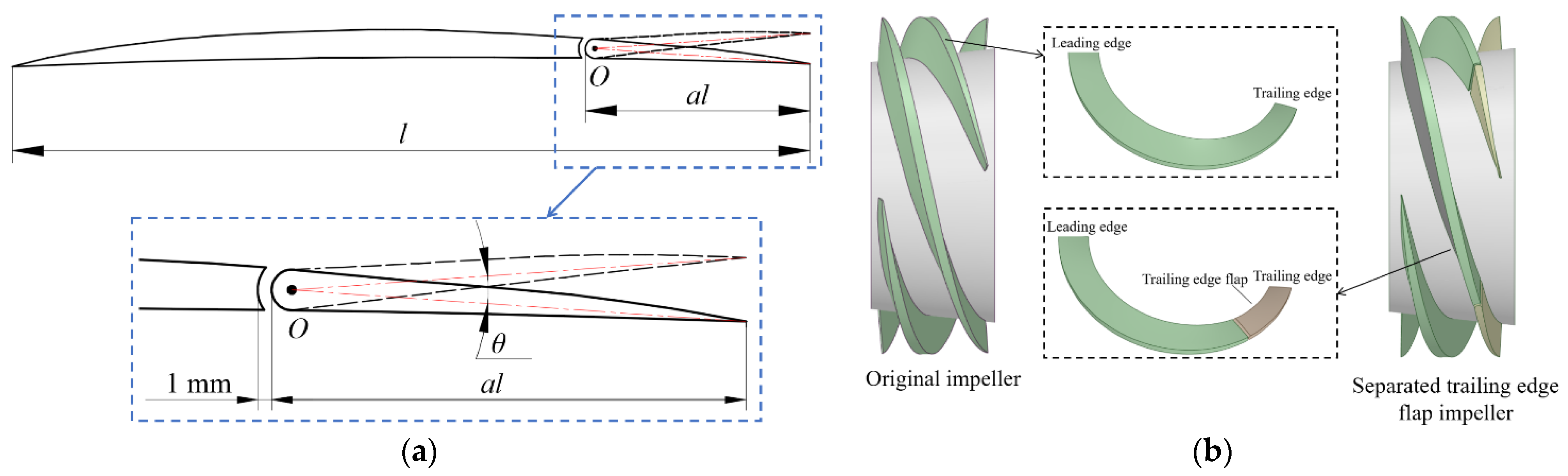

2.1. Geometric Models

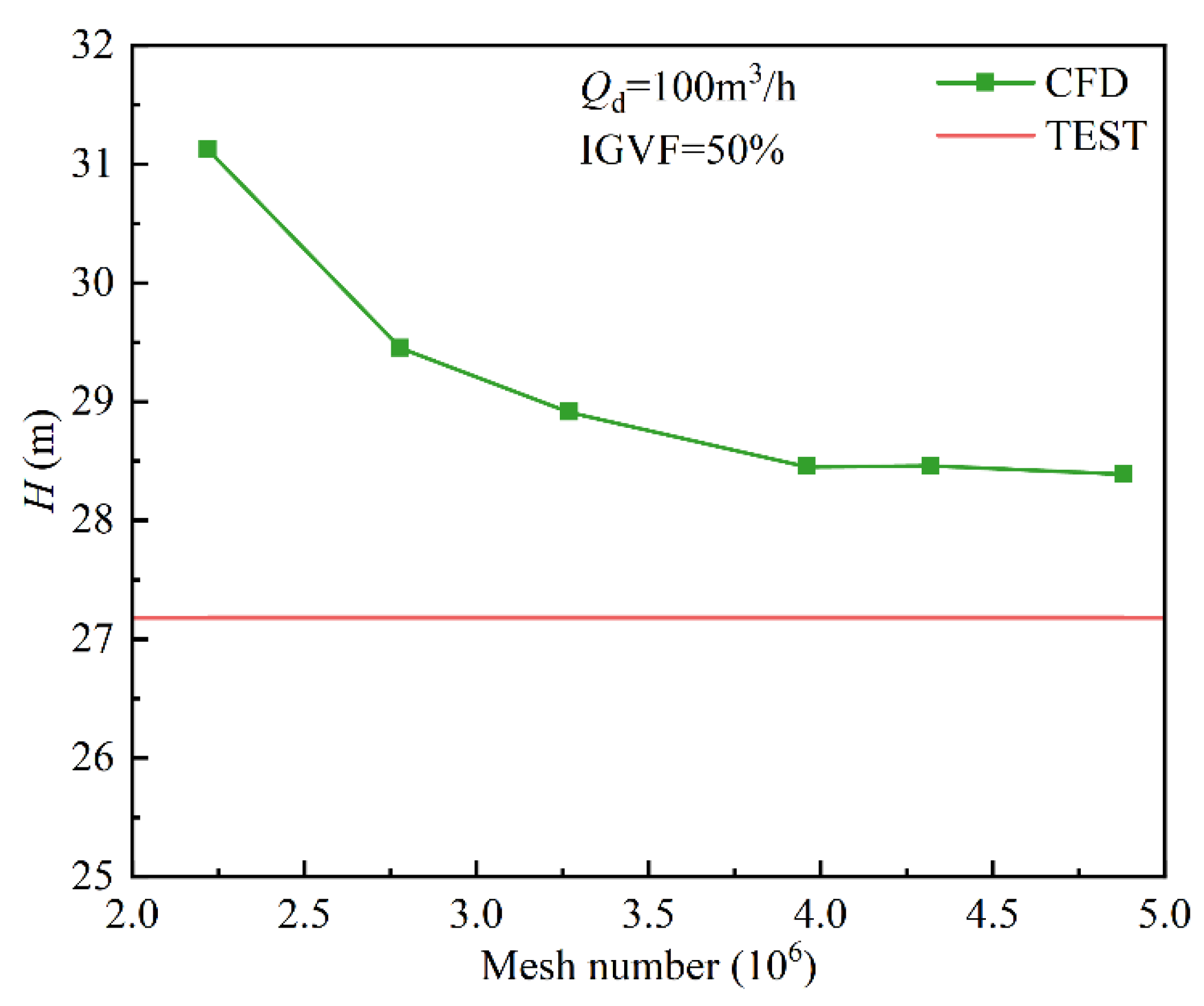

2.2. Mesh Generation

2.3. Governing Equations and Numerical Settings

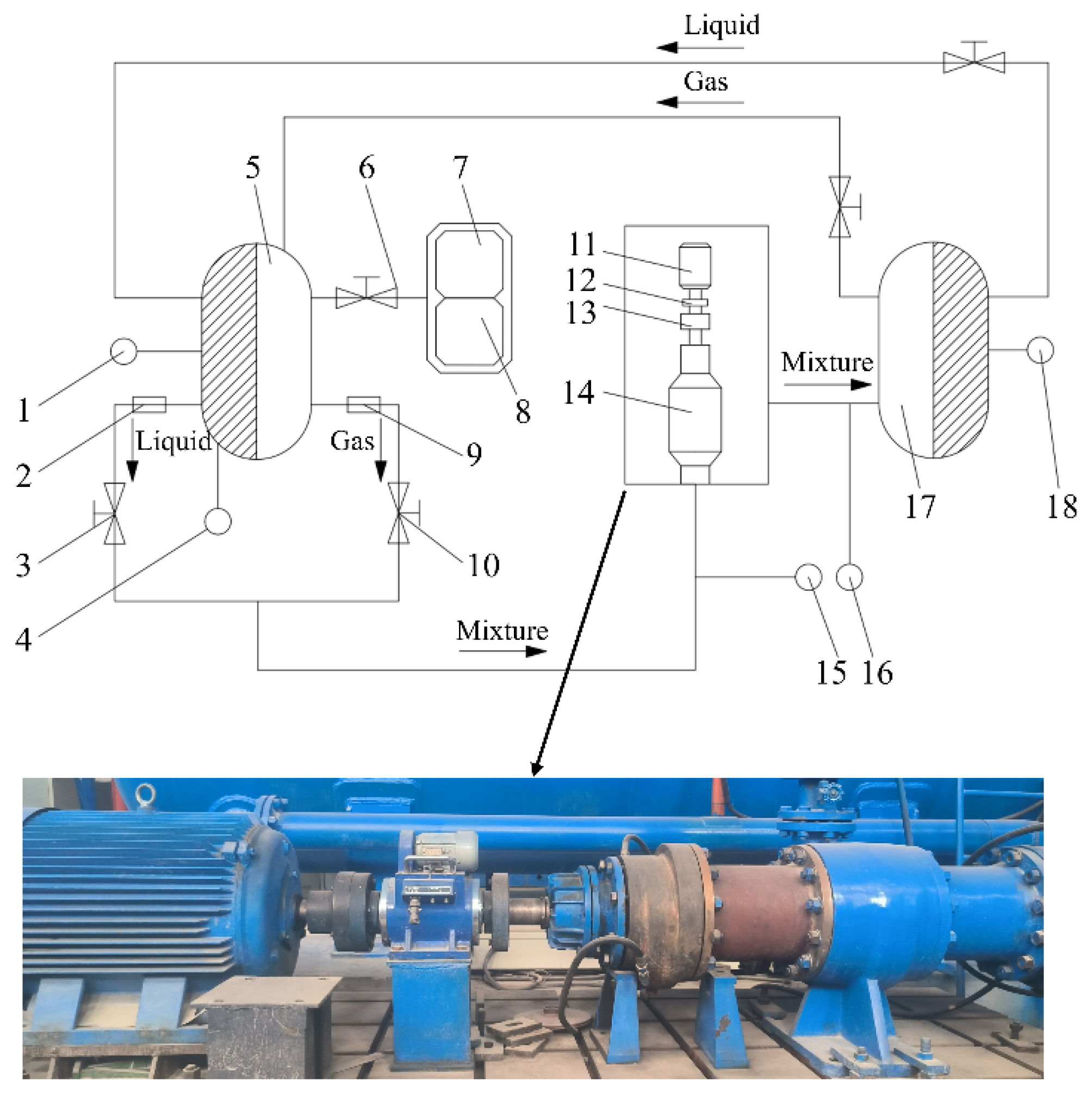

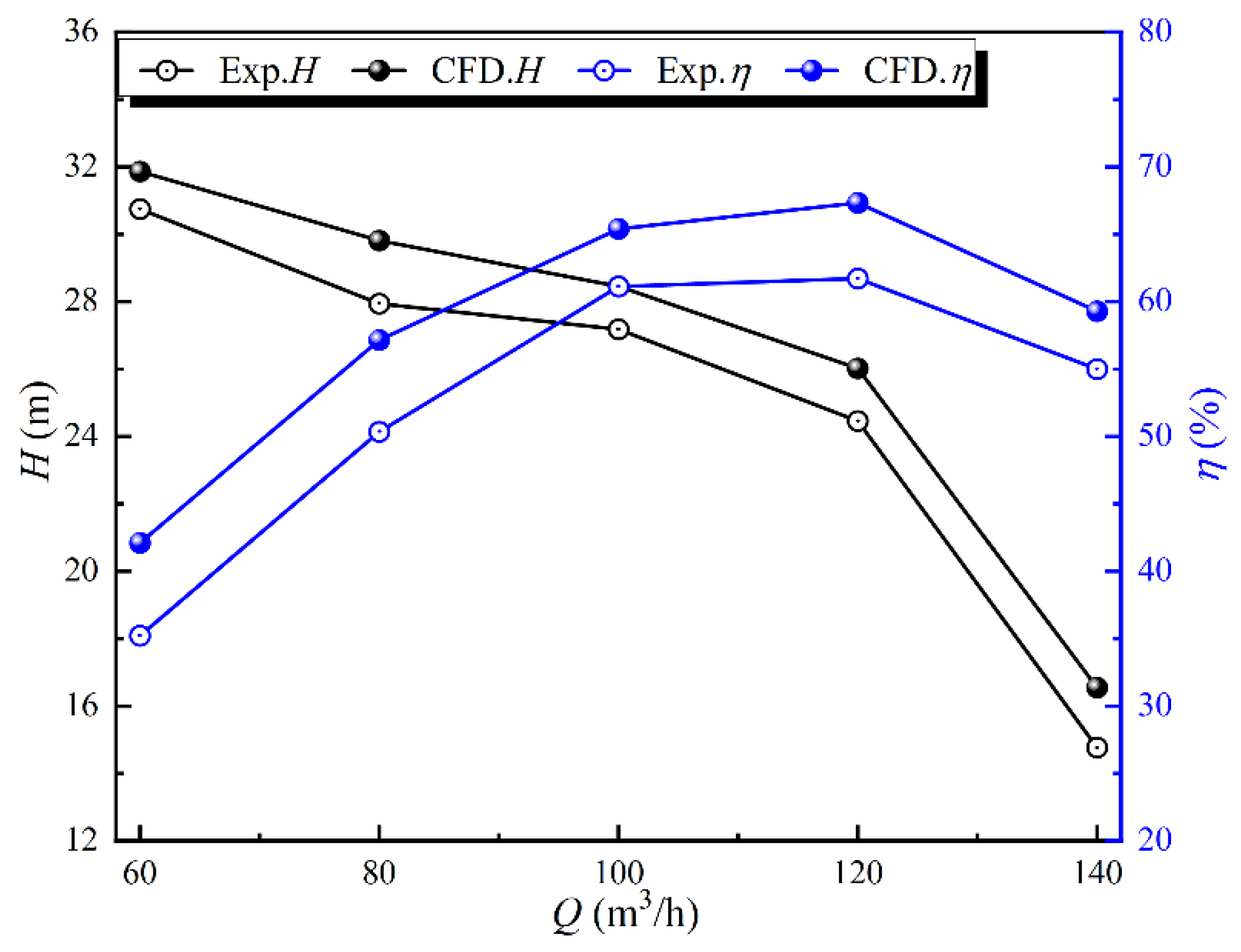

2.4. Experiment Verification

3. Design Schemes

4. Results

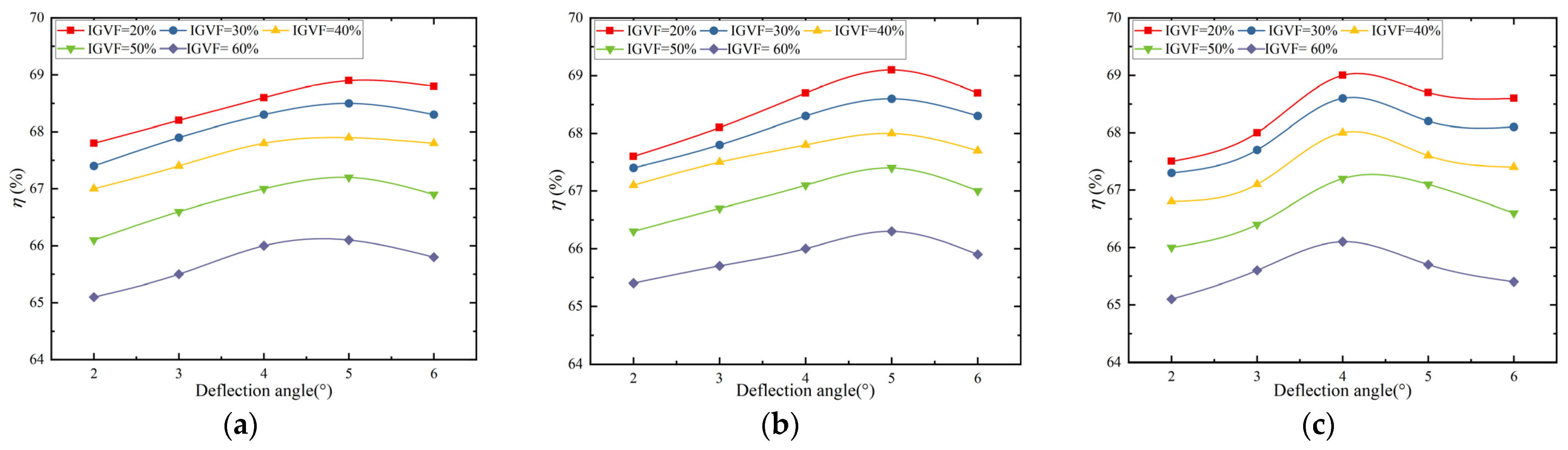

4.1. Hydraulic Performance Analysis

4.2. Internal Flow Characteristics of the Multiphase Pump with Trailing Edge Flap Length of 0.25 l

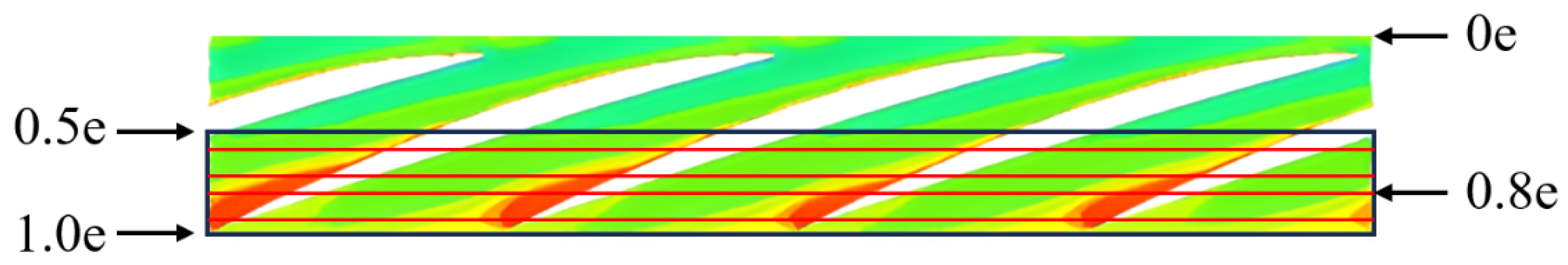

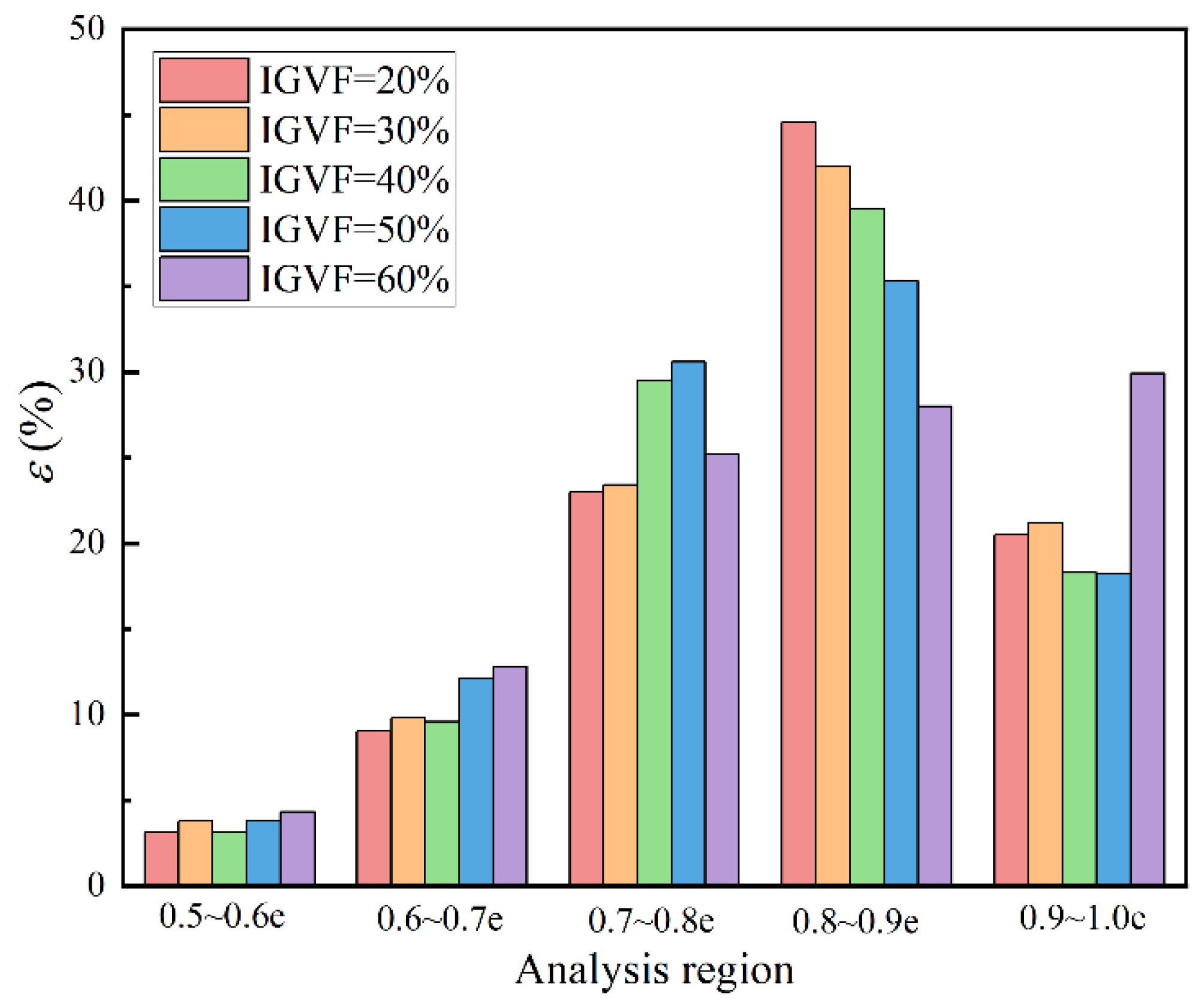

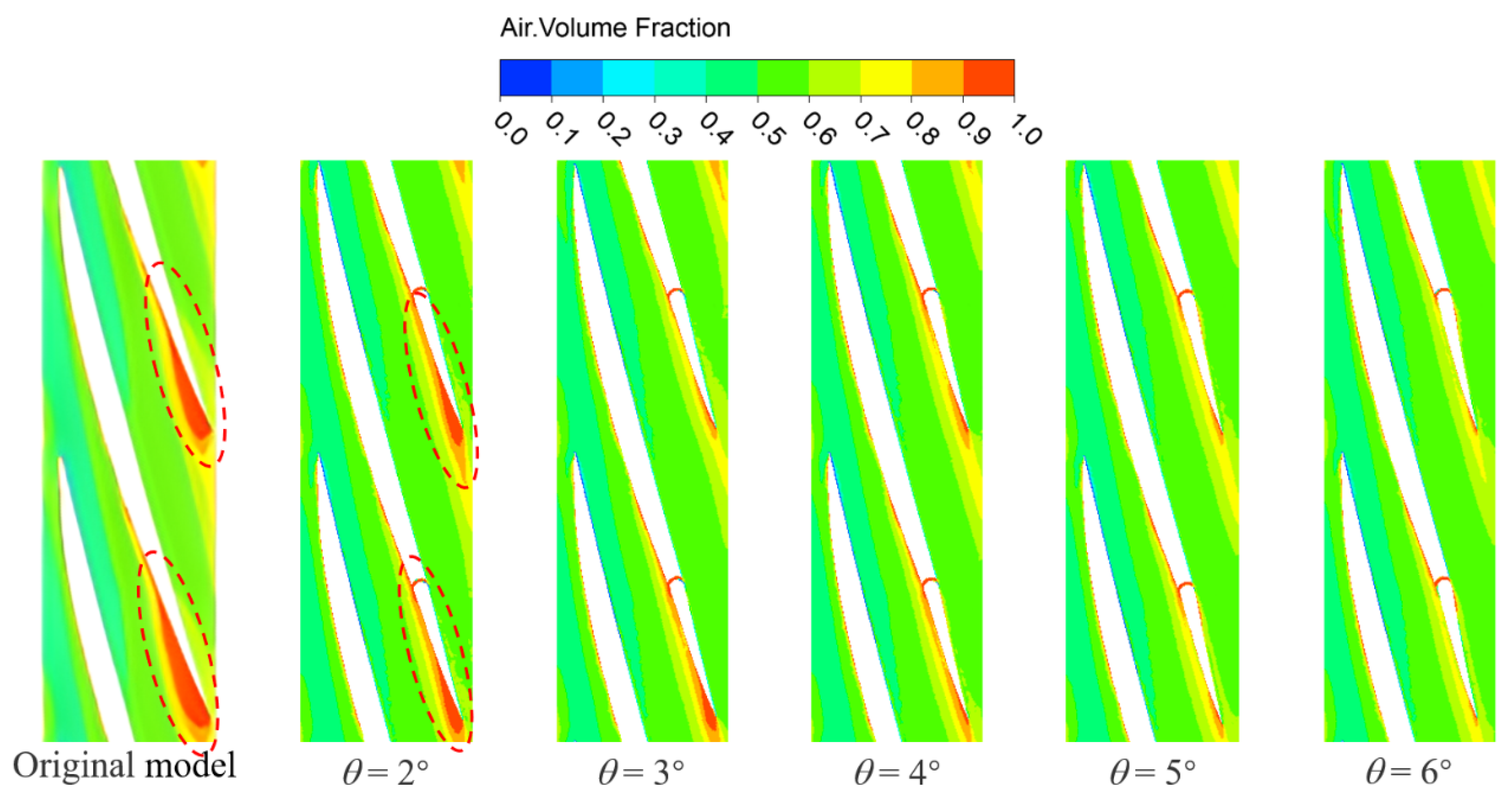

4.2.1. Gas-Phase Distribution Law

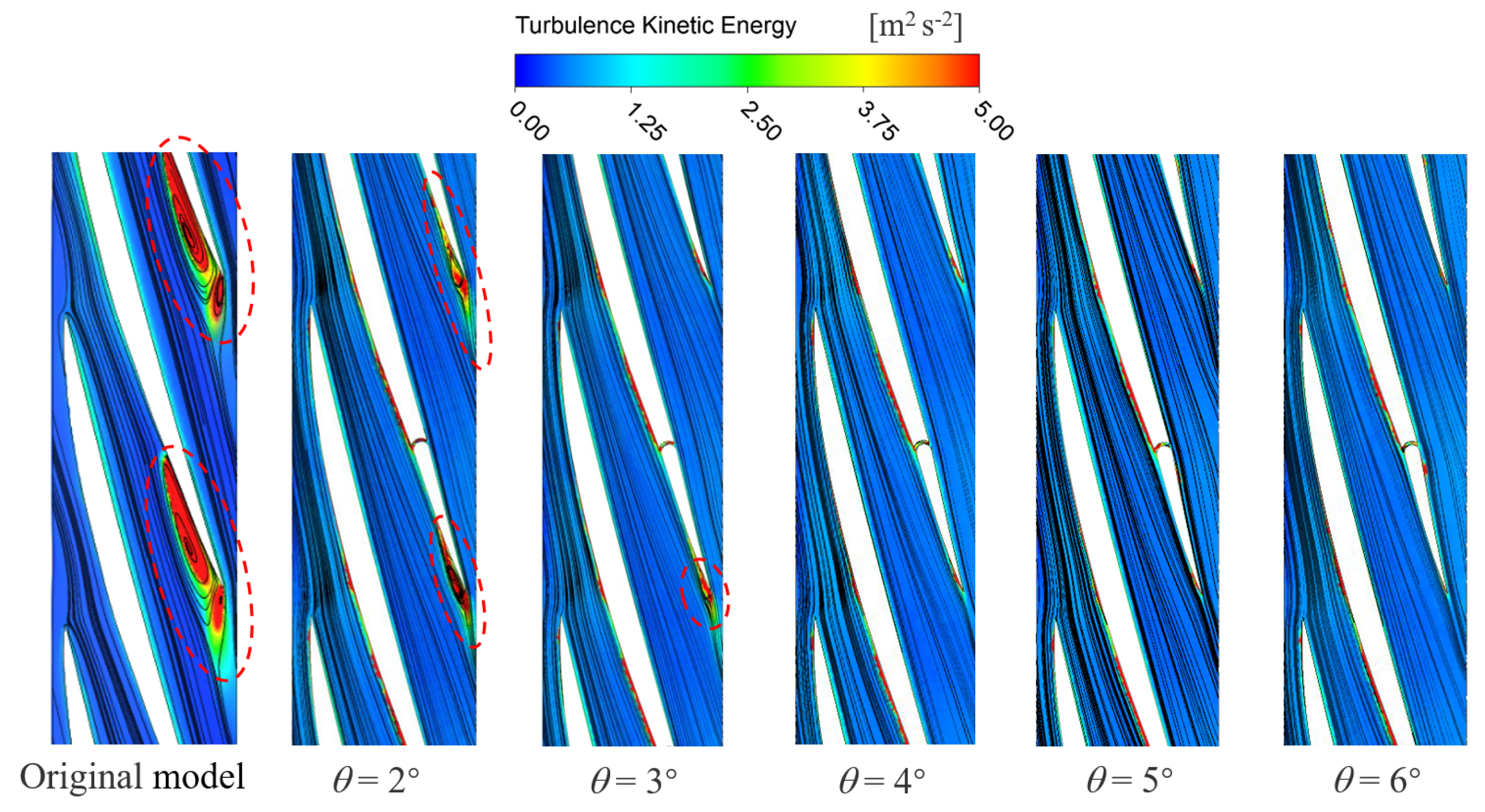

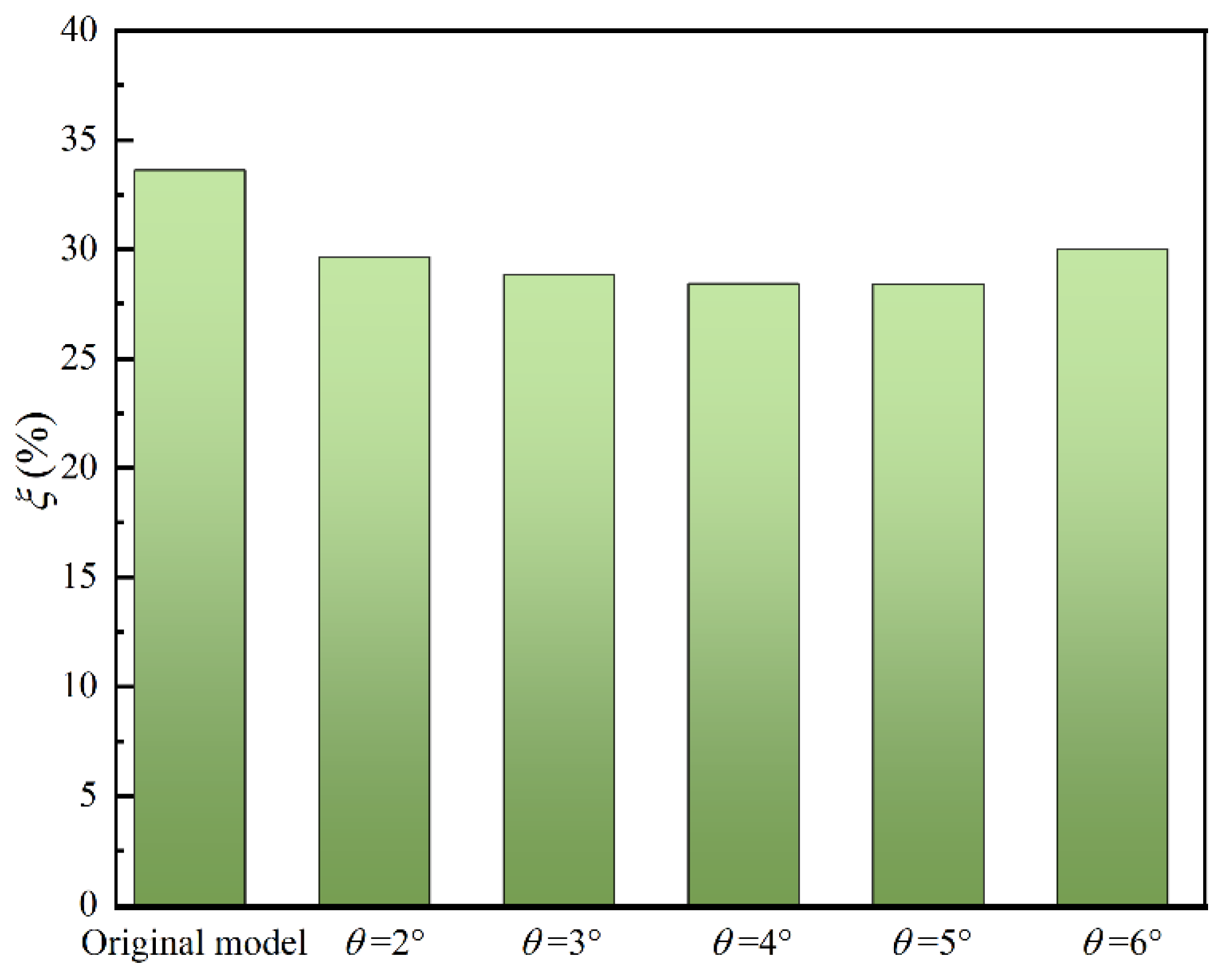

4.2.2. Energy LOSS characteristics

4.2.3. Pressure Distribution Laws

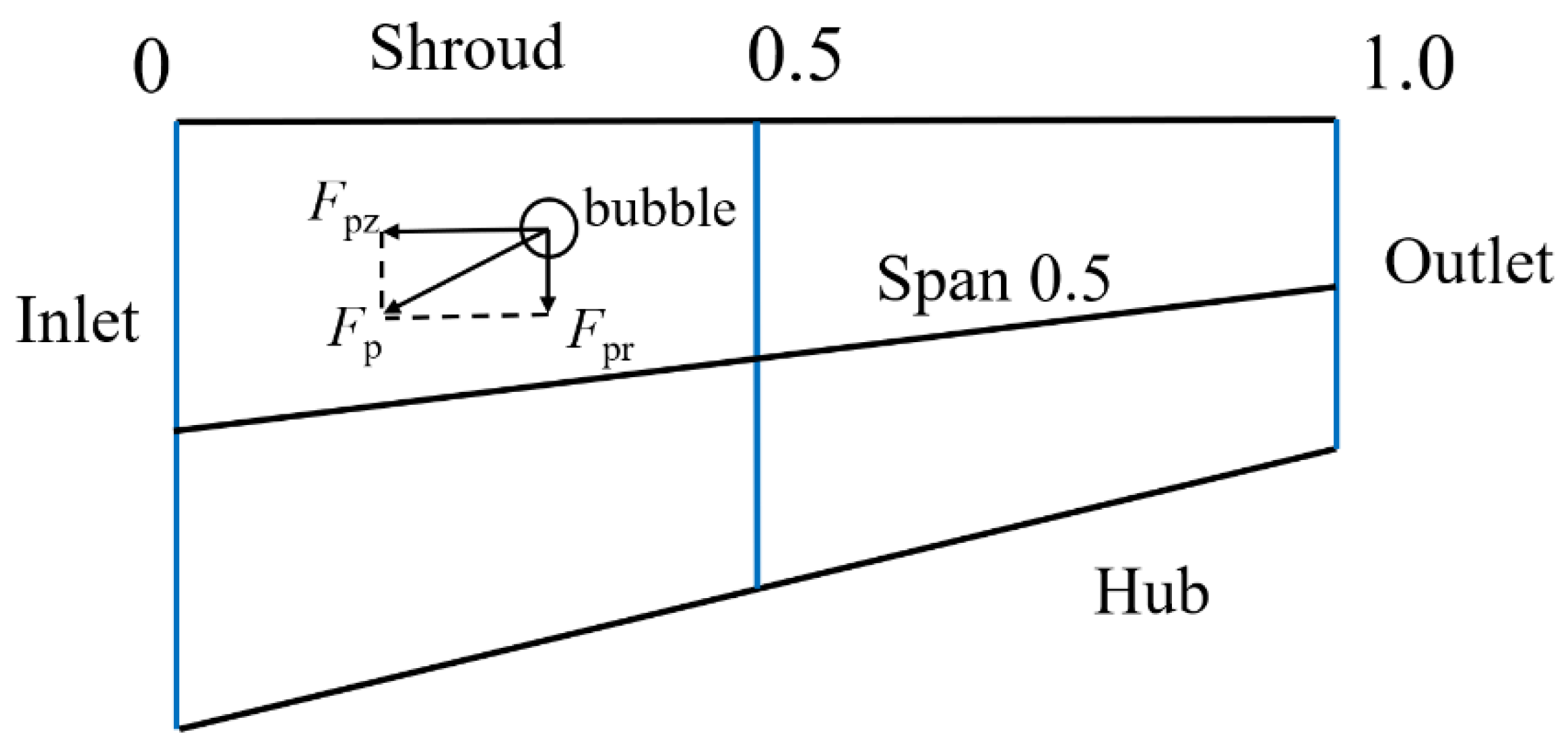

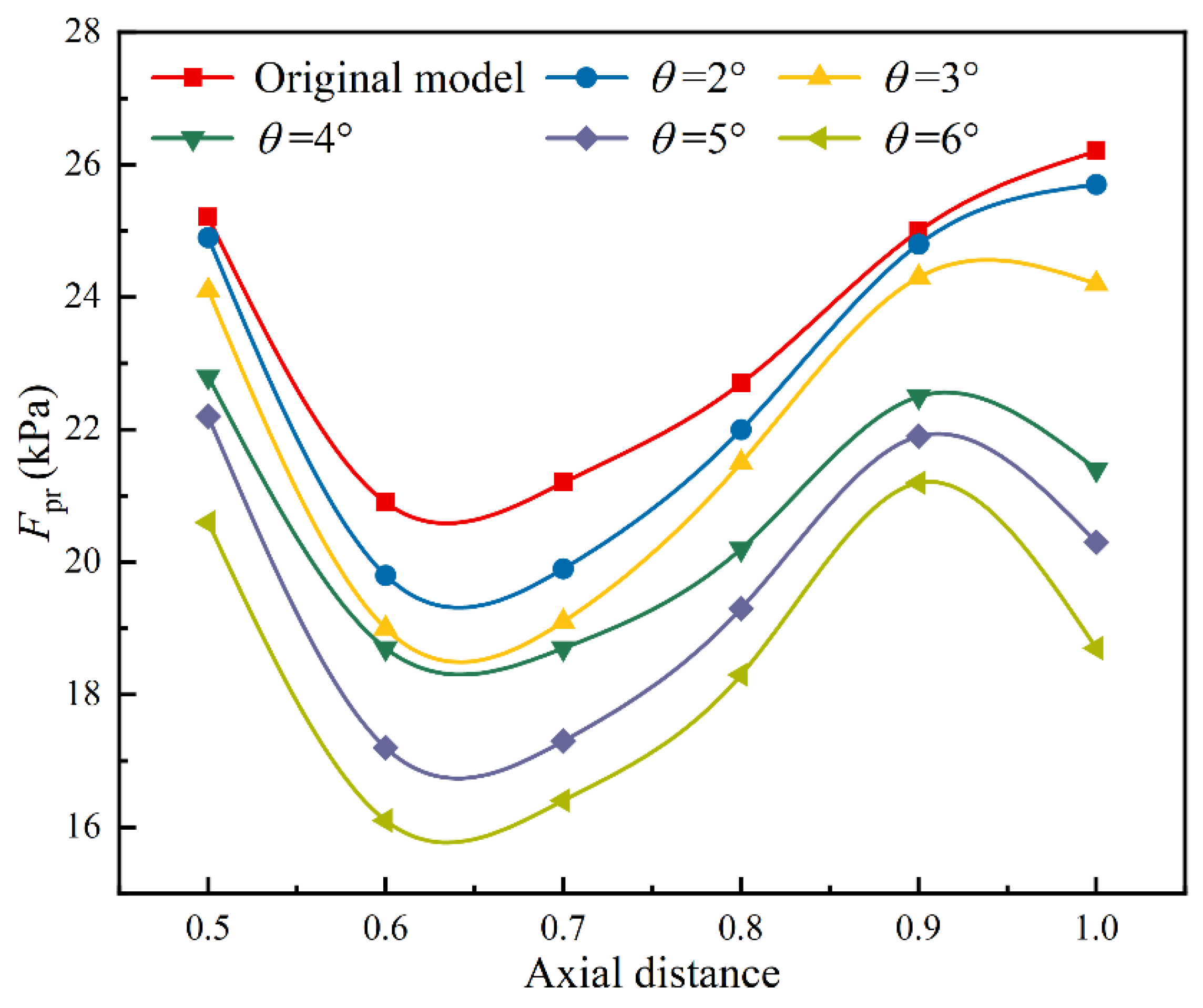

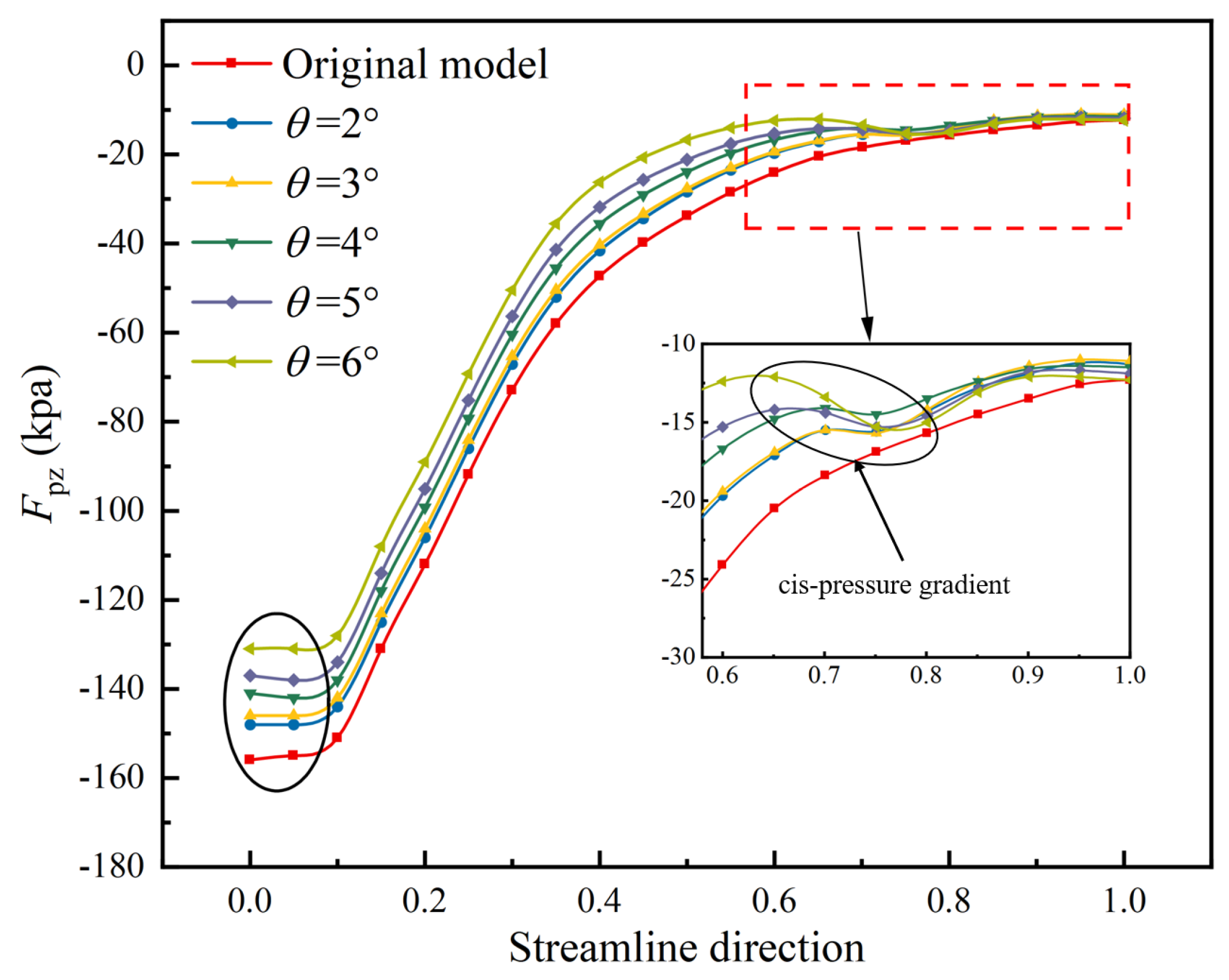

4.2.4. Pressure Gradient Analysis along the Streamwise Location

5. Conclusions

- (1)

- When the length of the trailing edge flap remains fixed, the efficiency curves for different deflection angles exhibit a parabolic trend, indicating the presence of an optimal efficiency point—the consistent location of the optimal point across various gas volume fractions. The gradually declining trend in the head suggests a loss in the pressure-raising capability of the blade structure. Upon comparison, it is evident that the highest efficiency is achieved when the trailing edge flap length is 0.25 l and with a deflection angle of 5°.

- (2)

- The introduction of the trailing edge flap significantly improves the aggregation of the gas phase near the trailing edge of the blade as the deflection angle increases. The internal fluid energy loss characteristics of each scheme were quantitatively analyzed through the defined energy dissipation rate. With an increase in the deflection angle of the trailing edge flap, the dissipation vortex structure on the blade’s suction surface diminishes gradually, thereby reducing the loss of fluid kinetic energy. However, when the deflection angle becomes excessive, the formation of impact near the connection of the trailing edge flap to the main blade structure could introduce new energy losses.

- (3)

- Analyzing the pressure field under different trailing edge flap schemes reveals that increasing the deflection angle, despite causing some loss in pressure-raising capacity, effectively reduces the radial pressure gradient at the trailing edge of the impeller passage. This effectively mitigates the separation of the gas–liquid two-phase fluid medium.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Variable Definitions | |

| D | Impeller shroud diameter (mm) |

| H | Head (m) |

| Qv | Design flow rate (m3·h−1) |

| l | Airfoil chord length (-) |

| le | Axial length (mm) |

| n | Rotational speed (rpm) |

| ns | Specific speed (-) |

| S | Analysis area (mm2) |

| Y+ | y plus value (-) |

| Ucom | Comprehensive uncertainty (%) |

| Uran | Random uncertainty (%) |

| Usys | System uncertainty (%) |

| Z | Impeller blade number (-) |

| θ | Deflection angle (%) |

| η | Efficiency (%) |

| ε | Gas-phase aggregation distribution ratio (%) |

| ξ | Energy dissipation coefficient (%) |

| β | Hub half cone angle (°) |

| Acronyms | |

| IGVF | Inlet gas void fraction |

References

- Wangxu, L.; Zhenggui, L.; Wanquan, D.; Lei, J.; Yilong, Q.; Huiyu, C. Particle image velocimetry flowmeter for natural gas applications. Flow Meas. Instrum. 2021, 82, 102072. [Google Scholar] [CrossRef]

- Han, W.; Li, X.; Su, Y.; Su, M.; Li, R.; Zhao, Y. Effect of Thickness Ratio Coefficient on the Mixture Transportation Characteristics of Helical–Axial Multiphase Pumps. Appl. Sci. 2020, 10, 345. [Google Scholar] [CrossRef]

- Suh, J.W.; Kim, J.H.; Choi, Y.S.; Joo, W.G.; Lee, K.Y. A study on numerical optimization and performance verification of multiphase pump for offshore plant. Proc. Inst. Mech. Eng. Part A J. Power Energy 2017, 231, 382–397. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Influence of viscosity on energy performance and flow field of a multiphase pump. Renew. Energy 2020, 162, 1151–1160. [Google Scholar] [CrossRef]

- Sano, T.; Wakai, T.; Reclari, M.; Xu, Y.; Cao, S.L. Investigation of internal flow pattern of a multiphase axial pump. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 062058. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, H.; Zhang, W.; Xie, Z. Energy performance and flow characteristics of a multiphase pump with different tip clearance sizes. Adv. Mech. Eng. 2019, 11, 1687814018823356. [Google Scholar] [CrossRef]

- Yi, S.; Hongwu, Z. Proposal of a stage-by-stage design method and its application on a multi-stage multiphase pump based on numerical simulations. Adv. Mech. Eng. 2021, 13, 1687814020987317. [Google Scholar]

- Yu, Z.; Zhu, B.; Cao, S. Interphase force analysis for air-water bubbly flow in a multiphase rotodynamic pump. Eng. Comput. 2015, 32, 2166–2180. [Google Scholar] [CrossRef]

- Yuxuan, D.; Xiaodong, W.; Jing, X.; Yanna, L.; Yanli, Z.; Chunyan, K. Gas–Liquid Interaction Characteristics in a Multiphase Pump under Different Working Conditions. Processes 2022, 10, 1977. [Google Scholar]

- Mohammadi, M.; Hosseinzadeh, K.; Ganji, D.D. Numerical analysis on the impact of axial grooves on vortex cooling behavior in gas turbine blade’s leading edge. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 77, 09544089231163113. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, W. Computation and validation of the interphase force models for bubbly flow. Int. J. Heat Mass Transf. 2016, 98, 799–813. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, S.; Sano, T.; Wakai, T.; Reclari, M. Experimental Investigation on Transient Pressure Characteristics in a Helico-Axial Multiphase Pump. Energies 2019, 12, 461. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, H.; Zhang, J.; Zhang, J.; Zhao, J. Experiment and numerical study of a new generation three-stage multiphase pump. J. Pet. Sci. Eng. 2018, 169, 471–484. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.; Zhang, J.; Zhu, J. Flow pattern recognition inside a rotodynamic multiphase pump via developed entropy production diagnostic model. J. Pet. Sci. Eng. 2020, 194, 107467. [Google Scholar] [CrossRef]

- Weihua, S.; Zhiyi, Y.; Ke, Z.; Zheng, L. Analysis of Tip Clearance Effect on the Transportation Characteristics of a Multiphase Rotodynamic Pump Based on the Non-Uniform Bubble Model. Fluids 2022, 7, 58. [Google Scholar]

- Xiao, W.; Tan, L. Design method of controllable velocity moment and optimization of pressure fluctuation suppression for a multiphase pump. Ocean. Eng. 2021, 220, 108402. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Xu, Y.; Cao, S. Optimization design method of multi-stage multiphase pump based on Oseen vortex. J. Pet. Sci. Eng. 2020, 184, 106532. [Google Scholar] [CrossRef]

- Cancan, P.; Xiaodong, Z.; Zhiguang, G.; Ju, W.; Yan, G. Research on cooperative optimization of multiphase pump impeller and diffuser based on adaptive refined response surface method. Adv. Mech. Eng. 2022, 14, 16878140211072944. [Google Scholar] [CrossRef]

- Patone, G.; Müller, W. Aeroflexible Oberflächenklappen als“Rückstrombremsen” nach Demvorbild der Eckfedern Desvogelflügels; Technical Report TR-96–05; Technical University: Berlin, Germany, 1996. [Google Scholar]

- Barlas, T.K.; Van Wingerden, W.; Hulskamp, A.W.; van Kuik, G.M.; Bersee, H.N. Smart dynamic rotor control using active flaps on a small-scale wind turbine: Aeroelastic modeling and comparison with wind tunnel measurements. Wind Energy 2013, 16, 1287–1301. [Google Scholar] [CrossRef]

- Jawahar, K.H.; Ai, Q.; Azarpeyvand, M. Experimental and numerical investigation of aerodynamic performance for airfoils with morphed trailing edges. Renew. Energy 2018, 127, 355–367. [Google Scholar] [CrossRef]

- Feszty, D.; Gillies, A.E.; Vezza, M. Alleviation of Airfoil Dynamic Stall Moments via Trailing-Edge Flap Flow Control. AIAA J. 2012, 42, 17–25. [Google Scholar] [CrossRef]

- Mansi, A.; Aydin, D. The impact of trailing edge flap on the aerodynamic performance of small-scale horizontal axis wind turbine. Energy Convers. Manag. 2022, 256, 115396. [Google Scholar] [CrossRef]

- Zhuang, C.; Yang, G.; Zhu, Y.; Hu, D. Effect of morphed trailing-edge flap on aerodynamic load control for a wind turbine blade section. Renew. Energy 2020, 148, 964–974. [Google Scholar] [CrossRef]

- Li, W.; Li, Z.; Han, W.; Li, Y.; Yan, S.; Zhao, Q.; Gu, Z. Pumping-velocity variation mechanisms of a ferrofluid micropump and structural optimization for reflow inhibition. Phys. Fluids 2023, 35, 052005. [Google Scholar]

- Wang, J.; Zha, H.; McDonough, J.M.; Zhang, D. Analysis and numerical simulation of a novel gas–liquid multiphase scroll pump. Int. J. Heat Mass Transf. 2015, 91, 27–36. [Google Scholar] [CrossRef]

- Ge, Z.; He, D.; Huang, R.; Zuo, J.; Luo, X. Application of CFD-PBM coupling model for analysis of gas-liquid distribution characteristics in centrifugal pump. J. Pet. Sci. Eng. 2020, 194, 107518. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, H.; Shi, G.; Liu, X. Flow characteristics and energy loss within the static impeller of multiphase pump. Processes 2021, 9, 1025. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, H.; Yin, B.; Xu, R.; Zhang, J. Numerical investigation of two-phase flow characteristics in multiphase pump with split vane impellers. J. Mech. Sci. Technol. 2019, 33, 1651–1661. [Google Scholar] [CrossRef]

- Li, W.; Li, Z.; Han, W.; Li, Y.; Yan, S.; Zhao, Q.; Chen, F. Measured viscosity characteristics of Fe3O4 ferrofluid in magnetic and thermal fields. Phys. Fluids 2023, 35, 012002. [Google Scholar] [CrossRef]

| Parameter | Numerical Value |

|---|---|

| Design flow rate Qv/(m3·h−1) | 100 |

| Head H/m | 30 |

| Rotational speed n/rpm | 4500 |

| Specific speed ns | 214.4 |

| Efficiency η/% | 62 |

| Impeller shroud diameter D/mm | 150 |

| Impeller blade number Z | 4 |

| Hub half cone angle β | 6° |

| Axial length le/mm | 55 |

| Parameter | Measuring Apparatus | Type | Range | Accuracy |

|---|---|---|---|---|

| Pressure (kPa) | Pressure sensor | MEX-3051TG | 0–900 | ±0.2% |

| Liquid flow rate (m3/h) | Electromagnetic Flowmeter | SR-LDEDN150 | 14–200 | ±0.5% |

| Gas flow rate (L/min) | Vortex flowmeter | SR-LWGYDN20 | 0–1500 | ±0.5% |

| Torque (N·m) | Rotational speed and torque sensor | NJ1 | 0–100 | ±0.2% |

| Rotational speed (r/min) | 0–10000 | ±0.2% |

| Ql (m3/h) | Qg (L/min) | H (m) | T (N·m) | N (r/min) | ||

|---|---|---|---|---|---|---|

| Test number | 1 | 50.14 | 831.34 | 27.11 | 12.81 | 4501.12 |

| 2 | 49.78 | 834.46 | 27.09 | 12.79 | 4502.63 | |

| 3 | 50.31 | 833.41 | 27.18 | 12.88 | 4500.81 | |

| 4 | 50.25 | 832.12 | 27.15 | 12.94 | 4501.54 | |

| 5 | 50.05 | 833.78 | 27.17 | 12.85 | 4500.62 | |

| Random uncertainty | Standard deviation | 0.63793 | 0.0015 | 0.0432 | 1.6089 | 0.0035 |

| Uran (%) | 0.0252 | 0.2029 | 0.5901 | 0.2165 | 0.6573 | |

| System uncertainty | Usys (%) | 0.5 | 0.5 | 0.2 | 0.2 | 0.2 |

| Comprehensive uncertainty | Ucom (%) | 0.5006 | 0.5396 | 0.6230 | 0.2947 | 0.6870 |

| θ (°) | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|

| 0.20 l | scheme1 | scheme4 | scheme7 | scheme10 | scheme13 |

| 0.25 l | scheme2 | scheme5 | scheme8 | scheme11 | scheme14 |

| 0.30 l | scheme3 | scheme6 | scheme9 | scheme12 | scheme15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Han, W.; Li, R.; Ma, X.; Wang, H.; Li, W. Flow Control in Multiphase Pumps Based on Separated Trailing Edge Flap. Processes 2023, 11, 3066. https://doi.org/10.3390/pr11113066

Zhou J, Han W, Li R, Ma X, Wang H, Li W. Flow Control in Multiphase Pumps Based on Separated Trailing Edge Flap. Processes. 2023; 11(11):3066. https://doi.org/10.3390/pr11113066

Chicago/Turabian StyleZhou, Juping, Wei Han, Rennian Li, Xiaoning Ma, Haojie Wang, and Wangxu Li. 2023. "Flow Control in Multiphase Pumps Based on Separated Trailing Edge Flap" Processes 11, no. 11: 3066. https://doi.org/10.3390/pr11113066

APA StyleZhou, J., Han, W., Li, R., Ma, X., Wang, H., & Li, W. (2023). Flow Control in Multiphase Pumps Based on Separated Trailing Edge Flap. Processes, 11(11), 3066. https://doi.org/10.3390/pr11113066