Abstract

This work describes a bibliometric analysis of recent articles addressing the applications of thermal processing in foods, as well as its effect on their physicochemical and rheological properties. The analysis involved utilizing the software tools VOSviewer and RStudio to map the knowledge domain. Initially, 665 articles from peer-reviewed journals were retrieved, but only 92 (13.8%) of them discussed thermal processing related to fruit applications and were published in indexed journals. However, this number was further narrowed down to 35 (5.3%) articles specifically focused on the target subject. A rigorous appraisal of these 35 articles allowed it to be classified according to its aim, kind of fruit used, thermal processing treatment, and its rheological, physicochemical, and other properties. The leading countries in the general area of food thermal processing research according to documents and citations were China, USA, Brazil, India and Spain. It is important to highlight that conventional thermal processing continues to be investigated for applications in fruits; on the other hand, it is expected that the use of unconventional or emerging technologies will bring significant advances to the food industry in the future.

1. Introduction

The thermal processing of foods refers to the application of heat to food products to achieve specific goals, such as improving their safety by avoiding potential contamination, prolonging their shelf life, and enhancing their physical or sensory properties. This process has been widely used in the food industry to ensure that products are safe and retain their quality throughout their intended shelf life. Advancements in thermal processing have allowed for more precise control over heating, so that temperature application can result in improvements in food properties without a loss in their nutritional aspects. Although traditional processes have been developed to preserve food and extend its shelf life without affecting the inherent qualities of food, this objective remains as a major challenge [1,2,3,4].

Among the conventional thermal processing methods used for the food industry, pasteurization, sterilization, cooking, drying, and blanching are the most cited. Pasteurization involves heating food products to a specific temperature (usually below the boiling point) for a certain period to reduce the number of harmful bacteria and extend the product’s shelf life. Sterilization, on the other hand, involves heating food products to a much higher temperature (usually above the boiling point) for a long period to kill all microorganisms and spores present in the food. Cooking is a process used to make food more palatable and safer for consumption. Drying is a technique that involves removing moisture from food, reducing its water activity to inhibit the growth of microorganisms and increase the shelf life of the final product. Blanching is mainly used to reduce enzymatic activity, destroy microorganisms, and remove impurities, making food safer and prolonging its shelf life. Generally, this process is widely used in foods such as fruits and vegetables [5,6].

Thermal processing is a type of operation that can alter the chemical degradation, release, and bioavailability of bioactive components in food, thus altering its biological activity. In addition, it can change the food structure; consequently, the rheological and physicochemical properties also change. In this sense, it is important to evaluate these properties after processing to meet consumers’ expectations for nutritious, tasty, convenient, safe, readily available, and high-quality food [7].

Concurrently, non-conventional and emergent technologies such as high-pressure technologies, pulsed electric fields, ultrasound, cold plasma, and other non-thermal methods, as well as their impacts on food properties, are being investigated. These technologies, which operate at ambient or sublethal temperatures, aim to minimize damage to temperature-sensitive components and offer the potential to enhance sensory and nutritional qualities when compared to traditional methods [8,9,10,11,12,13,14,15,16,17,18,19]. Consequently, some authors have suggested that these technologies may pose competition to traditional thermal techniques by mitigating the adverse impacts on nutritional and sensory quality associated with thermal degradation.

In order to justify the approach taken in this work related to heat treatment focused on fruits, currently, there is a search for fresh foods with characteristics equal to in natura, in line with a healthy and sustainable lifestyle. This modern lifestyle has increased the demand for practical and healthy products, which not only save time and effort, but also offer the benefits of fresh products, driving the fruit and fruit products market. However, all over the world, people have less time to eat properly and opt for faster meals that often do not meet the health criteria. In view of this, researchers and food producers use technology as an important ally for those who want to adopt healthier habits and not give up practicality when it comes to eating [12,14]. Regarding a healthy diet, fruits and fruit products are important sources of nutrients, while being practical to consume. However, fruits are living and breathing products that keep their metabolism active even after harvesting. They are easily perishable after harvest due to their high water activity, soft pulp texture, high metabolic activity, susceptibility to microbial contamination and sensitivity to mechanical damage, which restrict their market potential and consumer access. Therefore, it is necessary to look for methods that extend the shelf life and maintain the quality of the fruits during the post-harvest process. Among the various conservation processes used, heat treatments are the most effective and the most productive. Various heat treatments, including conventional and unconventional ones, have been reported as promising post-harvest approaches which have an effect on fruit quality [15].

The goal of this work is to present a bibliometric analysis of recent articles addressing the applications of thermal processing in foods, as well as how it affects their physicochemical and rheological properties, focusing on fruit processing.

2. Methodology

The bibliometric analysis is an essential tool for analyzing and mapping the evolution of a scientific area, facilitating the identification of emerging trends and research gaps. It also furnishes crucial information for decision making and the efficient allocation of resources in scientific research.

Through the literature databases, bibliometric analyses have the capability to recognize the most pertinent and context-specific studies, thereby offering valuable insights into research queries. This method is characterized by its transparency, replicability, and reliability, ensuring a thorough search of the literature grounded on pre-defined descriptors [20,21,22,23].

The systematic bibliometric analysis performed involved research from the Web of Science (WoS; Clarivate Analytics, London, UK) platform and was performed in five steps. Birkle et al. [20] reported that the Institute for Scientific Information (ISI) has maintained a well-established network of partners for over 50 years, which has facilitated the growth and evolution of the use of WoS.

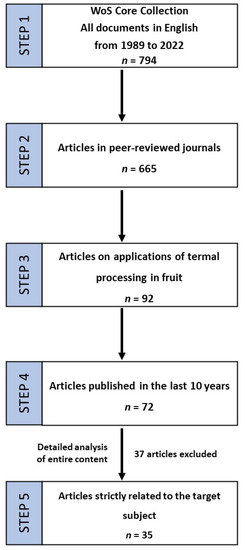

The analysis was performed by the extraction, selection, and appraisal of all relevant studies. In Step 1, all records associated with the general topic “(food* or fruit*) and (rheolog* or “physic* propert*”) and (thermal and (process* or technolog*)) not non-thermal” in the Title, Abstract and Author Keyword fields within the WoS Core Collection, published between January 1989 and December 2022 were identified. The search yielded 794 documents (Table 1), this being 665 peer-reviewed articles, 97 reviews, 41 proceedings, 13 early access, 1 book chapter, 1 correction and 1 reprint. Step 2 aimed to restrict the search only to papers published in peer-reviewed journals, totaling 665 articles.

Table 1.

Classification of articles obtained in Steps 1 and 2 according to the type of publication retrieved from the Web of Science covering the general topic of the research.

Step 3 consisted of the extraction of articles covering fruit, and this was achieved after the further filtering of those 665 documents, resulting in a total of 92 articles. In Steps 4 and 5, these 92 selected articles were evaluated in detail to verify the adequacy of their contents, as well as to include only those that had been published within the last ten years, to bring the recent directions of this subject. The whole process yielded 35 articles, which were analyzed thoroughly and classified according to their objectives, thermal processing treatment, and the rheological and physicochemical properties, as well as other properties, of the fruit samples used. This search, extraction, filtration, and selection process is shown in a PRISMA flow diagram (Figure 1) [24].

Figure 1.

PRISMA flow diagram of the bibliometric analysis, indicating the number of documents retrieved from the Web of Science at each stage of the research.

The bibliographic data were analyzed using VOSviewer (version 1.6 15) [25,26] and RStudio (version 1.3 1093) [26,27] in order to create knowledge domain maps. Descriptive analyses of the data were carried out using the Bibliometrix package within RStudio.

3. Results

3.1. Overview Analysis

The bibliometric analysis was used as a reference of the literature selected in the WoS database regarding the applications of thermal processing in food and how it can affect the physicochemical and rheological properties of these foods, during the timeframe 1989 to 2022.

The first step retrieved 794 documents produced by 2914 authors and 910 research organizations distributed over 71 countries and indexed according to 2188 keywords. From those documents, only 92 (11.6%) were related to applications in fruits. Besides that, when taking into account only articles closely related to the target subject and published in SCIE-listed journals, the number of papers focusing on the thermal processing of fruits and the effect over their properties was reduced to 35 (4.4%).

3.2. Analysis of the Search Performed Using Topic Descriptors (Step 1 to 2)

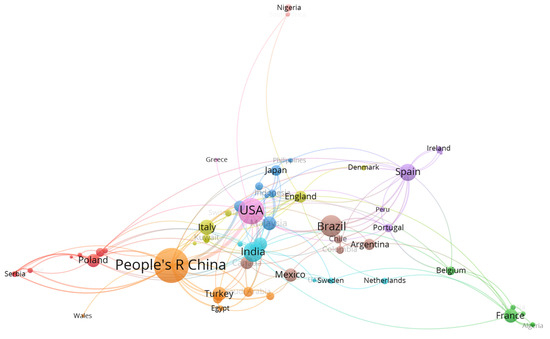

The analysis of the articles obtained through Steps 1 and 2 of the bibliometric investigation made it possible to verify the countries, research organizations, and authors with the highest productivity, as well as the most common source journals, disciplines, cited articles, and keywords, linked to research on the thermal processing of foods with a specific focus on fruit processing. In Figure 2, the network map (visualized using VOSviewer) displays each country as a nodal disc, where the size of the node corresponds to the country’s relative activity in the research into the thermal processing of food. Additionally, the links connecting the nodes depict the collaborative ties between the countries in this area of study, with thicker links indicating stronger ties. The leading countries in the general area of food thermal processing research with respective documents and citations were China (154; 23,158), the USA (89; 13,383), Brazil (59; 8872), India (49; 7368) and Spain (39; 5865), while collaborating countries showed a tendency to cluster together in some distinct groups (highlighted in colors such as orange, pink, brown and blue).

Figure 2.

Network map of the contributions of countries to the general area of the thermal processing of foods.

The individual organizations with the highest numbers of publications in the area of food thermal processing research were in China, Spain, Argentina, Brazil, France and Italy (Table 2). The Jiangnan University in China and Consejo Superior de Investigaciones Cientificas—CSIC in Spain were the leading institutions in terms of publications, with 15 and 14 peer-reviewed articles, respectively.

Table 2.

Top 10 organizations ranked according to their output in the general field of food thermal processing research.

In Figure 3, the network map illustrates the contributions of the leading research organizations to food thermal processing research, where the size of the nodal disc represents productivity and the links between nodes indicate collaboration between institutions. It can be observed that the Universidade Estadual de Campinas acts without major collaborations with other Institutions.

Figure 3.

Network map of the contributions of organizations to the general area of the thermal processing of foods.

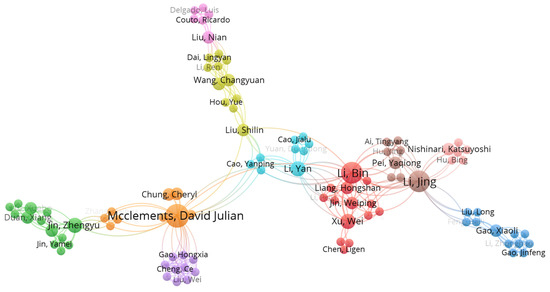

Table 3 presents the 10 most prolific authors in food thermal processing research, along with their research output indices and affiliated countries. In the present case, the author J. Ahmed from Kuwait was the most prolific (11 papers), followed by the Chinese authors B Li and J Li with 9 and 8 papers, respectively. In Figure 4, the knowledge domain map illustrates the contribution of various authors to food thermal processing research, where the size of the nodal disc indicates the number of co-authored articles published, and the links between nodes represent collaborative networks. The chart highlights that the collaboration clusters primarily consist of Chinese and American researchers.

Table 3.

Top 10 authors ranked according to their output in the general field of thermal food research.

Figure 4.

Network map of authors who have published in the general area of the thermal processing of foods.

The top 10 journals, all of which were SCIE-listed, are shown in Table 4, ranked according to the number of peer-reviewed papers retrieved on the general food thermal processing topic. The leading periodical Food Hydrocolloids publish research (experimental and review papers) mainly concerning the functional properties, characteristics, and applications of hydrocolloid materials in food products. The upcoming periodicals Journal of Food Process Engineering and Journal of Food Processing and Preservation are highly specialized in the field of food processing technologies, and, despite occupying the second and third places in this ranking, both presented the lowest values of the h index, total citations, citation average, article citations and citations per paper. Except for the International Journal of Biological Macromolecules, all other journals have “Foods” in their titles. As expected, most food thermal processing studies were carried out by researchers in the disciplines of food science and technology, applied chemistry and chemical engineering.

Table 4.

Top 10 journals and disciplines.

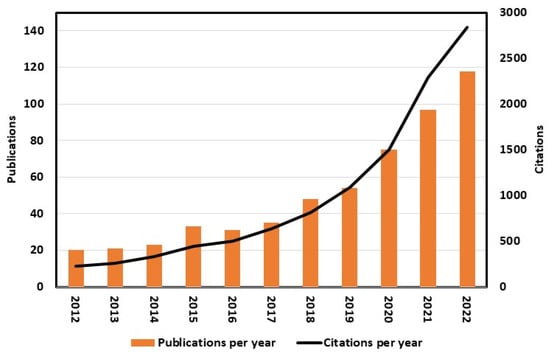

Figure 5 illustrates the number of articles published per year and their citations in order to understand the trend in this topic. There has been a growing increase in publications on this topic in the last 10 years, as well as a consequent increase in the respective citations.

Figure 5.

Publications and citations per year in the general area of the thermal processing of foods.

The 10 most cited food thermal processing articles [28,29,30,31,32,33,34,35,36,37] in the WoS database are listed in Table 5 and relate to studies published during the period from 1997 to 2013. As expected, most of these papers deal with samples of foods, except the top-ranked article by Ahmed et al., (2011), which provides a review of green packaging technology made from polylactides [28], as well as that of Barreca et al. (2007), who studied ZnO-TiO2 nanocomposites [35].

Table 5.

Top 10 most cited papers.

In the next sections, how thermal processing affects the physicochemical and rheological properties of fruits will be described. This reasoning was built from the detailed analysis of the 35 papers obtained in Step 5 (see Figure 1).

The most used keywords in the articles analyzed are identified in Figure 6. The frequency of occurrence of the keywords indicates that the most used terms highlighted for the works in this area were rheology, rheological properties, thermal properties, antioxidant activity, starch properties, microstructure and functional properties. However, various other terms such as stability, crystallinity, gelation, texture and thermal treatment also occurred with some frequency.

Figure 6.

Main keywords used in the study of rheological and physical properties affected by the thermal processing of foods.

3.3. Conventional Thermal Processing

The conventional thermal treatment is essentially based on generating heat and transferring it to the product through forms of heat expression (conduction and convection). Fruits are very perishable feedstock; therefore, the application of thermic treatment is the standard to assist their preservation, due to its capability to decrease deterioration, pathogenic microorganisms and enzymes that accelerate ripening. In addition, thermal treatment is a commonly used technology in the food industry and ensures the microbiological quality, and sensory and physicochemical characteristics of the products.

This review summarizes 35 articles that explain the application of different thermal processes, and 21 of these works have addressed the use of conventional thermal treatments [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53]. Table 6 shows a summary discussion about some of the conventional thermal processing techniques used in in natura fruits and in their sub-products, such as flours, juices, pulps, husks, almonds, etc. Conventional heating such as oven drying, sun drying, water baths, pasteurization, UHT (Ultra-High-Temperature), HTTP (high-pressure thermal processing), and HPP (high-pressure processing) are discussed here, as well as their effects.

Table 6.

The 35 articles strictly related to the thermal processing in fruit applications (step 5).

In these articles, in which conventional heat treatments were applied, the authors related that there is a concern when analyzing the impact of temperature on the stability of the bioactive compounds responsible for the functional characteristics of fruits and their sub-products. Buniowska et al., (2020) [38] used plate heat exchangers for the thermal treatment of a drink based on exotic fruit juices; the treatment was at 60 °C, a lower temperature than traditional industry processes that pasteurize beverages at 88–99 °C. In this article, the authors found that drinks subjected to conventional heat treatments retained a high level of their antioxidant properties.

Among the conventional heating techniques used for fruit preservation, some are more modern, such as UHT, HPTP and HPP. These treatments are very fast and, therefore, afford the sterilization of the fruits with minimum losses of their sensory characteristics and functional properties.

Hulle et al. (2017) [10] explored how high-pressure thermal processing (HPTP) and high-pressure processing (HPP) influenced the quality characteristics of an Aloe vera–lychee mixed beverage. High-pressure thermal processing (HPTP) combines high pressure and heating, and HPP is a new technology that submits fruits to high hydrostatic pressures. Both technologies have proved to be effective in inactivating deteriorated microorganisms, extending the shelf life of foodstuff and, thereby, preserving desirable functional properties. Although in one study, the enzyme activity and the microbial population was affected after thermal treatments of HPTP and HPP, the authors reported that the quality attributes of the mixed drinks, such as physical–chemical, nutritional, and sensory characteristics, were minimally affected.

Unlike contemporary methods, certain articles cited in this review employed the conventional approach of sun drying or oven drying. For instance, Takahashi et al. (2018) [42] investigated the impact of solar and oven drying processes on the physicochemical characteristics of an economically significant pepper variety known as “hihatsumodoki”. Their research aimed to identify optimal conditions that would preserve the pepper’s pungency and antioxidant properties, while simultaneously achieving a sufficiently low water-activity level to inhibit microbial growth and spoilage.

Sun drying is one of the methods of fruit preservation that have been practiced for centuries. The direct or indirect use of the sun, which is renewable and low-cost, favors farmers that harvest and process in small quantities. Oven-drying is efficient as it combines the factors of heat, a low humidity and air flow, ideal for drying of fruit. However, the use of oven drying needs energy sources. When the authors compared drying in the sun with drying in an oven, they concluded that, during drying using solar radiation, the relative weights of the fruits reduced after 18 h of drying. On the other hand, the authors observed that increasing the drying temperature in the oven resulted in a reduction in the drying time, and the desired dry mass was reached in 24, 6 and 4 h at 50, 70 and 90 °C, respectively. Similar trends were exhibited in water-activity (aw) values. However, for the optimal production of spices, suitable for long-term storage, the best result was obtained when the samples were dried in an oven at 70 °C for 6 h, as they retained their functional value, piperine content, and antioxidant properties, in addition also to it having a better economic viability.

3.4. Non-Conventional Thermal Processing

Table 6 lists some articles describing the applications of conventional and non-conventional thermal processing treatments, such as microwave, ultrasound, ohmic heating, osmotic distillation, nanofluid technology, electric field (EF), and others [8,9,14,18,45,48,49,50]. Among these papers, a lot of fruits and sub-products obtained from their processing were studied, such as concentrated blood-orange juice, papaya pulp from ripe papaya (C. papaya L.), watermelon juice, dried key-lime juice, fruit shells of Camellia oleifera, compounds from fiber-rich by-products, and others.

Non-conventional thermal processing has been a promising avenue in fruit processing and can improve their rheological properties (viscosity), physicochemical properties (total soluble solids (TSS), titrable acidity, ascorbic acid, and total phenolic content), and other properties such as microbial characterization and antioxidant activities.

Cassano et al. (2014) [50] evaluated the effect of the solids concentration (155–700 g/kg at 20–70 °C) on the rheological properties of orange juices by using a strain-controlled rheometer. The fresh juice exhibited a pseudoplastic flow behavior. On the other hand, ultrafiltered juice and concentrated juices showed Newtonian behavior. The presence of residual pulp in the fresh juice can explain the results reported by the authors.

In addition, Gomathy et al. (2015) [49] applied ohmic heating as a non-conventional thermal processing treatment to papaya pulp, which can be considered a successful substitute for the pasteurization of this product. Papaya pulp’s rheological behavior was non-Newtonian and pseudoplastic, with yield stress by the Herschel–Bulkley model (R2 = 0.99). The fresh pulp’s lower flow-behavior index values, when compared to those of the ohmic heated pulp, suggested that the apparent viscosity would grow more quickly under higher shear rates.

The alumina–water nanofluid processing of watermelon juice at high temperatures (75, 80, and 85 °C) for a brief period of time were studied by Jafari et al. (2017) [48]. Lycopene and vitamin C concentrations could be maintained after thermal processing using 0.2 and 4% nanofluids at 75 °C for 15 s. The pH and TSS indices of thermally treated watermelon juices do not significantly correlate with the heating media. The results showed that lycopene, vitamin C, and the color retention in the final product were all higher after processing the watermelon juice with alumina nanofluids compared to common thermal processing using water.

The electric field (EF) system described in the study reported by Altemimi et al. (2018) is one potential alternative technology, and showed superiority to heat pasteurization in terms of preserving the antioxidant activity, ascorbic acid, and total phenolic content of dried lime juice [18]. The healthful qualities of fruit juice can be enhanced during pasteurization to provide a product with a better retail value than one produced using conventional thermal processing. Furthermore, the results exhibited that neither the fresh-juice control samples nor all samples subjected to the electric-field (EF) system showed the growth of coliform bacteria, yeast, or mold.

Many studies conducted on specific fruits and vegetables have demonstrated that some alterations brought on by ultrasound involve a reduction in viscosity [14]. Cavitation processes alter their polysaccharide structures, which affects their viscosity by reducing particle sizes and molecular weights.

Li et al. (2022) [8] investigated an ultrasound technique, aiming to improve the physicochemical characteristics of betalain microcapsules. Under a low-intensity ultrasonic treatment (200 W, 5 min), the onset temperature and free-radical scavenging of betalain microcapsules rose by 1.6 °C and 12.24%, respectively, in comparison to the control sample. This rise might have been brought on by interactions between maltodextrin and the betalains, brought about by ultrasonification (as evidenced by FT-IR). Consequently, a low-intensity ultrasonic procedure can be employed for microencapsulation to increase betalains’ stability and, therefore, broaden their scope of use in the realm of heat-processed foods.

Different drying techniques and treatment parameters for all material types can be optimized in order to improve their yields and process qualities. Thus, in order to optimize and model the drying process and selected physical attributes of slices of ultrasound-treated kiwi fruits before microwave drying, response surface methodology (RSM) was used Kaveh et al. (2022) [9]. Three independent factors were investigated: the ultrasonic pretreatment time, sample thickness and microwave power. According to the obtained results, its drying time decreased when the microwave power and ultrasound pretreatment duration were increased, along with its thickness. Furthermore, reducing the microwave power and sample thickness and lengthening the treatment period reduced shrinkage and changed its color.

3.5. Perspectives and Future Trends

Food processing is a set of unit operations to convert unprocessed foods into foods that have an extended shelf life. These procedures allow storage, which eliminates or reduces the time or effort devoted to cooking procedures to increase consumption. The highest-quality foods that have the highest demand are also very perishable. Luckily, using current technology wisely can preserve most perishable foods. By successfully applying commercially available food preservation technologies, it is possible to increase the availability of perishable foods. Despite the increasing demand for new processed products, the fundamentals of food processing remain the same for sustained availability in times of shortage. Processed food industries are struggling to meet consumer expectations for the manufacture of nutritious, enjoyable, convenient, safe, easily available, and affordable food of the highest quality.

The contemporary food industry is dedicated to developing products that enhance the safety of modern food consumption. Food processing procedures play a pivotal role in altering the chemical degradation, release, and bioavailability of bioactive components within food items, thereby influencing their biological activity. Traditional food processing methods like pasteurization, sterilization, cooking, and dehydration can impact the stability, bioavailability, and bioactivity of these components. More recently, the effects of emerging processing technologies, such as ultrasound, pulsed electric field, high hydrostatic pressure, and other non-thermal approaches, have also come under scrutiny. Some authors suggest that these innovative technologies may eventually compete with traditional pasteurization methods, as they can circumvent the detrimental effects of thermal degradation on the nutritional and sensory qualities of food products. These non-thermal technologies operate at ambient or sublethal temperatures, minimizing damage to temperature-sensitive food components.

Among the most relevant non-thermal technologies are high-pressure processing, pulsed-electric-field treatment, ultrasound, and cold plasma technologies. These non-conventional methods have the potential to enhance the sensory and nutritional characteristics of food products when compared to conventional processing techniques.

4. Conclusions

The conventional and non-conventional thermal processing of food has been widely used in different applications, and the existence of cooperation between established groups, countries and institutions in its research has been observed. Among the main countries addressing this topic are China, USA, Brazil, India and Spain.

The findings concerning the involvement of various authors in research on thermal food processing reveal that the collaboration clusters primarily consisted of Chinese and American researchers. As expected, the majority of studies on thermal food processing were conducted by scholars in the fields of food science and technology, applied chemistry, and chemical engineering.

The proportion of total papers focusing on the thermal processing of fruit and the effect of some of its properties was reduced from 794 papers to 35, approximately 4.4%. These 35 articles explained the application of different thermal processes, and a total of 21 addressed the use of conventional thermal treatments. A summary discussion of some of the conventional thermal processing techniques was applied in in natura fruits and in their products, such as flours, juices, pulps, beverages, powders, husks, and almonds.

Non-conventional thermal processing has been promising in fruit processing and can improve their rheological properties (viscosity), physicochemical properties (total soluble solids (TSS), titratable acidity, ascorbic acid, total phenolics) and other properties, such as their microbial characterizations and antioxidant activities. While conventional thermal processing is still being studied for fruit applications, the utilization of emerging or non-conventional technologies has the potential to enhance the sensory and nutritional characteristics of these products in comparison to traditional methods. It is expected that these innovations have the potential to have a significant impact on the food industry in the future.

Author Contributions

Conceptualization, A.L.G.F. and S.M.A.; methodology, M.P.M. and I.G.V.; software, I.G.V.; validation, M.P.M., A.L.G.F. and I.G.V.; formal analysis, M.P.M., A.L.G.F., S.M.A., P.C.M.D.R., A.K.F.C. and I.G.V.; investigation, S.M.A., M.P.M., A.L.G.F., P.C.M.D.R., A.K.F.C. and I.G.V.; resources, I.G.V.; data curation, I.G.V., A.L.G.F. and M.P.M.; writing—original draft preparation, M.P.M., A.L.G.F., S.M.A., P.C.M.D.R., A.K.F.C. and I.G.V.; writing—review and editing, A.L.G.F., I.G.V. and M.P.M.; visualization, S.M.A., P.C.M.D.R. and A.K.F.C.; supervision, A.L.G.F. and M.P.M.; project administration, A.L.G.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created.

Conflicts of Interest

The authors declare no conflict of interests.

References

- Habibiasr, M.; Mokhtar, M.N.; Ibrahim, M.N.; Yunos, K.F.M.; Ibrahim, N.A. Effect of drying on the physical and chemical properties of palm kernel oil. J. Sci. Food Agric. 2022, 102, 4046–4053. [Google Scholar] [CrossRef] [PubMed]

- Velasco-Hernández, A.; Saucedo-Veloz, C.; Ramírez-Guzmán, M.E.; Chávez-Franco, S.H.; Valle-Guadarrama, S.; Saucedo-Reyes, D. Effect of moderate thermal treatments on the inactivation of a strain of Listeria monocytogenes and physicochemical properties of soursop pulp. Food Sci. Technol. Int. 2020, 26, 535–548. [Google Scholar] [CrossRef] [PubMed]

- Sonawane, A.; Pathak, S.; Pradhan, R.C. Effect of processing temperature on dynamic rheological properties and color degradation kinetics of bael fruit pulp. J. Sci. Food Agric. 2020, 100, 5596–5602. [Google Scholar] [CrossRef] [PubMed]

- Wibowo, S.; Afuape, A.L.; De Man, S.; Bernaert, N.; Van Droogenbroeck, B.; Grauwet, T.; Van Loey, A.; Hendrickx, M. Thermal processing of kale purée: The impact of process intensity and storage on different quality related aspects. Innov. Food Sci. Emerg. Technol. 2019, 58, 102213. [Google Scholar] [CrossRef]

- Ramamurthy, T.; Krishnan, S. Influence of viscosity on the thermal behavior of fluids in a sealed can. Alex. Eng. J. 2022, 61, 7833–7842. [Google Scholar] [CrossRef]

- Chumroenvidhayakul, S.; Thilavech, T.; Abeywardena, M.; Adisakwattana, S. Investigating the Impact of Dragon Fruit Peel Waste on Starch Digestibility, Pasting, and Thermal Properties of Flours Used in Asia. Foods 2022, 11, 2031. [Google Scholar] [CrossRef]

- Shinwari, K.J.; Rao, P.S. Rheological and physico-chemical properties of a reduced-sugar sapodilla Manilkara zapota L. jam processed under high-hydrostatic pressure. J. Food Process Eng. 2020, 43, e13388. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.-H.; Qiao, J.; Qu, W.; Wang, M.-S.; Gao, X.; Zhang, C.; Brennan, C.S.; Qi, X. Improvement of betalains stability extracted from red dragon fruit peel by ultrasound-assisted microencapsulation with maltodextrin. Ultrason. Sonochem. 2022, 82, 105897. [Google Scholar] [CrossRef]

- Kaveh, M.; Taghinezhad, E.; Witrowa-Rajchert, D.; Imanian, K.; Khalife, E.; Nowacka, M. Use of ultrasound pre-treatment before microwave drying of kiwifruits—An optimization approach with response surface methodology. J. Food Process. Preserv. 2022, 46, e16714. [Google Scholar] [CrossRef]

- Swami Hulle, N.R.; Chakraborty, S.; Rao, P.S. Effect of high pressure thermal processing on the quality attributes of Aloe vera-litchi mixed beverage. Innov. Food Sci. Emerg. Technol. 2017, 40, 68–77. [Google Scholar] [CrossRef]

- Kaya, Z.; Yıldız, S.; Ünlütürk, S. Effect of UV-C irradiation and heat treatment on the shelf life stability of a lemon–melon juice blend: Multivariate statistical approach. Innov. Food Sci. Emerg. Technol. 2015, 29, 230–239. [Google Scholar] [CrossRef]

- Andreone, A.; Schenk, M.; Ferrario, M.; Guerrero, S. Development of sweet confectioneries produced from pilot-scale UV-C treated orange juice, low-methoxyl pectin and different sugar-substitute blends. Impact on physicochemical, rheological and sensory properties. J. Food Process. Preserv. 2022, 46, e16403. [Google Scholar] [CrossRef]

- Alves, J.L.F.; Da Silva, J.C.G.; Di Domenico, M.; Galdino, W.V.D.A.; Andersen, S.L.F.; Alves, R.F.; De Sena, R.F. Exploring Açaí Seed (Euterpe oleracea) Pyrolysis Using Multi-component Kinetics and Thermodynamics Assessment Towards Its Bioenergy Potential. BioEnergy Res. 2021, 14, 209–225. [Google Scholar] [CrossRef]

- Martinez-Solano, K.C.; Garcia-Carrera, N.A.; Tejada-Ortigoza, V.; García-Cayuela, T.; Garcia-Amezquita, L.E. Ultrasound Application for the Extraction and Modification of Fiber-Rich By-Products. Food Eng. Rev. 2021, 13, 524–543. [Google Scholar] [CrossRef]

- Xiang, Q.; Fan, L.; Zhang, R.; Ma, Y.; Liu, S.; Bai, Y. Effect of UVC light-emitting diodes on apple juice: Inactivation of Zygosaccharomyces rouxii and determination of quality. Food Control 2020, 111, 107082. [Google Scholar] [CrossRef]

- Gao, R.; Ye, F.; Wang, Y.; Lu, Z.; Yuan, M.; Zhao, G. The spatial-temporal working pattern of cold ultrasound treatment in improving the sensory, nutritional and safe quality of unpasteurized raw tomato juice. Ultrason. Sonochem. 2019, 56, 240–253. [Google Scholar] [CrossRef]

- Lammerskitten, A.; Mykhailyk, V.; Wiktor, A.; Toepfl, S.; Nowacka, M.; Bialik, M.; Czyżewski, J.; Witrowa-Rajchert, D.; Parniakov, O. Impact of pulsed electric fields on physical properties of freeze-dried apple tissue. Innov. Food Sci. Emerg. Technol. 2019, 57, 102211. [Google Scholar] [CrossRef]

- Altemimi, A.; Ali, H.I.; Al-HiIphy, A.R.S.; Lightfoot, D.A.; Watson, D.G. Electric field applications on dried key lime juice quality with regression modeling. J. Food Process. Preserv. 2018, 42, e13637. [Google Scholar] [CrossRef]

- Mansor, A.; Shamsudin, R.; Mohd Adzahan, N.; Hamidon, M.N. Performance of UV Pasteurization with Quartz Glass Sleeve on Physicochemical Properties and Microbial Activity of Pineapple Juice. J. Food Process Eng. 2017, 40, e12263. [Google Scholar] [CrossRef]

- Birkle, C.; Pendlebury, D.A.; Schnell, J.; Adams, J. Web of Science as a data source for research on scientific and scholarly activity. Quant. Sci. Stud. 2020, 1, 363–376. [Google Scholar] [CrossRef]

- Subramanyam, K. Bibliometric studies of research collaboration: A review. J. Inf. Sci. 1983, 6, 33–38. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Visualizing Bibliometric Networks. In Measuring Scholarly Impact; Springer International Publishing: Cham, Switzerland, 2014; pp. 285–320. [Google Scholar]

- Oliveira, O.J.; Silva, F.F.; Juliani, F.; Barbosa, L.C.F.M.; Nunhes, T.V. Bibliometric Method for Mapping the State-of-the-Art and Identifying Research Gaps and Trends in Literature: An Essential Instrument to Support the Development of Scientific Projects. In Scientometrics Recent Advances; IntechOpen: Rijeka, Croatia, 2019. [Google Scholar]

- Hutton, B.; Salanti, G.; Caldwell, D.M.; Chaimani, A.; Schmid, C.H.; Cameron, C.; Ioannidis, J.P.A.; Straus, S.; Thorlund, K.; Jansen, J.P.; et al. The PRISMA Extension Statement for Reporting of Systematic Reviews Incorporating Network Meta-analyses of Health Care Interventions: Checklist and Explanations. Ann. Intern. Med. 2015, 162, 777. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. VOSViewer, v. 1.6.15.; Centre for Science and Technology Studies, Leiden University: Leiden, The Netherlands, 2020. [Google Scholar]

- Verzani, J. Getting Started with RStudio: An Integrated Development Environment for R, 1st ed.; O’Reilly Media: Sebastopol, CA, USA, 2011. [Google Scholar]

- Ahmed, J.; Varshney, S.K. Polylactides—Chemistry, Properties and Green Packaging Technology: A Review. Int. J. Food Prop. 2011, 14, 37–58. [Google Scholar] [CrossRef]

- Joly-Duhamel, C.; Hellio, D.; Djabourov, M. All Gelatin Networks: 1. Biodiversity and Physical Chemistry. Langmuir 2002, 18, 7208–7217. [Google Scholar] [CrossRef]

- Chantaro, P.; Devahastin, S.; Chiewchan, N. Production of antioxidant high dietary fiber powder from carrot peels. LWT—Food Sci. Technol. 2008, 41, 1987–1994. [Google Scholar] [CrossRef]

- Santhirasegaram, V.; Razali, Z.; Somasundram, C. Effects of thermal treatment and sonication on quality attributes of Chokanan mango (Mangifera indica L.) juice. Ultrason. Sonochem. 2013, 20, 1276–1282. [Google Scholar] [CrossRef]

- Jonoobi, M.; Khazaeian, A.; Tahir, P.M.; Azry, S.S.; Oksman, K. Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose 2011, 18, 1085–1095. [Google Scholar] [CrossRef]

- Zhang, M.; Bai, X.; Zhang, Z. Extrusion process improves the functionality of soluble dietary fiber in oat bran. J. Cereal Sci. 2011, 54, 98–103. [Google Scholar] [CrossRef]

- Nishinari, K. Rheological and DSC study of sol-gel transition in aqueous dispersions of industrially important polymers and colloids. Colloid Polym. Sci. 1997, 275, 1093–1107. [Google Scholar] [CrossRef]

- Barreca, D.; Comini, E.; Ferrucci, A.P.; Gasparotto, A.; Maccato, C.; Maragno, C.; Sberveglieri, G.; Tondello, E. First Example of ZnO−TiO2 Nanocomposites by Chemical Vapor Deposition: Structure, Morphology, Composition, and Gas Sensing Performances. Chem. Mater. 2007, 19, 5642–5649. [Google Scholar] [CrossRef]

- Lopez-Sanchez, P.; Nijsse, J.; Blonk, H.C.G.; Bialek, L.; Schumm, S.; Langton, M. Effect of mechanical and thermal treatments on the microstructure and rheological properties of carrot, broccoli and tomato dispersions. J. Sci. Food Agric. 2011, 91, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Manoi, K.; Rizvi, S.S.H. Emulsification mechanisms and characterizations of cold, gel-like emulsions produced from texturized whey protein concentrate. Food Hydrocoll. 2009, 23, 1837–1847. [Google Scholar] [CrossRef]

- Buniowska, M.; Carbonell-Capella, J.M.; Znamirowska, A.; Zulueta, A.; Frígola, A.; Esteve, M.J. Steviol glycosides and bioactive compounds of a beverage with exotic fruits and Stevia rebaudiana Bert. as affected by thermal treatment. Int. J. Food Prop. 2020, 23, 255–268. [Google Scholar] [CrossRef]

- Rahib, Y.; Sarh, B.; Chaoufi, J.; Bonnamy, S.; Elorf, A. Physicochemical and thermal analysis of argan fruit residues (AFRs) as a new local biomass for bioenergy production. J. Therm. Anal. Calorim. 2021, 145, 2405–2416. [Google Scholar] [CrossRef]

- Han, Y.-L.; Gao, J.; Yin, Y.-Y.; Jin, Z.-Y.; Xu, X.-M.; Chen, H.-Q. Extraction optimization by response surface methodology of mucilage polysaccharide from the peel of Opuntia dillenii haw. fruits and their physicochemical properties. Carbohydr. Polym. 2016, 151, 381–391. [Google Scholar] [CrossRef]

- Luciano, C.G.; Valencia, G.A.; Campanella, O.H.; Sobral, P.J.d.A.; Moraes, I.C.F. Influence of Extraction Method on the Rheological Properties of Jackfruit (Artocarpus heterophyllus) Seed Starch Dispersions. Food Biophys. 2018, 13, 155–162. [Google Scholar] [CrossRef]

- Takahashi, M.; Ohshiro, M.; Ohno, S.; Yonamine, K.; Arakaki, M.; Wada, K. Effects of solar- and oven-drying on physicochemical and antioxidant characteristics of hihatsumodoki (Piper retrofractum Vahl) fruit. J. Food Process. Preserv. 2018, 42, e13469. [Google Scholar] [CrossRef]

- Asmat-Campos, D.; Carreño-Ortega, A.; Paço, T.A. Closed flow solar dehydration with the use of silver nanoparticles: Application for the production of Pouteria lucuma flour. Dry. Technol. 2022, 40, 3036–3048. [Google Scholar] [CrossRef]

- Han, H.; Song, K. Bin Antioxidant activities of mandarin (Citrus unshiu) peel pectin films containing sage (Salvia officinalis) leaf extract. Int. J. Food Sci. Technol. 2020, 55, 3173–3181. [Google Scholar] [CrossRef]

- Zhou, L.; Luo, S.; Li, J.; Zhou, Y.; Wang, X.; Kong, Q.; Chen, T.; Feng, S.; Yuan, M.; Ding, C. Optimization of the extraction of polysaccharides from the shells of Camellia oleifera and evaluation on the antioxidant potential in vitro and in vivo. J. Funct. Foods 2021, 86, 104678. [Google Scholar] [CrossRef]

- Benjamin, O.; Gamrasni, D. Microbial, nutritional, and organoleptic quality of pomegranate juice following high-pressure homogenization and low-temperature pasteurization. J. Food Sci. 2020, 85, 592–599. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.S.; Nambi, E.; Shiva, K.N.; Vaganan, M.M.; Ravi, I.; Jeyabaskaran, K.J.; Uma, S. Thin layer drying kinetics of Banana var. Monthan (ABB): Influence of convective drying on nutritional quality, microstructure, thermal properties, color, and sensory characteristics. J. Food Process Eng. 2019, 42, e13020. [Google Scholar] [CrossRef]

- Jafari, S.M.; Saremnejad, F.; Dehnad, D. Nano-fluid thermal processing of watermelon juice in a shell and tube heat exchanger and evaluating its qualitative properties. Innov. Food Sci. Emerg. Technol. 2017, 42, 173–179. [Google Scholar] [CrossRef]

- Gomathy, K.; Thangavel, K.; Balakrishnan, M.; Kasthuri, R. Effect of Ohmic Heating on the Electrical Conductivity, Biochemical and Rheological Properties of Papaya Pulp. J. Food Process Eng. 2015, 38, 405–413. [Google Scholar] [CrossRef]

- Cassano, A.; Destani, F.; Rossi, C.O. Rheological behavior of blood orange juice concentrated by osmotic distillation and thermal evaporation. Appl. Rheol. 2014, 24, 63776. [Google Scholar] [CrossRef]

- Cordoba, L.d.P.; da Silva, R.G.; Gomes, D.d.S.; Schnitzler, E.; Waszczynskyj, N. Brazilian green banana: A thermal, structural and rheological investigation of resistant starch from different cultivars. J. Therm. Anal. Calorim. 2018, 134, 2065–2073. [Google Scholar] [CrossRef]

- Yadav, D.N.; Vishwakarma, R.K.; Borad, S.; Bansal, S.; Jaiswal, A.K.; Sharma, M. Development of protein fortified mango based ready-to-serve beverage. J. Food Sci. Technol. 2016, 53, 3844–3852. [Google Scholar] [CrossRef]

- Wu, B.; Patel, B.K.; Fei, X.; Jones, O.; Campanella, O.H.; Reuhs, B.L. Variations in physical-chemical properties of tomato suspensions from industrial processing. LWT 2018, 93, 281–286. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).