Abstract

Axial flow fans are commonly used for a system or machinery cooling process. It also used for ventilating warehouses, factories, and garages. In the fan manufacturing industry, the demand for varying fan operating points makes design parameters complicated because many design parameters affect the fan performance. This study combines the deep neural network (DNN) with a genetic algorithm (GA) for axial flow design and development. The characteristic fan curve (P-Q Curve) can be generated when the relevant fan parameters are imported into this system. The system parameters can be adjusted to achieve the required characteristic curve. After the wind tunnel test is performed for verification, the data are integrated and corrected to reduce manufacturing costs and design time. This study discusses a small axial flow fan NACA and analyzes fan features, such as the blade root chord length, blade tip chord length, pitch angle, twist angle, fan diameter, and blade number. Afterwards, the wind tunnel performance test was performed and the fan performance curve obtained. The feature and performance test data were discussed using deep learning. The Python programming language was used for programming and the data were trained repeatedly. The greater the number of parameter data, the more accurate the prediction. Whether the performance condition is met could be learnt from the training result. All parameters were calculated using a genetic algorithm. The optimized fan features and performance were screened out to implement the intelligent fan design. This method can solve many fan suppliers’ fan design problems.

1. Introduction

Axial flow fans have been used for many decades [1]. This fan forces the air to move parallel to the shaft about which the blades rotate. Axial fans are commonly used for system or machinery cooling processes, such as transferring heat from a condenser and cooling electronic equipment or computer rooms. Axial flow fans are also used for warehouse, factory, and garage ventilation. In the industry sector, the axial fan is often mounted to a motor to cool it.

Axial flow fan designs have been discussed in depth in many industries for fan development. In the fan manufacturing industry, the demand for varying fan operating points makes the design complicated since many design parameters affect the fan performance. There is numerous literature on axial flow fan design. Shahsavari et al. [2] increased the by-pass ratio in a constant diameter turbofan. The design is investigated in detail using a computational fluid dynamics (CFD) tool. The result indicates that the new design strategy is capable of more efficient performance in turbofan engines. Xu et al. [3] controlled axial-flow aerodynamic noise by designing fans using metal foams. Sarraf et al. [4] studied two blade thicknesses on the performances of an axial-flow fan. The overall performance was measured in a test bench design. Several aspects were discussed, such as the aerodynamic characteristic curve, the efficiency of thick blade fans, the total level of fluctuations, etc. Fan modeling is crucial for performance analysis. Podgaietsky et al. [5] advanced a methodology for axial fan efficiency mapping. The simulation model was built using a mathematical model called “blade element theory”. Different parameters were designed in the past using modeling and meshing simulations. These operations are time-consuming, as finishing a fan design can take as long as half a day.

Zhang et al. [6] improved the volume flowrate for an axial fan through optimizing the blade shape under the demand for a specific static pressure. The optimization was performed using a GA coupled with a NN. Lin et al. [7] combined the CFD and ANN to design a three-dimensional blade for an axial-flow fan. The DNN was used to set up the flow field models and forecast the axial-flow performance. Ding et al. [8] adopted bending and twisting laws for the blade design and optimization of a low-pressure axial flow fan. A multi-objective genetic algorithm was introduced to optimize the fan pressure and efficiency. Hang et al. [9] optimized the structural parameters combination and made an axial fan with the best performance using the back propagation neural network (BPNN) and a GA. The optimized result proved to be received using CFD simulation. The literature indicates that only a few studies adopt AI for axial flow fan design. In addition, there are few AI intelligent fan design predictions, especially for the design of customized small axial fans. Many industries mostly use big data for technical analysis, such as traditional industries, technology industries, etc., or water-cooled chiller equipment. The deep neural network (DNN) is used to predict different models after data collection, select the model with the least error in the test set as the best model, and implement the best predictive model to evaluate system performance and create maintenance plans [10,11,12,13,14,15,16,17,18].

With advances in science and technology, deep learning and a genetic algorithm (GA) can be used as a rapid and effective method for fan development. There are some important factors in fan design, including noise, manufacturing cost, fan performance, and manufacturing simplicity [1]. In this study, axial flow fan design focuses on fan performance, which is affected by Pratio and Qratio. The AI optimization design is applied in this study. A fan is designed using data collection, deep learning, and a GA. An artificial intelligence (AI) fan design application system can be conceived to shorten the development schedule. As long as the relevant fan parameters are imported into the system, the characteristic curve (P-Q Curve) for this fan can be generated. The parameters can be adjusted in the system to achieve the required characteristic curve. The fan is drawn using 3D modeling. When the sample is completed and the wind tunnel test verification is performed, the data are integrated and corrected to reduce the design cost and time [19,20,21,22,23,24,25,26].

2. Research Method

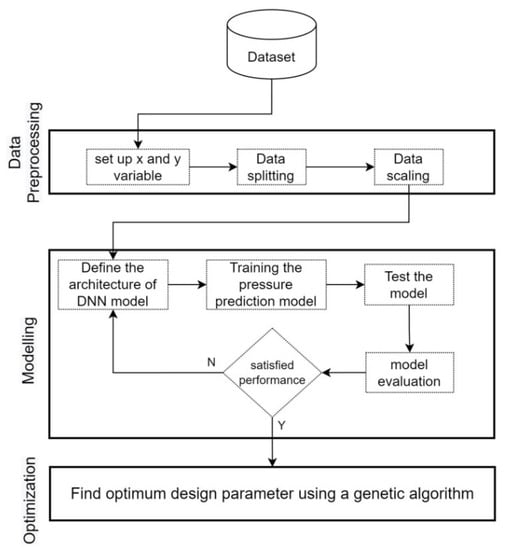

This study involves AI applications for small axial flow fans design by combining the DNN and a genetic algorithm. The DNN technique is used to build the fan modeling. The genetic algorithm is then used to find the optimum fan parameters values. This study used the Python programming language using Anaconda distribution. Several libraries also included scikit-learn, Keras, TensorFlow, and DEAP. Figure 1 shows an overview of the proposed approach. There are three main steps: data preprocessing, pressure prediction model, and design parameter optimization.

Figure 1.

A conceptual framework of the proposed approach.

2.1. Data Preprocessing

The dataset was collected from the axial fan parameters, chord length root, chord length tip, pitch angle, twist angle, impeller diameter, hub outer diameter, blade number, tip clearance, frame thickness, rotating speed, flowrate, and static pressure. The input or independent (x) and output or dependent (y) variables for each model should be determined. The data need to be split randomly into three parts: 70% for training data, 15% for validation data, and 15% for testing data. Data scaling is applied to avoid the models being dominated by large or small data ranges. A standardization technique is used to scale the data where the data values are centered on the mean with the standard deviation as formulated in Equation (1).

where , , , and s are the standardized data, observed data, sample mean, and sample standard deviation, respectively.

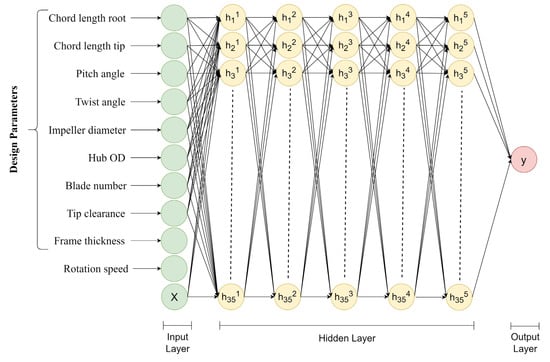

2.2. Modeling Using DNN

A fan design model was built using the DNN technique. DNN is an artificial neural network for executing complex tasks. It has multiple layers and multiple nodes. Figure 2 shows the DNN architecture diagram used in this study. The input layer consists of 11 neurons, which are nine design parameters, rotation speed, and x. The nine design parameters are chord length root, chord length tip, pitch angle, twist angle, impeller diameter, hub outer diameter, blade number, tip clearance, and frame thickness. There are five hidden layers. Each hidden layer consists of 35 neurons, while the output layer consists of 1 neuron [4,5,6,7]. Two DNN models were tested in this study: the flowrate model and the static pressure model. With reference to Figure 2, the flowrate model uses static pressure as and flowrate as . In contrast, the static pressure model uses flowrate as and static pressure as . One of the two models will be selected for further optimization in the GA based on evaluation assessment. The hyperparameters need to be determined before training the models. Manual hyperparameter tuning is applied to optimize the hyperparameter DNN training [27,28,29,30].

Figure 2.

DNN architecture diagram [13].

The neuron output is expressed as Equation (2), where is the neuron output, is the activation function, is the input variable, is the weight, and b is the bias. The weight and bias are learned during the training model. The training objective is to reduce the loss or the error between the algorithm and measured values using mean squared error (MSE) as the loss function, as shown in Equation (3). The activation function used in this study was a ReLU function, expressed as Equation (4), with the function 0 representing negative values and return x representing positive values [31,32,33].

This study used the coefficient of determination (R2), mean absolute error (MAE), and root mean square error (RMSE) as assessment criteria to evaluate the errors in different models, expressed as Equations (5)–(7). N is the number of samples, is the measurement value, is the predictive value, and is the average measurement value. The MAE and RMSE are correlated with the model; is uncorrelated with the model and hence can be used for studying the performance. The lower the MAE and RMSE values, the better the model performance. The value usually ranges from 0 to 1, or is negative. It varies with the model.

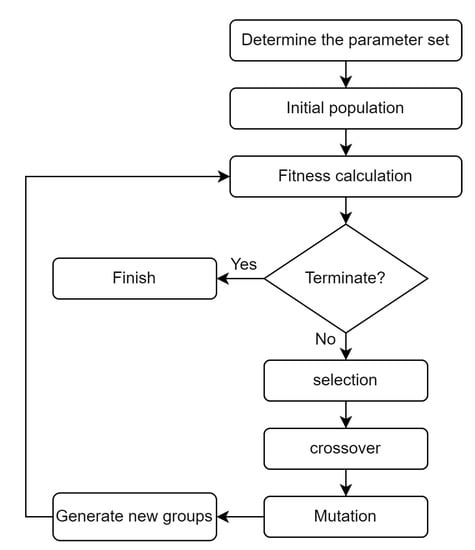

2.3. Optimization Using GA

The genetic algorithm (GA) is an evolution method developed from elimination and evolution in nature, and is also known as a hereditary algorithm. It was proposed by Dr. J. Holland in 1975 and evolved from the “survival of the fittest, elimination of the unfit” ethics in the evolutionary process of organisms. The fitness is calculated by random sampling and then the optimum value is calculated by crossover and mutation. This is generally used in the domains of machine learning, optimal combination, and signal processing. The GA is like a natural selection mechanism, where one chromosome imitates biological mating and mutation, and the objective of chromosomes is determined according to their fitness, to achieve optimization, as illustrated by the GA flow chart in Figure 3 [34,35,36,37].

Figure 3.

GA flow chart.

The goals of GAs are to find the optimum design parameters based on the operating points. The operating points are static pressure, flowrate, and rotating speed. The selected DNN model is included for fan modeling. Equation (8) shows the fitness function used in this study. The objective function minimizes the , where is the selected model whether pressure or flowrate, is the y operating point, and is the model output. Several constraints are applied: The and values should be in the 0.5~0.6 range. The chord length root should equal or be less than the chord length tip. A fixed penalty is applied if a constraint is violated. and are calculated using Equations (9) and (10), where and are the static pressure and flowrate operating points, respectively. is the maximum static pressure, or the static pressure when the flowrate is near 0. is the maximum flowrate, or the flowrate when the static pressure is near 0.

Fitness function = objective function + penalty

3. Results and Discussion

3.1. Axial Flow Fan Erection

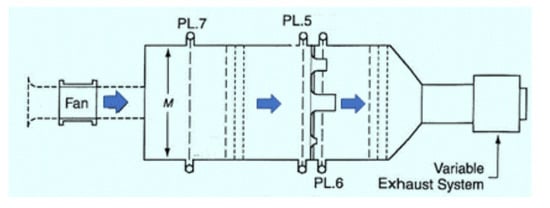

Air Movement and Control Association International, Inc. (AMCA) is an international not-for-profit organization dedicated to certifying the performance of fans, louvers, dampers, and other air-handling equipment. Currently, AMCA can provide third-party testing and certification for buyers and sellers for most manufacturers worldwide and has formulated some important industry standards, as shown in Figure 4 [38].

Figure 4.

Wind tunnel structure diagram.

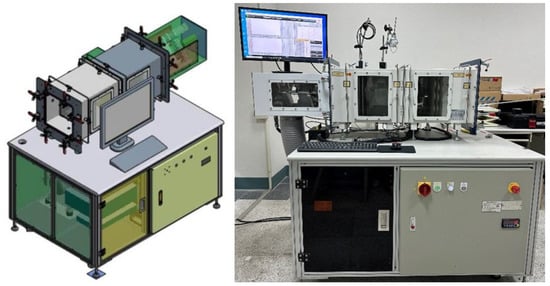

This research used the fan performance measurement system SW-300, as shown in Figure 5, which is a schematic diagram of the wind tunnel equipment. The equipment size is 1.9 m in length × 1.5 m in width × 1.4 m in height, and the power supply system is DC 60 V, 10 A 600 W, as shown in Table 1. Wind tunnel equipment is shown in the specification sheet. Fan performance tests were conducted on 19 small axial flow fans, knowing the pressure (P), flowrate (Q), and speed (RPM) of the fan. The characteristic fan parameters were analyzed, including chord length root, chord length blade tip, pitch angle, torsion angle, impeller diameter, outer hub diameter, number of blades, tip clearance, and frame thickness, as shown in Table 2, Table 3, Table 4 and Table 5 [38]. The existing 19 fan types were used for data collection. Deep learning training and genetic calculation were performed on the collected data.

Figure 5.

Fan performance measurement system SW-300 [38].

Table 1.

Fan performance measurement system specifications.

Table 2.

Fan characteristics.

Table 3.

Fan characteristics.

Table 4.

Fan characteristics.

Table 5.

Fan characteristics.

3.2. Fan Installation Process

Before conducting wind tunnel experiments:

- First, confirm that the relevant system connections were completed.

- Turn on the system and host computer power.

- Install the fan to be tested in a suitable location.

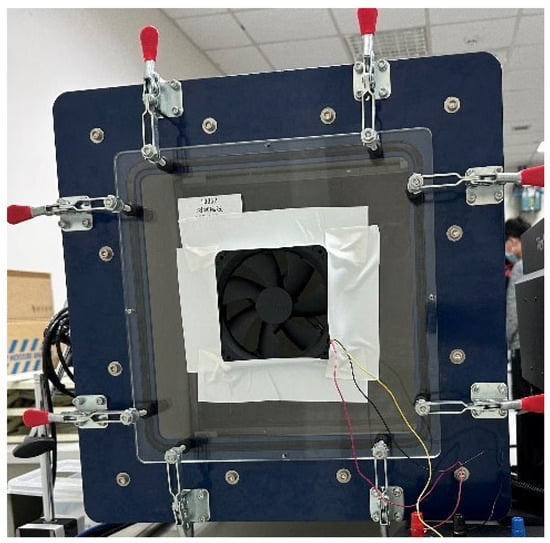

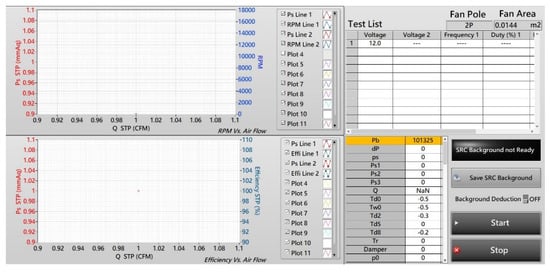

To avoid air leakage, seal the test unit tightly with tape, as shown in Figure 6. After the installation, open the test software, set the test parameters, and confirm whether the parameter values are correct, as shown in Figure 7. After the test is completed, the software will automatically output an Excel report. The P-Q Curve of each fan will be obtained based on an Excel report. The outputs are used for the subsequent study of deep learning and genetic algorithms.

Figure 6.

Schematic diagram of fan installation.

Figure 7.

Data collection interface.

3.3. Modeling

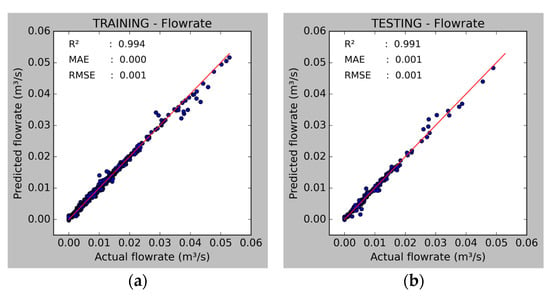

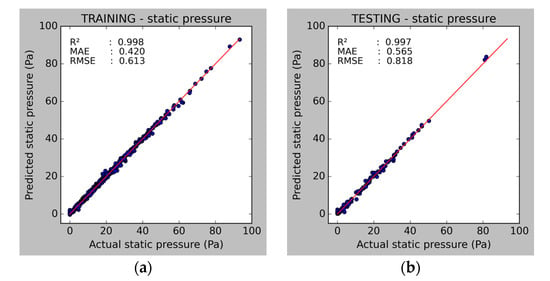

Two prediction models were built with the DNN model architecture: the flowrate model and the static pressure model. The dropout rate 0.01 is added to avoid overfitting after the first, second, third, and fourth hidden layers. The ReLU was selected as the activation function. The epochs were set as 1000, the batch was set as 32, the optimizer was adam, and the loss function was MSE. Figure 8 shows a scatterplot between the actual flowrate and the flowrate model output using (a) training data and (b) testing data. Figure 9 shows a scatterplot between the actual static pressure and the static pressure model output using (a) training data and (b) testing data. From Figure 8 and Figure 9, both flowrate and static pressure can be successfully predicted. Both models are evaluated using R2, MAE, and RMSE, as shown in Table 6.

Figure 8.

Scatterplot of the flowrate prediction model using (a) training data and (b) testing data.

Figure 9.

Scatterplot of the static pressure prediction model using (a) training data and (b) testing data.

Table 6.

Performance evaluation of flowrate and static pressure models.

The table above indicates that the R2 of the static pressure model is higher than that of the flowrate model for both training and testing. The MAE and RMSE of the static pressure model is lower than that of the flowrate model for both training and testing. Therefore, the static pressure model is selected for further optimization.

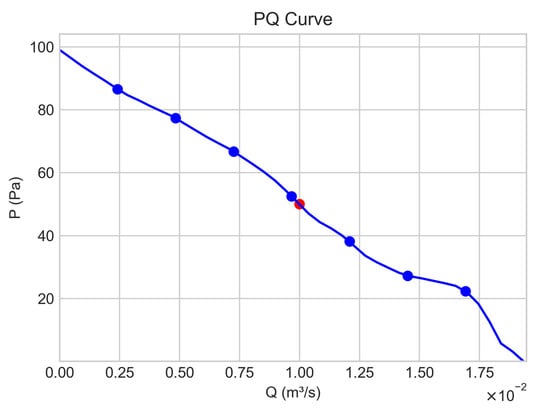

3.4. Optimization

The fan parameter range was given, with the minimum and maximum values for each parameter determined for the individual. The individual values will be converted into integers, as described in Table 7. The GA parameters used in this study are the population size is set to 300, the generation number is set to 300, the crossover probability is set to 0.8, the mutation is set to 0.1, the hall of fame is set to 30, the crowding factor is set to 20, and the penalty value is set to 10. The operating points are determined in advance, namely, 50 Pa of static pressure, 0.01 m3/s of flowrate, and 6000 RPM of rotating speed. From those operating points, the optimum fan parameters can then be obtained using a GA based on a static pressure DNN model. Table 8 shows the operating point, optimum design parameter, and assessment result. Using the optimum design parameter, flowrate, and rotating speed, the static pressure can be predicted, which is 49.96 Pa. It is similar to our design with 0.1% error. Qmax and Pmax can also be obtained, while and are still in our design range.

Table 7.

Design parameters range.

Table 8.

Operating point, optimum design parameter, and assessment result.

Figure 10 shows the P-Q Curve using the optimum design parameter. The red dot indicates the operating point and the blue dots indicate the static pressure values using flowrate variation. In Figure 10, the red point is on the P-Q Curve, meaning that the specified parameter conformed to the design range. and are 0.5, which is within the design range. Therefore, the red dot point is almost in the center of the blue line.

Figure 10.

P-Q Curve using optimum design parameter.

3.5. Discussion

The DNN is able to predict fan static pressure successfully, where the R2 is higher than 0.99. A GA is also then able to find the optimal design parameters with the specified operating point, and . Therefore, this technique will be implemented in the fan manufacture. Over time, a new fan design will be produced and tested using test measurements. The data will be collected as in the previous work. The fan dataset will be updated and will continue to be huge. The minimum and maximum operating parameters will be wider. Therefore, the AI fan design application will continue to perform better.

4. Conclusions

This study used a deep neural network to build two prediction models: the static pressure model and the flowrate model. The static pressure prediction model was selected for further optimization using GA. The performance model using testing data had R2 = 0.997, MAE = 0.565, and RMSE = 0.818. The inputs are nine design parameters, rotating speed, and flowrate. The nine design parameters are chord length root, chord length tip, pitch angle, twist angle, impeller diameter, hub outer diameter, blade number, tip clearance, and frame thickness. The goals of the GA were to find the optimum design parameters based on the operating points. The operating points are static pressure, flowrate, and rotating speed. Several constraints are applied: The GA will search for the design parameters that have and in the 0.5~0.6 range. The chord length root should equal or be less than the chord length tip. The operating points are determined in advance, namely, 50 Pa of static pressure, 0.01 m3/s of flowrate, and 6000 RPM of rotating speed. The results show that the GA is able to find the optimal design parameters with the specified operating points and constraints, with only 0.01% of static pressure error. The results can be used as a reference for engineers to evaluate whether the fan met requirements. This approach can reduce the design time and material. Various design parameters can be obtained from numerous data. Therefore, a new small axial flow fan was developed.

Author Contributions

Conceptualization, Y.-D.K. and C.-C.F.; methodology, Y.-D.K., Y.-L.L. and E.C.N.; software, Y.-D.K., Y.-L.L. and E.C.N.; investigation, Y.-D.K., Y.-L.L. and E.C.N.; resources, Y.-D.K. and C.-C.F.; data curation, Y.-L.L. and E.C.N.; writing—original draft preparation, Y.-L.L.; writing—review and editing, Y.-D.K. and W.-J.L. funding acquisition, Y.-D.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Taiwan Long-sheng Instrument Co., Ltd., funding number NCUT21-T-ER-053.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

The authors thank the Taiwan Long-sheng Instrument Co., Ltd.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wallis, A.R. Axial Flow Fans: Design and Practice; Academic Press, Inc: New York, NY, USA, 1961; ISBN 9781483227849. [Google Scholar]

- Shahsavari, A.; Nili-Ahmadabadi, M. A Novel Approach for the Design of Axial Flow Fan by Increasing By-Pass Ratio in a Constant-Diameter Turbofan. Propuls. Power Res. 2020, 9, 142–158. [Google Scholar] [CrossRef]

- Xu, C.; Mao, Y.; Hu, Z. Tonal and Broadband Noise Control of an Axial-Flow Fan with Metal Foams: Design and Experimental Validation. Appl. Acoust. 2017, 127, 346–353. [Google Scholar] [CrossRef]

- Sarraf, C.; Nouri, H.; Ravelet, F.; Bakir, F. Experimental Study of Blade Thickness Effects on the Overall and Local Performances of a Controlled Vortex Designed Axial-Flow Fan. Exp. Therm. Fluid Sci. 2011, 35, 684–693. [Google Scholar] [CrossRef]

- Podgaietsky, G.L.; de Oliveira, M.L.C.; Hermes, C.J.L. Model-Based Efficiency Mapping and Parametric Analysis of Low-Pressure Axial Fans. Int. J. Refrig. 2022, 144, 136–144. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Y.; Li, J. Volume Flow Rate Optimization of an Axial Fan by Artificial Neural Network and Genetic Algorithm. OJFD 2019, 9, 207–223. [Google Scholar] [CrossRef]

- Lin, B.-J.; Hung, C.-I.; Tang, E.-J. An Optimal Design of Axial-Flow Fan Blades by the Machining Method and an Artificial Neural Network. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2002, 216, 367–376. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, J.; Jiang, B.; Li, Z.; Xiao, Q.; Wu, L.; Xie, B. Multi-Objective Optimization for the Radial Bending and Twisting Law of Axial Fan Blades. Processes 2022, 10, 753. [Google Scholar] [CrossRef]

- Hang, J.; Dian-Rong, G.; Yunhua, L. Multi-objective Optimization for Axial Flow Fan Based on BP Neural Network and Genetic Algorithm. J. Chin. Soc. Mech. Eng. 2018, 39, 433–442. [Google Scholar] [CrossRef]

- Wen, L.; Zhou, K.; Yang, S. Load demand forecasting of residential buildings using a deep learning model. Electr. Power Syst. Res. 2020, 179, 106073. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, J. A novel ensemble method for hourly residential electricity consumption forecasting by imaging time series. Energy 2020, 203, 117858. [Google Scholar] [CrossRef]

- Hu, H.; Wang, L.; Peng, L.; Zeng, Y.-R. Effective energy consumption forecasting using enhanced bagged echo state network. Energy 2020, 193, 116778. [Google Scholar] [CrossRef]

- Kim, M.; Jung, S.; Kang, J. Artificial Neural Network-Based Residential Energy Consumption Prediction Models Considering Residential Building Information and User Features in South Korea. Sustainability 2019, 12, 109. [Google Scholar] [CrossRef]

- Chaerun Nisa, E.; Kuan, Y.-D. Comparative Assessment to Predict and Forecast Water-Cooled Chiller Power Consumption Using Machine Learning and Deep Learning Algorithms. Sustainability 2021, 13, 744. [Google Scholar] [CrossRef]

- Zokaee, F.; Li, B.; Chen, F. FeFET-Based Process-in-Memory Architecture for Low-Power DNN Training. In Proceedings of the 2021 IEEE/ACM International Symposium on Nanoscale Architectures (NANOARCH), AB, Canada, 8–10 November 2021. [Google Scholar]

- Lukac, P.; Tarabek, P. Improving DNN Solution using Repeated Training. In Proceedings of the 2019 International Conference on Information and Digital Technologies (IDT), Zilina, Slovakia, 25–27 June 2019. [Google Scholar]

- Nwankpa, C.; Ijomah, W.; Gachagan, A.; Marshall, S. Activation Functions: Comparison of trends in Practice and Research for Deep Learning. 2021. Available online: http://arxiv.org/abs/1811.03378 (accessed on 17 September 2022).

- Chen, L.; Wang, Y.; Li, H. Enhancement of DNN-based multilabel classification by grouping labels based on data imbalance and label correlation. Pattern Recognit. 2022, 132, 108964. [Google Scholar] [CrossRef]

- Liu, S.; Liu, X.; Lyu, Q.; Li, F. Comprehensive system based on a DNN and LSTM for predicting sinter composition. Appl. Soft Comput. 2020, 95, 106574. [Google Scholar] [CrossRef]

- Hewage, R.; Artificial Neural Network in Python. Medium. 2020. Available online: https://medium.com/datadriveninvestor/artificial-neural-network-in-python-704fae2e23 (accessed on 17 September 2022).

- Kwon, H.; Lai, L.; Pellauer, M.; Krishna, T.; Chen, Y.H.; Chandra, V. Heterogeneous Dataflow Accelerators for Multi-DNN Workloads. In Proceedings of the 2021 IEEE International Symposium on High-Performance Computer Architecture (HPCA), Seoul, Korea, 27 February 2021—3 March 2021. [Google Scholar]

- Teja KB, R.; Kumar, T.K. Real-Time Smart Drivers Drowsiness Detection Using DNN. In Proceedings of the 2021 5th International Conference on Trends in Electronics and Informatics (ICOEI), Telangana, India, 3–5 June 2021. [Google Scholar]

- Han, S.; Choi, H.; Choi, J.; Choi, J.H.; Kim, J. A DNN-based data-driven modeling employing coarse sample data for real-time flexible multibody dynamics simulations. Comput. Methods Appl. Mech. Eng. 2021, 373, 113480. [Google Scholar] [CrossRef]

- Savoldi, L.; Allio, A.; Leggieri, A. Optimization of the flow distribution in a gyrotron cavity using evolutionary CFD simulations driven by a genetic algorithm. Int. J. Heat Fluid Flow 2022, 96, 108987. [Google Scholar] [CrossRef]

- Gu, Z.; Pang, S.; Li, Y.; Li, Q.; Zhang, Y. Turbo-fan engine acceleration control schedule optimization based on DNN-LPV model. Aerosp. Sci. Technol. 2022, 128, 107797. [Google Scholar] [CrossRef]

- Dai, M.; Xu, A.; Huang, Q.; Zhang, Z.; Lin, X. Vertical federated DNN training. Phys. Commun. 2021, 49, 101465. [Google Scholar] [CrossRef]

- Tanghatari, E.; Kamal, M.; Afzali-Kusha, A.; Pedram, M. Distributing DNN training over IoT edge devices based on transfer learning. Neurocomputing 2022, 467, 56–65. [Google Scholar] [CrossRef]

- Zhang, M.; Fu, S.; Ren, H.; Ma, L.; Xu, Y. A hybrid FEM-DNN-based vortex-induced Vibration Prediction Method for Flexible Pipes under oscillatory flow in the time domain. Ocean. Eng. 2022, 246, 110488. [Google Scholar] [CrossRef]

- Somu, N.; Raman, M.R.G.; Ramamritham, K. A hybrid model for building energy consumption forecasting using long, short term memory networks. Appl. Energy 2020, 261, 114131. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, Y.; Srebric, J. Predictions of electricity consumption in a campus building using occupant rates and weather elements with sensitivity analysis: Artificial neural network vs. linear regression. Sustain. Cities Soc. 2020, 62, 102385. [Google Scholar] [CrossRef]

- Wang, P.; Fan, E.; Wang, P. Comparative analysis of image classification algorithms based on traditional machine learning and deep learning. Pattern Recognit. Lett. 2021, 141, 61–67. [Google Scholar] [CrossRef]

- Sivapatham, S.; Ramadoss, R.; Kar, A.; Majhi, B. Monaural speech separation using GA-DNN integration scheme. Appl. Acoust. 2020, 160, 107140. [Google Scholar] [CrossRef]

- Yang, D.; Yu, W.; Ding, X.; Zhou, A.; Wang, X. DP-Nets: Dynamic programming assisted quantization schemes for DNN compression and acceleration. Integration 2022, 82, 147–154. [Google Scholar] [CrossRef]

- Xue, Y.; Yang, C.; Dong, X.; Li, W.; Noblesse, F. Design of marine propellers with prescribed and optimal spanwise circulation distributions based on genetic algorithms and neural network. Appl. Ocean. Res. 2022, 127, 103318. [Google Scholar] [CrossRef]

- Hanandeh, S. Introducing mathematical modeling to estimate pavement quality index of flexible pavements based on genetic algorithm and artificial neural networks. Case Stud. Constr. Mater. 2022, 16, e00991. [Google Scholar] [CrossRef]

- Liu, J.; Xia, Y. A hybrid intelligent genetic algorithm for truss optimization based on deep neutral network. Swarm Evol. Comput. 2022, 73, 101120. [Google Scholar] [CrossRef]

- Haq, Z.U.; Ullah, H.; Khan, M.N.A.; Naqvi, S.R.; Ahsan, M. Hydrogen production optimization from sewage sludge supercritical gasification process using machine learning methods integrated with genetic algorithm. Chem. Eng. Res. Des. 2022, 184, 614–626. [Google Scholar] [CrossRef]

- AMCA Standard 210-16 ASHRAE Standard 51-16. Laboratory Methods of Testing Fans for Certified Aerodynamic Performance Rating, 2016. Long Vigtory Instruments: Taoyuan City, Taiwan, 2022; Operating Instructions, SW-300.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).