1. Introduction

Improving systems performance and enhancing process efficiency are key interests for companies in efforts made towards product and process quality development. Design of Experiment (DOE) is a helpful tool used in identifying the key variables that influence quality characteristics in a process. Designed experiment is a systematic approach to change the controllable factors (inputs) in a process and define the effect of these inputs on the parameters (the outputs) of the process. For DOE, it is vital to set the operating conditions of the process variables that will result in the best process performance; this can achieve the target value of the mean and minimize the variability of the quality characteristics (outputs) of the process [

1,

2,

3]. Several studies have investigated the use of DOE in different applications. Alagumurthi et al. investigated and optimized the process parameters of a grinding process, to obtain the optimal factor levels that deliver a superior quality and productivity while considering the economic factors. The DOE principles were implemented in the optimality procedures using the Taguchi method [

4]. Al Athamneh et al. explored the fatigue properties of SAC305 solder joints at different operating conditions. Since the reliability of the final product is one of the eight dimensions of quality, DOE rules were used in constructing a robust reliability model for solder joint fatigue life, as a function of the process parameters [

5]. In addition, Durakovic provided a formal guideline for the planning and execution of the experiments and for the analysis and interpretation of the results for different applications [

6].

The use of the Design of Experiment in the food industry has been examined in numerous studies. Ahmadabadi et al., in their study, investigated the use of DOE and Quality Function Deployment (QFD) for developing new food products. The study used several parameters for process improvement to satisfy the customer needs, and the results indicated the effectiveness of the use of DOE and QFD [

7]. Cucuz et al., in their study, found satisfactory results using DOE to optimize the process parameters in the food industry for grape pomace extracts, using the ultrasound-assisted extraction to produce a satisfactory yield of phenols and anthocyanins [

8]. Kumar et al. developed models of DOE and simulation to maximize the output of tomato concentrated pulp; the results highlighted the practical application of DOE to increase the throughput rate and the productivity in the food industry [

9]. In addition, other studies highlighted the impact of DOE for process improvement in different applications. Olveira et al. proposed a full factorial design in natural fibers as reinforcement in polymers, and they investigated the impact of some parameters on the physical properties of the coir fiber [

10,

11,

12]. Beg et al. proposed the application of DOE in pharmaceutical product and process optimization [

13]. Other case studies investigated the machinability performance during the various processes using DOE [

14,

15]. Moreover, other studies used fractional factorial designs. Moreira et al. found that the fractional design can be applied to optimizing an acid–alkaline pretreatment in rice husks [

16]. Rezende et al. used DOE to optimize milling time, temperature, double treatment, chemical concentration, and pretreatment time in acid–alkali (EA) and acid–organosolv (EO) pretreatments [

17].

Numerous optimization techniques are commonly used in optimizing the process parameters. Under the Taguchi method, various parameters can be examined simultaneously with a minimum number of experimental conditions [

18,

19]. The local optimal settings can be obtained with a reasonable number of experiments, and it is more powerful than fractional factorial because it has its orthogonal array. Moreover, it considers the mean and variance by using the signal-to-noise ratio (SNR). SNR has three main categories: larger-the-better, smaller-the-better, and nominal-the-best. Each of these categories has a special equation to calculate SNR, and this ratio is defined so that a maximum value of the ratio minimizes variability transmitted from the noise variables. In most manufacturing processes, several quality characteristics must be considered for process parameter optimization; this means that more than one response characteristic must be optimized at the same time. To obtain the overall optimal setting of process parameters concerning all the responses, an optimization strategy is required. The strategy that can deal with this type of problem is the multi-response optimization technique [

20,

21,

22,

23]. The approach seeks to modify the design parameters (known as control factors) such that the system response is robust; that is, insensitive to noise elements that are difficult or impossible to control. The Taguchi method contains system design, parameter design, and tolerance design procedures to achieve a robust process [

24]. The main thrust of Taguchi’s technique is the use of parameter design to determine the parameter (factor) settings, providing the optimum levels of a quality characteristic (performance measure) with the least variation. The process has three stages: System design, Parameter design and Tolerance design [

25]. Taguchi’s (SNR), which are log functions, are based on Orthogonal Array (OA) experiments that result in considerably reduced “variance” for the experiment with “optimal settings” of control parameters. Thus, the Taguchi Method combines the Design of Experiments with optimization of control parameters to reach the best outcomes. Orthogonal Arrays give a set of well-balanced (minimum) experiments and desired outputs, act as objective functions for optimization, improve data analysis, and forecast optimal results [

26,

27].

The Taguchi method has been efficient in optimizing the process performance in many applications [

28,

29,

30,

31]. For example, in the manufacturing field, Fratila and Caizar used the fractional orthogonal with the Taguchi method to optimize the lubrication and cutting parameters of a face-milling process. The examined quality responses in their study were surface roughness and power consumption. The contributions of the process parameters were determined using ANOVA analysis [

32]. A biodiesel production process was demonstrated by Esmaeili et al., where the reaction time, temperature, methanol-to-oil ratio and catalyst concentration were considered as process parameters for investigation. The Taguchi method was applied to obtain the factor levels that provide the optimal production performance [

33].

The Taguchi method also has many applications in the food industry; for example, in the study implemented by Patidar et al. DOE methodology using Taguchi orthogonal array (OA) was used to evaluate the influence of several factors on the pectinase production. The results indicated that Taguchi’s method is efficient for optimizing the experiments for the investigated case study [

34]. Noorwali, in his study, introduced a model based on the Taguchi method (along with applying the lean principles) to reduce the variability in the food processing industry, and found significant results [

35].

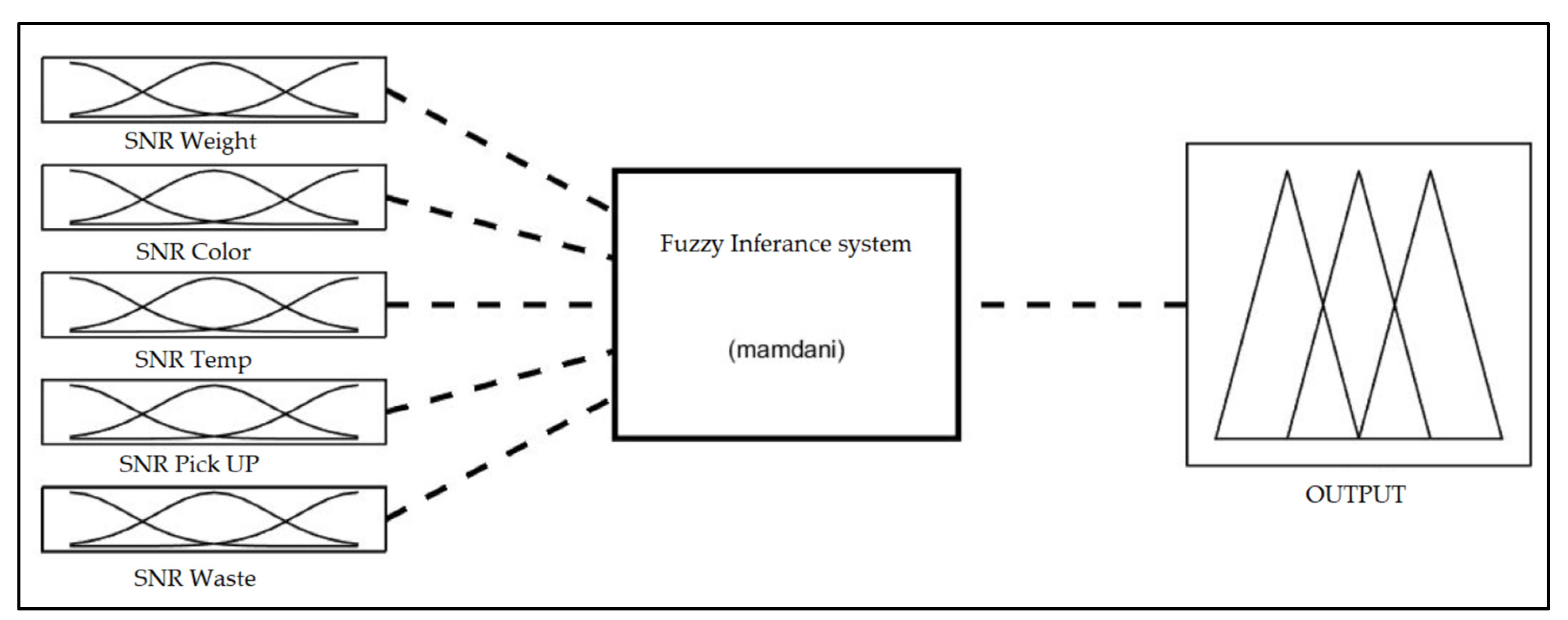

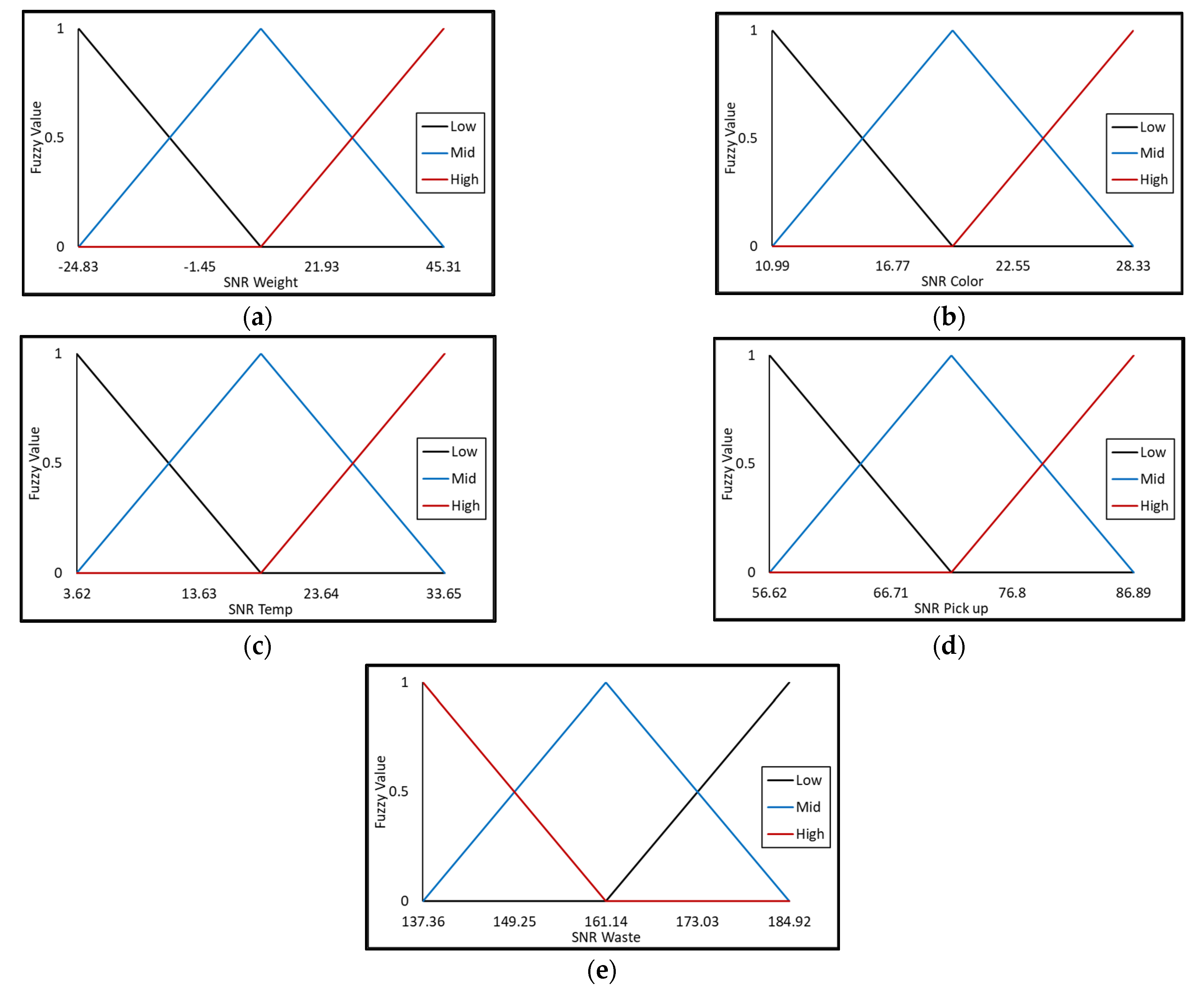

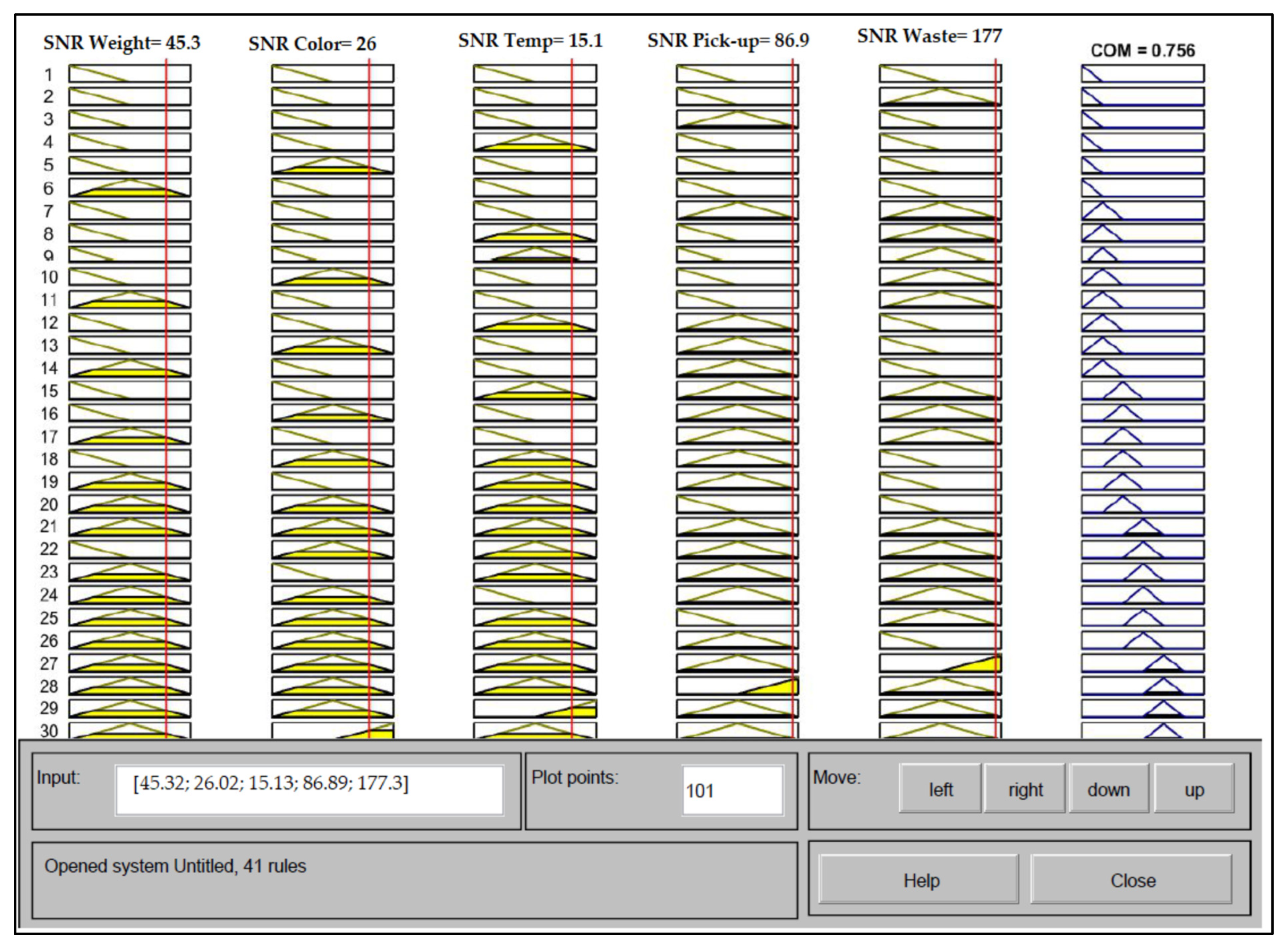

The Taguchi and DOE approaches showed a significant deficiency when the multi-criteria problem optimization was presented. There has been a lot of research undertaken on the various methods for dealing with multi-response problems, such as artificial neural networks (ANNs), fuzzy logic, fuzzy Taguchi method, neural fuzzy Taguchi method, genetic algorithm, utility method, goal programming, grey fuzzy method, principal component analysis, fuzzy regression, and response surface methodology [

36,

37,

38,

39,

40,

41,

42]. The principles of fuzzy logic are used to deal with ambiguous and uncertain data. Different case studies used fuzzy logic, fuzzy Taguchi method, grey fuzzy method, neural fuzzy Taguchi method, and fuzzy regression, and found significant results that the fuzzy measured values were in good agreement with the experimental values. Furthermore, confirmation tests were carried out to ensure that the Taguchi optimized levels and fuzzy-developed models accurately represent the measured responses [

43,

44,

45,

46].

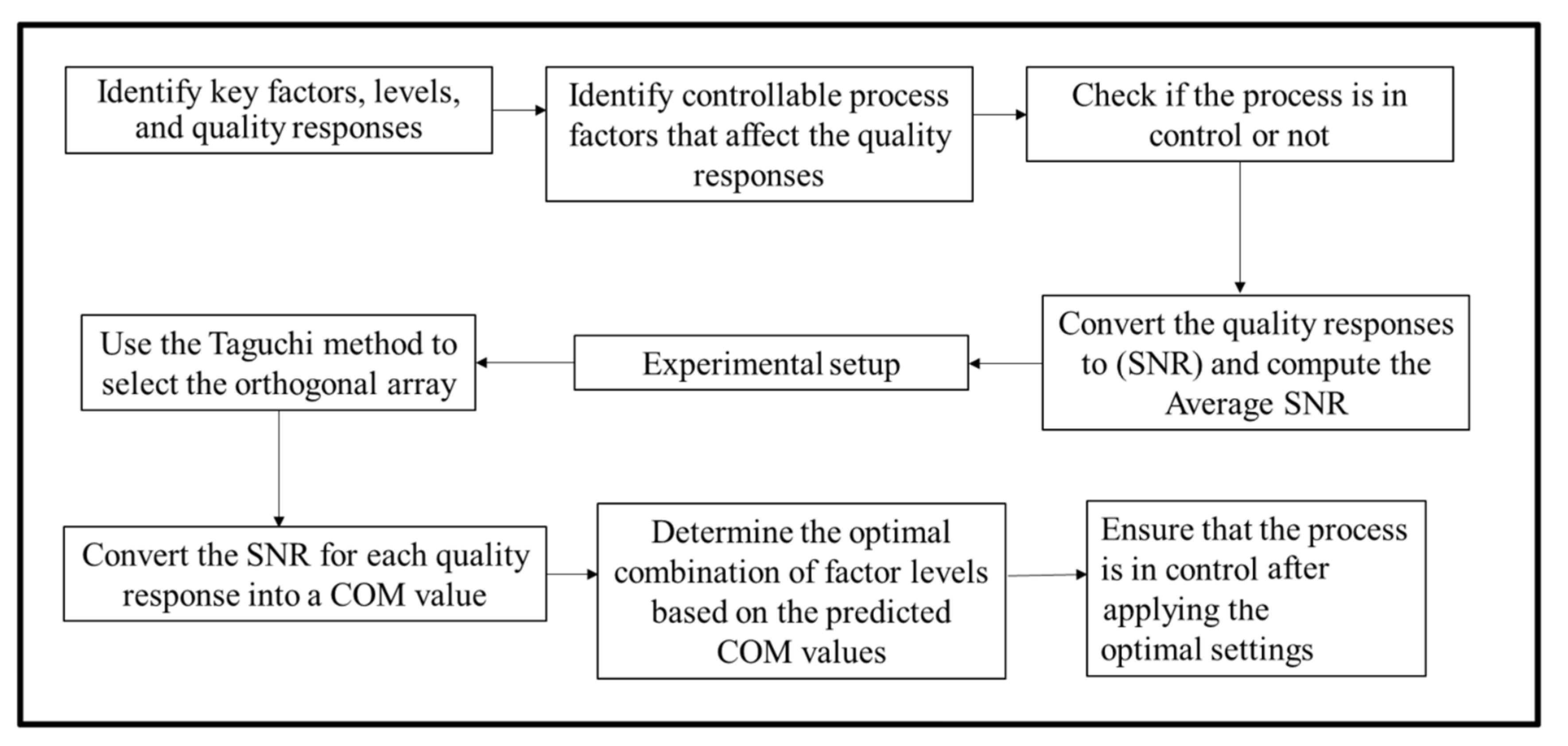

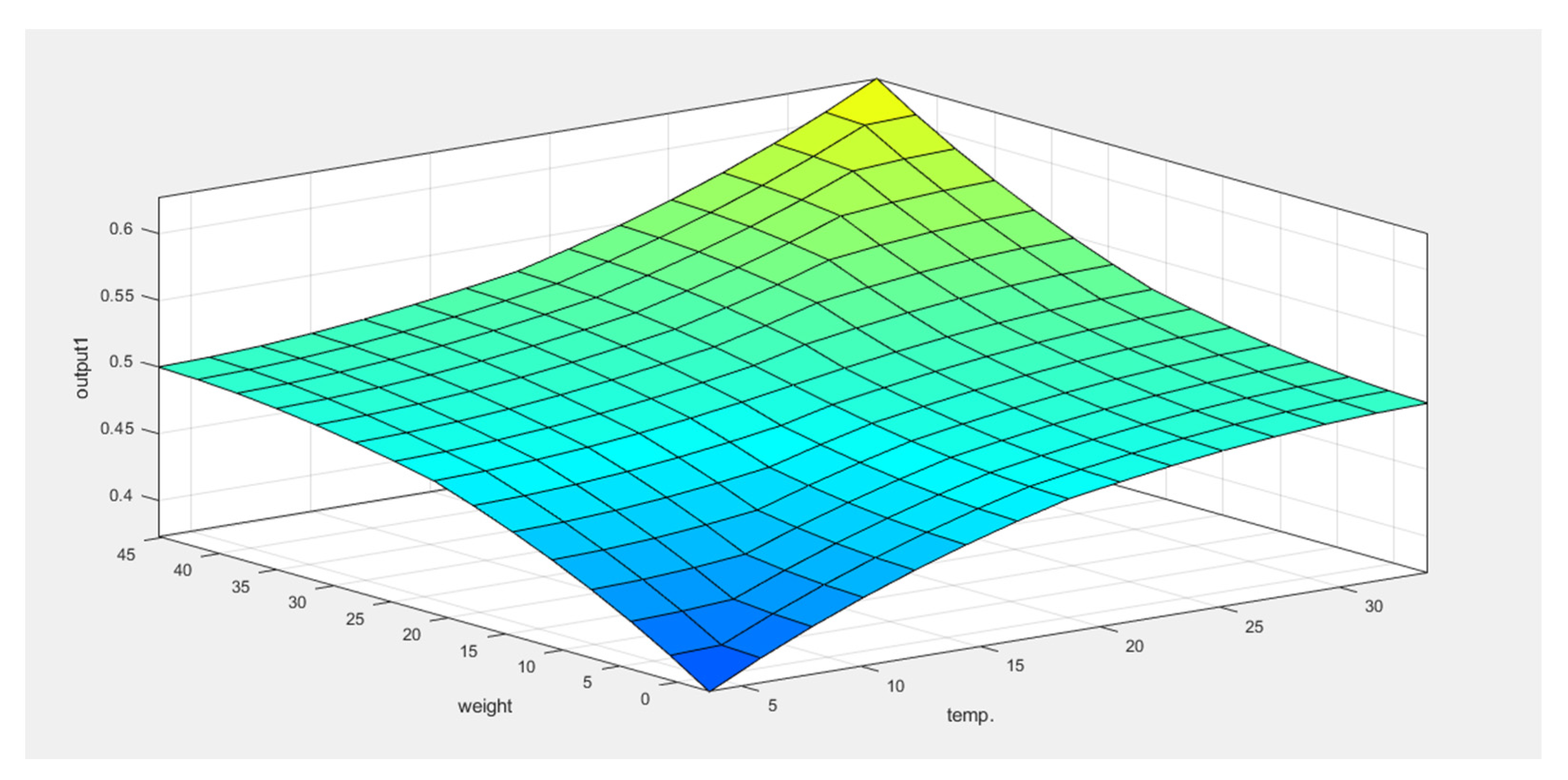

In the presented study, a case study in the food industry is investigated under which a multi-response problem is considered. The main aim is to achieve high quality in terms of (piece/product) best flavor, surface texture, dimensional accuracy, color, and high production rate. This will also consider reducing variability between (pieces/products), and machining economy in terms of cost savings. Moreover, other considerations will include increasing the performance and productivity (of the lines/machines) with the best utilization and the least amount of required rework, which comes in accordance with increasing customer satisfaction. The Taguchi-Fuzzy model has been used to optimize the process and to find the optimal settings of the controllable factors that achieve a target value of the mean and minimize the variability of all quality characteristics.