An Advanced Multifidelity Multidisciplinary Design Analysis Optimization Toolkit for General Turbomachinery

Abstract

:1. Introduction

2. Methodology

2.1. Overview

2.2. Design Variables and Constraints

2.3. Objective Function and Pareto Front

2.4. Search Algorithms

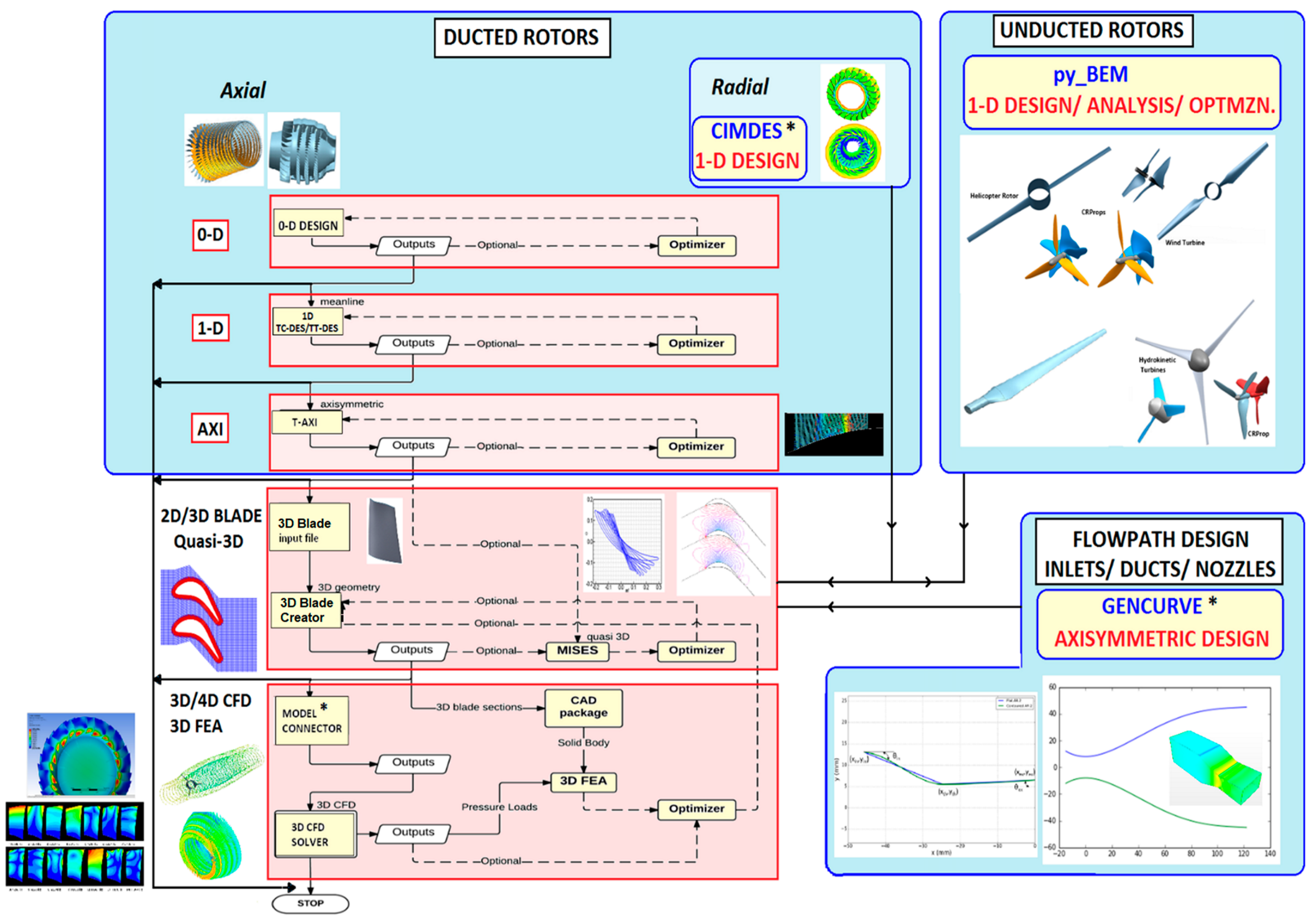

2.5. MDAO Framework

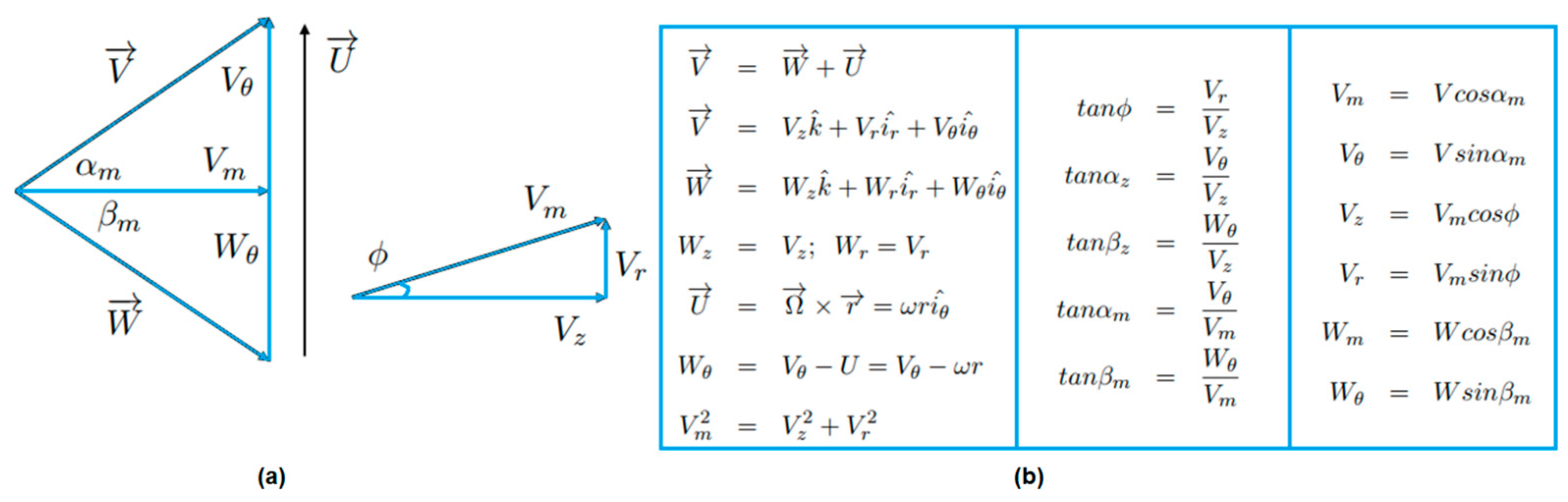

2.5.1. General Notation and Formalism

2.5.2. Ducted Rotors: 0D Design

2.5.3. Ducted Rotors: 1D Meanline Design

2.5.4. Ducted Rotors: Axisymmetric Design

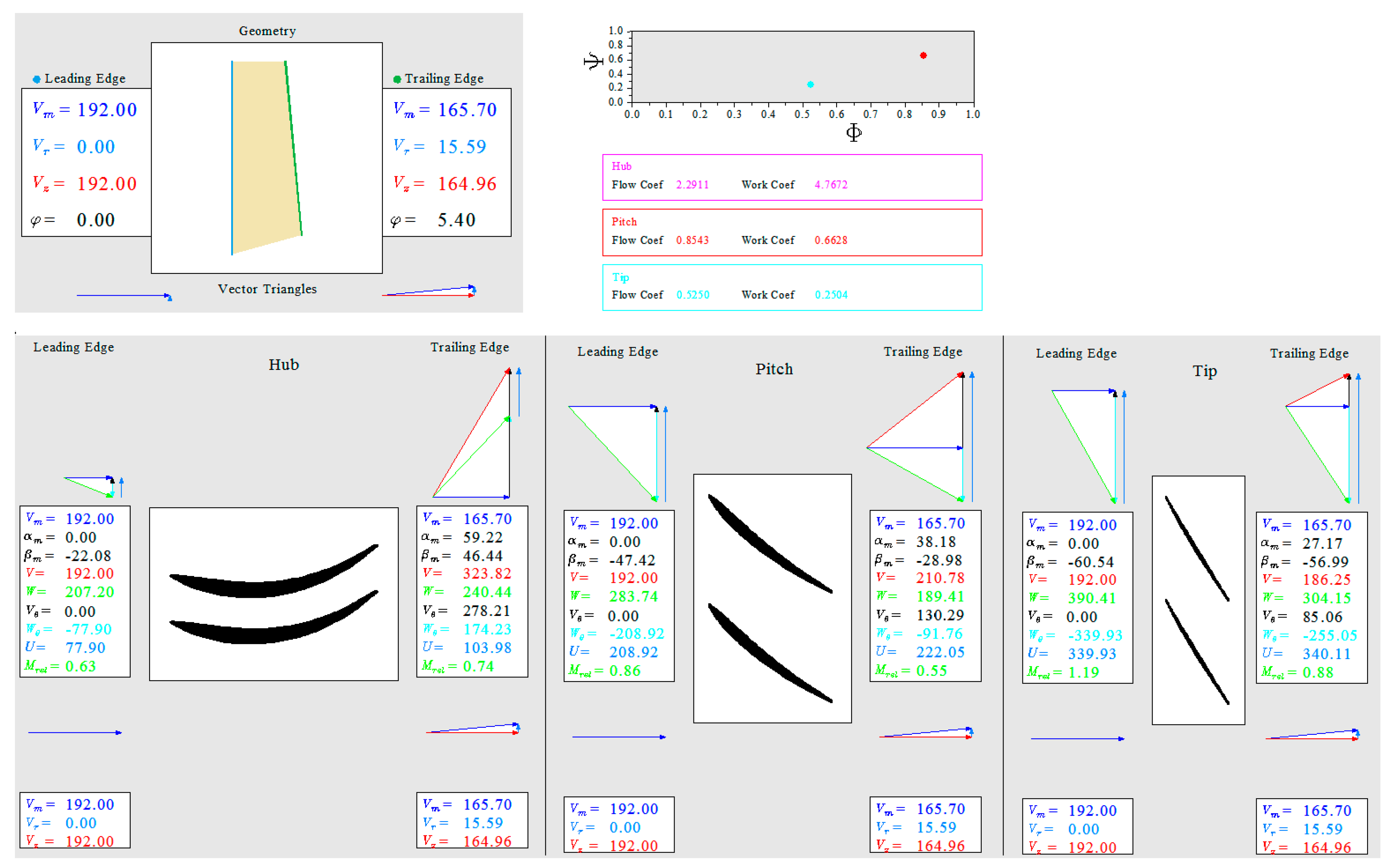

2.5.5. Ducted Rotors: Quasi-3D Design

2.5.6. Unducted Rotors: Axisymmetric Design

2.5.7. Unducted Rotors: 1D Spanwise Design

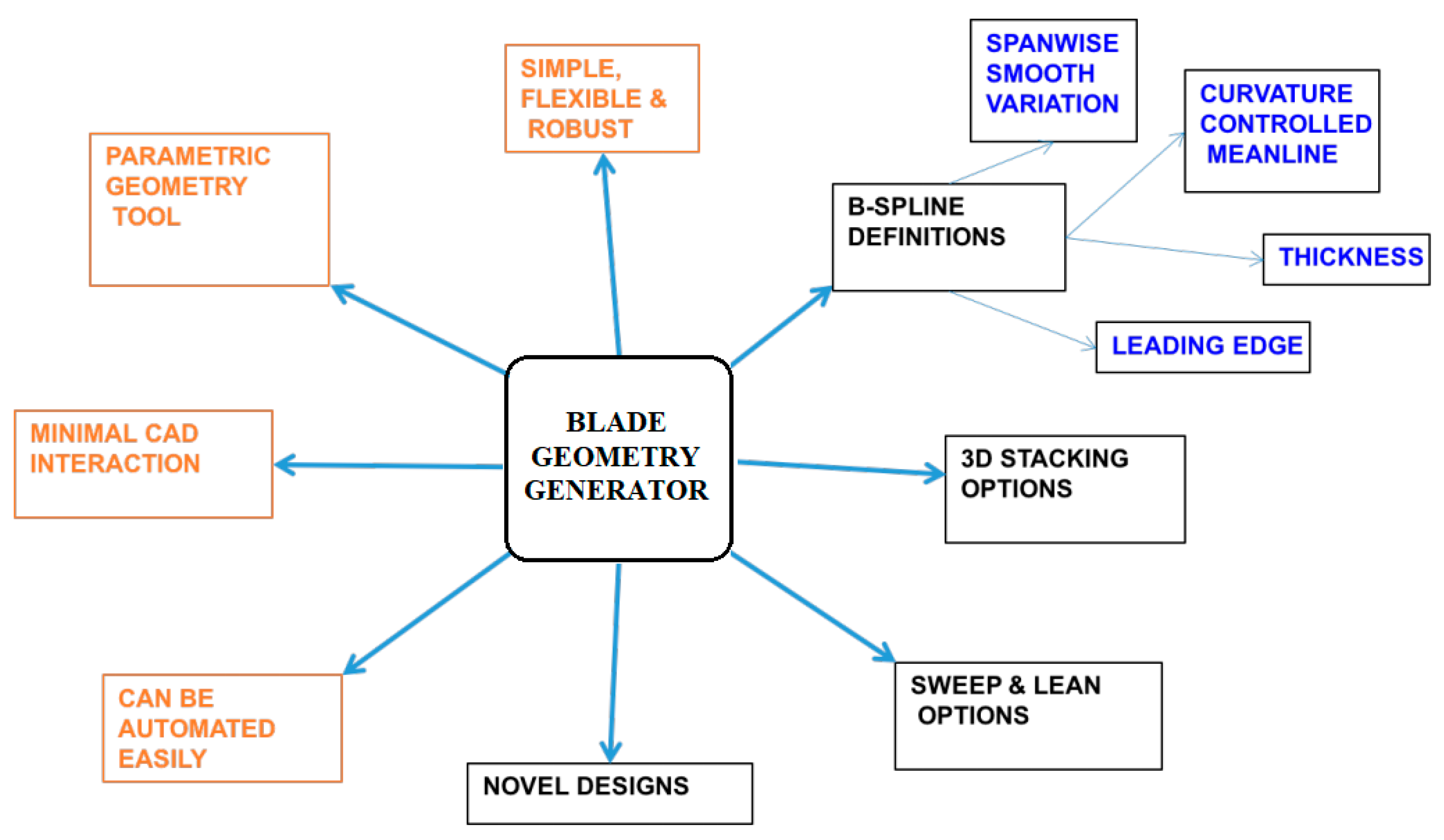

2.5.8. Parametric 3D Blade Geometry Generation

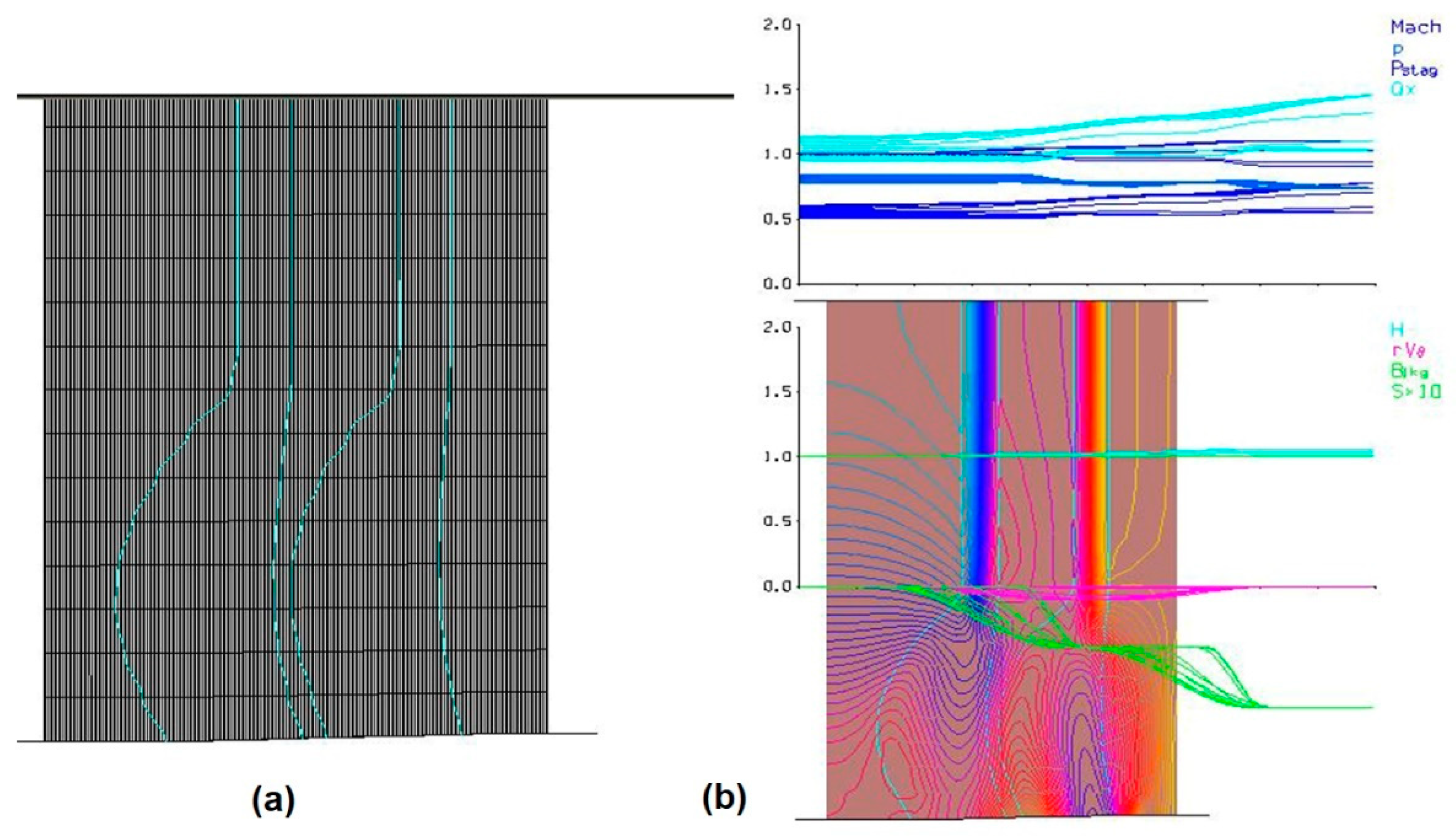

2.5.9. High-Fidelity Analysis

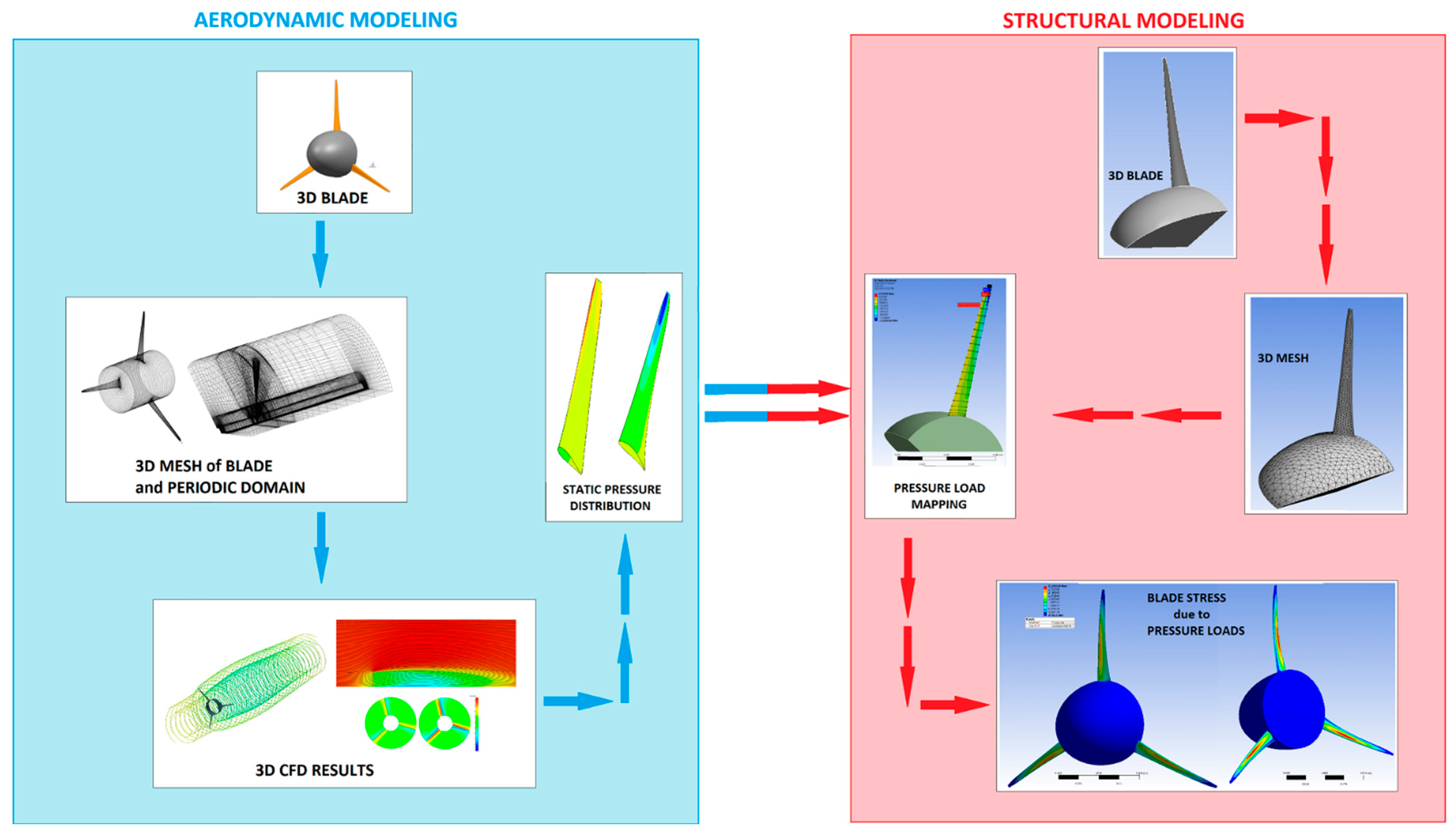

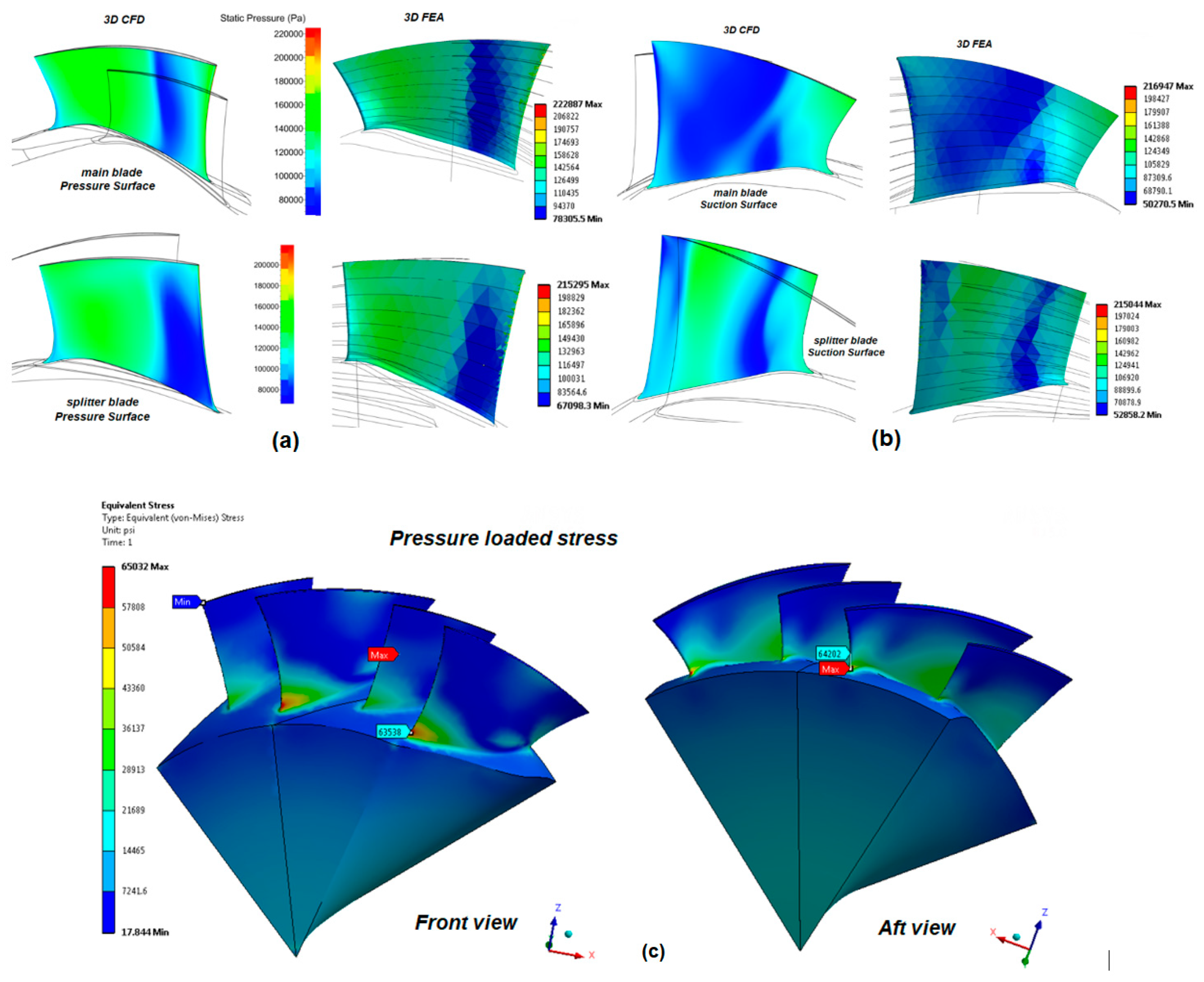

2.5.10. Fluid–Structure Interaction

3. Results

3.1. Ducted Axial Turbomachines

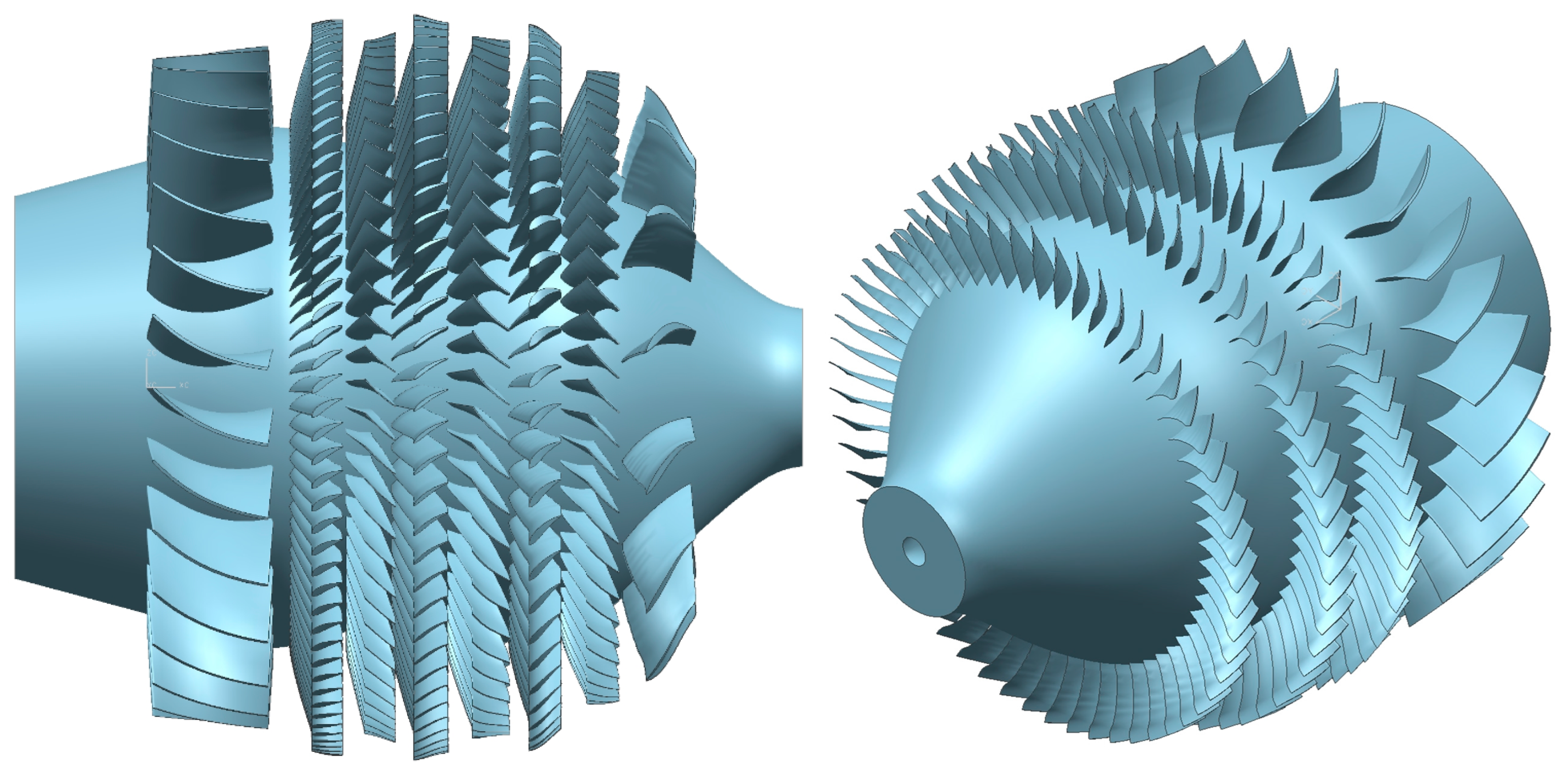

3.1.1. Multistage LPC Rotor with Optimized Flow Path

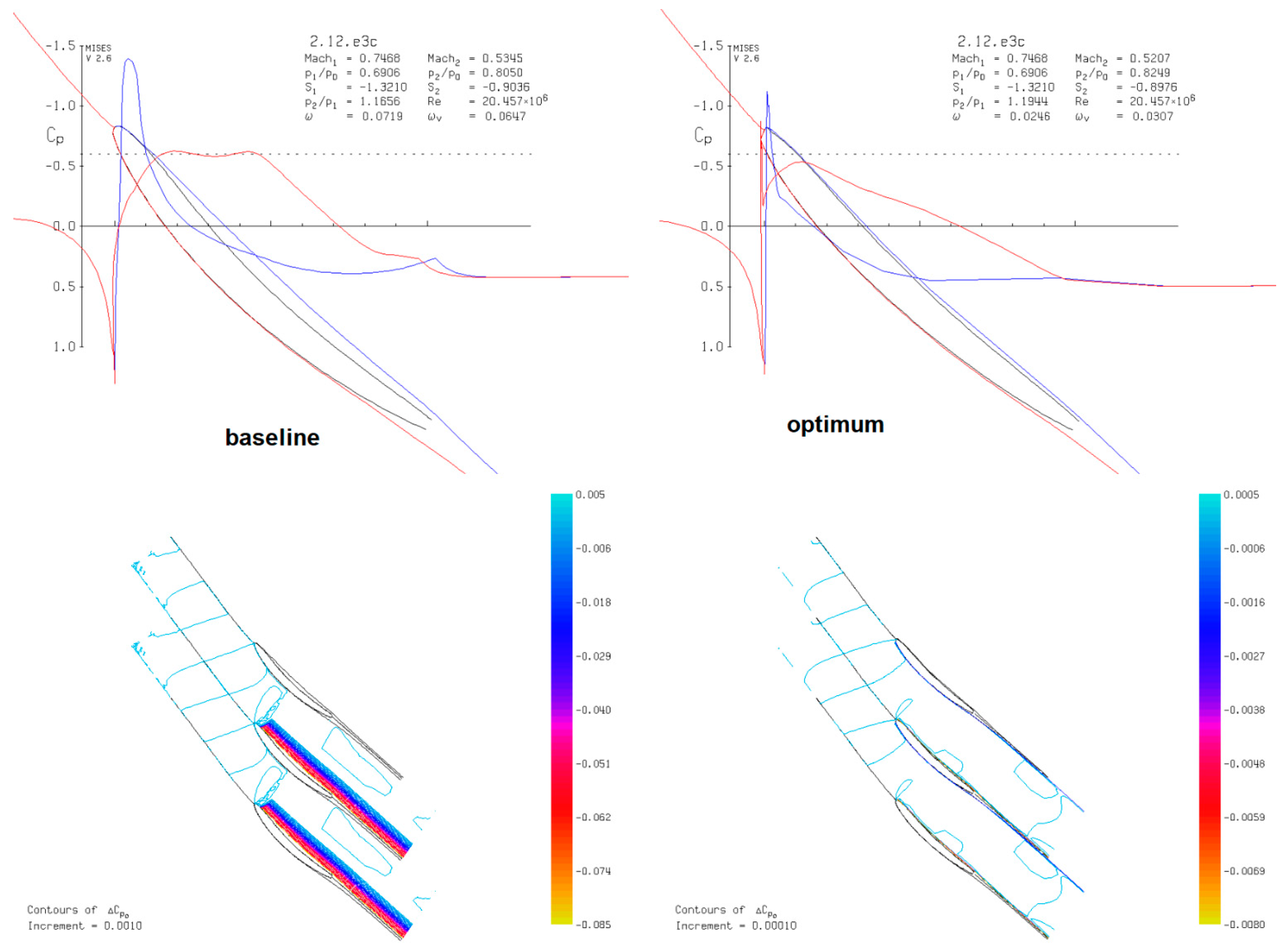

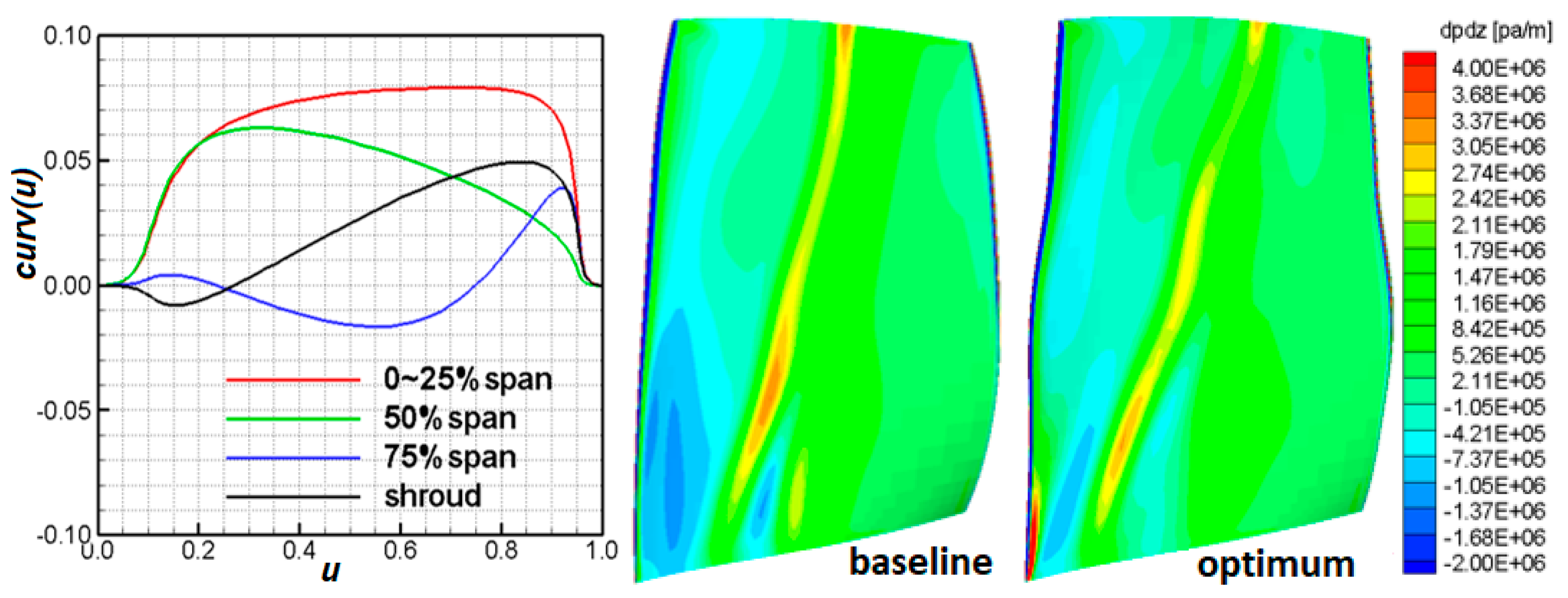

3.1.2. E3 HPC Rotor 6 Optimization

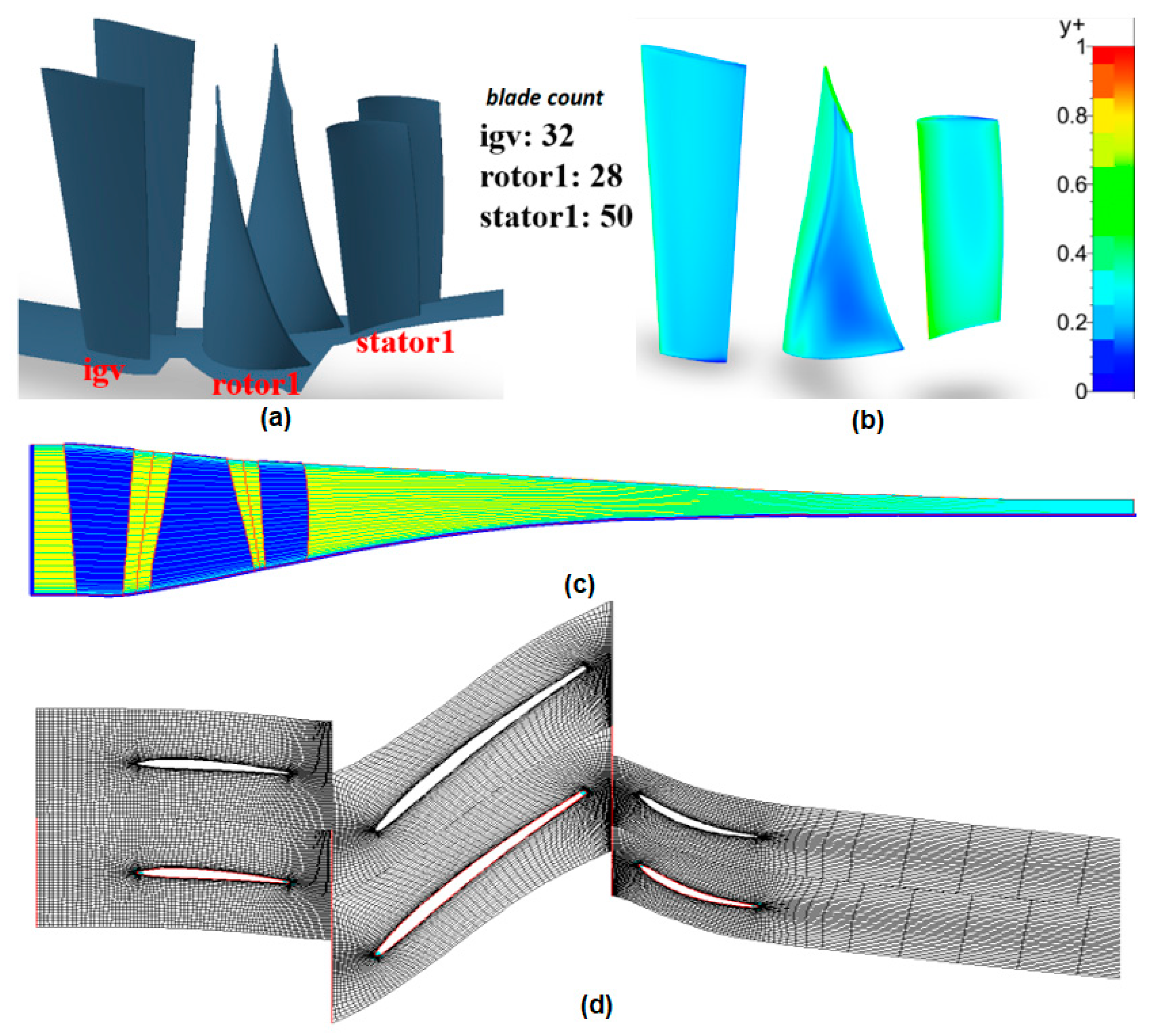

3.1.3. Optimized Rotor of 1.5 Stage E3 HPC

3.1.4. Fluid–Structure Interaction of Transonic Splittered Fan

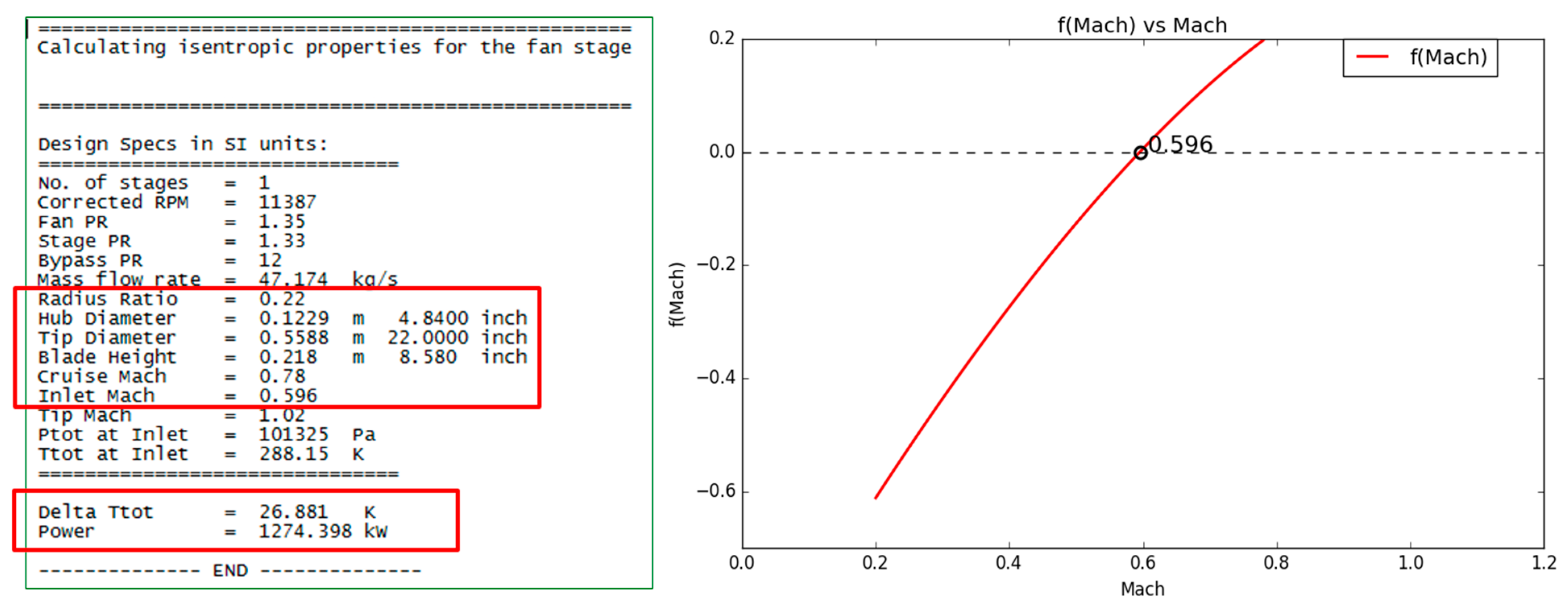

3.1.5. Preliminary Design for a Distortion-Tolerant Turbofan Stage

3.1.6. Axial Turbine Design for a Small JetCat Engine

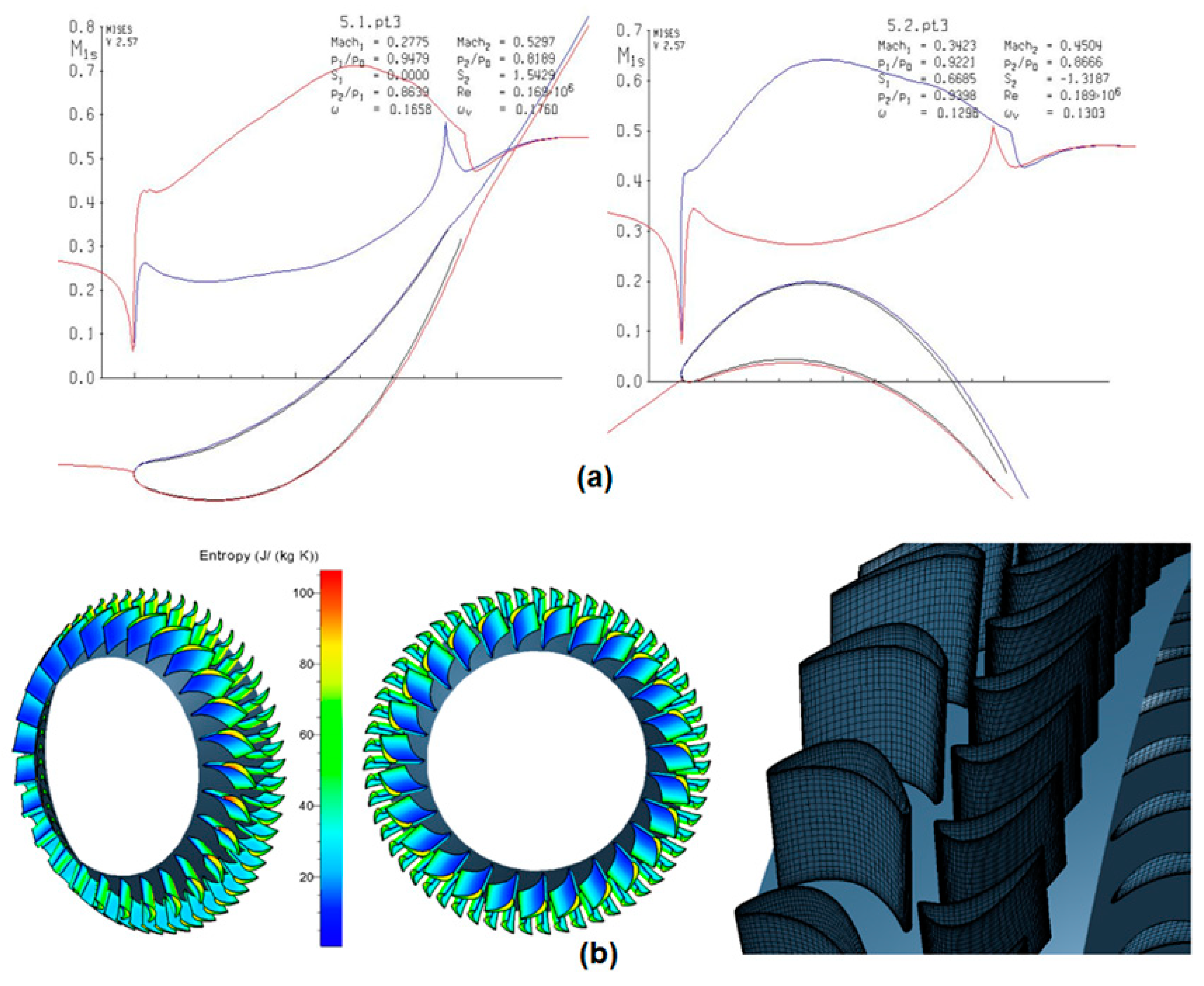

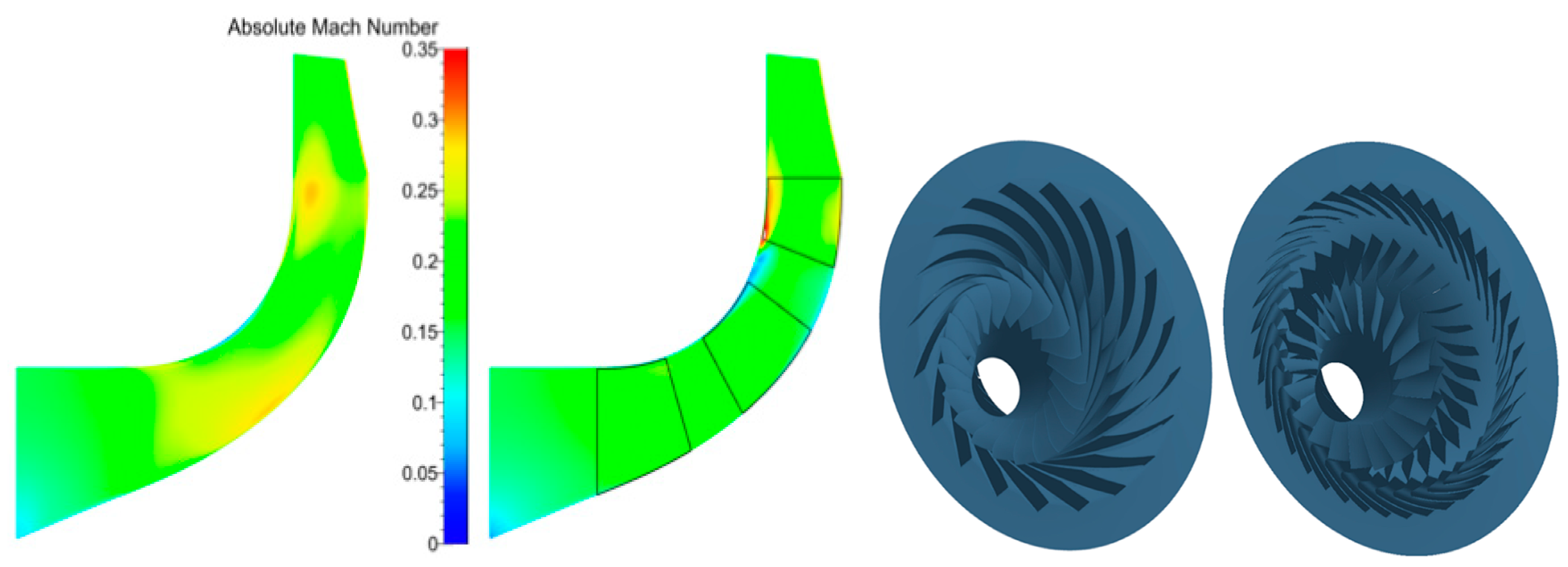

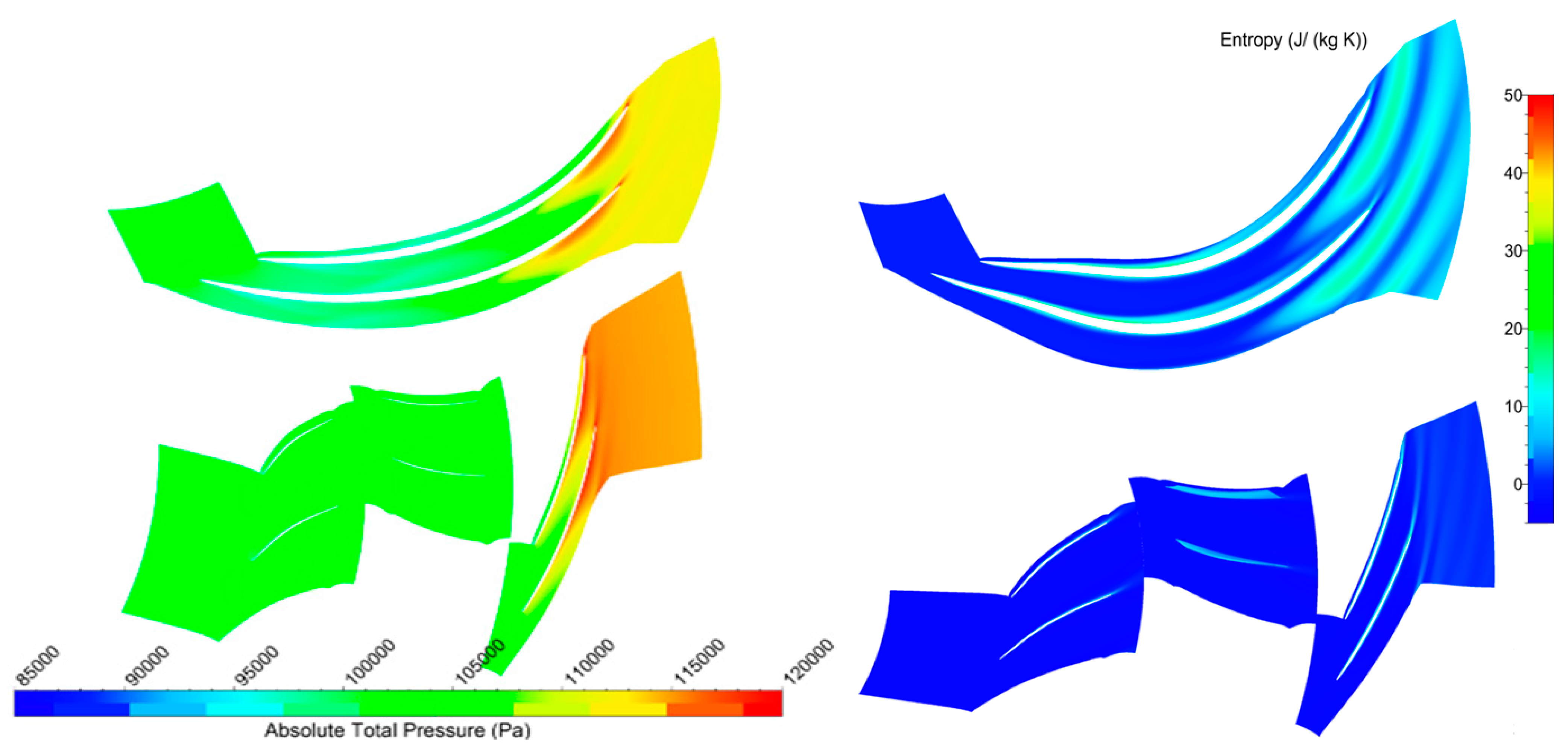

3.2. Ducted Radial Turbomachines

3.2.1. Single-Stage and Novel Centrifugal Compressor

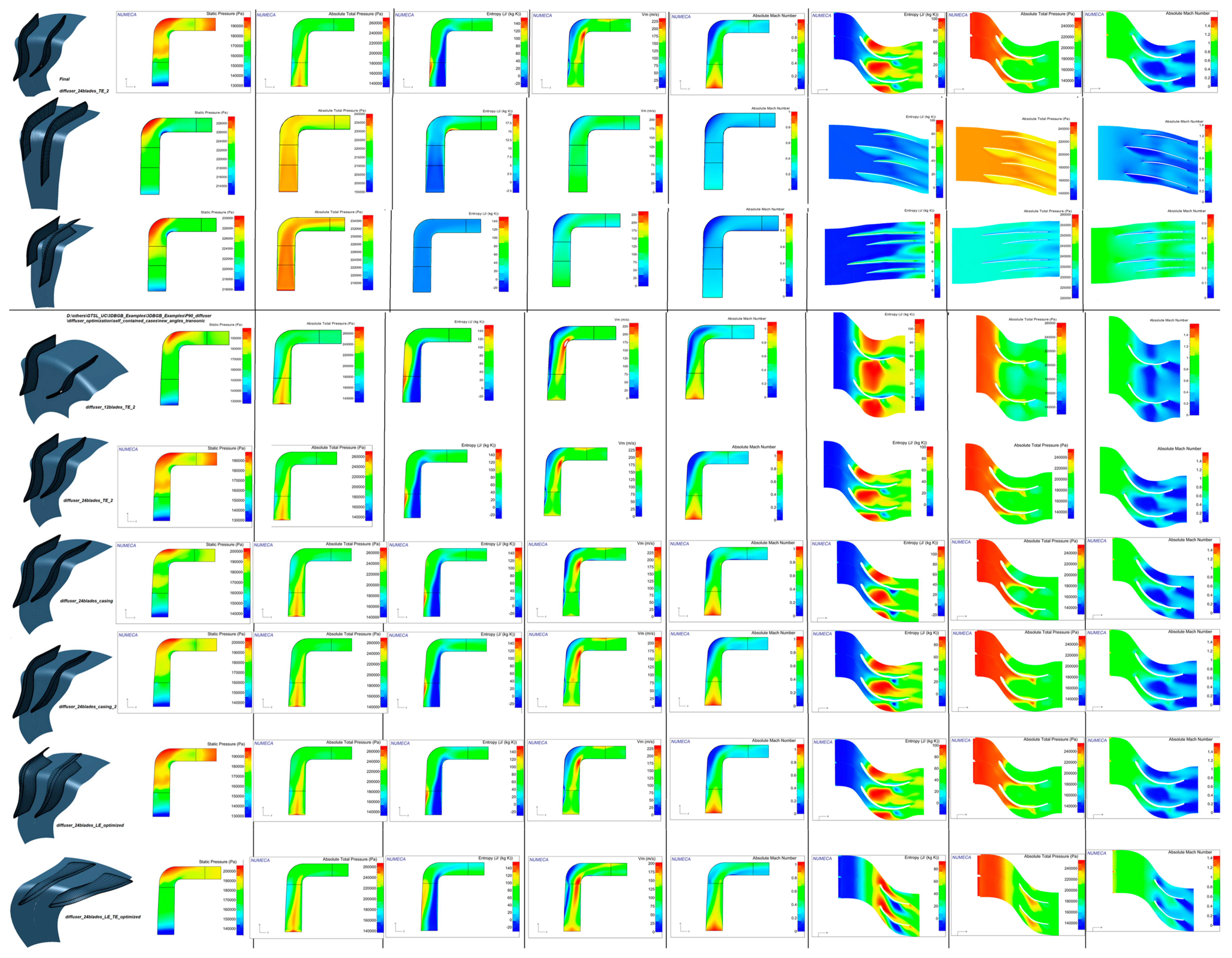

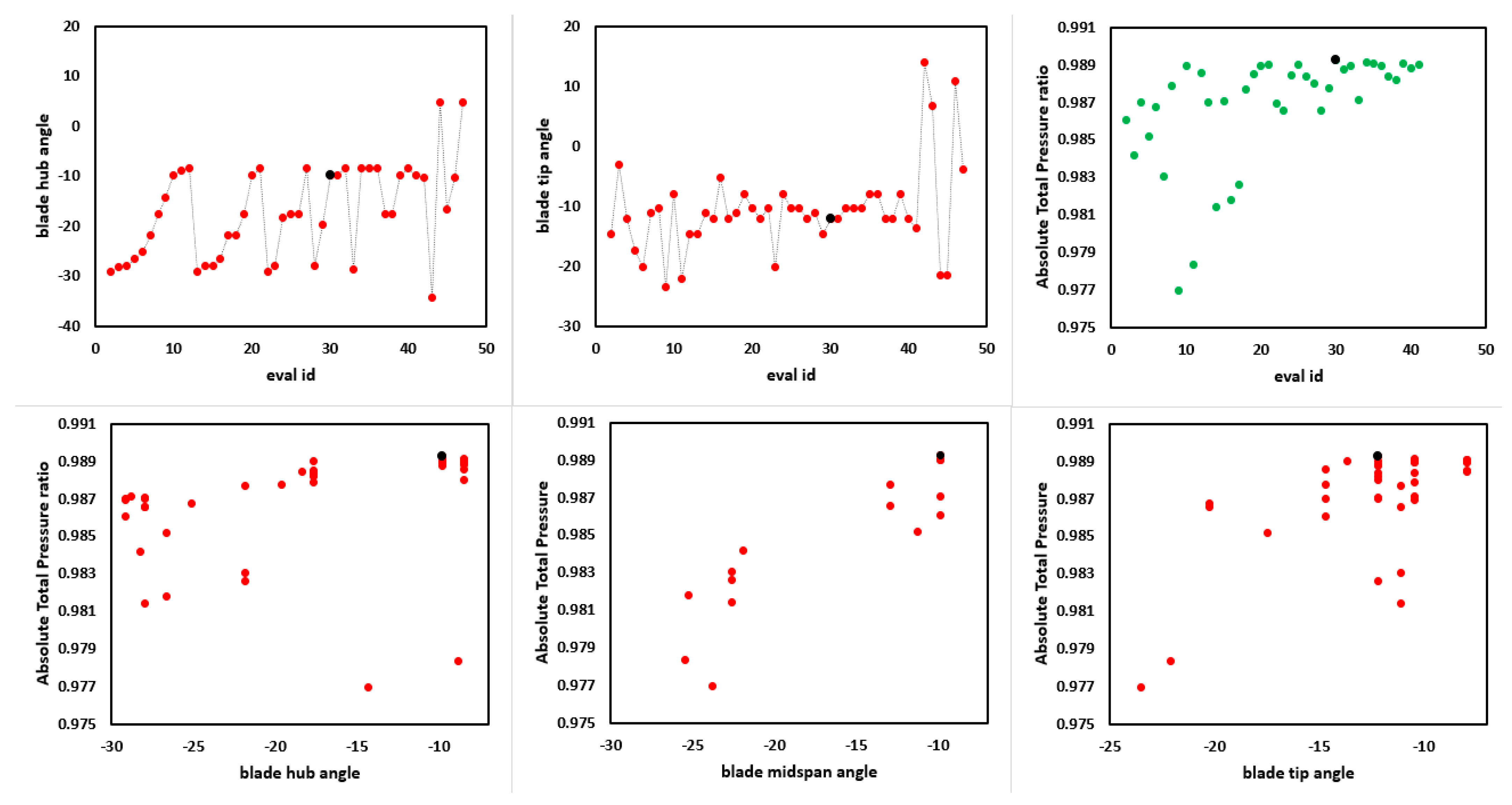

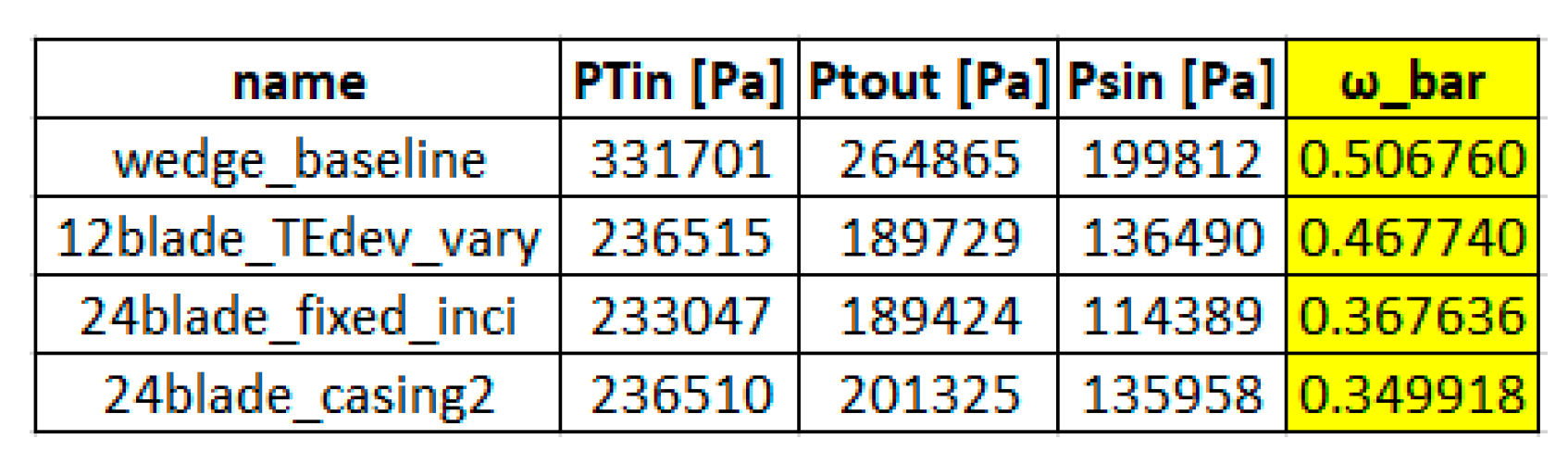

3.2.2. Radial Diffuser Vane for a Small Jet Engine

3.3. Unducted Rotors

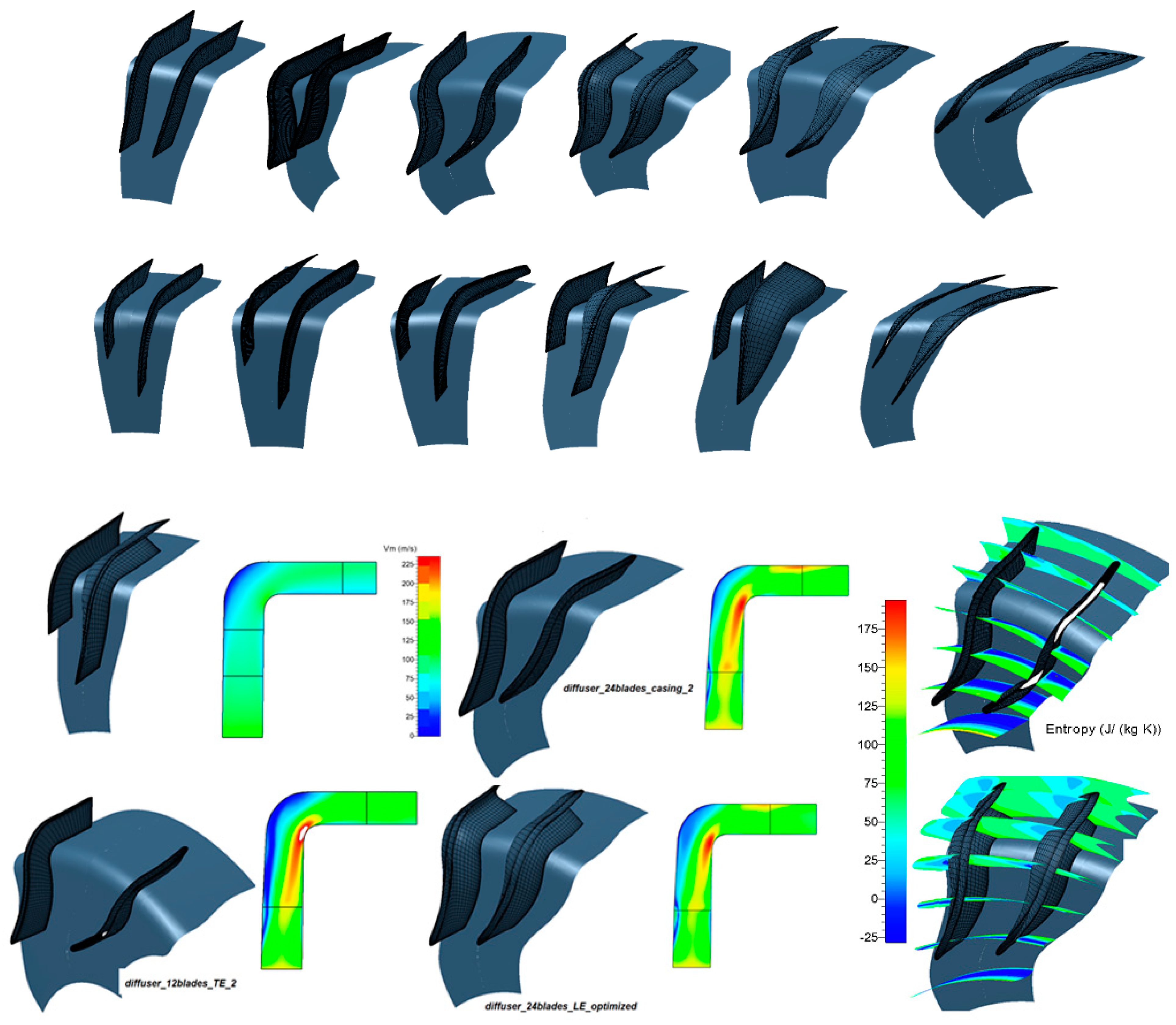

3.3.1. Contra-Rotating Propeller Rotor

3.3.2. Wind Turbine 2D Airfoil Optimization

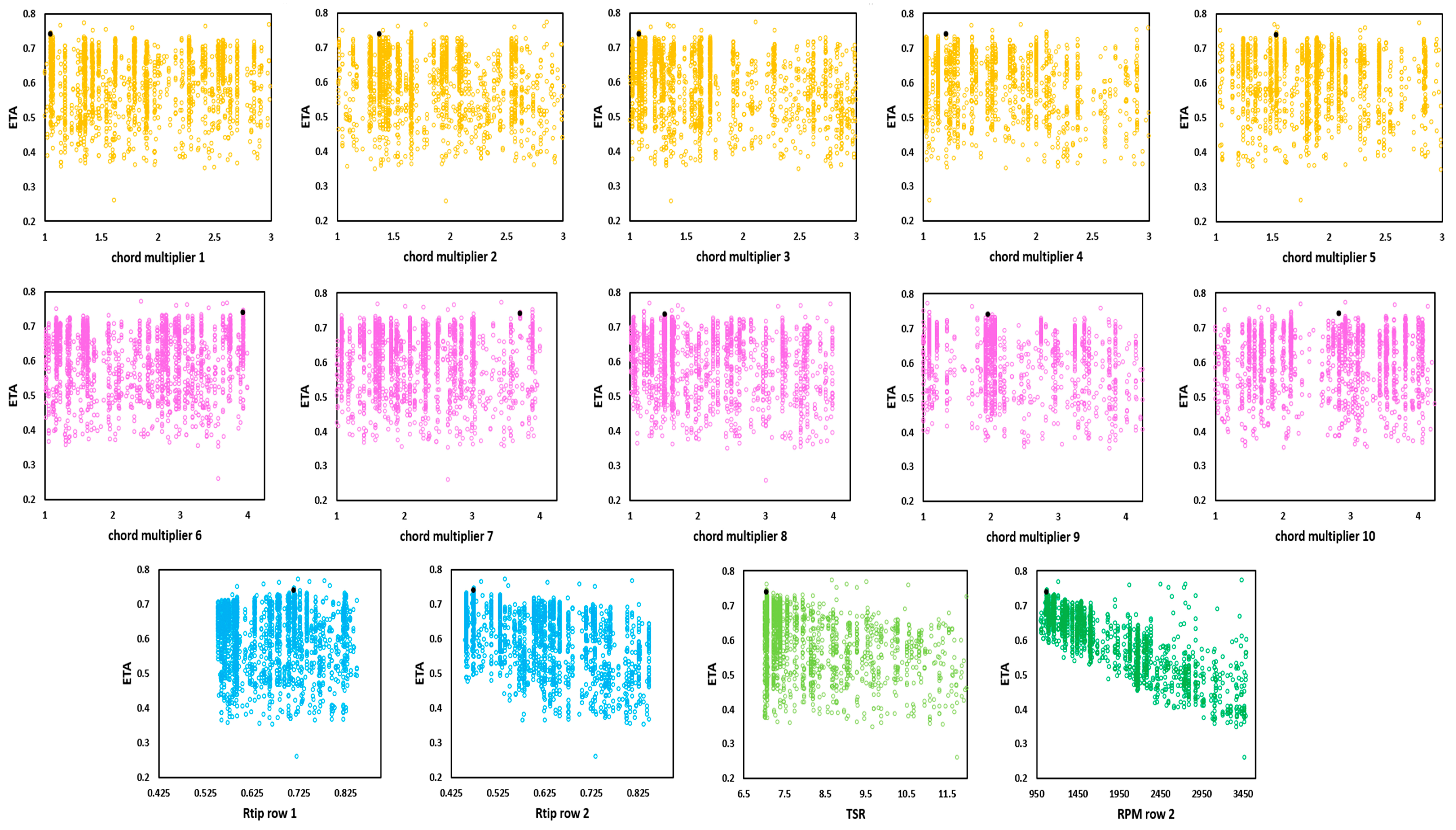

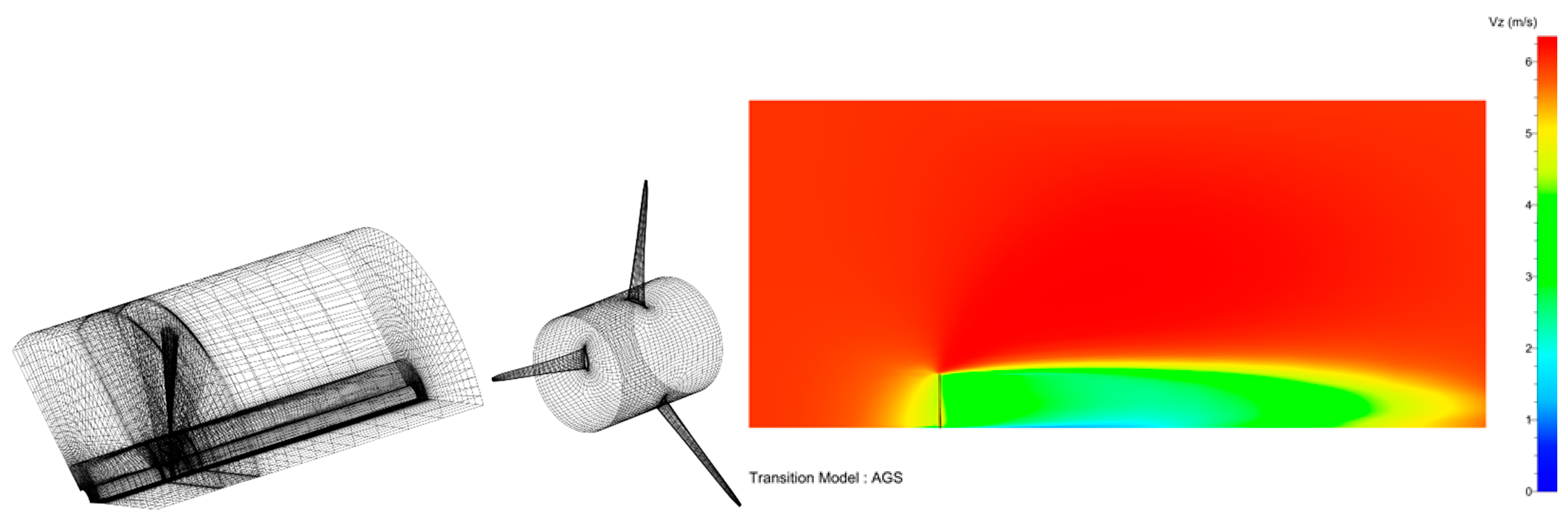

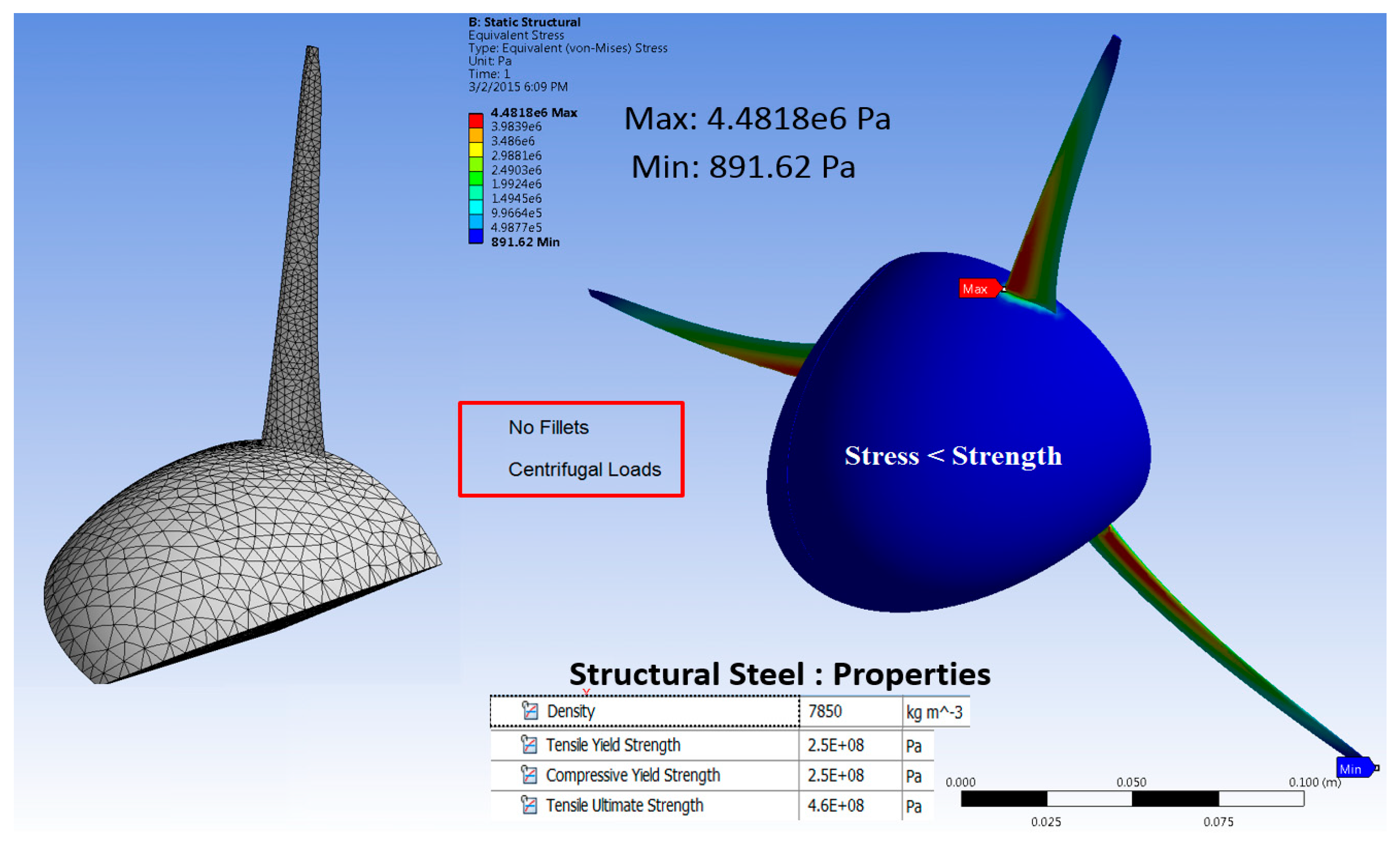

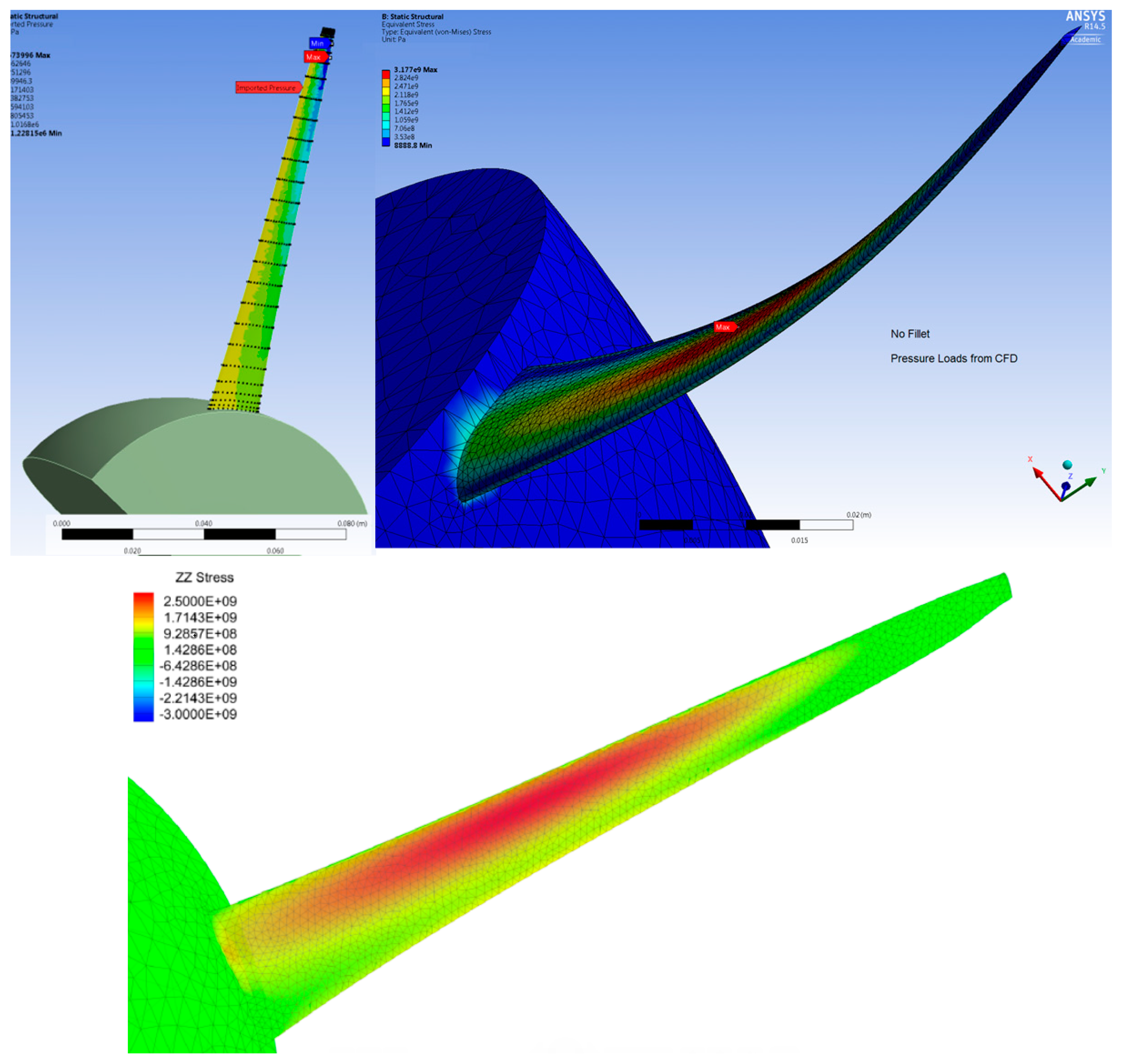

3.3.3. Hydrokinetic Turbine Rotor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Cl, Cd | Coefficient of lift and drag |

| CP, CT | Coefficient of power and thrust |

| M, m | Mach, meridional |

| R | Rotor |

| S | Stator |

| t | Tangential |

| thk | Thickness definition as a function of u |

| u | Normalized chordwise coordinate (0,1) |

| v | Meanline coordinates as a function of u |

| V | Vane, Velocity |

| x, y, z | Cartesian coordinates |

| y+ | Non-dimensional wall distance |

| α | Metal angle |

| φ | Slope of streamline |

| θ | Tangential coordinate |

| AGS | Abu-Ghannam/Shaw |

| BEMT | Blade element momentum theory |

| CAD | Computer-aided design |

| CFD | Computational fluid dynamics |

| E3 | Energy-efficient engine |

| HPC | High-pressure compressor |

| LE | Leading edge |

| LPC | Low-pressure compressor |

| LPT | Low-pressure turbine |

| NASA | National Aeronautics and Space Administration |

| NREL | National Renewable Energy Laboratory |

| OGV | Outlet guide vane |

| RANS | Reynolds-averaged Navier–Stokes |

| TE | Trailing edge |

| 2D, 3D | Two- and three-dimensional |

Appendix A

References

- Panchenko, Y.; Moustapha, H.; Mah, S.; Patel, K.; Dowhan, M.J.; Hall, D. Preliminary Multi-Disciplinary Optimization in Turbomachinery Design. In Proceedings of the RTO AVT Symposium on “Reduction of Military Vehicle Acquisition Time and Cost through Advanced Modelling and Virtual Simulation”, Paris, France, 22–25 April 2002. [Google Scholar]

- Pate, D.; Gray, J.S.; German, B. A Graph Theoretic Approach to Problem Formulation for Multidisciplinary Design Analysis and Optimization. Struct. Multidiscip. Optim. 2013, 51, 743–760. [Google Scholar] [CrossRef]

- Toal, D.J.J.; Keane, A.J.; Benito, D.; Dixon, J.A.; Yang, J.; Price, M.; Robinson, T.; Remouchamps, A.; Kill, N. Multi-Fidelity Multidisciplinary Whole Engine Thermo-Mechanical Design Optimization. J. Propuls. Power 2014, 30, 1654–1666. [Google Scholar] [CrossRef]

- Gray, J.S.; Hwang, J.T.; Martins, J.R.R.A.; Moore, K.T.; Naylor, B.A. OpenMDAO: An open-source framework for multidisciplinary design, analysis, and optimization. Struct. Multidiscip. Optim. 2019, 59, 1075–1104. [Google Scholar] [CrossRef]

- Sgueglia, A.; Schmollgruber, P.; Bartoli, N.; Benard, E.; Morlier, J.; Jasa, J.; Martins, J.R.R.A.; Hwang, J.T.; Gray, J.S. Multidisciplinary design optimization framework with coupled derivative computation for hybrid aircraft. J. Aircr. 2020, 57, 4. [Google Scholar] [CrossRef]

- Kontogiannis, S.G.; Savill, M.A. A generalized methodology for multidisciplinary design optimization using surrogate modelling and multifidelity analysis. Optim. Eng. 2021, 21, 723–759. [Google Scholar] [CrossRef]

- Dornberger, R.; Büche, D.; Stoll, P. Multidisciplinary optimization in turbomachinery design. In Proceedings of the European Congress on Computational Methods in Applied Sciences and Engineering, Barcelona, Spain, 11–14 September 2000. [Google Scholar]

- Kolonay, R.; Nagendra, S.; Laflen, J. Sensitivity analysis for turbine blade components. In Proceedings of the 40th Structures, Structural Dynamics, and Materials Conference and Exhibit, St. Louis, MO, USA, 12–15 April 1999. [Google Scholar]

- Xu, S.; Li, Y.; Huang, X.; Wang, D. Robust Newton–Krylov Adjoint Solver for the Sensitivity Analysis of Turbomachinery Aerodynamics. AIAA J. 2021, 59, 4014–4030. [Google Scholar] [CrossRef]

- McWilliam, M.K.; Dicholkar, A.C.; Zahle, F.; Kim, T. Post-Optimum Sensitivity Analysis with Automatically Tuned Numerical Gradients Applied to Swept Wind Turbine Blades. Energies 2022, 15, 2998. [Google Scholar] [CrossRef]

- Okui, H.; Verstraete, T.; den Braembussche, R.A.V.; Alsalihi, Z. Three-Dimensional Design and Optimization of a Transonic Rotor in Axial Flow Compressors. J. Turbomach. 2013, 135, 031009. [Google Scholar] [CrossRef]

- Eldred, M.S.; Adams, B.M.; Haskell, K.; Bohnhoff, W.J.; Eddy, J.P.; Gay, D.M.; Hart, W.E.; Hough, P.D.; Kolda, T.G.; Swiler, L.P.; et al. DAKOTA Reference Manual, 4.2 ed.; Sandia National Laboratories: Albuquerque, NM, USA, 2008. [Google Scholar]

- Kipouros, T.; Jaeggi, D.; Dawes, B.; Parks, G.; Savill, M. Multi-objective optimisation of turbomachinery blades using Tabu search. In Proceedings of the Evolutionary Multi-Criterion Optimization: Third International Conference, EMO 2005, Guanajuato, Mexico, 9–11 March 2005; Lecture Notes in Computer Science. Springer: Berlin/Heidelberg, Germany, 2005; Volume 3410, pp. 897–910. [Google Scholar]

- Kipouros, T.; Jaeggi, D.M.; Dawes, W.N.; Parks, G.T.; Savill, A.M.; Clarkson, P.J. Biobjective design optimization for axial compressors using tabu search. AIAA J. 2008, 46, 701–711. [Google Scholar] [CrossRef]

- Samareh, J. Survey of shape parameterization techniques for high-fidelity multidisciplinary shape optimization. AIAA J. 2001, 39, 877–884. [Google Scholar] [CrossRef]

- Sripawadkul, V.; Padulo, M.; Guenov, M. A comparison of airfoil shape parameterization techniques for early design optimization. In Proceedings of the 13th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference 2010, Ft. Worth, TX, USA, 13–15 September 2010. [Google Scholar]

- Sobester, A.; Barretty, T. The quest for a truly parsimonious airfoil parameterization scheme. In Proceedings of the 8th AIAA Aviation Technology, Integration and Operations (ATIO) Conference, Anchorage, AL USA, 14–19 September 2008. [Google Scholar]

- Castonguay, P.; Nadarajah, S. Effect of shape parameterization on aerodynamic shape optimization. In Collection of Technical Papers—45th AIAA Aerospace Sciences Meeting; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2007; Volume 1, pp. 561–580. [Google Scholar]

- Mousavi, A.; Castonguay, P.; Nadarajah, S. Survey of shape parameterization techniques and its effect on three-dimensional aerodynamic shape optimization. In Proceedings of the Collection of Technical Papers—18th AIAA Computational Fluid Dynamics Conference, Miami, FL, USA, 25–28 June 2007; Volume 1, pp. 234–254. [Google Scholar]

- He, Y.; Agarwal, R. Shape optimization of NREL s809 airfoil for wind turbine blades using a multi-objective genetic algorithm. Int. J. Aerosp. Eng. 2014, 2014, 864210. [Google Scholar] [CrossRef]

- Bhide, K.R. Shock Boundary Layer Interactions—A Multiphysics Approach. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2018. [Google Scholar]

- Bhide, K.; Siddappaji, K.; Abdallah, S. Influence of fluid–thermal–structural interaction on boundary layer flow in rectangular supersonic nozzles. Aerospace 2018, 5, 33. [Google Scholar] [CrossRef]

- ANSYS. Available online: www.ansys.com (accessed on 24 December 2020).

- Pierret, S.; Kato, H.; Coelho, R.F.; Merchant, A. Aero-mechanical optimization method with direct cad access: Application to counter rotating fan design. ASME Turbo Expo 2006, 2006, 1329–1341. [Google Scholar]

- Van den Braembussche, R.A. Numerical Optimization for Advanced Turbomachinery Design in Optimization and Computational Fluid Dynamics; Springer: Berlin/Heidelberg, Germany, 2008; Part II; pp. 147–189. ISBN 978-3-540-72152-9. [Google Scholar]

- Grasel, J.; Keskin, A.; Swoboda, M.; Przewozny, H.; Saxer, A. A full parametric model for turbomachinery blade design and optimization. In Proceedings of the International Design Engineering Technical Conference & Computers and Information in Engineering, Salt Lake City, UT, USA, 28 September–2 October 2004. [Google Scholar]

- Demeulenaere, A.; Purwanto, A.; Ligout, A.; Hirsch, C. Design and Optimization of an Industrial Pump: Application of Genetic Algorithms and Neural Network; ASME FEDSM2005-77487; ASME: New York, NY, USA, 2005. [Google Scholar]

- Demeulenaere, A.; LigoutI, A.; Hirsch, C. Application of Multipoint Optimization to the Design of Turbomachinery Blades; ASME GT2004-53110; ASME: New York, NY, USA, 2004. [Google Scholar]

- Chen, J.; Liu, C.; Xuan, L.; Zhang, Z.; Zou, Z. Knowledge-based turbomachinery design system via a deep neural network and multi-output Gaussian process. Knowl.-Based Syst. 2022, 252, 109352. [Google Scholar] [CrossRef]

- Luo, J.; Chen, Z.; Zheng, Y. A gradient-based method assisted by surrogate model for robust optimization of turbomachinery blades. Chin. J. Aeronaut. 2021, in press. [Google Scholar] [CrossRef]

- Staubach, J.B. Multidisciplinary Design Optimization, MDO, the Next Frontier of CAD/CAE in the Design of Aircraft Propulsion Systems; AIAA Paper; AIAA: Dayton, OH, USA, 2003; pp. 2003–2803. [Google Scholar]

- Benini, E. Three-Dimensional Multi-Objective Design Optimization of a Transonic Compressor Rotor. J. Propuls. Power 2004, 20, 559–565. [Google Scholar] [CrossRef]

- Oyama, A.; Liou, M.S.; Obayashi, S. Transonic Axial Flow Blade Optimization Evolutionary Algorithms Three-Dimensional Navier Stokes Solver. J. Propuls. Power 2004, 20, 612–619. [Google Scholar] [CrossRef]

- Jang, C.-M.; Li, P.; Kim, K.Y. Optimization of Blade Sweep in a transonic Axial Compressor Rotor. JSME Int. J. 2005, 48, 793–801. [Google Scholar] [CrossRef]

- Lian, Y.; Liou, M.S. Multi-Objective Optimization of Transonic Compressor Blade Using Evolutionary Algorithm. J. Propuls. Power 2005, 21, 979–987. [Google Scholar] [CrossRef]

- Koch, C.C. Stalling Pressure Rise Capability of Axial Flow Compressor Stages. J. Eng. Power 1981, 103, 645–656. [Google Scholar] [CrossRef]

- Nemnem, A.F. A General Multidisciplinary Turbomachinery Design Optimization System Applied to a Transonic Fan. Ph.D. Dissertation, University of Cincinnati, Cincinnati, OH, USA, 2014. [Google Scholar]

- James, A.; Jones, J. A Multidisciplinary Algorithm for the 3-d Design Optimization of Transonic Axial Compressor Blades. Ph.D. Thesis, Naval Postgraduate School, Monterey, CA, USA, June 2002. [Google Scholar]

- Ellbrant, L.; Eriksson, L.E.; Martensson, H. Design of Compressor Blades considering Efficiency and Stability using CFD based Optimization. ASME Turbo Expo 2012, 44748, 371–382. [Google Scholar]

- Ellbrant, L.; Eriksson, L.E.; Martensson, H. Balancing efficiency and stability in the design of transonic compressor stages. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Siller, U.; Vob, C.; Nicke, E. Automated Multidisciplinary Optimization of a Transonic Axial Compressor. In Proceedings of the 47th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009. [Google Scholar]

- Deng, X.; Guo, F.; Liu, Y.; Han, P. Aero-mechanical optimization design of a transonic fan blade. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Siller, U.; Aulich, M. Multidisciplinary 3d-Optimization of a Fan Stage Performance Map with Consideration of the Static and Dynamic Rotor Mechanics; GT2010-22792; ASME: New York, NY, USA, 2010. [Google Scholar]

- Vob, C.; Aulich, M.; Kaplan, B.; Nicke, E. Automated multiobjective optimisation in axial compressor blade design. ASME Turbo Expo 2006, 55232, V06BT43A014. [Google Scholar]

- Joly, M.; Verstraete, T.; Paniagua, G. Full design of a highly loaded and compact contra-rotating fan using multidisciplinary evolutionary optimization. ASME Turbo Expo 2013, 55232, V06BT43A009. [Google Scholar]

- Braembussche, R.; Alsalihi, Z.; Verstraete, T.; Matsuo, A.; Seiichi, I.; Sugimoto, K.; Isao, T. Multidisciplinary Multipoint Optimization of a Transonic Turbocharger Compressor. Proc. ASME Turbo Expo 2008, 44748, 903–913. [Google Scholar]

- Ceyhan, O. Aerodynamic design and optimization of horizontal axis wind turbines by using bem theory and genetic algorithm. In Praca Magisterska; Middle East Technical University: Ankara, Turkey, 2008. [Google Scholar]

- Kolekar, N.; Hu, Z.; Banerjee, A.; Du, X. Hydrodynamic design and optimization of hydro-kinetic turbines using a robust design method. In Proceedings of the 1st Marine Energy Technology Symposium, Washington, DC, USA, 10–11 April 2013. [Google Scholar]

- Bhide, K.; Siddappaji, K.; Abdallah, S.; Roberts, K. Improved Supersonic Turbulent Flow Characteristics Using Non-Linear Eddy Viscosity Relation in RANS and HPC-Enabled LES. Aerospace 2021, 8, 352. [Google Scholar] [CrossRef]

- Bhide, K.R.; Abdallah, S. Turbulence statistics of supersonic rectangular jets using Reynolds Stress Model in RANS and WALE LES. In AIAA AVIATION 2022 Forum; AIAA: Chicago, IL, USA, 2022. [Google Scholar]

- Bhide, K.; Abdallah, S. Anisotropic Turbulent Kinetic Energy Budgets in Compressible Rectangular Jets. Aerospace 2022, 9, 484. [Google Scholar] [CrossRef]

- Bhide, K. Supersonic retro propulsion: Aero-thermal-structural analysis. In Proceedings of the International Conference of Jets, Wakes, Separated Flows (ICJWSF), Tokyo, Japan, 7 March 2022. [Google Scholar]

- Turner, M.G.; Bruna, D.; Merchant, A. Applications of a turbomachinery design tool for compressors and turbines. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Cincinnati, OH, USA, 8–11 July 2007. [Google Scholar] [CrossRef]

- Gutzwiller, D.P. Automated design, analysis, and optimization of turbomachinery disks. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, September 2009. [Google Scholar]

- Gutzwiller, D.P.; Turner, M.G.; Downing, M.J. Educational software for blade and disk design. ASME Turbo Expo 2009, 48821, 827–838. [Google Scholar]

- Muppana, S. Multi-fidelity Design and Analysis of Single Hub Multi-Rotor High Pressure Centrifugal Compressor. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2018. [Google Scholar]

- Mishra, S. Developing Novel Computational Fluid Dynamics Technique for Incompressible Flow and Flow Path Design of Novel Centrifugal Compressor. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2016. [Google Scholar]

- Qiu, X.; Mallikarachchi, C.; Anderson, M. A new slip factor model for axial and radial impellers. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007. [Google Scholar]

- Drela, M. A User Guide for MISES 2.53; Technical Report; MIT Computational Science Laboratory: Cambridge, MA, USA, 1998; Volume 47950, pp. 957–966. [Google Scholar]

- Cherry, D.G.; Lenahan, D.T. Energy Efficient Engine. Low Pressure Turbine Test Hardware Detailed Design Report. NASA CR 1982, 167956, G3/07 24804. Available online: https://ntrs.nasa.gov/citations/19850002686 (accessed on 20 August 2022).

- Siddappaji, K. Parametric 3d blade geometry modeling tool for turbomachinery systems. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2012. [Google Scholar]

- Siddappaji, K. On the Entropy Rise in General Unducted Rotors Using Momentum, Vorticity and Energy Transport. Doctoral Dissertation, University of Cincinnati, Cincinnati, OH, USA, 2018. [Google Scholar]

- Drela, M. XFOIL: An Analysis and Design System for Low Reynolds Number Airfoils; Springer: Heidelberg/Berlin, Germany, 1989. [Google Scholar]

- Fineturbo/Autogrid, NUMECA International. Available online: https://www.numeca.com (accessed on 24 December 2020).

- Siddappaji, K.; Turner, M.G. Versatile Tool for Parametric Smooth Turbomachinery Blades. Aerospace 2022, 9, 489. [Google Scholar] [CrossRef]

- Park, K.; Turner, M.G.; Siddappaji, K.; Dey, S.; Merchant, A. Optimization of a 3-Stage Booster Part 1: The Axisymmetric Multidisciplinary Optimization Approach to Compressor Design; ASME Paper Number GT2011-46569; ASME: New York, NY, USA, 2011. [Google Scholar]

- Holloway, P.R.; Knight, G.L.; Koch, C.C.; Shaffer, S.J. Energy Efficient Engine High Pressure Compressor Detail Design Report; Technical Report; NASA-CR-165558; General Electric Company: Boston, MA, USA, 1982. [Google Scholar]

- Mahmood, S.M.H.; Turner, M.G.; Siddappaji, K.; Balasubramanian, K. Flow Characteristics of an Optimized Axial Compressor Rotor using Smooth Design Parameters. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Chen, H.; Turner, M.G.; Siddappaji, K.; Mahmood, S.M.H. Vorticity dynamics-based flow diagnosis for a 1.5-stage high pressure compressor with an optimized transonic rotor. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Somtrakool, S. Automated Campbell Diagram Module on Optimization of Transonic Fan. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2014. [Google Scholar]

- Gunn, E.J.; Hall, C.A. Aerodynamic of Boundary Layer Ingesting Fans. In Proceedings of the ASME Turbo Expo 2014: Turbine Technical Conference and Exposition, GT2014-26142, Dusseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Gunn., E.J.; Hall, C.A. Non-Axisymmetric Stator Design for Boundary Layer Ingesting Fans. In Proceedings of the ASME Turbo Expo 2017, Charlotte, NC, USA, 26–30 June 2017. GT2017-63082. [Google Scholar]

- Kumar, S.; Siddappaji, K.; Turner, M.G.; Celestina, M. Aerodynamic design system for non-axisymmetric boundary layer ingestion fans. ASME Turbo Expo 2018, 51012, V02CT42A048. [Google Scholar]

- Denton, J.D. Loss Mechanisms in Turbomachines. ASME J. Turbomach. 1993, 115, 621–656. [Google Scholar] [CrossRef]

- Smith, J.; Leroy, H.; Yeh, H. Sweep and Dihedral Effects in Axial-Flow Turbomachinery. J. ASME 1963, 85, 401–414. [Google Scholar] [CrossRef]

- JetCAT. Available online: https://www.jetcat.de/en/products/ (accessed on 24 December 2012).

- SolidConcepts. Available online: https://solidconceptsnc.com/ (accessed on 24 December 2012).

- Krain, H. Swirling impeller flow. J. Turbomach. 1988, 110, 122–128. [Google Scholar] [CrossRef]

- Hathaway, M.D. Laser anemometer measurements of the three-dimensional rotor flow field in the NASA low speed centrifugal compressor. Tech. Rep. 1995, 60, 3527, ARL-TR-333. Available online: https://www.researchgate.net/publication/24286133_Laser_anemometer_measurements_of_the_three-dimensional_rotor_flow_field_in_the_NASA_low-speed_centrifugal_compressor (accessed on 20 August 2022).

- Sato, K.; He, L. Effect of rotor-stator interaction on impeller performance in centrifugal compressors. Int. J. Rotating Mach. 1999, 5, 135–146. [Google Scholar] [CrossRef] [Green Version]

- Shaaban, A. Fluid Flow Controller Us Patent. 6589013 b2, 2001. [Google Scholar]

- Holden, J.R.; Caley, T.M.; Heberling, B.; Cantor, C.; Wesseling, E.; Hamed, A.A.; Turner, M.G.; Litke, P.J.; Grannan, N.D. Novel Design and Fabrication of JetCat P90 Diffuser using Parametric Design and Optimization Tools. In Proceedings of the AIAA 2016-2128—54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Feldhacker, J.; Staikoff, N.; Schwartzwalder, R.; Mitchell, F.; Hoffmann, D.; Begovich, M. A research paper on redesigning the compressor diffuser of a jetcat P90 turbine to improve the efficiency. In APOP 2015, Technical Report; University of Cincinnati: Cincinnati, OH, USA, 2015. [Google Scholar]

- Dey, S. Wind turbine blade design system, aerodynamic and structural analysis. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2011. [Google Scholar]

- Balasubramanian, K. Novel, Unified, Curvature-Based Airfoil Parameterization Model for Turbomachinery Blades and Wings. Master’s Thesis, University of Cincinnati, Cincinnati, OH, USA, 2018. [Google Scholar]

- Giguere, P.; Selig, M. Design of a tapered and twisted blade for the nrel combined experiment rotor. In Technical Report NREL/SR-500-26173; NREL: Golden, CO, USA, 1999. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddappaji, K.; Turner, M.G. An Advanced Multifidelity Multidisciplinary Design Analysis Optimization Toolkit for General Turbomachinery. Processes 2022, 10, 1845. https://doi.org/10.3390/pr10091845

Siddappaji K, Turner MG. An Advanced Multifidelity Multidisciplinary Design Analysis Optimization Toolkit for General Turbomachinery. Processes. 2022; 10(9):1845. https://doi.org/10.3390/pr10091845

Chicago/Turabian StyleSiddappaji, Kiran, and Mark G. Turner. 2022. "An Advanced Multifidelity Multidisciplinary Design Analysis Optimization Toolkit for General Turbomachinery" Processes 10, no. 9: 1845. https://doi.org/10.3390/pr10091845

APA StyleSiddappaji, K., & Turner, M. G. (2022). An Advanced Multifidelity Multidisciplinary Design Analysis Optimization Toolkit for General Turbomachinery. Processes, 10(9), 1845. https://doi.org/10.3390/pr10091845