Optimization Strategy of Hybrid Configuration for Volatility Energy Storage System in ADN

Abstract

:1. Introduction

- (1)

- The problem of the impact of fluctuating energy output on the configuration of energy storage systems is analyzed, laying the foundation for the subsequent development of operational dispatching strategies based on equivalent load curves.

- (2)

- A hybrid energy storage system using lead-acid batteries and supercapacitors is utilized to diversify the types of energy storage and expand the scope of optimization.

- (3)

- By considering both the distribution grid side and the energy side, a two-tier energy system optimization strategy with joint participation of wind storage in system frequency regulation is proposed. Through day-ahead optimization and intra-day correction multi-timescale hybrid energy storage configuration optimization, the distribution grid economy and renewable energy utilization are improved.

2. Impacts of Volatility Energy Power on ESS and Mathematical Model

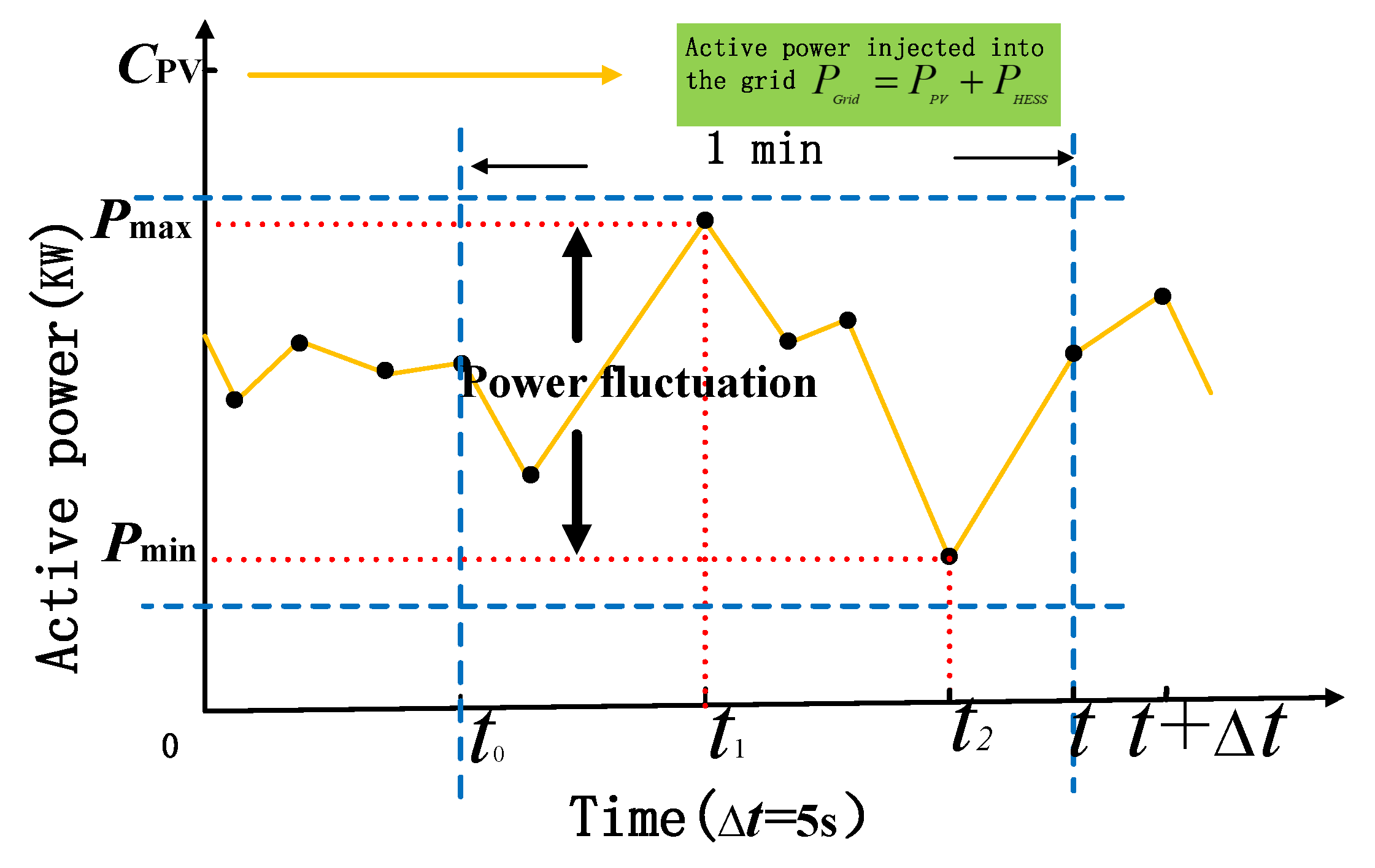

2.1. Analysis of the Impact of Volatility Energy Power on ESS

2.2. Mathematical Model of ESS

3. A Double-Layer Multi-Objective Optimization Model

3.1. Planning Layer Optimization Model

3.1.1. Objective Functions

- Comprehensive cost of a full-day life cycle;

- Network loss

- Node voltage deviation

3.1.2. Constraint Condition

- SOC of energy storage constraint;

- Node voltage constraints

- Branch circuit current constraints

- Power balance constraints

3.2. Operation Layer Optimization Model

3.2.1. Objective Function

- Minimal fluctuations in WG output

- Minimal system frequency deviation

3.2.2. Constraint Condition

- Charge and discharge power constraint

- Charge and discharge times constraint

4. Scheduling Strategy and Solution Algorithm

4.1. Scheduling Strategy for Energy Storage Systems

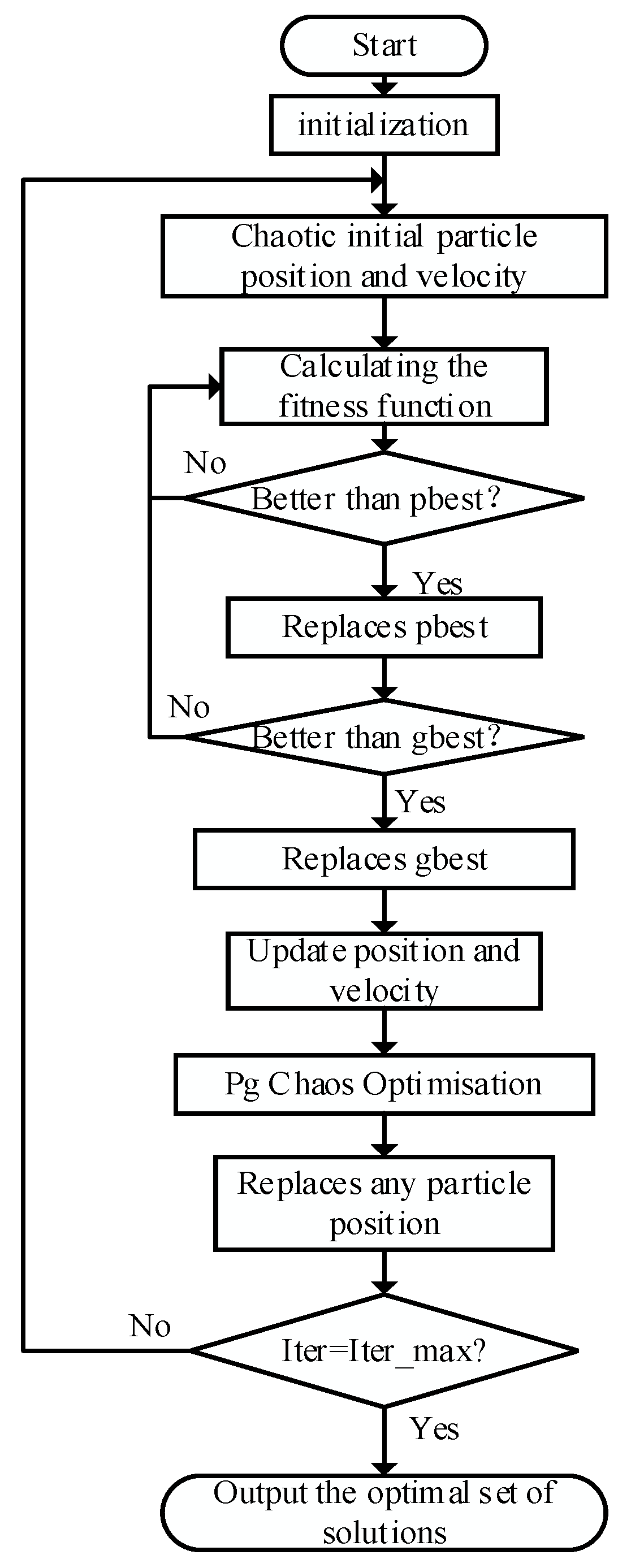

4.2. The Computational Flow of Multi-Objective Chaotic Particle Swarm Algorithm

5. Case Study

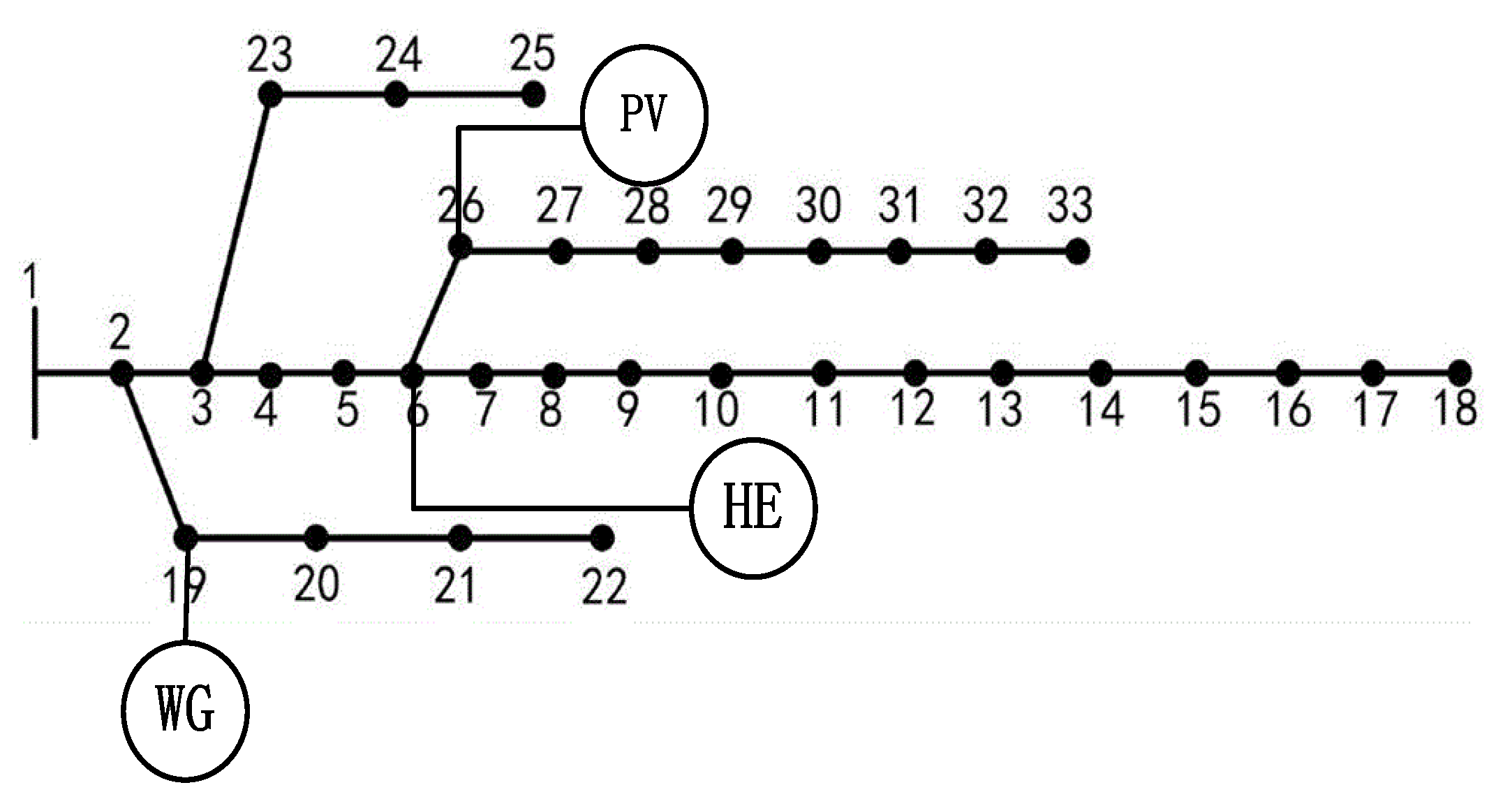

5.1. Basic Parameters for the Case

5.2. Analysis of the Impact of Energy Storage System Access Nodes

5.3. Interpretation of Result

5.3.1. Capacity Configuration Results and Economic Analysis

| Parameters | Scene 1 | Scene 2 | Scene 3 |

|---|---|---|---|

| capacity of lead-acid batteries | 464.55 | 425.32 | 157.34 |

| capacity of supercapacitors | 1100 | 926.93 | 695.64 |

| correction of supercapacitors | 0 | 5.25 | 5.95 |

| Parameters | Scene 1 | Scene 2 | Scene 3 |

|---|---|---|---|

| Investment costs | 3.34 × 106 | 2.86 × 106 | 1.91 × 106 |

| operation and maintenance costs | 201.62 | 176.61 | 84.23 |

| network loss costs | 3.49 | 3.27 | 2.67 |

| wind and PV operation and maintenance costs | 80.34 | 80.34 | 80.34 |

| power purchase costs | 52.27 | 50.25 | 45.29 |

| correction costs | 0 | 71.14 | 61.06 |

| total costs | 3,337,137.73 | 2,934,047.53 | 1,844,656.99 |

- (1)

- In Scene 1, a hybrid energy storage equipment is added to the system, and although the operation layer energy storage dispatching strategy does not take into account the system frequency deviation, it has a certain soothing effect on the equivalent load curve, achieving a certain effect of “Peak cut” and optimizing the operation of the grid.

- (2)

- Scene 2 is based on Scene 1, using a double-layer planning model, with only the lower layer of ESS taking part in the system’s FM. Therefore, the lower layer is used to correct the capacity of supercapacitors, with a correction value of 5.2456 kw, reducing the total cost by RMB 403,090.20. The cost reduction rate is about 12.08%, which achieves integrated planning of capacity dispatch and further improves the effect of peak and valley reduction.

- (3)

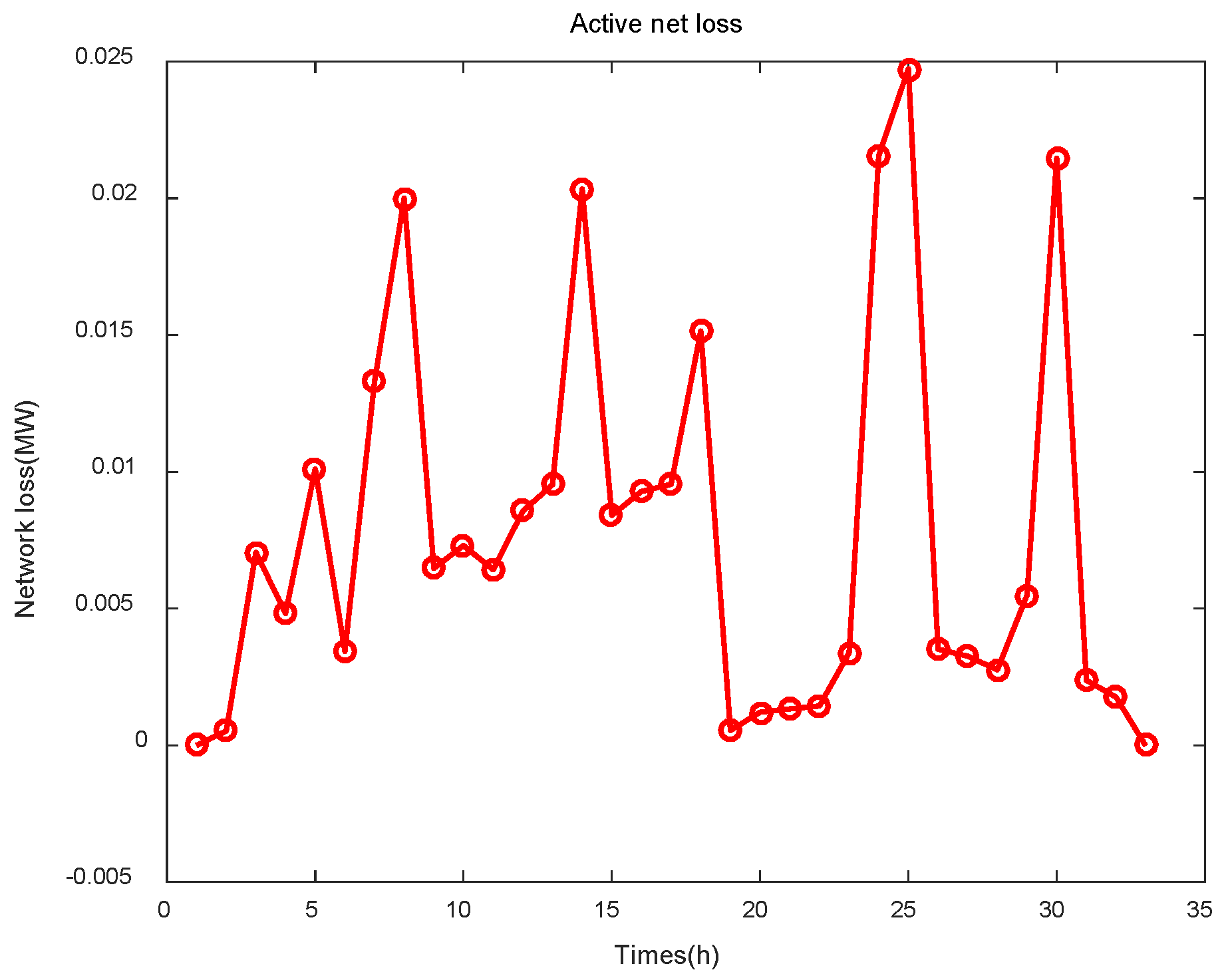

- Scene 3 is an optimized configuration of the HESS based on a double-layer planning model, with WG added to the lower layer to participate in system FM, correcting the supercapacitor capacity value of the improvement. The charging and discharging strategy for hess in Scene 3 is introduced in Figure 8. The total costs of Scene 3 relative to Scene 1 and Scene 2 are RMB 1,492,480.74 and RMB 1,089,390.54 saved, respectively. The reduction rates are approximately 44.72% and 37.13%, with a total cost reduction while the effect of network loss optimization is also more obvious.

| Parameters | NaS | Li-Ion |

|---|---|---|

| Investment costs | 3.40 × 106 | 3.75 × 106 |

| operation and maintenance costs | 249.38 | 343.32 |

| network loss costs | 3.26 | 3.36 |

| wind and PV operation and maintenance costs | 61.60 | 61.60 |

| power purchase costs | 50.93 | 49.93 |

| correction costs | 63.12 | 56.97 |

| total costs | 3,399,028.28 | 3,748,015.17 |

5.3.2. Network Loss Analysis after Optimization

5.3.3. Optimum Voltage Analysis of Distribution Network

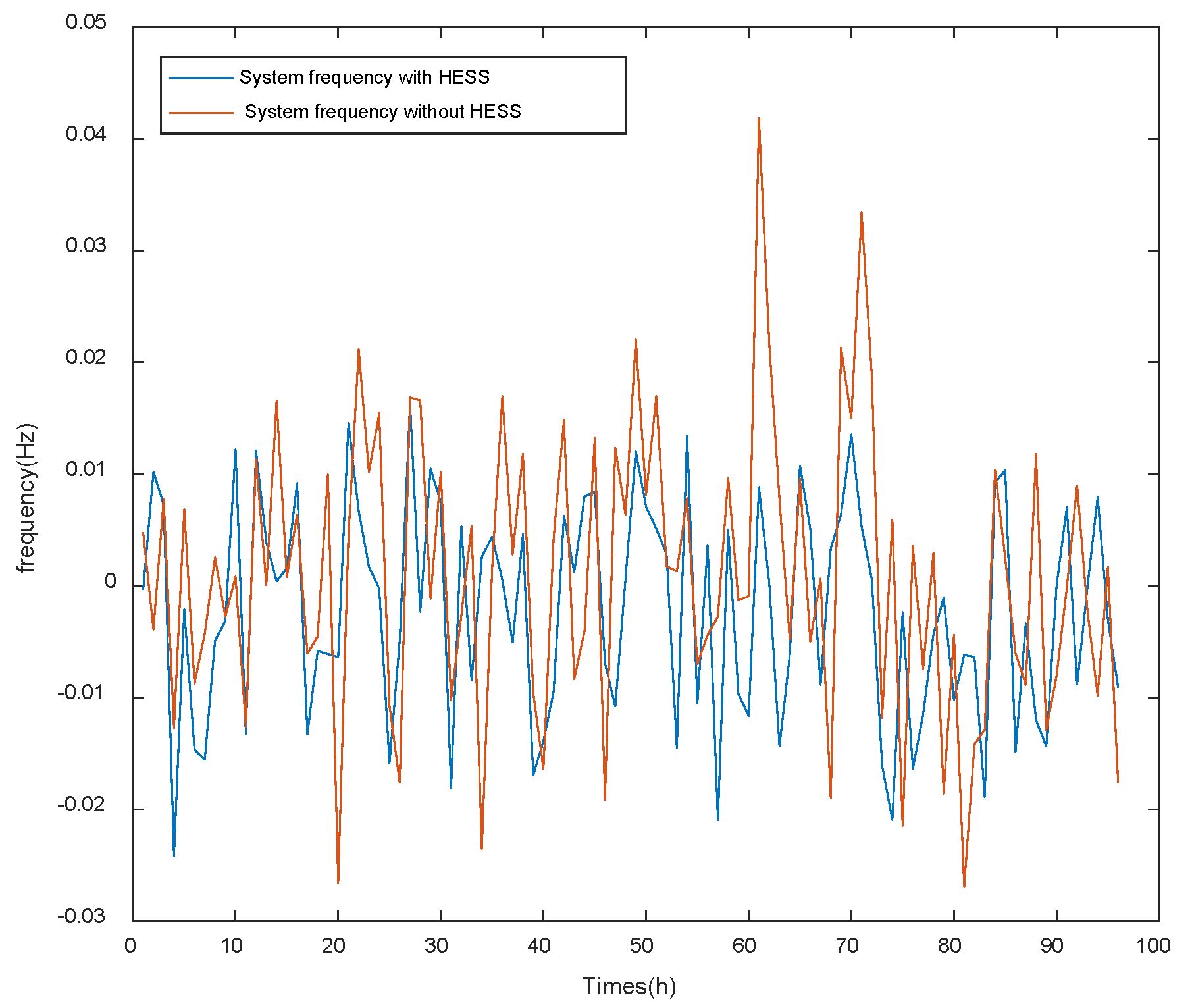

5.3.4. Analysis of the Frequency Bias after Optimization

6. Conclusions

- (1)

- The first layer is developed according to the equivalent load curve and proposes a charging and discharging strategy for the HESS considering the “time-of-day tariff”, while the second layer adopts WG and HESS to suppress fluctuations in the operation strategy, which can achieve better economic results and “Peak cut and fulfill valleys” with less investment and operation costs.

- (2)

- Optimizing the configuration of the HESS with “integrated planning of the configuration capacity and dispatching strategy” and establishing a mathematical model for the optimal configuration of the capacity ensures that research of energy storage configuration can be more reasonably and accurately grasped, and the risk of over-investment or under-investment can be reduced.

- (3)

- Consideration of the dynamic characteristics of HESS operation, which can achieve the goal of smoothing fluctuating energy’s power fluctuation, as well as improving the voltage quality of the distribution network and reducing network losses, which is of more practical significance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paul, S.; Dey, T.; Saha, P.; Dey, S.; Sen, R. Review on the development scenario of renewable energy in different country. In Proceedings of the 2021 Innovations in Energy Management and Renewable Resources (52042), Kolkata, India, 5–7 February 2021; pp. 1–2. [Google Scholar]

- Mokryani, G. Energy Storage Systems in Future Distribution Networks. In Future Distribution Networks: Planning, Operation, and Control; AIP Publishing: Melville, NY, USA, 2022. [Google Scholar] [CrossRef]

- Guo, X.; Chen, Q.; Liang, W.; Wang, S.; Wang, Y.; Qin, Y. Intelligent Optimization Algorithm of Active Distribution Network Based on Load Storage Cooperative Optimization of Source Network. In Proceedings of the 2021 IEEE 4th International Conference on Automation, Electronics and Electrical Engineering (AUTEEE), Shenyang, China, 19–21 November 2021; pp. 355–360. [Google Scholar]

- Wang, H.; Ma, C.; Sheng, W.; Sha, G.; Zhao, C.; Liu, N.; Duan, Q. Energy Storage Configuration Optimization Strategy for Islanded Microgrid Interconnection Based on Energy Consumption Characteristics. Discrete Dyn. Nat. Soc. 2021, 2021, 2826670. [Google Scholar] [CrossRef]

- Chen, T.; Yang, J.; Jiang, W.; Sui, Z.; Wang, Y. Optimal configuration of energy storage capacity in wind farms based on cloud energy storage service. IET Renew. Power Gener. 2022, 16, 211–222. [Google Scholar] [CrossRef]

- Mao, M.; Hong, J.; Zhang, L. Energy storage optimization configuration method considering conditional forecast error correction. Taiyangneng Xuebao 2021, 42, 410–416. [Google Scholar]

- Liu, Y.; Liu, Q.; Guan, H.; Li, X.; Bi, D.; Guo, Y.; Sun, H. Optimization Strategy of Configuration and Scheduling for User-Side Energy Storage. Electronics 2022, 11, 120. [Google Scholar] [CrossRef]

- Shi, X.; Shi, X.; Dong, W.; Zang, P.; Jia, H.; Wu, J.; Wang, Y. Research on energy storage configuration method based on wind and solar volatility. In Proceedings of the 2020 10th International Conference on Power and Energy Systems (ICPES), Chengdu, China, 25–27 December 2020; IEEE: New York, NY, USA, 2020; pp. 464–468. [Google Scholar]

- Wu, T.; Shi, X.; Li, L.; Zhou, C.; Zhou, H.; Su, Y. A capacity configuration control strategy to alleviate power fluctuation of hybrid energy storage system based on improved particle swarm optimization. Energies 2019, 12, 642. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, Y.; Tao, Q.; Xue, J.; Ye, J. Research on Planning and Configuration of Multi-objective Energy Storage System Solved by Improved Ant Colony Algorithm. In Proceedings of the 2018 China International Conference on Electricity Distribution (CICED), Tianjin, China, 17–19 September 2018; pp. 2279–2283. [Google Scholar]

- Gong, Q.; Wang, Y.; Fang, J.; Qiao, H.; Liu, D. Optimal configuration of the energy storage system in ADN considering energy storage operation strategy and dynamic characteristic. IET Gener. Transm. Distrib. 2020, 14, 1005–1011. [Google Scholar] [CrossRef]

- Li, J.; Xue, Y.; Tian, L.; Yuan, X. Research on optimal configuration strategy of energy storage capacity in grid-connected microgrid. Prot. Control Mod. Power Syst. 2017, 2, 35. [Google Scholar] [CrossRef]

- Yao, M.; Cai, X. Energy storage sizing optimization for large-scale PV power plant. IEEE Access 2021, 9, 75599–75607. [Google Scholar] [CrossRef]

- Song, J.; Hu, C.; Su, L. Distributed Wind Power and Photovoltaic Energy Storage Capacity Configuration Method under Big Data. In Proceedings of the 2021 International Conference on Electronic Communications, Internet of Things and Big Data (ICEIB), Yilan, Taiwan, 10–12 December 2021; pp. 318–322. [Google Scholar]

- Ma, T.; Gu, H.; Zha, Z.; Li, G.; Lou, H. A Two-Layer Optimization Model for Energy Storage Configuration in the Distribution Network. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 647, p. 012012. [Google Scholar]

- Ma, W.; Wang, W.; Wu, X.; Hu, R.; Tang, F.; Zhang, W. Control Strategy of a Hybrid Energy Storage System to Smooth Photovoltaic Power Fluctuations Considering Photovoltaic Output Power Curtailment. Sustainability 2019, 11, 1324. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, F.; Chen, Q. Bi-level optimal configuration of hybrid energy storage for wind farms considering battery life. J. Phys. Conf. Ser. 2022, 2247, 012005. [Google Scholar] [CrossRef]

- Wang, Y.; Song, F.; Ma, Y.; Zhang, Y.; Yang, J.; Liu, Y.; Zhang, F. Research on capacity planning and optimization of regional integrated energy system based on hybrid energy storage system. Appl. Therm. Eng. 2020, 180, 115834. [Google Scholar] [CrossRef]

- Liu, C. Optimal Configuration and Energy Management of Hybrid Energy Storage System with Lithium Battery and Supercapacitor; University of Science and Technology of China: Hefei, China, 2020. [Google Scholar]

- Shen, Y.; Hu, W.; Liu, M.; Fang, Y.; Hong, X. Energy storage optimization method for microgrid considering multi-energy coupling demand response. J. Energy Storage 2022, 45, 103521. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Y.; Zhang, C.; Sun, L.; Wu, X. Configuration of an Energy Storage System Considering the Frequency Response and the Dynamic Frequency Dispersion. Front. Energy Res. 2022, 9, 807763. [Google Scholar] [CrossRef]

- Liu, D.; Jin, Z.; Chen, H.; Cao, H.; Yuan, Y.; Fan, Y.; Song, Y. Peak Shaving and Frequency Regulation Coordinated Output Optimization Based on Improving Economy of Energy Storage. Electronics 2022, 11, 29. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Zeng, Z.; Bei, Y. Optimal charging plan for electric bus considering time-of-day electricity tariff. J. Intell. Connect. Veh. 2022, 5, 123–137. [Google Scholar] [CrossRef]

| Parameters | Lead-Acid Batteries | SC |

|---|---|---|

| SOCmin | 0.4 | 0.1 |

| SOCmax | 0.8 | 0.9 |

| charging and discharging efficiency (%) | 98 | 98 |

| capacity cost factor (RMB/kW) | 1500 | 2400 |

| capacity maintenance cost factor (RMB/year) | 0.045 | 0.015 |

| service life (year) | 10 | 20 |

| power cost factor (RMB/MW) | 300 | 300 |

| initial volume of SOC | 0.4 | 0.1 |

| discount rate (%) | 10 | 10 |

| power factor (%) | 98 | 98 |

| Access Nodes | Stability Index | VBN |

|---|---|---|

| 1 | 1 | 1 |

| 2 | 0.99 | 0.99 |

| 3 | 0.98 | 0.98 |

| 20 | 0.98 | 0.99 |

| 21 | 0.97 | 0.99 |

| 22 | 0.96 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, G.; Huang, Y.; Dai, N.; Cai, L.; Deng, L.; Li, S.; He, C. Optimization Strategy of Hybrid Configuration for Volatility Energy Storage System in ADN. Processes 2022, 10, 1844. https://doi.org/10.3390/pr10091844

Lei G, Huang Y, Dai N, Cai L, Deng L, Li S, He C. Optimization Strategy of Hybrid Configuration for Volatility Energy Storage System in ADN. Processes. 2022; 10(9):1844. https://doi.org/10.3390/pr10091844

Chicago/Turabian StyleLei, Guoping, Yinhua Huang, Nina Dai, Li Cai, Li Deng, Shenghao Li, and Chao He. 2022. "Optimization Strategy of Hybrid Configuration for Volatility Energy Storage System in ADN" Processes 10, no. 9: 1844. https://doi.org/10.3390/pr10091844

APA StyleLei, G., Huang, Y., Dai, N., Cai, L., Deng, L., Li, S., & He, C. (2022). Optimization Strategy of Hybrid Configuration for Volatility Energy Storage System in ADN. Processes, 10(9), 1844. https://doi.org/10.3390/pr10091844