Research on Dam Deformation Prediction Model Based on Optimized SVM

Abstract

:1. Introduction

- (1)

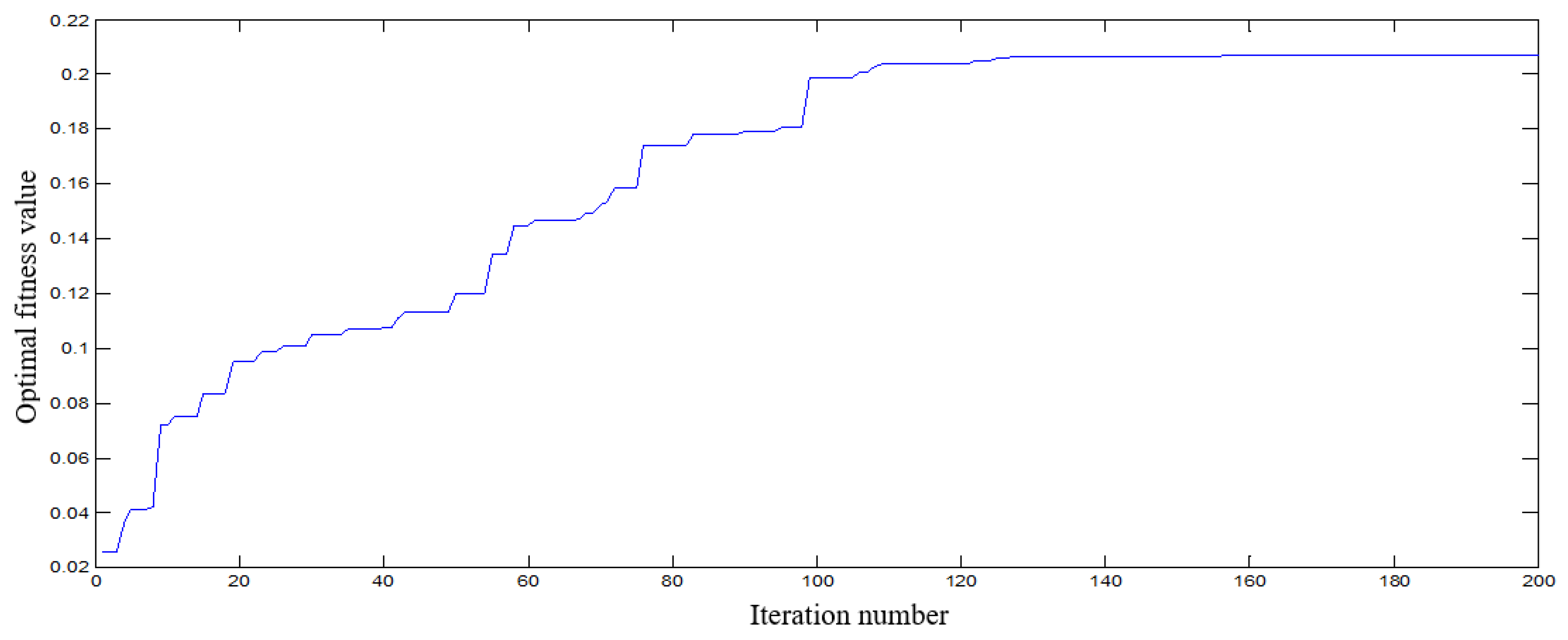

- A novel swarm intelligence optimization algorithm—the chicken swarm algorithm is proposed. In view of the defects of the basic chicken swarm algorithm, such as easy to fall into local optimization and slow convergence speed, an improved chicken swarm algorithm with adaptive inertia weight is proposed.

- (2)

- A prediction model of SVM optimized by an improved chicken swarm algorithm is proposed. Due to SVM being sensitive to selection of the penalty factor parameters and kernel function parameters, choosing inappropriate parameters has a great impact on the prediction results. Therefore, this paper proposes to use the improved chicken swarm algorithm to optimize the parameters of SVM.

- (3)

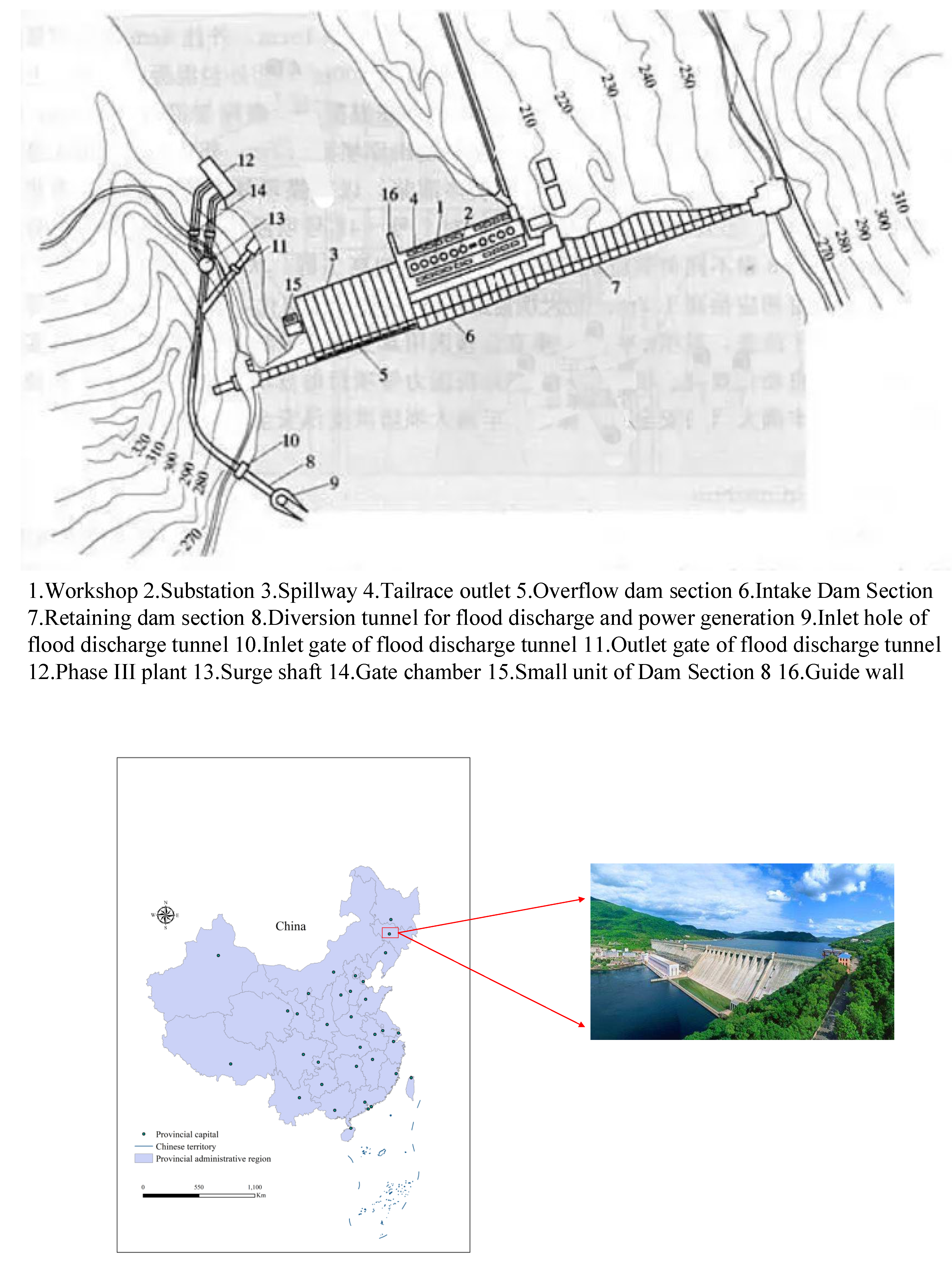

- Based on the horizontal displacement monitoring data of FengMan Dam, the influencing factors of horizontal displacement are analyzed, and the SVM prediction model optimized by the improved chicken swarm algorithm, the SVM prediction model optimized by the basic chicken swarm algorithm and the BP neural network prediction model optimized by the genetic algorithm are established, respectively.

2. Prediction Method

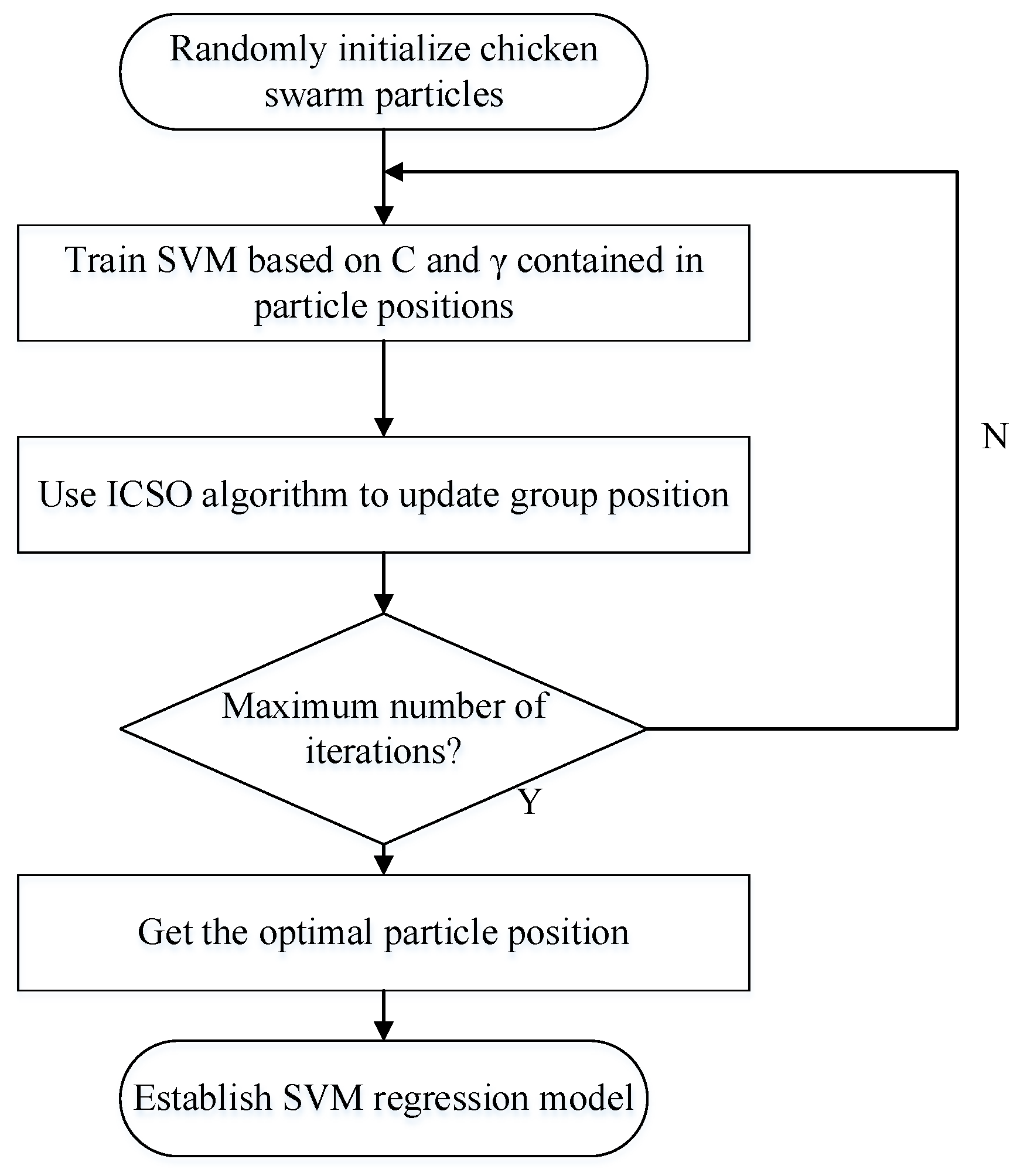

2.1. Support Vector Machine Prediction Model Based on Chicken Swarm Optimization

2.2. Prediction of Dam Horizontal Displacement Based on Genetic Neural Network

3. Dam Deformation Modeling and Prediction

3.1. Support Vector Machine Prediction Model Based on Improved Chicken Swarm Algorithm

3.2. Modeling of Nonlinear Systems

3.3. Evaluation Indicators

4. Case Study

4.1. Engineering Experiment

4.2. Causes of Deformation

- (1)

- Natural causes: One of the primary factors leading to the dam deformation is natural factors, especially under natural conditions such as complex soil physical properties, unclear engineering properties, and abnormal temperature fluctuations; dams are easily deformed [29]. For example, when the basic geological conditions of a dam are unstable, uneven subsidence may occur; when a dam is built on a soil foundation, the subsidence occurs due to the plastic deformation of the soil foundation; when the temperature and groundwater level in the area where the dam is located vary seasonally, regular changes in deformation will occur [30].

- (2)

- Causes of the dam itself: Another important factor leading to the dam deformation is the dam itself [31]. The structure design, its own weight, type, and the load of the dam are all directly related to the deformation. In addition, during the construction and operation process, because of the improper design, field survey, operation and management, it will also lead to some additional deformation of the dam. In this regard, in the overall design of the dam structure, the selection of the type frame, and the load and pressure experiments, it is necessary to combine the site, demonstrate scientifically, and follow the design requirements strictly [32]. Meanwhile, in the process of field survey, construction, management and maintenance, it is necessary to master the key points that may cause subsidence and strive to solve them by the most optimized method [33].

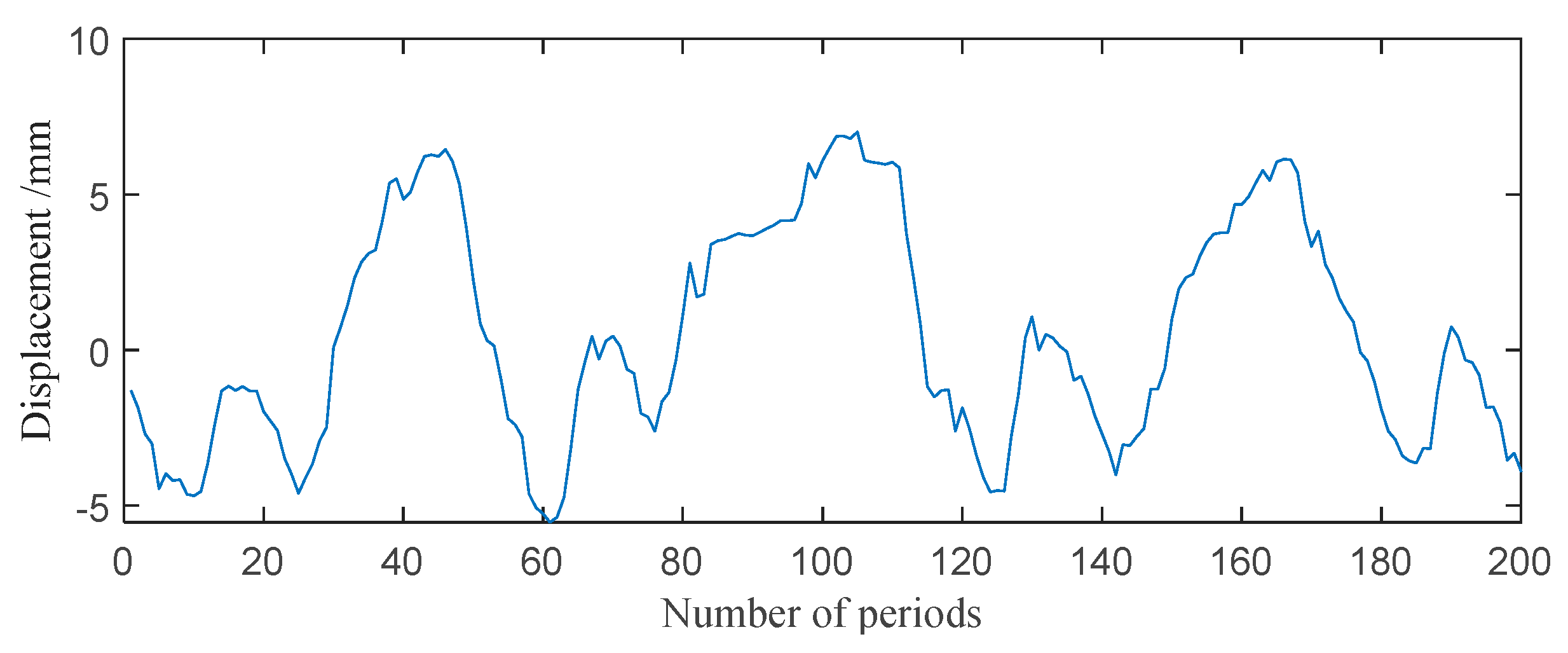

4.3. Data Preprocessing

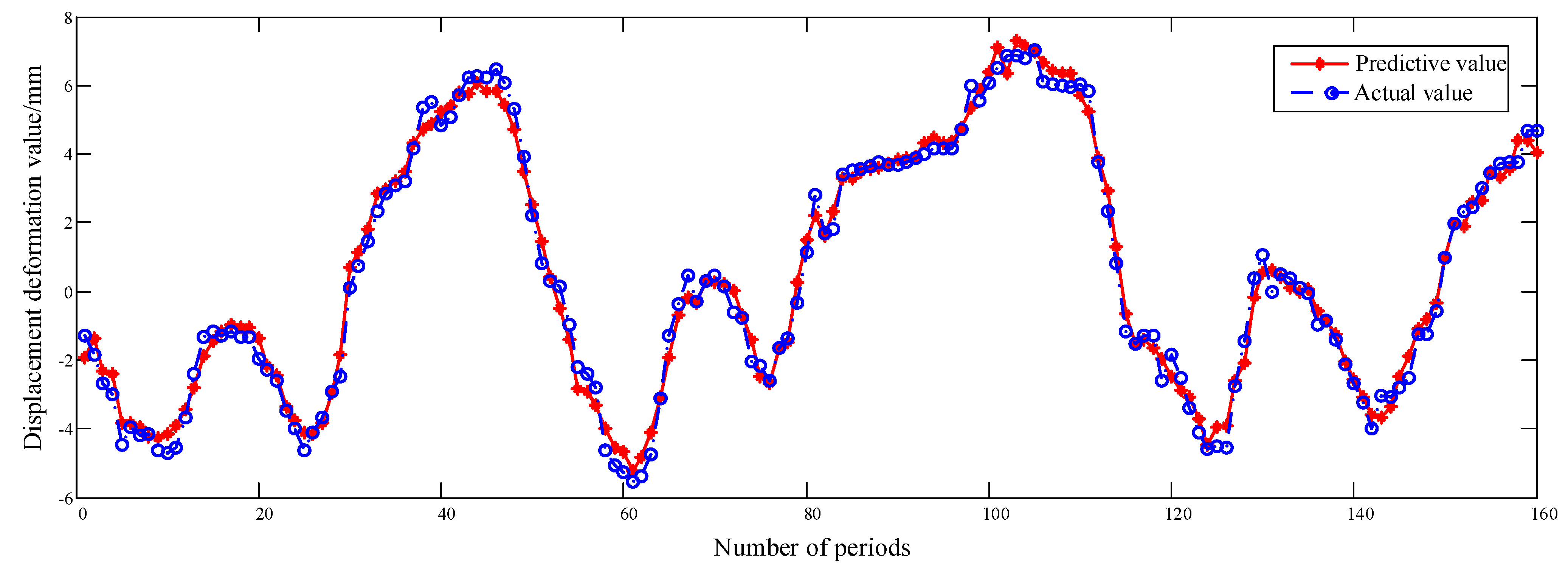

4.4. Dam Deformation Prediction

4.5. Results Analysis and Comparison

5. Discussion

- (1)

- There are many methods for predicting dam deformation, mainly including a time series model, regression analysis model, neural network model, gray prediction model, Kalman filter, etc. All of these models can predict the dam deformation, but the accuracy of them is different. Some models have high accuracy, and the prediction effect can meet the needs, while others have low accuracy, and the prediction effect is not satisfactory. Therefore, many scholars began to combine a single model into a combined model. By choosing suitable sub-models and combining methods, the advantages of each model can be exploited to effectively improve the prediction accuracy. However, if the sub-model or combination method is selected improperly, instead of improving the prediction accuracy, it rather affects the prediction effect, which requires scholars to conduct sufficient and reliable research on their prediction models.

- (2)

- This paper studies the prediction model, which is verified by an example through the horizontal displacement monitoring data of the dam. However, the dam safety monitoring model is not only the monitoring and forecasting of the horizontal displacement but also the vertical displacement and land subsidence. It is of great engineering application value to carry out modeling prediction and comprehensively evaluate the safe operation status of dams.

- (3)

- With the development of surveying and mapping science and technology, the methods and means of dam deformation monitoring are becoming more and more advanced. The degree of automatic dam deformation monitoring becomes higher, and research, analysis and prediction of real-time dynamic monitoring data is a hot field today.

- (4)

- Dam deformation monitoring is a multi-disciplinary and multi-field work. Experts and scholars need to continue to improve it by introducing the latest research results of other emerging disciplines.

6. Conclusions

- (1)

- The CSO algorithm has been improved. Since the CSO algorithm easily falls into the local optimum and the convergence speed is slow in the evolution process, this paper integrates the inertia weight, which is determined by the foraging speed, and the aggregation degree into the optimization process of the CSO algorithm to increase the optimization time of the CSO regarding the population diversity and improve the ability of individual chickens to break through the local optimum. The simulation experiment is carried out through the test function, and the experimental results show that the optimization accuracy of the ICSO algorithm is better than that of the basic CSO algorithm, and the prediction accuracy has been improved several times.

- (2)

- A dam deformation prediction model based on the ICSO algorithm to optimize SVM is established. Compared with the traditional CSO algorithm, the ICSO algorithm optimizes the SVM model with a higher prediction accuracy and stronger model generalization ability. The ICSO algorithm performs better than the CSO algorithm in the parameters optimization process, and the model prediction accuracy has been further improved. The dam deformation prediction model based on the ICSO algorithm optimizing SVM has good prediction ability of dam deformation. By selecting the appropriate network structure and assigning the optimal parameters obtained by the ICSO algorithm to the SVM network, the dam deformation prediction value with high accuracy can be calculated.

- (3)

- The model is applied to an engineering example. Through the prediction and analysis of settlement data of the FengMan Dam monitoring point, the deformation prediction results for FengMan Dam by the combined model ICSO-SVM as well as other combined models CSO-SVM and GA-BP are compared and analyzed. The prediction accuracy of each model is ranked as ICSO-SVM model, CSO-SVM model and GA-BP model sequentially. The RMSE and MAE values of the ICSO-SVM model with the best prediction performance are the minimum values, while exceeds 0.9, and the prediction accuracy can meet the actual needs of the project.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salazar, F.; Morán, R.; Toledo, M.Á.; Oñate, E. Data-based models for the prediction of dam behaviour: A review and some methodological considerations. Arch. Comput. Methods Eng. 2017, 24, 1–21. [Google Scholar] [CrossRef]

- Pisaniello, J.D.; Dam, T.T.; Tingey-Holyoak, J.L. International small dam safety assurance policy benchmarks to avoid dam failure flood disasters in developing countries. J. Hydrol. 2015, 531, 1141–1153. [Google Scholar] [CrossRef]

- Ge, W.; Sun, H.; Zhang, H.; Li, Z.; Guo, X.; Wang, X.; Qin, Y.; Gao, W.; van Gelder, P. Economic risk criteria for dams considering the relative level of economy and industrial economic contribution. Sci. Total Environ. 2020, 725, 138139. [Google Scholar] [CrossRef] [PubMed]

- Stefaniak, K.; Wróżyńska, M. On possibilities of using global monitoring in effective prevention of tailings storage facilities failures. Environ. Sci. Pollut. Res. 2018, 25, 5280–5297. [Google Scholar] [CrossRef]

- Kaloop, M.R.; Elbeltagi, E.; Hu, J.W.; Elrefai, A. Recent advances of structures monitoring and evaluation using GPS-time series monitoring systems: A review. ISPRS Int. J. Geo-Inf. 2017, 6, 382. [Google Scholar] [CrossRef]

- Liu, N.; Dai, W.; Santerre, R.; Kuang, C. A MATLAB-based Kriged Kalman Filter software for interpolating missing data in GNSS coordinate time series. GPS Solut. 2018, 22, 25. [Google Scholar] [CrossRef]

- Yu, X.; Dan, D. Online frequency and amplitude tracking in structural vibrations under environment using APES spectrum postprocessing and Kalman filtering. Eng. Struct. 2022, 259, 114175. [Google Scholar] [CrossRef]

- Li, G.; Dai, W.; Yang, G.; Liu, B. Application of Space-Time Auto-Regressive Model in Dam Deformation Analysis. Geomat. Inf. Sci. Wuhan Univ. 2015, 40, 877–881. (In Chinese) [Google Scholar]

- Oro, S.R.; Mafioleti, T.R.; Neto, A.C.; Garcia, S.R.P.; Júnior, C.N. Study of the influence of temperature and water level of the reservoir about the displacement of a concrete dam. Int. J. Appl. Mech. Eng. 2016, 21, 107–120. [Google Scholar] [CrossRef]

- Qin, X.Y.; Liu, L.L.; Chen, J.; Chen, F.D.; Huang, L.K.; Xie, S.F. Dam deformation forecast based on EMD-PSO-BP neural network model. J. Guilin Univ. Technol. 2017, 4, 641–646. (In Chinese) [Google Scholar]

- Zhang, L.; Zhikuan, X.U.; Luo, Y.; Cheng, P. Dam deformation prediction based on evolutionary multiple kernels relevance vector machine. Sci. Surv. Mapp. 2017, 42, 188–192. (In Chinese) [Google Scholar]

- Su, H.Z.; Li, X.; Yang, B.B.; Wen, Z. Wavelet support vector machine-based prediction model of dam deformation. Mech. Syst. Signal Process. 2018, 110, 412–427. [Google Scholar] [CrossRef]

- Zhang, X.; Kano, M.; Tani, M.; Mori, J.; Ise, J.; Harada, K. Prediction and causal analysis of defects in steel products: Handling nonnegative and highly overdispersed count data. Control. Eng. Pract. 2020, 95, 104258. [Google Scholar] [CrossRef]

- Guo, Y.; Hu, S.; Wu, W.; Wang, Y.; Senthilnath, J. Multitemporal time series analysis using machine learning models for ground deformation in the Erhai region, China. Environ. Monit. Assess. 2020, 192, 464. [Google Scholar] [CrossRef] [PubMed]

- Bian, K.; Wu, Z. Data-based model with EMD and a new model selection criterion for dam health monitoring. Eng. Struct. 2022, 260, 114171. [Google Scholar] [CrossRef]

- Li, M.; Pan, J.; Liu, Y.; Liu, H.; Wang, J.; Zhao, Z. A Deformation Prediction Model of High Arch Dams in the Initial Operation Period Based on PSR-SVM-IGWO. Math. Probl. Eng. 2021, 2021, 8487997. [Google Scholar] [CrossRef]

- Meng, X.; Liu, Y.; Gao, X.; Zhang, H. A New Bio-Inspired Algorithm: Chicken Swarm Optimization. In Proceedings of the International Conference in Swarm Intelligence, Beijing, China, 25–28 June 2014; Springer: Cham, Switzerland, 2014; pp. 86–94. [Google Scholar]

- Song, Y.; Wang, F.; Chen, X. An improved genetic algorithm for numerical function optimization. Appl. Intell. 2019, 49, 1880–1902. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Ding, Y.; Fu, X. Kernel-based fuzzy c-means clustering algorithm based on genetic algorithm. Neurocomputing 2016, 188, 233–238. [Google Scholar] [CrossRef]

- Liang, H.; Wei, Q.; Lu, D.; Li, Z. Application of GA-BP neural network algorithm in killing well control system. Neural Comput. Appl. 2021, 33, 949–960. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Liu, L. Process optimization and weld forming control based on GA-BP algorithm for riveting-welding hybrid bonding between magnesium and CFRP. J. Manuf. Processes 2021, 70, 97–107. [Google Scholar] [CrossRef]

- Sayed, G.I.; Tharwat, A.; Hassanien, A.E. Chaotic dragonfly algorithm: An improved metaheuristic algorithm for feature selection. Appl. Intell. 2019, 49, 188–205. [Google Scholar] [CrossRef]

- Wen, L.; Cao, Y. Influencing factors analysis and forecasting of residential energy-related CO2 emissions utilizing optimized support vector machine. J. Clean. Prod. 2020, 250, 119492. [Google Scholar] [CrossRef]

- Bharanidharan, N.; Rajaguru, H. Improved chicken swarm optimization to classify dementia MRI images using a novel controlled randomness optimization algorithm. Int. J. Imaging Syst. Technol. 2020, 30, 605–620. [Google Scholar] [CrossRef]

- Dai, B.; Gu, C.; Zhao, E.; Qin, X. Statistical model optimized random forest regression model for concrete dam deformation monitoring. Struct. Control. Health Monit. 2018, 25, e2170. [Google Scholar] [CrossRef]

- Wei, B.; Chen, L.; Li, H.; Yuan, D.; Wang, G. Optimized prediction model for concrete dam displacement based on signal residual amendment. Appl. Math. Model. 2020, 78, 20–36. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, X.; Xie, J.; Kou, P. An improved long short-term memory model for dam displacement prediction. Math. Probl. Eng. 2019, 2019, 6792189. [Google Scholar] [CrossRef]

- Xiao, R.; Jiang, M.; Li, Z.; He, X. New insights into the 2020 Sardoba dam failure in Uzbekistan from Earth observation. Int. J. Appl. Earth Obs. Geoinf. 2022, 107, 102705. [Google Scholar] [CrossRef]

- Du, Z.; Ge, L.; Ng, A.H.M.; Zhu, Q.; Horgan, F.G.; Zhang, Q. Risk assessment for tailings dams in Brumadinho of Brazil using InSAR time series approach. Sci. Total Environ. 2020, 717, 137125. [Google Scholar] [CrossRef]

- Mata, J. Interpretation of concrete dam behaviour with artificial neural network and multiple linear regression models. Eng. Struct. 2011, 33, 903–910. [Google Scholar] [CrossRef]

- Liu, C.; Ahn, C.R.; An, X.; Lee, S. Life-cycle assessment of concrete dam construction: Comparison of environmental impact of rock-filled and conventional concrete. J. Constr. Eng. Manag. 2013, 139, A4013009. [Google Scholar] [CrossRef]

- Xia, J.; Zhang, Y.Y.; Xiong, L.H.; He, S.; Wang, L.F.; Yu, Z.B. Opportunities and challenges of the Sponge City construction related to urban water issues in China. Sci. China Earth Sci. 2017, 60, 652–658. [Google Scholar] [CrossRef]

- Liguori, A.; Markovic, R.; Dam, T.T.H.; Frisch, J.; van Treeck, C.; Causone, F. Indoor environment data time-series reconstruction using autoencoder neural networks. Build. Environ. 2021, 191, 107623. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Kryman, M.; Laine, E. Profiling technological failure and disaster in the energy sector: A comparative analysis of historical energy accidents. Energy 2015, 90, 2016–2027. [Google Scholar] [CrossRef]

- Liang, T.; Wang, S.; Lu, C.; Jiang, N.; Long, W.; Zhang, M.; Zhang, R. Environmental impact evaluation of an iron and steel plant in China: Normalized data and direct/indirect contribution. J. Clean. Prod. 2020, 264, 121697. [Google Scholar] [CrossRef]

| Number of Observation Periods | Observation Date | Horizontal Displacement (mm) | Upstream Water Level H (m) | Temperature T (℃) |

|---|---|---|---|---|

| 1 | 4/01/1985 | −1.30 | 251.20 | −15.40 |

| 2 | 11/01/1985 | −1.86 | 250.27 | −17.20 |

| 3 | 18/01/1985 | −2.69 | 249.47 | −12.60 |

| 4 | 28/01/1985 | −3.01 | 248.68 | −25.30 |

| 5 | 8/02/1985 | −4.45 | 248.22 | −3.50 |

| 6 | 15/02/1985 | −3.97 | 247.75 | −10.10 |

| 7 | 26/02/1985 | −4.20 | 247.12 | −12.80 |

| 8 | 6/03/1985 | −4.17 | 246.65 | −8.50 |

| 9 | 13/03/1985 | −4.64 | 246.14 | −6.50 |

| 10 | 22/03/1985 | −4.69 | 245.84 | 0.20 |

| … | … | … | ||

| 196 | 17/06/1988 | −1.83 | 252.66 | 15.6 |

| 197 | 22/06/1988 | −2.34 | 252.68 | 24.30 |

| 198 | 2/07/1988 | −3.54 | 252.52 | 20.50 |

| 199 | 8/07/1988 | −3.32 | 252.52 | 22.70 |

| 200 | 13/07/1988 | −3.91 | 252.81 | 25.90 |

| Sample | Input | Output | |||||

|---|---|---|---|---|---|---|---|

| /°C | Horizontal Displacement Value/mm | ||||||

| 1 | 251.200 | −15.400 | 0 | 0 | 0 | 0 | −1.300 |

| 2 | 250.270 | −17.200 | 0.120 | 0.238 | 0.070 | −2.659 | −1.860 |

| 3 | 249.470 | −12.600 | 0.239 | 0.464 | 0.140 | −1.966 | −2.690 |

| 4 | 248.680 | −25.300 | 0.402 | 0.735 | 0.240 | −1.427 | −3.010 |

| 5 | 248.220 | −3.500 | 0.567 | 0.934 | 0.350 | −1.050 | −4.450 |

| 6 | 247.750 | −10.100 | 0.662 | 0.992 | 0.420 | −0.868 | −3.970 |

| 7 | 247.120 | −12.800 | 0.791 | 0.968 | 0.530 | −0.635 | −4.200 |

| 8 | 246.650 | −8.500 | 0.868 | 0.863 | 0.610 | −0.494 | −4.170 |

| 9 | 246.140 | −6.500 | 0.921 | 0.718 | 0.680 | −0.386 | −4.640 |

| 10 | 245.840 | 0.200 | 0.970 | 0.471 | 0.770 | −0.261 | −4.690 |

| … | … | … | … | … | … | … | … |

| … | … | … | … | … | … | … | … |

| 199 | 252.520 | 22.700 | −0.060 | 0.120 | 12.810 | 2.550 | −3.320 |

| 200 | 258.810 | 25.900 | −0.146 | 0.289 | 12.860 | 2.554 | −3.910 |

| Number of Periods | Measured Displacement Value/mm | ICSO-SVM | CSO-SVM | ||

|---|---|---|---|---|---|

| Predictive Value/mm | Prediction Error/mm | Predictive Value/mm | Prediction Error/mm | ||

| 161 | 4.930 | 5.344 | 0.414 | 5.128 | 0.198 |

| 162 | 5.370 | 5.616 | 0.246 | 5.281 | −0.089 |

| 163 | 5.770 | 5.768 | −0.002 | 5.187 | −0.583 |

| 164 | 5.450 | 5.910 | 0.460 | 5.166 | −0.284 |

| 165 | 6.050 | 6.151 | 0.101 | 5.147 | −0.903 |

| 166 | 6.130 | 5.682 | −0.448 | 4.751 | −1.379 |

| 167 | 6.120 | 6.086 | −0.034 | 4.833 | −1.287 |

| 168 | 5.690 | 5.907 | 0.217 | 4.578 | −1.112 |

| 169 | 4.150 | 5.580 | 1.430 | 4.385 | 0.235 |

| 170 | 3.330 | 5.065 | 1.735 | 4.270 | 0.940 |

| 171 | 3.820 | 4.470 | 0.650 | 3.643 | −0.177 |

| 172 | 2.750 | 3.197 | 0.447 | 2.846 | 0.096 |

| 173 | 2.320 | 2.114 | −0.206 | 1.742 | −0.578 |

| 174 | 1.650 | 0.789 | −0.861 | 0.578 | −1.072 |

| 175 | 1.240 | 0.335 | −0.905 | 0.166 | −1.074 |

| 176 | 0.910 | −0.246 | −1.156 | −0.311 | −1.221 |

| 177 | −0.080 | −0.427 | −0.347 | −0.423 | −0.343 |

| 178 | −0.350 | −0.684 | −0.334 | −0.639 | −0.289 |

| 179 | −1.020 | −0.923 | 0.097 | −0.838 | 0.182 |

| 180 | −1.910 | −1.353 | 0.557 | −1.216 | 0.694 |

| 181 | −2.610 | −1.963 | 0.647 | −1.770 | 0.840 |

| 182 | −2.880 | −2.192 | 0.688 | −1.979 | 0.901 |

| 183 | −3.400 | −2.298 | 1.102 | −2.075 | 1.325 |

| 184 | −3.560 | −2.877 | 0.683 | −2.657 | 0.903 |

| 185 | −3.640 | −3.203 | 0.437 | −2.941 | 0.699 |

| 186 | −3.150 | −2.537 | 0.613 | −2.294 | 0.856 |

| 187 | −3.180 | −2.566 | 0.614 | −2.288 | 0.892 |

| 188 | −1.400 | −1.282 | 0.118 | −1.126 | 0.274 |

| 189 | −0.100 | −0.840 | −0.740 | −0.700 | −0.600 |

| 190 | 0.750 | 0.069 | −0.681 | 0.028 | −0.722 |

| 191 | 0.400 | −0.084 | −0.484 | −0.035 | −0.435 |

| 192 | −0.320 | 0.045 | 0.365 | 0.067 | 0.387 |

| 193 | −0.400 | 0.098 | 0.498 | 0.107 | 0.507 |

| 194 | −0.810 | −0.076 | 0.734 | −0.025 | 0.785 |

| 195 | −1.860 | −0.516 | 1.344 | −0.348 | 1.512 |

| 196 | −1.830 | −0.791 | 1.039 | −0.626 | 1.204 |

| 197 | −2.340 | −1.264 | 1.076 | −0.994 | 1.346 |

| 198 | −3.540 | −1.644 | 1.896 | −1.394 | 2.146 |

| 199 | −3.320 | −1.868 | 1.452 | −1.599 | 1.721 |

| 200 | −3.910 | −1.944 | 1.966 | −1.662 | 2.248 |

| Number of Periods | Measured Displacement Value/mm | ICSO-SVM | GA-BP | ||

|---|---|---|---|---|---|

| Predictive Value/mm | Prediction Error/mm | Predictive Value/mm | Prediction Error/mm | ||

| 161 | 4.930 | 5.344 | 0.414 | 4.979 | 0.049 |

| 162 | 5.370 | 5.616 | 0.246 | 5.362 | −0.008 |

| 163 | 5.770 | 5.768 | −0.002 | 5.921 | 0.151 |

| 164 | 5.450 | 5.910 | 0.460 | 6.111 | 0.661 |

| 165 | 6.050 | 6.151 | 0.101 | 6.316 | 0.266 |

| 166 | 6.130 | 5.682 | −0.448 | 6.734 | 0.604 |

| 167 | 6.120 | 6.086 | −0.034 | 6.693 | 0.573 |

| 168 | 5.690 | 5.907 | 0.217 | 6.309 | 0.619 |

| 169 | 4.150 | 5.580 | 1.430 | 5.865 | 1.715 |

| 170 | 3.330 | 5.065 | 1.735 | 5.608 | 2.278 |

| 171 | 3.820 | 4.470 | 0.650 | 4.444 | 0.624 |

| 172 | 2.750 | 3.197 | 0.447 | 3.401 | 0.651 |

| 173 | 2.320 | 2.114 | −0.206 | 2.494 | 0.174 |

| 174 | 1.650 | 0.789 | −0.861 | 1.332 | −0.318 |

| 175 | 1.240 | 0.335 | −0.905 | 1.584 | 0.344 |

| 176 | 0.910 | −0.246 | −1.156 | 1.467 | 0.557 |

| 177 | −0.080 | −0.427 | −0.347 | 1.623 | 1.703 |

| 178 | −0.350 | −0.684 | −0.334 | 1.280 | 1.630 |

| 179 | −1.020 | −0.923 | 0.097 | 0.857 | 1.877 |

| 180 | −1.910 | −1.353 | 0.557 | −0.063 | 1.847 |

| 181 | −2.610 | −1.963 | 0.647 | −1.306 | 1.304 |

| 182 | −2.880 | −2.192 | 0.688 | −1.741 | 1.139 |

| 183 | −3.400 | −2.298 | 1.102 | −2.022 | 1.378 |

| 184 | −3.560 | −2.877 | 0.683 | −3.260 | 0.300 |

| 185 | −3.640 | −3.203 | 0.437 | −4.027 | −0.387 |

| 186 | −3.150 | −2.537 | 0.613 | −3.712 | −0.562 |

| 187 | −3.180 | −2.566 | 0.614 | −3.561 | −0.381 |

| 188 | −1.400 | −1.282 | 0.118 | −2.253 | −0.853 |

| 189 | −0.100 | −0.840 | −0.740 | −0.926 | −0.826 |

| 190 | 0.750 | 0.069 | −0.681 | 0.546 | −0.204 |

| 191 | 0.400 | −0.084 | −0.484 | 0.325 | −0.075 |

| 192 | −0.320 | 0.045 | 0.365 | 0.479 | 0.799 |

| 193 | −0.400 | 0.098 | 0.498 | 0.532 | 0.932 |

| 194 | −0.810 | −0.076 | 0.734 | 0.174 | 0.984 |

| 195 | −1.860 | −0.516 | 1.344 | −0.647 | 1.213 |

| 196 | −1.830 | −0.791 | 1.039 | −1.176 | 0.654 |

| 197 | −2.340 | −1.264 | 1.076 | −1.802 | 0.538 |

| 198 | −3.540 | −1.644 | 1.896 | −2.287 | 1.253 |

| 199 | −3.320 | −1.868 | 1.452 | −2.352 | 0.968 |

| 200 | −3.910 | −1.944 | 1.966 | −2.184 | 1.726 |

| Model | MAE/mm | RMSE/mm | |

|---|---|---|---|

| ICSO-SVM | 0.696 | 0.854 | 0.9558 |

| CSO-SVM | 0.826 | 0.979 | 0.9556 |

| GA-BP | 0.828 | 1.010 | 0.9457 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Y.; Chen, Y.; Huang, S.; Wang, P.; Xiang, Y. Research on Dam Deformation Prediction Model Based on Optimized SVM. Processes 2022, 10, 1842. https://doi.org/10.3390/pr10091842

Xing Y, Chen Y, Huang S, Wang P, Xiang Y. Research on Dam Deformation Prediction Model Based on Optimized SVM. Processes. 2022; 10(9):1842. https://doi.org/10.3390/pr10091842

Chicago/Turabian StyleXing, Yin, Yang Chen, Saipeng Huang, Peng Wang, and Yunfei Xiang. 2022. "Research on Dam Deformation Prediction Model Based on Optimized SVM" Processes 10, no. 9: 1842. https://doi.org/10.3390/pr10091842

APA StyleXing, Y., Chen, Y., Huang, S., Wang, P., & Xiang, Y. (2022). Research on Dam Deformation Prediction Model Based on Optimized SVM. Processes, 10(9), 1842. https://doi.org/10.3390/pr10091842