Extraction, Isolation, and Purification of Value-Added Chemicals from Lignocellulosic Biomass

Abstract

:1. Introduction

2. Methodology

- Levulinic acid;

- Lactic acid;

- 3-hydroxypropionic acid (3-HP);

- Succinic acid;

- Vanillic acid and vanillin;

- Itaconic acid;

- Adipic acid;

- 2,5-furandicarboxylic acid (FDCA); and

- 5-hydroxymethylfurfural (HMF).

- Xylitol;

- Furfural;

- Chitosan;

- 2,3-butanediol (2,3-BD); and

- Xylo-oligosaccharides (XOs)

3. Top Value-Added Chemicals

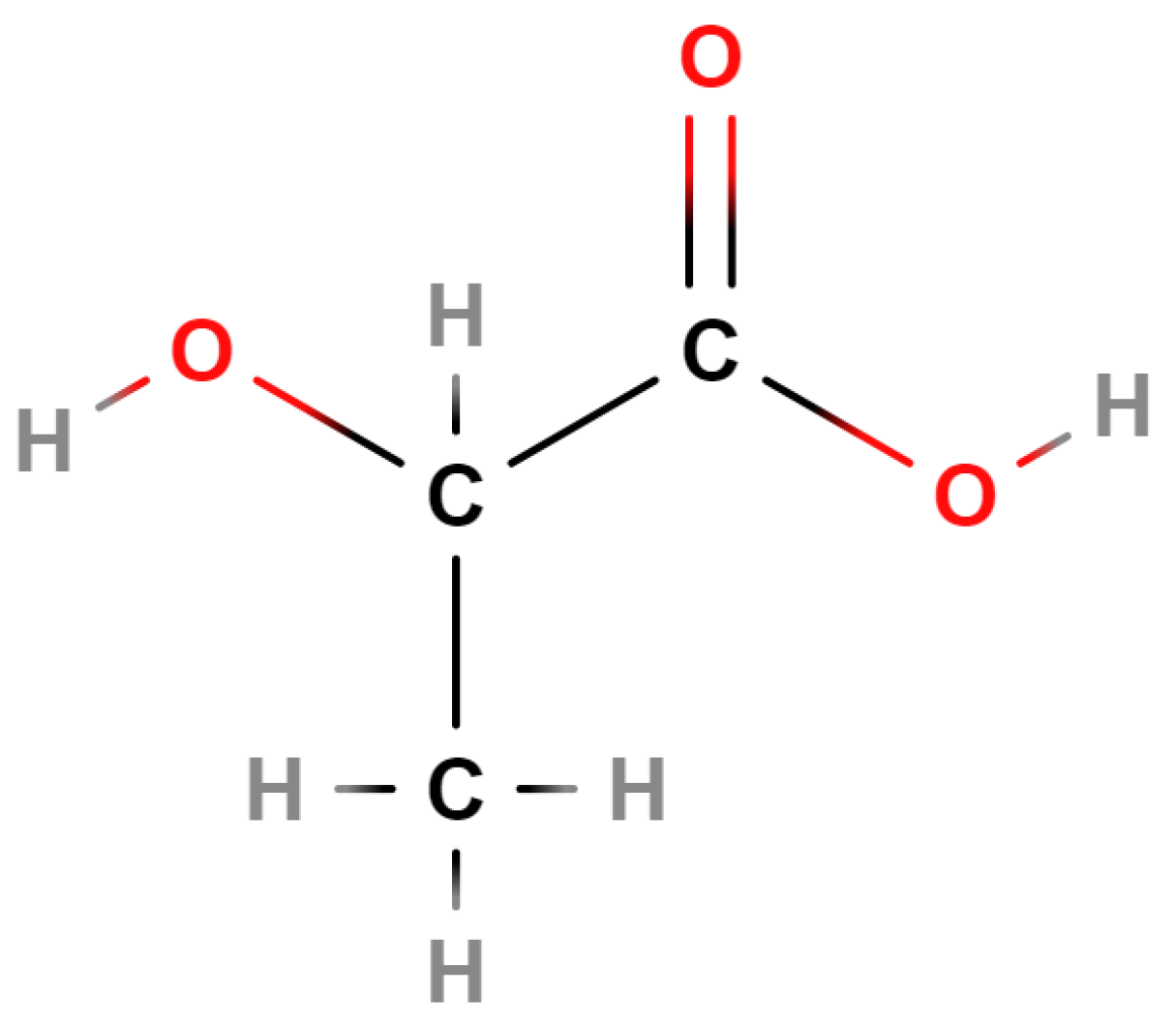

3.1. Levulinic Acid

3.2. Lactic Acid

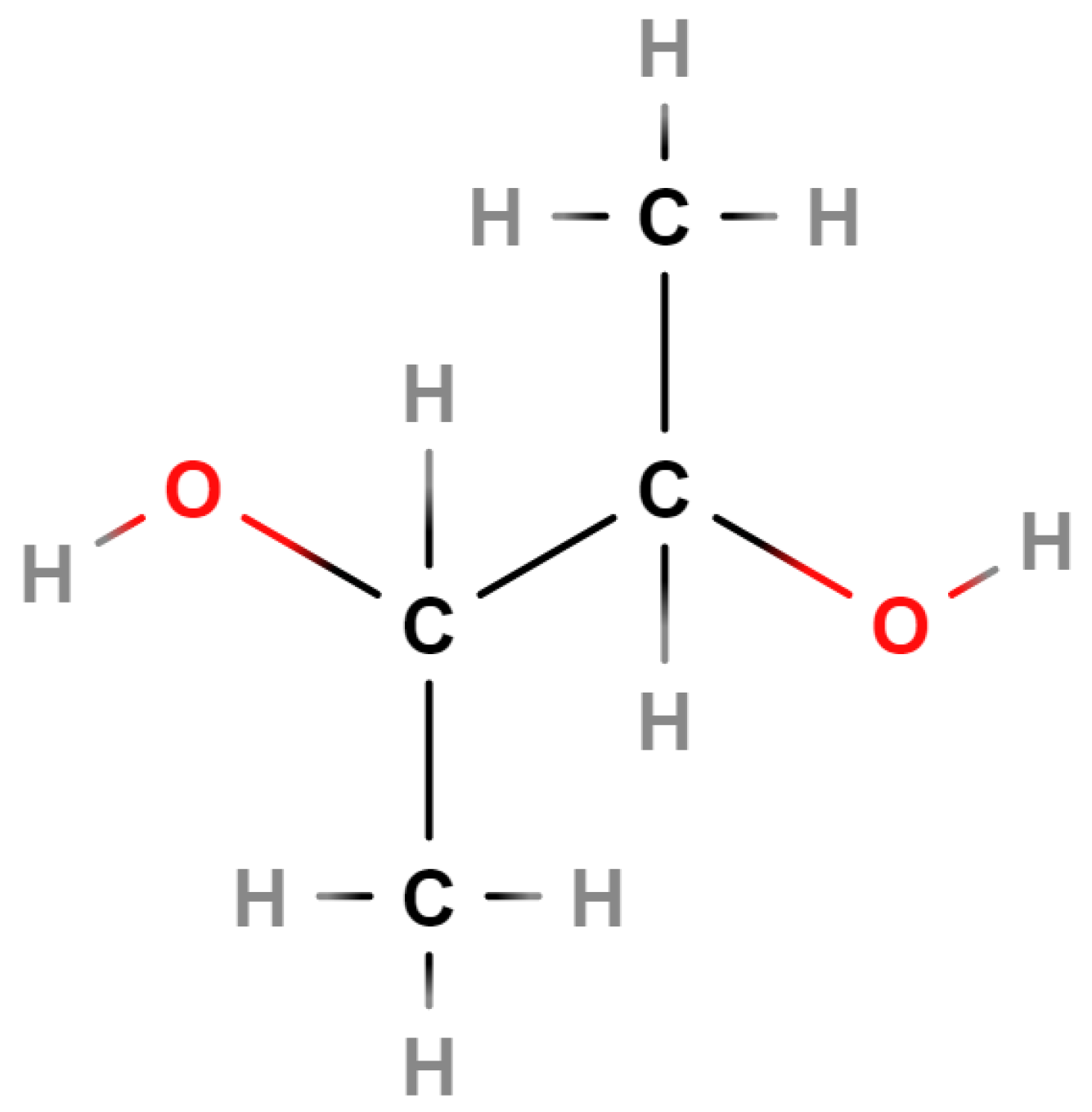

3.3. 3-Hydroxypropionic Acid

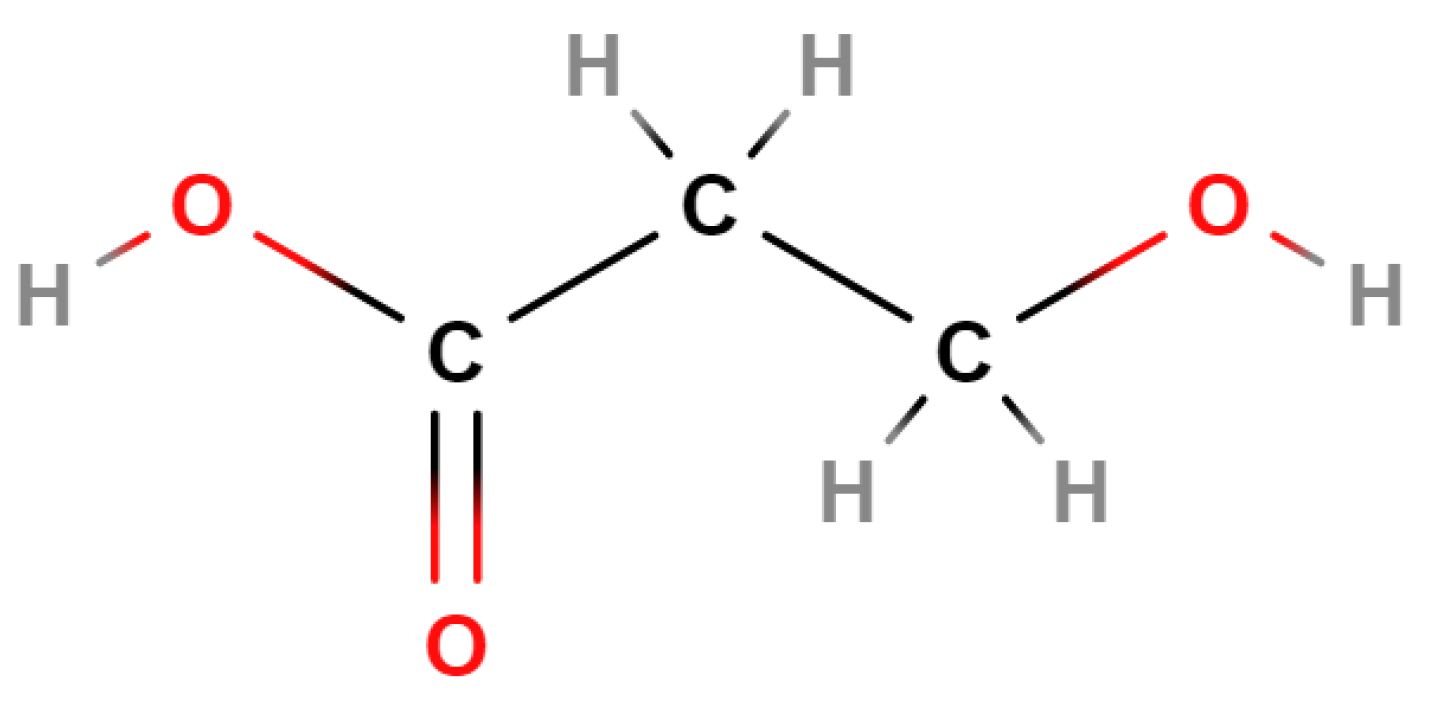

3.4. Succinic Acid

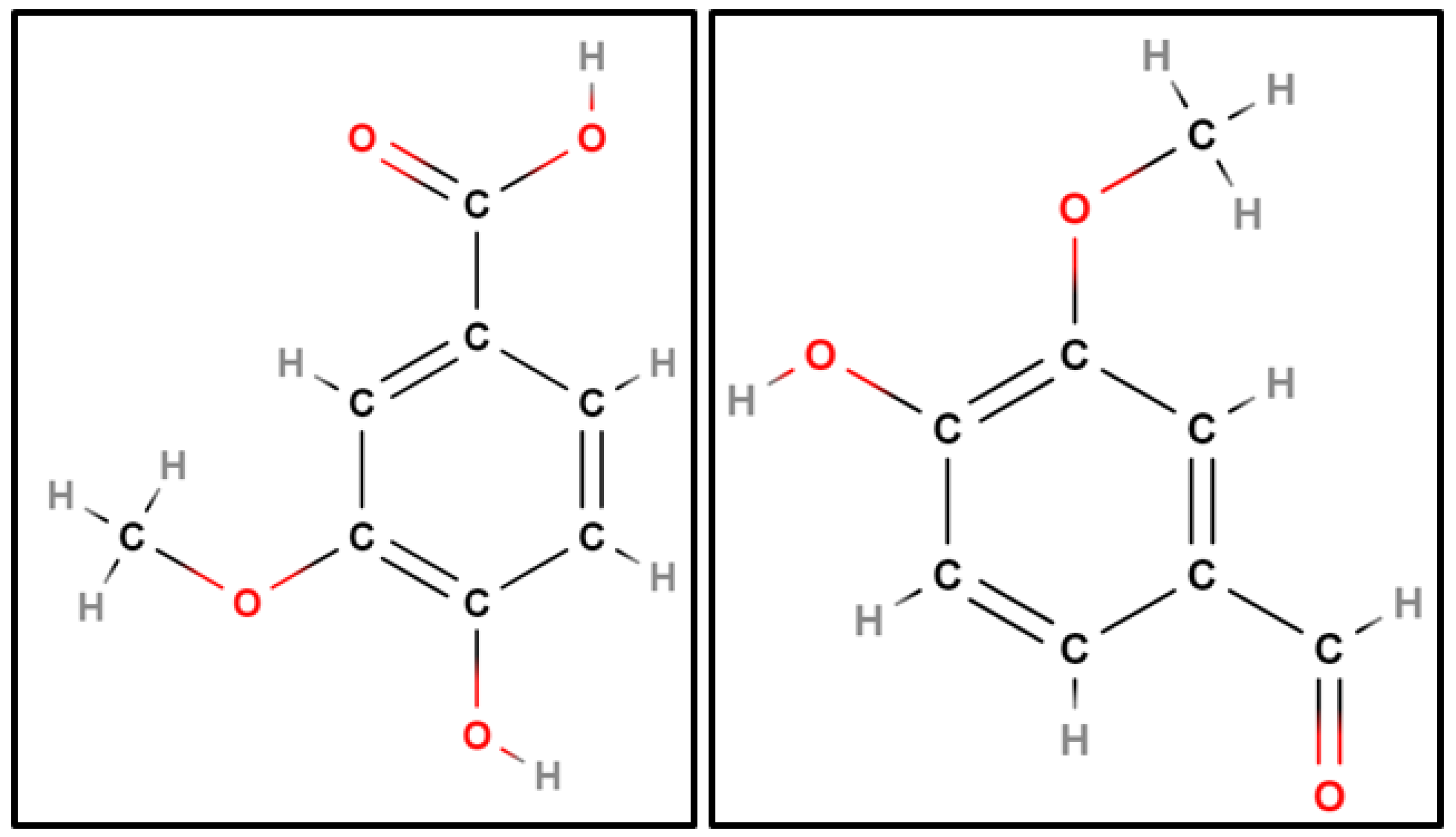

3.5. Vanillic Acid and Vanillin

3.6. Itaconic Acid

3.7. Adipic Acid

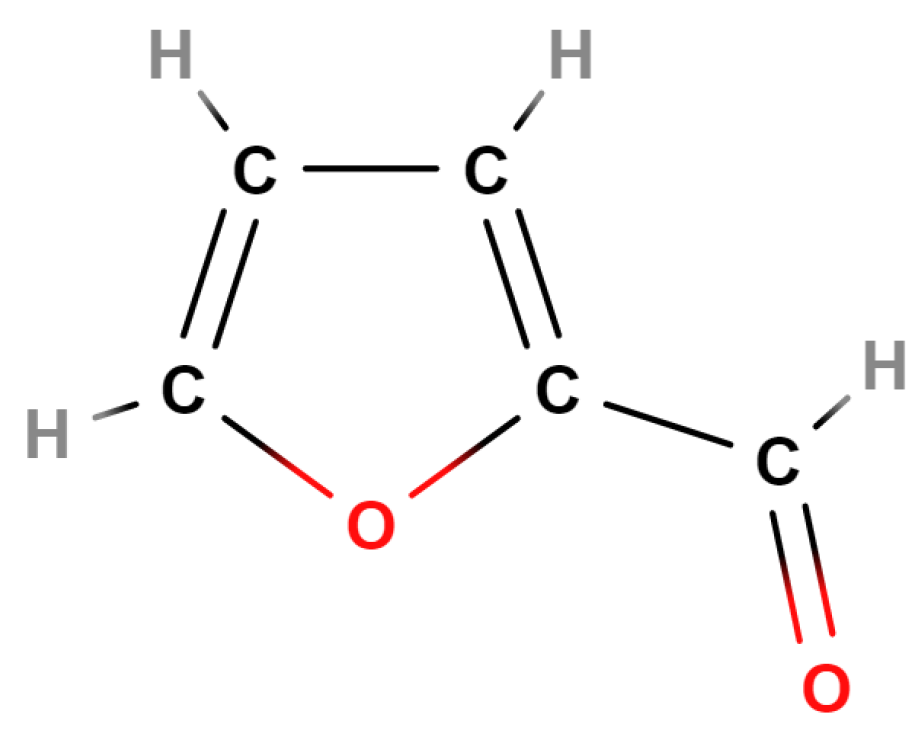

3.8. Furfural

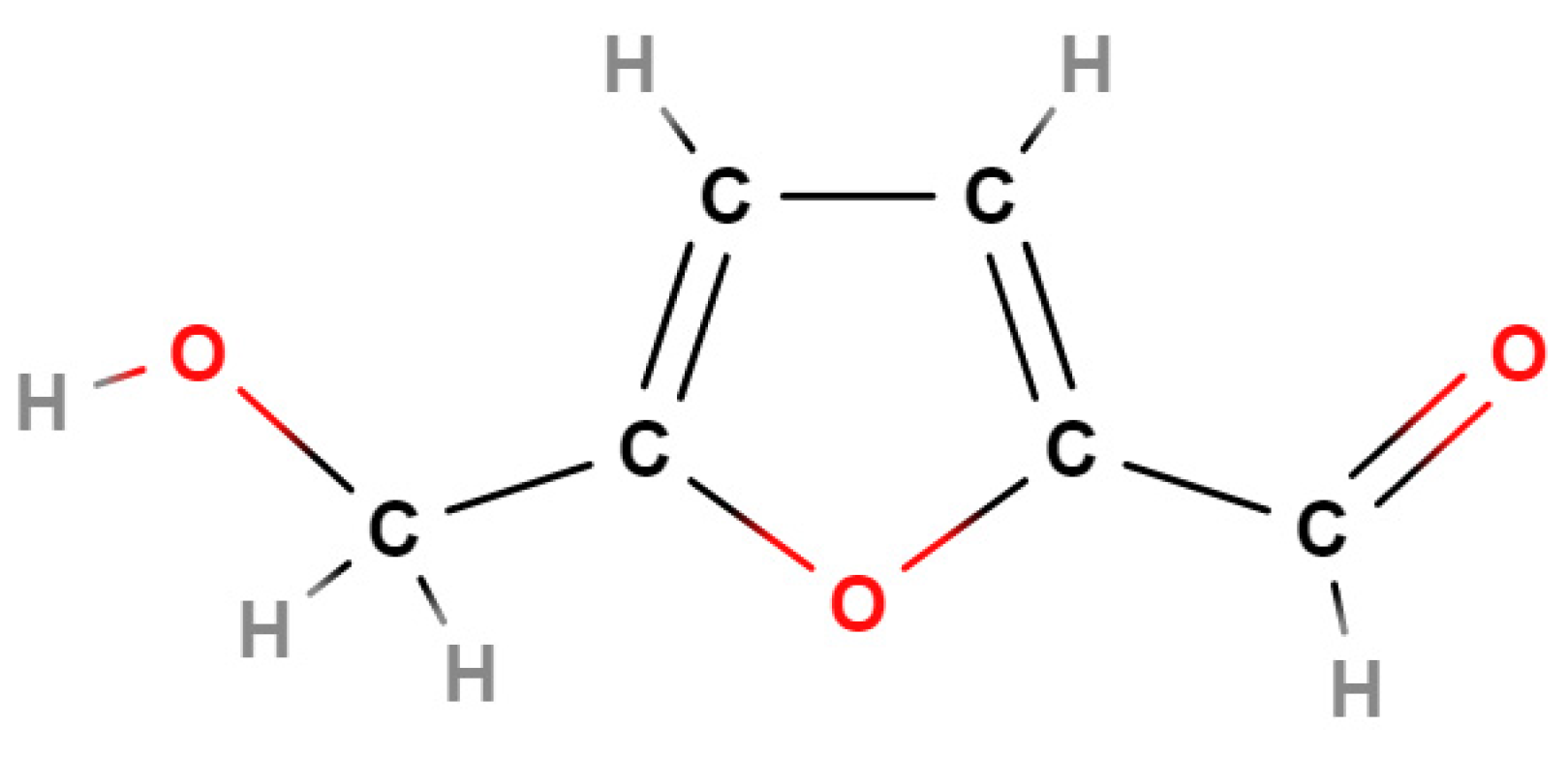

3.9. 5-Hydroxymethylfurfural (HMF)

| Biomass | Feedstock Content | Pretreatment/Catalyst | Operating Temp. (°C) | Time (min) | Concentrations | Unit | Ref. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Furans | Organic Acids | Phenolics | |||||||||||||||

| Furoic Acid | Furfural | 5 HMF | Lactic Acid | Succinic Acid | Glutaric Acid | Itaconic Acid | Adipic Acid | Vanillin | Vanillic Acid | Ferulic Acid | |||||||

| Corn Stover | 34.4% glucan, 22.8% xylan, and 11% lignin | 0.7% H2SO4 (w/w) | 180 | 8 | 2.4 | 220 | 44 | 20 | 2.9 | 0.57 | 7.2 | 0.11 | 4 | 3.3 | 6.6 | g/L | [80] |

| 0.07% H2SO4 (w/w) | 1.1 | 26 | 11 | 17.8 | 1.7 | 0.24 | 2 | 0.14 | 2.8 | 1.5 | 2.6 | g/L | |||||

| Liquid hot water | 0.88 | 8 | 2.3 | 5.5 | 2.2 | 0.23 | 1.2 | 0.15 | 2.6 | 2.6 | 2.2 | g/L | |||||

| Deionized water saturated with oxygen at 174 psi | 1.2 | 6.5 | 2.8 | 24 | 5.2 | 0.65 | 2.1 | 0.2 | 6.7 | 4.3 | 1 | g/L | |||||

| Aqueous ammonia 0.1% (w/w) | 1.1 | 0.4 | 0.89 | 38 | 6.5 | 1.2 | 3.2 | 0.18 | 2.6 | 3.2 | 4.2 | g/L | |||||

| 34.4% glucan, 22.4% xylan, 4.2% arabinan, 0.6% mannan, 1.4% galactan, 11% lignin, 2.3% protein, 6.1% ash, and 3.8% uronic acids | Ammonia fiber expansion (AFEX) | 130 | 15 | 0.006 | 0.003 | 0.642 | 0.318 | 0.596 | 0.008 | 0.022 | 0.003 | 0.195 | 0.046 | 0.103 | g/g DM | [81] | |

| 30% H2SO4 (w/w) | 190 | 0.155 | 7.94 | 15.7 | 1.5 | 0.26 | 0.012 | 0.58 | 0.005 | 0.281 | 0.124 | 1.314 | g/g DM | ||||

| N/A | 1% H2SO4 (w/w) | 160 | 8 | N/A | 18.7 | 0.701 | 41 | N/A | N/A | N/A | N/A | 0.06 | 0.034 | N/A | mM | [82] | |

| Poplar | 43.8% glucan, 14.85% xylan, 3.94% mannan, and 29.12% lignin | 0.7% H2SO4 (w/w) | 180 | 8 | 3.1 | 220 | 64 | 29 | 2.5 | 0.61 | 0.11 | 0.057 | 5.5 | 5.9 | 0.19 | g/L | [80] |

| 0.07% H2SO4 (w/w) | 1.7 | 31 | 4 | 19 | 0.93 | 0.26 | 0.13 | 0.1 | 5.6 | 5.7 | 0.46 | g/L | |||||

| Liquid hot water | 0.94 | 2.6 | 0.45 | 1.8 | 2.3 | 0.23 | 0.093 | 0.048 | 3.1 | 4.1 | 0.23 | g/L | |||||

| Deionized water saturated with oxygen at 12 bar | 0.76 | 2.1 | 0.39 | 22 | 2.4 | 0.25 | 0.17 | 0.14 | 9.1 | 5.3 | 0.07 | g/L | |||||

| Aqueous ammonia 0.1% (w/w) | 0.49 | 0.5 | 0.079 | 26 | 1.7 | 0.35 | 0.088 | 0.13 | 2.8 | 2.5 | 0.13 | g/L | |||||

| 48.9% glucan, 15.7% xylan, 27.7% lignin, and 1.2% ash | Steam explosion | 214 | 6 | N/A | 5.9 | 2.6 | N/A | N/A | N/A | N/A | N/A | 0.035 | N/A | N/A | mg/g DM | [83] | |

| Pine | 40% glucan, 8.9% xylan, 16% mannan, and 27.7% lignin | 0.7% H2SO4 (w/w) | 180 | 8 | 1.1 | 190 | 170 | 3.7 | 0.73 | 0.37 | 0.07 | 0.076 | 4.6 | 5.2 | 0.12 | g/L | [80] |

| 0.07% H2SO4 (w/w) | 0.8 | 13 | 9.5 | 4.5 | 0.34 | 0.18 | 0.032 | 0.09 | 5.8 | 3.6 | 0.22 | g/L | |||||

| Liquid hot water | 0.83 | 2.5 | 1.3 | 8.7 | 0.75 | 0.16 | 0.09 | 0.054 | 2.4 | 2.3 | 0.31 | g/L | |||||

| Deionized water saturated with oxygen at 12 bar | 0.91 | 1.9 | 0.64 | 18 | 1.8 | 0.31 | 0.24 | 0.18 | 7.1 | 4.8 | 0.14 | g/L | |||||

| Aqueous ammonia 0.1% (w/w) | 0.55 | 0.65 | 0.16 | 36 | 2.39 | 0.66 | 0.099 | 0.13 | 3.2 | 4.8 | 0.16 | g/L | |||||

| Spruce | 41.6% glucan, 11.5% mannan, 4.7% xylan, 2% galactan, 1.1% arabinan, 25.7% lignin, and 5.4% extractives | 0.5% H2SO4 (w/w) | 222 | 7 | N/A | 1 | 5.9 | N/A | N/A | N/A | N/A | N/A | 0.12 | 0.034 | N/A | g/L | [84] |

| Wheat Straw | 36.3% cellulose, 30.9% hemicellulose, and 7.1% lignin | 6.5g/L Na2CO3 | 185 | 10 | N/A | N/A | N/A | 0.461 | 0.899 | N/A | N/A | N/A | 0.008 | 0.004 | 0.009 | g/100 g DM | [85] |

| 2g/L Na2CO3 | 195 | 15 | 0.017 | 0.146 | 0.016 | N/A | 0.447 | N/A | N/A | N/A | 0.096 | 0.084 | 0.015 | ||||

| Barley Straw | 33% glucan, 20% xylan, 3.8% arabinan, 1% galactan, 16.1% lignin, 7.6% ash, and 13.8% extractives | N/A | 210 | 5 | N/A | 0.28 | 0.08 | N/A | N/A | N/A | N/A | N/A | 25 | 4.4 | 10 | mg/100 g DM | [86] |

3.10. 2,5-Furandicarboxylic Acid

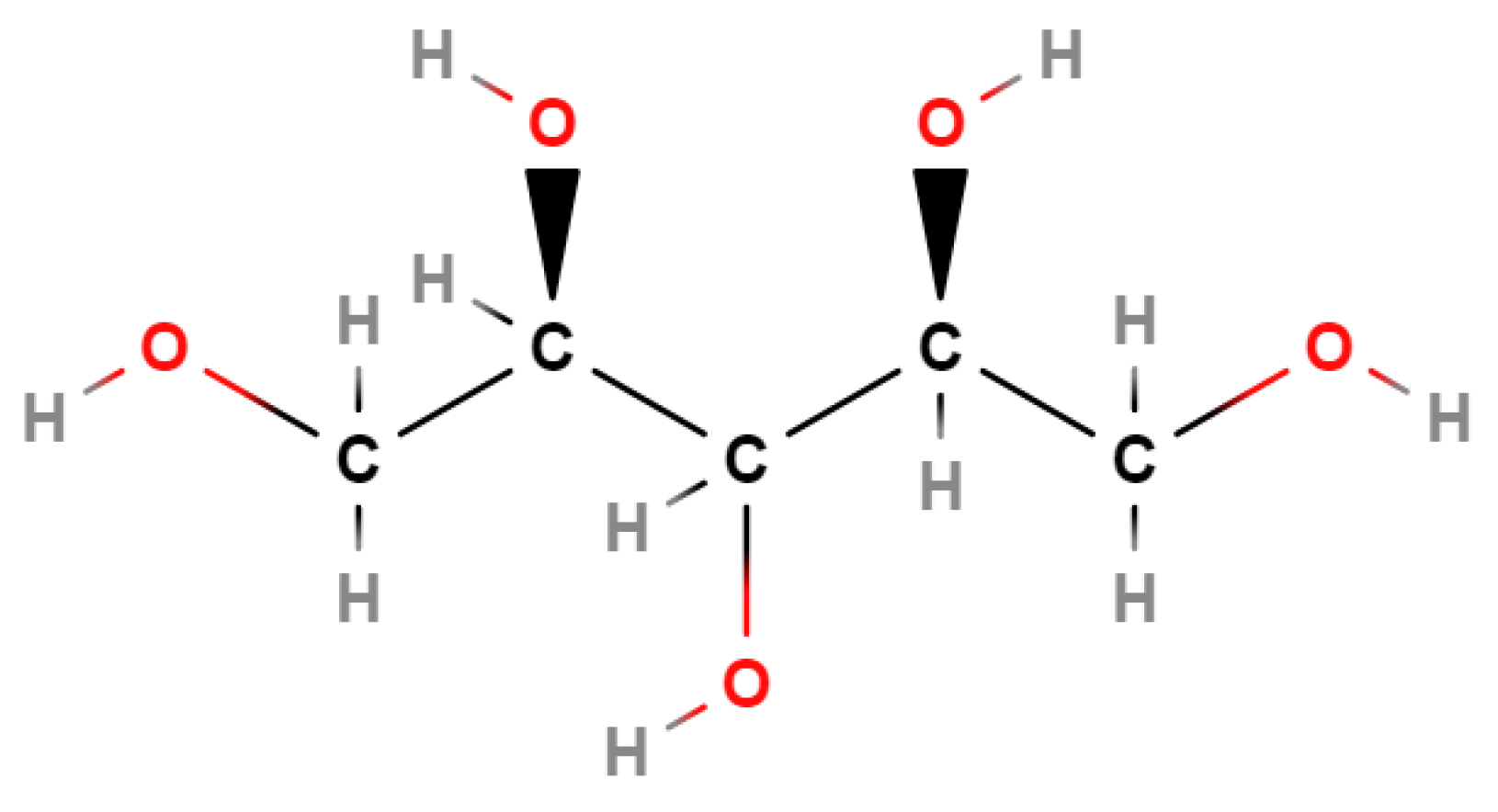

3.11. Xylitol

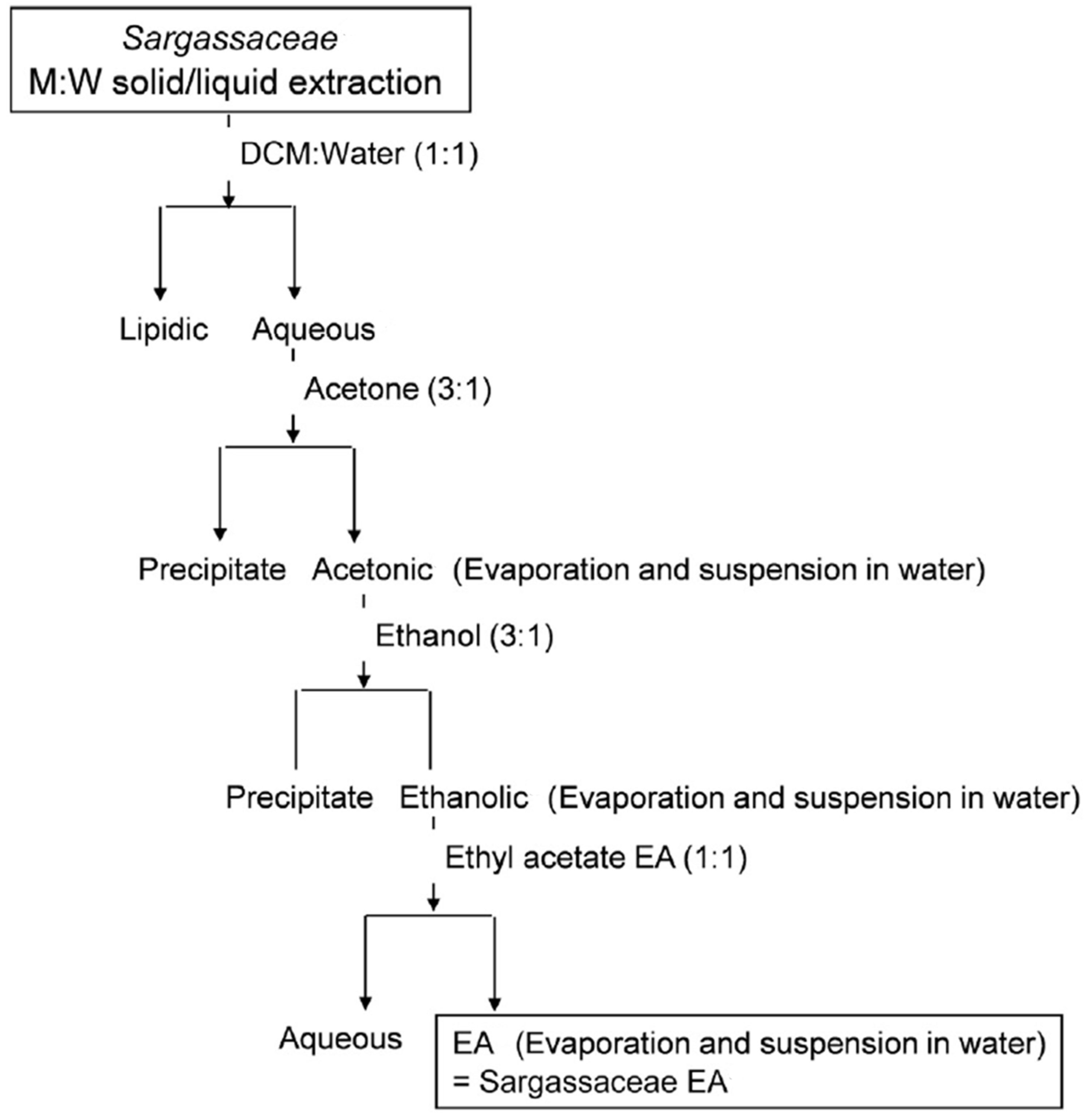

3.12. Chitosan

3.13. 2,3 Butanediol (2,3-BD)

3.14. Xylo-Oligosaccharides (XOs)

| Biomass | Feedstock Content | Acid Conc. | Operating Temp. (°C) | Time (min) | Hydrolysate | Strain | Xylitol Reported | Reference |

|---|---|---|---|---|---|---|---|---|

| Corncob | 20.91 g/L of Xylose | 1% H2SO4 (v/v) | 121 | 30 | 40.16 g/L and 52.71 g/L of xylose (hydrolysate concentrated through rotavapor and microwave, respectively) | Candida tropicalis | 1.2-fold increase in yield and 1.8-fold increase in productivity | [128] |

| 31.2 g/L of xylose and 3.3 g/L of glucose | 1% H2SO4 (v/v) | 121 | 40 | 160 g/L of xylose | Candida tropicalis As 2.1776 | Yield of 0.83 g/g and productivity of 1.01 g/L/h. Maximum xylitol production of 96.5 g/L | [129] | |

| 41.2% cellulose, 33.4% hemicellulose, and 18.7% lignin | 1% H2SO4 (v/v) | 125 | 60 | 21.67 g/L of xylose | Candida tropicalis CCTCC M2012462 | Maximal xylitol concentration of 38.8 g/L. Yield of 0.7 g/g of xylose and a productivity of 0.46 g/L/h | [130] | |

| 42.7% cellulose, 34.3% hemicellulose, and 17.5% lignin | 1% H2SO4 (v/v) | 120 | 60 | 28.7 g/L of xylose | Candida tropicalis W103 | Maximal xylitol concentration of 68.4 g/L. Yield of 0.7 g/g xylose and a productivity of 0.95 g/L/h | [131] | |

| 32% cellulose, 35% hemicellulose, 20% lignin, and 4% ash and others | 1% H2SO4 (v/v) | 121 | 60 | 24.9 g/L of Xylose | Candida magnoliae | Production rate of 0.51 g/L/h and 18.7 g xylitol/L | [132] | |

| Sugarcane bagasse | - | - | - | - | 65% xylose, 15% arabinose, and 8% glucose | Debaryomyces hansenii | Maximum yield of 0.76 and 0.82 g/g using free and immobilized cells, respectively, with corresponding volumetric productivities of 0.44 and 0.46 g/L/h at 100 g/L initial xylose concentration | [133] |

| 17.5% DM loading | 1% H2SO4 | 150 | 30 | 15.73 g/L of D-xylose | Candida guilliermondii FTI 20037 | Maximal xylitol production of 50.5 g/L. Yield of 0.81 g/g of xylose and productivity of 0.6 g/L/h | [134] | |

| 9.3 xylose, 15.2 glucose, and 8.5 lignin (% of DM) | 100 mg of sulfuric acid per g of bagasse (dry wt) | 121 | 10 | Hydrolysate 64.7 g/L xylose, 3.08 g/L glucose, 4.23 g/L arabinose, and 1.84 g/ L acetic acid | Candida guilliermondii | Maximum xylitol concentration of 28.7 g/L, xylitol yield on consumed xylose of 0.49 g/g, and a xylitol volumetric productivity of 0.24 g/L/h | [135] | |

| 10% DM loading | 1% H2SO4 (v/v) | 121 | 60 | Sugar composition in hydrolysate xylose 56%, glucose 15%, and arabinose 24% | Candida tropicalis | Xylitol yield was 0.65 g/g of xylose | [136] | |

| Corn Fiber | 20% DM loading | 1% H2SO4 (v/v) | 121 | 60 | Sugar composition in hydrolysate xylose 30%, glucose 38%, arabinose 22%, and galactose 4%. | Candida tropicalis | Xylitol yield was 0.65 g/g of xylose |

| Biomass | Treatment Conditions | Xylose (g/L) | Fungal Strain | Chitosan Extraction | Biomass Production (g/L/day) | Chitosan Content (g/g Biomass) | Comment | Ref. |

|---|---|---|---|---|---|---|---|---|

| Corn Stover | 2% H2SO4 100 °C 2 h | 22.4 | Rhizopus oryzae ME-F12 | 1 M NaOH at 121 °C for 15 min + 2% acetic acid at 95 °C for 24 h | 5.2 | 0.09 | Total production | [104] |

| Autoclave at 121 °C for 20 min | N/A | Aspergillus niger | 1 M NaOH at 121 °C for 20 min + 2% acetic acid at 95 °C for 6–8 h | 15.8 | 6.8 | (g/kg) Solid-state fermentation | [107] | |

| Autoclave at 21 °C 20 for min | N/A | Rhizopus oryzae | 1 M NaOH at 121 °C for 20 min + 2% acetic acid at 95 °C for 6-8 h | 14.6 | 8.6 | |||

| Acid-assisted steam explosion, 0.8 MPa | 30 | Rhizopus oryzae AS 3.819 | 1 M NaOH at 121 °C for 15 min + 2% acetate at 95 °C for 24 h | 3.7 | 0.09 | N/A | [105] | |

| Elm Wood | 85% H3PO4 at 60 ° for C 45 min + enzymatic | ND | Mucor indicus CCUG 22424 | 0.5 M NaOH at 121 °C for 20 min (alkali-insoluble material) | 3.3 | 0.06 | Determined as the amount of glucosamine | [106] |

| Pine Wood | 85% H3PO4 at 60 °C for 45 min + enzymatic | 6.9 | Mucor indicus CCUG 22424 | 0.5 M NaOH at 121 °C for 20 min (alkali-insoluble material) | 2.8 | 0.06 | ||

| Rice Straw | 85% H3PO4 at 60 °C for 45 min + enzymatic | ND | Mucor indicus CCUG 22424 | 0.5 M NaOH at 121 °C for 20 min (alkali-insoluble material) | 3.1 | 0.06 | ||

| Wheat Straw | NMMO * 120 °C 3 h + enzymatic | 19.8 | Mucor indicus CCUG 22424 | Autolysis + NaOH treatment + extraction | N/A | 0.13 | N-methylmorpholine -N-oxide | [137] |

| Biomass | Pretreatment | Hydrolysis | Strain | Productivity (g/L/h) | 2,3-BD Conc. (g/L) | Yield (%) | Ref. |

|---|---|---|---|---|---|---|---|

| Corn cob | 2% NaOH at 80 °C for 2 h | Enzymatic | Enterobacter cloacae CICC 10011 | 0.9 | N/A | 42 | [138] |

| Corn stover | 0.1 M NaOH at 80 °C | Enzymatic | Zymomonas mobilis | N/A | 10 | N/A | [114] |

| N/A | Enzymatic | Paenibacillus polymyxa | 1.1 | 18.8 | 31 | [139] | |

| N/A | N/A | Bacillus licheniformis | 2.3 | 119.4 | 95 | [112] | |

| Jerusalem Artichoke Stalk | 1% H2SO4 at 130 °C for 90 min | Enzymatic | Klebsiella pneumoniae | N/A | 80.5 | 16.8 | [111] |

| Oil Plan Frond | 3% NaOH at 121 °C for 20 min | Enzymatic | Enterobacter cloacae SG1 | 0.3 | 30.7 | N/A | [113] |

| Pine Tree | N/A | N/A | Klebsiella oxytoca CHA006 | 0.7 | 5.8 | 30 | [110] |

| Rice Straw | 0.375 M NaOH at 120 °C for 20 min | Enzymatic | Klebsiella sp. Zmd30 | 2.4 | N/A | 62 | [140] |

| Rice Waste | Na2CO3 + NaHCO3 + Na2SO4 at 100 °C for 3 h | Enzymatic | Klebsiella pneumoniae KMK-05 | 0.48 | 11.5 | 38.4 | [141] |

| Sorghum Stalk | 1.25% NaOH at 121 °C for 30 min | Enzymatic | Bacillus licheniformis DSM 8785 | 1 | N/A | 45 | [109] |

| Sugarcane Bagasse | 0.375 M NaOH at 120 °C for 20 min | Enzymatic | Klebsiella sp. Zmd30 | 0.7 | N/A | 15 | [140] |

| 10% NaOH at 90 °C for 90 min | Enzymatic | Klebsiella pneumoniae CGMCC 1.9131 | N/A | 9 | N/A | [142] | |

| 1% H2SO4 at 121 °C for 30 min | N/A | Enterobacter aerogenes EMY-22 | 0.8 | 66.4 | 42 | [110] | |

| 5% Na2CO3 + 5% Na2SO3 at 100 °C for 4 h | N/A | Enterobacter aerogenes EMY-22 | N/A | N/A | 39.5 | [143] | |

| Sunflower Stalk | N/A | N/A | Klebsiella oxytoca CHA006 | 0.8 | 4.3 | 34 | [110] |

| Wood | 24 N H2SO4 at 30 °C for 60 min + diluted acid at 105 °C for 60 min | N/A | Enterobacter aerogenes | N/A | 9.9 | N/A | [116] |

| N/A | N/A | Bacillus licheniformis DSM 8785 | 1.6 | N/A | 40 | [109] |

| Biomass | Hemicellulose (%) | Xylan (%) | Extraction/Pretreatment | Hydrolysis | XO Conc. (g/L) | Yield | Unit | Ref. |

|---|---|---|---|---|---|---|---|---|

| Barley Husk | N/A | 26.8 | N/A | Autohydrolysis at 220 °C for 0.75 h | N/A | 27.1 | % | [120] |

| Corn Cob | N/A | 30.6 | N/A | Non-isotherm autohydrolysis at 202 °C | N/A | 78.7 | gXOs/100 g xylan | [126] |

| 38.8 | N/A | 12% NaOH + steam at 121 °C for 45 min | 0.25 M H2SO4 at 90 °C for 60 h | 0.9 | N/A | N/A | [144] | |

| 38.9 | N/A | 4–16% NaOH + steam at 121 °C for 45 min | Enzymatic at 40.9–41.4 °C for 16.6–17.3 h | <2.0 | N/A | N/A | [145] | |

| N/A | N/A | 1.25 M NaOH at 37 °C for 180 min | Enzymatic at 45 °C for 8 h | 6.7 | 60 | % | [124] | |

| N/A | 31.3 | N/A | Autohydrolysis at 220 °C for 0.75 h | N/A | 24.8 | % | [120] | |

| N/A | 31.9 | 2% NaOH at 20 °C for 6 h | Enzymatic at 50 °C for 24–36 h | 8.2 | 86.7 | % | [125] | |

| N/A | 34.8 | 1.0 g/L H2SO4 + steam at 135 °C for 30 min | Enzymatic at 50 °C for 24 h | N/A | 67.7 | gXOs/100 g xylan | [127] | |

| Eucalyptus Wood | N/A | 16.6 | N/A | Autohydrolysis at 220 °C for 0.75 h | N/A | 15.4 | % | [120] |

| Maize Silage | 35.1 | N/A | 1 M NaOH + steam at 121 °C for 15 min | Enzymatic at 50 °C for 24 h | 3.5 | N/A | N/A | [117] |

| Oil Palm Frond | 30.4 | N/A | Steam at 121 °C for 60 min | Enzymatic at 40 °C for 24 h | N/A | 17.5 | w/w% | [146] |

| Reed | N/A | 21.2 | Steam at 170 °C for 30 min | Enzymatic at 50 °C for 48 h | N/A | 68.1 | gXOs/100 g xylan | [147] |

| Rice Husk | N/A | 15.6 | N/A | Autohydrolysis at 220 °C for 0.75 h | N/A | 18 | % | [120] |

| 25 | N/A | 18% NaOH + steam at 120 °C for 45 min | Enzymatic at 50 °C for 9 h | N/A | 34.7 | gXOs/100 g xylan | [148] | |

| 11.2 | N/A | N/A | Enzymatic at 50 °C for 24 h | N/A | 69 | gXOs/100 g xylan | [122] | |

| Ryegrass Silage | 36.6 | N/A | 1 M NaOH + steam at 121 °C for 15 min | Enzymatic at 50 °C for 24 h | 2.4 | N/A | N/A | [117] |

| Sugar Cane Bagasse | N/A | 20.6 | Aqueous ammonia + steam at 121 °C for 30 min | Enzymatic at 50 °C for 30 h | N/A | >99 | % | [123] |

| N/A | N/A | N/A | 0.1% H2SO4 at 140 °C for 1 h | N/A | 92.28 | gXOs/100 g xylan | [121] | |

| N/A | N/A | 6% Alkaline peroxide at 20 °C for 180 min | Enzymatic at 50 °C for 96 h | N/A | 31.5 | % | [149] | |

| N/A | N/A | 10% Acetic acid + steam at 150 °C for 45 min | Enzymatic at 30 °C for 1.25 h | N/A | 39.1 | gXOs/100 g xylan | [150] | |

| 23.2 | N/A | 12% NaOH + steam at 121 °C for 15 min | Enzymatic at 40 °C for 8 h | 1.72 | N/A | N/A | [151] | |

| Sunflower Stalk | N/A | 18.9 | 24% KOH at 35 °C for 120 min | Enzymatic at 40 °C for 24 h | 3.2 | N/A | N/A | [152] |

| N/A | 19.1 | 24% KOH at 35 °C for 120 min | 0.25 M H2SO4 at 100 °C for 30 h | N/A | 12.6 | gXOs/100 g xylan | [119] | |

| Wheat Straw | N/A | 20.6 | 24% KOH at 35 °C for 120 min | Enzymatic 4 at 0 °C for 24 h | 2.3 | N/A | N/A | [152] |

| N/A | 20.9 | 24% KOH at 35 °C for 120 min | 0.25 M H2SO4 at 100 °C for 30 h | N/A | 10.2 | gXOs/100 g xylan | [119] | |

| N/A | N/A | 2% NaOH at 80 °C for 90 min | Enzymatic at 60 °C for 15 h | N/A | 39.8 | gXOs/100 g xylan | [153] |

4. Extraction Methods

4.1. Hansen Solubility Parameters

4.2. Solvent Extraction

4.3. Subcritical Water Extraction

4.4. Extraction at Varying pH Values

4.5. Ultrasound Extraction

4.6. Enzymatic Extraction

5. Isolation and Purification Methods

5.1. Membrane Filtration

5.2. Liquid–Liquid Extraction

5.3. Purification Using Preparative-HPLC

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dutta, K.; Daverey, A.; Lin, J.G. Evolution Retrospective for Alternative Fuels: First to Fourth Generation. Renew. Energy 2014, 69, 114–122. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H. Principles of Biorefining. In Biofuels: Alternative Feedstocks and Conversion Processes; Pandey, A., Larroche, C., Ricke, S.C., Dussap, C.-G., Gnansounou, E., Dussap, C.-G., Eds.; Academic Press: Cambridge, MA, USA, 2011; pp. 3–24. ISBN 9780123850997. [Google Scholar]

- Cherubini, F.; Jungmeier, G.; Wellisch, M.; Willke, T.; Skiadas, I.; Van Ree, R.; de Jong, E. Toward a Common Classification Approach for Biorefinery Systems. Biofuels Bioprod. Biorefining 2009, 3, 534–546. [Google Scholar] [CrossRef]

- Henrich, E.; Dahmen, N.; Dinjus, E. Cost Estimate for Biosynfuel Production via Biosyncrude Gasification. Biofuels, Bioprod. Biorefining 2009, 3, 28–41. [Google Scholar] [CrossRef]

- Werpy, T.; Petersen, G. Top Value Added Chemicals from Biomass Volume I—Results of Screening for Potential Candidates from Sugars and Synthesis Gas; U.S. Department of Energy: Washington, DC, USA, 2004; Volume 1. [Google Scholar]

- Holladay, J.E.; White, J.F.; Bozell, J.J.; Johnson, D. Top Value Added Chemicals from Biomass-Volume II, Results of Screening for Potential Candidates from Biorefinery Lignin; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2007; Volume 2. [Google Scholar]

- Choi, S.; Song, C.W.; Shin, J.H.; Lee, S.Y. Biorefineries for the Production of Top Building Block Chemicals and Their Derivatives. Metab. Eng. 2015, 28, 223–239. [Google Scholar] [CrossRef]

- Girisuta, B. Levulinic Acid from Lignocellulosic Biomass. Ph.D. Thesis, University of Gronigen, Groningen, The Netherlands, 2007. [Google Scholar]

- Rackemann, D.W.; Doherty, W.O.S. The Conversion of Lignocellulosics to Levulinic Acid. Biofuels Bioprod. Biorefining 2011, 5, 198–214. [Google Scholar] [CrossRef]

- Fitzpatrick, S.W. Production of Levulinic Acid from Carbohydrate-Containing Materials. U.S. Patent 5,608,105, 4 March 1997. [Google Scholar]

- Chang, C.; Cen, P.; Ma, X. Levulinic Acid Production from Wheat Straw. Bioresour. Technol. 2007, 98, 1448–1453. [Google Scholar] [CrossRef]

- Yan, L.; Yang, N.; Pang, H.; Liao, B. Production of Levulinic Acid from Bagasse and Paddy Straw by Liquefaction in the Presence of Hydrochloride Acid. CLEAN–Soil Air Water 2008, 36, 158–163. [Google Scholar] [CrossRef]

- Efremov, A.A.; Pervyshina, G.G.; Kuznetsov, B.N. Production of Levulinic Acid from Wood Raw Material in the Presence of Sulfuric Acid and Its Salts. Chem. Nat. Compd. 1998, 34, 182–185. [Google Scholar] [CrossRef]

- Binder, J.B.; Raines, R.T. Fermentable Sugars by Chemical Hydrolysis of Biomass. Proc. Natl. Acad. Sci. USA 2010, 107, 4516–4521. [Google Scholar] [CrossRef]

- Sah, P.P.T.; Ma, S.-Y. Levulinic Acid and Its Esters. J. Am. Chem. Soc. 1930, 52, 4880–4883. [Google Scholar] [CrossRef]

- Thomas, R.W.; Schuette, H.A. Studies on Levulinic Acid. I. Its Preparation from Carbohydrates by Digestion with Hydrochloric Acid under Pressure. J. Am. Chem. Soc. 1931, 53, 2324–2328. [Google Scholar] [CrossRef]

- Redmon, B.C. Process for the Production of Levulinic Acid. U.S. Patent 2,738,367, 13 March 1956. [Google Scholar]

- McKibbins, S.W. Kinetics of the Acid Catalyzed Conversion of Glucose to 5-Hydroxymethyl-2-Furaldehyde and Levulinic Acid; The University of Wisconsin-Madison: Madison, WI, USA, 1958; ISBN 1084403552. [Google Scholar]

- Carlson, L.J. Process for the Manufacture of Levulinic Acid. U.S. Patent 3,065,263, 20 November 1962. [Google Scholar]

- Lourvanij, K.; Rorrer, G.L. Dehydration of Glucose to Organic Acids in Microporous Pillared Clay Catalysts. Appl. Catal. A Gen. 1994, 109, 147–165. [Google Scholar] [CrossRef]

- Lourvanij, K.; Rorrer, G.L. Reaction Rates for the Partial Dehydration of Glucose to Organic Acids in Solid-acid, Molecular-sieving Catalyst Powders. J. Chem. Technol. Biotechnol. Int. Res. Process. Environ. Clean Technol. 1997, 69, 35–44. [Google Scholar] [CrossRef]

- Sumiki, Y. Levulinic Acid. Japanese Patent 176,438, 30 June 1948. [Google Scholar]

- Sassenrath, C.P.; Shilling, W.L. Preparation of Levulinic Acid from Hexose-Containing Material. U.S. Patent 3,258,481, 28 June 1966. [Google Scholar]

- Kin, Z.; Stawecka, J. Use of Waste Lignocellulose for the Production of Levulinic Acid. Prz. Pap. 1968, 303–306. [Google Scholar]

- Efremov, A.A.; Pervyshina, G.G.; Kuznetsov, B.N. Thermocatalytic Transformations of Wood and Cellulose in the Presence of HCl, HBr, and H2SO4. Chem. Nat. Compd. 1997, 33, 84–88. [Google Scholar] [CrossRef]

- Abdel-Rahman, M.A.; Tashiro, Y.; Sonomoto, K. Lactic Acid Production from Lignocellulose-Derived Sugars Using Lactic Acid Bacteria: Overview and Limits. J. Biotechnol. 2011, 156, 286–301. [Google Scholar] [CrossRef]

- Wee, Y.-J.; Yun, J.-S.; Park, D.-H.; Ryu, H.-W. Biotechnological Production of L (+)-Lactic Acid from Wood Hydrolyzate by Batch Fermentation of Enterococcus Faecalis. Biotechnol. Lett. 2004, 26, 71–74. [Google Scholar] [CrossRef]

- Guo, W.; Jia, W.; Li, Y.; Chen, S. Performances of Lactobacillus Brevis for Producing Lactic Acid from Hydrolysate of Lignocellulosics. Appl. Biochem. Biotechnol. 2010, 161, 124–136. [Google Scholar] [CrossRef]

- Shen, X.; Xia, L. Lactic Acid Production from Cellulosic Material by Synergetic Hydrolysis and Fermentation. Appl. Biochem. Biotechnol. 2006, 133, 251–262. [Google Scholar] [CrossRef]

- Moldes, A.B.; Torrado, A.; Converti, A.; Dominguez, J.M. Complete Bioconversion of Hemicellulosic Sugars from Agricultural Residues into Lactic Acid by Lactobacillus Pentosus. Appl. Biochem. Biotechnol. 2006, 135, 219–227. [Google Scholar] [CrossRef]

- Zhu, Y.; Lee, Y.Y.; Elander, R.T. Conversion of Aqueous Ammonia-Treated Corn Stover to Lactic Acid by Simultaneous Saccharification and Cofermentation. Appl. Biochem. Biotechnol. 2007, 137, 721–738. [Google Scholar] [PubMed]

- Cui, F.; Li, Y.; Wan, C. Lactic Acid Production from Corn Stover Using Mixed Cultures of Lactobacillus Rhamnosus and Lactobacillus Brevis. Bioresour. Technol. 2011, 102, 1831–1836. [Google Scholar] [CrossRef] [PubMed]

- Garde, A.; Jonsson, G.; Schmidt, A.S.; Ahring, B.K. Lactic Acid Production from Wheat Straw Hemicellulose Hydrolysate by Lactobacillus Pentosus and Lactobacillus Brevis. Bioresour. Technol. 2002, 81, 217–223. [Google Scholar] [CrossRef]

- Iyer, P.V.; Thomas, S.; Lee, Y.Y. High-Yield Fermentation of Pentoses into Lactic Acid. In Proceedings of the Twenty-First Symposium on Biotechnology for Fuels and Chemicals, Fort Collins, CO, USA, 2–6 May 1999; Walt, D.R., Ed.; Springer: Berlin/Heidelberg, Germany, 2000; pp. 665–677. [Google Scholar]

- Adsul, M.; Khire, J.; Bastawde, K.; Gokhale, D. Production of Lactic Acid from Cellobiose and Cellotriose by Lactobacillus Delbrueckii Mutant Uc-3. Appl. Environ. Microbiol. 2007, 73, 5055–5057. [Google Scholar] [CrossRef] [PubMed]

- Laopaiboon, P.; Thani, A.; Leelavatcharamas, V.; Laopaiboon, L. Acid Hydrolysis of Sugarcane Bagasse for Lactic Acid Production. Bioresour. Technol. 2010, 101, 1036–1043. [Google Scholar] [CrossRef]

- Yun, J.-S.; Wee, Y.-J.; Kim, J.-N.; Ryu, H.-W. Fermentative Production of Dl-Lactic Acid from Amylase-Treated Rice and Wheat Brans Hydrolyzate by a Novel Lactic Acid Bacterium, Lactobacillus sp. Biotechnol. Lett. 2004, 26, 1613–1616. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Fernandes, M.; Mancilha, I.M.; Roberto, I.C. Effects of Medium Supplementation and PH Control on Lactic Acid Production from Brewer’s Spent Grain. Biochem. Eng. J. 2008, 40, 437–444. [Google Scholar] [CrossRef]

- Kumar, V.; Ashok, S.; Park, S. Recent Advances in Biological Production of 3-Hydroxypropionic Acid. Biotechnol. Adv. 2013, 31, 945–961. [Google Scholar] [CrossRef]

- Matsakas, L.; Hrůzová, K.; Rova, U.; Christakopoulos, P. Biological Production of 3-Hydroxypropionic Acid: An Update on the Current Status. Fermentation 2018, 4, 13. [Google Scholar] [CrossRef]

- Kildegaard, K.R.; Jensen, N.B.; Schneider, K.; Czarnotta, E.; Özdemir, E.; Klein, T.; Maury, J.; Ebert, B.E.; Christensen, H.B.; Chen, Y.; et al. Engineering and Systems-Level Analysis of Saccharomyces Cerevisiae for Production of 3-Hydroxypropionic Acid via Malonyl-CoA Reductase-Dependent Pathway. Microb. Cell Factories 2016, 15, 1–13. [Google Scholar] [CrossRef]

- Borodina, I.; Kildegaard, K.R.; Jensen, N.B.; Blicher, T.H.; Maury, J.; Sherstyk, S.; Schneider, K.; Lamosa, P.; Herrgård, M.J.; Rosenstand, I.; et al. Establishing a Synthetic Pathway for High-Level Production of 3-Hydroxypropionic Acid in Saccharomyces Cerevisiae via β-Alanine. Metab. Eng. 2015, 27, 57–64. [Google Scholar] [CrossRef] [Green Version]

- Kildegaard, K.R.; Wang, Z.; Chen, Y.; Nielsen, J.; Borodina, I. Production of 3-Hydroxypropionic Acid from Glucose and Xylose by Metabolically Engineered Saccharomyces Cerevisiae. Metab. Eng. Commun. 2015, 2, 132–136. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Z.; Jiang, J.; Wu, H.; Li, Z.; Ye, Q. Enhanced Production of 3-Hydroxypropionic Acid from Glucose via Malonyl-CoA Pathway by Engineered Escherichia coli. Bioresour. Technol. 2016, 200, 897–904. [Google Scholar] [CrossRef]

- Liu, C.; Ding, Y.; Zhang, R.; Liu, H.; Xian, M.; Zhao, G. Functional Balance between Enzymes in Malonyl-CoA Pathway for 3-Hydroxypropionate Biosynthesis. Metab. Eng. 2016, 34, 104–111. [Google Scholar] [CrossRef]

- Jung, I.Y.; Lee, J.W.; Min, W.K.; Park, Y.C.; Seo, J.H. Simultaneous Conversion of Glucose and Xylose to 3-Hydroxypropionic Acid in Engineered Escherichia coli by Modulation of Sugar Transport and Glycerol Synthesis. Bioresour. Technol. 2015, 198, 709–716. [Google Scholar] [CrossRef]

- Suyama, A.; Higuchi, Y.; Urushihara, M.; Maeda, Y.; Takegawa, K. Production of 3-Hydroxypropionic Acid via the Malonyl-CoA Pathway Using Recombinant Fission Yeast Strains. J. Biosci. Bioeng. 2017, 124, 392–399. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, J.; Wu, Y.; Wu, W.; Zhang, Y.; Liu, D. Metabolic Engineering of Corynebacterium Glutamicum for the Production of 3-Hydroxypropionic Acid from Glucose and Xylose. Metab. Eng. 2017, 39, 151–158. [Google Scholar] [CrossRef]

- Su, M.; Li, Y.; Ge, X.; Tian, P. 3-Hydroxypropionaldehyde-Specific Aldehyde Dehydrogenase from Bacillus Subtilis Catalyzes 3-Hydroxypropionic Acid Production in Klebsiella Pneumoniae. Biotechnol. Lett. 2014, 37, 717–724. [Google Scholar] [CrossRef]

- Huang, Y.; Li, Z.; Shimizu, K.; Ye, Q. Co-Production of 3-Hydroxypropionic Acid and 1,3-Propanediol by Klebseilla Pneumoniae Expressing AldH under Microaerobic Conditions. Bioresour. Technol. 2013, 128, 505–512. [Google Scholar] [CrossRef] [PubMed]

- Ko, Y.; Seol, E.; Sundara Sekar, B.; Kwon, S.; Lee, J.; Park, S. Metabolic Engineering of Klebsiella Pneumoniae J2B for Co-Production of 3-Hydroxypropionic Acid and 1,3-Propanediol from Glycerol: Reduction of Acetate and Other by-Products. Bioresour. Technol. 2017, 244, 1096–1103. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Ge, X.; Tian, P. High Production of 3-Hydroxypropionic Acid in Klebsiella Pneumoniae by Systematic Optimization of Glycerol Metabolism. Sci. Reports 2016, 6, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Tian, P. Engineering Plasmid-Free Klebsiella Pneumoniae for Production of 3-Hydroxypropionic Acid. Curr. Microbiol. 2016, 74, 55–58. [Google Scholar] [CrossRef]

- Ko, Y.; Ashok, S.; Zhou, S.; Kumar, V.; Park, S. Aldehyde Dehydrogenase Activity Is Important to the Production of 3-Hydroxypropionic Acid from Glycerol by Recombinant Klebsiella Pneumoniae. Process Biochem. 2012, 47, 1135–1143. [Google Scholar] [CrossRef]

- Kumar, V.; Sankaranarayanan, M.; Jae, K.; Durgapal, M.; Ashok, S.; Ko, Y.; Sarkar, R.; Park, S. Co-Production of 3-Hydroxypropionic Acid and 1,3-Propanediol from Glycerol Using Resting Cells of Recombinant Klebsiella Pneumoniae J2B Strain Overexpressing Aldehyde Dehydrogenase. Appl. Microbiol. Biotechnol. 2012, 96, 373–383. [Google Scholar] [CrossRef]

- Kumar, V.; Sankaranarayanan, M.; Durgapal, M.; Shengfang, Z.; Yeounjoo, K.; Ashok, S.; Sarkar, R.; Park, S. Simultaneous Production of 3-Hydroxypropionic Acid and 1,3-Propanediol from Glycerol Using Resting Cells of the Lactate Dehydrogenase-Deficient Recombinant Klebsiella Pneumoniae Overexpressing an Aldehyde Dehydrogenase. Bioresour. Technol. 2013, 135, 555–563. [Google Scholar] [CrossRef]

- Ashok, S.; Raj, S.M.; Rathnasingh, C.; Park, S. Development of Recombinant Klebsiella Pneumoniae ∆dhaT Strain for the Co-Production of 3-Hydroxypropionic Acid and 1,3-Propanediol from Glycerol. Appl. Microbiol. Biotechnol. 2011, 90, 1253–1265. [Google Scholar] [CrossRef]

- Ashok, S.; Sankaranarayanan, M.; Ko, Y.; Jae, K.-E.; Ainala, S.K.; Kumar, V.; Park, S. Production of 3-Hydroxypropionic Acid from Glycerol by Recombinant Klebsiella Pneumoniae ΔdhaTΔyqhD Which Can Produce Vitamin B12 Naturally. Biotechnol. Bioeng. 2013, 110, 511–524. [Google Scholar] [CrossRef]

- Zhao, L.; Lin, J.; Wang, H.; Xie, J.; Wei, D. Development of a Two-Step Process for Production of 3-Hydroxypropionic Acid from Glycerol Using Klebsiella Pneumoniae and Gluconobacter Oxydans. Bioprocess Biosyst. Eng. 2015, 38, 2487–2495. [Google Scholar] [CrossRef]

- Jung, W.S.; Kang, J.H.; Chu, H.S.; Choi, I.S.; Cho, K.M. Elevated Production of 3-Hydroxypropionic Acid by Metabolic Engineering of the Glycerol Metabolism in Escherichia coli. Metab. Eng. 2014, 23, 116–122. [Google Scholar] [CrossRef]

- Chu, H.S.; Kim, Y.S.; Lee, C.M.; Lee, J.H.; Jung, W.S.; Ahn, J.-H.; Song, S.H.; Choi, I.S.; Cho, K.M. Metabolic Engineering of 3-Hydroxypropionic Acid Biosynthesis in Escherichia coli. Biotechnol. Bioeng. 2015, 112, 356–364. [Google Scholar] [CrossRef]

- Lim, H.G.; Noh, M.H.; Jeong, J.H.; Park, S.; Jung, G.Y. Optimum Rebalancing of the 3-Hydroxypropionic Acid Production Pathway from Glycerol in Escherichia coli. ACS Synth. Biol. 2016, 5, 1247–1255. [Google Scholar] [CrossRef] [PubMed]

- Sankaranarayanan, M.; Somasundar, A.; Seol, E.; Chauhan, A.S.; Kwon, S.; Jung, G.Y.; Park, S. Production of 3-Hydroxypropionic Acid by Balancing the Pathway Enzymes Using Synthetic Cassette Architecture. J. Biotechnol. 2017, 259, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Sankaranarayanan, M.; Ashok, S.; Park, S. Production of 3-Hydroxypropionic Acid from Glycerol by Acid Tolerant Escherichia Coli. J. Ind. Microbiol. Biotechnol. 2014, 41, 1039–1050. [Google Scholar] [CrossRef] [PubMed]

- Raj, S.M.; Rathnasingh, C.; Jung, W.-C.; Park, S. Effect of Process Parameters on 3-Hydroxypropionic Acid Production from Glycerol Using a Recombinant Escherichia coli. Appl. Microbiol. Biotechnol. 2009, 84, 649–657. [Google Scholar] [CrossRef]

- Rathnasingh, C.; Raj, S.M.; Jo, J.-E.; Park, S. Development and Evaluation of Efficient Recombinant Escherichia Coli Strains for the Production of 3-Hydroxypropionic Acid from Glycerol. Biotechnol. Bioeng. 2009, 104, 729–739. [Google Scholar] [CrossRef]

- Tsuruno, K.; Honjo, H.; Hanai, T. Enhancement of 3-Hydroxypropionic Acid Production from Glycerol by Using a Metabolic Toggle Switch. Microb. Cell Factories 2015, 14, 1–14. [Google Scholar] [CrossRef]

- Honjo, H.; Tsuruno, K.; Tatsuke, T.; Sato, M.; Hanai, T. Dual Synthetic Pathway for 3-Hydroxypropionic Acid Production in Engineered Escherichia coli. J. Biosci. Bioeng. 2015, 120, 199–204. [Google Scholar] [CrossRef]

- Dishisha, T.; Pereyra, L.P.; Pyo, S.-H.; Britton, R.A.; Hatti-Kaul, R. Flux Analysis of the Lactobacillus Reuteri Propanediol-Utilization Pathway for Production of 3-Hydroxypropionaldehyde, 3-Hydroxypropionic Acid and 1,3-Propanediol from Glycerol. Microb. Cell Fact. 2014, 13, 1–11. [Google Scholar] [CrossRef]

- Zaushitsyna, O.; Dishisha, T.; Hatti-Kaul, R.; Mattiasson, B. Crosslinked, Cryostructured Lactobacillus Reuteri Monoliths for Production of 3-Hydroxypropionaldehyde, 3-Hydroxypropionic Acid and 1,3-Propanediol from Glycerol. J. Biotechnol. 2017, 241, 22–32. [Google Scholar] [CrossRef]

- Garai-Ibabe, G.; Ibarburu, I.; Berregi, I.; Claisse, O.; Lonvaud-Funel, A.; Irastorza, A.; Dueñas, M.T. Glycerol Metabolism and Bitterness Producing Lactic Acid Bacteria in Cidermaking. Int. J. Food Microbiol. 2008, 121, 253–261. [Google Scholar] [CrossRef]

- Kaur, B.; Chakraborty, D. Biotechnological and Molecular Approaches for Vanillin Production: A Review. Appl. Biochem. Biotechnol. 2013, 169, 1353–1372. [Google Scholar] [CrossRef] [PubMed]

- Kruyer, N.S.; Peralta-Yahya, P. Metabolic Engineering Strategies to Bio-Adipic Acid Production. Curr. Opin. Biotechnol. 2017, 45, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Polen, T.; Spelberg, M.; Bott, M. Toward Biotechnological Production of Adipic Acid and Precursors from Biorenewables. J. Biotechnol. 2013, 167, 75–84. [Google Scholar] [CrossRef]

- Steinbach, D.; Kruse, A.; Sauer, J. Pretreatment Technologies of Lignocellulosic Biomass in Water in View of Furfural and 5-Hydroxymethylfurfural Production—A Review. Biomass Convers. Biorefinery 2017, 7, 247–274. [Google Scholar] [CrossRef]

- Zeitsch, K.J. The Chemistry and Technology of Furfural and Its Many by-Products; Elsevier: Amsterdam, The Netherlands, 2000; ISBN 0080528996. [Google Scholar]

- Ji, L.; Tang, Z.; Yang, D.; Ma, C.; He, Y.-C. Improved One-Pot Synthesis of Furfural from Corn Stalk with Heterogeneous Catalysis Using Corn Stalk as Biobased Carrier in Deep Eutectic Solvent–Water System. Bioresour. Technol. 2021, 340, 125691. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S.; Lee, J.; Won, W. Simultaneous Production of 1,6-Hexanediol, Furfural, and High-Purity Lignin from White Birch: Process Integration and Techno-Economic Evaluation. Bioresour. Technol. 2021, 331, 125009. [Google Scholar] [CrossRef]

- Bozell, J.J.; Petersen, G.R. Technology Development for the Production of Biobased Products from Biorefinery Carbohydrates—the US Department of Energy’s “Top 10” Revisited. Green Chem. 2010, 12, 539. [Google Scholar] [CrossRef]

- Du, B.; Sharma, L.N.; Becker, C.; Chen, S.-F.; Mowery, R.A.; van Walsum, G.P.; Chambliss, C.K. Effect of Varying Feedstock–Pretreatment Chemistry Combinations on the Formation and Accumulation of Potentially Inhibitory Degradation Products in Biomass Hydrolysates. Biotechnol. Bioeng. 2010, 107, 430–440. [Google Scholar] [CrossRef]

- Chundawat, S.P.S.; Vismeh, R.; Sharma, L.N.; Humpula, J.F.; da Costa Sousa, L.; Chambliss, C.K.; Jones, A.D.; Balan, V.; Dale, B.E. Multifaceted Characterization of Cell Wall Decomposition Products Formed during Ammonia Fiber Expansion (AFEX) and Dilute Acid Based Pretreatments. Bioresour. Technol. 2010, 101, 8429–8438. [Google Scholar] [CrossRef]

- Chen, S.F.; Mowery, R.A.; Castleberry, V.A.; Van Walsum, G.P.; Chambliss, C.K. High-Performance Liquid Chromatography Method for Simultaneous Determination of Aliphatic Acid, Aromatic Acid and Neutral Degradation Products in Biomass Pretreatment Hydrolysates. J. Chromatogr. A 2006, 1104, 54–61. [Google Scholar] [CrossRef]

- Cantarella, M.; Cantarella, L.; Gallifuoco, A.; Spera, A.; Alfani, F. Effect of Inhibitors Released during Steam-Explosion Treatment of Poplar Wood on Subsequent Enzymatic Hydrolysis and SSF. Biotechnol. Prog. 2004, 20, 200–206. [Google Scholar] [CrossRef]

- Larsson, S.; Reimann, A.; Nilvebrant, N.-O.; Jönsson, L.J. Comparison of Different Methods for the Detoxification of Lignocellulose Hydrolyzates of Spruce. Larssonal. Appl. Biochem. Biotechnol. 1999, 77, 77–79. [Google Scholar]

- Klinke, H.B.; Ahring, B.K.; Schmidt, A.S.; Thomsen, A.B. Characterization of Degradation Products from Alkaline Wet Oxidation of Wheat Straw. Bioresour. Technol. 2002, 82, 15–26. [Google Scholar] [CrossRef]

- García-Aparicio, M.P.; Ballesteros, I.; González, A.; Oliva, J.M.; Ballesteros, M.; Negro, M.J. Effect of Inhibitors Released During Steam-Explosion Pretreatment of Barley Straw on Enzymatic Hydrolysis. Twenty-Seventh Symp. Biotechnol. Fuels Chem. 2006, 129, 278–288. [Google Scholar] [CrossRef]

- van der Pol, E.C.; Bakker, R.R.; Baets, P.; Eggink, G. By-Products Resulting from Lignocellulose Pretreatment and Their Inhibitory Effect on Fermentations for (Bio) Chemicals and Fuels. Appl. Microbiol. Biotechnol. 2014, 98, 9579–9593. [Google Scholar] [CrossRef]

- Banerjee, A.; Dick, G.R.; Yoshino, T.; Kanan, M.W. Carbon Dioxide Utilization via Carbonate-Promoted C-H Carboxylation. Nature 2016, 531, 215–219. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, H.; Wang, X.; Liu, Y. Convergent Production of 2,5-Furandicarboxylic Acid from Biomass and CO2. Green Chem. 2019, 21, 2923–2927. [Google Scholar] [CrossRef]

- Boisen, A.; Christensen, T.B.; Fu, W.; Gorbanev, Y.Y.; Hansen, T.S.; Jensen, J.S.; Klitgaard, S.K.; Pedersen, S.; Riisager, A.; Ståhlberg, T.; et al. Process Integration for the Conversion of Glucose to 2,5-Furandicarboxylic Acid. Chem. Eng. Res. Des. 2009, 87, 1318–1327. [Google Scholar] [CrossRef]

- Deshan, A.D.K.; Atanda, L.; Moghaddam, L.; Rackemann, D.W.; Beltramini, J.; Doherty, W.O.S. Heterogeneous Catalytic Conversion of Sugars Into 2,5-Furandicarboxylic Acid. Front. Chem. 2020, 8, 659. [Google Scholar] [CrossRef] [PubMed]

- Motagamwala, A.H.; Won, W.; Sener, C.; Alonso, D.M.; Maravelias, C.T.; Dumesic, J.A. Toward Biomass-Derived Renewable Plastics: Production of 2,5-Furandicarboxylic Acid from Fructose. Sci. Adv. 2018, 4, eaap9722. [Google Scholar] [CrossRef]

- Yang, Z.; Qi, W.; Su, R.; He, Z. Selective Synthesis of 2,5-Diformylfuran and 2,5-Furandicarboxylic Acid from 5-Hydroxymethylfurfural and Fructose Catalyzed by Magnetically Separable Catalysts. Energy Fuels 2017, 31, 533–541. [Google Scholar] [CrossRef]

- Yangyang, J.Z.; Zhou, F.; Ma, H.X.; Li, X.L.; Yuan, X.Z.; Liang, F.X.; Zhang, J. One Step Synthesis of 2,5-Furandicarboxylic Acid from Fructose Catalyzed by Ce Modified Ru/HAP. Ranliao Huaxue Xuebao/J. Fuel Chem. Technol. 2020, 48, 942–948. [Google Scholar] [CrossRef]

- Rathod, P.V.; Jadhav, V.H. Efficient Method for Synthesis of 2,5-Furandicarboxylic Acid from 5-Hydroxymethylfurfural and Fructose Using Pd/CC Catalyst under Aqueous Conditions. ACS Sustain. Chem. Eng. 2018, 6, 5766–5771. [Google Scholar] [CrossRef]

- Karich, A.; Kleeberg, S.; Ullrich, R.; Hofrichter, M. Enzymatic Preparation of 2,5-Furandicarboxylic Acid (FDCA)—A Substitute of Terephthalic Acid—By the Joined Action of Three Fungal Enzymes. Microorganisms 2018, 6, 5. [Google Scholar] [CrossRef] [PubMed]

- Hayashi, E.; Yamaguchi, Y.; Kamata, K.; Tsunoda, N.; Kumagai, Y.; Oba, F.; Hara, M. Effect of MnO2 Crystal Structure on Aerobic Oxidation of 5-Hydroxymethylfurfural to 2,5-Furandicarboxylic Acid. J. Am. Chem. Soc. 2019, 141, 899–900. [Google Scholar] [CrossRef] [PubMed]

- Casanova, O.; Iborra, S.; Corma, A. Biomass into Chemicals: Aerobic Oxidation of 5-Hydroxymethyl-2-Furfural into 2,5-Furandicarboxylic Acid with Gold Nanoparticle Catalysts. ChemSusChem 2009, 2, 1138–1144. [Google Scholar] [CrossRef]

- Mishra, D.K.; Lee, H.J.; Kim, J.; Lee, H.S.; Cho, J.K.; Suh, Y.W.; Yi, Y.; Kim, Y.J. MnCo2O4 Spinel Supported Ruthenium Catalyst for Air-Oxidation of HMF to FDCA under Aqueous Phase and Base-Free Conditions. Green Chem. 2017, 19, 1619–1623. [Google Scholar] [CrossRef]

- Venkateswar Rao, L.; Goli, J.K.; Gentela, J.; Koti, S. Bioconversion of Lignocellulosic Biomass to Xylitol: An Overview. Bioresour. Technol. 2016, 213, 299–310. [Google Scholar] [CrossRef]

- Insights, G.M. Alkyl Polyglucosides (APG) Biosurfactants Biosurfactants Market Size. 2022. Available online: https://www.Gminsights.Com/Industry-Analysis/Alkyl-Polyglucosides-Apg-Biosurfactants-Market (accessed on 10 July 2016).

- Delgado Arcaño, Y.; Valmaña García, O.D.; Mandelli, D.; Carvalho, W.A.; Magalhães Pontes, L.A. Xylitol: A Review on the Progress and Challenges of Its Production by Chemical Route. Catal. Today 2020, 344, 2–14. [Google Scholar] [CrossRef]

- Ikeuchi, T.; Azuma, M.; Kato, J.; Ooshima, H. Screening of Microorganisms for Xylitol Production and Fermentation Behavior in High Concentrations of Xylose. Biomass Bioenergy 1999, 16, 333–339. [Google Scholar] [CrossRef]

- Tai, C.; Li, S.; Xu, Q.; Ying, H.; Huang, H.; Ouyang, P. Chitosan Production from Hemicellulose Hydrolysate of Corn Straw: Impact of Degradation Products on Rhizopus Oryzae Growth and Chitosan Fermentation. Lett. Appl. Microbiol. 2010, 51, 278–284. [Google Scholar] [CrossRef]

- Yang, L.; Li, X.; Lai, C.; Fan, Y.; Ouyang, J.; Yong, Q. Fungal Chitosan Production Using Xylose Rich of Corn Stover Prehydrolysate by Rhizopus oryzae. Biotechnol. Biotechnol. Equip. 2017, 31, 1160–1166. [Google Scholar] [CrossRef] [Green Version]

- Satari, B.; Karimi, K.; Zamani, A. Oil, Chitosan, and Ethanol Production by Dimorphic Fungus Mucor Indicus from Different Lignocelluloses. J. Chem. Technol. Biotechnol. 2016, 91, 1835–1843. [Google Scholar] [CrossRef]

- Omogbai, B.A.; Ikenebomeh, M. Solid-State Fermentative Production and Bioactivity of Fungal Chitosan. J. Microbiol. Biotechnol. Food Sci. 2013, 3, 172–175. [Google Scholar]

- Cybulska, I.; Chaturvedi, T.; Thomsen, M.H. Lignocellulosic Thermochemical Pretreatment Processes. In Biorefinery; Bastidas-Oyanedel, J.R., Schmidt, J., Eds.; Springer: Cham, Switzerland, 2019; pp. 153–165. [Google Scholar]

- Guragain, Y.N.; Chitta, D.; Karanjikar, M.; Vadlani, P.V. Appropriate Lignocellulosic Biomass Processing Strategies for Efficient 2,3-Butanediol Production from Biomass-Derived Sugars Using Bacillus Licheniformis DSM 8785. Food Bioprod. Process. 2017, 104, 147–158. [Google Scholar] [CrossRef]

- Cha, J.W.; Jang, S.H.; Kim, Y.J.; Chang, Y.K.; Jeong, K.J. Engineering of Klebsiella oxytoca for Production of 2,3-butanediol Using Mixed Sugars Derived from Lignocellulosic Hydrolysates. GCB Bioenergy 2020, 12, 275–286. [Google Scholar] [CrossRef]

- Li, D.; Dai, J.Y.; Xiu, Z.L. A Novel Strategy for Integrated Utilization of Jerusalem Artichoke Stalk and Tuber for Production of 2,3-Butanediol by Klebsiella Pneumoniae. Bioresour. Technol. 2010, 101, 8342–8347. [Google Scholar] [CrossRef]

- Li, L.; Li, K.; Wang, K.; Chen, C.; Gao, C.; Ma, C.; Xu, P. Efficient Production of 2,3-Butanediol from Corn Stover Hydrolysate by Using a Thermophilic Bacillus Licheniformis Strain. Bioresour. Technol. 2014, 170, 256–261. [Google Scholar] [CrossRef] [PubMed]

- Hazeena, S.H.; Nair Salini, C.; Sindhu, R.; Pandey, A.; Binod, P. Simultaneous Saccharification and Fermentation of Oil Palm Front for the Production of 2,3-Butanediol. Bioresour. Technol. 2019, 278, 145–149. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Mohagheghi, A.; Franden, M.A.; Chou, Y.C.; Chen, X.; Dowe, N.; Himmel, M.E.; Zhang, M. Metabolic Engineering of Zymomonas Mobilis for 2,3-Butanediol Production from Lignocellulosic Biomass Sugars. Biotechnol. Biofuels 2016, 9, 189. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.J.; Huang, H.; Ouyang, P.K. Microbial 2,3-Butanediol Production: A State-of-the-Art Review. Biotechnol. Adv. 2011, 29, 351–364. [Google Scholar] [PubMed]

- Joo, J.; Lee, S.J.; Yoo, H.Y.; Kim, Y.; Jang, M.; Lee, J.; Han, S.O.; Kim, S.W.; Park, C. Improved Fermentation of Lignocellulosic Hydrolysates to 2,3-Butanediol through Investigation of Effects of Inhibitory Compounds by Enterobacter Aerogenes. Chem. Eng. J. 2016, 306, 916–924. [Google Scholar] [CrossRef]

- Quiñones, T.S.; Retter, A.; Hobbs, P.J.; Budde, J.; Heiermann, M.; Plöchl, M.; Ravella, S.R. Production of Xylooligosaccharides from Renewable Agricultural Lignocellulose Biomass. Biofuels 2015, 6, 147–155. [Google Scholar] [CrossRef]

- Santibáñez, L.; Henríquez, C.; Corro-Tejeda, R.; Bernal, S.; Armijo, B.; Salazar, O. Xylooligosaccharides from Lignocellulosic Biomass: A Comprehensive Review. Carbohydr. Polym. 2021, 251, 117118. [Google Scholar]

- Akpinar, O.; Erdogan, K.; Bostanci, S. Production of Xylooligosaccharides by Controlled Acid Hydrolysis of Lignocellulosic Materials. Carbohydr. Res. 2009, 344, 660–666. [Google Scholar] [CrossRef]

- Parajó, J.C.; Garrote, G.; Cruz, J.M.; Dominguez, H. Production of Xylooligosaccharides by Autohydrolysis of Lignocellulosic Materials. Trends Food Sci. Technol. 2004, 15, 115–120. [Google Scholar]

- Otieno, D.O.; Ahring, B.K. The Potential for Oligosaccharide Production from the Hemicellulose Fraction of Biomasses through Pretreatment Processes: Xylooligosaccharides (XOS), Arabinooligosaccharides (AOS), and Mannooligosaccharides (MOS). Carbohydr. Res. 2012, 360, 84–92. [Google Scholar]

- da Silva Menezes, B.; Rossi, D.M.; Squina, F.; Ayub, M.A.Z. Xylooligosaccharides Production by Fungi Cultivations in Rice Husk and Their Application as Substrate for Lactic Acid Bacteria Growth. Bioresour. Technol. Reports 2018, 2, 100–106. [Google Scholar] [CrossRef]

- Reddy, S.S.; Krishnan, C. Production of High-Pure Xylooligosaccharides from Sugarcane Bagasse Using Crude β-Xylosidase-Free Xylanase of Bacillus Subtilis KCX006 and Their Bifidogenic Function. LWT—Food Sci. Technol. 2016, 65, 237–245. [Google Scholar] [CrossRef]

- Chapla, D.; Pandit, P.; Shah, A. Production of Xylooligosaccharides from Corncob Xylan by Fungal Xylanase and Their Utilization by Probiotics. Bioresour. Technol. 2012, 115, 215–221. [Google Scholar] [CrossRef]

- Aachary, A.A.; Prapulla, S.G. Value Addition to Corncob: Production and Characterization of Xylooligosaccharides from Alkali Pretreated Lignin-Saccharide Complex Using Aspergillus Oryzae MTCC 5154. Bioresour. Technol. 2009, 100, 991–995. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, M.J.; Alonso, J.L.; Domínguez, H.; Parajó, J.C. Enhancing the Potential of Oligosaccharides from Corncob Autohydrolysis as Prebiotic Food Ingredients. Ind. Crops Prod. 2006, 24, 152–159. [Google Scholar] [CrossRef]

- Yang, R.; Xu, S.; Wang, Z.; Yang, W. Aqueous Extraction of Corncob Xylan and Production of Xylooligosaccharides. LWT—Food Sci. Technol. 2005, 38, 677–682. [Google Scholar] [CrossRef]

- Misra, S.; Raghuwanshi, S.; Saxena, R.K. Evaluation of Corncob Hemicellulosic Hydrolysate for Xylitol Production by Adapted Strain of Candida Tropicalis. Carbohydr. Polym. 2013, 92, 1596–1601. [Google Scholar] [CrossRef]

- Li, M.; Meng, X.; Diao, E.; Du, F. Xylitol Production by Candida Tropicalis from Corn Cob Hemicellulose Hydrolysate in a Two-Stage Fed-Batch Fermentation Process. J. Chem. Technol. Biotechnol. 2012, 87, 387–392. [Google Scholar] [CrossRef]

- Ping, Y.; Ling, H.Z.; Song, G.; Ge, J.P. Xylitol Production from Non-Detoxified Corncob Hemicellulose Acid Hydrolysate by Candida Tropicalis. Biochem. Eng. J. 2013, 75, 86–91. [Google Scholar] [CrossRef]

- Cheng, K.K.; Zhang, J.A.; Ling, H.Z.; Ping, W.X.; Huang, W.; Ge, J.P.; Xu, J.M. Optimization of PH and Acetic Acid Concentration for Bioconversion of Hemicellulose from Corncobs to Xylitol by Candida Tropicalis. Biochem. Eng. J. 2009, 43, 203–207. [Google Scholar] [CrossRef]

- Tada, K.; Horiuchi, J.I.; Kanno, T.; Kobayashi, M. Microbial Xylitol Production from Corn Cobs Using Candida Magnoliae. J. Biosci. Bioeng. 2004, 98, 228–230. [Google Scholar] [CrossRef]

- Prakash, G.; Varma, A.J.; Prabhune, A.; Shouche, Y.; Rao, M. Microbial Production of Xylitol from D-Xylose and Sugarcane Bagasse Hemicellulose Using Newly Isolated Thermotolerant Yeast Debaryomyces Hansenii. Bioresour. Technol. 2011, 102, 3304–3308. [Google Scholar] [CrossRef]

- de Arruda, P.V.; de Cássia Lacerda Brambilla Rodrigues, R.; da Silva, D.D.V.; das Graças de Almeida Felipe, M. Evaluation of Hexose and Pentose in Pre-Cultivation of Candida Guilliermondii on the Key Enzymes for Xylitol Production in Sugarcane Hemicellulosic Hydrolysate. Biodegradation 2010, 22, 815–822. [Google Scholar] [CrossRef]

- da Cunha, M.A.A.; Converti, A.; Santos, J.C.; Ferreira, S.T.S.; da Silva, S.S. PVA-Hydrogel Entrapped Candida Guilliermondii for Xylitol Production from Sugarcane Hemicellulose Hydrolysate. Appl. Biochem. Biotechnol. 2008, 157, 527–537. [Google Scholar] [CrossRef] [PubMed]

- Rao, R.S.; Jyothi, C.P.; Prakasham, R.S.; Sarma, P.N.; Rao, L.V. Xylitol Production from Corn Fiber and Sugarcane Bagasse Hydrolysates by Candida Tropicalis. Bioresour. Technol. 2006, 97, 1974–1978. [Google Scholar] [CrossRef] [PubMed]

- Asachi, R.; Karimi, K. Enhanced Ethanol and Chitosan Production from Wheat Straw by Mucor Indicus with Minimal Nutrient Consumption. Process Biochem. 2013, 48, 1524–1531. [Google Scholar] [CrossRef]

- Ling, H.Z.; Cheng, K.K.; Ge, J.P.; Ping, W.X. Corncob Mild Alkaline Pretreatment for High 2,3-Butanediol Production by Spent Liquor Recycle Process. Bioenergy Res. 2017, 10, 566–574. [Google Scholar] [CrossRef]

- Ma, K.; He, M.; You, H.; Pan, L.; Wang, Z.; Wang, Y.; Hu, G.; Cui, Y.; Maeda, T. Improvement of (R,R)-2,3-Butanediol Production from Corn Stover Hydrolysate by Cell Recycling Continuous Fermentation. Chem. Eng. J. 2018, 332, 361–369. [Google Scholar] [CrossRef]

- Wong, C.L.; Huang, C.C.; Lu, W.B.; Chen, W.M.; Chang, J.S. Producing 2,3-Butanediol from Agricultural Waste Using an Indigenous Klebsiella Sp. Zmd30 Strain. Biochem. Eng. J. 2012, 69, 32–40. [Google Scholar] [CrossRef]

- Saratale, G.D.; Jung, M.Y.; Oh, M.K. Reutilization of Green Liquor Chemicals for Pretreatment of Whole Rice Waste Biomass and Its Application to 2,3-Butanediol Production. Bioresour. Technol. 2016, 205, 90–96. [Google Scholar] [CrossRef]

- Zhao, X.; Song, Y.; Liu, D. Enzymatic Hydrolysis and Simultaneous Saccharification and Fermentation of Alkali/Peracetic Acid-Pretreated Sugarcane Bagasse for Ethanol and 2,3-Butanediol Production. Enzyme Microb. Technol. 2011, 49, 413–419. [Google Scholar] [CrossRef]

- Um, J.; Kim, D.G.; Jung, M.Y.; Saratale, G.D.; Oh, M.K. Metabolic Engineering of Enterobacter Aerogenes for 2,3-Butanediol Production from Sugarcane Bagasse Hydrolysate. Bioresour. Technol. 2017, 245, 1567–1574. [Google Scholar] [CrossRef]

- Samanta, A.K.; Senani, S.; Kolte, A.P.; Sridhar, M.; Sampath, K.T.; Jayapal, N.; Devi, A. Production and in Vitro Evaluation of Xylooligosaccharides Generated from Corn Cobs. Food Bioprod. Process. 2012, 90, 466–474. [Google Scholar] [CrossRef]

- Samanta, A.K.; Jayapal, N.; Kolte, A.P.; Senani, S.; Sridhar, M.; Dhali, A.; Suresh, K.P.; Jayaram, C.; Prasad, C.S. Process for Enzymatic Production of Xylooligosaccharides from the Xylan of Corn Cobs. J. Food Process. Preserv. 2015, 39, 729–736. [Google Scholar] [CrossRef]

- Sabiha-Hanim, S.; Noor, M.A.M.; Rosma, A. Effect of Autohydrolysis and Enzymatic Treatment on Oil Palm (Elaeis Guineensis Jacq.) Frond Fibres for Xylose and Xylooligosaccharides Production. Bioresour. Technol. 2011, 102, 1234–1239. [Google Scholar] [CrossRef]

- Chen, M.; Lu, J.; Cheng, Y.; Li, Q.; Wang, H. Novel Process for the Coproduction of Xylo-Oligosaccharide and Glucose from Reed Scraps of Reed Pulp Mill. Carbohydr. Polym. 2019, 215, 82–89. [Google Scholar] [CrossRef]

- Khat-udomkiri, N.; Sivamaruthi, B.S.; Sirilun, S.; Lailerd, N.; Peerajan, S.; Chaiyasut, C. Optimization of Alkaline Pretreatment and Enzymatic Hydrolysis for the Extraction of Xylooligosaccharide from Rice Husk. AMB Express 2018, 8, 115. [Google Scholar] [CrossRef] [PubMed]

- Brienzo, M.; Carvalho, W.; Milagres, A.M.F. Xylooligosaccharides Production from Alkali-Pretreated Sugarcane Bagasse Using Xylanases from Thermoascus Aurantiacus. Appl. Biochem. Biotechnol. 2010, 162, 1195–1205. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Y. Integrative Process for Sugarcane Bagasse Biorefinery to Co-Produce Xylooligosaccharides and Gluconic Acid. Bioresour. Technol. 2019, 282, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Jayapal, N.; Samanta, A.K.; Kolte, A.P.; Senani, S.; Sridhar, M.; Suresh, K.P.; Sampath, K.T. Value Addition to Sugarcane Bagasse: Xylan Extraction and Its Process Optimization for Xylooligosaccharides Production. Ind. Crops Prod. 2013, 42, 14–24. [Google Scholar] [CrossRef]

- Akpinar, O.; Erdogan, K.; Bostanci, S. Enzymatic Production of Xylooligosaccharide from Selected Agricultural Wastes. Food Bioprod. Process. 2009, 87, 145–151. [Google Scholar] [CrossRef]

- Faryar, R.; Linares-Pastén, J.A.; Immerzeel, P.; Mamo, G.; Andersson, M.; Stålbrand, H.; Mattiasson, B.; Karlsson, E.N. Production of Prebiotic Xylooligosaccharides from Alkaline Extracted Wheat Straw Using the K80R-Variant of a Thermostable Alkali-Tolerant Xylanase. Food Bioprod. Process. 2015, 93, 1–10. [Google Scholar] [CrossRef]

- Ruiz, H.A.; Thomsen, M.H.; Trajano, H.L. Hydrothermal Processing in Biorefineries; Ruiz, H.A., Thomsen, M.H., Trajano, H.L., Eds.; Springer: Cham, Switzerland, 2017; ISBN 9783319564562. [Google Scholar]

- Ruiz, H.A.; Conrad, M.; Sun, S.N.; Sanchez, A.; Rocha, G.J.M.; Romaní, A.; Castro, E.; Torres, A.; Rodríguez-Jasso, R.M.; Andrade, L.P.; et al. Engineering Aspects of Hydrothermal Pretreatment: From Batch to Continuous Operation, Scale-up and Pilot Reactor under Biorefinery Concept. Bioresour. Technol. 2020, 299, 122685. [Google Scholar] [CrossRef]

- Camel, V. Microwave-Assisted Solvent Extraction of Environmental Samples. TrAC—Trends Anal. Chem. 2000, 19, 229–248. [Google Scholar] [CrossRef]

- He, B.; Zhang, L.L.; Yue, X.Y.; Liang, J.; Jiang, J.; Gao, X.L.; Yue, P.X. Optimization of Ultrasound-Assisted Extraction of Phenolic Compounds and Anthocyanins from Blueberry (Vaccinium Ashei) Wine Pomace. Food Chem. 2016, 204, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Mumper, R.J. Plant Phenolics: Extraction, Analysis and Their Antioxidant and Anticancer Properties. Molecules 2010, 15, 7313–7352. [Google Scholar] [CrossRef] [PubMed]

- Pompeu, D.; Silva, E.; Rogez, H. Optimisation of the Solvent Extraction of Phenolic Antioxidants from Fruits of Euterpe Oleracea Using Response Surface Methodology. Bioresour. Technol. 2009, 100, 6076–6082. [Google Scholar] [CrossRef] [PubMed]

- Monroy, Y.M.; Rodrigues, R.A.; Sartoratto, A.; Cabral, F.A. Optimization of the Extraction of Phenolic Compounds from Purple Corn Cob (Zea mays L.) by Sequential Extraction Using Supercritical Carbon Dioxide, Ethanol and Water as Solvents. J. Supercrit. Fluids 2013, 116, 10–19. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, T.; Fu, X.; Abbasi, A.M.; Zheng, B.; Liu, R.H. Phenolics Content, Antioxidant and Antiproliferative Activities of Dehulled Highland Barley (Hordeum vulgare L.). J. Funct. Foods 2015, 19, 439–450. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, T.; Fu, X.; Brennan, M.; Abbasi, A.M.; Zheng, B.; Liu, R.H. The Use of an Enzymatic Extraction Procedure for the Enhancement of Highland Barley (Hordeum Vulgare L.) Phenolic and Antioxidant Compounds. Int. J. Food Sci. Technol. 2016, 51, 1916–1924. [Google Scholar] [CrossRef]

- Varun, T.K.; Senani, S.; Jayapal, N.; Chikkerur, J.; Roy, S.; Tekulapally, V.B.; Gautam, M.; Kumar, N. Extraction of Chitosan and Its Oligomers from Shrimp Shell Waste, Their Characterization and Antimicrobial Effect. Vet. World 2017, 10, 170–175. [Google Scholar] [CrossRef]

- Riveiro, E.; González, B.; Domínguez, Á. Extraction of Adipic, Levulinic and Succinic Acids from Water Using TOPO-Based Deep Eutectic Solvents. Sep. Purif. Technol. 2020, 241, 116692. [Google Scholar] [CrossRef]

- Marták, J.; Schlosser, Š. Extraction of Lactic Acid by Phosphonium Ionic Liquids. Sep. Purif. Technol. 2007, 57, 483–494. [Google Scholar] [CrossRef]

- Slak, J.; Pomeroy, B.; Kostyniuk, A.; Grilc, M.; Likozar, B. A Review of Bio-Refining Process Intensification in Catalytic Conversion Reactions, Separations and Purifications of Hydroxymethylfurfural (HMF) and Furfural. Chem. Eng. J. 2022, 429, 132325. [Google Scholar] [CrossRef]

- Galanakis, C.; Goulas, V.; Tsakona, S.; Manganaris, G.; Gekas, V. A Knowledge Base for The Recovery of Natural Phenols with Different Solvents. Int. J. food Prop. 2013, 16, 382–396. [Google Scholar] [CrossRef]

- Hansen, C.M. The Three Dimensional Solubility Parameter; Danish Technical Press: Copenhagen, Denmark, 1967. [Google Scholar]

- Hansen, C.M. Methods of Characterization—Surfaces. In Hansen Solubility Parameters: A Users Handbook, 2nd ed.; CRC Press: Raton, FL, USA, 2007; pp. 113–123. ISBN 9781420006834. [Google Scholar]

- Moulik, S.; Bukke, V.; Sajja, S.C.; Sridhar, S. Chitosan-Polytetrafluoroethylene Composite Membranes for Separation of Methanol and Toluene by Pervaporation. Carbohydr. Polym. 2018, 193, 28–38. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Mohan, M.; George, A.; Simmons, B.A.; Xu, Y.; Gladden, J.M. Integration of Acetic Acid Catalysis with One-Pot Protic Ionic Liquid Configuration to Achieve High-Efficient Biorefinery of Poplar Biomass. Green Chem. 2021, 23, 6036–6049. [Google Scholar] [CrossRef]

- Qin, C.; Li, H.; Xiao, Q.; Liu, Y.; Zhu, J.; Du, Y. Water-Solubility of Chitosan and Its Antimicrobial Activity. Carbohydr. Polym. 2006, 63, 367–374. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, G.; Zhao, J.; Ma, M.; Bao, X.; Zeng, Z.; Gong, X.; Yu, P.; Wen, X.; Gong, D. Influence of Phenolic Compounds on the Structural Characteristics, Functional Properties and Antioxidant Activities of Alcalase-Hydrolyzed Protein Isolate from Cinnamomum Camphora Seed Kernel. LWT 2021, 148, 111799. [Google Scholar] [CrossRef]

- Zuorro, A.; Iannone, A.; Lavecchia, R. Water–Organic Solvent Extraction of Phenolic Antioxidants from Brewers’ Spent Grain. Processes 2019, 7, 126. [Google Scholar] [CrossRef]

- Sacchi, K.L.; Bisson, L.F.; Adams, D.O. A Review of the Effect of Winemaking Techniques on Phenolic Extraction in Red Wines. Am. J. Enol. Vitic. 2005, 56, 197–206. [Google Scholar]

- Silva, A.M.; Lago, J.P.; Pinto, D.; Moreira, M.M.; Grosso, C.; Cruz Fernandes, V.; Delerue-Matos, C.; Rodrigues, F. Salicornia Ramosissima Bioactive Composition and Safety: Eco-Friendly Extractions Approach (Microwave-Assisted Extraction vs. Conventional Maceration). Appl. Sci. 2021, 11, 4744. [Google Scholar] [CrossRef]

- Luque de Castro, M.D.; Priego-Capote, F. Soxhlet Extraction: Past and Present Panacea. J. Chromatogr. A 2010, 1217, 2383–2389. [Google Scholar] [CrossRef]

- Medini, F.; Bourgou, S.; Lalancette, K.G.; Snoussi, M.; Mkadmini, K.; Coté, I.; Abdelly, C.; Legault, J.; Ksouri, R. Phytochemical Analysis, Antioxidant, Anti-Inflammatory, and Anticancer Activities of the Halophyte Limonium Densiflorum Extracts on Human Cell Lines and Murine Macrophages. S. Afr. J. Bot. 2015, 99, 158–164. [Google Scholar] [CrossRef]

- Fredsgaard, M.; Hulkko, L.S.S.; Chaturvedi, T.; Thomsen, M.H. Process Simulation and Techno-Economic Assessment of Salicornia Sp. Based Jet Fuel Refinery through Hermetia Illucens Sugars-to-Lipids Conversion and HEFA Route. Biomass Bioenergy 2021, 150, 106142. [Google Scholar] [CrossRef]

- Dalmeida Daffodil, E.; Rajalakshmi, K.; Mohan, V.R. Antioxidant Activity, Total Phenolics and Flavonoids of Salicornia Brachiata Rox. Leaf Extracts (Chenopodiaceae). World J. Pharm. Pharm. Sci. 2014, 2, 352–366. [Google Scholar]

- Zhang, J.; Wen, C.; Zhang, H.; Duan, Y.; Ma, H. Recent Advances in the Extraction of Bioactive Compounds with Subcritical Water: A Review. Trends Food Sci. Technol. 2020, 95, 183–195. [Google Scholar] [CrossRef]

- Yu, X.-M.; Zhu, P.; Zhong, Q.-P.; Li, M.-Y.; Ma, H.-R. Subcritical Water Extraction of Antioxidant Phenolic Compounds from XiLan Olive Fruit Dreg. J. Food Sci. Technol. 2015, 52, 5012–5020. [Google Scholar] [CrossRef]

- Aliakbarian, B.; Fathi, A.; Perego, P.; Dehghani, F. Extraction of Antioxidants from Winery Wastes Using Subcritical Water. J. Supercrit. Fluids 2012, 65, 18–24. [Google Scholar] [CrossRef]

- Duba, K.S.; Casazza, A.A.; Mohamed, H.B.; Perego, P.; Fiori, L. Extraction of Polyphenols from Grape Skins and Defatted Grape Seeds Using Subcritical Water: Experiments and Modeling. Food Bioprod. Process. 2015, 94, 29–38. [Google Scholar] [CrossRef]

- Mazzutti, S.; Salvador Ferreira, S.R.; Herrero, M.; Ibañez, E. Intensified Aqueous-Based Processes to Obtain Bioactive Extracts from Plantago Major and Plantago Lanceolata. J. Supercrit. Fluids 2017, 119, 64–71. [Google Scholar] [CrossRef]

- Pourali, O.; Asghari, F.S.; Yoshida, H. Production of Phenolic Compounds from Rice Bran Biomass under Subcritical Water Conditions. Chem. Eng. J. 2010, 160, 259–266. [Google Scholar] [CrossRef]

- Friedman, M.; Jürgens, H.S. Effect of PH on the Stability of Plant Phenolic Compounds. J. Agric. Food Chem. 2000, 48, 2101–2110. [Google Scholar] [CrossRef]

- Peanparkdee, M.; Patrawart, J.; Iwamoto, S. Physicochemical Stability and in Vitro Bioaccessibility of Phenolic Compounds and Anthocyanins from Thai Rice Bran Extracts. Food Chem. 2020, 329, 127157. [Google Scholar] [CrossRef] [PubMed]

- Dawidowicz, A.L.; Typek, R. The Influence of PH on the Thermal Stability of 5-O-Caffeoylquinic Acids in Aqueous Solutions. Eur. Food Res. Technol. 2011, 233, 223–232. [Google Scholar] [CrossRef]

- Wang, D.; Liu, J.; Qiu, S.; Wang, J.; Song, G.; Chu, B.; Li, L.; Xiao, G.; Gong, J.; Zheng, F. Ultrasonic Degradation Kinetics and Isomerization of 3- and 4-O-Caffeoylquinic Acid at Various PH: The Protective Effects of Ascorbic Acid and Epigallocatechin Gallate on Their Stability. Ultrason. Sonochem. 2021, 80, 105812. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.K.; Cao, Q.E.; Liu, H.T.; Wang, K.T.; Yan, A.X.; Hu, Z.D. Determination of Baicalin, Chlorogenic Acid and Caffeic Acid in Traditional Chinese Medicinal Preparations by Capillary Zone Electrophoresis. Chromatographia 2000, 51, 483–486. [Google Scholar] [CrossRef]

- Narita, Y.; Inouye, K. Degradation Kinetics of Chlorogenic Acid at Various PH Values and Effects of Ascorbic Acid and Epigallocatechin Gallate on Its Stability under Alkaline Conditions. J. Agric. Food Chem. 2013, 61, 966–972. [Google Scholar] [CrossRef]

- Bussemaker, M.J.; Zhang, D. Effect of Ultrasound on Lignocellulosic Biomass as a Pretreatment for Biorefinery and Biofuel Applications. Ind. Eng. Chem. Res. 2013, 52, 3563–3580. [Google Scholar] [CrossRef]

- Ríos-González, L.J.; Medina-Morales, M.A.; Rodríguez-De la Garza, J.A.; Romero-Galarza, A.; Medina, D.D.; Morales-Martínez, T.K. Comparison of Dilute Acid Pretreatment of Agave Assisted by Microwave versus Ultrasound to Enhance Enzymatic Hydrolysis. Bioresour. Technol. 2021, 319, 124099. [Google Scholar] [CrossRef]

- Bussemaker, M.J.; Xu, F.; Zhang, D. Manipulation of Ultrasonic Effects on Lignocellulose by Varying the Frequency, Particle Size, Loading and Stirring. Bioresour. Technol. 2013, 148, 15–23. [Google Scholar] [CrossRef]

- Wang, Z.; Hou, X.; Sun, J.; Li, M.; Chen, Z.; Gao, Z. Comparison of Ultrasound-Assisted Ionic Liquid and Alkaline Pretreatment of Eucalyptus for Enhancing Enzymatic Saccharification. Bioresour. Technol. 2018, 254, 145–150. [Google Scholar] [CrossRef]

- Fang, Z.; Richard, L.; Smith, J.; Qi, X. Production of Biofuels and Chemicals with Ultrasound. In Biofuels and Biorefineries; Fang, Z., Smith, R.L., Qi, X., Eds.; Springer: Dordrecht, The Netherlands, 2015; Volume 4. [Google Scholar]

- Corbin, C.; Fidel, T.; Leclerc, E.A.; Barakzoy, E.; Sagot, N.; Falguiéres, A.; Renouard, S.; Blondeau, J.P.; Ferroud, C.; Doussot, J.; et al. Development and Validation of an Efficient Ultrasound Assisted Extraction of Phenolic Compounds from Flax (Linum usitatissimum L.) Seeds. Ultrason. Sonochem. 2015, 26, 176–185. [Google Scholar] [CrossRef]

- Padalino, L.; Costa, C.; Del Nobile, M.A.; Conte, A. Extract of Salicornia Europaea in Fresh Pasta to Enhance Phenolic Compounds and Antioxidant Activity. Int. J. Food Sci. Technol. 2019, 54, 3051–3057. [Google Scholar] [CrossRef]

- Zikeli, F.; Ters, T.; Fackler, K.; Srebotnik, E.; Li, J. Wheat Straw Lignin Fractionation and Characterization as Lignin-Carbohydrate Complexes. Ind. Crop. Prod. 2016, 85, 309–317. [Google Scholar] [CrossRef]

- Bartolomé, B.; Gómez-Cordovés, C. Barley Spent Grain: Release of Hydroxycinnamic Acids (Ferulic Andp-Coumaric Acids) by Commercial Enzyme Preparations. J. Sci. Food Agric. 1999, 79, 435–439. [Google Scholar] [CrossRef]

- Torres-Mancera, M.T.; Cordova-Lopez, J.; Rodriguez-Serrano, G.; Roussos, S.; Ramirez-Coronel, M.A.; Favela-Torres, E.; Saucedo-Castaneda, G. Enzymatic Extraction of Hydroxycinnamic Acids from Coffee Pulp. Food Technol. Biotechnol. 2011, 49, 369–373. [Google Scholar]

- Faulds, C.B.; Robertson, J.A.; Waldron, K.W. Effect of PH on the Solubilization of Brewers’ Spent Grain by Microbial Carbohydrases and Proteases. J. Agric. Food Chem. 2008, 56, 7038–7043. [Google Scholar] [CrossRef]

- Cristina, C.; Lucia, P.; Sara, S.; Francesco, S.; Nobile, D.; Alessandro, M.; Conte, A.; Amalia, C. Study of the Efficacy of Two Extraction Techniques from Crithmum Maritimum and Salicornia Europaea. J. Food Nutr. Res. 2018, 6, 456–463. [Google Scholar] [CrossRef]

- Huang, H.J.; Ramaswamy, S.; Tschirner, U.W.; Ramarao, B.V. A Review of Separation Technologies in Current and Future Biorefineries. Sep. Purif. Technol. 2008, 62, 1–21. [Google Scholar] [CrossRef]

- Galanakis, C.M.; Tornberg, E.; Gekas, V. Clarification of High-Added Value Products from Olive Mill Wastewater. J. Food Eng. 2010, 99, 190–197. [Google Scholar] [CrossRef]

- Galanakis, C.M. Separation of Functional Macromolecules and Micromolecules: From Ultrafiltration to the Border of Nanofiltration. Trends Food Sci. Technol. 2015, 42, 44–63. [Google Scholar] [CrossRef]

- Castro-Muñoz, R.; Yáñez-Fernández, J.; Fíla, V. Phenolic Compounds Recovered from Agro-Food by-Products Using Membrane Technologies: An Overview. Food Chem. 2016, 213, 753–762. [Google Scholar] [CrossRef]

- Stiger-Pouvreau, V.; Jégou, C.; Cérantola, S.; Guérard, F.; Lann, K. Le Phlorotannins in Sargassaceae Species from Brittany (France): Interesting Molecules for Ecophysiological and Valorisation Purposes. In Advances in Botanical Research; Sibout, R., Ed.; Academic Press Inc.: Cambridge, MA, USA, 2014; Volume 71, pp. 379–411. [Google Scholar]

- Kim, J.Y.; Cho, J.Y.; Ma, Y.K.; Park, K.Y.; Lee, S.H.; Ham, K.S.; Lee, H.J.; Park, K.H.; Moon, J.H. Dicaffeoylquinic Acid Derivatives and Flavonoid Glucosides from Glasswort (Salicornia herbacea L.) and Their Antioxidative Activity. Food Chem. 2011, 125, 55–62. [Google Scholar] [CrossRef]

- Xavier, L.; Freire, M.S.; Vidal-Tato, I.; González-Álvarez, J. Aqueous Two-Phase Systems for the Extraction of Phenolic Compounds from Eucalyptus (Eucalyptus globulus) Wood Industrial Wastes. J. Chem. Technol. Biotechnol. 2014, 89, 1772–1778. [Google Scholar] [CrossRef]

- Bokhary, A.; Leitch, M.; Liao, B.Q. Liquid–Liquid Extraction Technology for Resource Recovery: Applications, Potential, and Perspectives. J. Water Process Eng. 2021, 40, 101762. [Google Scholar] [CrossRef]

- Meyer, V.R. Practical High-Performance Liquid Chromatography, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Hanai, T. HPLC A Practical Guide. In Chromatography Monographs; Smith, R.M., Ed.; Royal Society of Chemistry: Cambridge, UK, 1999. [Google Scholar]

- Snyder, L.R.; Kirkland, J.J.; Glajch, J.L. Practical HPLC Method Development, 2nd ed.; Wiley-Interscience: Hoboken, NJ, USA, 1997. [Google Scholar]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Review of High-Value Food Waste and Food Residues Biorefineries with Focus on Unavoidable Wastes from Processing. Resour. Conserv. Recycl. 2019, 149, 413–426. [Google Scholar] [CrossRef]

- Valanciene, E.; Jonuskiene, I.; Syrpas, M.; Augustiniene, E.; Matulis, P.; Simonavicius, A.; Malys, N. Advances and Prospects of Phenolic Acids Production, Biorefinery and Analysis. Biomolecules 2020, 10, 874. [Google Scholar] [CrossRef] [PubMed]

- Latif, Z.; Sarker, S.D. Isolation of Natural Products by Preparative High Performance Liquid Chromatography (Prep-HPLC). Methods Mol. Biol. 2012, 864, 255–274. [Google Scholar] [CrossRef]

| Biomass | Cellulose Content % | Acid Concentration | Operating Temperature (°C) | Time (h) | Theoretical Yield (mol%) | Reference |

|---|---|---|---|---|---|---|

| Kraft Paper Pulp Residue | 80 | 1–5% H2SO4 | 1st Stage 210–230 2nd Stage 195–215 | N/A | 70–80 | [10] |

| Wheat Straw | 40 | 3.5% H2SO4 | 210 | N/A | 68.8 | [11] |

| 40.4 | 4.5% H2SO4 | 220 | N/A | 79.6 | [12] | |

| 3.5% H2SO4 | 210 | 0.63 | 19.8 | [13] | ||

| Bagasse | 42 | 4.5% HCl | 220 | N/A | 82.7 | [12] |

| 1.5% H2SO4 | 25–195 | 2 | 17.5 | [14] | ||

| Glucose | 32 | 20% HCl | 100 | 24 | 15 | [15] |

| 29 | 6.5% HCl | 162 | 1 | 24 | [16] | |

| 27 | Amberlite IR-120 | Room Temperature | 124 | 5.8 | [17] | |

| 5–20 | 0.1–4% H2SO4 | 160–240 | N/A | 35.4 | [18] | |

| 10 | 6% HCl | 160 | 0.25 | 41.4 | [19] | |

| 12 | 3% Clay Catalyst (Fe-pillared montmorillonite) | 150 | 24 | 12 | [20] | |

| 12 | 3% HY Zeolite | 150 | 24 | 6 | [21] | |

| Rice Hull | N/A | 1% HCl | 160 | 3 | 10.3 | [22] |

| Rice Straw | N/A | 1% HCl | 160 | 3 | 5.5 | |

| Corn Stalks | N/A | 1% HCl | 160 | 3 | 7.5 | |

| Wood Sawdust | N/A | 1.5% HCl | 190 | 0.5 | 9 | [23] |

| Oakwood | N/A | 3% H2SO4 | 180 | 3 | 17.5 | [24] |

| Aspen, Pine, and Spruce | N/A | 5% H2SO4 | 200–240 | 2–4 | 13–18 | [13] |

| Cellulose | N/A | 1–5% H2SO4 | 150–250 | 2–7 | <25 | [25] |

| 1–5% HCl | <28 | |||||

| 1–5% HBr | <27 | |||||

| Aspen Wood | N/A | 1–5% H2SO4 | 150–250 | 2–7 | <15.5 | |

| 1–5% HCl | <12.4 | |||||

| 1–5% HBr | <13 |

| Biomass | Strain | Concentration (g/L) | Yield a (g/g) | Productivity b (g/L/h) | Reference |

|---|---|---|---|---|---|

| Wood Hydrolysate | E. mundtii QU 25 | 93 | 0.93 | 1.7 | [27] |

| Corn Cob/Stover | Lb. brevis | 39.1 | 0.7 | 0.81 | [28] |

| L. delbrueckii ZU-S2 | 48.7/44.2 | 0.95/0.92 | 1.01/5.7 | [29] | |

| L. pentosus | 26 | 0.53 | 0.34 | [30] | |

| L. pentosus ATCC 8041 | 74.8 | 0.65 | N/A | [31] | |

| L. rhamnosus and L. brevis | 20.95 | 0.7 | 0.58 | [32] | |

| Wheat Straw | L. brevis and L. pentosus | 7.1 | 0.95 | N/A | [33] |

| Softwood | L. casei subsp. rhamnosus | 21.1–23.75 | 0.74–0.83 | 0.15–0.23 | [34] |

| Sugarcane Bagasse | L. delbrueckii subsp. delbrueckii Mutant Uc-3 | 67 | 0.83 | 0.93 | [35] |

| L. lactis IO-1 | 10.9 | 0.36 | 0.17 | [36] | |

| Rice and Wheat Barn | L. rhamnosus ATCC 9595 (CET288) | 129 | 0.95 | 2.9 | [37] |

| Brewer’s Spent Grain | L. delbrueckii UFV H2B20 | 35.5 | 0.99 | 0.59 | [38] |

| Substrate | Host Microorganism | Concentration (g/L) | Productivity (g/L/h) | Reference |

|---|---|---|---|---|

| Glucose | S. cerevisiae | 9.8 | 0.1 | [41] |

| 13.7 | 0.17 | [42] | ||

| 7.4 | 0.06 | [43] | ||

| E. coli | 10.1 | 0.28 | [44] | |

| 40.6 | 0.56 | [45] | ||

| 31.1 | 0.63 | [7] | ||

| 29.7 | 0.54 | [46] | ||

| S. pombe | 7.6 | 0.25 | [47] | |

| C. glutamicum | 62.6 | 0.87 | [48] | |

| Glycerol | K. pneumoniae | 18 | 0.77 | [49] |

| 48.9 | 1.75 | [50] | ||

| 43 | 0.9 | [51] | ||

| 83.8 | 1.16 | [52] | ||

| 0.9 | 0.04 | [53] | ||

| 24.4 | 1.02 | [50] | ||

| 16 | 0.3 | [54] | ||

| 11.3 | 0.94 | [55] | ||

| 22.7 | 0.38 | [56] | ||

| 28.1 | 0.58 | [57] | ||

| 22 | 0.46 | [58] | ||

| 60.5 | 1.12 | [59] | ||

| E. coli | 42.1 | 1.32 | [60] | |

| 71.9 | 1.8 | [61] | ||

| 40.5 | 1.35 | [62] | ||

| 56.4 | 1.18 | [63] | ||

| 41.5 | 0.86 | [64] | ||

| 31 | 0.43 | [65] | ||

| 38.7 | 0.54 | [66] | ||

| 6.06 | 0.13 | [67] | ||

| 5.05 | 0.105 | [68] | ||

| L. reuteri | 10.6 | 1.08 | [69] | |

| 3.3 | 0.09 | [70] | ||

| L. collinoides | 0.55 | 0.07 | [71] |

| Substrate | Catalyst | Reagents | Temp. (°C) | Time (h) | Pressure (Bar) | Substr. Conv. (%) | FDCA Yield (%) | Ref. |

|---|---|---|---|---|---|---|---|---|

| 5-HMF | Lignin-derived Co SAs/N@C | Na2CO3, O2 | 85 | 3 | 1 | 99.4 | 74.4 | [89] |

| 85 | 8 | 1 | 100 | 99.5 | ||||

| MnO2 | NaHCO3 | 100 | 24 | 10 | >99 | 91 | [97] | |

| Au-TiO2 | N/A | 65 | 8 | 10 | N/A | >99 | [98] | |

| 5% Pt/C | O2 | 100 | 20 | 40 | N/A | 94 | [92] | |

| Magnetic ZnFe1.65Ru0.35O | Dimethyl sulfoxide | 130 | 16 | N/A | N/A | 91.2 | [94] | |

| Ru/HAP | N/A | 160 | 4 | 20 | N/A | 34.2 | [94] | |

| Pd/CC | K2CO3, O2 | 140 | 30 | N/A | N/A | 85 | [95] | |

| Ru (4%)/MnCo2O4 | N/A | 120 | 10 | 24 | 100 | 99.1 | [99] | |

| Fungal enzymes: aryl alcohol oxidase, peroxygenase, galactose oxidase | H2O2, phosphate buffer | N/A | >24 | N/A | N/A | 80 | [96] | |

| 2-furoic acid | N/A | Cs2CO2, CO2 | 200 | 5 | 8 | N/A | 77 | [88] |

| Lignin-derived Co SAs/N@C | Cs2CO2, CO2 | 260 | 36 | Flowing | 85.8 | 71.1 | [89] |

| Compound | δD | δP | δH | Compound | δD | δP | δH |

|---|---|---|---|---|---|---|---|

| 1,4-Dioxane | 19 | 1.8 | 7.4 | Iso-butanol | 15.1 | 5.7 | 15.9 |

| 1-Butanol | 16 | 5.7 | 15.8 | Methanol | 14.7 | 12.3 | 22.3 |

| 1-Propanol | 16 | 6.8 | 17.4 | Methyl cyclohexane | 16 | 0 | 1 |

| 2-Butanol | 15.8 | 5.7 | 14.5 | Methyl ethyl ketone | 16 | 9 | 5.1 |

| 2-Propanol | 15.8 | 6.1 | 16.4 | Methyl isobutyl ketone | 15.3 | 6.1 | 4.1 |

| Acetone | 15.5 | 10.4 | 7 | Methylene dichloride | 18.2 | 6.3 | 6.1 |

| Acetonitrile | 15.3 | 18 | 6.1 | N,N-dimethyl acetamide | 16.8 | 11.5 | 10.2 |

| Benzene | 18.4 | 0 | 2 | N,N-dimethyl formamide | 17.4 | 13.7 | 11.3 |

| Benzyl Alcohol | 18.4 | 6.3 | 13.7 | n-Butyl acetate | 15.8 | 3.7 | 6.3 |

| Carbon tetrachloride | 17.8 | 0 | 0.6 | n-Heptane | 15.3 | 0 | 0 |

| Chlorobenzene | 19 | 4.3 | 2 | n-Hexane | 14.9 | 0 | 0 |

| Chloroform | 17.8 | 3.1 | 5.7 | n-Nonane | 15.7 | 0 | 0 |

| Cyclohexane | 16.8 | 0 | 0.2 | n-Octane | 15.5 | 0 | 0 |

| Cyclohexanone | 17.8 | 6.3 | 5.1 | n-Pentane | 15.6 | 0 | 0 |

| Decalin (cis) | 18 | 0 | 0 | sec-Butyl acetate | 15 | 3.7 | 7.6 |

| Dichloromethane | 8.9 | 3.1 | 3 | Styrene | 18.6 | 1 | 4.1 |

| Diethyl Ether | 14.5 | 2.9 | 4.6 | Tetralin | 19.6 | 2 | 2.9 |

| Dimethyl Phthalate | 18.6 | 10.8 | 4.9 | Tetramethylene sulfoxide | 18.2 | 11 | 9.1 |

| Dimethyl Sulfoxide | 18.4 | 16.4 | 10.2 | Toluene | 18 | 1.4 | 2 |

| Ethanol | 15.8 | 8.8 | 19.4 | Water | 18.1 | 17.1 | 16.9 |

| Ethyl Acetate | 15.8 | 5.3 | 7.2 | Xylene | 17.6 | 1 | 3.1 |

| Ethyl Benzene | 17.8 | 0.6 | 1.4 | γ-Butyrolactone | 19 | 16.6 | 7.4 |

| Ethylene Carbonate | 19.4 | 21.7 | 5.1 |

| Solute | δD | δP | δH |

|---|---|---|---|

| Lactic acid | 17.0 | 8.3 | 28.4 |

| Adipic acid | 17.1 | 9.0 | 14.6 |

| Vanillin * | 19.4 | 9.8 | 11.2 |

| Furfural | 18.6 | 14.9 | 5.1 |

| Ferulic acid * | 19.0 | 6.6 | 15.1 |

| 4-Hydroxy cinnamic acid * | 19.1 | 6.7 | 15.9 |

| Chitosan | 23.0 | 17.3 | 25.7 |

| Xylo-oligosaccharides | 25.4 | 7.4 | 15.5 |

| Solute | R1 | R2 | R3 | R4 |

| Lactic acid | MeOH | EtOH | 1-Propanol | 2-Propanol |

| Succinic acid Adipic acid | EtOAc | n-Butyl acetate | Sec-Butyl acetate | Chloroform |

| Vanillin * | Tetramethylene sulfoxide | Benzyl alcohol | N,N-dimethyl acetamide | N,N-dimethyl formamide |

| Furfural | γ-Butyrolactone | Dimethyl phthalate | Dimethyl sulfoxide | Tetramethylene sulfoxide |

| Ferulic acid * | Benzyl alcohol | 1-Butanol | 1-Propanol | 2-Butanol |

| 4-Hydroxy cinnamic acid * | Benzyl alcohol | 1-Butanol | 1-Propanol | 2-Propanol |

| Chitosan | Water | MeOH | EtOH | Dimethyl sulfoxide |

| Xylo-oligosaccharides | Benzyl alcohol | 1,4-Dioxane | Tetramethylene sulfoxide | Dichloromethane |

| Detection Method | Raw Material | Temperature (°C) | Pressure (MPa) | Time (min) | Ref. |

|---|---|---|---|---|---|

| Folin–Ciocalteu | Oleaceae europaea pulp residue | 160 | - | 30 | [182] |

| Vitis vinifera pomace | 140 | 15 | 130 | [183] | |

| Vitis vinifera pomace | 120 | 10 | 120 | [184] | |

| Plantago major | 100 | 10 | 2 | [185] | |

| Plantago lanceolata | 100 | 10 | 2 | [185] | |

| Japonica-type rice (Oryza sativa) | 100–360 | 18 | 10–30 | [186] |

| Compound | Stable at pH | High Degradation at pH | Refs. |

|---|---|---|---|

| Gallic acid | <7 | >10 | [187] |

| Protocatechuic acid | <5 | >7 | [188] |

| Vanillic acid | <5 | >7 | [188] |

| Caffiec acid | <7 | >10 | [187] |

| Ferulic acid | <9 | >11 | [187,188] |

| Quercetin | N/A | >6 | [53] |

| (-)-catechin | <7 | >10 | [187] |

| Rutin | <11 | N/A | [187] |

| Neochlorogenic acid | <6 | >9 | [189] |

| Cryptochlorogenic acid | <5 | >9 | [190] |

| Chlorogenic acid | <5 | >7 | [191,192] |

| Biomass | Method | Optimal or Experimental Conditions | References |

|---|---|---|---|

| Flax | USE | 0.2 M NaOH in water at 25 °C for 60 min at 30 kHz | [198] |

| Crithmum maritimum and Salicornia europaea | USE | Water:ethanol, 40:60 v/v% at 50 °C for 20 min | [199,204] |

| Wheat straw | Solvent | Water:ethanol, 60:40 v/v%, 8 w% NaOH at 70 °C for 18 h | [200] |

| Barley straw | Alkaline + solvent | Pretreatment: 2 M NaOH for 1 h, nitrogen atmosphere. Solvent: EtOAc. | [161,162] |

| Enzymatic | Pepsin, Pancreatin, Pronase E, Viscozyme L | ||

| Used coffee bean pulp | Enzymatic + fungi + solvent | Pectinase, Rhizomucor pusillus, and EtOAc | [202] |

| Brewer’s spent grain | Enzymatic | DEPOL 740 L, pH 8 at 50 °C | [203] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaturvedi, T.; Hulkko, L.S.S.; Fredsgaard, M.; Thomsen, M.H. Extraction, Isolation, and Purification of Value-Added Chemicals from Lignocellulosic Biomass. Processes 2022, 10, 1752. https://doi.org/10.3390/pr10091752

Chaturvedi T, Hulkko LSS, Fredsgaard M, Thomsen MH. Extraction, Isolation, and Purification of Value-Added Chemicals from Lignocellulosic Biomass. Processes. 2022; 10(9):1752. https://doi.org/10.3390/pr10091752

Chicago/Turabian StyleChaturvedi, Tanmay, Laura Sini Sofia Hulkko, Malthe Fredsgaard, and Mette Hedegaard Thomsen. 2022. "Extraction, Isolation, and Purification of Value-Added Chemicals from Lignocellulosic Biomass" Processes 10, no. 9: 1752. https://doi.org/10.3390/pr10091752

APA StyleChaturvedi, T., Hulkko, L. S. S., Fredsgaard, M., & Thomsen, M. H. (2022). Extraction, Isolation, and Purification of Value-Added Chemicals from Lignocellulosic Biomass. Processes, 10(9), 1752. https://doi.org/10.3390/pr10091752