Optimum Design of Square Blank Dimension with Low Energy Consumption and Low Cost for Milling Based on Business Compass Concept

Abstract

:1. Introduction

2. Business Compass and Blank Dimension Design

2.1. Business Compass Analysis

2.2. Blank Dimension Design and Business Compass

3. Multi-Objective Function Construction Considering Blank Dimension

3.1. Energy Consumption Function

3.2. Cost Function

4. Constraints

5. Case Study

5.1. Problem Background

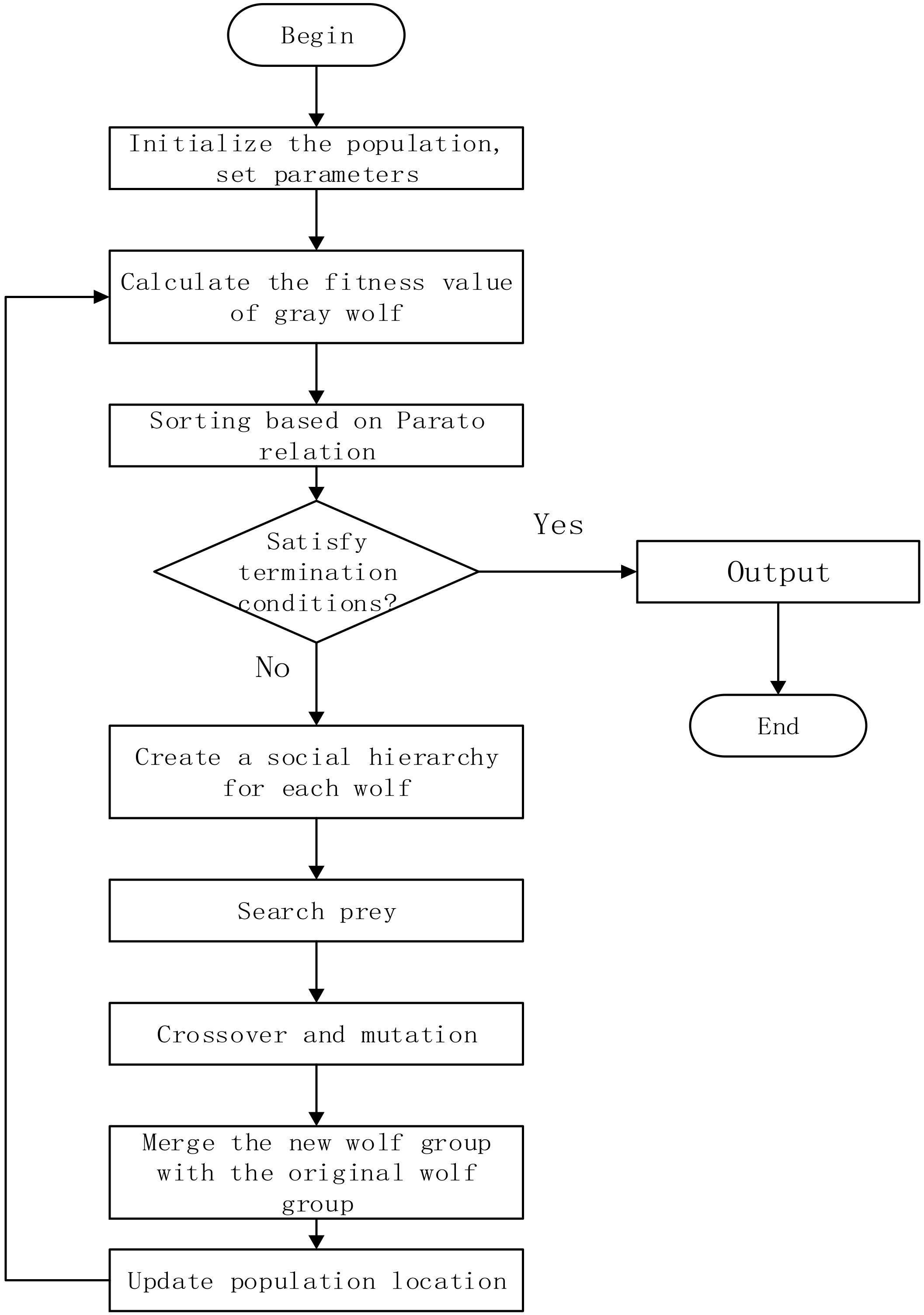

5.2. Analysis of Grey Wolf Optimization Algorithm

5.3. The Experimental Process of Business Compass Guidance

5.4. Simulation Results

5.5. Discussion

5.5.1. Theoretical Implication

5.5.2. Managerial Implication

5.6. Compared with Previous Works

6. Conclusions

- Based on the guidance of the business compass model, the business compass model of enterprise is established to correspond with the logic of human, design method, environment, equipment, and enterprise management. From the point of view of management, this paper analyzes and studies the influence of blank dimension optimization on the business process of enterprises, and reflects the importance of blank dimension optimization design;

- Based on the calculation model of energy consumption and cost in the process of blank production and use, a method of blank dimension optimization design is established. Based on the optimal processing parameters of the whole process energy consumption and cost objective, The optimal blank dimension was obtained by inverse method;

- As an advanced calculation method, Grey Wolf Algorithm is chosen to optimize the energy consumption and cost of different blank dimension;

- The empirical study shows that the method can effectively design the most suitable blank dimension, which provides a scientific basis for the improvement of enterprise operation and management and the optimization path of enterprise production process.

Limitations and Future Research Direction

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Ma, J.; Chen, R.; Su, H. Driving factors and decoupling analysis on industrial energy consumption in China. J. Stat. Inf. 2021, 36, 70–81. [Google Scholar]

- Wang, J.; Zhao, T.; Zhang, X. Energy and environmental unified efficiency of industrial sub-sectors and its influencing factors in China. Resour. Sci. 2016, 38, 311–320. [Google Scholar]

- Liu, H.; Fan, L.; Shao, Z. Threshold effects of energy consumption, technological innovation, and supply chain management on enterprise performance in China’s manufacturing industry. J. Environ. Manag. 2021, 300, 113687. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Xu, X.; Lv, Z.; Mao, H.; Wu, J. Environmental impact assessment of wastewater discharge with multi-pollutants from iron and steel industry. J. Environ. Manag. 2019, 245, 210–215. [Google Scholar] [CrossRef]

- Yumei, H.; Wasim, L.; Ghulam, M.S.; Nadeem, L.; Yasir, A.S.; Arooj, F. Measuring Energy Efficiency and Environmental Performance: A Case of South Asia. Processes 2019, 7, 325. [Google Scholar]

- Kitayama, S.; Natsume, S.; Yamazaki, K. Numerical optimization of blank shape considering flatness and variable blank holder force for cylindrical cup deep drawing. Int. J. Adv. Manuf. Technol. 2016, 85, 2389–2400 . [Google Scholar] [CrossRef]

- Chen, M.H.; Wu, X.; Xie, L. Two-Layer process and optimal blank design for hollow titanium wide-chord fan blades with complex geometries. Rare Met. Mater. Eng. 2019, 48, 1717–1724. [Google Scholar]

- Liu, M.J.; Zhai, J.; Lin, J.; Guan, Y. Preform optimization of complex part based on quasi-equipotential field and response surface methods. J. Netshape Form. Eng. 2017, 9, 33–38. [Google Scholar]

- Gharehchahi, H.; Kazemzadeh, M.J.; Afsari, A. Optimum blank shape design in deep drawing process using a new boundary updating formula. Int. J. Mater. Form. 2021, 14, 1375–1389. [Google Scholar] [CrossRef]

- Giuliano, G.; Polini, W. Optimal design of blank thickness in superplastic AZ31 alloy to decrease forming time and product weight. Int. J. Adv. Manuf. Technol. 2021, 118, 2153–2162. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Mu, Z.G. Research on Optimization Design Technology of Part Blank Based on Laser Scanning. Aeronaut. Manuf. Technol. 2019, 62, 92–101. [Google Scholar]

- Zhang, W.; Gao, J.; Cao, J. Blank geometry design for carbon fiber reinforced plastic (CFRP) preforming using finite element analysis (FEA). Procedia Manuf. 2020, 48, 197–203. [Google Scholar] [CrossRef]

- Cai, W.; Lai, K.; Liu, C.; Wei, F.; Ma, M.; Jia, S.; Jiang, Z.; Lv, L. Promoting sustainability of manufacturing industry through the lean energy-saving and emission-reduction strategy. Sci. Total. Environ. 2019, 665, 23–32. [Google Scholar] [CrossRef]

- Cai, W.; Liu, C.; Zhang, C.; Ma, M.; Rao, W.; Li, W.; He, K.; Gao, M. Developing the ecological compensation criterion of industrial solid waste based on energy for sustainable development. Energy 2018, 157, 940–948. [Google Scholar] [CrossRef]

- Ni, H.X.; Yan, C.; Chen, J. Multi-objective optimization and decision-making method of high speed dry gear hobbing processing parameters. China Mech. Eng. 2021, 32, 832–838. [Google Scholar]

- Dong, S.; Jiang, M. A novel multi-objective lion swarm intelligent optimization based on cloud model for manufacturing scheduling problem. J. Phys. Conf. Ser. 2021, 2025, 012030. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, H.; Jiang, Z.G.; Hon, K.K. Multi-objective optimization of arc welding parameters: The trade-offs between energy and thermal efficiency. J. Clean. Prod. 2016, 140, 1842–1849. [Google Scholar]

- Albertelli, P.; Keshari, A.; Matta, A. Energy oriented multi cutting parameter optimization in face milling. J. Clean. Prod. 2016, 137, 1602–1618. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Li, X.; Chen, P. Energy-efficient multi-pass turning operation using multi-objective backtracking search algorithm. J. Clean. Prod. 2016, 137, 1516–1531. [Google Scholar] [CrossRef] [Green Version]

- Lv, L.X.; Deng, C.H.; Liu, T. Multi-layer and multi-objective optimization model and applications of grinding process plan for cleaner production. China Mech. Eng. 2022, 33, 11. [Google Scholar]

- Zhang, Z.; Xu, F.; Sun, X. Optimization of process parameters during hydroforming of tank bottom using NSGA-III algorithm. Int. J. Adv. Manuf. Technol. 2022, 119, 4043–4055. [Google Scholar] [CrossRef]

- Zhan, X.L.; Zhang, C.Y.; Meng, L.; Hong, H. Low carbon modeling and optimization of milling parameters based on improved gravity search algorithm. China Mech. Eng. 2020, 31, 1481–1491. [Google Scholar]

- Feng, C.; Guo, H.; Zhang, J. A systematic method of optimization of machining parameters considering energy consumption, machining time, and surface roughness with experimental analysis. Int. J. Adv. Manuf. Technol. 2022, 119, 7383–7401. [Google Scholar] [CrossRef]

- Li, B.; Tian, X.; Zhang, M. Modeling and multi-objective optimization method of machine tool energy consumption considering tool wear. Int. J. Precis. Eng. Manuf. Green Technol. 2022, 9, 127–141. [Google Scholar] [CrossRef]

- Tian, G.; Yuan, G.; Aleksandrov, A.; Zhang, T.; Li, Z.; Fathollahi-Fard, A.M.; Ivanov, M. Recycling of spent Lithium-ion Batteries: A comprehensive review for identification of main challenges and future research trends. Sustain. Energy Technol. Assess. 2022, 53, 102447. [Google Scholar] [CrossRef]

- Wang, R.P.; Yi, J. Characteristics and Mission of Management Thinking with Chinese Characteristics Based on the Business Compass Perspective. In Proceedings of the 8th International Symposium on Project Management (ISPM 2020), Beijing, China, 4–5 July 2020. [Google Scholar]

- Wen, H. Chinese Philosophy; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Wang, R.P. Business Compass; Science Press China: Beijing, China, 2020. [Google Scholar]

- Xiao, Y.M.; Jiang, Z.G.; Gu, Q.; Yan, W.; Wang, R.P. A novel approach to CNC machining center processing parameters optimization considering energy-saving and low-cost. J. Manuf. Syst. 2021, 59, 535–548. [Google Scholar] [CrossRef]

- Xiao, Y.M.; Wang, R.P.; Yan, W.; Ma, L.N. Optimum Design of Blank Dimensions Guided by a Business Compass in the Machining Process. Processes 2021, 9, 1286. [Google Scholar] [CrossRef]

- Xiao, Q.G.; Li, C.B.; Tang, Y.; Li, L. A knowledge-driven method of adaptively optimizing process parameters for energy efficient turning. Energy 2019, 166, 142–156. [Google Scholar] [CrossRef]

- Zhou, B.; Lei, Y. Bi-objective grey wolf optimization algorithm combined Levy flight mechanism for the FMC green scheduling problem. Appl. Soft Comput. 2021, 111, 107717. [Google Scholar] [CrossRef]

- Huang, G.; Cai, Y.; Liu, J. A novel hybrid discrete grey wolf optimizer algorithm for multi-UAV path planning. J. Intell. Robot. Syst. 2021, 103, 1–18. [Google Scholar] [CrossRef]

- Teng, Z.J.; Lv, J.L.; Guo, L.W. An improved hybrid grey wolf optimization algorithm. Soft Comput. 2019, 23, 6617–6631. [Google Scholar] [CrossRef]

- Li, Y.; Lin, X.; Liu, J. An improved gray wolf optimization algorithm to solve engineering problems. Sustainability 2021, 13, 3208. [Google Scholar] [CrossRef]

- Tian, G.; Zhang, C.; Fathollahi-Fard, A.M.; Li, Z.; Zhang, C.; Jiang, Z. An Enhanced Social Engineering Optimizer for Solving an Energy-Efficient Disassembly Line Balancing Problem Based on Bucket Brigades and Cloud Theory. IEEE Trans. Ind.Inform. 2022, 1–11. [Google Scholar] [CrossRef]

| Spindle Speed | Feed Speed | Maximum Milling Force | Maximum Power | Power Effective Coefficient |

|---|---|---|---|---|

| 40–8000 | 1–6000 | 5500 | 7.5 | 0.8 |

| 8311 | 0.019 | 0.17 | 0.34 | 0.08 | 229 | 0.9 | 0.26 | 60 | 120 |

| 0.723 | 2278 | 1 | 1.3 | 1.1555 |

| 0.2 | 2.5 | 0.5 | 15 | 90.115 | 2 × 10−5 | 1.243 | 1.7 × 104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Liu, X.; Wang, R.; Zhang, H.; Li, J.; Zhou, J. Optimum Design of Square Blank Dimension with Low Energy Consumption and Low Cost for Milling Based on Business Compass Concept. Processes 2022, 10, 1514. https://doi.org/10.3390/pr10081514

Xiao Y, Liu X, Wang R, Zhang H, Li J, Zhou J. Optimum Design of Square Blank Dimension with Low Energy Consumption and Low Cost for Milling Based on Business Compass Concept. Processes. 2022; 10(8):1514. https://doi.org/10.3390/pr10081514

Chicago/Turabian StyleXiao, Yongmao, Xiaoqin Liu, Ruping Wang, Hao Zhang, Jieyun Li, and Jincheng Zhou. 2022. "Optimum Design of Square Blank Dimension with Low Energy Consumption and Low Cost for Milling Based on Business Compass Concept" Processes 10, no. 8: 1514. https://doi.org/10.3390/pr10081514

APA StyleXiao, Y., Liu, X., Wang, R., Zhang, H., Li, J., & Zhou, J. (2022). Optimum Design of Square Blank Dimension with Low Energy Consumption and Low Cost for Milling Based on Business Compass Concept. Processes, 10(8), 1514. https://doi.org/10.3390/pr10081514