Study of the Polishing Characteristics by Abrasive Flow Machining with a Rotating Device

Abstract

:1. Introduction

2. Materials and Methods

2.1. RDSM-AFM Setup and Fixture Design

2.2. Experimental Materials

3. Results and Discussion

3.1. Effects of the Rotational Speed on Surface Roughness

3.2. Effects of Rotation Direction on Surface Roughness

3.3. Effects of the Reciprocating Cycles on Surface Roughness

3.4. Effects of Abrasive Mesh Size on Surface Roughness

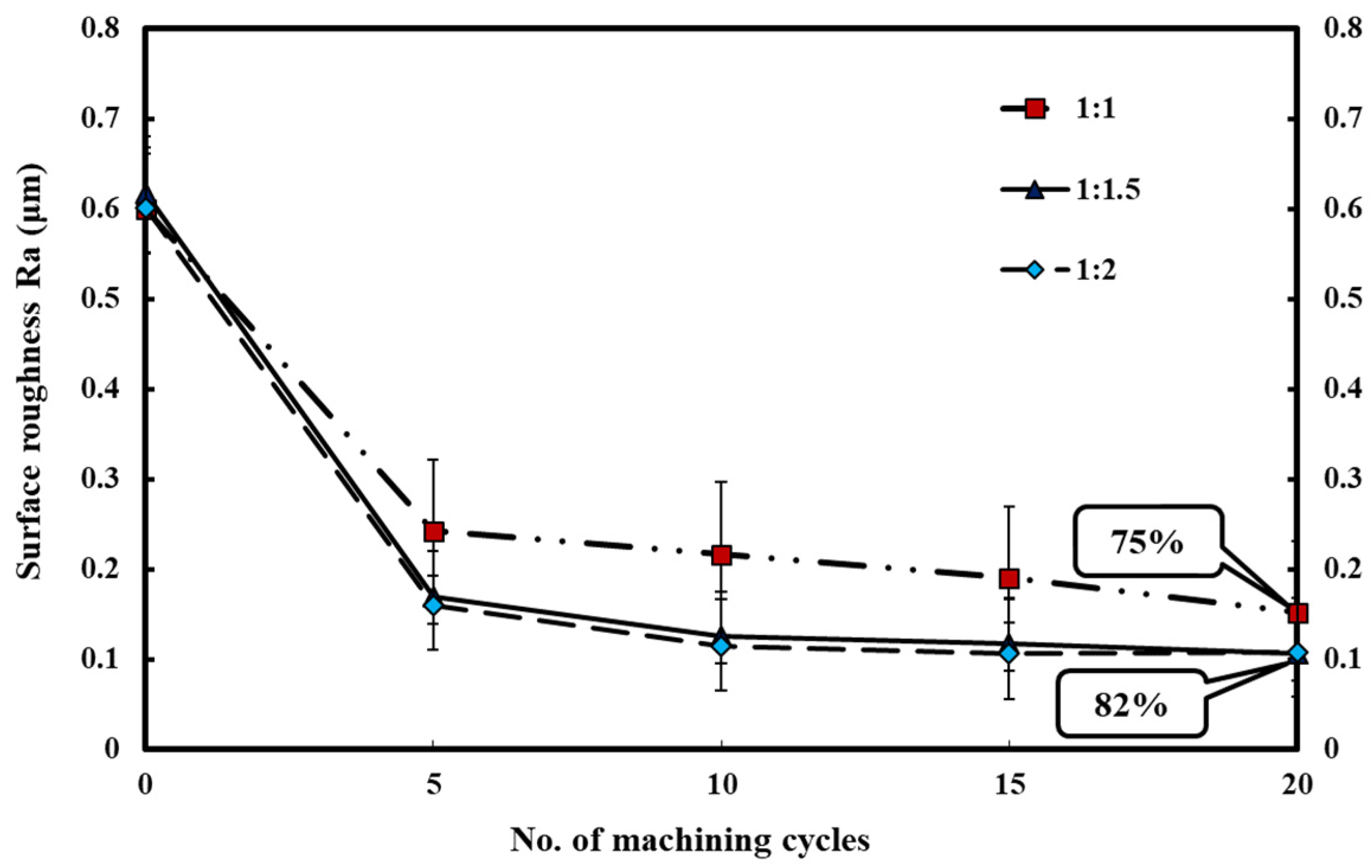

3.5. Effects of the Silicone Gel/Abrasive Concentration Ratio on Surface Roughness

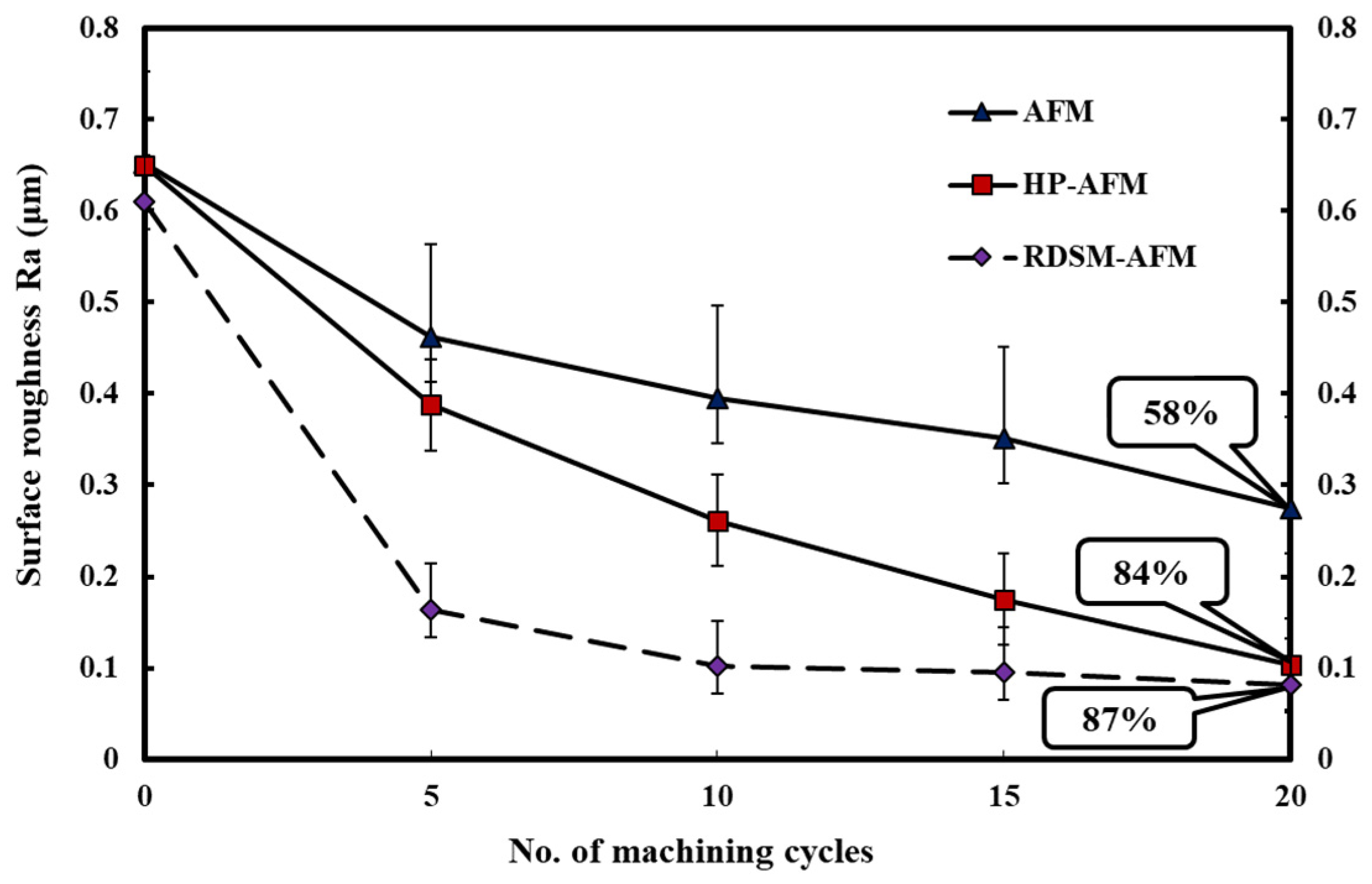

3.6. Effect of AFM Methods on Surface Roughness

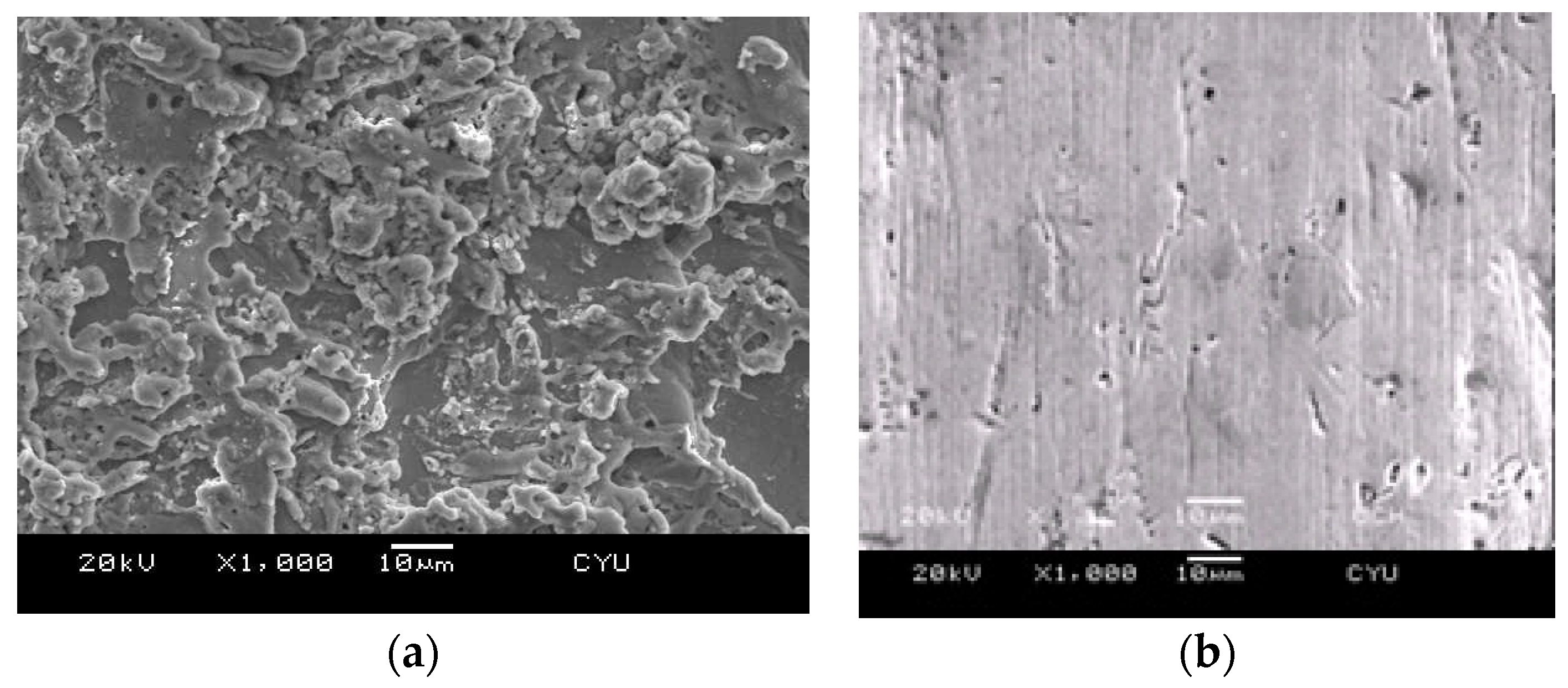

3.7. Finishing Results of the Polished Surface

4. Conclusions

- Surface roughness of the circular holes was decreased by increasing the rotational speeds in RDSM-AFM, however, the finishing results quickly reached a critical value at rotational speeds of 10 rpm and 15 rpm.

- Since the workpiece changed rotating direction after 10 machining cycles, and surface roughness of the circular hole was already at a saturated level, therefore, the workpiece with staggered rotation directions could not effectively enhance surface roughness.

- Surface roughness of the inner hole could quickly decrease to the saturated values only after 5 machining cycles, it indicated that RDSM-AFM could effectively reduce the cost of the surface polishing.

- The small abrasive mesh #60 produced better surface roughness than the large abrasive mesh #500, the RIR of the abrasive mesh #60 reached 61% at five reciprocating cycles, but the RIR of the abrasive mesh #500 only reached 16% at the same working cycles.

- High silicone gel/abrasive concentration ratios resulted in good polishing effect in RDSM-AFM, the RIR of the concentration ratios 1.0:1.5 and 1.0:2.0 reached 82% at the rotational speed of 10 rpm.

- RDSM-AFM performed significantly better than traditional AFM and HP-AFM in short time periods; the RIR of RDSM-AFM almost reached 80% at five working cycles with a rotational speed of 15 rpm, but the RIR of traditional AFM and HP-AFM only reached 25% and 38% under the same conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jain, V.K.; Adsul, S.G. Experimental investigations into abrasive flow machining (AFM). Int. J. Mach. Tools Manuf. 2002, 40, 1003–1021. [Google Scholar] [CrossRef]

- Wang, A.C.; Liu, C.H.; Liang, K.Z.; Pai, S.H. Study of the rheological properties and the finishing behavior of abrasive gels in abrasive flow machining. J. Mech. Sci. Tech. 2007, 21, 1593–1598. [Google Scholar] [CrossRef]

- Wang, A.C.; Weng, S.H. Developing the polymer abrasive gels in AFM process. J. Mater. Pro. Tech. 2007, 192, 486–490. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.; Aggarwal, V.; Pimenoy, D.Y.; Giasin, K.; Nadolny, K. Hand and Abrasive Flow Polished Tungsten Carbide Die: Optimization of Surface Roughness, Polishing Time and Comparative Analysis in Wire Drawing. Materials 2022, 15, 1287. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.C.; Tsai, L.; Liang, K.Z.; Liu, C.H.; Weng, S.H. Uniform surface polished method of complex holes in abrasive flow machining. T. Nonferr. Metal. Soc. 2009, 19, 250–257. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, Y.G.; Kim, K.H. Characterization of Deburring by Abrasive Flow Machining for AL6061. Appl. Sci. 2022, 12, 2048. [Google Scholar] [CrossRef]

- Sambharia, J.; Mali, H.; Grag, V. Experimental investigation on unidirectional abrasive flow machining of trim die workpiece. Mater. Manuf. Proc. 2018, 33, 651–660. [Google Scholar] [CrossRef]

- Petare, A.; Jain, N. Improving spur gear microgeometry and surface finish by AFF process. Mater. Manuf. Proc. 2018, 33, 923–934. [Google Scholar] [CrossRef]

- Wang, A.C.; Cheng, K.C.; Chen, K.Y.; Lin, Y.C. Finishing Performance of the Abrasive Flow Machining in Complex Holes by Using Helical Cores. K. Eng. Mater. 2020, 831, 52–56. [Google Scholar] [CrossRef]

- Wang, A.C.; Cheng, K.C.; Chen, K.Y.; Lin, Y.C. Elucidating the surface precision for the helical passageways in Abrasive Flow Machining. Mater. Manuf. Proc. 2014, 29, 153–159. [Google Scholar] [CrossRef]

- Sankar, M.R.; Jain, V.K.; Ramkumar, J. Experimental investigations into rotating workpiece abrasive flow finishing. Wear 2009, 267, 43–51. [Google Scholar] [CrossRef]

- Sankar, M.R.; Jain, V.K.; Ramkumar, J. Rotational abrasive flow finishing (R-AFF) process and its effects on finished surface topography. Int. J. Mach. Tools Manuf. 2010, 50, 637–650. [Google Scholar] [CrossRef]

- Das, M.; Jain, V.K.; Ghoshdastidar, P.S. The out-of-roundness of the internal surfaces of stainless steel tubes finished by the rotational magnetorheological abrasive flow finishing process. Mater. Manuf. Process. 2011, 26, 1073–1084. [Google Scholar] [CrossRef]

- Sankar, M.R.; Jain, V.K.; Ramkumar, J.; Sareen, S.K.; Singh, S. Medium rheological characterization and performance study during rotational abrasive flow finishing (R-AFF) of Al alloy and Al alloy/SiC MMCs. Int. J. Adv. Manuf. Technol. 2019, 100, 1149–1163. [Google Scholar] [CrossRef]

- Azami, A.; Azizi, A.; Khoshanjam, A. Nano-finishing of stainless-steel tubes using rotational abrasive finishing (RAF) process. J. Manuf. Proc. 2018, 34, 281–291. [Google Scholar] [CrossRef]

- Singh, S.; Shan, H.S. Development of magneto abrasive flow machining process. Int. J. Mach. Tools Manuf. 2002, 42, 953–959. [Google Scholar] [CrossRef]

- Wang, A.C.; Tsai, L.; Liu, C.H.; Liang, K.Z.; Lee, S.J. Elucidating the Optimal Parameters in Magnetic Finishing with Gel Abrasive. Mater. Manuf. Process. 2011, 26, 786–791. [Google Scholar] [CrossRef]

- Cheng, K.C.; Chen, K.Y.; Tsui, H.P.; Wang, A.C. Characteristics of the polishing effects for the stainless tubes in magnetic finishing with gel abrasive. Processes 2021, 9, 1561. [Google Scholar] [CrossRef]

- Sathish, T. Exploration on surface roughness in abrasive water jet cutting of AA6063-TiC Composites for Vehicle Structural Applications’. Int. J. Vehicle Struct. Syst. 2019, 11, 417–421. [Google Scholar] [CrossRef]

- Chairman, C.A.; Ravichandran, M.; Mohanavel, V.; Sathish, T.; Rashedi, A.; Alarifi, I.M.; Badruddin, I.A.; Anqi, A.E.; Afzal, A. Mechanical and Abrasive Wear Performance of Titanium Di-Oxide Filled Woven Glass Fibre Reinforced Polymer Composites by Using Taguchi and EDAS Approach. Materials 2021, 14, 5257. [Google Scholar] [CrossRef] [PubMed]

| Mesh Number | Size (μm) |

|---|---|

| #60 | 250–300 |

| #100 | 125–150 |

| #220 | 53–75 |

| #500 | 31–37 |

| Factor | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| Rotation direction | 5 (+) | 10 (+) | ||

| Rotational speed (rpm) | 0 | 5 | 10 | 15 |

| Abrasive mesh size | #60 | #100 | #220 | #500 |

| Concentration ratio (wt.%) | 1:1 | 1:1.5 | 1:2 | / |

| Machining reciprocating cycle | 5 | 10 | 15 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, K.-C.; Wang, A.-C.; Chen, K.-Y.; Huang, C.-Y. Study of the Polishing Characteristics by Abrasive Flow Machining with a Rotating Device. Processes 2022, 10, 1362. https://doi.org/10.3390/pr10071362

Cheng K-C, Wang A-C, Chen K-Y, Huang C-Y. Study of the Polishing Characteristics by Abrasive Flow Machining with a Rotating Device. Processes. 2022; 10(7):1362. https://doi.org/10.3390/pr10071362

Chicago/Turabian StyleCheng, Ken-Chuan, A-Cheng Wang, Kuan-Yu Chen, and Chien-Yao Huang. 2022. "Study of the Polishing Characteristics by Abrasive Flow Machining with a Rotating Device" Processes 10, no. 7: 1362. https://doi.org/10.3390/pr10071362

APA StyleCheng, K.-C., Wang, A.-C., Chen, K.-Y., & Huang, C.-Y. (2022). Study of the Polishing Characteristics by Abrasive Flow Machining with a Rotating Device. Processes, 10(7), 1362. https://doi.org/10.3390/pr10071362