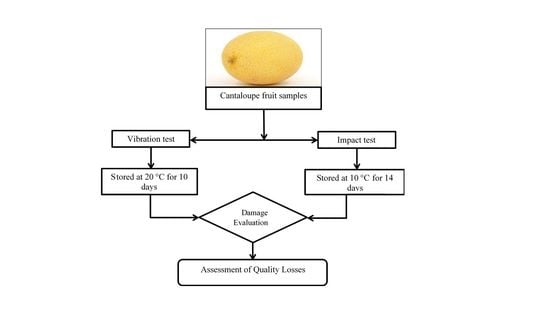

Assessment of the Quality Losses of Cantaloupe Fruit during Transportation

Abstract

:1. Introduction

2. Materials and Methods

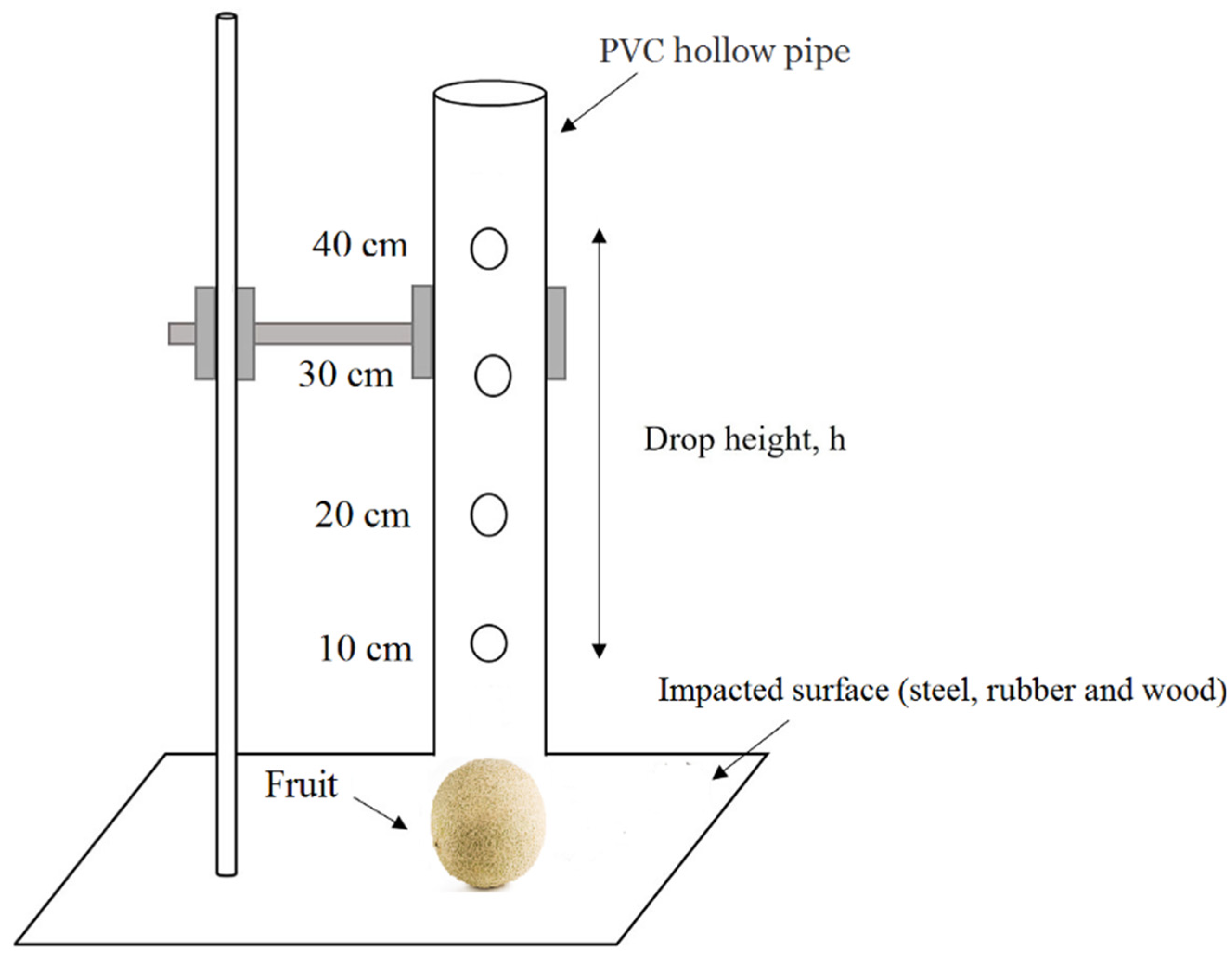

2.1. Impact Testing

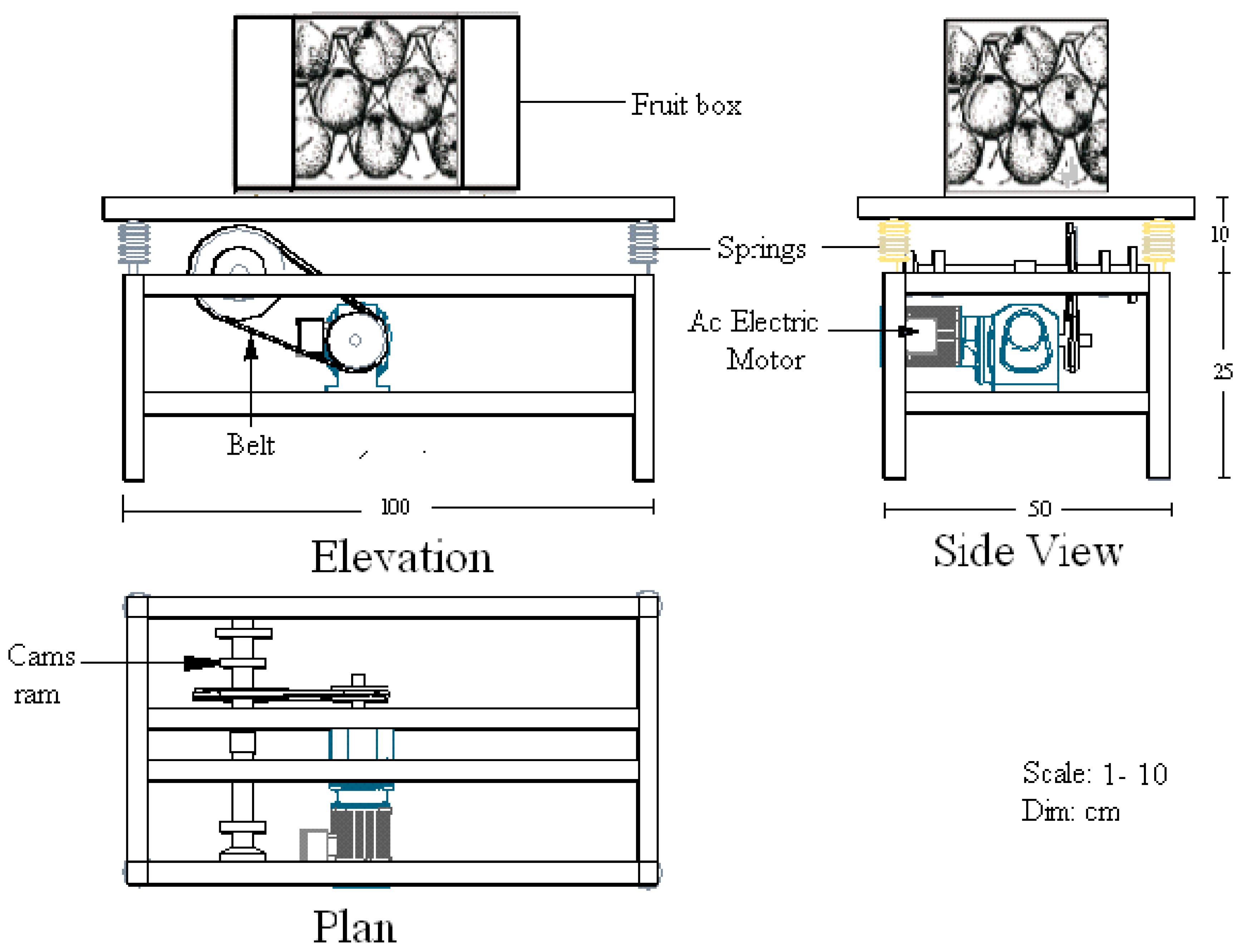

2.2. Vibration Testing

3. Results and Discussion

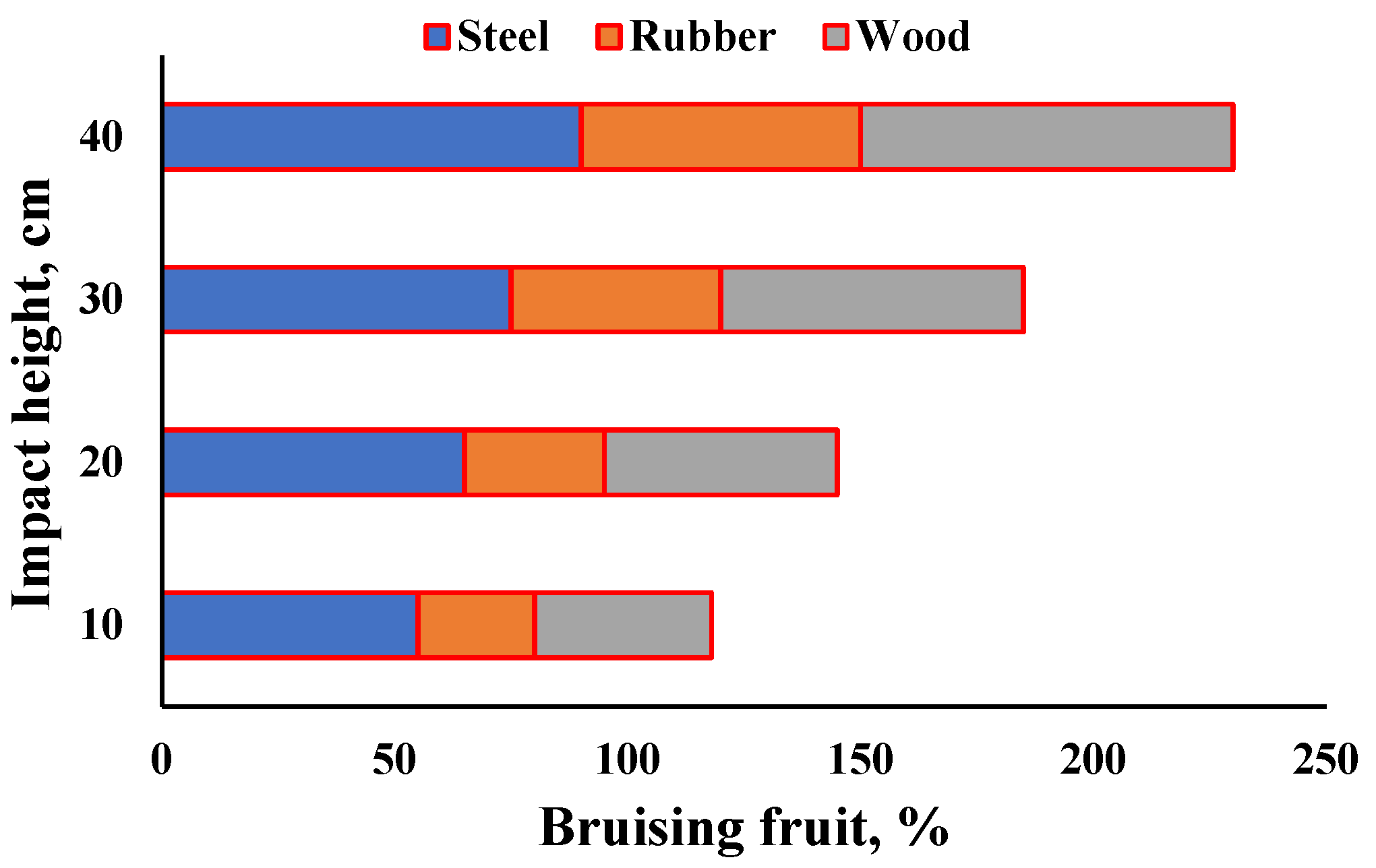

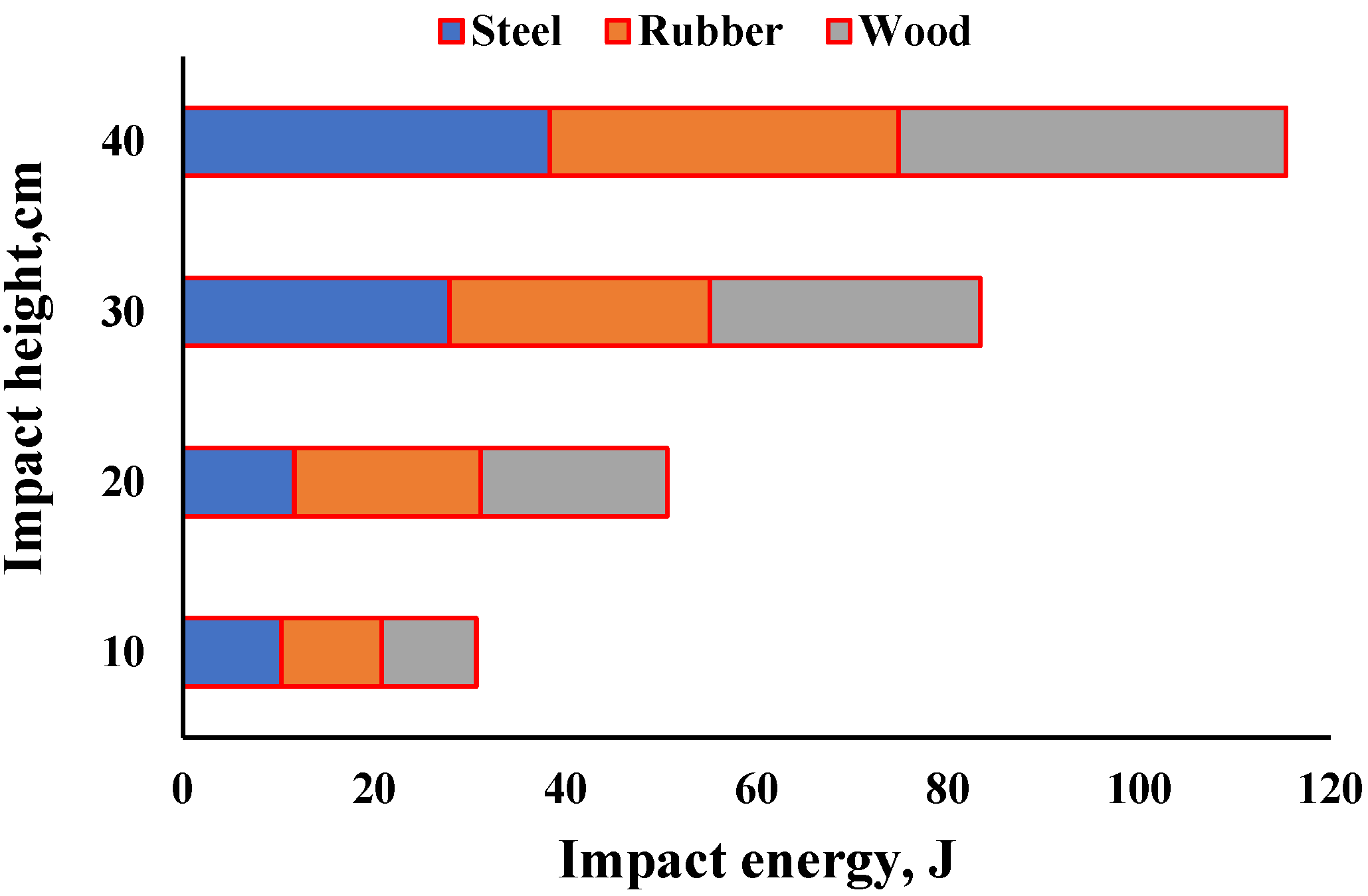

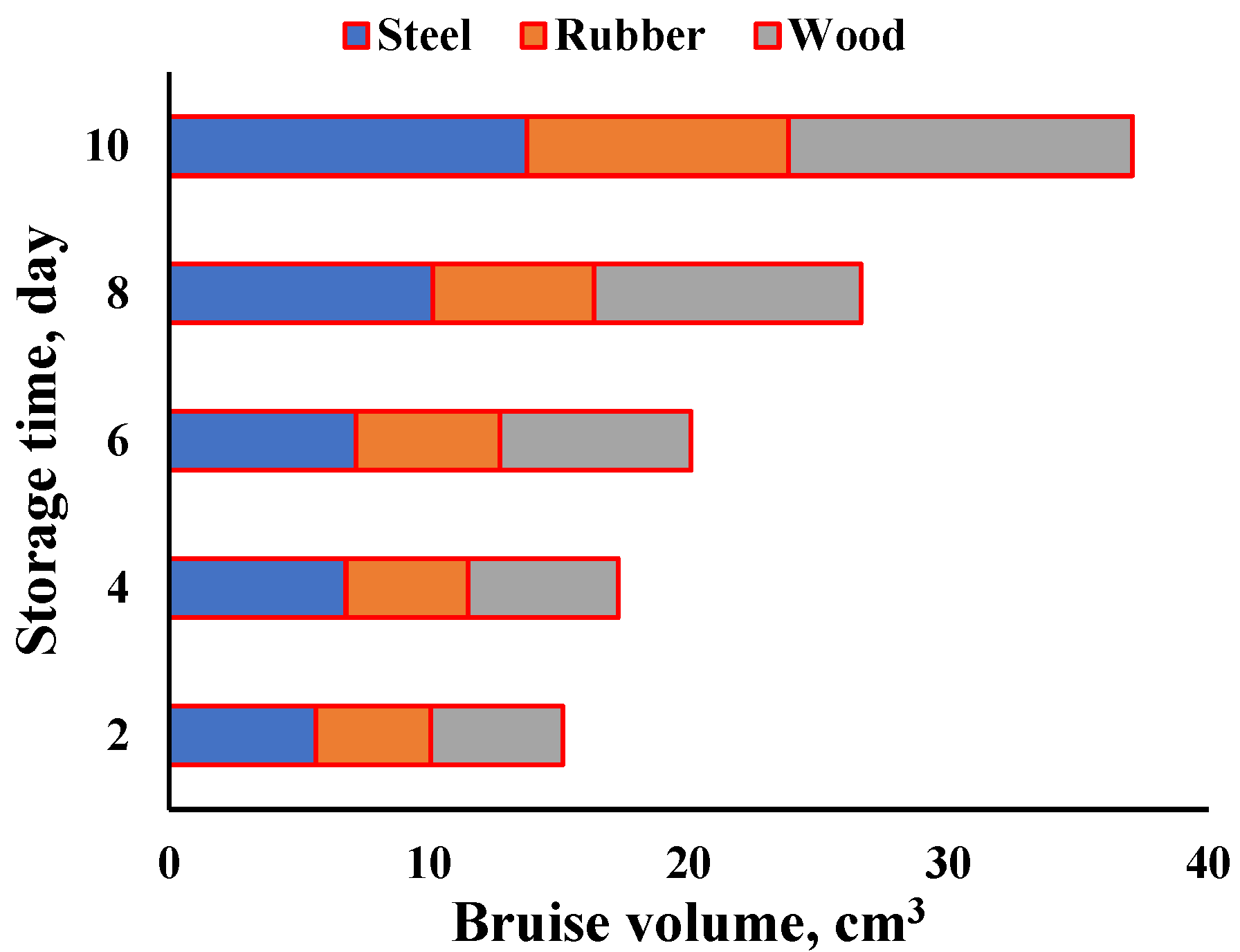

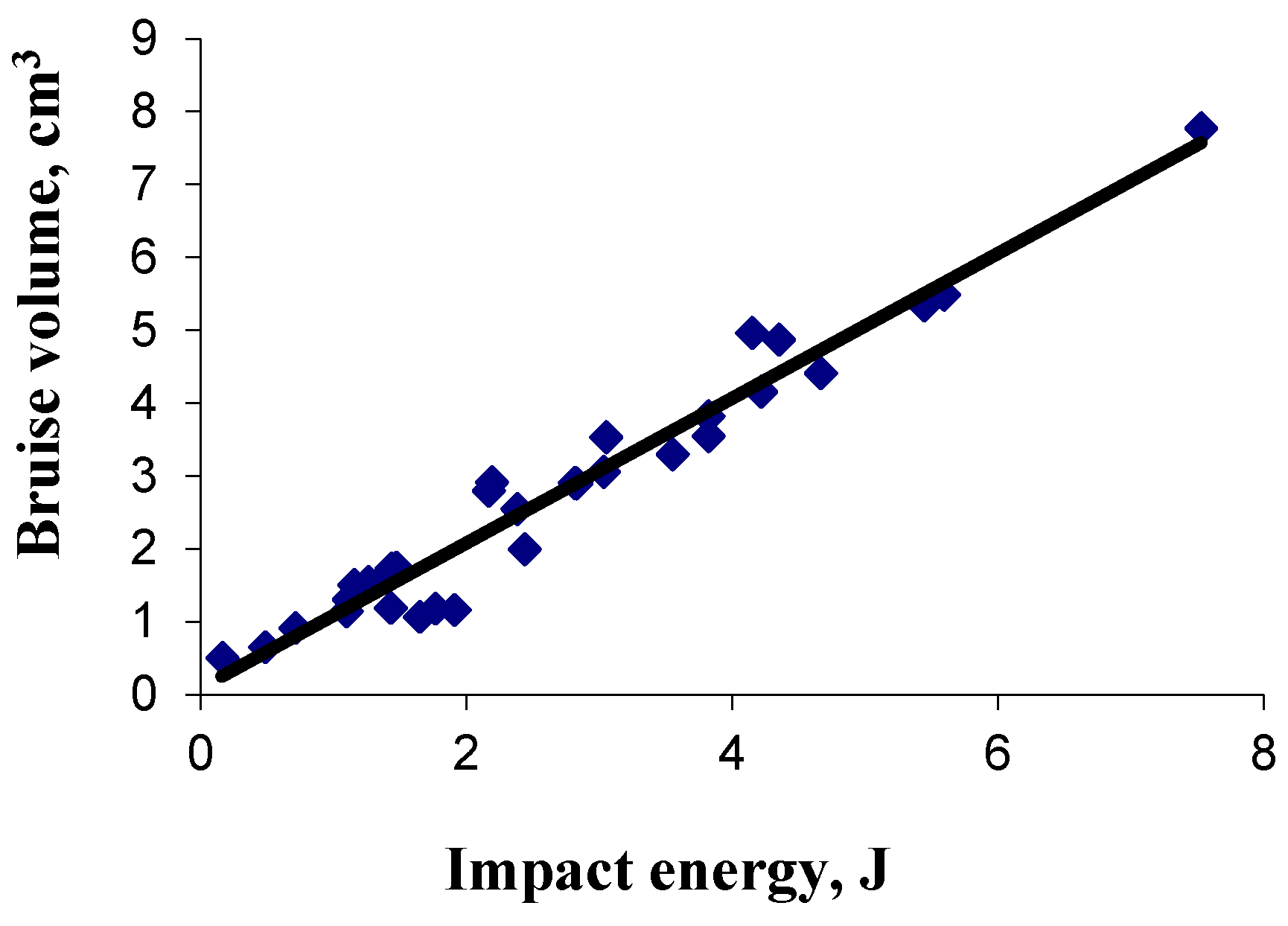

3.1. Impact Testing

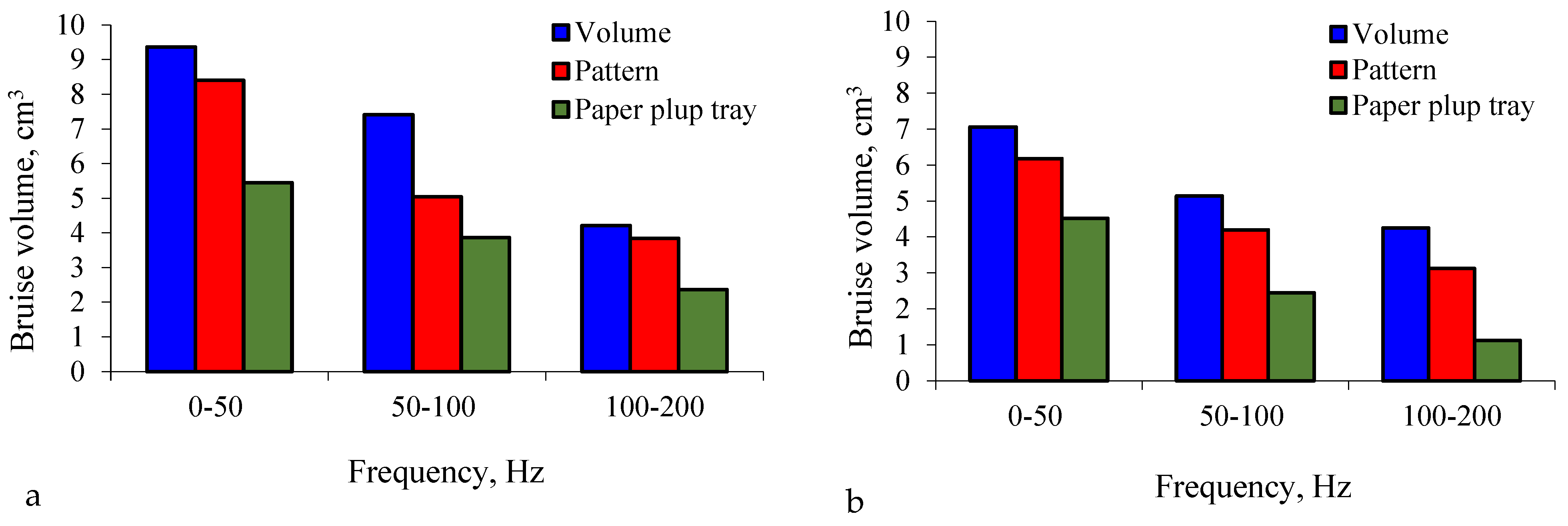

3.2. Effect of Mechanical Vibrations and Packing Method on the Damage of Cantaloupe Fruits

3.3. Effect of Packing Method on the Number of Bruise Cantaloupe at Different Vibration Frequencies

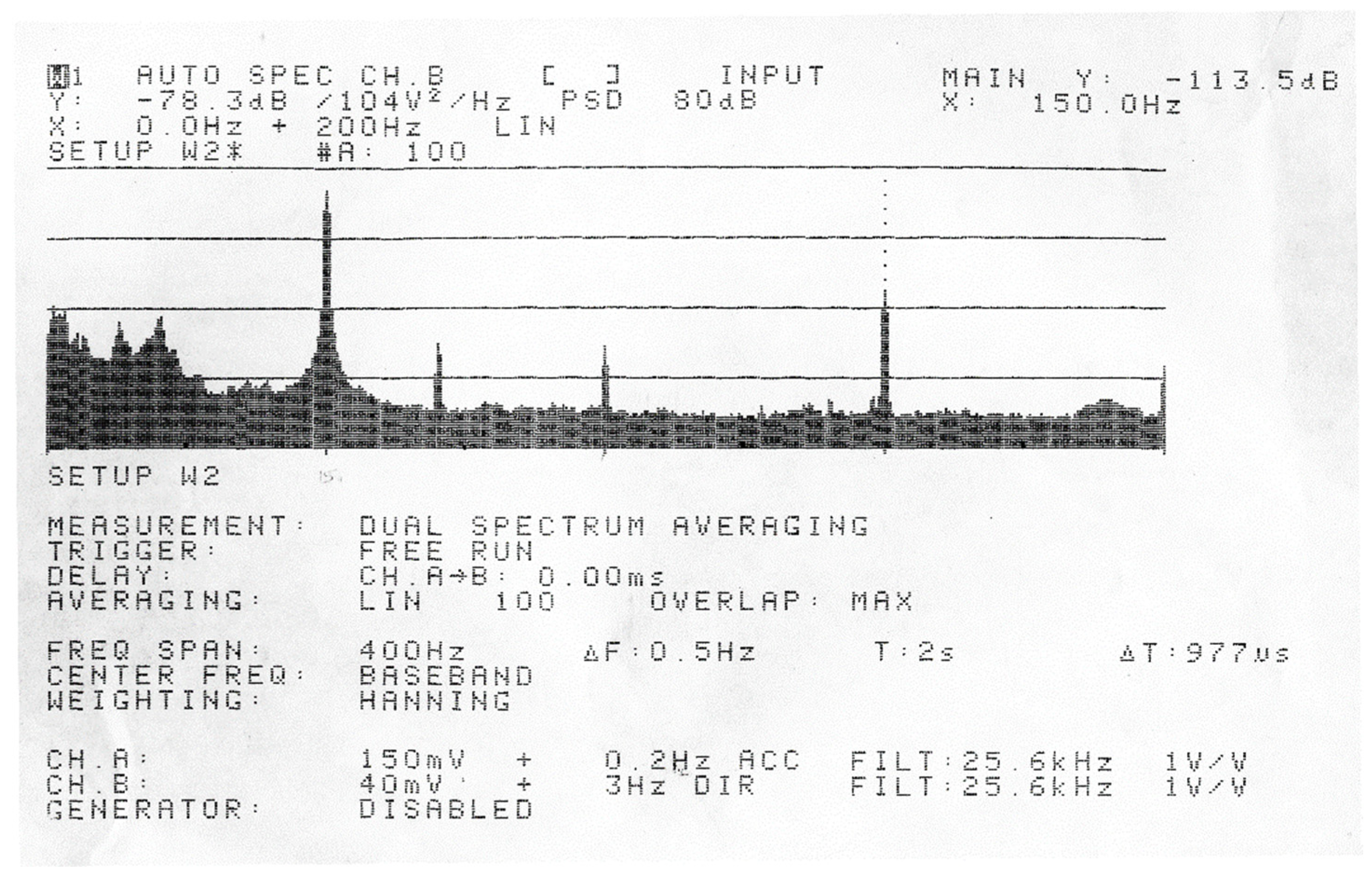

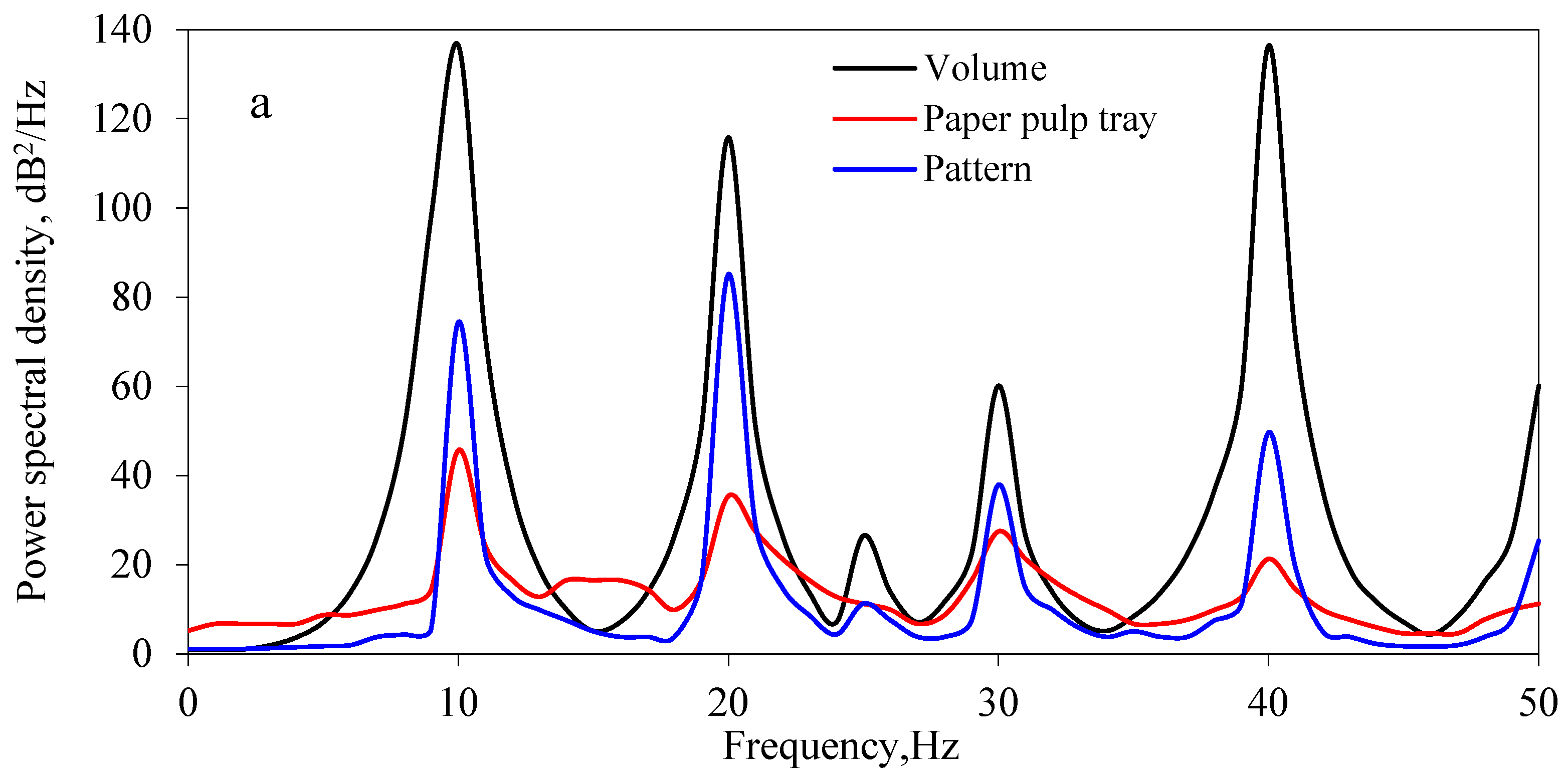

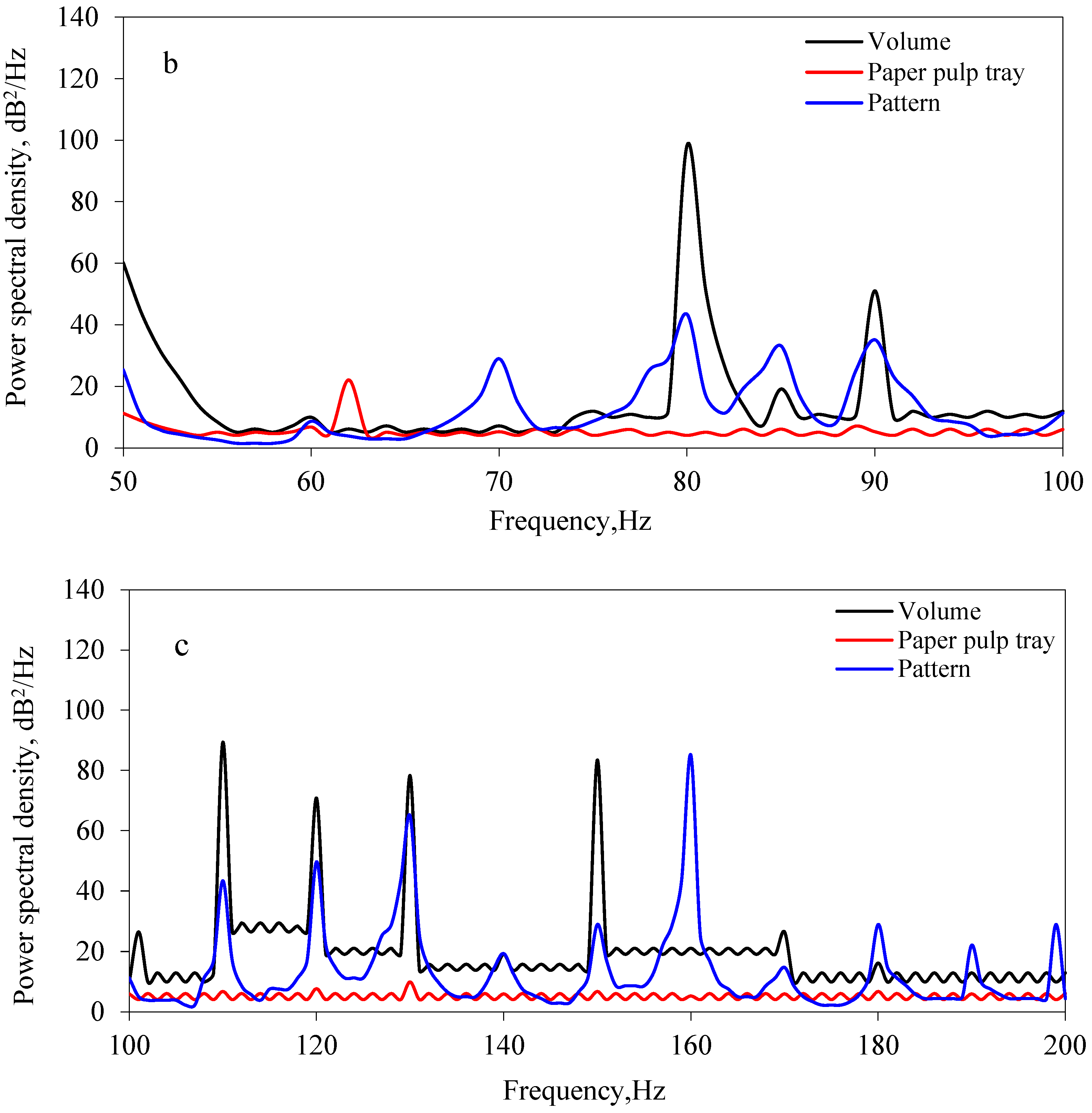

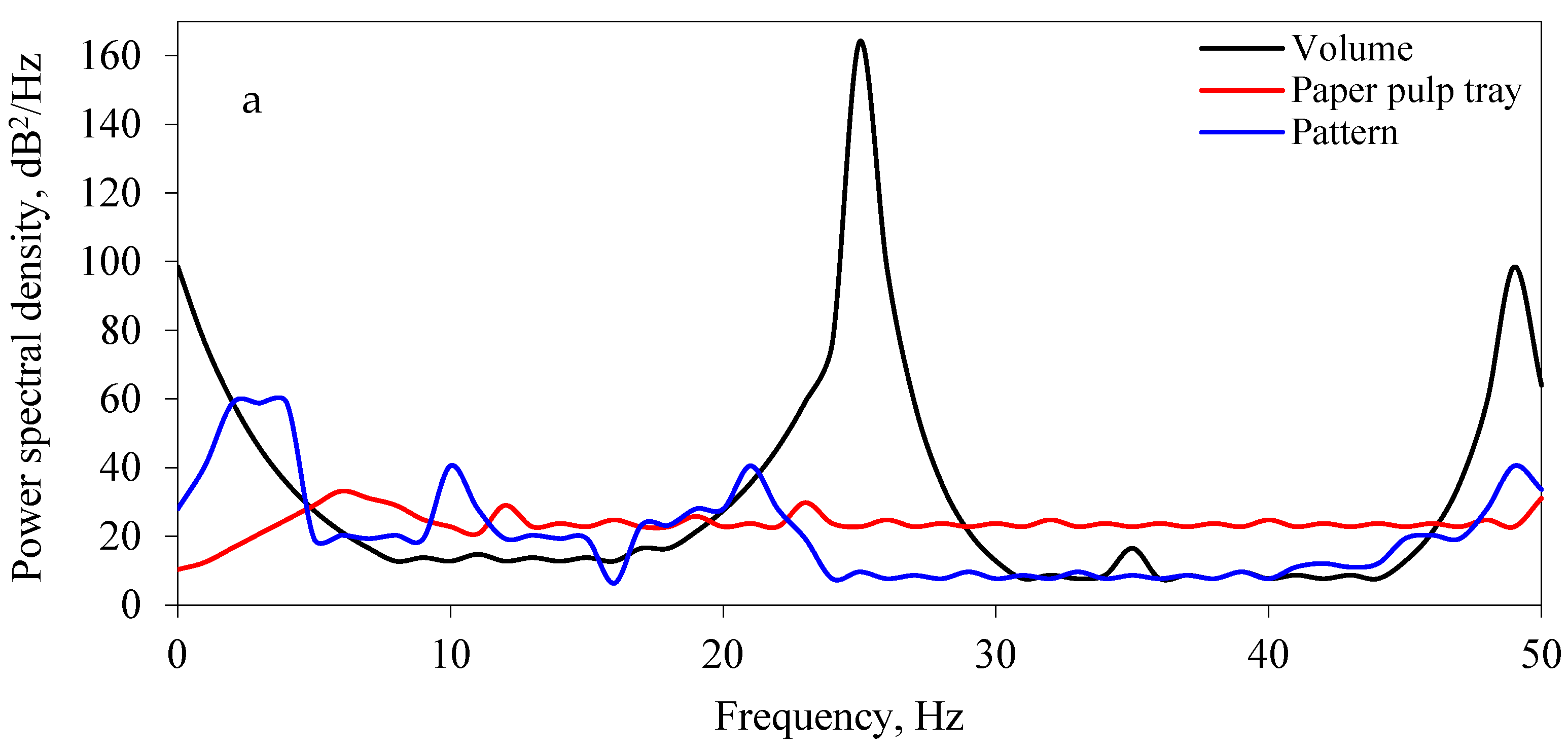

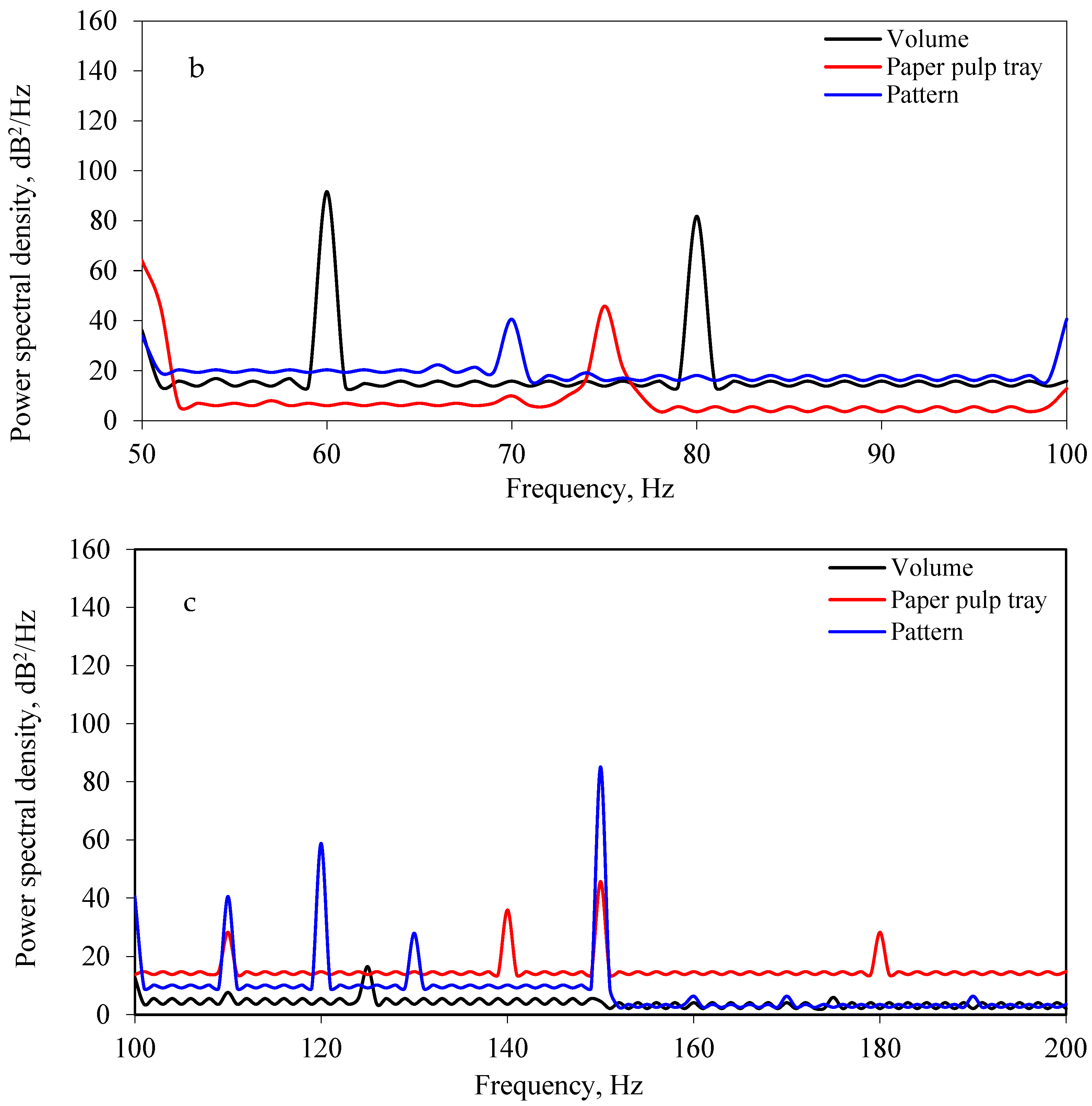

3.4. The Effect of Different Levels of Vibration Frequency on the Dynamic Properties of Cantaloupe during Excitation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amer, B.M.A.; Azam, M.M. Using hot water as a pretreatment to extend the shelf life of cucumbers (Cucumis sativus L.) under cold storage system. J. Food Process Eng. 2019, 42, e12958. [Google Scholar] [CrossRef]

- Peleg, K.; Hinga, S. Simulation of vibration damage in produce transportation. Trans. ASAE 1986, 29, 633–641. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Kitazawa, H.; Shiina, T. Vibration and Shock Analysis of Fruit and Vegetables Transport “Cherry Transport from Yamagata to Taipei”. JARQ 2009, 43, 129–135. [Google Scholar] [CrossRef] [Green Version]

- Zhou, R.; Wu, Q. Simulate the effects of different levels of road transportation vibration on the softening and pectin degradation of cantaloupe. Zhejiang J. Agric. Sci. 2018, 30, 1832–1838. [Google Scholar]

- Abera, G.; Ibrahim, A.M.; Forsido, S.F.; Kuyu, C.G. Assessment on post-harvest losses of tomato (Lycopersicon esculentem Mill.) in selected districts of East Shewa Zone of Ethiopia using a commodity system analysis methodology. Heliyon 2020, 6, e03749. [Google Scholar] [CrossRef]

- Imanpanah, H.; Kasraei, M.; Raoufat, M.H.; Nejadi, J. Development and evaluation of a portable apparatus for bioyield detection: A case study with apple and peach fruits. Int. J. Food Prop. 2015, 18, 1434–1445. [Google Scholar] [CrossRef]

- Kawai, T.; Matsumori, F.; Akimoto, H.; Sakurai, N.; Hirano, K.; Nakano, R.; Fukuda, F. Nondestructive detection of split-pit peach fruit on trees with an acoustic vibration method. Hortic. J. 2018, 87, 499–507. [Google Scholar] [CrossRef] [Green Version]

- Vergano, P.J.; Testin, R.F.; Newall, W.C., Jr. Peach bruising: Susceptibility to impact, vibration and compression abuse. Trans. ASAE 1991, 34, 2110–2116. [Google Scholar] [CrossRef]

- Ogut, H.; Peker, A.; Aydin, C. Simulated transit studies on peaches: Effects of containers cushion materials and vibration on elasticity modulus. Agric. Mech. Asia Afr. Lat. Am. 1999, 30, 59–62. [Google Scholar]

- Khodaei, M.; Seiiedlou, S.; Sadeghi, M. The evaluation of vibration damage in fresh apricots during simulated transport. Res. Agric. Eng. 2019, 65, 112–122. [Google Scholar] [CrossRef]

- Turczyn, M.T.; Grant, S.W.; Ashby, B.H.; Wheaton, F.W. Potato shatter bruising during laboratory handling and transport simulation. Trans. ASAE 1986, 29, 1171–1175. [Google Scholar] [CrossRef]

- Azam, M.M.; Amer Eissa, A.H. Comprehensive Evaluation of Dynamic Impact as a Measure of Potato Quality. Int. J. Food Eng. Technol. 2015, 1, 1–10. [Google Scholar]

- Pathare, P.B.; Al-Dairi, M. Effect of Simulated Vibration and Storage on Quality of Tomato. Horticulturae 2021, 7, 417. [Google Scholar] [CrossRef]

- Albaloushi, N.; Azam, M.M.; Amer Eissa, A.H. Mechanical Properties of Tomato Fruits under Storage Conditions. J. Appl. Sci. Res. 2012, 8, 3053–3064. [Google Scholar]

- La Scalia, G.; Aiello, G.; Miceli, A.; Nasca, A.; Alfonzo, A.; Settanni, L. Effect of Vibration on the Quality of Strawberry Fruits Caused by Simulated Transport. J. Food Process Eng. 2015, 39, 140–156. [Google Scholar] [CrossRef]

- Vursavuş, K.; Özgüven, F. Determining the effects of vibration and packaging method on mechanical damage in golden delicious apples. Turk. J. Agric. For. 2004, 28, 311–320. [Google Scholar]

- Acıcan, T.; Alibas, K.; Özelkök, I.S. Mechanical damage to apples during transport in wooden crates. Biosyst. Eng. 2007, 96, 239–248. [Google Scholar] [CrossRef]

- Gomaa, F.R.; Gamea, G.R.; Azam, M.M.; Amer Eissa, A.H. Health Monitoring of Packed Agricultural Products Using Dynamic Analysis. Eng. Res. J. 2011, 34, 377–394. [Google Scholar]

- Amer Eissa, A.H.; Gamaa, G.R.; Gomaa, F.R.; Azam, M.M. Comparison of Package Cushioning Materials to Protect Vibration Damage to Golden Delicious. Int. J. Latest Trends Agric. Food Sci. 2012, 2, 36–57. [Google Scholar]

- Amer Eissa, A.H.; Albaloushi, N.; Azam, M.M. Vibration Analysis Influence During Crisis Transport of the Quality of Fresh Fruit on Food Security. Agric. Eng. Int. CIGR J. 2013, 15, 181–190. [Google Scholar]

- Ding, C.; Feng, Z.; Wang, D.; Cui, D.; Li, W. Acoustic vibration technology: Toward a promising fruit quality detection method. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1655–1680. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yuan, P.P.; Deng, X.Y. Watermelon ripeness detection by wavelet multiresolution decomposition of acoustic impulse response signals. Postharvest Biol. Technol. 2018, 142, 135–141. [Google Scholar] [CrossRef]

- Ding, C.; Wu, H.; Feng, Z.; Wang, D.; Li, W.; Cui, D. Online assessment of pear firmness by acoustic vibration analysis. Postharvest Biol. Technol. 2020, 160, 111042. [Google Scholar] [CrossRef]

- Hui, Z.; Jie, W.; Zhao, Z.; Wang, Z. Nondestructive firmness measurement of differently shaped pears with a dual-frequency index based on acoustic vibration. Postharvest Biol. Technol. 2018, 138, 11–18. [Google Scholar] [CrossRef]

- Jarimopas, B.; Singh, S.P.; Saengnil, W. Measurement and analysis of truck transport vibration levels and damage to packaged tangerines during transit. Packag. Technol. Sci. 2005, 18, 179–188. [Google Scholar] [CrossRef]

- Khalifa, S.; Komarizadeh, M.H.; Tousi, B. Usage of fruit response to both force and forced vibration applied to assess fruit firmness—A review. Aust. J. Crop Sci. 2011, 5, 516–522. [Google Scholar]

- Xuan, Y.; Xu, L.; Liu, G.; Zhou, J. The vibrational response of simulated Ginkgo biloba fruit based on their frequency spectrum characteristics. PLoS ONE 2020, 15, e0235494. [Google Scholar] [CrossRef]

- Xu, S.X.; Wu, H.Y.; Chen, H.J.; Han, Q. Effects of vibration stress on fruit quality and antioxidant enzyme activities of blueberry. For. Sci. 2017, 53, 26–34. [Google Scholar]

- Çakmak, B.; Can, H.Z.; Akdeniz, R.C.; Alayunt, F.N.; Aksoy, U. The Effect of Fruit Packaging Properties (Ficus carica L.) on Quality Loses of Fresh Fig Fruits During Transportation. Ege Üniversitesi Ziraat Fakültesi Derg. 2007, 44, 123–135. [Google Scholar]

- FAO. Prevention of Postharvest Food Losses: Fruits, Vegetables and Root Crops; A training Manual, FAO Training Series, No. 17/2; Food and Agriculture Organization of the United Nations: Italy, Rome, 1985. [Google Scholar]

- Osifo, E.O. Storage of perishable commodities. J. Trop. Post Harvest. 1995, 2, 43–50. [Google Scholar]

- Vigneault, C.; Thompson, J.; Wu, S. Designing container for handling fresh horticultural produce. Postharvest Technol. Hortic. Crops 2009, 2, 25–47. [Google Scholar]

- Abbaszadeh, R.; Moosavian, A.; Rajabipour, A.; Najafi, G. An intelligent procedure for watermelon ripeness detection based on vibration signals. J. Food Sci. Technol. 2015, 52, 1075–1081. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abbaszadeh, R.; Rajabipour, A.; Delshad, M.; Mahjoob, M.; Ahmadi, H. Prediction of watermelon consumer acceptability based on vibration response spectrum. Int. J. Agric. Biosyst. Eng. 2011, 5, 365–368. [Google Scholar] [CrossRef]

- Fu, X.; Sun, J.; Lyu, C.; Meng, X.; Guo, H.; Yang, D. Evaluation on simulative transportation and storage quality of sweet cherry by different varieties based on principal component analysis. Food Sci. Technol. 2022, 42, 1–10. [Google Scholar] [CrossRef]

- Abbaszadeh, R.; Rajabipour, A.; Mahjoob, M.; Delshad, M.; Ahmadi, H. Evaluation of watermelons texture using their vibration responses. Biosyst. Eng. 2013, 115, 102–105. [Google Scholar] [CrossRef]

- Abdelsalam, A.M.; Sayed, M.S. Real-time defects detection system for orange citrus fruits using multi-spectral imaging. In Proceedings of the 2016 IEEE 59th International Midwest Symposium on Circuits and Systems (MWSCAS), Abu Dhabi, United Arab Emirates, 16–19 October 2016; pp. 65–68. [Google Scholar] [CrossRef]

- Aboonajmi, M.; Jahangiri, M.; Hassan-Beygi, S.R. A review on application of acoustic analysis in quality evaluation of agro-food products. J. Food Processing Preserv. 2015, 39, 3175–3188. [Google Scholar] [CrossRef]

- Chen, H.; Cao, S.; Fang, X.; Mu, H.; Yang, H.; Wang, X.; Xu, Q.; Gao, H. Changes in fruit firmness, cell wall composition and cellwall degrading enzymes in postharvest blueberries during storage. Sci. Hortic. 2015, 188, 44–48. [Google Scholar] [CrossRef]

- Landahl, S.; Terry, L.A. Non-destructive discrimination of avocado fruit ripeness using laser Doppler vibrometry. Biosyst. Eng. 2020, 194, 251–260. [Google Scholar] [CrossRef]

- Li, H.; Pidakala, P.; Billing, D.; Burdon, J. Kiwifruit firmness: Measurement by penetrometer and non-destructive devices. Postharvest Biol. Technol. 2016, 120, 127–137. [Google Scholar] [CrossRef]

- Kupferman, E. Minimizing Bruising in Apples; Postharvest Information Network; Washington State University, Tree Fruit Research and Extension Center: Washington, DC, USA, 2008. [Google Scholar]

- Ministry of Agriculture, Forestry and Fisheries. Food Balance Sheet. 2008. Available online: http://www.maff.go.jp/j/zyukyu/fbs/index.html (accessed on 1 April 2021). (In Japanese).

- Jahanbakhshi, A.; Abbaspour-Gilandeh, Y.; Ghamari, B.; Heidarbeigi, K. Assessment of physical, mechanical, and hydrodynamic properties in reducing postharvest losses of cantaloupe (Cucumis melo var. Cantaloupensis). J. Food Process Eng. 2019, 42, e13091. [Google Scholar] [CrossRef]

- Barchi, G.L.; Berardinelli, A.; Guarnieri, A.; Ragni, L.; Totaro Fila, C. Damage to loquats by vibration simulating intra-state transport. Biosyst. Eng. 2002, 82, 305–312. [Google Scholar] [CrossRef]

- Lu, Y.; Li, Z.; Pu, H.; Wang, D. Determination of storage time of watermelon based on acoustic impulse method. J. Zhejiang Agric. 2016, 28, 682–687. [Google Scholar] [CrossRef]

- Mayorga-Martinez, A.A.; Olvera-Trejo, D.; Elias-Zuniga, A.; Parra-Saldivar, R.; Chuck-Hernandez, C. Non-destructive assessment of guava (Psidium guajava L.) maturity and firmness based on mechanical vibration response. Food Bioprocess Technol. 2016, 9, 1471–1480. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Investigating bruise susceptibility of pomegranate cultivars during postharvest handling. Afr. J. Rural. Dev. 2017, 2, 33–39. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P.B. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Peleg, K. Produce Handling Packaging and Distribution; AVI Publishing Company: Westport, CT, USA, 1985. [Google Scholar]

- Brandenberg, R.K.; Lee, J.J. Fundamentals of Packaging Dynamics; MTS Systems Corporation: Minneapolis, MN, USA, 1985. [Google Scholar]

- Nourain, J.; Ying, Y.; Wang, J.; Rao, X.; Yu, C. Firmness evaluation of melon using its vibration characteristic and finite element analysis. J. Zhejiang Univ. Sci. 2005, 6, 483–490. [Google Scholar] [CrossRef]

- Zarifneshat, S.; Ghassemzadeh, H.R.; Sadeghi, M.; Abbaspour-Fard, M.H.; Ahmadi, E.; Javadi, A.; Shervani-Tabar, M.T. Effect of Impact Level and Fruit Properties on Golden Delicious Apple Bruising. Am. J. Agric. Biol. Sci. 2010, 5, 114–121. [Google Scholar]

- Amer Essa, A.H.; Gamea, G.R. Physical and mechanical properties of bulb onions. Miser J. Agric. Eng. 2003, 20, 661–676. [Google Scholar]

- Shahbazi, F.; Rajabipour, A.; Mohtasebi, S.; Rafie, S. Simulated in-transit vibration damage to watermelons. J. Agric. Sci. Technol. 2010, 12, 23–34. [Google Scholar]

- Pretorius, C.J.; Steyn, W. Influence of road roughness on the transportation of fresh produce. In Proceedings of the 31st Southern African Transport Conference (SATC 2012), Pretoria, South Africa, 9–12 July 2012; Abdollahi, M., Abdoola, S., Eds.; pp. 142–153. [Google Scholar]

- Schulte, P.; Timm, E.J.; Brown, G.K.; Marshall, D.E.; Burton, C.L. Apple damage assessment during intrastate transportation. Trans. ASAE 1990, 6, 753–758. [Google Scholar]

| Items | Duration Time | Mean | Range | SD * | SE * | CV * | |

|---|---|---|---|---|---|---|---|

| Min. | Max. | ||||||

| (0–50 Hz) | |||||||

| P.S.D (dB2/Hz) | 5 | 30 | 1.00 | 136.46 | 33.31 | 8.60 | 28.66 |

| 10 | 31.49 | 7.69 | 164.06 | 32.16 | 8.30 | 26.36 | |

| (50–100 Hz) | |||||||

| P.S.D (dB2/Hz) | 5 | 15.06 | 5.15 | 98.30 | 17.22 | 4.45 | 29.52 |

| 10 | 18.06 | 13.84 | 91.65 | 14.39 | 3.71 | 20.58 | |

| (100–200 Hz) | |||||||

| P.S.D (dB2/Hz) | 5 | 18.96 | 9.92 | 89.38 | 13.74 | 3.55 | 18.71 |

| 10 | 4.09 | 2.15 | 16.53 | 2.01 | 0.52 | 12.67 | |

| Items | Duration Time | Mean | Range | SD | SE | CV | |

|---|---|---|---|---|---|---|---|

| Min. | Max. | ||||||

| (0–50 Hz) | |||||||

| P.S.D (dB2/Hz) | 5 | 13.24 | 4.61 | 45.71 | 8.04 | 2.07 | 15.68 |

| 10 | 23.76 | 10.38 | 33.20 | 3.81 | 0.98 | 4.14 | |

| (50–100 Hz) | |||||||

| P.S.D (dB2/Hz) | 5 | 5.49 | 4.06 | 22.06 | 2.73 | 0.70 | 12.82 |

| 10 | 9.14 | 3.58 | 64.06 | 11.45 | 2.96 | 32.36 | |

| (100–200 Hz) | |||||||

| P.S.D (dB2/Hz) | 5 | 5.13 | 4.06 | 9.91 | 1.15 | 0.30 | 5.79 |

| 10 | 15.13 | 13.84 | 45.71 | 4.25 | 1.08 | 7.25 | |

| Items | Duration Min | Mean | Range | SD | SE | CV | |

|---|---|---|---|---|---|---|---|

| Min. | Max. | ||||||

| (0–50 Hz) | |||||||

| P.S.D (dB/Hz2) | 5 | 11.49 | 1.14 | 85.11 | 16.95 | 4.38 | 38.08 |

| 10 | 20.35 | 6.37 | 58.77 | 13.84 | 3.57 | 17.56 | |

| (50–100 Hz) | |||||||

| P.S.D (dB/Hz2) | 5 | 12.14 | 1.50 | 43.41 | 10.03 | 2.59 | 21.35 |

| 10 | 19.39 | 16.08 | 40.58 | 5.12 | 1.32 | 6.82 | |

| (100–200 Hz) | |||||||

| P.S.D (dB/Hz2) | 5 | 12.72 | 2.24 | 85.11 | 13.33 | 3.44 | 27.06 |

| 10 | 8.56 | 2.52 | 85.11 | 11.10 | 2.87 | 33.48 | |

| Mode | Frequency, Hz | Damping Ratio, % | Elasticity, MPa | Stiffness ×104 Hz2 kg2/3 |

|---|---|---|---|---|

| Mode, 1 | 25.3 | 5.838 | 0.0013 | 0.0173 |

| Mode, 2 | 45.26 | 5.011 | 0.0043 | 0.0552 |

| Mode, 3 | 85.17 | 4.835 | 0.0052 | 0.0679 |

| Mode, 4 | 165.09 | 4.237 | 0.0158 | 0.2045 |

| Mode, 5 | 200.0 | 4.229 | 0.0835 | 1.0839 |

| Mode | Frequency, Hz | Damping Ratio, % | Elasticity, MPa | Stiffness, ×104 Hz2 kg2/3 |

|---|---|---|---|---|

| Mode, 1 | 38.76 | 2.438 | 0.0031 | 0.0405 |

| Mode, 2 | 51.4 | 1.623 | 0.2067 | 2.6821 |

| Mode, 3 | 91.3 | 1.521 | 0.5411 | 7.0211 |

| Mode, 4 | 175.7 | 0.9925 | 0.7176 | 9.3124 |

| Mode, 5 | 197.6 | 0.6586 | 0.8985 | 11.6594 |

| Mode | Frequency, Hz | Damping Ratio, % | Elasticity, MPa | Stiffness, ×104 Hz2 kg2/3 |

|---|---|---|---|---|

| Mode, 1 | 52.5 | 6.953 | 0.0483 | 0.6270 |

| Mode, 2 | 91.4 | 1.565 | 0.5477 | 7.1066 |

| Mode, 3 | 125.3 | 1.031 | 0.7118 | 9.2365 |

| Mode, 4 | 175.02 | 0.5172 | 1.1594 | 15.0450 |

| Mode, 5 | 195.3 | 0.3527 | 1.2489 | 16.2066 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azam, M.M.; Saad, A.; Amer, B.M.A. Assessment of the Quality Losses of Cantaloupe Fruit during Transportation. Processes 2022, 10, 1187. https://doi.org/10.3390/pr10061187

Azam MM, Saad A, Amer BMA. Assessment of the Quality Losses of Cantaloupe Fruit during Transportation. Processes. 2022; 10(6):1187. https://doi.org/10.3390/pr10061187

Chicago/Turabian StyleAzam, Mostafa M., AbdelGawad Saad, and Baher M. A. Amer. 2022. "Assessment of the Quality Losses of Cantaloupe Fruit during Transportation" Processes 10, no. 6: 1187. https://doi.org/10.3390/pr10061187

APA StyleAzam, M. M., Saad, A., & Amer, B. M. A. (2022). Assessment of the Quality Losses of Cantaloupe Fruit during Transportation. Processes, 10(6), 1187. https://doi.org/10.3390/pr10061187