2.1. Mining Explorer Robot Implementation Methods

Mobile robots are robots that are not tied to one physical place and are able to move in their environment [

11,

12]. Mobile robots can move both autonomously, without the use of navigation devices in an uncontrolled environment, or along a predetermined route, when using navigation devices in a relatively controlled space.

The main components of a mobile robot are a control device, software for the control device, sensors, a drive, and a set of actuators. The control device is usually a microcontroller, laptop or personal computer [

13]. Software of mobile robots can be a low-level language, a high-level language, or special software for real-time systems. The sensors used depend on the functionality of the robot; for example, accurate calculation, tactile and non-contact sounding, triangulation, collision avoidance, positioning and other specific applications.

Vision systems are widely used as a means of perception for mobile robots [

14]. This type of robot sensing system makes it possible to generate control signals for controlling the robot based on the perception and processing of video information. Currently, serial production of a wide variety of robot vision systems is expanding worldwide [

15,

16,

17,

18]. The issues of creating mobile robots are of interest to many specialists involved in the design, implementation and operation of robotic technological complexes and flexible production systems.

However, the specifics of robotic applications impose a number of requirements on the design of mobile robots, which are not only complex in themselves, but can also conflict with each other. Creating efficient mobile robots is not possible by simply combining hardware and algorithmic software developed independently of each other. When organizing such complex systems as those of mobile robots, it is necessary to take into account the combined influence of these components on the result. In particular, it should be borne in mind that high-performance computing means are not used in the design of mobile robots. Therefore, from the very beginning of the formulation of functional tasks for vision systems, one should strive to simplify them as much as possible.

Thus, to create a mobile robot, it is necessary to solve the problem of a rational choice of equipment and algorithmic support, and then coordinate these components in the robot design.

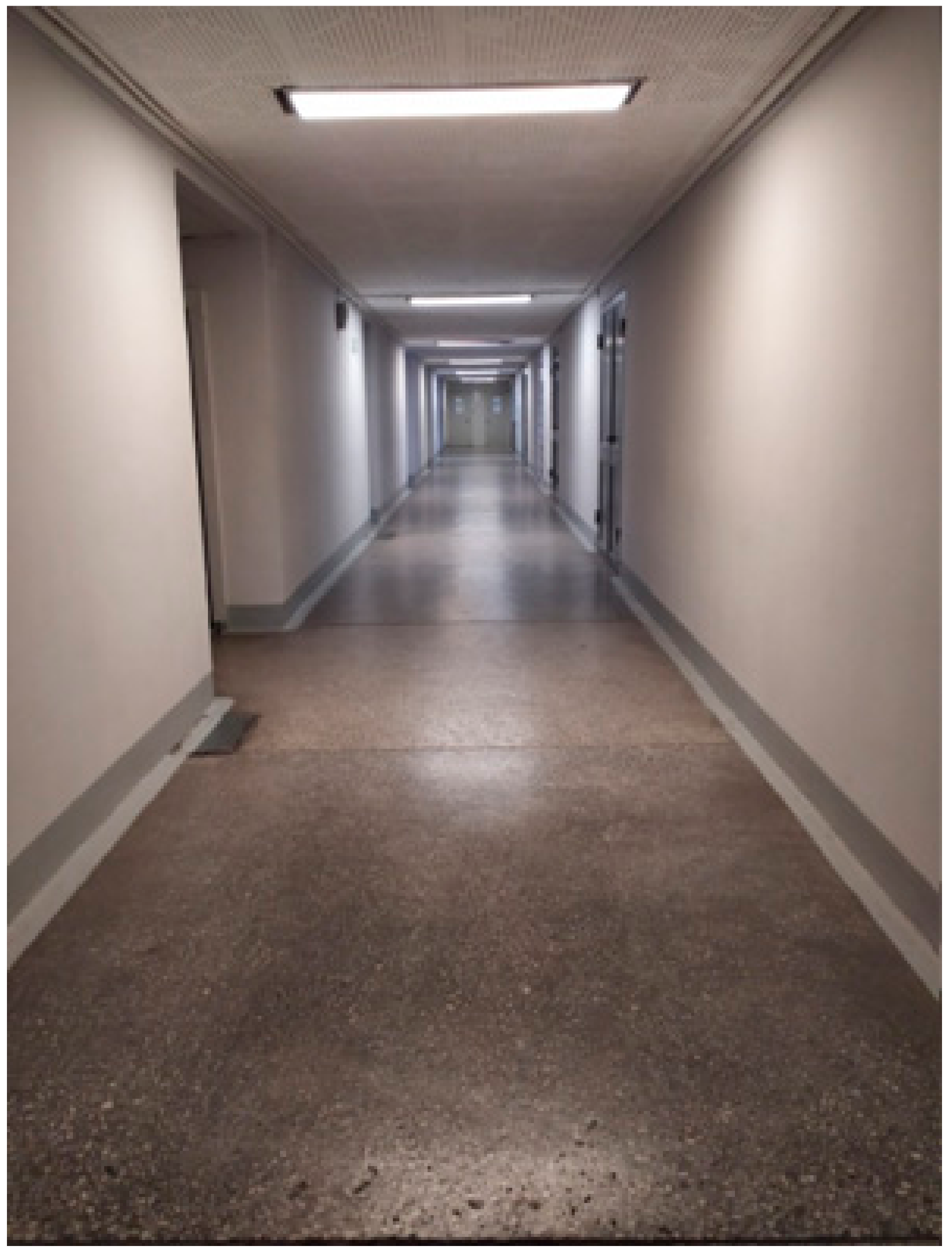

Mines are hazardous industrial environments and require regular inspections to ensure the safety of mining personnel and the smooth running of mining operations. Modern legislation requires regulatory inspections at active mines. These checks primarily ensure safe ventilation and operation. Reclamation is envisaged at the end of the life of the mines. However, the owners often ignore inspections and routine maintenance related to the restoration of mining workings. Abandoned mines are becoming more and more dangerous for personnel over time. Therefore, using a mining robot explorer to carry out an inspection in such a mine is the safest solution [

5].

When inspecting a mine, a robot has to overcome a number of dangers and challenges. These include lack of ventilation, unstable ground support, water inside the mine, the creation of a mesh communication network with the control point, and the need for video transmission to determine the condition of the mine. Therefore, autonomous mobile robots are often used as inspection robots in the mining industry.

Autonomous mobile robots do not need any external guidance, such as cables, magnetic strips or sensors, to move. They can move in dynamic environments with very little external input. Autonomous mobile robots are equipped with sophisticated sensors to detect objects around them. The on-board intelligent system of such robots allows one to explore an area by loading an existing map or building one’s own map. As a result, autonomous mobile robots can operate in virtually any industrial environment. This is necessary for mines because they are inherently dynamic.

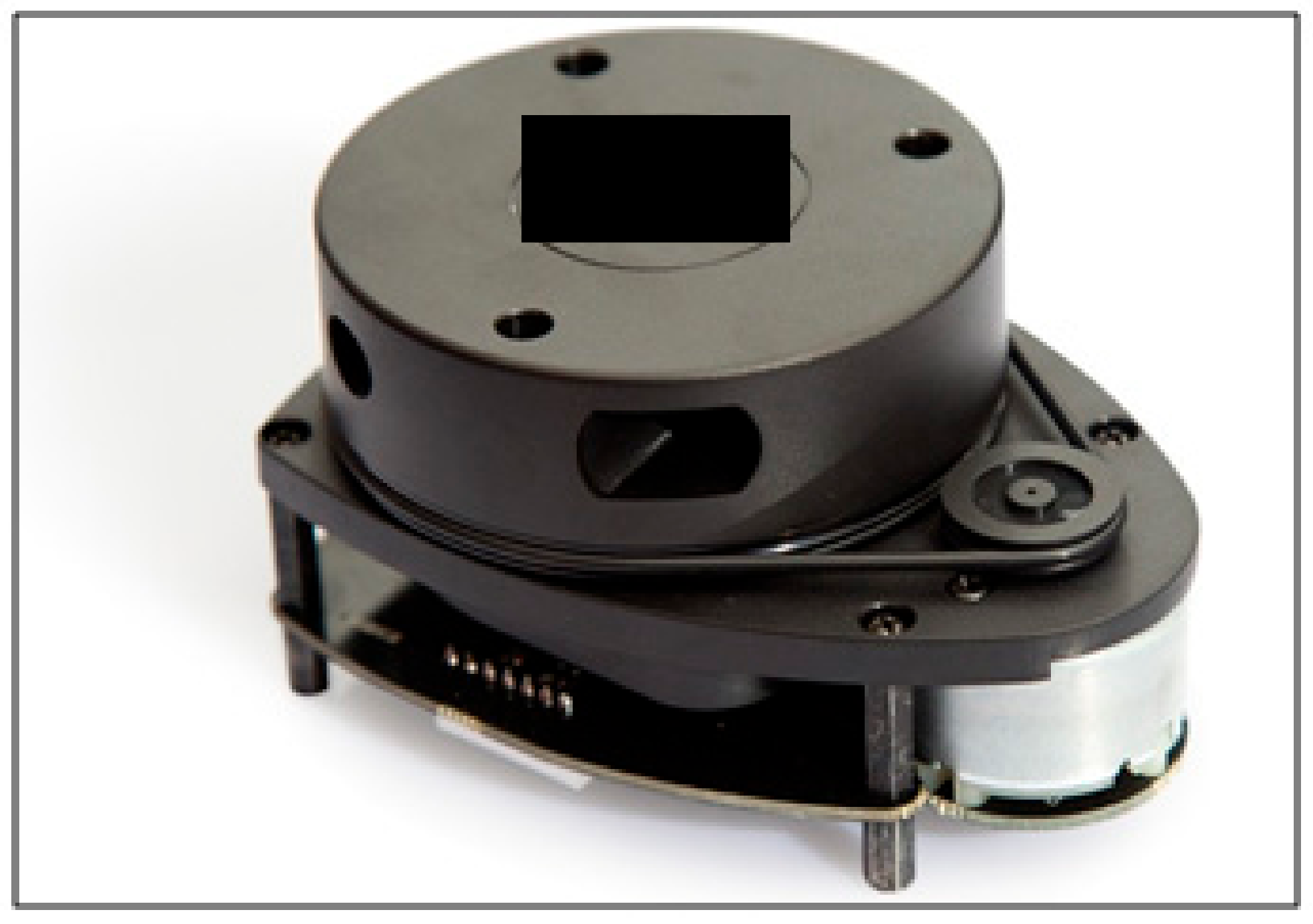

By combining a mining robot with LiDAR technology, mobile robots get the most out of their high-resolution 3D and 2D data. The sensors can provide the robot with a 360-degree real-time map so that it can navigate safely and autonomously by detecting and avoiding obstacles. LiDAR sensors are easy to install, have low power consumption, and are easily programmable with a web configuration tool [

19,

20].

Autonomous mobile robots are good at specialized tasks, but they cannot work outside the parameters of the environment [

21]. Self-driving cars, for example, are far from ready precisely because of the complexities associated with many of the parameters that ensure safe driving. In urban conditions, it takes more than just keeping the car on a straight line. In this case, the specificity of the problem requires constant identification of all kinds of risks (cyclists, pedestrians, and other vehicles) and their prevention. The human brain is well adapted to such things and can process them without much difficulty. Nevertheless, getting robots to do this task is still very difficult. However, if the robot works in a section where people cannot venture, then its tasks are simplified [

21]. Sufficient administrative and uncomplicated technical restrictions to ensure the absence of people in the dangerous area are necessary. Then, the robot does not need to worry about the possibility of causing harm to anyone. The same principle applies to the physical environment of a mine. A robot in a mine does not need to deal with high speeds, such as when driving on a highway, or tackle complex problems to identify obstacles in a forest or field. While it is difficult for a robot moving on the surface to distinguish a stone or other large obstacle in grass, it is easier for a robot working underground to distinguish between what is an obstacle and what is not. Taking into account these features of the working environment of the mine robot will reduce the financial costs of complex security systems [

21]. In addition, the released computing power of the on-board computer can be used to solve other tasks.

To achieve a successful combination of various aspects of the concept under consideration in a specific robot, it is necessary to create a prototype of a mining explorer robot. The tasks to be solved include the creation of a prototype of a robot on a widespread hardware and software base, the choice of the optimal type of robot movement drive, the development of a sensing system, and the development of a communication system by the control point. A separate scientific task will be the choice of a navigation system. The solution of the above tasks will largely depend on the solution of this problem.

2.2. Robot Navigation System Methods

The design of existing navigation systems for mobile robots is based on the solution of three basic tasks:

Determination and bypass of various obstacles in the way of movement;

Making the necessary changes to the current path in the event of an emergency;

Ensuring the most accurate movement on a narrow path or uneven surface.

There are three main types of navigation systems [

22]:

Global navigation systems are designed for operational navigation of ground moving objects. The use of such systems is limited to the areas of availability of satellite signal, which makes it impossible to determine a robot position inside ground and underground structures, near tall buildings and trees.

Personal navigation systems determine the position taking into account nearby objects. They are suitable for positioning a robot in a specific small area. They are used to define the position when the robot moves along cables, lines, or by marks.

Local systems use the starting point for positioning. These systems are used over relatively large known areas. Local navigation systems are used when it is necessary to control the movement of a mobile robot along a safe trajectory in confined spaces, or positioning in conditions of inaccessibility of data from external sources.

Navigation systems can be passive and active systems. The passive navigation system receives information about its own coordinates and other characteristics of its movement from external sources. An active navigation system is an inertial navigation system that determines positions using only its onboard sensor systems [

22].

For mobile robots with a passive local navigation system, artificial beacons are required to determine their location [

23]. Beacons are located at fixed points on the route, and the robot loses the ability to avoid obstacles that appear or choose an alternative path of movement. The main disadvantage of passive local systems for use in mines remains the need to maintain artificial beacons on the route. A robot with passive local navigation is able to bind its coordinates to static elements of the environment (tall tree, mountain). In this case, there is a problem with the presence of static key objects in mines when environmental conditions change (for example, the level of illumination). When working in a mine, an autonomous robot is in an environment where landmarks are very few, or they are difficult to distinguish, or are too large and cannot be used as a material point.

Thus, active local navigation systems must be used to position an autonomous robot operating in a mine. In a confined space, there are many different types of interference. Active local navigation systems use various sensors that analyze the external environment; for example, light sensors, rangefinders, and force sensors. The advantage of such systems is high accuracy, as well as being able to work in conditions of high levels of environmental interference or the absence of satellite navigation. The environment introduces imprecision and uncertainty in communication channels. The use of active local navigation systems solves navigation problems in conditions when there are problems with signal reflection, uneven lighting, and difficult terrain [

24]. The most accurate solution to the navigation problem can be obtained with the help of technical vision systems, based on video cameras, laser rangefinders and other sensors. Such systems also make it possible to form a description of the area surrounding the robot, to identify potential hazards, and to find landmarks for targets [

25].

For the optimal choice of the navigation system in our particular case, we will analyze the existing methods to solving such problems.

2.2.1. SLAM

Today, the most advanced technology on which robot navigation is implemented is SLAM (Simultaneous localization and mapping).

SLAM is a method of mapping in an unknown space, while monitoring current location and the distance traveled [

21]. When using this method, the map is built synchronously and the robot’s position is determined. Navigation goes on the map under construction. At the heart of any SLAM method is the ability to measure the distance to objects in the surrounding space, and evaluate change in position relative to them. SLAM is used when:

The robot should be autonomous;

Nothing is known about the environment;

It is not possible to install beacons;

It is not possible to use global navigation systems indoors, underground or under water.

In SLAM, the robot builds a map step by step and determines its location on this map as it enlarges and refines. When developing an algorithm, it is necessary to define a way to describe and store an environment map in which the robot will operate. In its pure form, SLAM is limited to small areas, due to poor computational scalability of probabilistic filters. The increase in uncertainty at large distances from the map origin makes the presentation of uncertainty inaccurate. Matching data to relevant items is very difficult with high uncertainty.

Currently, most SLAM algorithms are based on three different approaches: an extended Kalman filter for SLAM, a particle filter SLAM (using the Monte Carlo method), and SLAM based on graphs (Graph-Based SLAM) [

26,

27].

2.2.2. Extended Kalman Filter for SLAM

This approach is based on a nonlinear Kalman filter. For a long time, the extended Kalman filter was the only method for solving the aforementioned problems. Kalman filter is a recursive filter that calculates the condition of the system k from the state k-1. Kalman’s algorithm works iteratively. At each step, the algorithm receives data from the sensors (with noise and other negative factors), and the state vector from the previous step and, using these data, estimates the condition of the system at the current step. The algorithm keeps track of the probability that the current state vector corresponds to some spread of values for each variable in the vector. In the extended Kalman filter, the state transition and observation models do not have to be linear state functions; they can be differentiable functions. The algorithm complexity is estimated as O (N

3), where N is the number of landmarks relative to which a robot position in space is determined. There are methods to reduce the complexity of the algorithm to O (N

2) [

28].

2.2.3. FastSLAM

The FastSLAM method assumes the use of the Bayes network and particle filters. This algorithm presents one large map as a set of local maps. In this case, there is no dependence between landmarks and the time for reassessing a condition of the system is noticeably reduced [

27]. Partial filters are mathematical models that represent a probability distribution as a discrete collection of particles that occupy a state space. The map is stored in the form of a connected graph, in the form of a balanced binary tree, at the vertices of which some condition is stored. The method advantage is that in this algorithm, the SLAM task is divided into (m + 1) tasks, and none of the estimates of the landmark position depend on the others. The complexity of the calculation algorithm is simplified to O (M log N), where M is the number of particles, N is the number of landmarks, relative to which a robot position in space is determined [

28]. FastSLAM monitors several possible routes at the same time. FastSLAM can efficiently compute the complete follow-up SLAM. Motion updates, landmark updates, and computation of importance weights can be done in constant time for each particle. FastSLAM can be used to map over a million landmarks using the capabilities of a standard desktop computer. The disadvantages of the algorithm include a potential drop in accuracy associated with ignoring the correlation of errors in estimating the positions of landmarks [

29].

2.2.4. DP-SLAM

DP-SLAM is one of the approaches to solving the problem of positioning a mobile robot using the SLAM method, which uses a relatively uncomplicated particle filter over an array of maps and positions of the robot [

30]. In the DP-SLAM algorithm, the map is stored as an array, where the elements reflecting the position of obstacles have a value of 1, and all the others—0. The map is stored as a connected graph of the tree type, at the nodes of which there are particles. The computational algorithm DP-SLAM does not use landmarks, allocated in the workspace of the robot. The method disadvantage is the need to process and update significant amounts of information in memory, taking into account hundreds of sections of locally measured terrain maps. The worst-case algorithm has log-square complexity, depending on the number of particles, and linear complexity, depending on the area viewed by the laser sensor [

29,

31].

The SLAM task can be described as a sparse graph and links between nodes. Graph nodes are robot locations and map elements. The graph-based SLAM method has a constant refresh time of graphs and the required memory is linearly dependent on number of elements. However, the final graph optimization can be computationally expensive if the robot has traveled a long enough distance.

Thus, there are no ready-made, universal SLAM solutions for solving navigation problems. The SLAM algorithm is developed individually for the robot being used, taking into account the environmental conditions. One of the simplest and most efficient SLAM implementations is based on a particle filter. Based on these considerations, the FastSLAM algorithm was applied to control the prototype of the mining explorer robot [

32].

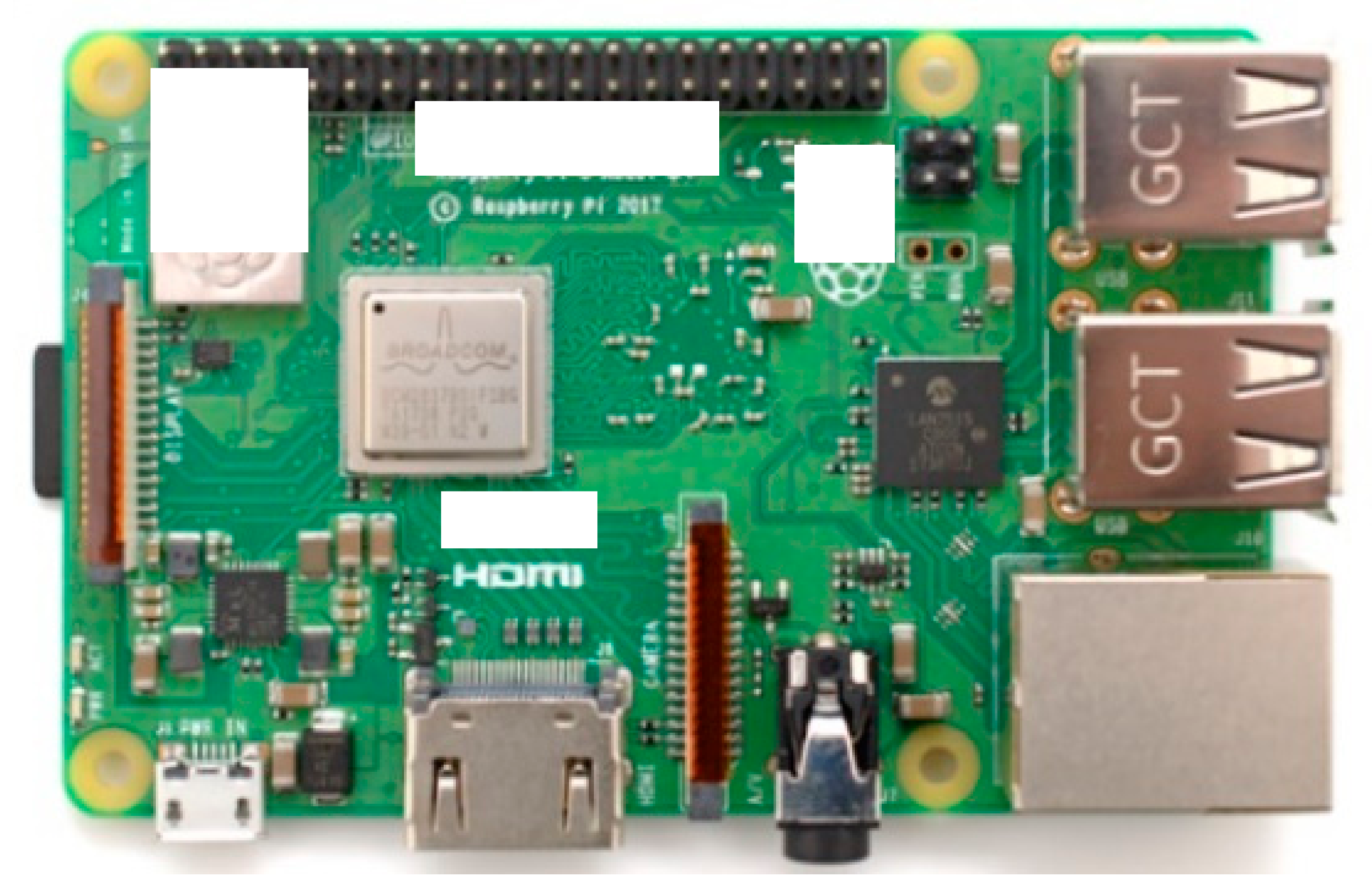

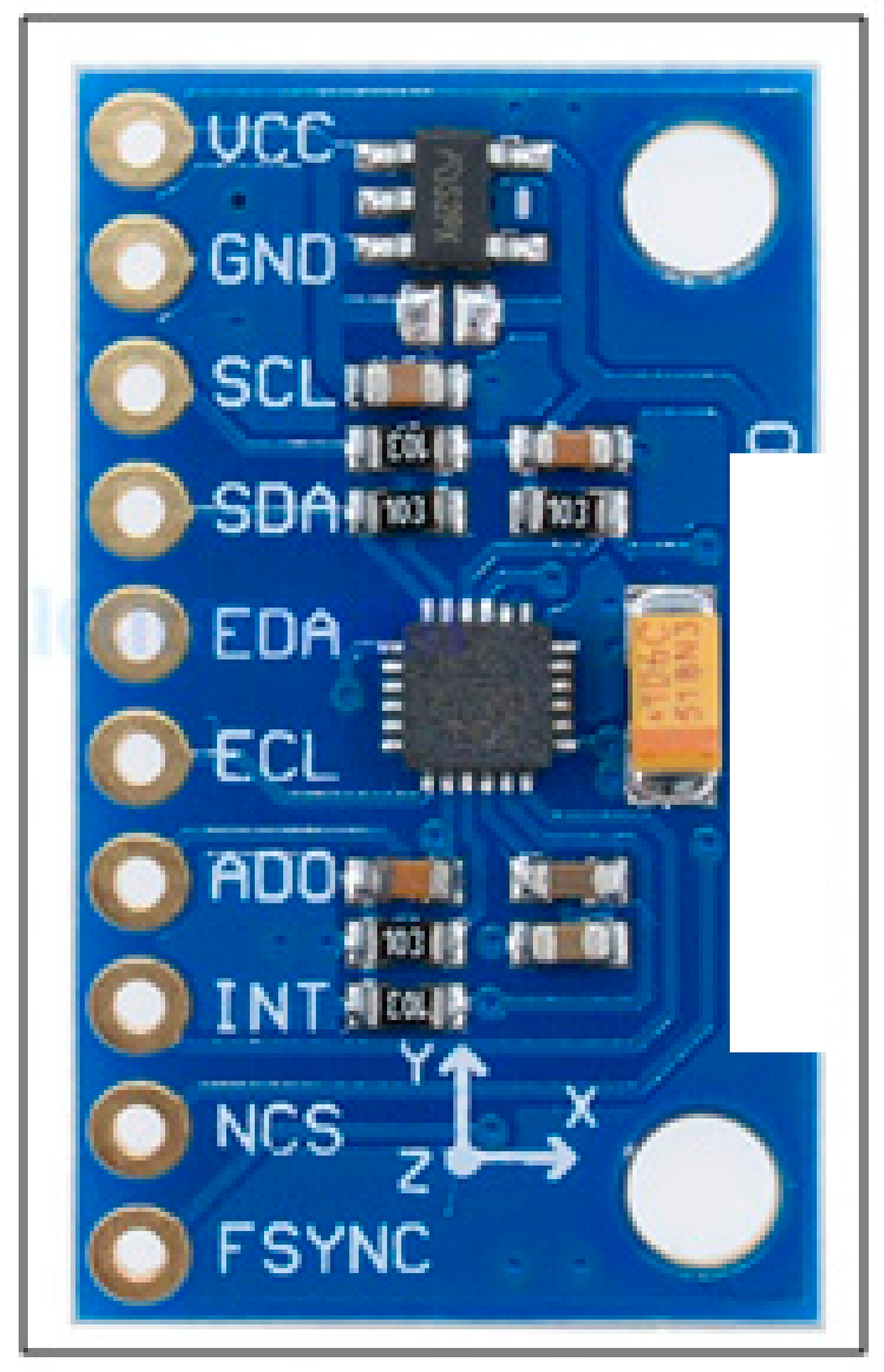

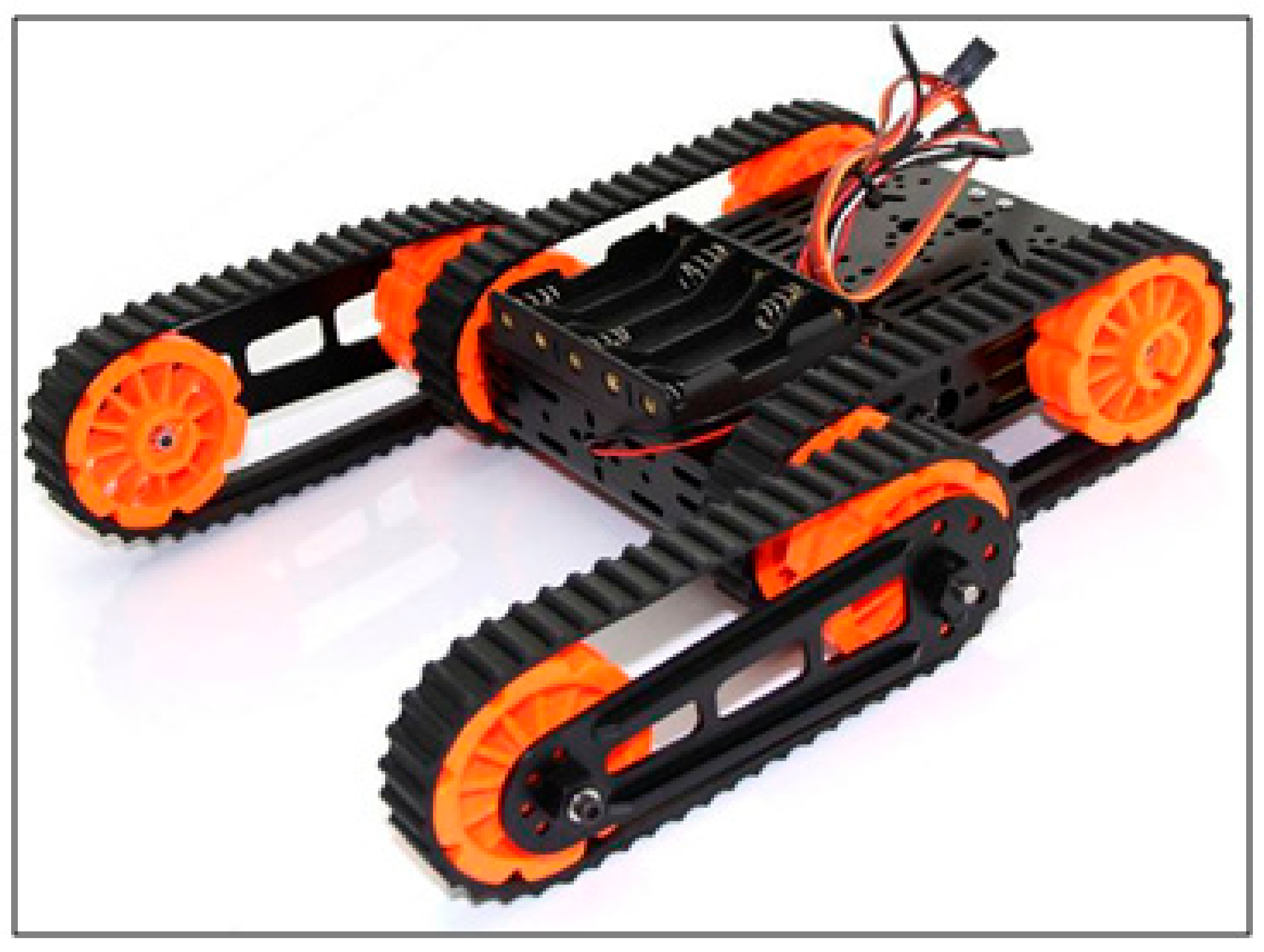

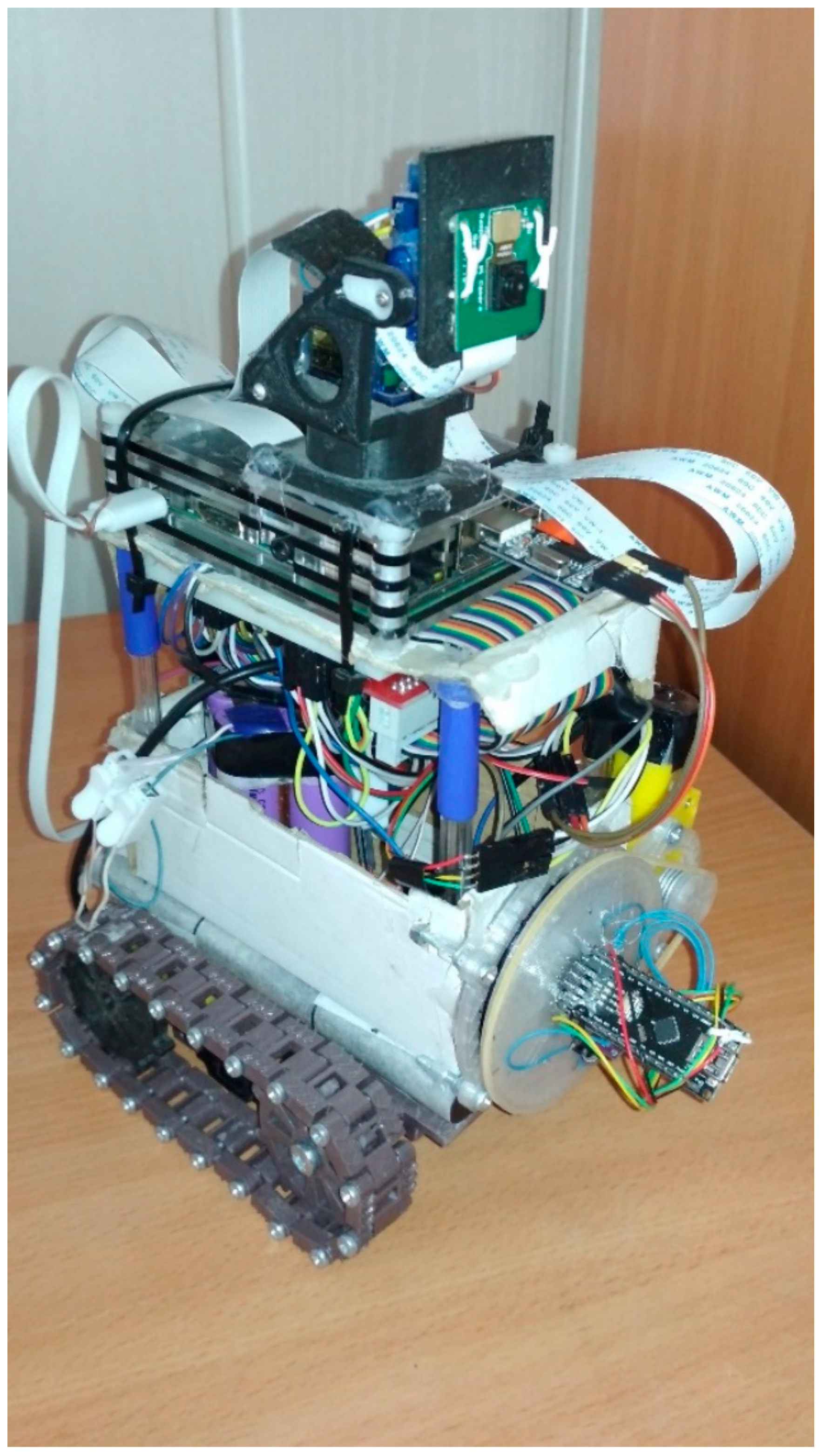

2.3. Materials

To test in action the concept of implementation and the algorithms of the developed device, it is necessary to mount a mining explorer robot prototype. The implementation was carried out from universal equipment available for mass sale [

33,

34]. The main components used to create the robot prototype are shown in

Figure 1,

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7, and their characteristics in

Table 1,

Table 2,

Table 3,

Table 4,

Table 5,

Table 6,

Table 7, respectively.

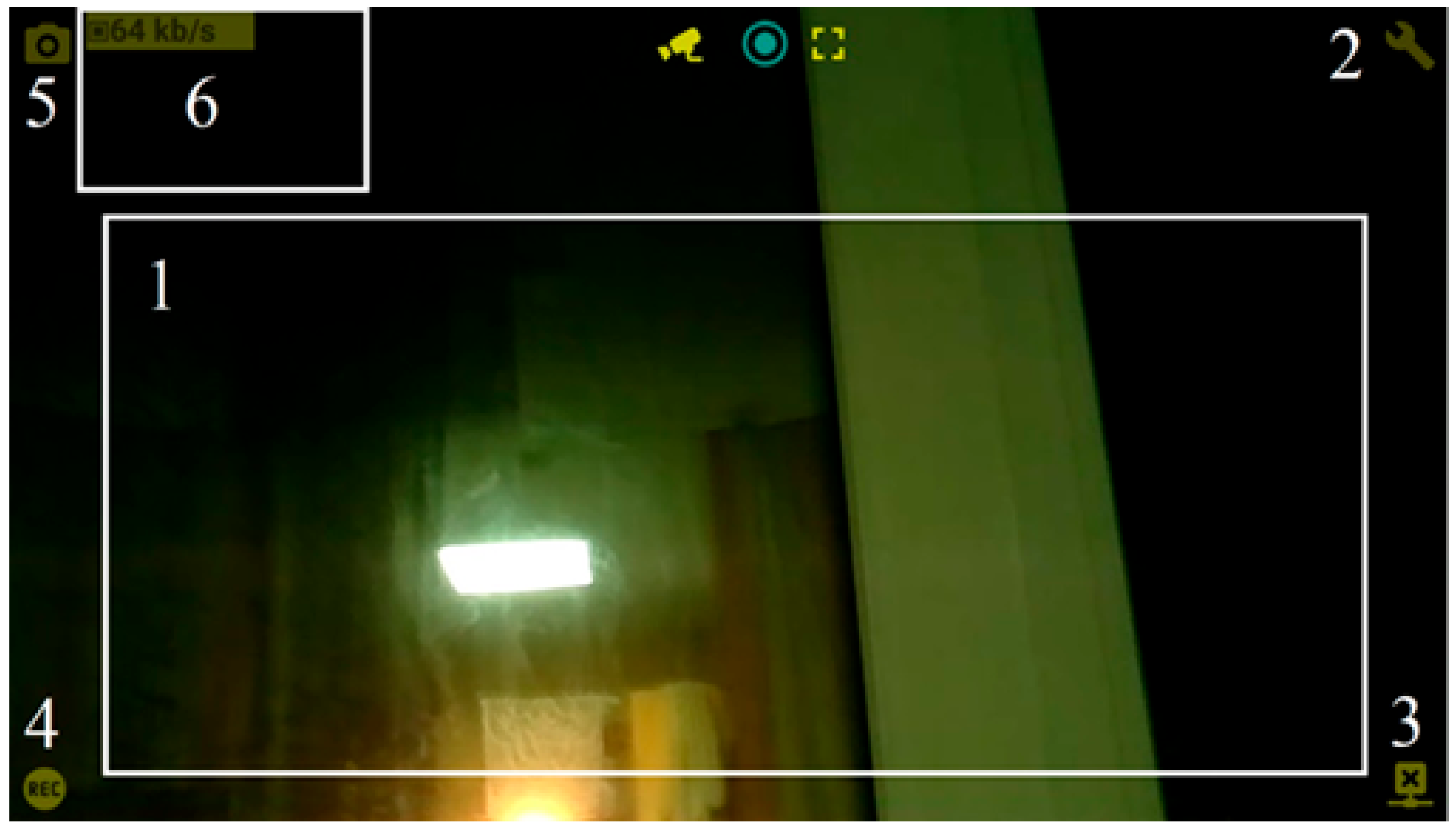

Additionally, in the construction of the prototype robot, the ultrasonic distance sensor, gas sensor, temperature, pressure and humidity sensor, and infrared sensor are used. The video image transmission from the robot’s camera was carried out on an Android smartphone.

When programming, in order to reduce the cost of the robot prototype, free software was used.

To create a mobile application, the popular, freely distributed, integrated development environment, Android Studio, was chosen. For programming a single-board computer, the Python programming language was chosen. This is because Python has many ready-made solutions for working with peripherals through general-purpose input/output ports.

The Socket interface was used to provide communication between processes as part of the study. The interface provides communication between computers using the TCP/IP protocol stack. The robot serves as the server socket, while the laptop and VR headset serve as the client socket.

When developing applications with Python, there is a need to use a GUI (graphical user interface). When creating a robot prototype, the Tkinter tool was used. Tkinter is a cross-platform GUI development library for Python. Tkinter is also free software.

For the laptop, the Linux distribution Ubuntu was chosen as the operating system. This distribution is free. Popular programming languages on Linux distributions are:

C;

C++;

Java;

Python;

JavaScript;

Shell.

For greater compatibility with the robot on the Socket interface, the Python language was chosen.

The Visualization Toolkit (VTK) was chosen as a means of displaying maps on a laptop. This open-source cross-platform library provides developers with a rich set of tools for 3D graphics, imaging and visualization. VTK supports a wide range of visualization algorithms, as well as modern computer simulation methods. The toolkit supports parallel data processing technologies, and also has extensive integration with various types of databases in software tools with a graphical interface, such as Qt and Tk.